Abstract

Natural plant fiber-reinforced polymer composites (PFRP) have emerged as an environmental-friendly material in the construction industry, but their creep behavior is a critical concern for load-bearing structures. This study investigates the creep behavior of flax fiber-reinforced polymer composites (FFRP) using the time–temperature superposition principle (TTSP). Due to the application of TTSP on the tensile creep behavior of FFRP is not fully understood, three potential methods for calculating the critical parameters during TTSP are compared to obtain an efficient application method to build the creep master curve. A 2,000-h long-term creep test is conducted parallelly on the same sample to validate the accuracy of the creep analysis results. The study proposes an ideal method to determine the key parameters in TTSP, providing valuable insights for the practical application of PFRP in the construction industry. Meanwhile, the research results in this study would be helpful in better understanding the creep behavior of FFRP via short-term accelerated tests.

1 Introduction

Natural plant fiber-reinforced polymer composites (PFRP) have gained attention due to their potential to reduce dependence on petroleum-based materials. Composites made of plant fibers and bio-based polymer resins have shown comparable mechanical properties to conventional composites and are promising materials for structural applications [1,2,3]. For example, a fully bio-based pedestrian bridge at the TU/e campus was constructed using flax fiber-reinforced polymer (FFRP) in 2016 [4]. However, as an emerging construction material, the long-term mechanical performance and durability of FFRP need further study before large-scale application in the construction industry.

The investigation of creep is crucial when utilizing PFRP as a load-bearing structure. In contrast to steel or concrete, polymers display viscoelastic properties even under daily temperatures, resulting in an apparent creep behavior of fiber-reinforced polymer (FRP) materials. The deformation and movement of fibers contribute to the complexity of FRP’s creep properties [5]. The hierarchical nature of plant fibers presents a time-dependent non-linear property that may lead to an intrinsic viscoelastic nature of composites reinforced by natural fibers [6]. As a result, the creep behavior of PFRP is believed to differ from that of conventional FRP materials, and several studies have been conducted to investigate it. Durante et al. [7] examined the creep behavior of polylactic acid (PLA) reinforced by woven hemp fabric with varying fiber volume fractions and found that 30% is the ideal volume fraction for minimal creep strain. Acha et al. [8] evaluated the influence of interfacial adhesion between fibers and the matrix on the creep behavior of jute/PP composites and discovered that creep deformation could be directly linked to interfacial properties. Morreale et al. [9] investigated the creep behavior of PLA-based polymers reinforced by flax and jute hybrid woven fabrics at different temperatures (i.e., 40 and 60°C). In addition, Jia and Fiedler [10] also reported that environmental humidity affects the creep properties of FRP composites through a creep test on a universal testing machine. Nevertheless, the research on the creep behavior of PFRP in load-bearing structures is still inadequate due to the limited time and resources for long-term creep testing. The development of an accelerated creep testing method enables the investigation of the long-term creep behavior of PFRP within the theoretical framework of the time–temperature superposition principle (TTSP).

The viscoelastic properties of PFRP make it possible to use analytical and phenomenological modeling techniques to describe their creep behavior [11,12]. It has been observed that the creep compliance of PFRP increases with temperature, indicating that the TTSP may be used to perform accelerated creep tests on PFRP [13,14]. The creep development of the material is essentially caused by the viscoelastic flow of the polymer chains, which can be accelerated by raising the temperature or stress [15,16]. Sun and Wan evaluated the viscoelasticity constitutive models in the short-term tensile creep property of bamboo scrimber and found the viscoelasticity model can properly represent the creep behavior of the bamboo scrimber [17]. By elevating the temperature or stress, the reorientation of polymer chains can be facilitated, resulting in equivalent results at the normal temperature for a more extended period [18]. The viscoelastic properties of PFRP are found sensitive to environmental humidity [19], which means the environment of the creep test is an influential factor.

To predict the long-term creep behavior of PFRP under the reference temperature T ref, short-term creep tests are first conducted at an elevated temperature T i . The relationship between the predicted creep at the reference temperature and the accelerated creep at an elevated temperature curve is J (T ref , t) = J (T i , t/α T). The shifting factors α T are the key parameters used in shift creep curves obtained from accelerated creep tests to construct the creep master curves that predict long-term creep development. Based on this, the TTSP is increasingly employed in research on the long-term creep behavior of PFRP.

For instance, Yang et al. [20] studied the relationship between fiber content and creep behavior of bamboo fiber-reinforced lactic acid using TTSP and reported that perfect superposition of master curves could be obtained. Similarly, Amiri et al. [21] investigated the application process of TTSP on bio-based resin reinforced with flax fiber and reported that the creep master curves could be comparable to the bending creep test results tested for 24 h. Xu et al. proposed a theoretical framework for unidirectional fiber composites which could benefit the durability verification and the evaluation of the high cycle fatigue performance of composite structures [22]. Georgiopoulos et al. [23] studied the effect of stress and temperature on the creep behavior of polymer wood FRP by fitting creep master curves of accelerated creep test by Findley’s and Burger’s viscoelastic model. Acha et al. [8] reported that the Burger model provides agreeable theoretical and experimental results for the polypropylene and jute fiber composite samples. Cyras et al. [13] studied the influence of fiber content on the flexural creep behavior of sisal-PLC starch composites by fitting a four-parameter creep model to the long-term creep curve generated by TTSP. Alvarez et al. [24] studied the creep behavior of sisal fiber-reinforced cellulose derivatives blends, considering different fiber content and temperature effects in the burgers model and claimed that TTSP provides agreeable results with the experiment. Moreover, the addition of sisal fiber to the polymeric matrix promotes a significant improvement in the composites’ creep resistance.

However, since the TTSP is a semi-empirical application, the methods for determining shifting factors are not uniform for different materials. In previous research, the shifting factors could be determined either graphically by the visual-based method [25,26] or by computation using empirical equations [20,27]. Most of these studies are based on the bending creep behavior. The application of TTSP on the tensile creep behavior of PFRP (especially for unidirectional flax fiber-reinforced composites) is limited, and there are few studies on the application of TTSP on samples with different fiber configurations, such as the sample with fiber in 0°, 90°, and ±45°, which are critical for engineering design. It is crucial to find a suitable method to calculate shifting factors for the application process of TTSP on FFRP to enrich the knowledge and experience of accelerated creep test theory.

