Abstract

In order to improve the utilization value of recycled materials, the study considers recycled materials such as polyester/nylon/spandex as raw materials. Using polyester/polyamide/spandex as raw materials, the recycled polyester/polyamide/spandex mixed materials were first pretreated to obtain the pretreated mixed materials. Then, the pretreated mixed materials were evenly mixed with hydrogenated petroleum resin. The composite materials were prepared through extrusion and injection molding. By comparing the mechanical properties, the effects of different hydrogenated petroleum resins and their additives on the tensile strength, bending strength, impact strength, elongation at break, and bending modulus of the composites were investigated. And the microstructure of the fracture surface was characterized by scanning electron microscopy. The results showed that: (a) when the addition amount of hydrogenated C5 petroleum resin was 4.5%, the maximum impact strength and fracture elongation were 18.03 kJ/m2 and 15.92%, respectively. (b) The maximum tensile strength, bending strength, and bending modulus could reach 22.9, 38.72, and 2217.9 MPa, when the addition amount of hydrogenated C9 petroleum resin was 4.5, 29.5, and 39.5%, respectively.

1 Introduction

Polyester has the advantages of high strength and high modulus in mechanical properties [1,2]. As a general material, polyamide/spandex are similar to polyester. In recent years, the use and recycling of polyamide/spandex have been increasing. Polyester/nylon/spandex recycling usually comes in the form of a mixture; therefore, it is of great practical significance to study the recycling of mixed materials such as polyester/polyamide/spandex. On the issue of recycling polyester materials, need to add some additives to solve the compatibility problem between polyester and other materials. For example, by adding compatibilizer [3,4], the compatibility between polyester and high density polyethylene [5] and polypropylene (PP) [6,7,8] could be solved, which provides ideas for the comprehensive utilization of polyester/polyamide/spandex mixed materials.

In previous studies, our research group studied the process of mixed polyester/polyamide/spandex to modify PP by adding different compatibles [9] and using different pretreatment processes [10]. In the process of research, it is also found that the “bonding” between polyester/nylon/spandex and the modified matrix material was not obvious due to the differences in compatibility and bonding of the mixture material of polyester/nylon/spandex. Therefore, the microstructure of the fracture surface of the composite material was defective, and the mechanical properties were also affected to some extent. Hydrogenated petroleum resin has good advantages in compatibility, viscosity enhancement, and thermal stability [11]. Similarly, hydrogenated petroleum resins were widely used in the coatings, paints, adhesives, rubber, and other fields. It plays a significant role in improving the microstructure and mechanical properties of materials [12,13].

In this study, hydrogenated C9 petroleum resin and hydrogenated C5 petroleum resin were used to modify polyester/nylon/spandex mixtures to prepare composite materials with better mechanical properties, and the mechanical properties and fracture surface microstructure of the prepared composite materials were characterized. They found that with the change in the amount of hydrogenated C5 petroleum resin and hydrogenated C9 petroleum resin, the mechanical properties of the composite material such as tensile strength, bending strength, impact strength, fracture elongation, and bending modulus also changed, and the optimal mechanical properties of the composite material were obtained. The research results of this article can provide theoretical basis and data support for the recycling of polyester/nylon/spandex materials.

2 Experimental method

2.1 Main experimental materials

Starting materials such as maleic anhydride grafted polypropylene (PP-g-MAH) and hydroglyceryl methacrylate grafted with ethylene-octene copolymer (POE-g-GMA) were purchased from Ningbo Nengzhiguang New Material Technology Co., Ltd. Hydrogenated C5 petroleum resin (Model: H5-1000, Softening point: 101.3°C, Gardner color number: #0–1) and hydrogenated C9 petroleum resin (Model: HM-1000, Softening point: 100.7°C, Gardner color number: #0–1) were purchased from Zhejiang Henghe Petrochemical Co., Ltd. Polyester/nylon/spandex and other short fiber materials were provided by market sorting and recycling companies (tensile strength: 15.17 MPa, bending strength: 24.34 MPa, impact strength: 10.275 kJ/m2, fracture elongation: 3.72%, and bending modulus: 1427.84 MPa). All other reagents and solvents were of reagent grade and used without further purification.

2.2 Pretreatment of experimental materials

The polyester/nylon/polyurethane were evenly mixed according to the molar ratio of 1:1:1, and the pellet pretreatment method was carried out according to literature [10]. Similarly, the pretreated material was placed in an oven at 120°C for 4 h, and cooled for later use. The hydrogenated C5 petroleum resin, hydrogenated C9 petroleum resin, compatibilizer, and other materials were put into the oven at 100°C for 4 h, then removed and cooled for later use. The pretreatment materials, hydrogenated C5 petroleum resin, hydrogenated C9 petroleum resin, compatibilizer, antioxidant, and other materials were mixed according to Tables 1 and 2.

