Abstract

Nanocomposite polyurethane (PU) materials have broad application prospects in the fields of optics and artistic colors, but there are few systematic studies on the application of nano-titanium dioxide (TiO₂), nano-zinc oxide (ZnO), and nano-silver (Ag) in PU matrices. The aim of this study is to prepare a PU matrix with the same transmittance but better UV absorption by adding these nanoparticles to improve the optical properties and UV resistance of the material. In this study, the solution method was used to prepare and characterize nano-TiO2, ZnO and Ag particles, and their addition amount and dispersion state were precisely controlled to prepare composite materials with different mass fractions. The properties of these composites were comprehensively evaluated by UV-visible spectroscopy analysis, transmission electron microscopy observation, and color measurement methods. The results showed that nano-TiO₂ significantly improved the transparency and UV blocking ability of the material, nano-ZnO enhanced the UV stability, and nano-Ag improved the transparency, antibacterial properties, and color stability. The specific data are as follows: the transmittance of nano-TiO2 and ZnO dropped from 85 to 55%, respectively, and the transmittance of nano-Ag dropped from 90 to 60%; in terms of ultraviolet absorption rate, nano-TiO2 increased from 10 to 45%, ZnO increased from 15 to 50%, and Ag increased from 20 to 55%. In addition, the study evaluated the effects of UV irradiation on the optical properties and color stability of the nanocomposites and found that the addition of nanoparticles significantly improved the material’s resistance to UV aging. In summary, the kind and location of nanoparticles have a substantial impact on the properties of PU composites. This study provides a scientific basis for the creation of high-performance nanocomposite PU materials.

1 Introduction

Because of its superior mechanical qualities, resistance to chemicals, and high elasticity, polyurethane (PU) materials are widely employed in a variety of industries, including building, electronics, textiles, and medicine. However, these materials are susceptible to photoaging under long-term UV exposure, resulting in decreased transparency and optical properties, which in turn affects their appearance and mechanical properties and shortens their service life [1,2]. To address this problem, researchers have explored a variety of methods, including adding UV absorbers, using antioxidants, and introducing nanoparticles. Because of their high surface area to volume ratio and distinctive quantum effects, nanoparticles have demonstrated significant promise in enhancing the optical characteristics and UV resistance of materials [3,4].

This study focuses on the addition of nano-titanium dioxide (TiO₂), nano-zinc oxide (ZnO), and nano-silver (Ag) to the PU matrix to synthesize nanocomposite PU materials with excellent optical properties and color stability. Experimental results show that these nanoparticles significantly improve the optical properties and color stability of PU materials. Specifically, nano-TiO₂ improves the transparency and UV blocking ability of the material, nano-ZnO enhances the UV stability of the material, and nano-Ag not only improves transparency but also significantly enhances antibacterial properties and color stability. Through UV-visible spectroscopy analysis, this study revealed in detail the specific impact mechanism of different nanoparticles on material properties, providing a scientific basis for the optical and artistic applications of nanocomposite PU materials.

This study is organized as follows: Section 1 outlines the research background, purpose, and significance. Section 2 reviews the research progress on the application of nanomaterials in PU composites, with a special focus on photoaging issues and the results of previous applications using nanoparticles. Section 3 describes in detail the preparation methods and characterization techniques of nano-TiO₂, nano-ZnO, and nano-Ag composites. The experimental results, including the material’s mechanical, optical, and artistic color representation, are examined in Section 4. The study’s key findings and potential avenues for further research are outlined in Section 5.

2 Related work

The optical properties of materials are closely related to the characterization of artistic colors. Understanding the optical properties of materials helps to gain a deeper understanding of color generation and variation. Bahbishi et al. found through experiments that bulk fill material has higher color stability than general resins, but lower surface microhardness. The ΔE value of Filtek Z350 is the highest, and there is a significant difference in microhardness [5]. Chen and others studied the characteristics of structural color materials with different structures, and concluded that structural color materials based on elastomers and hydrogels can achieve color change by adjusting structural parameters under mechanical stimulation [6]. Wang et al. explained their optical absorption and scattering phenomena through Mie theory. Precious metal nanoparticles have the most significant applications in biomedical fields and demonstrate their potential in other fields, with significant advantages [7]. Wei et al. studied the dispersion, distribution, orientation, and nanostructure control of nanoparticles in glass, and found that glass materials containing optically active nanoparticles exhibit unique optical properties, which has promoted in-depth research by scientists on this hybrid optical material [8]. Mei et al. verified the performance of CsPbX3/ZIF-8 composite material in remote white light emitting devices through experiments, and found that the material has high photoluminescence quantum yield and narrowband emission, with better stability than bare quantum dots [9]. Existing research has made some progress in improving the optical properties of materials, but there are still shortcomings in color stability and characterization analysis.

Nanocomposite PU materials have broad application prospects in multiple fields due to their unique physical and chemical properties. Cai et al. discussed the synthesis of waterborne PU and the influence of material selection on its performance, emphasizing the importance of strategies for improving performance and the structure performance relationship for the final application [10]. Allami et al. investigated the role of hydrogen bonding in phase separation kinetics of soft and hard PU fragments to explore the morphological annealing of PU [11]. Stachak and others prepared Non-isocyanate polyurethane (NIPU) through the addition reaction of cyclic carbonates with multifunctional amines. They found that this material has excellent chemical, mechanical, and thermal stability and can be used as an environmentally friendly polymer composite material [12]. Lee et al. proposed that PU graphene nanocomposites have a positive impact on cell behavior, promoting nerve and vascular regeneration. The flexibility of PU makes it suitable for biocompatible scaffolds, demonstrating potential application value in neural tissue engineering [13]. Ahmadi and Ahmad proposed that adding different types of nanofillers to waterborne polyurethane (WPU) can significantly improve its thermal stability, water resistance, and mechanical properties, promoting the design and construction of new materials [14]. Although there has been some progress in the optical properties and color characterization of nanocomposite PU materials, existing research mainly focuses on the role of single nanoparticles and lacks a systematic and comprehensive analysis.

3 Experimental materials

3.1 Main raw materials for the experiment

The nanoparticle material parameters of this study are shown in Table 1.

Nanoparticle material parameters

| Nanoparticle | Average particle size (nm) | Shape | Phase | Manufacturer | Model |

|---|---|---|---|---|---|

| TiO₂ | 21 | Irregular | Anatase | Anhui Ruibang Chemical Co., Ltd, China | P25 |

| ZnO | 20 | Irregular | — | Hunan Jinniu New Materials Co., Ltd | — |

| Ag | 10 | Irregular | — | Shanghai Macklin Biochemical Co., Ltd | 730793 |

Silane coupling agent (KH550) can be used for surface modification. The PU matrix adopts thermoplastic polyurethane elastomer (TPU) produced by Shandong Dongyue Group. The compatibility of TPU matrix is improved by using Isophorone diisocyanate (IPDI) and Dimethylolpropionic Acid (DMPA). The specific ratio is as follows: 0.8 g TiO₂, 0.4 g KH550, 2.5 g IPDI, and 1.2 g DMPA are added to every 100 g TPU matrix to prepare composite materials with 0, 1, 2, 3, 4, and 5% mass fractions, respectively.

Since these nanoparticles have special physical and chemical characteristics and can greatly enhance the optical qualities and color stability of PU materials, nano-TiO₂, nano-ZnO, and nano-Ag were selected to be added to the PU matrix. Nano-TiO₂ can greatly increase the material’s transparency, UV blocking capacity, and anti-UV aging properties. Nano-ZnO effectively improves the UV stability and overall optical properties of the material, making it more stable under UV irradiation. In addition to improving transparency, nano-Ag also greatly improves color stability and antibacterial qualities, offering a solid scientific foundation for the creation of high-performance nanocomposite PU materials.