This study investigates the tensile creep behavior of FFRP samples with fiber orientations at 0°, 90°, and ±45° from the loading direction. The objective is to optimize the application process of TTSP on FFRP by conducting accelerated creep tests under a range of isothermal conditions. Dynamic mechanical analysis (DMA) was performed. To determine the viscoelastic properties of the FFRP samples on the manufactured specimens, three potential methods were employed to construct the creep master curve to find the method that can represent the long-term creep behavior of FFRP. Additionally, a 2,000-h tensile creep test is conducted on the same FFRP sample. By comparing the results obtained from the accelerated creep test with the real-time measured creep in the 2,000-h creep test, the most efficient method for calculating the shifting factors during the application of TTSP on FFRP was confirmed.

2 Material and methods

The accelerated creep test on natural plant-based composites would benefit the selection of the raw material and the structural design. The shifting factors are key parameters for building the creep master curves representing the predicted long-term creep development. At the same time, a long-term creep test is necessary to validate the accuracy of the accelerated testing results. This section describes in detail the preparation process of the FFRP samples first, following the accelerated creep testing methods and the long-term creep test.

2.1 Sample preparation

FFRP plates with a 40% fiber volume fraction were manufactured using the vacuum infusion method, as illustrated in Figure 1(a). The matrix of the composites was unsaturated polyester, and the reinforcement fabrics for the 0° and 90° fiber samples were unidirectional flax fabrics with an areal density of 280 g/m2. For ±45° fiber plates, ±45° flax fiber fabrics with an areal density of 300 g/m2 were used. The flax fabrics were stored in a climate chamber in which the temperature was 23°C, and relative humidity was 65% before the vacuum injection. The vacuum pressure of the infusion system was kept at −1 Bar during the injection process. After the injection of resin, the samples underwent a 12-h post-curing at 120°C following the 6-h initial curing. Then, the sample plates were placed in the environment with a temperature of 23°C and relative humidity at 60% for at least 2 weeks until fully cured (Figure 1(b)). The plates were then cut into rectangular specimens with dimensions of 40 mm × 5 mm for the DMA machine and 250 mm × 15 mm for the long-term creep test equipment.

(a) Manufacturing configuration and (b) the manufactured sample plate.

2.2 Testing methods

2.2.1 Accelerated creep test

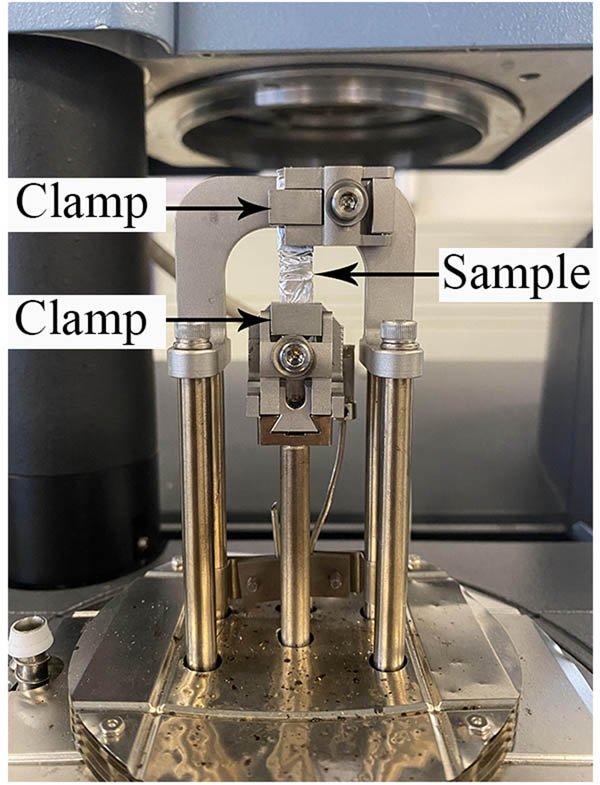

Accelerated tensile creep tests were performed on the DMA Q800 machine with six isothermal steps. The temperatures for the isothermal steps for 0° fiber samples are 20, 40, 60, 80, 100, and 120°C, respectively; for 90° and ±45°, fiber samples are 20, 30, 40, 50, 60, and 70°C respectively. A pre-load force (0.01 N) was applied to the specimen to keep the sample straight, and then, the specimen was subjected to constant stress for 60 min at each isothermal step. To prevent sample damage, the creep stress for 0° fiber samples was set as 5 MPa, and for samples with 90° and ±45° fibers, it was set at 2 MPa. As the glass transition temperature had been tested in the previous property test to be higher than 130°C and the creep stress was low compared to the ultimate tensile stress of the material (ultimate stress of 0° fiber samples is 300 MPa, for 90° fiber samples is 60 MPa), the samples are considered to exhibit linear viscoelastic behavior under all isothermal steps.

Because the FFRP is highly susceptible to changes in environmental humidity, it is necessary to maintain a consistent moisture content of the FFRP sample to ensure accurate mechanical testing results. Despite the availability of humidity control accessories for the testing machine, it is worth noting that FFRP samples also exhibit increased moisture absorption at elevated temperatures due to an increase in their saturated water percentage. In this regard, a Vaseline coating was directly applied to the FFRP specimens and subsequently wrapped in tinfoil to impede water evaporation, as depicted in Figure 2, and thus maintain uniform moisture content. The tinfoil was folded to reserve adequate deformation space for the tested area, ensuring that the mechanical response of the sample remained unaffected. As illustrated in Figure 3, the stress–strain test results of the pure tinfoil suit without a sample indicate an ultimate stress not exceeding 0.01 MPa and a modulus of approximately 0.5 MPa, which is negligible compared to the creep stress. Consequently, the tinfoil used for moisture protection is not expected to influence the mechanical properties of the samples.

Testing configuration on DMA Q800.

The strain–stress relationship of the outer tinfoil of the sample.