Material composition in the modification experiment of hydrogenated carbon 9 petroleum resin (%)

| Number | Pretreatment material | Antioxidant 225 | PP-g-MAH | POE-g-GMA | Hydrogenated C9 petroleum resin |

|---|---|---|---|---|---|

| 1 | 54 | 0.5 | 4 | 2 | 39.5 |

| 2 | 64 | 0.5 | 4 | 2 | 29.5 |

| 3 | 74 | 0.5 | 4 | 2 | 19.5 |

| 4 | 84 | 0.5 | 4 | 2 | 9.5 |

| 5 | 89 | 0.5 | 4 | 2 | 4.5 |

Material composition in the modification experiment of hydrogenated carbon 5 petroleum resin (%)

| Number | Pretreatment material | Antioxidant 225 | PP-g-MAH | POE-g-GMA | Hydrogenated C5 petroleum resin |

|---|---|---|---|---|---|

| 6 | 54 | 0.5 | 4 | 2 | 39.5 |

| 7 | 64 | 0.5 | 4 | 2 | 29.5 |

| 8 | 74 | 0.5 | 4 | 2 | 19.5 |

| 9 | 84 | 0.5 | 4 | 2 | 9.5 |

| 10 | 89 | 0.5 | 4 | 2 | 4.5 |

2.3 Sample preparation

The materials in Tables 1 and 2 were extruded and pelleted by twin screw extruder (WLG10A, Shanghai Xinshuo Precision Machinery Co. Ltd), respectively. The extrusion conditions of the extruder were set as follows: the temperature of the upper cavity plate was 200°C, the temperature of the lower cavity plate was 200°C, the working time was 16.5 s, and the screw speed was 74 rpm. The pellet was injected by the injection molding machine. The injection molding conditions were set as follows: the mold temperature was 43°C, the cylinder temperature was 200°C, and the pressure holding time was 6 s. The detailed schematic diagrams for sample preparation can be seen from Figure 1.

Schematic diagrams for sample preparation.

2.4 Performance test

Tensile performance test: according to GB/T 10400.1-2018 standard test, using type Ⅱ spline (CMT6104, Shenzhen New Think Material Testing Co., Ltd), test speed was 5 mm/min. Bending performance test: according to GB/T 9341-2000 standard test, the test speed was 5 mm/min. Notched impact strength performance test: according to GB/T 1843-2008 standard test, the impact energy was 2.75 J. Using V-shaped splines in pendulum testing experiments, pendulum speed was 9 m/s. Scanning electron microscopy (SEM) analysis: the plastic profile sample was taken and fixed on the conductive tape, and treated with gold spraying. The appearance of the cutting surface was observed. And the accelerated voltage was 20 kV. Cold field emission scanning electron microscope (SEM): Quanta-600FEG, FEI Company, the Netherlands.

3 Results and discussion

3.1 Influence of petroleum resin content on mechanical properties of composites

3.1.1 Tensile strength

As can be seen from Figure 2, with the increase in hydrogenated C5 petroleum resin and hydrogenated C9 petroleum resin, the tensile strength of the composite showed a law of obvious decrease. When the additive content of petroleum resin was less it may be because of the high strength of chemical fiber material acting as skeleton [14]. The bonding property of petroleum resin strengthens the skeleton action of chemical fiber material, so the tensile strength of the composite material was larger. First, as the additive content of petroleum resin increased, petroleum resin has obvious dilution effect on the whole composite system [15]. On the other hand, the composition of the high-strength chemical fiber material decreases, while the matrix viscosity gradually increases, the regularity of the chemical fiber material decreases, and the skeleton cannot be evenly dispersed, so the tensile strength of the composite material decreases significantly.

Effect of hydrogenated petroleum resin content on tensile strength.

When the content of petroleum resin was 4.5%, the mechanical properties of the composites prepared by hydrogenated C9 petroleum resin were slightly stronger than those prepared by hydrogenated C5 petroleum resin. This may be due to the fact that hydrogenated C5 petroleum resin mainly has aliphatic hydrocarbon structure, and hydrogenated C9 petroleum resin molecule contains benzene ring and other structures. So, hydrogenated C9 petroleum resin has better compatibility with chemical fiber materials under the action of compatibilant, resulting in better mechanical properties of tensile strength.