3.2 Experimental instruments and equipment

The main instruments used in the experiment are the KQ-3000V ultrasonic generator produced by Kunshan Ultrasonic Instrument Co., Ltd, which is used for the dispersion of nanoparticles. The Cary 5000 UV Visible Spectrometer produced by Agilent in the United States is used to test the optical properties of materials. The HT7700 transmission electron microscope (TEM) produced by Hitachi in Japan is used to observe the dispersion state of nanoparticles in TPU matrix. The Spectra Guide colorimeter produced by Germany’s BYK company is used to measure the color stability of samples. The 3851CE hot press machine produced by Carver Company in the United States is used for preparing nanocomposite thin films. The Secura224-1S electronic balance produced by Sartorius in Germany is used for precise weighing of nanoparticles and TPU matrix. The VO500 vacuum drying oven produced by German company Memmert is used for sample drying treatment.

3.3 Sample preparation

3.3.1 Preparation of nano-TiO₂ PU composite materials

The preparation of nano-TiO2 modified with silane coupling agent can be carried out first. 0.8 g TiO₂ can be dispersed in 50 g toluene and sonicated for 20 min. This mixture was vigorously stirred in a three necked flask, adding 0.4 g KH550 and an appropriate amount of triethylamine (TEA). The mixture is then refluxed at 120°C for 3 h. After the reaction is complete, it is filtered and washed three times with anhydrous ethanol, and dried in a vacuum drying oven for 20 h to obtain KH550 TiO₂ [15]. The specific modification process is shown in Figure 1.

Modified nano-TiO2 reaction formula.

Next this article focuses on the preparation of TiO2/PU composite materials. A certain molar ratio of IPDI, polybutylene terephthalate (PBT), and DMPA are added to a 500 mL dry three necked flask. Acetone is removed by vacuum distillation, and the mixture is poured into a mold. The composite material film with a thickness of 1 mm is formed by hot pressing at 180°C using a hot press. The film is then placed in a vacuum drying oven to ensure complete solvent evaporation [16,17]. According to the content of KH550 TiO₂ (accounting for 0, 1, 2, 3, 4, and 5% of the total weight of IPDI, PBT, and DMPA). A series of samples can be prepared and named as TiO₂-PU 0%, TiO₂-PU 1%, TiO₂-PU 2%, TiO₂-PU 3%, TiO₂-PU 4%, and TiO₂-PU 5%.

3.3.2 Preparation of nano-ZnO PU composite materials

In order to prepare nano-ZnO PU composite, it is necessary to first prepare nano-ZnO modified with silane coupling agent. 0.7 g ZnO powder is dried at 130°C for 3 h for later use. 0.7 g ZnO is dispersed in a mixture of 55 g anhydrous ethanol and water, and treated for 30 min using a KQ-3000V ultrasonic generator. Subsequently, 0.3 g KH550 can be added dropwise and placed on a magnetic stirrer to prepare a mixture for later use. Next the preparation of ZnO/WPU composite materials is carried out. In the flask, 100 g PBT is added. After dissolving at 80°C, 2 g IPDI is quickly added under dry nitrogen protection and reacted for 1 h. Then, 1 g DMPA is added and dissolved in N-Methyl-2-pyrrolidone and reacted at 80°C for 3 h to obtain WPU prepolymer. To lower the system temperature, 30 g acetone is added to reduce viscosity, and TEA is added to neutralize and salt for 0.5 h. Then, the system is cooled to below 40°C with water, and 0.5 g ethylenediamine is added as a chain extender. The chain extension reaction can be carried out at room temperature for 1 h to prepare WPU lotion. The mixture can be poured into the mold and formed by hot pressing at 180°C using a hot press to obtain a composite material film with a thickness of 1 mm. The film can be placed in a vacuum drying oven to ensure complete solvent evaporation [18,19]. According to KH550-ZnO content (accounting for 0, 1, 2, 3, 4, and 5% of the total weight of IPDI, PBT, and DMPA), a series of samples were prepared and named ZnO-PU 0%, ZnO-PU 1%, ZnO-PU 2%, ZnO-PU 3%, ZnO-PU 4%, and ZnO-PU 5%.

3.3.3 Preparation of nano-Ag-PU composite materials

In a 250 mm three necked flask, 150 mL of deionized water is added, followed by 0.5 g silver nitrate (AgNO₃) and stirred to dissolve. Then, 1 g sodium borohydride (NaBH₄) solution is slowly added to react to produce silver nanoparticles. The solution was stirred in an ice bath for 1 h to ensure complete reaction. Finally, pure silver nanoparticles were obtained by centrifugation and washing with deionized water and ethanol [20]. Acetone is removed by vacuum distillation, and the mixture is poured into a mold and hot pressed into shape at 180°C using a hot press to obtain a composite material film with a thickness of 1 mm. The film is placed in a vacuum drying oven to ensure complete solvent evaporation [21,22]. According to the nano-Ag content (accounting for 0, 1, 2, 3, 4, and 5% of the total weight of IPDI, PBT, and DMPA), a series of samples can be prepared and named Ag-PU 0%, Ag-PU 1%, Ag-PU 2%, Ag-PU 3%, Ag-PU 4%, and Ag-PU 5%.

The constructed samples are shown in Table 2.

Composition of nanoparticle-modified polyurethane composites

| Sample name | Nanoparticle type | Nanoparticle content (wt%) | Composite material name |

|---|---|---|---|

| TiO₂-PU 0% | TiO₂ | 0 | PU without nanoparticles |

| TiO₂-PU 1% | TiO₂ | 1 | PU composite with 1% TiO₂ |

| TiO₂-PU 2% | TiO₂ | 2 | PU composite with 2% TiO₂ |

| TiO₂-PU 3% | TiO₂ | 3 | PU composite with 3% TiO₂ |

| TiO₂-PU 4% | TiO₂ | 4 | PU composite with 4% TiO₂ |

| TiO₂-PU 5% | TiO₂ | 5 | PU composite with 5% TiO₂ |

| ZnO-PU 0% | ZnO | 0 | PU without nanoparticles |

| ZnO-PU 1% | ZnO | 1 | PU composite with 1% ZnO |

| ZnO-PU 2% | ZnO | 2 | PU composite with 2% ZnO |

| ZnO-PU 3% | ZnO | 3 | PU composite with 3% ZnO |

| ZnO-PU 4% | ZnO | 4 | PU composite with 4% ZnO |

| ZnO-PU 5% | ZnO | 5 | PU composite with 5% ZnO |

| Ag-PU 0% | Ag | 0 | PU without nanoparticles |

| Ag-PU 1% | Ag | 1 | Pu composite with 1% Ag |

| Ag-PU 2% | Ag | 2 | PU composite with 2% Ag |

| Ag-PU 3% | Ag | 3 | PU composite with 3% Ag |

| Ag-PU 4% | Ag | 4 | PU composite with 4% Ag |

| Ag-PU 5% | Ag | 5 | PU composite with 5% Ag |

4 Sample characterization analysis and formula

In the study of nanocomposites, scanning electron microscope (SEM) can be used as an important characterization method to visually show the dispersion state and interface characteristics of nano-particles in the polymer matrix. Since PU is an insulator material, in order to reduce the influence of surface charge, we sprayed gold on the sample before SEM analysis. Gold spraying not only improves the conductivity of the sample, but also ensures the clarity and resolution of the SEM image, so as to more accurately observe the distribution of nanoparticles and interface bonding.