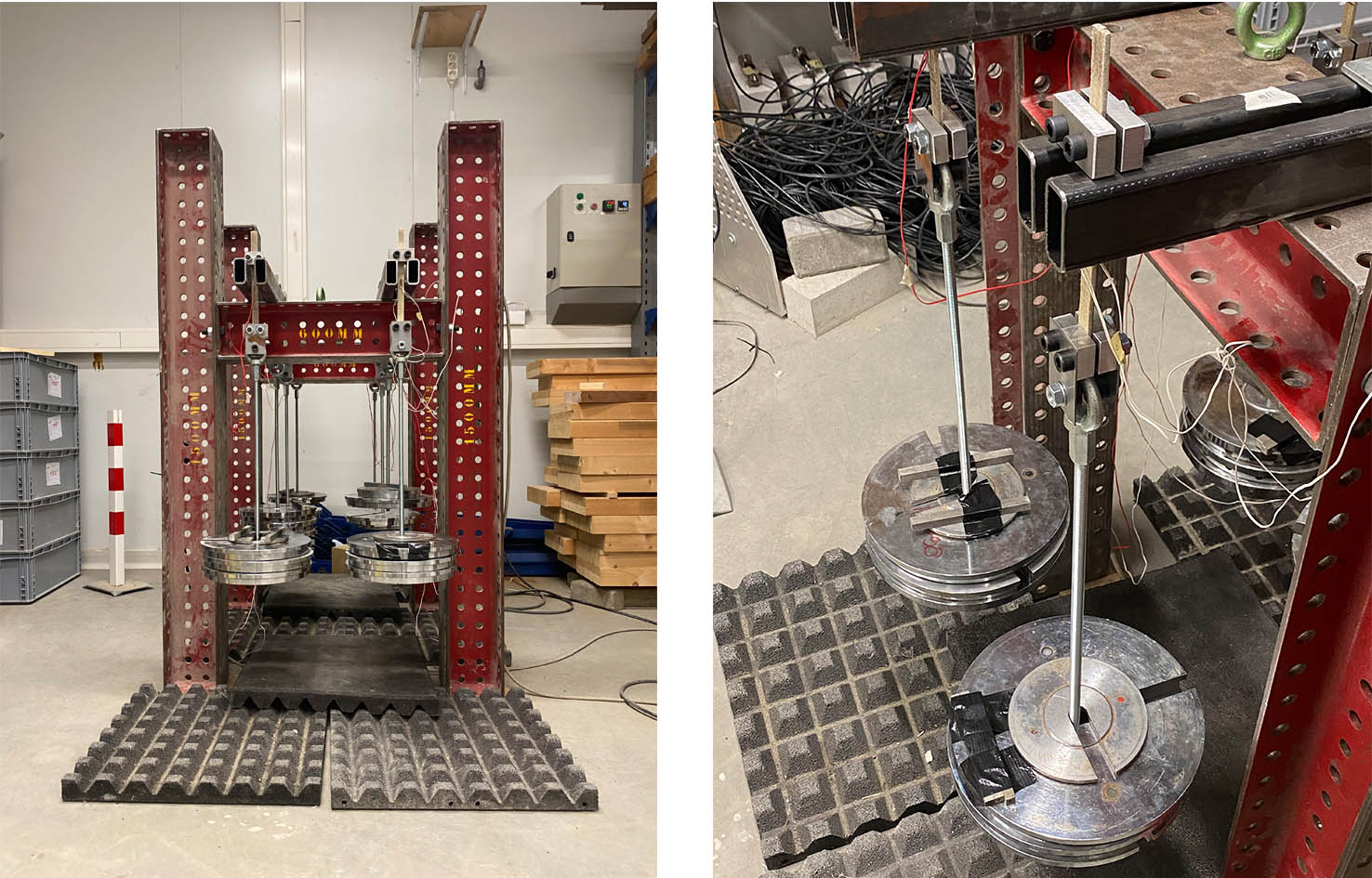

2.2.2 Long-term creep test

A self-made creep test equipment was developed for investigating the long-term tensile creep behavior of FRP samples, as depicted in Figure 4. The samples were clamped using custom-made grips, with the upper clamps supported on a steel beam, and the lower clamps connected to the loading weights. The distance between the upper and lower clamps was fixed at 100 mm. To ensure that the samples were subjected to tensile loading and not affected by shear force, they were strictly installed to be perpendicular to the clamps, and the weights were kept aligned with the sample. The fiber volume fraction of the long-term test samples was consistent with that used in the accelerated creep test. To monitor the strain change induced by creep, a strain gauge was placed on each side of the sample. The creep stress was set to 5 MPa for samples with 0° fiber and 2 MPa for samples with 0° and ±45° fiber orientations. The stress applied was calculated based on the sample size measurement. The testing system was situated in a climate room maintained at a constant relative humidity of 60% and temperature of 20°C. For each sample, long-term loading was sustained for 2,000 h.

Long-term creep testing equipment.

2.2.3 DMA

In order to construct creep master curves of FFRP using various methods, two sets of dynamic sweeping tests were conducted. The first test involved an isochronal temperature sweep where specimens were cyclically loaded at frequencies ranging from 4 to 32 Hz, with a heating rate of 2°C/min, while the temperature was increased from 25 to 125°C. The primary objective of this test was to establish the relationship between T g and loading frequency, which is crucial in the construction of creep master curves for FFRP. The selected range of frequencies allowed for a comprehensive analysis of the viscoelastic properties of the material under varying conditions.