3.1.2 Bending strength and bending modulus

As can be seen from Figure 3(a), with the increase in petroleum resin content, the bending strength of composite materials decreased first and then increased. When the content of hydrogenated C9 petroleum resin was 29.5%, the bending strength of the composite reached the maximum. When the content of hydrogenated C5 petroleum resin was 4.5%, the bending strength of the composite reached the maximum. The bending strength of the composites prepared by hydrogenated C9 petroleum resin was stronger than that of the composites prepared by hydrogenated C5 petroleum resin.

(a) Effect of hydrogenated petroleum resin content on bending strength and (b) effect of hydrogenated petroleum resin content on bending modulus.

When the amount of hydrogenated petroleum resin was 4.5%, the chemical fiber material has a high strength to act as a skeleton [14], which was strengthened by the adhesive property of hydrogenated petroleum resin. With the increase in hydrogenated petroleum resin content, this skeleton effect was weakened, so the mechanical properties of bending strength showed a decreasing trend. When the amount of hydrogenated petroleum resin was between 9.5 and 29.5%, the bending strength of the composite was significantly improved. When the amount of hydrogenated petroleum resin was 29.5%, the bending strength reaches its maximum. Hydrogenated petroleum resin may have the most obvious effect on the stiffness enhancement of the composite skeleton [15].

When the content of hydrogenated petroleum resin continued to increase, the mechanical properties of hydrogenated petroleum resin materials had more obvious influence on the mechanical properties of composite materials because the skeleton effect of chemical fiber materials continues to weaken. With the increase in hydrogenated petroleum resin, hydrogenated petroleum resin made materials become brittle [16]. Therefore, material properties were significantly reduced. On the other hand, with the increase in hydrogenated petroleum resin components, due to the bonding effect of hydrogenated petroleum resin, the molecular structure regularity of chemical fiber materials decreased, and the framework of chemical fiber materials could not be evenly dispersed. These two factors lead to a significant decrease in the mechanical properties of the composite bending strength.

It can also be seen from Figure 3(a) that hydrogenated C9 petroleum resin is superior to hydrogenated C5 petroleum resin in terms of mechanical properties of composite bending strength. It may be that the molecular structure polarity of hydrogenated C9 petroleum resin was greater than that of hydrogenated C5 petroleum resin and it had better compatibility with chemical fiber materials.

As can be seen from Figure 3(b), with the increase in hydrogenated petroleum resin content, the bending modulus of the composite decreased first and then increased significantly. The maximum bending modulus of hydrogenated C9 petroleum resin composite was 2217.9 MPa, the maximum bending modulus of hydrogenated C5 petroleum resin composite was 1654.2 MPa, and the maximum bending modulus of reference product was 1427.84 MPa.

When the hydrogenated petroleum resin content was low, the chemical fiber material skeleton effect had a large effect on the composite material. Therefore, the bending modulus of composite materials decreased gradually. With the increase in hydrogenated petroleum resin content, the hydrogenated petroleum resin had the strength of the frame, and the performance of the composite material was gradually improved.

The bending modulus and mechanical properties of the composites prepared by hydrogenated C9 petroleum resin were obviously better than those of hydrogenated C5 petroleum resin. This was due to the structural differences between the two hydrogenated petroleum resins. Because the molecular structure of hydrogenated C5 petroleum resin was less polar, it had poor compatibility with the framework of chemical fiber materials. Hydrogenated C9 petroleum resin molecules contained rigid groups such as benzene ring and other structures, the material rigidity was strong, and hydrogenated C9 petroleum resin molecules had greater polarity and better compatibility with chemical fiber materials.

3.1.3 Impact strength

It can be seen from Figure 4 that the impact strength of the composite prepared by hydrogenated C5 petroleum resin decreased first and then increased. The impact strength reached the maximum (18.03 kJ/m2) when the addition amount of hydrogenated C5 petroleum resin was 4.5%. The impact strength of the composites prepared by hydrogenated C9 petroleum resin increased first and then decreased. When the addition of hydrogenated C9 petroleum resin was 29.5%, the impact strength reached the maximum (15.878 kJ/m2).

Effect of hydrogenated petroleum resin content on impact strength.

For the composite prepared by hydrogenated C5 petroleum resin, when the hydrogenated C5 petroleum resin increased from 4.5 to 29.5%, it may act as a skeleton due to the high strength of chemical fiber materials [14]. With the increase in hydrogenated C5 petroleum resin content, the effect of this framework was weakened, so the mechanical properties of impact strength showed a decreasing trend. While the content of hydrogenated C5 petroleum resin continues to increase, which may be due to the stiffening effect of hydrogenated petroleum resin [15], the mechanical properties of hydrogenated C5 petroleum resin material itself play a major role.