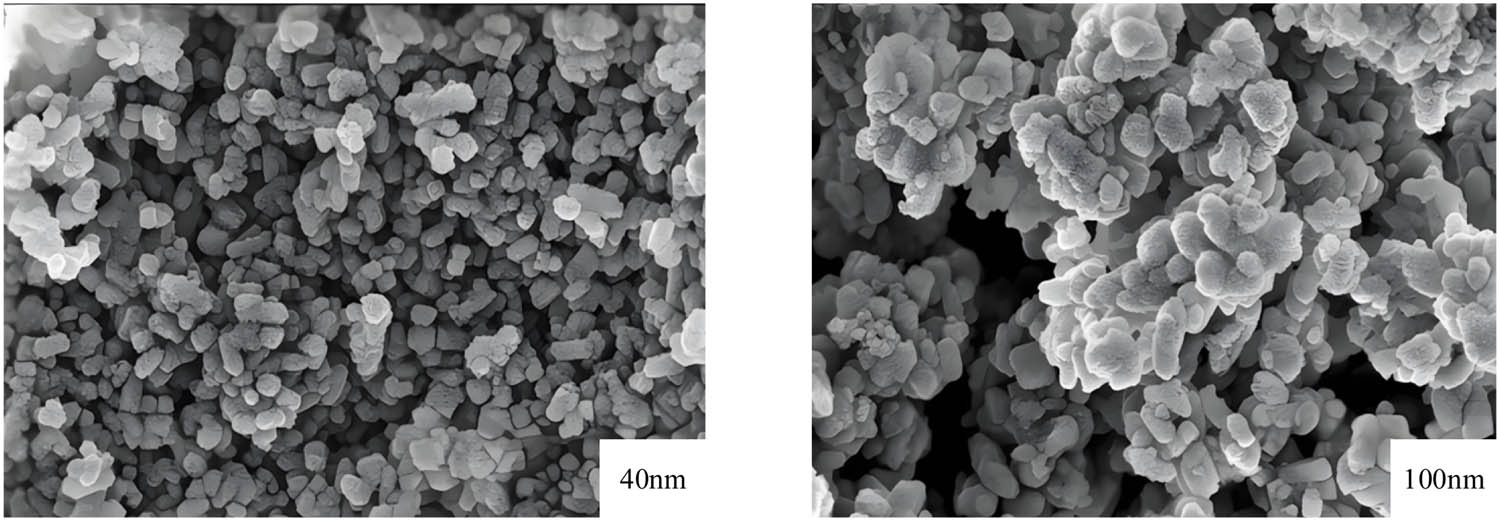

4.1 SEM image analysis of nano-TiO₂-PU composite materials

In order to examine the dispersion and interfacial bonding effect of modified TiO₂ particles in the PU matrix and to give evidence in favor of enhancing the performance of composite materials, this work employed SEM to characterize nano TiO₂-PU composites. Figure 2 displays the specific experimental results.

SEM image of nano-TiO₂-PU composite material.

The dispersion of TiO₂ particles in PU matrix is shown in Figure 2. In SEM images at 40 and 100 nm, TiO₂ particles exhibit irregular shapes and uniform sizes, evenly dispersed within the PU matrix without any aggregation. This demonstrates the modified TiO₂ particles’ excellent dispersibility and compatibility.

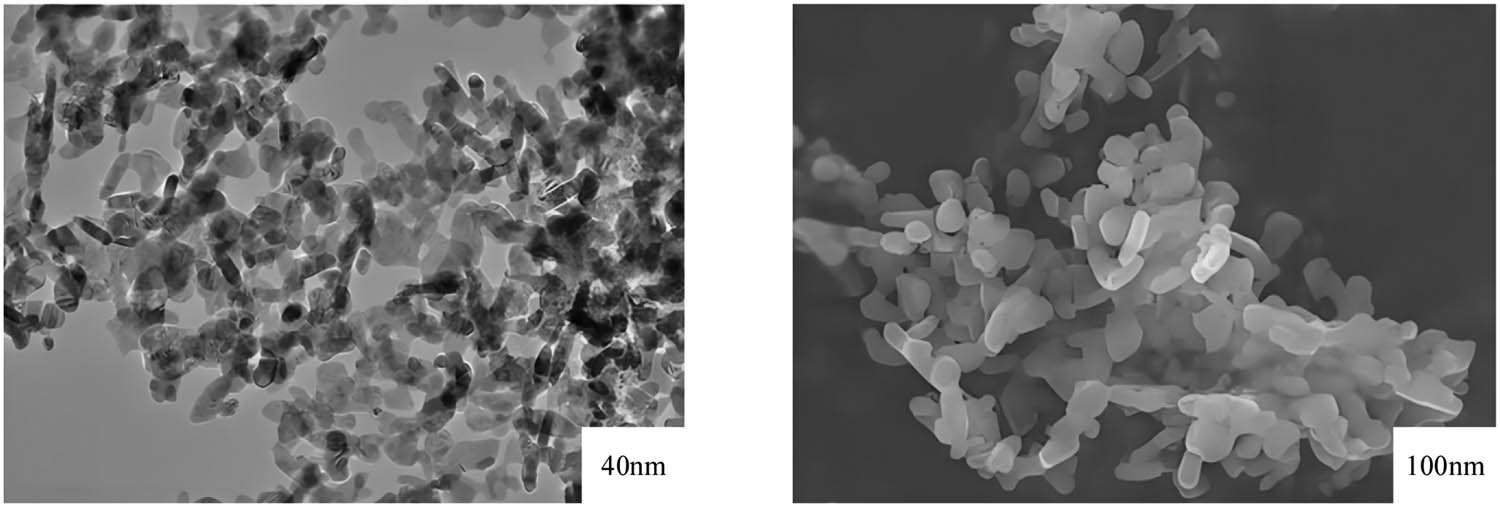

4.2 SEM image analysis of nano-ZnO-PU composite materials

In order to study in detail the distribution of modified nano-ZnO particles in the PU matrix and its interface bonding effect, this study used SEM for observation and analysis. Details are shown in Figure 3.

SEM image of nano-ZnO-PU composite material.

In Figure 3, in the SEM image at 40 nm, the ZnO particles are evenly distributed in the PU matrix, with irregular shapes and uniform particle sizes, and good dispersibility. The surface of the modified ZnO particles is smooth, without obvious sharp edges, which helps them form a strong interface bond with the PU matrix. In the 100 nm image on the right, there are no cracks or voids between the ZnO particles and the matrix, indicating a very tight interfacial bond. This strong interfacial bonding enhances the mechanical properties and durability of the composite material, resulting in superior performance in various applications.