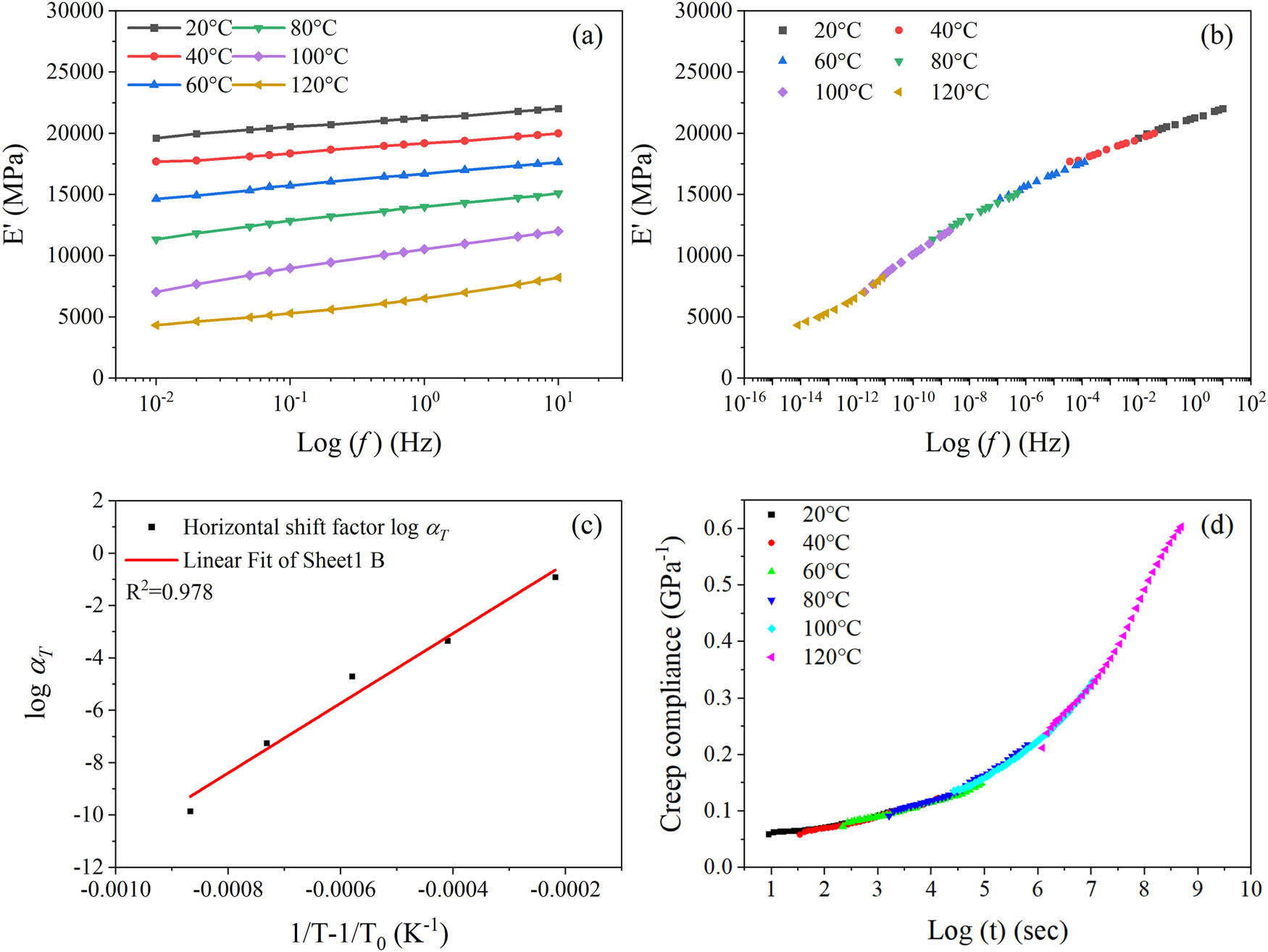

The second set of tests involved an isothermal step frequency sweep in which the mechanical properties were evaluated for various frequencies at different isothermal temperature steps ranging from 20 to 120°C. At each temperature step, a frequency sweep was performed at specific frequencies ranging from 0.01 to 10 Hz. The storage modulus E′ and loss factor tan δ were recorded to construct a creep master curve by superposition consistency of the viscoelastic properties, as described in previous literature [21,28]. The primary objective of this test was to investigate the possibility of constructing the creep master curve using the same superposition shifting factors as the storage modulus of the FFRP. This evaluation aimed to validate the feasibility of using the storage modulus as a master curve to predict the creep behavior of FFRP under different loading conditions.

3 Results and discussions

The long-term creep behavior of the FFRP could be represented by the creep master curves generated by the accelerated creep tests. During the process, proper methods for determining shifting factors are necessary. This section mainly introduces three potential ways to calculate the shifting factors, and the results are compared and validated by the long-term creep test to determine the best method to generate the creep master curve. In addition, the reason for the phenomenon is discussed.

3.1 Building of the master curve based on the short-term creep

The TTSP is a widely used method for predicting the long-term creep performance of viscoelastic materials at elevated temperatures based on short-term creep responses obtained in accelerated tests. In this study, short-term creep tests were conducted on samples at six different temperatures, and the resulting individual creep strains over 60 min were plotted on a logarithmic scale (Figure 5). To apply TTSP to the short-term creep test results, samples at 0° were chosen as an example to perform the application of the superposition process. To predict the long-term creep behavior, a creep master curve was constructed by shifting the creep curves obtained at elevated temperatures using the shifting factors presented in equations (1) and (2). All short-term creep curves were horizontally shifted on a log scale using the corresponding shifting factor by determining the appropriate shifting factors for each elevated temperature.

where J is the creep compliance (GPa−1) as a function of time t (s) and temperature T (°C); T ref is the reference temperature, T elev is the elevated temperature, α T is the shifting factor, and t r is the reduced time.

Creep compliance of 0° fiber sample in the accelerated creep test.

A practical application of TTSP can be identified by two conditions [15]: (1) the creep master curve generated is smooth enough; (2) the shifting factors can conform to the WLF Equation [29] or Arrhenius Equation [14]. However, in most cases, the WLF Equation is suggested to work in a temperature range from T g to T g + 100°C [15], which is not the target working temperature of FFRP studied in this study. Therefore, the Arrhenius Equation is employed here to evaluate the method for determining the shifting factors (α T i ). The shifting factors can be related to temperature and time, as equation (3) shows.

where T i is the elevated temperature (K); α T i is the shifting factor corresponding to temperature T i ; T 0 is the reference temperature (K); E a is the activation energy of the glass transition relaxation (kJ/mol); R is the universal gas constant (8.314 J/K/mol).

Determining shifting factors in composite materials can be achieved graphically by manually shifting curves or through computational methods using empirical equations. For the estimation of the shiftings, there are two potential computations ever successfully used for similar materials: by the frequency dependence of T g and by the consistency of the viscoelastic properties. These potential approaches were involved in this study to determine the effective method for calculating shifting factors for the creep behavior of FFRP, and the results were evaluated based on the two necessary conditions for the application of TTSP, namely the generation of a smooth creep master curve and the determination of shifting factors that conform to the Arrhenius equation. Additionally, the predicted long-term creep behavior of the FFRP composite was validated by comparing it with the actual long-term creep test results obtained from a 2,000-h creep test conducted on a sample with the same formulation. The comparison was carried out to confirm the accuracy of the predicted long-term creep behavior of the FFRP composite.

3.1.1 Determine shifting factors by the frequency dependence of T g

Based on the Arrhenius Equation (equation (3)), shifting factors can be determined by the material’s properly estimated activation energy E a. In this method, the activation energy for the creep of the composites is considered to be approximately equivalent to the activation energy of glass transition [20,27]. The activation energy could be calculated and estimated by the frequency dependence of T g (equation (4))

where f is the loading frequency (Hz); T g is the glass transition temperature (K); R is the universal gas constant (8.314 J/K/mol).

Figure 6(a) illustrates the relationship between the loss factor tan δ and temperature at various loading frequencies. The glass transition temperature T g, defined as the temperature corresponding to the peak of tan δ, is found to increase monotonically with loading frequency. Linear regression analysis results as depicted in Figure 6(b) demonstrate a good fit between ln(f) and (1/T g). Accordingly, the activation energy (E a) can be determined from the fitted results using equation (2), based on the calculated E a shifting. However, it is observed that the segments of creep are shifted excessively, resulting in a non-smooth master curve. This finding is consistent with prior research on unidirectional carbon FRP composites [21]. This discrepancy could be attributed to the difference in the polymer reinforced by long-unidirectional fiber used in this study, as opposed to the polymer reinforced by short-random fiber in previous research [20,27]. Therefore, it is concluded that utilizing the frequency dependence T g to calculate shifting factors is unsuitable for the creep of unidirectional fiber FFRP investigated in this study.