However, the impact strength of the composite prepared by hydrogenated C9 petroleum resin increased significantly when the addition amount was 4.5−29.5%. On the one hand, the hydrogenated C9 petroleum resin molecule had greater polarity and better compatibility with chemical fiber materials. On the other hand, the hydrogenated C9 petroleum resin molecule contained benzene ring and other rigid groups. When the addition amount was greater than 29.5%, the impact strength of the composite had a downward trend, which was due to the bonding effect of hydrogenated C9 petroleum resin, which reduced the regularity of the chemical fiber material and made it unable to disperse evenly.

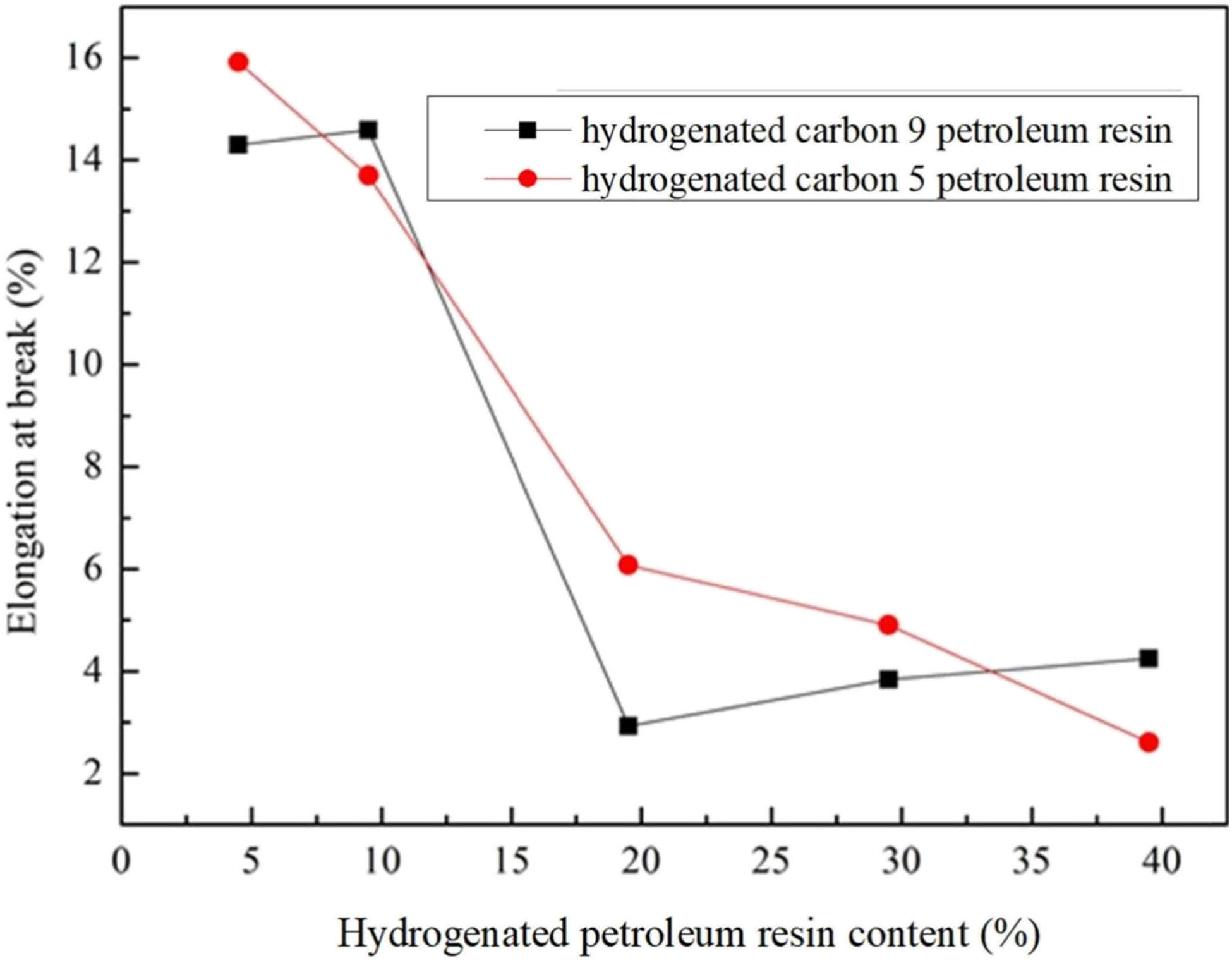

3.1.4 Elongation at break

As can be seen from Figure 5, the fracture elongation of hydrogenated C5 petroleum resin composite decreased with the increase in hydrogenated petroleum resin content, and the maximum fracture elongation was 15.92%. The fracture elongation of hydrogenated C9 petroleum resin composite increased weakly and then decreased sharply, and then increased slowly, and the maximum fracture elongation was 14.59%. First, it was possible that the elongation of composite materials was mainly determined by chemical fiber materials. With the increase in hydrogenated petroleum resin, the hydrogenated petroleum resin made the materials brittle [16] and had an obvious dilution effect on the entire composite system [17]. Second, due to the bonding effect of hydrogenated petroleum resin, the regularity of chemical fiber materials was reduced and could not be evenly dispersed. Therefore, it had great influence on fracture elongation of composites.

