Abstract

This study investigates the influence of radiation-induced vulcanization and carbon black reinforcement on the thermal and structural properties of Ethylene Propylene Diene Monomer (EPDM) rubber. Gamma irradiation was applied at varying doses to EPDM composites containing different concentrations of carbon black. The results revealed that the swelling ratio of the rubber composites in hydraulic and engine oils decreased with increasing radiation dose and carbon black content, while a slight increase occurred with rising oil temperature. Differential scanning calorimetry (DSC) showed that the glass transition temperature increased with radiation dose, indicating enhanced crosslinking density and restricted molecular mobility of the EPDM chains. Scanning Electron Microscopy (SEM) analysis confirmed improved filler dispersion and surface homogeneity up to 150 kGy, beyond which degradation occurred. The abrasion resistance increased with radiation dose up to 150 kGy and then decreased at higher doses due to chain scission. These findings highlight the potential of controlled gamma radiation to enhance the performance and durability of EPDM-based composites for industrial applications.

1 Introduction

Ethylene Propylene Diene Monomer (EPDM) is an important class of synthetic rubber that has found widespread industrial applications due to its exceptional balance of elasticity, weatherability, and thermal stability. Developed in the early 1960s, EPDM is a terpolymer consisting of ethylene, propylene, and a non-conjugated diene (such as ethylidene norbornene or dicyclopentadiene). The presence of ethylene provides crystallinity and tensile strength, while propylene enhances flexibility, and the diene component introduces reactive sites for crosslinking during vulcanization [1], 2]. This unique molecular architecture allows EPDM to maintain its mechanical integrity under harsh environmental conditions, including prolonged exposure to heat, UV radiation, and oxidative media [3], [4], [5]. These intrinsic structural features explain its superior toughness, weather resistance, and wide temperature operating range compared to other elastomers.

Vulcanization is a key process that transforms raw rubber into a mechanically robust and chemically stable material through the formation of crosslinks between polymer chains. Traditional vulcanization methods rely on sulfur or peroxide curing agents; however, these approaches may leave residual chemicals that can adversely affect the thermal stability or environmental performance of rubber products. Radiation-induced vulcanization has emerged as an alternative technique, offering precise control over crosslink density without the need for chemical additives. Gamma radiation, in particular, can simultaneously initiate crosslinking and chain scission, influencing the final mechanical, thermal, and structural characteristics of elastomers [6], [7], [8].

In earlier studies, atomic force microscopy (AFM) and spectroscopic analyses were used to monitor the initiation of chain scission and crosslink formation in elastomers exposed to gamma radiation, confirming the role of radiation in modifying polymer networks [9], 10].

Several researchers have explored the effects of gamma radiation on EPDM-based materials. For example, the application of controlled radiation doses to EPDM/recycled fiber composites resulted in notable improvements in tensile strength and wear resistance due to enhanced interfacial bonding [11], 12]. Other studies demonstrated that increasing radiation doses could enhance polymer durability and thermal resistance, although excessive exposure may promote degradation through chain scission [13], [14], [15]. Investigations on nitrile and EPDM elastomers revealed a direct correlation between radiation dose and crosslink density, confirming that optimal doses are crucial for balancing crosslinking and degradation effects [16], 17].

Fillers such as carbon black play a crucial role in reinforcing EPDM rubber. Carbon black enhances stiffness, thermal conductivity, and oil resistance by improving the filler–matrix interaction and limiting polymer chain mobility [18], 19]. Studies have also shown that combining carbon black with nanofillers such as graphene can produce synergistic effects, further improving electrical and mechanical performance [20], 21]. However, most of these studies remain descriptive and focus primarily on the individual effects of radiation or fillers rather than their combined influence. Moreover, the literature provides limited insights into how varying carbon black concentrations interact with gamma radiation to influence crosslinking density, oil resistance, and structural uniformity in EPDM composites.

Fillers such as carbon black play a vital role in reinforcing EPDM rubber by improving stiffness, abrasion resistance, and oil resistance through enhanced filler–matrix interaction. Carbon black contributes to the formation of a more compact polymer network, which limits molecular mobility and improves thermal conductivity and mechanical performance [22], [23], [24]. Similarly, studies have shown that the composition and concentration of carbon black strongly influence the mechanical strength, swelling resistance, and durability of EPDM vulcanizates [25], [26], [27].

Furthermore, the ratio of natural rubber (NR) to EPDM and the structure of the carbon black have been reported to affect the overall mechanical and dynamic properties of the resulting composites [28]. Surface modification of fillers can also promote better phase compatibility and dispersion within the EPDM matrix, leading to improved mechanical and environmental performance [29], 30].

Although these studies collectively confirm that carbon black reinforcement significantly enhances the thermal and mechanical behavior of EPDM rubber, most of them have focused primarily on conventional or chemically cured systems. Limited attention has been given to the combined influence of gamma radiation and carbon black on the crosslinking mechanisms, structural uniformity, and oil resistance of EPDM composites.

Therefore, the present study aims to systematically investigate the effect of gamma radiation at different doses on the structural, thermal, and oil-resistance properties of EPDM rubber reinforced with various amounts of carbon black. The objectives are to (i) determine how the radiation dose and filler content affect the degree of crosslinking and swelling behavior, (ii) analyze changes in thermal transition using differential scanning calorimetry (DSC), and (iii) examine the morphological evolution and wear resistance of irradiated EPDM composites. By addressing the limited understanding of the combined effects of radiation and filler reinforcement, this work contributes to optimizing radiation vulcanization as a sustainable and controllable method for enhancing the performance of EPDM-based materials in industrial environments.

