Abstract

With the continuous expansion of the construction scale of the State Grid and the gradual improvement of people’s awareness of environmental protection, the power contradictions and disputes caused by the North–South Power Transmission and Transformation Project have become increasingly prominent, which has attracted widespread attention from all walks of life. This study focuses on the development of conductive silicone gel for UHV transmission lines using carbon fiber (CF) powder, carbon black (CB), and carbon nanotubes as fillers, and organic silicone polymer as the matrix. The aim was to address the issues of corona noise and detachment. We prepared a series of conductive silicone gels with different proportions of CF and CB conductive fillers and conducted a comprehensive analysis of their electrical conductivity, tensile performance, hydrophobicity, and rheological properties. The research results demonstrated that the maximum electrical conductivity of the conductive silicone gel was achieved when the CF and CB contents reached a ratio of 2:1. In the case of a 70% organic silicone polymer gel, the electrical conductivity reached 0.73 S/cm, while it increased to 1.17 S/cm in an 80% organic silicone polymer gel. This indicates that optimizing the proportion of fillers can significantly enhance the electrical conductivity of the conductive silicone gel, meeting the requirements of UHV transmission lines. Additionally, the study evaluated the tensile performance, hydrophobicity, and rheological properties of the conductive silicone gel. The results showed that the 70% organic silicone polymer gel exhibited a tensile strength, Young’s modulus, and elongation at a break of 678.6 MPa, 1.3 MPa, and 15.22%, respectively. The corresponding values for the 80% organic silicone polymer gel were 129.9 MPa, 1.6 MPa, and 55.89%. This indicates that the conductive silicone gel possesses excellent mechanical properties and ductility, enabling it to withstand stress and deformation in UHV transmission lines while providing anti-detachment effects. In summary, this study successfully developed a conductive silicone gel that meets the requirements of UHV transmission lines. By optimizing the ratio of CF and CB contents, the electrical conductivity of the gel was maximized. Furthermore, the conductive silicone gel exhibited favorable tensile performance, electrical conductivity, and anti-detachment effects, effectively addressing corona noise and detachment issues in UHV transmission lines. These research findings are of great significance for the design and application of UHV transmission lines.

1 Introduction

China has a vast territory, and the climate of the north and south is changeable. The winter temperature in the north generally reaches −20°C, with the temperature difference between morning and evening being large. The general wire lines are easy to crack, and the prevention of aging and falling off of wires is an important consideration in the design of transmission lines and power equipment. Corona characteristics are another important consideration in the design of transmission lines and power equipment. At present, to reduce the corona loss of transmission lines at home and abroad, there has been more use of increasing the number of splits, the diameter of the wire, or the height of the tower and other means. Although these methods can achieve the effect of reducing corona loss, a lot of manpower and material resources are required; moreover, large-scale replacement of wires or improving the method of pole tower is impractical [1]. However, these methods cannot fundamentally solve the corona discharge caused by bumps, scratches, wires, and residual metal protrusions that are difficult to be avoided during construction. At present, the existing anti-corona coatings are mostly used in generator windings and there is no good conductive anti-shedding coating for high-voltage transmission lines.

Silicone polymer is a kind of rubber that relies on moisture in the air to cure [2] and has excellent mechanical properties, chemical resistance, and high gloss and color retention [3]. In addition, solvent-based silicone polymers are widely used in engineering construction because of their lightweight, high structural stability, good electrical conductivity, non-toxicity, and harmless and strong adhesion to metals [4,5,6,7]. In the field of composite materials, according to Adin and Kılıçkap [8], the use of conductive fillers such as carbon fiber (CF) powder and carbon black (CB) can significantly enhance the electrical conductivity of composite materials. Furthermore, Adin and Adin [9] investigated the influence of different combinations of conductive fillers on the performance of composites, highlighting the crucial impact of the mixing ratio of CF powder and CB on the electrical conductivity. Conductive fillers (such as carbon nanotubes (CNT) and graphene )is a key step in the preparation of conductive silicone polymer cement with excellent properties [10,11,12,13,14]. Therefore, in this study, carbon fiber powder (CF) and carbon black (CB) were introduced into the conductive organic silica gel mud as conductive fillers. These conductive fillers cooperate with silicone polymer matrix to form a composite system of conductive silicone polymer. Conductive silicone polymer is widely used in practical applications because of its excellent conductivity and its ability to suppress corona noise of UHV transmission lines. The improvement of conductivity can reduce the intensity and frequency of corona discharge and reduce the corona noise. At the same time, the addition of conductive fillers can also improve the conductivity of the material, improve the continuity of the conductive path and conductive ability, so as to enhance the suppression effect of conductive silicone polymer on corona noise. [15,16,17].