Effect of hydrogenated petroleum resin content on elongation at break.

3.2 Microstructure of fracture surface of composite material

Figure 6(a) and (b) shows the scanning electron micrograph of fracture surface of composite material experiment No. 2 in Table 1 and experiment No. 7 in Table 2. The addition amount of hydrogenated petroleum resin, chemical fiber aggregate, PP-g-MAH, POE-g-GMA, and antioxidant were 29.5, 64, 4, 2, and 0.5%, respectively. As can be seen from Figure 6(a), most of the fiber materials could be evenly dispersed with hydrogenated C5 petroleum resin, and there were “small pits” on the fracture surface. This was where some of the fibers were pulled out of the matrix. As can be seen from Figure 6(b), most of the fiber materials could be evenly dispersed with hydrogenated C9 petroleum resin. Similarly, there were “small pits” on the fracture surface.

(a) SEM of fracture surface of hydrogenated C5 petroleum resin composite and (b) SEM of fracture surface of hydrogenated C9 petroleum resin composite.

By comparing Figure 6(a) and (b), it can be seen that by using hydrogenated C5 petroleum resin, the fracture surface “small pit” was relatively obvious, and many fibers were pulled out from the matrix of composite materials. By using hydrogenated C9 petroleum resin, the bond between fiber and composite matrix was more firm, and the force was obviously strengthened. This verifies that hydrogenated C9 petroleum resin had better compatibility with chemical fiber materials because of its larger molecular polarity.

In the fracture surface structure, it was also found that the chemical fiber material was relatively less, and the matrix material seemed to be mainly petroleum resin. The main reason may be that with the increase in the content of petroleum resin, stickiness increased, so that chemical fiber materials bond in hydrogenated petroleum resin, resulting in uneven dispersion of chemical fiber materials and hydrogenated petroleum resin. During the experiment, it was also found that the content of hydrogenated petroleum resin was greater than 39.5%, the viscosity of hydrogenated petroleum resin and chemical fiber material melt body was large, and the operation of extrusion and injection molding was more and more difficult. Therefore, in the process of using hydrogenated petroleum resin to modify chemical fiber materials, it was necessary to consider the mechanical property index and processing difficulty, and select the appropriate addition ratio, which can also provide reference for the optimization of the process of using hydrogenated petroleum resin to modify other materials.

4 Results and prospects

The aim of this study was to improve the utilization value of recycled materials such as polyester/nylon/spandex. Polyester/polyamide/spandex composite were prepared by hydrogenated petroleum resin blending modified polyester/polyamide/spandex by hydrogenated C5 petroleum resin and hydrogenated C9 petroleum resin. It was found that the mechanical properties of the composite prepared by hydrogenated C5 petroleum resin are better in impact strength and fracture elongation. The mechanical properties of the composites prepared by hydrogenated C9 petroleum resin were better in tensile strength, bending strength, and bending modulus. The results showed that the maximum impact strength and fracture elongation were 18.03 kJ/m2 and 15.92%, respectively, when the addition amount of hydrogenated C5 petroleum resin was 4.5%. The maximum tensile strength of hydrogenated C9 petroleum resin was 22.9 MPa when the addition amount was 4.5%, the maximum bending strength was 38.72 MPa when the addition amount is 29.5%, and the maximum bending modulus was 2217.9 MPa when the addition amount is 39.5%. In the future, when hydrogenated C5 petroleum resin and hydrogenated C9 petroleum resin are used to modify other chemical fiber materials to prepare composite materials, the appropriate addition ratio can be selected according to the comprehensive consideration of the mechanical property index and the difficulty of the processing process, and even further, other engineering plastics can be modified by blending hydrogenated C5 petroleum resin or hydrogenated C9 petroleum resin and chemical fiber materials.