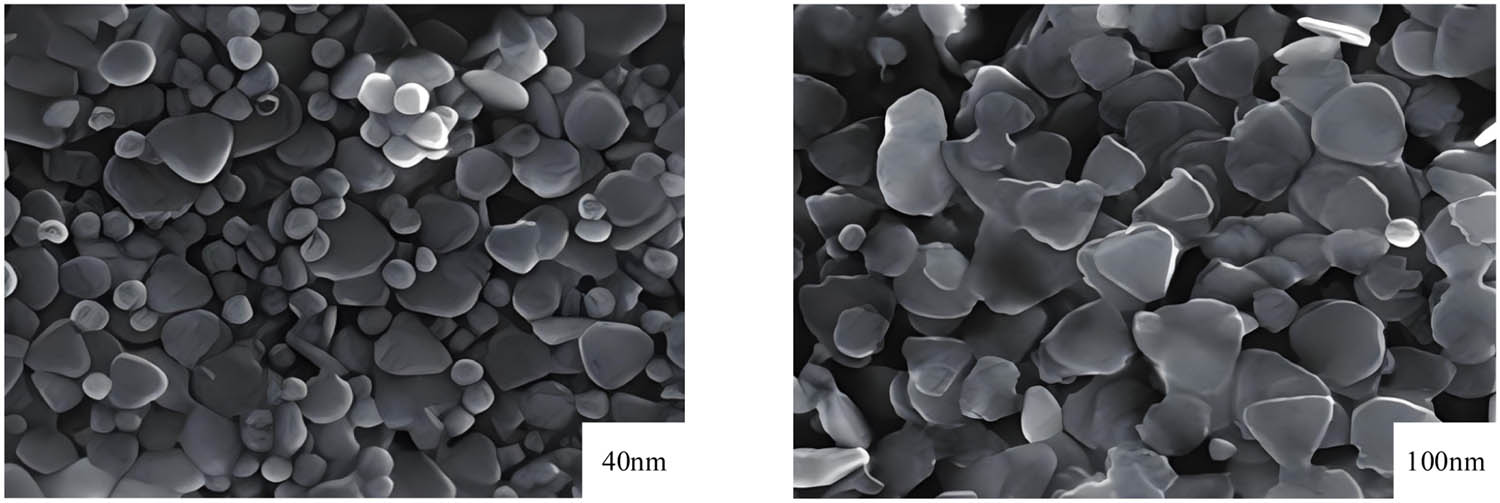

4.3 SEM image analysis of nano-Ag-PU composite materials

The distribution and interfacial bonding of silver particles in the PU matrix of nano-Ag and PU composite materials were characterized by SEM. Details are shown in Figure 4.

SEM image of nano-Ag-PU composite material.

In Figure 4, in the SEM image, Ag particles have irregular shapes, and when zoomed in, the size can be divided into 40 nm and 100 nm. In the left figure, a small amount of agglomeration can be seen, but the overall distribution is uniform, indicating that the modified silver particles have good dispersibility and compatibility. The surface of the particles is smooth without obvious sharp edges, which can help improve the interfacial adhesion between the particles and the PU matrix. There are no obvious cracks or gaps in the image, indicating good interfacial bonding between the silver particles and the PU matrix. The dispersion and interfacial bonding of silver nanoparticles in PU matrix provide important experimental basis for improving preparation process and enhancing material properties.

Although a small amount of agglomeration was observed in the SEM images, the overall distribution was still relatively uniform. The mechanical and optical characteristics of materials are significantly impacted by nanoparticle agglomeration. The agglomeration phenomenon may lead to excessively high concentrations of nanoparticles in local areas, thus forming stress concentration points, which will, to some extent, reduce the mechanical properties of the material, such as tensile strength and elongation at break. In addition, agglomerated nanoparticles may form larger scattering centers, resulting in increased light scattering, thereby reducing the transparency and transmittance of the material. However, due to the less agglomeration and uniform overall distribution in this study, these negative effects were effectively controlled at a low level.

4.4 Performance indicator analysis formula

The evaluation of performance indicators is crucial for the research of nanocomposites. This article systematically analyzes the mechanical properties, optical properties, thermal properties, and artistic color characterization of nanocomposite PU materials through a series of performance tests and mathematical formulas. The following is a detailed list of performance indicator formulas and related explanations used in this article.

4.4.1 Mechanical performance

Mechanical performance is an important indicator for evaluating the strength and toughness of composite materials.

The material's ability to withstand maximum stress during tensile loading (stretching) is quantified using Formula 1 [23].

where

Young’s modulus is the ratio of stress to strain in the elastic deformation stage of a material, which is an important parameter for measuring the stiffness of a material, as shown in formula 2 [24].

The elongation at break reflects the deformation ability of a material when stretched to fracture, as shown in formula 3 [25].

4.4.2 Optical performance

This article mainly analyzes the transmittance, UV absorption, and optical band gap of composite materials. The transmittance indicates the ability of light to pass through a medium, and the higher the value, the more transparent the material is, as shown in formula 4 [26].

Absorbance represents the material’s ability to absorb ultraviolet light. The calculation formula is shown in formula 5 [27].

The optical band gap is an important parameter in the optical activity of materials. The specific indicator formula is shown in Equation (6) [28].

4.4.3 Artistic color representation

This study primarily focuses on the color difference and chromaticity coordinates of the composite materials. Artistic color characterization is a crucial indicator for evaluating the stability and color difference of composite materials, as detailed in Equation (7) [29].

where

5 Experimental results

5.1 Fourier transform infrared (FTIR) analysis of PU composite materials

FTIR spectroscopy can identify chemical bonds and functional groups within materials and elucidate the impact of incorporating nanoparticles on the chemical structure of the PU matrix. This study conducts FTIR analysis on PU composites containing nano-TiO₂, nano-ZnO, and nano-Ag, revealing the interactions between the nanoparticles and the PU matrix and their effects on material properties. Details are shown in Figure 5.

FTIR spectra of different nano PU composite materials.

From Figure 5, it is evident that in the range of 3,200–3,500 cm⁻¹, the blue spectrum exhibits a distinct absorption peak, corresponding to the stretching vibrations of amine and hydroxyl groups. This indicates that TiO₂ nanoparticles form hydrogen bonds with these functional groups in the PU matrix enhance their vibrational modes. Near 1,250 cm⁻¹, an obvious absorption peak appeared, indicating the existence and activity of C═O bond. The green spectral line shows a clear absorption peak. These peaks indicate that ZnO interacts with the carbonyl groups in the matrix, changing the chemical structure and properties of the material. Obviously, the silver nanoparticles have obvious interactions with the amino and hydroxyl groups in the PU matrix, and the red spectral line shows a strong absorption peak in the range of 3,500–3,700 cm−1. Although the chemical inertness of silver particles is low, active sites still exist on their surfaces that can form hydrogen bonds with the matrix. In the range of 1,000–1,400 cm⁻¹, the absorption peak of the red spectral line shows the interaction between silver particles and carbonyl groups, which improves the conductivity and antibacterial properties of the material.

5.2 Impact of material mechanical properties

When studying nanocomposites, mechanical properties are one of the important indicators for measuring material quality. This article evaluates the effect of different nano content on the mechanical properties of PU composite materials through tensile strength and elongation at break. The following is an analysis of the influence of different nanoparticle contents on the mechanical properties of PU composite materials obtained through experiments. The details are shown in Figure 6.

The influence of mass fraction on mechanical performance.

The left subgraph of Figure 6 shows that as the TiO₂ content increases, the tensile strength increases from 15 to 21 MPa, followed by a slight decrease. When an appropriate amount of TiO₂ is added, the tensile strength of the composite material is significantly improved, but excessive TiO₂ can lead to a decrease in the cohesion of the material. The tensile strength of ZnO-PU composite materials increases from 15 to 20 MPa with the increase in ZnO content, and begins to decrease when it reaches its peak. The introduction of ZnO effectively improves the tensile strength of the material, but excessive ZnO can also affect the cohesion of the material. The tensile strength of Ag-PU composite materials increases from 15 to 18 MPa with the increase in Ag content, and also gradually decreases. Although the reinforcement effect of Ag particles on materials is not as good as TiO₂ and ZnO, they can still improve the strength of materials to a certain extent.