2 Materials and methods

The materials used in this study and their specifications are as follows. The rubber phase consisted of Ethylene Propylene Diene Monomer (EPDM 756 grade) sourced from SABIC in Saudi Arabia, characterized by an ethylene content of 69 %, ethylidene norbornene content of 5 %, and a Mooney viscosity (1 + 4, 125 °C) of 72 MU. Carbon Black N330, obtained from Cabot Corporation in the USA, featured an ash content of 0.5 %, purity of 99 %, specific density of 1.8 g/cm3, and surface area of 110 m2/g. Zinc Oxide in the form of a white fine powder was supplied by Zinc Oxide Manufacturing Co., Ltd from China, with a density of 5.61 g/cm3, melting point of 1,975 °C, and acting as an electrical insulator under normal conditions while being insoluble in water and having a boiling point of 2,360 °C. Stearic Acid (C18H36O2) was procured from Shanghai Jinsen Chemical Co., Ltd in China, presenting as a white crystalline solid with molecular weight of 248.48 g/mol, purity of 95 %, melting point of 70 °C, and density of 0.9 g/cm3. The antioxidant system included Butylated Hydroxytoluene (BHT, C15H24O) from Zhejiang Jianye Chemical Co., Ltd in China, a white crystalline powder with molecular weight of 220.36 g/mol, purity of 99 %, and density of approximately 0.98 g/cm3. Di(2-ethylhexyl) phthalate plasticizer, supplied by Shandong Qilu Plasticizer Co., Ltd in China, appeared as a colorless oily liquid with chemical formula C24H38O4, molecular weight of 390.57 g/mol, density of 0.986 g/cm3, and purity of 99 %. Two lubricating oils were employed: Hydraulic Oil SO VG 68 from Castrol in Japan, exhibiting viscosity of 68 cSt at 40 °C, pour point of −15 °C, and flash point of 230 °C; and Toyota Genuine Motor Oil 20W-50 from Toyota in Japan, with flash point of 240 °C and density of 0.86 g/cm3. All sample preparation was conducted using an internal mixer operating at 75 °C with a rotational speed of 60 rpm for a total mixing cycle of 10 min.

The samples were prepared in an internal mixer at a temperature of 75 °C and a rotational speed of 60 revolutions per minute (rpm). The total mixing cycle lasted 10 min. The samples were then mixed with carbon black using a laboratory rubber mixer with a capacity of 1 kg. The kneading process was carried out according to the ASTM D3182 standard, which includes the working temperature, the sequence of adding materials to the machine, and the time required for homogenization. After obtaining homogeneous samples with varying thicknesses containing different proportions of carbon black (0–90 phr), as shown in (Table 1), the samples were cured using a German-made COLLIN laboratory press with dimensions of 200 × 200 × 2 mm. The samples were heated to a temperature of 90 °C at a pressure of 150 bar for 5 min. Subsequently, the samples were cooled with water under constant pressure to a temperature of 25 °C.

Composition ratios of rubber samples.

| Function | Ingredients | Concentration (phr*) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rubber matrix | EPDM | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Processing aid | Stearic acid | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Activator | Zinc oxide | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Antioxidant | BHT | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Plasticizers | Di(2-ethylhexyl) phthalate | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Reinforced filler | N330 | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

2.1 Irradiation of samples

The vulcanized composites were irradiated in air at room temperature and atmospheric pressure using a Cobalt-60 (Co60) source with an energy of 1.2 MeV. Different gamma radiation doses (0, 50, 100, 150, 200, 250, 300 kGy) were applied at a dose rate of 20.5 kGy/h, with five samples tested per dose level.

2.2 Swelling test

The swelling test was conducted according to the ASTM-D471 standard. Composite samples with dimensions of 50 × 25 × 2 mm were weighed to determine their dry weight (W d ). They were then immersed in two different solvents: hydraulic oil SO VG 68 and engine oil 20W-50, in tightly sealed glass containers. The containers were stored at room temperature and at 80 °C. The samples were weighed at regular intervals, and the swelling ratio was calculated using the formula:

W d – dry weight of the sample before immersion (g);

W w – swollen weight of the sample after immersion (g).

2.3 Thermal measurements using differential scanning calorimetry (DSC)

A differential scanning calorimeter (DSC) provided by Setaram, France, was used, as shown in (Figure 1). This device operates within a temperature range of (−150 to 700 °C), and an inert nitrogen atmosphere is maintained. The device uses aluminum crucibles with a capacity of 30 μL, with a test sample weight of (3–8 mg) and a heating rate of 10 °C/min.

Differential scanning calorimeter (DSC).

2.4 Morphological study using Scanning Electron Microscopy (SEM)

The surface morphology and distribution of carbon black particles were examined using a Scanning Electron Microscope (SEM) equipped with energy-dispersive X-ray spectroscopy (EDS) as shown in (Figure 2).

Scanning electron microscope (SEM).