Acknowledgements

This work was supported by the following funds or institutions: Ningbo Polytechnic’s 2022 project: Study on Modification of PE with Petroleum Resin Coated Polyester, Nylon, and Spandex (Program No: NZ22004); Key Research and Development Program of Shaanxi (Program No. 2023-YBNY-245); Science and Technology Guidance Project from China Textile Industry Association (Program No. 2022042); The Science and Technology Plan of Beilin District (Grant No. GX2302); and Zhang Farao Academician workstation of Ningbo.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Shi SY, Wang LN, Zhao K, Song HF, Wang YF. Structure and mechanical property of recycled PET fiber/PP Composite. Acta Mater Compos Sin. 2017;34(7):1511–6 (Chinese).Search in Google Scholar

[2] Parvinzadeh M, Ebrahimi I. Atmospheric airplasma treatment of polyester fiber to improve the performance of nanoemulsion silicone. Appl Surf Sci. 2011;257:4062–8.10.1016/j.apsusc.2010.11.175Search in Google Scholar

[3] Kalfoglou NK, Skafidas DS, Kallitsls JK, Lambert JC, Van der Stappen L. Comparison of compatibilizer effectiveness for PET/HDPE blends. Polymer. 1995;36(23):4453–62.10.1016/0032-3861(95)96853-ZSearch in Google Scholar

[4] Zhang Y. Super toughness in recycled poly(ethylene terephthalate)/polyethylene compatibilized blend. Shanghai: East China University of Science and Technology; 2011.Search in Google Scholar

[5] He MS, Wang ZK, Cao XW, Sun XM, Lu XZ. The properties and morphology of PET/PE allots. Plastics. 2016;45(6):13–6 (Chinese).Search in Google Scholar

[6] Qi YH, Sun J, Ma YH, Dong JH, Luo Z, Wei LQ. Effect of compatilizers contents on foaming and mechanical properties of PET/IPP blend. Plastics. 2016;45(2):69–72 (Chinese).Search in Google Scholar

[7] Qiu LQ, Liu HZ, Zhao SY, Liu RL. Preparation and characterization of crystallization and thermal property of poly(ethylene terephthalate) and poly(lactic acid) blends promoted by compatilizer. Polym Mater Sci Eng. 2018;34(3):73–80 (Chinese).Search in Google Scholar

[8] Wang CG, Huang T, Yan JF, Liu SQ, Tang HQ. Effect of PET fiber on crystallization behavior and mechanical properties of PP. China Synth Resin Plastic. 2018;35(4):70–4 (Chinese).Search in Google Scholar

[9] Kuang XM, Su MR, Li H, Shen XL, Yuan ZY, Yan XD, et al. Effects of pretreatment process on mechanical properties of recycled polyester/nylon/spandex mixed fiber modified polypropylene. Eng Plast Appl. 2020;48(9):78–82 (Chinese).Search in Google Scholar

[10] Kuang XM, Su MR, Li H, Yuan ZY, Yang WQ. Study on property of polypropylene modified by polyester/nylon/spandex fiber with compatibilizer. N Chem Mater. 2021;49(9):98–101, 106 (Chinese).Search in Google Scholar

[11] Liu X, Liu WB, Ma ZJ, Zhang Q. Hydrogenated C5 petroleum resin to qualitative research. Contemporary Chem Ind. 2014;43(1):15–6, 20 (Chinese).Search in Google Scholar

[12] Colombo RP, Ibarra JG, Bidondo LF, Bidondo LF, Silvani VA, Bompadre MJ, et al. Arbuscular mycorrhizal fungal association in genetically modified drought-tolerant corn. J Env Qual. 2016;46(1):227–31.10.2134/jeq2016.04.0125Search in Google Scholar PubMed

[13] Porfirio S, Silva MD, Cabrita MJ, Azadi P. Reviewing current knowledge on olive adventitious root formation. Sci Hortic-Amsterdam. 2016;198:207–26.10.1016/j.scienta.2015.11.034Search in Google Scholar

[14] Tang XL, Tan HS, Tan H, Wang YG. Long aramid fiber reinforced impact polypropylene copolymer composites. Eng Plast Appl. 2013;41(2):5–9 (Chinese).Search in Google Scholar

[15] Mu YJ, Chai HM. Application of stiffening agent to polypropylene. Plast Sci Technol. 2005;33(2):11–4, 19 (Chinese).Search in Google Scholar

[16] Cimmino S, Silvestre C, Vecchia GD. Morphology and properties of isotactic polypropylene modified with hydrocarbon resin MBG273. I. Binary blends. J Appl Polym Sci. 2010;92(6):3454–65.10.1002/app.20307Search in Google Scholar

[17] Liang WJ, Ge JF, Chen SD, Zheng WL, Lin JL, Sheng YH, et al. Compatibility and mechanical properties of SEBS-g-MAH/hydrogenated C5 petroleum resin blends. J ZhongKai Univ Agric Technol. 2015;28(1):31–4 (Chinese).Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Effects of cellulose nanofibers on flexural behavior of carbon-fiber-reinforced polymer composites with delamination