(a) tan δ curves for a range of frequencies at a heating rate of 1°C/min; (b) frequency in a log scale versus the inverse of T g; (c) the superposition results of FFRP shifted with the factors calculated by the frequency dependence of T g.

3.1.2 Determine shifting factors by the consistency of viscoelastic properties

Another potential method for calculating shifting factors is to use the consistency of viscoelastic properties, where the shifting factors for different properties are substituted for each other. This method assumes that the superposition process should be the same for all viscoelastic properties and has been previously used for storage modulus and creep development [18,30]. The applicability of this method to the FFRP is investigated in this study.

The results of storage modulus in frequency sweep tests under the same isothermal steps as the accelerated creep test are presented in Figure 7(a). The two-dimensional minimization superposition program [31], integrated with the TA Instruments Data analysis software, is utilized to horizontally and vertically shift the storage modulus curves. The generated master curve of the storage modulus is smooth and continuous, as shown in Figure 7(b). The relationship between the shifting factors and the temperature in Figure 7(c) fits well with equation (1), as determined through linear regression analysis. The activation energy (E a) calculated from the fitted results is 144.45 kJ/mol. The applicability conditions of TTSP are satisfied by the superposition of the storage modulus. Therefore, the accelerated creep curves are shifted by the same factors used in the storage modulus superposition process. A smooth and continuous creep master curve is constructed, as shown in Figure 7(d), indicating that this method can provide suitable shifting factors for predicting long-term creep.

(a) Frequency sweep results of FFRP at different temperature steps. (b) The master curve of the elastic modulus. (c) Relationship between horizontal shifting factors and temperature. (d) The creep master curve constructed with shifting factors calculated by the consistency of viscoelastic properties.

3.1.3 Determine shifting factors by visual graphical method

The visual graphical method is a commonly employed approach for calculating shifting factors in TTSP applications [28,32]. This method involves manually shifting short-term creep curves to construct a continuous and smooth creep master curve. Figure 8 shows the creep master curve generated using the visual method, which is smooth and continuous. During the shifting process, the creep curves from the accelerated creep test were horizontally and vertically shifted together to make the master curve as smooth as possible.

Creep master curve of 0° fiber sample generated manually by the visual method.

In contrast to the mathematical methods, the visual method relies on the judgment and expertise of the researcher to manually adjust the creep curves to generate a smooth master curve. This method is particularly useful when the mathematical methods fail to produce a smooth master curve due to the complex nature of the viscoelastic behavior of the material. The visual method allows for more flexibility and control in the shifting process, as the researcher can visually assess and adjust the creep curves as needed. However, this method is subjective and may vary depending on the researcher’s experience and interpretation of the data. It is therefore important to carefully analyze and validate the results obtained using the visual method. Overall, the visual method is a valuable tool for calculating shifting factors in TTSP applications and can be used in conjunction with mathematical methods to ensure accurate and reliable results.

3.2 Comparison of the methods to generate creep master curve

Figure 6(c) shows that the shifting factors calculated by the frequency dependency of glass transition temperature result in superposition results that are too large to construct a smooth curve. This suggests that the activation energy for the creep of FFRP is much lower than the activation energy needed for the glass transition and cannot be approximated by it. Upon examining the creep master curves generated by the other two methods, it was found that both methods can help construct a smooth and continuous creep master curve. However, there were differences in the speed of creep development over a long-term period in the master curves generated by the two methods. To investigate the effectiveness of the two methods, the actual measurement results of the creep test on 0° fiber samples for 2,000 h were employed to compare with the creep master curves (Figure 9). It was found that the creep master curve generated by using the consistency of viscoelastic properties agrees better with the long-term measurement value than the visual results. The creep master curve generated by the visual method can predict the trend of creep development, but there is a non-negligible overestimation of creep. Although there is still a difference between the creep master curve generated by the consistency of viscoelastic properties and the predicted values, it is able to reflect the long-term development characteristics of creep.

The comparison of predicted creep results with long-term tested results.

The advantage of using the consistency of viscoelastic properties is the parameterization of the application of TTSP. Although additional frequency sweep tests are needed to use this method, it is still an efficient method to obtain the long-term creep behavior in the structural design process, when compared with traditional long-term creep measurements. The visual method provides a simpler way to know the trend of creep, but the creep master curve is influenced by subjectivity. It may be helpful in material selection before the structural design, but the error caused by the instability during the curve-shifting process should be considered in practical operation.

To further support the use of the consistency of the viscoelastic properties method, it should be noted that this approach offers several advantages beyond its efficiency. First, it allows for better control and understanding of the creep behavior of the composite material, which is essential for predicting the material’s long-term performance in structural applications. This method also provides a more accurate representation of the creep behavior by incorporating the frequency dependency of viscoelastic properties, which can improve the accuracy of the creep master curve. Additionally, using this method can aid in optimizing the composite material composition and processing parameters, as it provides a more detailed understanding of the material’s viscoelastic properties.

On the other hand, the visual method may still have applications in certain scenarios, such as when a quick assessment of creep behavior is required or when dealing with materials with relatively simple creep behavior. However, the limitations of this method should be kept in mind, as the curve-shifting process can introduce errors and inaccuracies. Therefore, it is important to carefully consider the trade-offs between the different methods when choosing an appropriate approach for generating creep master curves for composite materials. Overall, the consistency of the viscoelastic properties method is a promising approach that offers a more accurate and efficient way to obtain long-term creep behavior for composite materials.

During the creep master curve construction process, vertical shifting is required to achieve a smooth and continuous curve. This phenomenon has been observed in similar materials loaded in the direction of the fiber [32]. Vertical shifting is believed to improve the accuracy of creep analysis without affecting its accuracy. Figure 10 shows that the relationship between vertical shifting factors and testing temperature is approximately linear, indicating that the vertical shifting factors may counteract the effect of heating on properties other than creep. As shown in Figure 11, the same TTSP application process was used to generate the creep master curve of FFRP samples with fiber at 90° and ±45°. In contrast to the 0° fiber samples, there is no need for vertical shifting during the construction of creep master curves for 90° and ±45° fiber samples. The reasons for this phenomenon are complex and varied, but one important reason is the sensitivity of the initial instantaneous elastic strain to temperature. The instantaneous elastic strain of 0° fiber samples depends primarily on the stiffness of the flax fiber, resulting in a mismatch between the change in instantaneous strain and creep as the temperature increases. In contrast, the instantaneous elastic strain of the other two types of samples is determined jointly by the matrix and fiber, resulting in an initial strain increase proportional to the temperature increase and allowing for the master curve to be generated without the need for vertical shifting factors.