2.5 Friction resistance test

The friction resistance was tested according to the international standard DIN 53516 by calculating the volume loss of the material using a device as shown in (Figure 3). The wear volume was determined as a function of the abrasion degree of the sandpaper, with values taken according to the standard ISO 1891, Part 1. The lost volume (V) was then calculated using the relation:

where:

Abrasion resistant rubber testing machine.

V – lost volume (mm3);

Δm = m 1 − m 2 – weight of the removed material (mg);

m 1 – weight of the sample before the test (mg);

m 2 – weight of the sample after the test (mg);

S o = 200 mg – constant for calculated wear degree based on a standard friction distance;

s – smoothness index of the sandpaper;

α – density of the sample, calculated based on the volume displaced by the liquid.

2.6 Swelling test

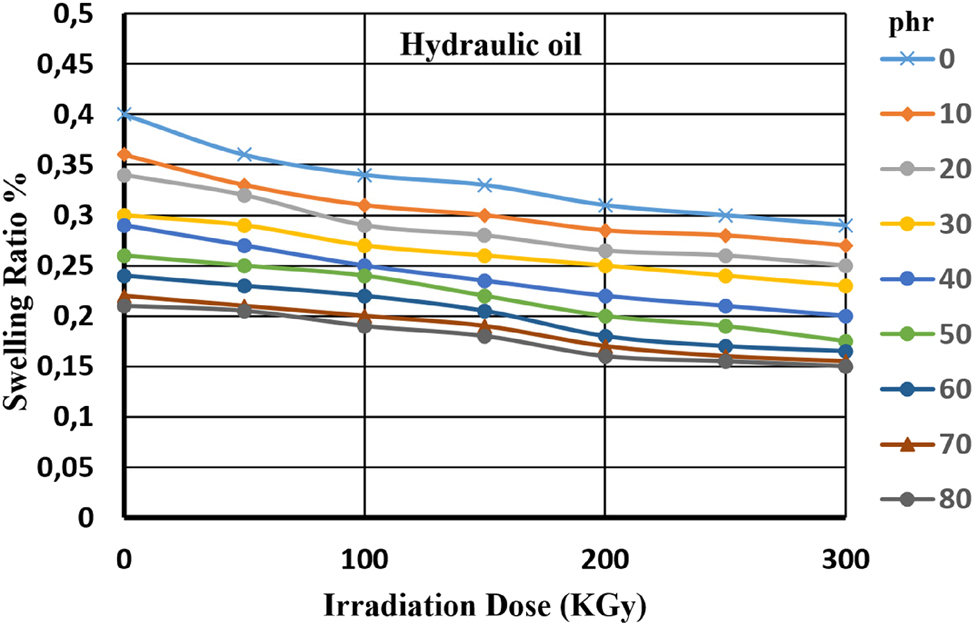

Figure 4 illustrates the swelling values of rubber composites made from EPDM rubber at different carbon black (CB) loading levels, ranging from 0 to 80 phr, in two widely used industrial oils – hydraulic oil and engine oil – as a function of radiation dose.

Swelling of composites in hydraulic oil at room temperature using different radiation doses.

The swelling degree of the prepared samples was measured at room temperature after immersing them in these oils for 30 days, with the final reading recorded to calculate the maximum equilibrium swelling, which represents the highest oil absorption capacity.

From Figure 4, it can be observed that the swelling values decrease with increasing radiation dose. This reduction is primarily attributed to the radiation-induced crosslinking of rubber chains, which increases the crosslink density of the rubber’s molecular chains, forming a three-dimensional network that hinders oil penetration and diffusion within the rubber structure, thereby reducing oil absorption.

Additionally, the incorporation of carbon black particles into the voids between rubber chains reduces the free volume, further restricting the entry and diffusion of oil molecules within the rubber composite structure [31].

Carbon black particles tend to form agglomerates that prevent oil from penetrating into the rubber matrix. The increase in the number of physical and chemical bonds formed between carbon black and the macromolecular rubber molecules significantly contributes to reducing the degree of swelling. The filler material acts as a barrier (to organic solvents), and therefore its presence within the rubber structure reduces oil absorption by the rubber. Additionally, loading with carbon black promotes the crosslinking of the rubber structure, which prevents oil molecules from infiltrating the molecular chains of the rubber, thereby lowering the swelling rate.

When the oil temperature is raised to 80 °C, it is observed that the maximum swelling value of the rubber samples modified with carbon black increases compared to the samples immersed in hydraulic oil at room temperature, as shown in (Figure 5). This is attributed to the decrease in oil viscosity with increasing temperature, making it easier for the oil to enter and spread within the molecular chains of the rubber. Consequently, swelling values are higher at all radiation doses and carbon black loading levels, although these values remain very low, demonstrating the inherent resistance of the rubber to oils and hydraulic fluids due to the role played by the ethylene and propylene monomers, which are known for their resistance to hydrocarbon oils and engine fluids.

Swelling of composites in hydraulic oil at 80 °C and different radiation doses.