Herein, CF powder and CB were added to the silicone polymer matrix as conductive fillers and a UHV transmission line was prepared to suppress corona noise and anti-shedding conductive silicone cement, which can effectively prevent wire peeling, suppress corona noise, and facilitate on-site construction. This conductive silicone gel demonstrates significant application values in UHV transmission lines. First, the selection of CF, CB, and CNT as excellent conductive fillers is noteworthy. These fillers exhibit favorable electrical conductivity and mechanical strength, enabling effective current conduction and enhancing the overall conductivity of the material. By precisely adjusting the filler content, we can achieve the desired level of conductivity required for UHV transmission lines. In addition, the plasticity of the conductive silicone polymer cement can be used to repair the damage to the surface of UHV transmission lines and their gaps, which can change the radius of curvature of the local charged body to a certain extent, to reduce the local field strength of the high-voltage transmission line and inhibit the occurrence of corona noise at the tip.

Second, the use of organic silicone polymer as the matrix material is crucial, as it possesses remarkable characteristics such as high-temperature resistance, electrical stress resistance, and weather resistance, making it highly suitable as an insulation material for UHV transmission lines. By incorporating conductive fillers into the organic silicone polymer matrix, we successfully combine conductivity with insulation. The good fluidity of conductive silicone polymer cement is used to make the surface of UHV transmission lines smooth and rounded so that, to a certain extent, it can show the effect of equivalent diameter expansion and further suppress the generation of corona noise [18].

Additionally, we conducted a comprehensive analysis of the conductive silicone gel’s performance, including conductivity, tensile strength, hydrophobicity, and rheological properties, among others. Through experiments and testing, we verified the excellent performance of the conductive silicone gel in various performance indicators, thereby demonstrating its rationality and feasibility as a material choice for ultra-high-voltage transmission lines.

In summary, this research successfully develops a conductive silicone gel that effectively suppresses corona noise and prevents detachment by combining outstanding conductive fillers and an organic silicone polymer matrix. This study demonstrates innovation in material composition and performance optimization, providing a novel solution for the application of ultra-high-voltage transmission lines.

2 Experimental section

2.1 Main raw materials and instruments

Raw materials used were the following: organic silicon polymer (organosilicon polymer, PP, industrial grade, Suzhou Fulu Biotechnology Co., Ltd.), CF powder (Yancheng Xiangsheng Carbon Fiber Technology Co., Ltd.), CB (Kaisa Graphene Co., Ltd.), CNT (Kaisa Graphene Co., Ltd.), and silane coupling agent 3-aminopropyltriethoxysilane (KH550, chemically pure, Macklin).

RTS-9 double electric test four-probe tester (Guangzhou Four-Probe Technology Co., Ltd.), Kruss contact goniometer (DSA100, Germany), Instron 5967 Universal Testing Machine (Inmstrand), and MARS Type III Hack Rheometer (Thermo Fisher Scientific USA) were used in the experiments.

2.2 Preparation of conductive silicone polymerization cement

2.2.1 Preparation of CF powder modified by the silane coupling agent

During the experiment, the environmental temperature was maintained within the range of room temperature, approximately 25°C. The humidity was maintained at 60%. About 200 g of CF was placed into a 600°C muffle furnace and calcined at a high temperature for 5 h. The product was washed with ethanol and filtered three times to wash off impurities to obtain pure CF. The pure CF was added to the pre-configured KH550 silane coupling agent (mass fraction of 30%); then ammonia was added to alkalinize, followed by mechanical stirring for 5 h at room temperature. The product was washed with ethanol, filtered, and dried to obtain the modified CF powder. The modified CF powder particles were ground evenly with a natural agate mortar.