Relationship between vertical shifting factors for 0° fiber samples.

Creep master curve of samples made of (a) 90° fiber and (b) ±45° fiber.

This phenomenon highlights the importance of considering fiber orientation and material composition when designing experiments to obtain creep master curves. While the vertical shifting factors are necessary for 0° fiber samples, they are not required for samples with fibers oriented at 90° or ±45°. This is due to the joint contribution of the matrix and fiber in determining the instantaneous elastic strain for these samples. The temperature sensitivity of the initial strain in these samples results in an increase in strain with an increase in temperature, allowing the creep master curve to be generated without vertical shifting factors.

Understanding the factors influencing creep behavior and developing accurate predicting methods is crucial for designing composite materials structures. The TTSP method, with its efficient and parameterized approach, can be a valuable tool for determining the long-term creep behavior of these materials. The insights gained from this study can aid in developing more robust and reliable models for predicting the creep behavior of composite materials, ultimately leading to safer and more durable structures.

4 Conclusion

After conducting accelerated creep tests on FFRP composites, this experimental study has investigated the application of the TTSP to construct creep master curves. The results revealed that the frequency dependency of glass transition temperature is unsuitable for generating long-term creep curves of the FFRP made of long unidirectional flax fiber. Instead, shifting factors calculated by the consistency of viscoelastic properties and the visual method can be employed to generate a smooth creep curve. However, it has been found that the creep prediction curve generated by the consistency of viscoelastic properties is more accurate than that by visual methods when validated by the creep results measured in 2,000 h. Therefore, TTSP is a viable method for predicting the creep development of FFRP. Using the consistency of viscoelastic properties to calculate shifting factors effectively ensures its accurate application.

In conclusion, this study has demonstrated the potential of using accelerated creep tests and TTSP to predict the long-term creep behavior of FFRP composites. The findings suggest that the consistency of viscoelastic properties is a more accurate parameterization method for the application of TTSP in predicting creep behavior. This research can provide helpful guidance for the structural design of FFRP composites, and the results can be extended to other composite materials. Further studies could focus on exploring the effect of different factors such as temperature, humidity, and loading rate on the creep behavior of FFRP composites to improve their accuracy and applicability further.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The data that support the findings of this study are available from the corresponding author, B. XU upon reasonable request.

References

[1] Dittenber DB, Gangarao HVS. Critical review of recent publications on use of natural composites in infrastructure. Compos Part A Appl Sci Manuf. 2012;43:1419–29.10.1016/j.compositesa.2011.11.019Suche in Google Scholar

[2] Yan L, Chouw N, Jayaraman K. Flax fibre and its composites – A review. Compos Part B Eng. 2014;56:296–317.10.1016/j.compositesb.2013.08.014Suche in Google Scholar

[3] Pickering KL, Efendy MGA, Le TM. A review of recent developments in natural fibre composites and their mechanical performance. Compos Part A Appl Sci Manuf. 2016;83:98–112.10.1016/j.compositesa.2015.08.038Suche in Google Scholar

[4] Blok R, Smits J, Gkaidatzis R, Teuffel P. Bio-based composite footbridge: Design, production and in situ monitoring. Struct Eng Int. 2019 [cited 2022 Jan 28];29:453–65.10.1080/10168664.2019.1608137Suche in Google Scholar

[5] Foster DC. Composite durability and aging in civil infrastructures. In: Pochiraju K, Tandon G, Schoeppner G, editors. Long-Term Durability of Polymeric Matrix Composites. US: Springer; 2012. p. 625–656.10.1007/978-1-4419-9308-3_16Suche in Google Scholar

[6] Santulli C. Creep behaviour of plant fibre composites. Adv High Strength Nat Fibre Compos Constr. 2017;459–77.10.1016/B978-0-08-100411-1.00018-2Suche in Google Scholar

[7] Durante M, Formisano A, Boccarusso L, Langella A, Carrino L. Creep behaviour of polylactic acid reinforced by woven hemp fabric. Compos Part B Eng. 2017;124:16–22.10.1016/j.compositesb.2017.05.038Suche in Google Scholar

[8] Acha BA, Reboredo MM, Marcovich NE. Creep and dynamic mechanical behavior of PP–jute composites: Effect of the interfacial adhesion. Compos Part A Appl Sci Manuf. 2007;38:1507–16.10.1016/j.compositesa.2007.01.003Suche in Google Scholar

[9] Morreale M, Mistretta MC, Fiore V. Creep behavior of poly(lactic acid) based biocomposites. Mater (Basel). 2017 [cited 2022 Aug 20];10(4):395. PMID: 28772755.10.3390/ma10040395Suche in Google Scholar PubMed PubMed Central

[10] Jia Y, Fiedler B. Tensile creep behaviour of unidirectional flax fibre reinforced bio-based epoxy composites. Compos Commun. 2020;18:5–12.10.1016/j.coco.2019.12.010Suche in Google Scholar

[11] Raghavan J, Meshii M. Creep rupture of polymer composites. Compos Sci Technol. 1997;57:375–88.10.1016/S0266-3538(96)00156-XSuche in Google Scholar

[12] Miller SA. Natural fiber textile reinforced bio-based composites: Mechanical properties, creep, and environmental impacts. J Clean Prod. 2018 [cited 2022 Aug 20];198:612–23.10.1016/j.jclepro.2018.07.038Suche in Google Scholar

[13] Cyras VP, Martucci JF, Iannace S, Vazquez A. Influence of the fiber content and the processing conditions on the flexural creep behavior of sisal-PCL-starch composites. J Thermoplast Compos Mater. 2016 [cited 2022 Dec 4];15:253–65. 10.1177/0892705702015003454.Suche in Google Scholar

[14] Xu Y, Wu Q, Lei Y, Yao F. Creep behavior of bagasse fiber reinforced polymer composites. Bioresour Technol. 2010;101:3280–6. PMID: 20064712.10.1016/j.biortech.2009.12.072Suche in Google Scholar PubMed

[15] Ferry JD. Viscoelastic properties of polymers. Vol. 672. 3rd edn. New York: Wiley; 1980 [cited 2022 Aug 20].Suche in Google Scholar

[16] Nakada M. Accelerated testing methodology for long-term creep and fatigue strengths of polymer composites. In Creep and Fatigue in Polymer Matrix Composites (Second Edition). Woodhead Publishing; 2019. p. 325–348.10.1016/B978-0-08-102601-4.00011-4Suche in Google Scholar

[17] Songsong S, Maosong W. Evaluation of the applicability of different viscoelasticity constitutive models in bamboo scrimber short-term tensile creep property research. Sci Eng Compos Mater. 2021 [cited 2023 May 25];28:363–71.10.1515/secm-2021-0034Suche in Google Scholar