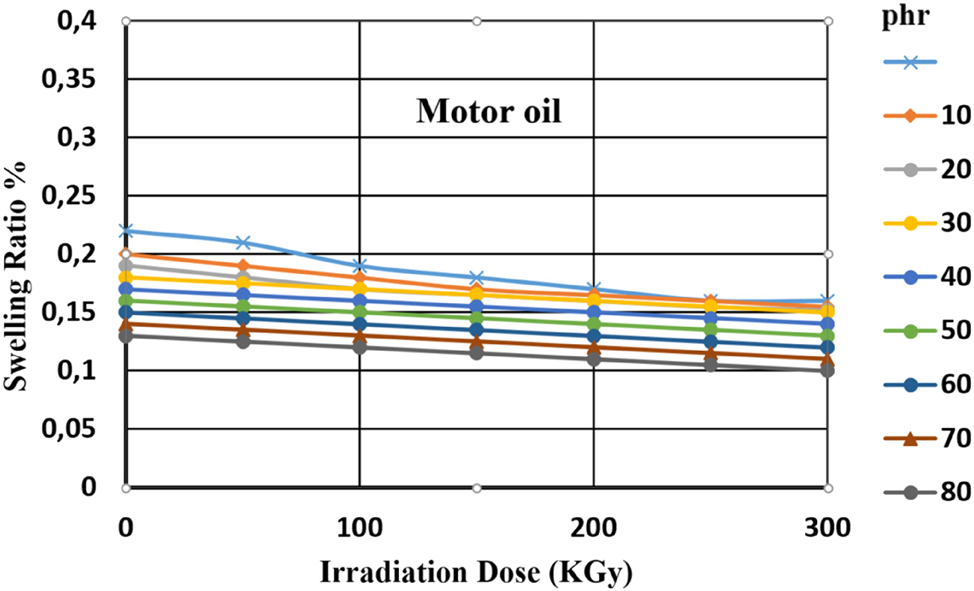

The study results demonstrated minimal swelling in engine oil after 30 days (Figure 6), with only a slight increase at 80 °C (Figure 7). This lower swelling rate, compared to that in hydraulic oil, is primarily due to the chemical nature of the fluids. Engine oil contains larger, more complex molecules and additive packages with lower mobility, which hinders their diffusion into the EPDM polymer network. Hydraulic oil, composed of smaller, less viscous hydrocarbon molecules, can penetrate the rubber matrix more easily, resulting in greater swelling.

Swelling of composites in engine oil at room temperature and different radiation doses.

Swelling of composites in engine oil at 80 °C and different radiation doses.

2.7 Differential Scanning Calorimetry (DSC) analysis

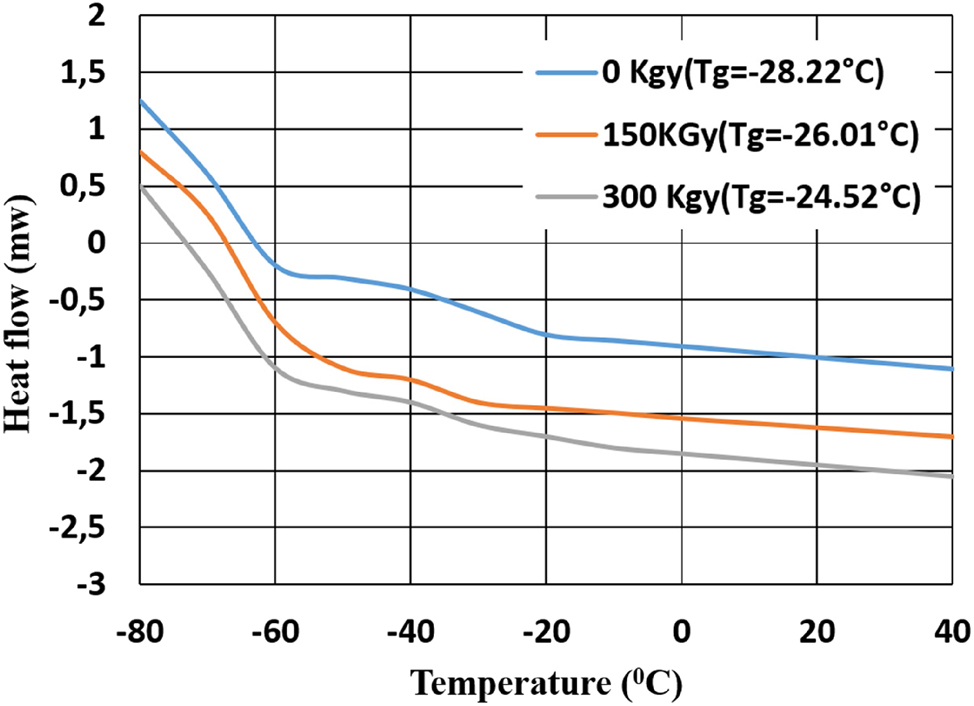

The DSC curves for EPDM rubber, shown in Figure 8, display only the glass transition temperature (T∼g∼) as EPDM is an amorphous polymer. The results indicate that T∼g∼ increases with increasing radiation dose. This is a direct consequence of the radiation-induced crosslinking, which restricts the mobility of the EPDM rubber chains, thereby increasing the energy required for the glass transition. This finding aligns with the fundamental principle that increased crosslink density elevates T∼g∼ [32]. While the chemical composition of EPDM, with its non-polar ethylene and propylene monomers, inherently maintains a low T∼g∼ suitable for low-temperature applications [33], the data clearly show that radiation crosslinking is a dominant factor in modifying its thermal transitions, leading to a harder and less flexible material at higher doses.