- Damage mechanisms of bismaleimide matrix composites under transverse loading via quasi-static indentation

- Experimental study on hydraulic fracture behavior of concrete with wedge-splitting testing

- The assessment of color adjustment potentials for monoshade universal composites

- Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property

- The effect of temperature on the tensile properties and failure mechanisms of two-dimensional braided composites

- The influence of preparation of nano-ZrO2/α-Al2O3 gradient coating on the corrosion resistance of 316L stainless steel substrate

- A numerical study on the spatial orientation of aligning fibrous particles in composites considering the wall effect

- A simulative study on the effect of friction coefficient and angle on failure behaviors of GLARE subjected to low-velocity impact

- Impact resistance capacity and degradation law of epoxy-coated steel strand under the impact load

- Analytical solutions of coupled functionally graded conical shells of revolution

- The influence of water vapor on the structural response of asphalt pavement

- A non-invasive method of glucose monitoring using FR4 material based microwave antenna sensor

- Chloride ion transport and service life prediction of aeolian sand concrete under dry–wet cycles

- Micro-damage analysis and numerical simulation of composite solid propellant based on in situ tensile test

- Experimental study on the influence of high-frequency vibratory mixing on concrete performance

- Effects of microstructure characteristics on the transverse moisture diffusivity of unidirectional composite

- Gradient-distributed ZTAp-VCp/Fe45 as new anti-wear composite material and its bonding properties during composite casting

- Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field

- Mechanical and tribological properties of C/C–SiC ceramic composites with different preforms

- Mechanical property improvement of oil palm empty fruit bunch composites by hybridization using ramie fibers on epoxy–CNT matrices

- Research and analysis on low-velocity impact of composite materials

- Optimizing curing agent ratios for high-performance thermosetting phthalonitrile-based glass fibers

- Method for deriving twisting process parameters of large package E-glass yarn by measuring physical properties of bobbin yarn

- A probability characteristic of crack intersecting with embedded microcapsules in capsule-based self-healing materials

- An investigation into the effect of cross-ply on energy storage and vibration characteristics of carbon fiber lattice sandwich structure bionic prosthetic foot

- Preparation and application of corona noise-suppressing anti-shedding materials for UHV transmission lines

- XRD analysis determined crystal cage occupying number n of carbon anion substituted mayenite-type cage compound C12A7: nC

- Optimizing bending strength of laminated bamboo using confined bamboo with softwoods

- Hydrogels loaded with atenolol drug metal–organic framework showing biological activity

- Creep analysis of the flax fiber-reinforced polymer composites based on the time–temperature superposition principle

- A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously

- Effect of aggregate characteristics on properties of cemented sand and gravel

- An integrated structure of air spring for ships and its strength characteristics

- Modeling and dynamic analysis of functionally graded porous spherical shell based on Chebyshev–Ritz approach

- Failure analysis of sandwich beams under three-point bending based on theoretical and numerical models

- Study and prediction analysis on road performance of basalt fiber permeable concrete

- Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method

- Study on properties of recycled mixed polyester/nylon/spandex modified by hydrogenated petroleum resin

- Effect of particle size distribution on microstructure and chloride permeability of blended cement with supplementary cementitious materials

- In situ ligand synthesis affording a new Co(ii) MOF for photocatalytic application

- Fracture research of adhesive-bonded joints for GFRP laminates under mixed-mode loading condition

- Influence of temperature and humidity coupling on rutting deformation of asphalt pavement

- Review Articles

- Sustainable concrete with partial substitution of paper pulp ash: A review

- Durability and microstructure study on concrete made with sewage sludge ash: A review (Part Ⅱ)

- Mechanical performance of concrete made with sewage sludge ash: A review (Part Ⅰ)

- Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II)

- Communication

- Calculation of specific surface area for tight rock characterization through high-pressure mercury intrusion

- Special Issue: MDA 2022

- Vibration response of functionally graded material sandwich plates with elliptical cutouts and geometric imperfections under the mixed boundary conditions

- Analysis of material removal process when scratching unidirectional fibers reinforced polyester composites

- Tailoring the optical and UV reflectivity of CFRP-epoxy composites: Approaches and selected results

- Fiber orientation in continuous fiber-reinforced thermoplastics/metal hybrid joining via multi-pin arrays

- Development of Mg-based metal matrix biomedical composites for acicular cruciate ligament fixation by reinforcing with rare earth oxide and hydroxyapatite – A mechanical, corrosion, and microstructural perspective

- Special Issue: CACMSE

- Preparation and application of foamed ceramic panels in interior design

Articles in the same Issue

- Regular Articles

- Effects of cellulose nanofibers on flexural behavior of carbon-fiber-reinforced polymer composites with delamination