The subgraph on the right shows that with the increase in TiO₂ content, the elongation at break decreases from 300 to 260%. This indicates that although TiO₂ improves the strength of the material, it has a certain negative impact on its toughness. With the increase in ZnO content, the elongation at break decreased from 300 to 265%. The addition of ZnO particles also has a negative impact on the toughness of the material, but its effect on improving strength is more significant. The increase in Ag content resulted in a decrease in elongation at break from 300 to 270%. The addition of Ag particles affects the toughness of the material to a certain extent, but its antibacterial and conductive properties give it advantages in specific applications. Therefore, it can be concluded that reasonable control of the content of nanoparticles can optimize the comprehensive performance of PU composite materials.

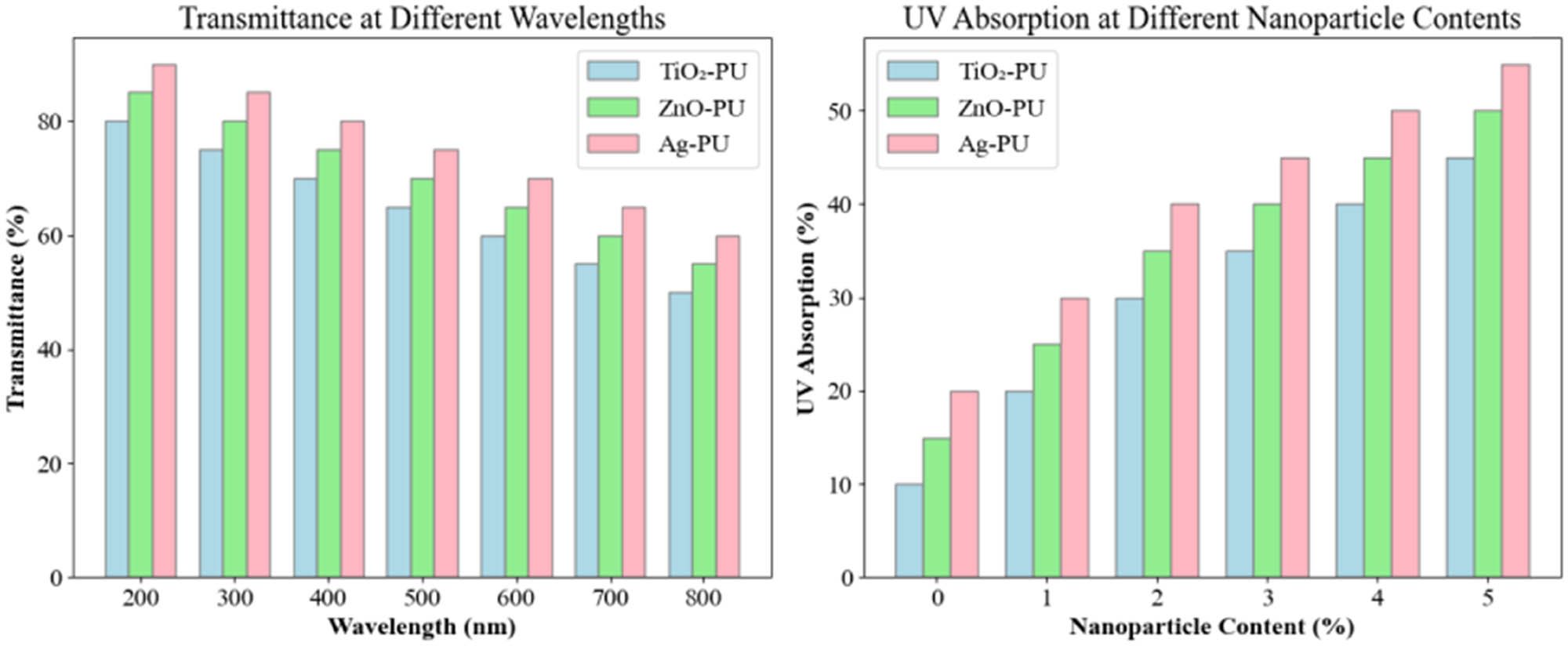

5.3 Optical performance analysis

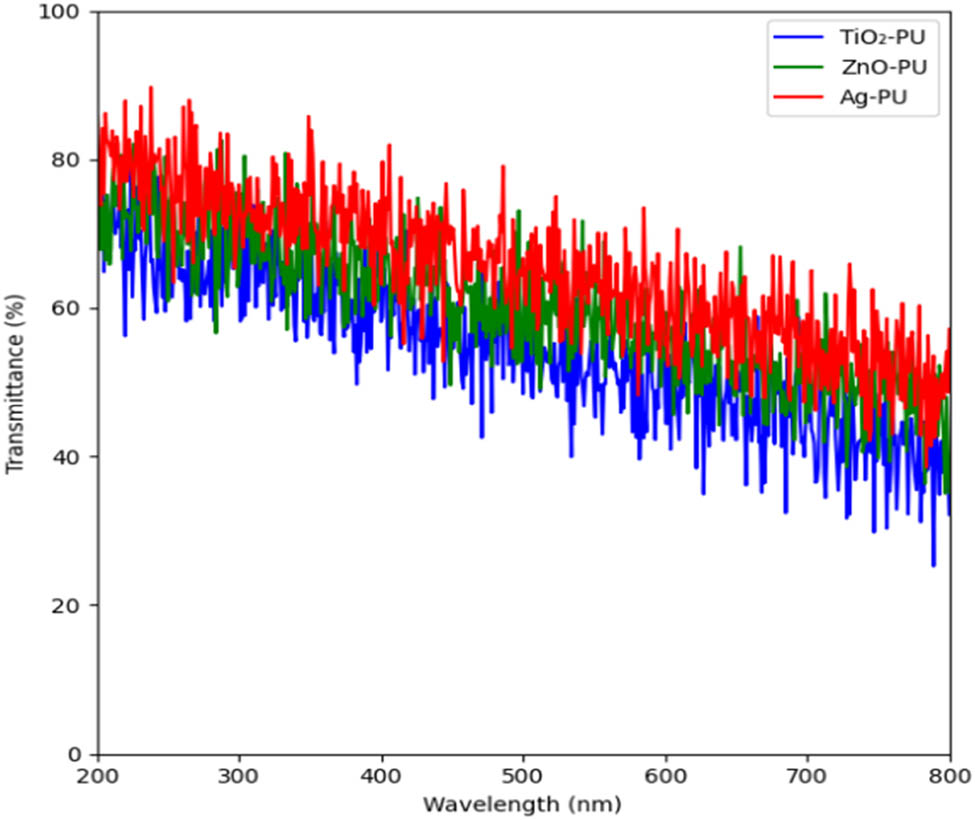

This study mainly evaluates the effect of different nanoparticle contents on the optical properties of PU composites by two indicators: transmittance and UV absorbance. Optical properties are a crucial aspect of nanocomposites in practical applications, especially in the fields of transparent coatings, optical devices, display technology, etc. In order to accurately measure the transmittance of the samples, this study used the Cary 5000 UV-visible spectrometer produced by Agilent Technologies, USA. All samples were prepared into films with a thickness of 1 mm to ensure that the thickness of the samples was consistent during the measurement process, thereby ensuring the comparability of the transmittance measurement. The transmittance measurement was carried out in the wavelength range of 200–800 nm to comprehensively evaluate the optical properties of the samples in the ultraviolet and visible light regions. The UV wavelength was selected according to the ISO 9050 standard, which provides guidance for the measurement of optical properties of architectural glass and ensures the scientific nature and international comparability of the measurement method. The effect of nanoparticle addition on the optical properties of the PU matrix was analyzed by comparing the transmittance spectra of different nanocomposite samples. In the experiment, this study analyzed the effects of three different nanomaterials (nano-TiO2, nano-ZnO, and nano-Ag) at different mass fractions on the transmittance and UV absorption of PU composites. The experimental data are shown in Figure 7, its spectrum is shown in Figure 8.