Differential Scanning Calorimetry (DSC) curves of EPDM rubber, loaded with 50 phr of carbon black at different radiation doses.

2.8 Morphological study using Scanning Electron Microscopy (SEM)

Figure 9 shows a homogeneous distribution of the reinforcing material within the EPDM matrix, with the surface appearing smoother as the radiation dose increases. The carbon black particles appear spherical with an average size of approximately 70 nm as shown in Figure 9b. An increase in the bonding between the reinforcing particles and the rubber matrix is also evident, indicating mutual interaction between the reinforcing particles and the polymer chains through reactive groups present on the surface of the carbon black, such as hydroxyl, carbonyl, acidic groups, and others [28]. Additionally, the surface topography appears smoother with an increase in the radiation dose up to 150 kGy, as shown in Figure 9c.

Microscopic images of EPDM rubber loaded with 50 phr of carbon black and exposed to different radiation doses.

However, when the radiation dose increases to 300 kGy, the surface of the sample cross-sections becomes rougher, as shown in Figure 9d. This is attributed to the degradation of rubber chains caused by the high radiation energy, leading to weakening of the rubber matrix. The distribution of carbon black becomes less uniform and tends to agglomerate, indicating deterioration in the rubber structure and loss of the desired mechanical properties.

2.9 Abrasion resistance

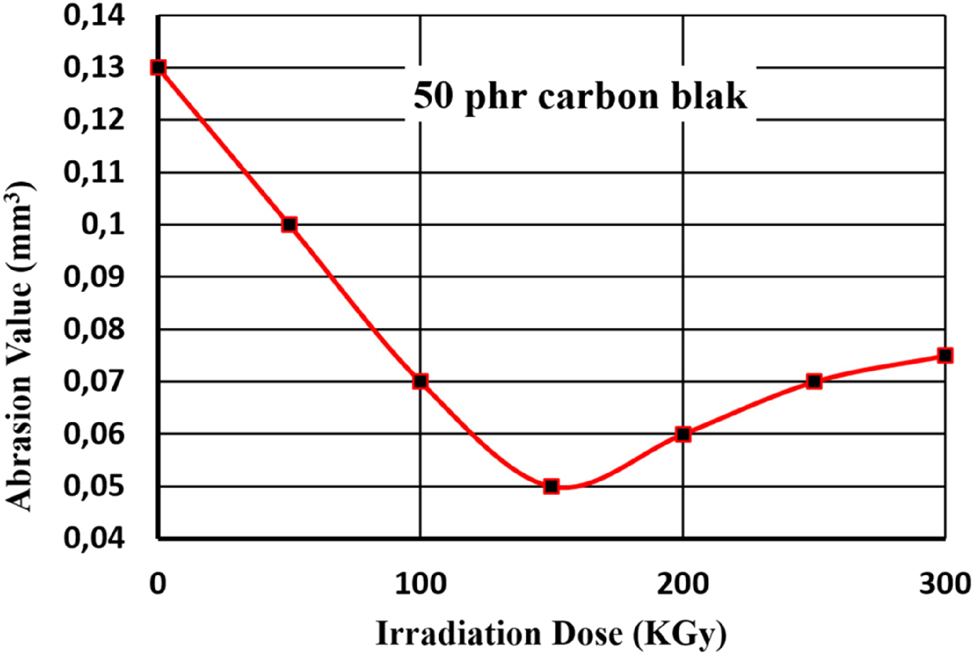

Figure 10 shows the results of the wear resistance of EPDM samples modified with 50 phr of carbon black at different radiation doses. The horizontal axis represents the radiation dose to which the rubber samples were exposed, while the vertical axis represents the wear volume in mm3. It is observed from the figure that the wear volume decreases with increasing radiation dose.

Effect of radiation dose on the abrasion resistance of EPDM rubber loaded with 50 phr of carbon black.

This is attributed to radiation-induced vulcanization, which leads to the crosslinking of the rubber molecular chains and to a homogeneous distribution of the reinforcing material within the rubber matrix, as demonstrated by microscopic analysis using SEM (Scanning Electron Microscope).

This effect results from the radiation energy causing chemical and structural changes in the rubber composites, in addition to increasing the bonding between the filler particles and the rubber through acidic, carboxyl, and carbonyl polar side groups present on the surface of the carbon black.

However, an increase in wear values is noticed above the dose of 150 kGy due to the dominance of chain scission reactions in the EPDM rubber molecular chains. High-dose irradiation leads to the breaking of the main chains of the macromolecules of EPDM rubber and causes oxidation reactions that result in the deterioration of the mechanical properties of the rubber composites.

3 Conclusions and recommendations

This study successfully demonstrated the synergistic effect of gamma radiation and carbon black on enhancing the properties of EPDM rubber. The key findings are:

Oil resistance: The swelling ratio in both hydraulic and engine oils significantly decreased with increasing radiation dose and CB content, establishing superior oil resistance. Engine oil exhibited lower swelling than hydraulic oil, likely due to compositional differences.

Thermal properties: The glass transition temperature (T∼g∼) increased with radiation dose, confirming the formation of a more rigid, crosslinked network that restricts polymer chain mobility.

Morphology: SEM analysis revealed an optimal, homogeneous dispersion of CB at radiation doses up to 150 kGy. Doses above this threshold induced chain scission, leading to surface roughness and filler agglomeration.