2.2.2 Preparation of CB modified by the silane coupling agent

During the experiment, the environmental temperature was maintained within the range of room temperature, approximately 25°C. The humidity was maintained at 60%. About 200 g of CB was added to the pre-configured KH550 silane coupling agent (mass fraction of 30%); then, ammonia was added to alkalize followed by mechanical stirring at room temperature for 5 h. The product was washed with ethanol, filtered, and dried to obtain the modified CF powder. The modified CB particles were ground evenly with a natural agate mortar.

2.2.3 Preparation of silicone polymer mastic films

During the experiment, the environmental temperature was maintained within the range of room temperature, approximately 25°C. The humidity was maintained at 60%. The silane coupling agent-modified CF powder and CB were added to the silicone polymer, and then hydroxylated CNT was added and dispersed. The above mixed sample was mechanically stirred for 30 min to disperse the conductive silicone polymer cement evenly, and then the obtained cement was evenly coated on the PTFE plate (30 cm × 30 cm) using a small brush. The solvent was completely volatilized to obtain a conductive silicone polymer cement film [19].

2.2.4 Preparation of CF and CB samples with different contents

In order to prepare the conductive silicone polymer cement with good mechanical properties and owing to a large number of experimental experiences in the early stage, the total mass ratio of the silicone polymer matrix and CF and CB filler is set to 80:20 and 70:30. On this basis, the mass ratio of CF and CB is set to 0:1, 1:2, 1:1, 2:1, 1:0, and the samples are named respectively as follows: F80CF0CB20, F80CF6CB14, PP80CF10CB10, PP80CF14CB6, F80CF20CB0; PP70CF0CB30, PP70CF10CB20, PP70CF15CB15, PP70CF20CB10, and PP70CF30CB0.

2.3 Testing and characterization

2.3.1 Tensile property test

During the experiment, the environmental temperature was maintained within the range of room temperature, approximately 25°C. The humidity was maintained at 60%. The tensile properties of the conductive silicone cement to suppress corona noise have been tested using a universal testing machine, and the reference test standard is GB/T 1040-2006; the tensile speed was 5 mm/min [20].

2.3.2 Rheological tests

The rheological properties and curing of corona noise-suppressing conductive silicone cement were tested using a Hack rheometer: the linear viscoelastic zone of the sample was determined by strain scanning, followed by frequency sweeping to test the viscosity and modulus change of the sample (3% strain). The test angle frequency range was 0.25–100 rad/s.

2.3.3 Conductivity test

The conductivity of the conductive silicone cement that suppresses corona noise was tested by a double electric test four-probe tester, and each sample was tested eight times. The conductivity was taken as the average of the last test.

2.3.4 Hydrophobic performance test

The hydrophobic properties of corona noise-suppressing anti-shedding conductive silicone cement were determined using a contact angle measuring instrument. Before the contact angle test of the sample, it was necessary to ensure the dryness of the sample. The test process mainly determined the size of the surface water droplets of the sample.

2.3.5 Anti-shedding performance test

The conductive silicone cement that suppresses corona noise and prevents shedding was evenly coated on the wire, dried, and cured. It was then into the ultraviolet aging box, and after 15 days of high-temperature aging, it was observed whether the surface of the wire before and after high-temperature ultraviolet aging had fallen off.

3 Results and discussion

3.1 Tensile properties

Tensile performance is a key factor limiting the production and application of conductive cement; therefore, the effect of CF and CB content on the tensile performance of conductive silicone cement to suppress corona noise was further studied; the experimental results are shown in Figure 1. It can be seen from Figure 1 that when the ratio of CF and CB reaches 2:1, the tensile energy of the conductive silicone polymer cement is the best, and the tensile strength, Young’s modulus, and elongation at break of PP70CF20CB10 reached 678.6 MPa, 1.3 MPa, and 15.22%, respectively. The tensile strength, Young’s modulus, and elongation at break of PP80CF14CB6 reached 129.9 MPa, 1.6 MPa, and 55.89%, respectively. Compared with the conductive silicone polymer cement without PP70CF20CB10, PP80CF14CB6 has an increase in elongation at break by 267.21%, Young’s modulus increase of 1.9%, and a slight decrease in the tensile strength.