[18] Shaw MT, Macknight WJ. Introduction to polymer viscoelasticity. 3rd ed. New Jersey: John Wiley & Sons; 2005.10.1002/0471741833Suche in Google Scholar

[19] Xu B, Blok R, Teuffel P. An investigation of the effect of relative humidity on viscoelastic properties of flax fiber reinforced polymer by fractional-order viscoelastic model. Compos Commun. 2023;37:101406.10.1016/j.coco.2022.101406Suche in Google Scholar

[20] Yang TC, Wu TL, Hung KC, Chen YL, Wu JH. Mechanical properties and extended creep behavior of bamboo fiber reinforced recycled poly(lactic acid) composites using the time–temperature superposition principle. Constr Build Mater. 2015;93:558–63.10.1016/j.conbuildmat.2015.06.038Suche in Google Scholar

[21] Amiri A, Yu A, Webster D, Ulven C. Bio-based resin reinforced with flax fiber as thermorheologically complex materials. Polym (Basel). 2016 [cited 2022 Aug 20];8:153. PMID: 30979245.10.3390/polym8040153Suche in Google Scholar PubMed PubMed Central

[22] Xu F, Arthur Jones I, Li S. A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading. Sci Eng Compos Mater. 2022 [cited 2023 May 25];29:488–99.10.1515/secm-2022-0012Suche in Google Scholar

[23] Georgiopoulos P, Kontou E, Christopoulos A. Short-term creep behavior of a biodegradable polymer reinforced with wood-fibers. Constr Compos Part B Eng. 2015;80:134–44.10.1016/j.compositesb.2015.05.046Suche in Google Scholar

[24] Alvarez VA, Kenny JM, Vázquez A. Creep behavior of biocomposites based on sisal fiber reinforced cellulose derivatives/starch blends. Polym Compos. 2004 [cited 2022 Dec 4];25:280–8.10.1002/pc.20022Suche in Google Scholar

[25] Hung KC, Wu TL, Chen YL, Wu JH. Assessing the effect of wood acetylation on mechanical properties and extended creep behavior of wood/recycled-polypropylene composites. Constr Build Mater. 2016;108:139–45.10.1016/j.conbuildmat.2016.01.039Suche in Google Scholar

[26] Press WH, Teukolsky SA, Vetterling WT, Flannery BP. Numerical Recipes in Fortran 90: The art of scientific computing. 2nd ed. New York: Press Syndicate of the University of Cambridge; 1997.Suche in Google Scholar

[27] LaPlante G, Lee-Sullivan P. Moisture effects on FM300 structural film adhesive: Stress relaxation, fracture toughness, and dynamic mechanical analysis. J Appl Polym Sci. 2005 [cited 2022 Aug 20];95:1285–94.10.1002/app.21353Suche in Google Scholar

[28] Tajvidi M, Falk RH, Hermanson JC. Time-temperature superposition principle applied to a kenaf-fiber/high- density polyethylene composite. J Appl Polym Sci. 2005 [cited 2022 Jan 28];97:1995–2004.10.1002/app.21648Suche in Google Scholar

[29] Williams ML, Landel RF, Ferry JD. The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J Am Chem Soc. 1955 [cited 2022 Aug 17];77:3701–7.10.1021/ja01619a008Suche in Google Scholar

[30] Ward IM, Sweeney J. Mechanical properties of solid polymers. 3rd ed. Leeds: John Wiley and Sons; 2012.10.1002/9781119967125Suche in Google Scholar

[31] Teukolsky SA, Flannery BP, Press WH, Vetterling WT. Numerical recipes in C. SMR. 1992;693:59–70.Suche in Google Scholar

[32] Peng H, Jiang J, Lu J, Cao J. Application of time–temperature superposition principle to Chinese fir orthotropic creep. J Wood Sci. 2017 [cited 2022 Aug 20];63:455–63.10.1007/s10086-017-1635-2Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Effects of cellulose nanofibers on flexural behavior of carbon-fiber-reinforced polymer composites with delamination

- Damage mechanisms of bismaleimide matrix composites under transverse loading via quasi-static indentation

- Experimental study on hydraulic fracture behavior of concrete with wedge-splitting testing

- The assessment of color adjustment potentials for monoshade universal composites

- Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property

- The effect of temperature on the tensile properties and failure mechanisms of two-dimensional braided composites

- The influence of preparation of nano-ZrO2/α-Al2O3 gradient coating on the corrosion resistance of 316L stainless steel substrate

- A numerical study on the spatial orientation of aligning fibrous particles in composites considering the wall effect

- A simulative study on the effect of friction coefficient and angle on failure behaviors of GLARE subjected to low-velocity impact

- Impact resistance capacity and degradation law of epoxy-coated steel strand under the impact load

- Analytical solutions of coupled functionally graded conical shells of revolution

- The influence of water vapor on the structural response of asphalt pavement

- A non-invasive method of glucose monitoring using FR4 material based microwave antenna sensor

- Chloride ion transport and service life prediction of aeolian sand concrete under dry–wet cycles

- Micro-damage analysis and numerical simulation of composite solid propellant based on in situ tensile test

- Experimental study on the influence of high-frequency vibratory mixing on concrete performance

- Effects of microstructure characteristics on the transverse moisture diffusivity of unidirectional composite

- Gradient-distributed ZTAp-VCp/Fe45 as new anti-wear composite material and its bonding properties during composite casting

- Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field

- Mechanical and tribological properties of C/C–SiC ceramic composites with different preforms

- Mechanical property improvement of oil palm empty fruit bunch composites by hybridization using ramie fibers on epoxy–CNT matrices

- Research and analysis on low-velocity impact of composite materials

- Optimizing curing agent ratios for high-performance thermosetting phthalonitrile-based glass fibers

- Method for deriving twisting process parameters of large package E-glass yarn by measuring physical properties of bobbin yarn

- A probability characteristic of crack intersecting with embedded microcapsules in capsule-based self-healing materials

- An investigation into the effect of cross-ply on energy storage and vibration characteristics of carbon fiber lattice sandwich structure bionic prosthetic foot

- Preparation and application of corona noise-suppressing anti-shedding materials for UHV transmission lines

- XRD analysis determined crystal cage occupying number n of carbon anion substituted mayenite-type cage compound C12A7: nC

- Optimizing bending strength of laminated bamboo using confined bamboo with softwoods

- Hydrogels loaded with atenolol drug metal–organic framework showing biological activity

- Creep analysis of the flax fiber-reinforced polymer composites based on the time–temperature superposition principle