Mechanical performance: Abrasion resistance improved with radiation dose, reaching an optimum at 150 kGy for a fixed CB loading (50 phr), beyond which degradation mechanisms caused a decline in performance.

The novelty of this work lies in the systematic identification of the optimal processing window (≤150 kGy radiation dose combined with high CB loading) for maximizing the performance of EPDM composites. These findings are significant for industries requiring durable rubber components with enhanced resistance to oils, heat, and wear, such as in automotive seals and gaskets.

For future work, it is recommended to:

Investigate the combined effect of other nanofillers (e.g., silica, nanoclay) with radiation vulcanization.

Conduct long-term aging studies to assess the durability of the radiation-vulcanized composites.

Explore the application of these optimized composites in specific components like fuel cell gaskets or hydraulic seals.

Acknowledgments

The author would like to thank the Don State Technical University for their support and for facilitating the research.

-

Conflict of interest: The author states no conflict of interest.

-

Funding information: The author states no funding involved.

References

1. Banerjee, S, Sinha, NK, Gayathri, N, Ponraju, D, Dash, S, Tyagi, AK, et al.. Detecting onset of chain scission and crosslinking of gamma-ray irradiated elastomer surfaces using frictional force microscopy 2005;1–18. arXiv:cond-mat/0508749. https://doi.org/10.48550/arXiv.cond-mat/0508749.Search in Google Scholar

2. Raslan Heba, A, Abu Ganima Hend, G, Hassan Medhat, M, Abdel Aal, SE, Mahmoud Wagiha, H. Effect of gamma irradiation on the properties of short glass fibre-reinforced elastomers based on nitrile butadiene rubber and devulcanised waste rubber. Int J Environ Anal Chem 2020;100:1763–76. https://doi.org/10.1080/03067319.2019.1657853.Search in Google Scholar

3. Mahmoud Ali, MA, El-Nemr, KF, Hamada, A. Effect of gamma irradiation on mechanical behavior of EPDM rubber-recycled news print microfibers composites. J Sci Res Sci 2018;34:333−59. https://doi.org/10.21608/jsrs.2018.14712.Search in Google Scholar

4. Elshereafy, E, Mohamed, MA, Mai el zayat Mai, El Miligy, A. Gamma radiation curing of nitrile rubber/high density polyethylene blends. J Radioanal Nucl Chem 2012;193:941–7. https://doi.org/10.1007/s10967-012-1801-3.Search in Google Scholar

5. Naikwadi, AT, Sharma, BK, Bhatt, KD, Mahanwar, PA. Gamma radiation processed polymeric materials for high performance applications: a review. Front Chem 2022;10:837111. https://doi.org/10.3389/fchem.2022.837111.Search in Google Scholar PubMed PubMed Central

6. Song, I, Kim, D, Lee, T, Ryu, K, Kim, JH. Study of gamma irradiation effect on mechanical properties and structure of nitrile butadiene rubber and ethylene propylene diene rubber. Trans Korean Nuclear Society Virtual Autumn Meeting 2020:12–18.Search in Google Scholar

7. J Guo, P Xu, J Lv, X Han, Y Sun, D Hou, et al.., “Ageing behaviour and molecular/network structure evolution of EPDM/carbon black composites under compression and in thermal-oxidative environments,” Polym Degrad Stabil, 14 110417 (2023). https://doi.org/10.1016/j.polymdegradstab.2023.110417 Search in Google Scholar

8. Mohamed, MA. Swelling characteristics and application of gamma-radiation on irradiated SBR-carboxymethylcellulose (CMC) blends. Arab J Chem 2012;5:207–11.10.1016/j.arabjc.2010.08.014Search in Google Scholar

9. Wazzan, AA. Influence of fillers and curing systems on the physico-mechanical properties and stability of EPDM vulcanizates. J Polym Mater 2005;54:783−94. https://doi.org/10.1080/00914030490463214 Search in Google Scholar

10. Valentini, L, Bittolo Bon, S, Lopez-Manchado, MA, Verdejo, R, Bolognini, A, Alvino, A, et al.. Synergistic effect of graphite nanoplatelets and carbon black in multifunctional EPDM nanocomposites. arXiv:1508.06902v2 2015. https://doi.org/10.48550/arXiv.1508.06902.Search in Google Scholar

11. Costa, NL, Hiranobe, CT, Cardim, HP, Dognani, G, Sanchez, JC, Carvalho, JA, et al.. A review of EPDM (ethylene propylene diene monomer) rubber-based nanocomposites: properties and progress. Polymers 2024;16:1720. https://doi.org/10.3390/polym16121720.Search in Google Scholar PubMed PubMed Central

12. Daniel, F. Recent progress in materials current advancements in the behavior analysis of EPDM elastomers in peripheral applications of the cathodic side of PEMFC systems. Recent Prog Mater 2024;6:3−28. https://doi.org/10.21926/rpm.2404026.Search in Google Scholar

13. Marković, G, Marinović-Cincović, M, Vodnik, V, Radovanović, B, Budinski-Simendić, J, Gordana, OV. Thermal stability of acrylonitrile/chlorosulphonated polyethylene rubber blend. J Therm Anal Calorim 2009;97:999–1006. https://doi.org/10.1007/s10973-009-0162-9.Search in Google Scholar