Tensile properties of conductive silicone polymer mastic films: (a) and (b) 70 and 80% conductive silicone polymer tensile strength and Young’s modulus, respectively, and the relationship between elongation at break and CF and CB content.

This shows that the addition of CF improves the tensile properties of conductive silicone polymer cement, and the enhancement of its tensile strength can ensure that the cement can still have good durability in the harsh natural environment. On the other hand, since CF is a nano-filler with certain ductility, it can undergo a certain level of stretching and deformation when subjected to stress without easily fracturing. When CF is added to conductive mortar, it can bear a portion of the stress and distribute it to the surrounding materials, reducing the stress on individual components and improving the overall toughness [21].

The addition of CF improves the interface bonding between the nanomaterial filler and the matrix of the conductive mortar. CF has a high surface area, allowing for more contact points with the matrix. This enhances the physical and chemical adsorption between the nanomaterial filler and the matrix. The improved interface bonding facilitates more effective stress transfer to the filler, thereby increasing the overall strength and toughness of the material.

CF, as a filler, can fill the voids and defects in the conductive mortar, thereby increasing its density and continuity. This filling effect effectively hinders the propagation and expansion of cracks, thereby improving the toughness of the conductive mortar. The filling effect also enhances the material’s energy absorption capacity, enabling it to withstand external impacts and vibrations more effectively.

In summary, the addition of CF improves the flexibility, interface bonding, and filling effect in conductive mortar, leading to an overall improvement in toughness. This enhancement enables the conductive mortar to withstand stress and deformation more effectively, contributing to its increased toughness.