Transparency and UV absorption.

Spectrum of the experimental data.

In Figure 7, the left subfigure shows the relationship between transmittance and wavelength, while the right subfigure shows the relationship between UV absorption rate and nano content. As shown in the left figure, with the increase in wavelength, the transmittance of TiO₂-PU composite material gradually decreases from 80% at 200 nm to 50% at 800 nm, indicating that TiO₂ particles have strong absorption and scattering effects on light. The introduction of TiO2₂ particles increases the scattering and absorption of the material, thereby reducing the transmittance of light. Especially in the shorter wavelength range, there is a significant decrease in transmittance. The green bar chart shows that the transmittance of ZnO-PU composite material is relatively high in various wavelength ranges, but it gradually decreases with the increase in wavelength. According to the experimental results, the transmittance of ZnO particles at 200–800 nm decreased from 85 to 55%. The introduction of Ag particles has little effect on the scattering and absorption of light, and the transmittance at 200–800 nm decreased from 90 to 60%. Ag-PU composites have the highest transmittance in each wavelength range. The right figure shows that as the mass fraction of nano-Ag increases from 0 to 5%, the UV absorption rate also increases from 20 to 55%. Therefore, Ag particles still have a certain UV protection ability, especially in antibacterial and conductive materials.

5.4 Color representation

The representation of artistic color is an important indicator of the performance of nanocomposites in visual and artistic applications. This article evaluates the impact of different nano contents on the artistic color of PU composite materials through color changes and chromaticity parameters. This analysis is crucial for developing materials with specific visual effects and aesthetic value. The details are shown in Figure 9.

Color space distribution.

An opposition space is used to depict colors in Figure 9, with the L axis standing for brightness (from 0 for black to 100 for white), the a axis for color change from green (negative value) to red (positive value), and the b axis for color change from blue (negative value) to yellow (positive value). The distribution of TiO2-PU samples in the CIELAB color space is mainly concentrated in areas with high L values (80–90) and low a values (−5 to 0), as shown in the contour map of the nano-TiO2-PU composite material. The nano-TiO₂-PU composite material exhibits increased brightness, while its red and green tones remain relatively stable. However, as the content increases, the color changes from blue to yellow. TiO₂ particles not only improve brightness, but also have a significant impact on chromaticity parameters.

The ZnO-PU sample is a nanocomposite of ZnO and PU, mainly distributed in the CIELAB color space, with high L* values (79–92) and low a* values (−4 to 0). Compared with the TiO2-PU sample, the brightness of the ZnO-PU sample is lower. As the ZnO content increases, the b* value increases significantly and the color changes from blue to green and yellow. ZnO particles significantly affect the colorimetric parameters of the material.

In the CIELAB color space, the distribution of Ag-PU samples is mainly concentrated in the high-brightness area, with L values between 81 and 94 and low a values ranging from −3 to 0. Compared with the other two nanomaterials, the Ag-PU sample has the highest brightness and the smallest change in hue. As the Ag content increases, the b* value increases, but the change range is smaller. Ag is excellent in color stability.

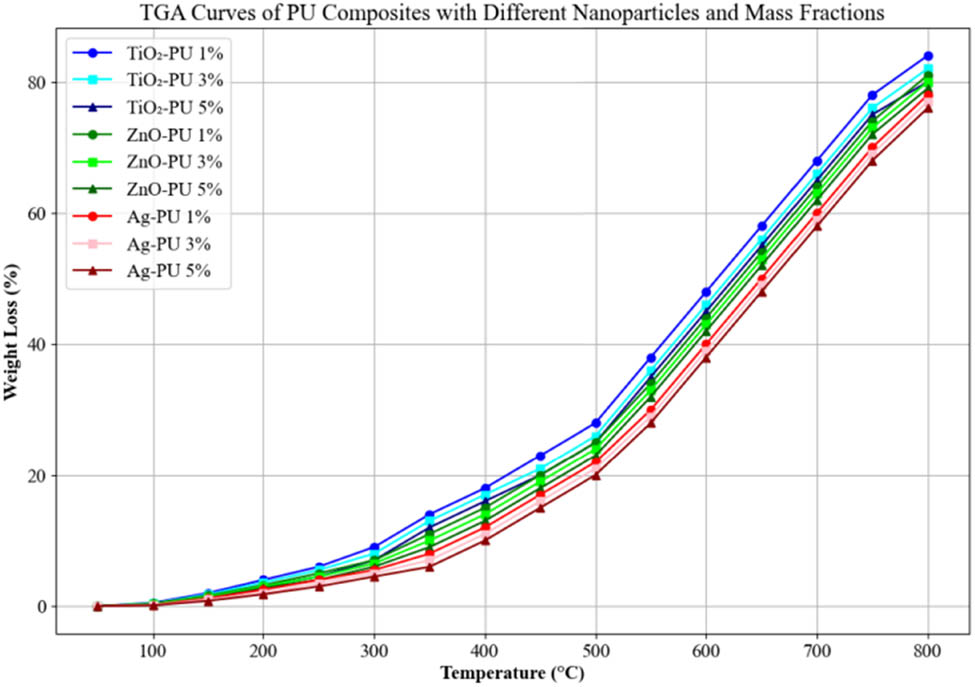

5.5 Thermal performance analysis and discussion

This article evaluates the effect of different nano content on the thermal properties of PU composite materials through thermogravimetric analysis (TGA). Thermal performance is an important indicator for evaluating the performance of nanocomposites in different temperature environments, especially their stability and heat resistance under high temperature conditions. In the experiment, three different nanomaterials were selected and TGA tests were conducted at different mass fractions (1, 3, 5%). TGA testing measures the mass loss of materials during heating to evaluate their thermal stability and decomposition temperature. Figure 10 shows the specific results and analysis of the experiment.

TGA thermal curve.

In Figure 10, TiO2-PU samples with different mass fractions (1, 3, 5%) exhibit small mass loss in the temperature range of 50–300°C, demonstrating good thermal stability. As the temperature increases, the mass loss gradually increases, with mass losses of 84, 82, and 80% at 800°C. Therefore, it can be concluded that TiO2 particles with lower mass fractions can effectively prevent thermal decomposition. In the low temperature range (50–300°C), the mass loss mainly ranges from 0 to 14%. The TGA curve of ZnO-PU is similar to that of TiO2-PU, but the overall mass loss at each temperature point is relatively small. At 800°C, the mass loss is 81, 80, and 79%, respectively. ZnO particles exhibit better thermal stability at different mass fractions. At higher quality scores, the material is more heat-resistant. In the intermediate temperature range (300–500°C), the mass loss is smaller and the contribution to thermal stability is greater. The Ag-PU sample exhibits better thermal stability in the TGA curve. From 50 to 300°C, the quality loss is very small, maintaining below 5.5%. At 800°C, the mass loss is 78, 77, and 76%. The addition of nano silver improves the thermal stability of PU composite materials. In the high temperature range (500–800°C), Ag-PU samples exhibit the best thermal stability.

In summary, it can be concluded that nano-Ag, nano-TiO2, and nano-ZnO improve the thermal stability of PU composites, and nano-Ag plays the greatest role, providing an important foundation for further improving the preparation process and practical application of nanocomposite PU materials.