14. Jacques, WM. Recent advances in sponge technology of EPDM-rubber in automotive weatherstrips: a review. Sage J 1997;16. https://doi.org/10.1177/0262489319971605001.Search in Google Scholar

15. Hattori, I, Ressnig, D, Thakur, V, Li Pi Shan, C. EPDM developments for automotive sealing applications via advanced molecular catalyst (AMC) technology. Nippon Gomu Kyokaishi 2018;91:115−20. https://doi.org/10.2324/gomu.91.Search in Google Scholar

16. Halisdemir, O. Synthesis and characterization of ethylene propylene diene monomer (EPDM) rubber mixture. J Eng Sci 2019;8:1299–306. https://doi.org/10.28948/ngumuh.479347.Search in Google Scholar

17. Pirityi, DZ, Bárány, T, Pölöskei, K. Recycling of EPDM rubber via thermomechanical devulcanization: batch and continuous operations. Polym Degrad Stabil 2024;230:111014.10.1016/j.polymdegradstab.2024.111014Search in Google Scholar

18. Wang, X, Huang, C, Wang, X, Luo, Y, Wang, X. Multiscale simulation study on radiation aging of EPDM and preparation of radiation-resistant materials. Compos Sci Technol 2024;252:110595. https://doi.org/10.1016/j.compscitech.2024.110595.Search in Google Scholar

19. Shamsabadi, A, Farahani, A, Shirkavand, MM, Javad Hafezi, M, Tohidian, M. Carbon black/ethylene propylene diene monomer (EPDM) rubber as polymer electrolyte membrane fuel cell gaskets. Iran Polym J 2023;33:169–83. https://doi.org/10.1007/s13726-023-01239-9.Search in Google Scholar

20. Jovanović, SS, Jovanović, V, Cincović, M, Simendić, J, Marković, G. Comparative study of radiation effect on rubber–carbon black compounds. Compos B Eng 2022;62:1831–190. https://doi.org/10.1016/j.compositesb.2014.02.029.Search in Google Scholar

21. Khankishiyeva, RF, Mammadov, SM, Mammadov, AK, Akhundzada, HN, Azadaliyev, AI1. Effect of gamma irradiation on mechanical and structure properties of elastomer blend filled with different types of carbon black. J Radiat Researches 2018;5:5.Search in Google Scholar

22. Harussani, MM, Sapuan, SM, Nadeem, G, Rafin, T, Kirubaanand, W. Recent applications of carbon-based composites in defence industry: a review. Def Technol 2022;18:1281–300. https://doi.org/10.1016/j.dt.2022.03.006.Search in Google Scholar

23. Lee, B-J, Yoo, H-M. Effects of carbon Black on mechanical properties and oil resistance of liquid silicone rubber. Polymers 2024;16:933. https://doi.org/10.3390/polym16070933.Search in Google Scholar PubMed PubMed Central

24. Mayasari, H, Yuniari, A. Effect of vulcanization system and carbon black on mechanical and swelling properties of EPDM blends. Majalah Kulit, Karet dan Plastik 2016;32:59–64. https://doi.org/10.20543/mkkp.v32i1.706.Search in Google Scholar

25. Maciejewska, M, Sowińska, A. Thermal characterization of the effect of fillers and ionic liquids on the vulcanization and properties of acrylonitrilebutadiene elastomer. J Therm Anal Calorim 2019;138:4359–73. https://doi.org/10.1007/s10973-019-08187-8.Search in Google Scholar

26. Anggaravidya, M, Saputra, DA, Gumelar, MD, Taqwatomo, G, Husin, S, Arti, DK, et al.. Comparative analysis of NR/EPDM ratio and carbon black selection on mechanical properties of vulcanized pneumatic fenders. Evergreen 2023;10:2145–52. https://doi.org/10.5109/7160889.Search in Google Scholar

27. Marković, G, Marinović-Cincović, M, Jovanović, V, Samaržija-Jovanović, S, Budinski-Simendic, J. The effect of gamma radiation on the ageing of sulfur cured NR/CSM and NBR/CSM rubber blends reinforced by carbon black. Chem Industry Chem Eng Quart CICEQ 2009;15:291–8. https://doi.org/10.2298/CICEQ0904291M.Search in Google Scholar

28. El-Zayat, MM. Radiation curing of rubber/thermoplastic composites containing different inorganic fillers. Nasr City, Egypt: Menoufia university, Faculty of Science, Chemistry Department; 2012:147 p.Search in Google Scholar

29. Lee, S-H, Park, G-W, Kim, H-J, Chung, K, Jang, K-S. Effects of filler functionalization on filler-embedded natural rubber/ethylene-propylene-diene monomer composites. Polymers 2022;14:3502. https://doi.org/10.3390/polym1417350.Search in Google Scholar

30. Aly, RO. Influence of gamma irradiation on mechanical and thermal properties of waste polyethylene/nitrile butadiene rubber blend. Arab J Chem 2016;9:1547–54.10.1016/j.arabjc.2012.04.007Search in Google Scholar

31. John, SD. Rubber technology: compounding and testing for performance. New York Basel: CRC Press; 2001, 808.Search in Google Scholar

32. Khankishiyeva, RF, Mammadov, SM, Mammadov, AK, Akhundzada, HN, Azadaliyev, AI. Effect of gamma irradiation on mechanical and structure properties of elastomer blend filled with different types of carbon black. J Radiat Res 2018;5:5.Search in Google Scholar