- Damage mechanisms of bismaleimide matrix composites under transverse loading via quasi-static indentation

- Experimental study on hydraulic fracture behavior of concrete with wedge-splitting testing

- The assessment of color adjustment potentials for monoshade universal composites

- Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property

- The effect of temperature on the tensile properties and failure mechanisms of two-dimensional braided composites

- The influence of preparation of nano-ZrO2/α-Al2O3 gradient coating on the corrosion resistance of 316L stainless steel substrate

- A numerical study on the spatial orientation of aligning fibrous particles in composites considering the wall effect

- A simulative study on the effect of friction coefficient and angle on failure behaviors of GLARE subjected to low-velocity impact

- Impact resistance capacity and degradation law of epoxy-coated steel strand under the impact load

- Analytical solutions of coupled functionally graded conical shells of revolution

- The influence of water vapor on the structural response of asphalt pavement

- A non-invasive method of glucose monitoring using FR4 material based microwave antenna sensor

- Chloride ion transport and service life prediction of aeolian sand concrete under dry–wet cycles

- Micro-damage analysis and numerical simulation of composite solid propellant based on in situ tensile test

- Experimental study on the influence of high-frequency vibratory mixing on concrete performance

- Effects of microstructure characteristics on the transverse moisture diffusivity of unidirectional composite

- Gradient-distributed ZTAp-VCp/Fe45 as new anti-wear composite material and its bonding properties during composite casting

- Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field

- Mechanical and tribological properties of C/C–SiC ceramic composites with different preforms

- Mechanical property improvement of oil palm empty fruit bunch composites by hybridization using ramie fibers on epoxy–CNT matrices

- Research and analysis on low-velocity impact of composite materials

- Optimizing curing agent ratios for high-performance thermosetting phthalonitrile-based glass fibers

- Method for deriving twisting process parameters of large package E-glass yarn by measuring physical properties of bobbin yarn

- A probability characteristic of crack intersecting with embedded microcapsules in capsule-based self-healing materials

- An investigation into the effect of cross-ply on energy storage and vibration characteristics of carbon fiber lattice sandwich structure bionic prosthetic foot

- Preparation and application of corona noise-suppressing anti-shedding materials for UHV transmission lines

- XRD analysis determined crystal cage occupying number n of carbon anion substituted mayenite-type cage compound C12A7: nC

- Optimizing bending strength of laminated bamboo using confined bamboo with softwoods

- Hydrogels loaded with atenolol drug metal–organic framework showing biological activity

- Creep analysis of the flax fiber-reinforced polymer composites based on the time–temperature superposition principle

- A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously

- Effect of aggregate characteristics on properties of cemented sand and gravel

- An integrated structure of air spring for ships and its strength characteristics

- Modeling and dynamic analysis of functionally graded porous spherical shell based on Chebyshev–Ritz approach

- Failure analysis of sandwich beams under three-point bending based on theoretical and numerical models

- Study and prediction analysis on road performance of basalt fiber permeable concrete

- Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method

- Study on properties of recycled mixed polyester/nylon/spandex modified by hydrogenated petroleum resin

- Effect of particle size distribution on microstructure and chloride permeability of blended cement with supplementary cementitious materials

- In situ ligand synthesis affording a new Co(ii) MOF for photocatalytic application

- Fracture research of adhesive-bonded joints for GFRP laminates under mixed-mode loading condition

- Influence of temperature and humidity coupling on rutting deformation of asphalt pavement

- Review Articles

- Sustainable concrete with partial substitution of paper pulp ash: A review

- Durability and microstructure study on concrete made with sewage sludge ash: A review (Part Ⅱ)

- Mechanical performance of concrete made with sewage sludge ash: A review (Part Ⅰ)

- Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II)

- Communication

- Calculation of specific surface area for tight rock characterization through high-pressure mercury intrusion

- Special Issue: MDA 2022

- Vibration response of functionally graded material sandwich plates with elliptical cutouts and geometric imperfections under the mixed boundary conditions

- Analysis of material removal process when scratching unidirectional fibers reinforced polyester composites

- Tailoring the optical and UV reflectivity of CFRP-epoxy composites: Approaches and selected results

- Fiber orientation in continuous fiber-reinforced thermoplastics/metal hybrid joining via multi-pin arrays

- Development of Mg-based metal matrix biomedical composites for acicular cruciate ligament fixation by reinforcing with rare earth oxide and hydroxyapatite – A mechanical, corrosion, and microstructural perspective

- Special Issue: CACMSE

- Preparation and application of foamed ceramic panels in interior design