3.2 Rheological properties

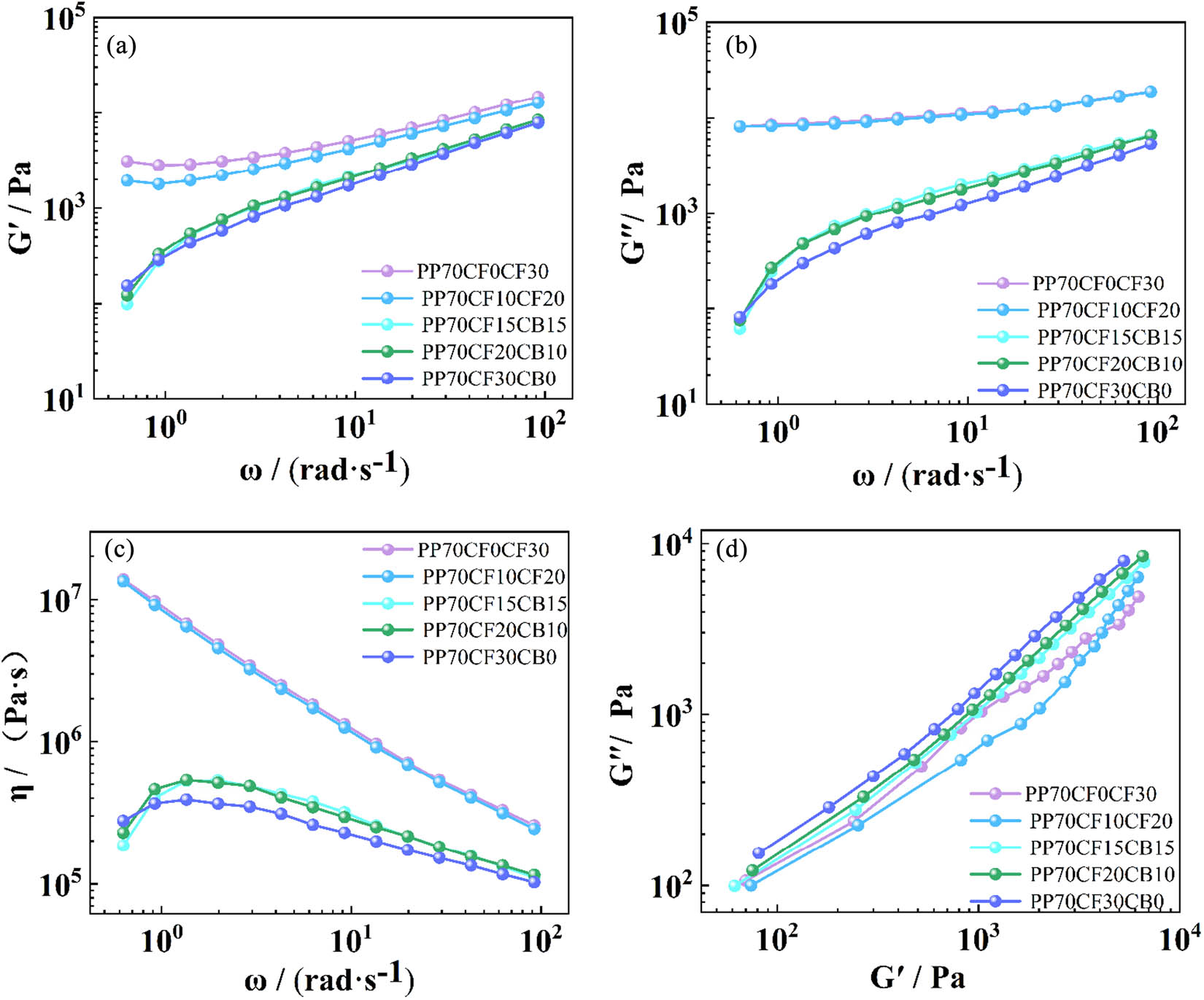

In order to further explore the rheological properties of PP/CF/CB silicone cement, the change curves of the measured cement storage modulus G′, loss modulus G″, and complex viscosity η* with angular frequency ω were used to characterize, and the relationship curve (Cole–Cole curve) between G′ and G″ was studied (as shown in Figures 2 and 3). It can be seen from Figure 2a and b that with the increase of CF content, the storage modulus and loss modulus of the sample increase, indicating that CF can increase the modulus of silicone polymer, thereby increasing the material’s tensile strength, which is also the reason for the increase of tensile strength. When CF nanofillers are incorporated into the silicone resin polymer, they reinforce the material and increase its rigidity and strength. It can be seen from Figure 2c that the complex viscosity of the sample decreases with the increase of angular frequency, indicating that under this test condition, the sample exhibits the properties of non-Newtonian fluid; with the increase of the CF content, its complex viscosity increases, indicating that the addition of nanofiller changes the fluidity of the silicone polymer and its fluidity deteriorates. It can be seen from Figure 2d that the slope of the Cole–Cole curve of the conductive silicone polymer cement is lower than 1.8 with different CF contents, and the slope of the curve decreases slightly with the increase of the CF content. A slope smaller than 1.8 indicates that the material’s dielectric response is nonlinear and exhibits complex non-homogeneous structures containing various phases and configurations.

Rheological properties of 70% PP/CF/CB conductive silicone polymer cement: (a) relationship curve between storage modulus and angular frequency; (b) relationship curve between loss modulus and angular frequency; (c) relationship curve between complex viscosity and angular frequency; and (d) Cole–Cole relationship diagram of storage modulus and loss modulus.

Rheological properties of 80% PP/CF/CB conductive silicone polymer cement: (a) relationship curve between storage modulus and angular frequency; (b) relationship curve between loss modulus and angular frequency; (c) relationship curve between complex viscosity and angular frequency; and (d) Cole–Cole relationship diagram of storage modulus and loss modulus.

The presence of these complex non-homogeneous structures with different phases and configurations can be attributed to the addition of CF nanofillers, which may induce phase separation or the formation of local aggregates within the material. These different phases and configurations lead to changes in the electrical and mechanical properties of the material.

The non-homogeneous nature of the material has a certain influence on its rheological behavior and performance. The presence of non-homogeneous structures can cause variations in viscosity, nonlinear response in rheological properties, as well as alterations in fatigue and damage behavior. Therefore, with the increase in CF content, the internal non-homogeneous nature of the conductive silicone polymer cement undergoes further changes.