33. C Donnet, R, Bansal, M-J. “Carbon Black” science and technology, 2nd ed., Revised and Expanded New York: J.-BCRC Press; 1993:987 p.Search in Google Scholar

© 2025 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Investigation on cutting of CFRP composite by nanosecond short-pulsed laser with rotary drilling method

- Antibody-functionalized nanoporous silicon particles as a selective doxorubicin vehicle to improve toxicity against HER2+ breast cancer cells

- Study on the effects of initial stress and imperfect interface on static and dynamic problems in thermoelastic laminated plates

- Analysis of the laser-assisted forming process of CF/PEEK composite corner structure: Effect of laser power and forming rate on the spring-back angle

- Phase transformation and property improvement of Al–0.6Mg–0.5Si alloys by addition of rare-earth Y

- A new-type intelligent monitoring anchor system for CFRP strand wires based on CFRP self-sensing

- Optical properties and artistic color characterization of nanocomposite polyurethane materials

- Effect of 200 days of cyclic weathering and salt spray on the performance of PU coating applied on a composite substrate

- Experimental analysis and numerical simulation of the effect of opening hole behavior after hygrothermal aging on the compression properties of laminates

- Engineering properties and thermal conductivity of lightweight concrete with polyester-coated pumice aggregates

- Optimization of rGO content in MAI:PbCl2 composites for enhanced conductivity

- Collagen fibers as biomass templates constructed multifunctional polyvinyl alcohol composite films for biocompatible wearable e-skins

- Early age temperature effect of cemented sand and gravel based on random aggregate model

- Properties and mechanism of ceramizable silicone rubber with enhanced flexural strength after high-temperature

- Buckling stability analysis of AFGM heavy columns with nonprismatic solid regular polygon cross-section and constant volume

- Reusable fibre composite crash boxes for sustainable and resource-efficient mobility

- Investigation into the nonlinear structural behavior of tapered axially functionally graded material beams utilizing absolute nodal coordinate formulations

- Mechanical experimental characteristics and constitutive model of cemented sand and gravel (CSG) material under cyclic loading with varying amplitudes

- Synthesis and properties of octahedral silsesquioxane with vinyl acetate side group

- The effect of radiation-induced vulcanization on the thermal and structural properties of Ethylene Propylene Diene Monomer (EPDM) rubber

- Review Articles

- State-of-the-art review on the influence of crumb rubber on the strength, durability, and morphological properties of concrete

- Recent advances in carbon and ceramic composites reinforced with nanomaterials: Manufacturing methods, and characteristics improvements

- Special Issue: Advanced modeling and design for composite materials and structures

- Validation of chromatographic method for impurity profiling of Baloxavir marboxil (Xofluza)

Articles in the same Issue

- Research Articles

- Investigation on cutting of CFRP composite by nanosecond short-pulsed laser with rotary drilling method

- Antibody-functionalized nanoporous silicon particles as a selective doxorubicin vehicle to improve toxicity against HER2+ breast cancer cells

- Study on the effects of initial stress and imperfect interface on static and dynamic problems in thermoelastic laminated plates

- Analysis of the laser-assisted forming process of CF/PEEK composite corner structure: Effect of laser power and forming rate on the spring-back angle

- Phase transformation and property improvement of Al–0.6Mg–0.5Si alloys by addition of rare-earth Y

- A new-type intelligent monitoring anchor system for CFRP strand wires based on CFRP self-sensing

- Optical properties and artistic color characterization of nanocomposite polyurethane materials

- Effect of 200 days of cyclic weathering and salt spray on the performance of PU coating applied on a composite substrate

- Experimental analysis and numerical simulation of the effect of opening hole behavior after hygrothermal aging on the compression properties of laminates

- Engineering properties and thermal conductivity of lightweight concrete with polyester-coated pumice aggregates

- Optimization of rGO content in MAI:PbCl2 composites for enhanced conductivity

- Collagen fibers as biomass templates constructed multifunctional polyvinyl alcohol composite films for biocompatible wearable e-skins

- Early age temperature effect of cemented sand and gravel based on random aggregate model

- Properties and mechanism of ceramizable silicone rubber with enhanced flexural strength after high-temperature

- Buckling stability analysis of AFGM heavy columns with nonprismatic solid regular polygon cross-section and constant volume

- Reusable fibre composite crash boxes for sustainable and resource-efficient mobility

- Investigation into the nonlinear structural behavior of tapered axially functionally graded material beams utilizing absolute nodal coordinate formulations

- Mechanical experimental characteristics and constitutive model of cemented sand and gravel (CSG) material under cyclic loading with varying amplitudes

- Synthesis and properties of octahedral silsesquioxane with vinyl acetate side group

- The effect of radiation-induced vulcanization on the thermal and structural properties of Ethylene Propylene Diene Monomer (EPDM) rubber

- Review Articles

- State-of-the-art review on the influence of crumb rubber on the strength, durability, and morphological properties of concrete

- Recent advances in carbon and ceramic composites reinforced with nanomaterials: Manufacturing methods, and characteristics improvements

- Special Issue: Advanced modeling and design for composite materials and structures

- Validation of chromatographic method for impurity profiling of Baloxavir marboxil (Xofluza)