6 Conclusion

This study reveals the significant role of these nanoparticles in improving the optical properties and color stability of materials through systematic analysis of nano-TiO₂, nano-ZnO, and nano-Ag-PU composites. Nano-TiO2 effectively improves the transparency and UV blocking ability of the material, enhancing its absorption of short-wave ultraviolet radiation. Nano-ZnO significantly improves the material’s UV stability and overall optical performance through its excellent UV absorption characteristics. Nano Ag not only enhances transparency, but also endows the material with excellent antibacterial properties and color stability. The research results indicate that the type and distribution of nanoparticles have a significant impact on the optical properties and color performance of PU composite materials, and their respective mechanisms have a modifying effect on the material properties. However, some shortcomings were also found during the experiment. Nano-TiO₂ and nano-ZnO effectively enhanced the strength of the material, but had a certain negative impact on its toughness. Moreover, excessive content of nanoparticles can lead to a decrease in the cohesion of the material. Future research should continue to optimize the dispersion technology of nanoparticles, explore the combination effect of nanoparticles, expand the application potential of these nanocomposites in other high-performance fields, and provide more comprehensive theoretical and experimental basis for the development of new high-performance nanocomposites.

-

Funding information: The authors state no funding involved.

-

Author contributions: Jiaju Hu: writing – original draft preparation. Youqiang Zhang – editing, data curation, and supervision.

-

Conflict of interest: The authors state no conflict of interest.

-

Ethical statement: Not Applicable.

-

Data availability statement: No/Not applicable (this manuscript does not report data generation or analysis).

References

[1] Lu H-F, Wang M, Chen X-M, Lin B-P, Yang H. Interpenetrating liquid-crystal polyurethane/polyacrylate elastomer with ultrastrong mechanical property. J Am Chem Soc. 2019;141(36):14364–69.10.1021/jacs.9b06757Suche in Google Scholar PubMed

[2] Fang J, Tu J. Effect of ultraviolet (UV) aging on rheology properties and microstructure of polyurethane (PU) modified asphalt. Mater Res Express. 2019;6(12):125318–24.10.1088/2053-1591/ab558fSuche in Google Scholar

[3] Tang A, Huang Y, Zhang W, Yu Y, Yang Y, Yuan Z. Effect of the nano-titanium dioxide (nano-TiO2) coating on the photoaging properties of thermally treated bamboo. Wood Mater Sci Eng. 2022;17(6):895–904.10.1080/17480272.2021.1972334Suche in Google Scholar

[4] Rajeshkumar S, Yadav K, Sridharan M, Roopan SM. Nano silver: An overview of shape, size-controlled synthesis and their antibacterial property. High Energy Chem. 2023;57(3):205–16.10.1134/S001814392303013XSuche in Google Scholar

[5] Bahbishi N, Mzain W, Badeeb B, Nassar HM. Color stability and micro-hardness of bulk-fill composite materials after exposure to common beverages. Materials. 2020;13(3):787.10.3390/ma13030787Suche in Google Scholar PubMed PubMed Central

[6] Chen G, Hong W. Mechanochromism of structural‐colored materials. Adv Opt Mater. 2020;8(19):2000984.10.1002/adom.202000984Suche in Google Scholar

[7] Wang L, Hasanzadeh Kafshgari M, Meunier M. Optical properties and applications of plasmonic‐metal nanoparticles. Adv Funct Mater. 2020;30(51):2005400.10.1002/adfm.202005400Suche in Google Scholar

[8] Wei Y, Ebendorff‐Heidepriem H, Zhao J. Recent advances in hybrid optical materials: Integrating nanoparticles within a glass matrix. Adv Opt Mater. 2019;7(21):1900702.10.1002/adom.201900702Suche in Google Scholar

[9] Mei S, Yang B, Wei X, Dai H, Chen Z, Cui Z, et al. Facile synthesis and optical properties of CsPbX3/ZIF-8 composites for wide-color-gamut display. Nanomaterials. 2019;9(6):832.10.3390/nano9060832Suche in Google Scholar PubMed PubMed Central

[10] Cai J, Murugadoss V, Jiang J, Gao X, Lin Z, Huang M, et al. Waterborne polyurethane and its nanocomposites: a mini-review for anti-corrosion coating, flame retardancy, and biomedical applications. Adv Compos Hybrid Mater. 2022;5(2):641–50.10.1007/s42114-022-00473-8Suche in Google Scholar

[11] Allami T, Alamiery A, Nassir MH, Kadhum AH. Investigating physio-thermo-mechanical properties of polyurethane and thermoplastics nanocomposite in various applications. Polymers. 2021;13(15):2467–71.10.3390/polym13152467Suche in Google Scholar PubMed PubMed Central

[12] Stachak P, Lukaszewska I, Hebda E, Pielichowski K. Recent advances in fabrication of non-isocyanate polyurethane-based composite materials. Materials. 2021;14(13):3497–502.10.3390/ma14133497Suche in Google Scholar PubMed PubMed Central

[13] Lee T-H, Yen C-T, Hsu S-H. Preparation of polyurethane-graphene nanocomposite and evaluation of neurovascular regeneration. ACS Biomater Sci & Eng. 2019;6(1):597–609.10.1021/acsbiomaterials.9b01473Suche in Google Scholar PubMed

[14] Ahmadi Y, Ahmad S. Recent progress in the synthesis and property enhancement of waterborne polyurethane nanocomposites: promising and versatile macromolecules for advanced applications. Polym Rev. 2020;60(2):226–66.10.1080/15583724.2019.1673403Suche in Google Scholar

[15] Taghi-Akbari L, Naimi-Jamal MR, Ahmadi S. Flammability, smoke production, and mechanical properties of thermoplastic polyurethane composites with an intumescent flame-retardant system and nano-silica. Iran Polym J. 2023;32(9):1165–78.10.1007/s13726-023-01188-3Suche in Google Scholar

[16] Tian X-Z, Yang R, Ma J-J, Ni Y-H, Deng H-B, Dai L. A novel ternary composite of polyurethane/polyaniline/nanosilica with antistatic property and excellent mechanical strength: Preparation and mechanism. Chin J Polym Sci. 2022;40(7):789–98.10.1007/s10118-022-2703-7Suche in Google Scholar

[17] Li X, Wang H, Zhang Z, Tan Y, Tian J, Chen G. Preparation and mechanical properties of poly (γ‐benzyl l‐glutamate) modified nano‐silica reinforced polyurea composites. Polym Adv Technol. 2022;33(1):270–9.10.1002/pat.5514Suche in Google Scholar

[18] Rahman MM. Polyurethane/zinc oxide (PU/ZnO) composite—synthesis, protective property and application. Polymers. 2020;12(7):1535–5.10.3390/polym12071535Suche in Google Scholar PubMed PubMed Central

[19] El Mogy S, Youssef RS, Abd El Megeed AA. Processing of polyurethane nanocomposite reinforced with nanosized zinc oxide: effect on mechanical and acoustic properties. Egypt J Chem. 2019;62(2):333–41.Suche in Google Scholar

[20] Cheng L, Ren S, Lu X. Application of eco-friendly waterborne polyurethane composite coating incorporated with nano cellulose crystalline and silver nano particles on wood antibacterial board. Polymers. 2020;12(2):407–12.10.3390/polym12020407Suche in Google Scholar PubMed PubMed Central

[21] Zhao B, Qian Y, Qian X, Fan J, Feng Y. Fabrication and characterization of waterborne polyurethane/silver nanocomposite foams. Polym Compos. 2019;40(4):1492–8.10.1002/pc.24888Suche in Google Scholar