- A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously

- Effect of aggregate characteristics on properties of cemented sand and gravel

- An integrated structure of air spring for ships and its strength characteristics

- Modeling and dynamic analysis of functionally graded porous spherical shell based on Chebyshev–Ritz approach

- Failure analysis of sandwich beams under three-point bending based on theoretical and numerical models

- Study and prediction analysis on road performance of basalt fiber permeable concrete

- Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method

- Study on properties of recycled mixed polyester/nylon/spandex modified by hydrogenated petroleum resin

- Effect of particle size distribution on microstructure and chloride permeability of blended cement with supplementary cementitious materials

- In situ ligand synthesis affording a new Co(ii) MOF for photocatalytic application

- Fracture research of adhesive-bonded joints for GFRP laminates under mixed-mode loading condition

- Influence of temperature and humidity coupling on rutting deformation of asphalt pavement

- Review Articles

- Sustainable concrete with partial substitution of paper pulp ash: A review

- Durability and microstructure study on concrete made with sewage sludge ash: A review (Part Ⅱ)

- Mechanical performance of concrete made with sewage sludge ash: A review (Part Ⅰ)

- Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II)

- Communication

- Calculation of specific surface area for tight rock characterization through high-pressure mercury intrusion

- Special Issue: MDA 2022

- Vibration response of functionally graded material sandwich plates with elliptical cutouts and geometric imperfections under the mixed boundary conditions

- Analysis of material removal process when scratching unidirectional fibers reinforced polyester composites

- Tailoring the optical and UV reflectivity of CFRP-epoxy composites: Approaches and selected results

- Fiber orientation in continuous fiber-reinforced thermoplastics/metal hybrid joining via multi-pin arrays

- Development of Mg-based metal matrix biomedical composites for acicular cruciate ligament fixation by reinforcing with rare earth oxide and hydroxyapatite – A mechanical, corrosion, and microstructural perspective

- Special Issue: CACMSE

- Preparation and application of foamed ceramic panels in interior design

Artikel in diesem Heft

- Regular Articles

- Effects of cellulose nanofibers on flexural behavior of carbon-fiber-reinforced polymer composites with delamination

- Damage mechanisms of bismaleimide matrix composites under transverse loading via quasi-static indentation

- Experimental study on hydraulic fracture behavior of concrete with wedge-splitting testing

- The assessment of color adjustment potentials for monoshade universal composites

- Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property

- The effect of temperature on the tensile properties and failure mechanisms of two-dimensional braided composites

- The influence of preparation of nano-ZrO2/α-Al2O3 gradient coating on the corrosion resistance of 316L stainless steel substrate

- A numerical study on the spatial orientation of aligning fibrous particles in composites considering the wall effect

- A simulative study on the effect of friction coefficient and angle on failure behaviors of GLARE subjected to low-velocity impact

- Impact resistance capacity and degradation law of epoxy-coated steel strand under the impact load

- Analytical solutions of coupled functionally graded conical shells of revolution

- The influence of water vapor on the structural response of asphalt pavement

- A non-invasive method of glucose monitoring using FR4 material based microwave antenna sensor

- Chloride ion transport and service life prediction of aeolian sand concrete under dry–wet cycles

- Micro-damage analysis and numerical simulation of composite solid propellant based on in situ tensile test

- Experimental study on the influence of high-frequency vibratory mixing on concrete performance

- Effects of microstructure characteristics on the transverse moisture diffusivity of unidirectional composite

- Gradient-distributed ZTAp-VCp/Fe45 as new anti-wear composite material and its bonding properties during composite casting

- Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field

- Mechanical and tribological properties of C/C–SiC ceramic composites with different preforms

- Mechanical property improvement of oil palm empty fruit bunch composites by hybridization using ramie fibers on epoxy–CNT matrices

- Research and analysis on low-velocity impact of composite materials

- Optimizing curing agent ratios for high-performance thermosetting phthalonitrile-based glass fibers

- Method for deriving twisting process parameters of large package E-glass yarn by measuring physical properties of bobbin yarn

- A probability characteristic of crack intersecting with embedded microcapsules in capsule-based self-healing materials

- An investigation into the effect of cross-ply on energy storage and vibration characteristics of carbon fiber lattice sandwich structure bionic prosthetic foot

- Preparation and application of corona noise-suppressing anti-shedding materials for UHV transmission lines

- XRD analysis determined crystal cage occupying number n of carbon anion substituted mayenite-type cage compound C12A7: nC

- Optimizing bending strength of laminated bamboo using confined bamboo with softwoods

- Hydrogels loaded with atenolol drug metal–organic framework showing biological activity

- Creep analysis of the flax fiber-reinforced polymer composites based on the time–temperature superposition principle

- A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously

- Effect of aggregate characteristics on properties of cemented sand and gravel

- An integrated structure of air spring for ships and its strength characteristics

- Modeling and dynamic analysis of functionally graded porous spherical shell based on Chebyshev–Ritz approach

- Failure analysis of sandwich beams under three-point bending based on theoretical and numerical models

- Study and prediction analysis on road performance of basalt fiber permeable concrete

- Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method

- Study on properties of recycled mixed polyester/nylon/spandex modified by hydrogenated petroleum resin

- Effect of particle size distribution on microstructure and chloride permeability of blended cement with supplementary cementitious materials

- In situ ligand synthesis affording a new Co(ii) MOF for photocatalytic application

- Fracture research of adhesive-bonded joints for GFRP laminates under mixed-mode loading condition

- Influence of temperature and humidity coupling on rutting deformation of asphalt pavement

- Review Articles

- Sustainable concrete with partial substitution of paper pulp ash: A review

- Durability and microstructure study on concrete made with sewage sludge ash: A review (Part Ⅱ)

- Mechanical performance of concrete made with sewage sludge ash: A review (Part Ⅰ)

- Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II)

- Communication

- Calculation of specific surface area for tight rock characterization through high-pressure mercury intrusion

- Special Issue: MDA 2022

- Vibration response of functionally graded material sandwich plates with elliptical cutouts and geometric imperfections under the mixed boundary conditions

- Analysis of material removal process when scratching unidirectional fibers reinforced polyester composites

- Tailoring the optical and UV reflectivity of CFRP-epoxy composites: Approaches and selected results

- Fiber orientation in continuous fiber-reinforced thermoplastics/metal hybrid joining via multi-pin arrays

- Development of Mg-based metal matrix biomedical composites for acicular cruciate ligament fixation by reinforcing with rare earth oxide and hydroxyapatite – A mechanical, corrosion, and microstructural perspective

- Special Issue: CACMSE

- Preparation and application of foamed ceramic panels in interior design