[22] Sun J-T, Li J-W, Tsou C-H, Pang J-C, Chung R-J, Chiu C-W. Polyurethane/nanosilver-doped halloysite nanocomposites: Thermal, mechanical properties, and antibacterial properties. Polymers. 2020;12(11):2729–35.10.3390/polym12112729Suche in Google Scholar PubMed PubMed Central

[23] Mori K, Matsumoto N, Yabe M, Konho Y. Tensile test analysis of carbon fiber composite material by molecular dynamics simulation. Adv Composite Mater. 2020;29(2):179–90.10.1080/09243046.2019.1669003Suche in Google Scholar

[24] Firestein KL, von Treifeldt JE, Kvashnin DG, Fernando JFS, Zhang C, Kvashnin AG, et al. Young’s modulus and tensile strength of Ti3C2 MXene nanosheets as revealed by in situ TEM probing, AFM nanomechanical mapping, and theoretical calculations. Nano Lett. 2020;20(8):5900–8.10.1021/acs.nanolett.0c01861Suche in Google Scholar PubMed

[25] Abral H, Atmajaya A, Mahardika M, Hafizulhaq F, Kadriadi, Handayani D, et al. Effect of ultrasonication duration of polyvinyl alcohol (PVA) gel on characterizations of PVA film. J Mater Res Technol. 2020;9(2):2477–86.10.1016/j.jmrt.2019.12.078Suche in Google Scholar

[26] Chen H, Baitenov A, Li Y, Vasileva E, Popov S, Sychugov I. Thickness dependence of optical transmittance of transparent wood: chemical modification effects. ACS Appl Mater Interfaces. 2019;11(38):35451–7.10.1021/acsami.9b11816Suche in Google Scholar PubMed PubMed Central

[27] Kiomarsipour N, Ghasemi M, Ghani K. Synthesis and evaluation of several high absorbance black pigments for spacecraft thermal control coatings. Color Res Appl. 2019;44(6):917–24.10.1002/col.22418Suche in Google Scholar

[28] Mannino G, Deretzis I, Smecca E, La Magna A, Alberti A, Ceratti D, et al. Temperature-dependent optical band gap in CsPbBr3, MAPbBr3, and FAPbBr3 single crystals. J Phys Chem Lett. 2020;11(7):2490–6.10.1021/acs.jpclett.0c00295Suche in Google Scholar PubMed PubMed Central

[29] Durand LB. Color, lightness, chroma, hue, and translucency adjustment potential of resin composites using CIEDE2000 color difference formula. J Esthetic Restor Dent. 2021;33(6):836–43.10.1111/jerd.12689Suche in Google Scholar PubMed

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Investigation on cutting of CFRP composite by nanosecond short-pulsed laser with rotary drilling method

- Antibody-functionalized nanoporous silicon particles as a selective doxorubicin vehicle to improve toxicity against HER2+ breast cancer cells

- Study on the effects of initial stress and imperfect interface on static and dynamic problems in thermoelastic laminated plates

- Analysis of the laser-assisted forming process of CF/PEEK composite corner structure: Effect of laser power and forming rate on the spring-back angle

- Phase transformation and property improvement of Al–0.6Mg–0.5Si alloys by addition of rare-earth Y

- A new-type intelligent monitoring anchor system for CFRP strand wires based on CFRP self-sensing

- Optical properties and artistic color characterization of nanocomposite polyurethane materials

- Effect of 200 days of cyclic weathering and salt spray on the performance of PU coating applied on a composite substrate

- Experimental analysis and numerical simulation of the effect of opening hole behavior after hygrothermal aging on the compression properties of laminates

- Engineering properties and thermal conductivity of lightweight concrete with polyester-coated pumice aggregates

- Optimization of rGO content in MAI:PbCl2 composites for enhanced conductivity

- Collagen fibers as biomass templates constructed multifunctional polyvinyl alcohol composite films for biocompatible wearable e-skins

- Early age temperature effect of cemented sand and gravel based on random aggregate model

- Properties and mechanism of ceramizable silicone rubber with enhanced flexural strength after high-temperature

- Buckling stability analysis of AFGM heavy columns with nonprismatic solid regular polygon cross-section and constant volume

- Reusable fibre composite crash boxes for sustainable and resource-efficient mobility

- Investigation into the nonlinear structural behavior of tapered axially functionally graded material beams utilizing absolute nodal coordinate formulations

- Mechanical experimental characteristics and constitutive model of cemented sand and gravel (CSG) material under cyclic loading with varying amplitudes

- Synthesis and properties of octahedral silsesquioxane with vinyl acetate side group

- The effect of radiation-induced vulcanization on the thermal and structural properties of Ethylene Propylene Diene Monomer (EPDM) rubber

- Review Articles

- State-of-the-art review on the influence of crumb rubber on the strength, durability, and morphological properties of concrete

- Recent advances in carbon and ceramic composites reinforced with nanomaterials: Manufacturing methods, and characteristics improvements

- Special Issue: Advanced modeling and design for composite materials and structures

- Validation of chromatographic method for impurity profiling of Baloxavir marboxil (Xofluza)

Artikel in diesem Heft

- Research Articles

- Investigation on cutting of CFRP composite by nanosecond short-pulsed laser with rotary drilling method

- Antibody-functionalized nanoporous silicon particles as a selective doxorubicin vehicle to improve toxicity against HER2+ breast cancer cells

- Study on the effects of initial stress and imperfect interface on static and dynamic problems in thermoelastic laminated plates

- Analysis of the laser-assisted forming process of CF/PEEK composite corner structure: Effect of laser power and forming rate on the spring-back angle

- Phase transformation and property improvement of Al–0.6Mg–0.5Si alloys by addition of rare-earth Y

- A new-type intelligent monitoring anchor system for CFRP strand wires based on CFRP self-sensing

- Optical properties and artistic color characterization of nanocomposite polyurethane materials

- Effect of 200 days of cyclic weathering and salt spray on the performance of PU coating applied on a composite substrate

- Experimental analysis and numerical simulation of the effect of opening hole behavior after hygrothermal aging on the compression properties of laminates

- Engineering properties and thermal conductivity of lightweight concrete with polyester-coated pumice aggregates

- Optimization of rGO content in MAI:PbCl2 composites for enhanced conductivity

- Collagen fibers as biomass templates constructed multifunctional polyvinyl alcohol composite films for biocompatible wearable e-skins

- Early age temperature effect of cemented sand and gravel based on random aggregate model

- Properties and mechanism of ceramizable silicone rubber with enhanced flexural strength after high-temperature

- Buckling stability analysis of AFGM heavy columns with nonprismatic solid regular polygon cross-section and constant volume

- Reusable fibre composite crash boxes for sustainable and resource-efficient mobility

- Investigation into the nonlinear structural behavior of tapered axially functionally graded material beams utilizing absolute nodal coordinate formulations

- Mechanical experimental characteristics and constitutive model of cemented sand and gravel (CSG) material under cyclic loading with varying amplitudes

- Synthesis and properties of octahedral silsesquioxane with vinyl acetate side group

- The effect of radiation-induced vulcanization on the thermal and structural properties of Ethylene Propylene Diene Monomer (EPDM) rubber

- Review Articles

- State-of-the-art review on the influence of crumb rubber on the strength, durability, and morphological properties of concrete

- Recent advances in carbon and ceramic composites reinforced with nanomaterials: Manufacturing methods, and characteristics improvements

- Special Issue: Advanced modeling and design for composite materials and structures

- Validation of chromatographic method for impurity profiling of Baloxavir marboxil (Xofluza)