In summary, the addition of CF has an impact on the rheological properties of the conductive silicone polymer cement. It increases the storage modulus and loss modulus, thereby enhancing the material’s rigidity and strength. Additionally, it alters the material’s flow behavior, leading to an increase in composite viscosity. These changes can be attributed to the modification of the internal structure and phase configuration of the material due to the addition of CF, which in turn influences the rheological performance.

It can be seen from Figure 3a and b that with the increase of the CF content, the storage modulus and loss modulus of the sample increase, indicating that CF can increase the modulus of the silicone polymer. As can be seen from Figure 3c, the complex viscosity of the sample decreases with the increase of angular frequency, indicating that under this test condition, the material exhibits the properties of a non-Newtonian fluid, and with the increase of the CF content, its complex viscosity increases, indicating that the addition of CF changes the fluidity of the silicone polymer. It can be seen from Figure 2d that the slope of the Cole–Cole curve of the cement is lower than 1.8, and the slope of the curve decreases slightly with the increase of the CF content. This shows that the addition of CF improves the rigidity of the cement, that is, the ability of the cement to resist deformation.

3.3 Conductivity

Conductivity is the key factor affecting the suppression of corona noise by conductive silicone cement, so the influence of the content of CF and CB on the conductivity of conductive silicone cement to suppress corona noise was first studied; the experimental results are shown in Figure 4. It can be seen from Figure 4 that when only CF or CB is present in the conductive silicone cement, the conductivity of conductive silicone cement is weak. When the content of CF and CB in conductive silicone cement reaches a ratio of 2:1 mixed, the conductivity of the conductive silicone cement reaches a maximum. The conductivity of 70 and 80% silicone polymer cement reaches 0.73 and 1.17 S/cm, respectively. This shows that in the conductive network of conductive silicone cement, simply adding CF or CB cannot build a perfect conductive network, in which CF constitutes the main conductivity channel and CB, a coupling anchor. When the content of CF and CB in the conductive silicone cement reaches 2:1, CB can form more contact sites with CF, and the internal conductive network is further improved, so the conductive silicone polymer cement has better conductivity.

Conductivity of the silicone polymer cement: (a) conductivity of the 70% silicone polymer cement and (b) conductivity of the 80% silicone polymer cement.

3.4 Hydrophobic properties

The corona phenomenon on the surface of a high-voltage conductor is closely related to the smoothness of the wire surface; therefore, the hydrophobic properties of the PP/CF/CB conductive silicone polymer cement were further tested; the results are shown in Figure 5. For the silicone polymer cement with 70% content, with the increase of the CF mass fraction, the surface contact angle showed a trend of first increasing and then decreasing, and reached a maximum value of 107 ± 0.54° when the CF content fraction was 10%. For the 80% silicone polymer cement, with the increase of the CF mass fraction, the surface contact angle showed a trend of first increasing and then decreasing, and reached a maximum value of 108 ± 0.39° when the CF content fraction was 10%. In addition, it can be seen from the comparative analysis that when the ratio of CF/CB = 1:2, the contact angle on the surface of the silicone polymer cement is relatively large, which can significantly improve the hydrophobic performance of the high-voltage conductor, thereby inhibiting the generation of the corona.

Surface wetting of the silicone polymer cement: (a) surface wetting performance of the 70% silicone polymer cement and (b) surface wetting performance of the 80% silicone polymer cement.

3.5 Anti-shedding performance test

The anti-shedding conductive silicone cement (PP80CF14CB6) prepared in this study was used to further study the effect of anti-corona noise anti-shedding conductive silicone cement on the performance of anti-shedding conductive silicone cement after high-temperature aging; the experimental results are shown in Figure 6. It can be seen from Figure 6 that the conductive cement prepared can be evenly coated on a wire 7 cm long and 0.25 cm wide, and after high-temperature aging, the cement does not produce cracks and the surface of the cement is relatively smooth, which indicates that the conductive silicone cement prepared to suppress corona noise and prevent shedding can be applied to wire lines to prevent wires from falling off.

Comparison before and after high-temperature aging of the silicone polymer cement (PP80CF14CB6): (a) before aging of the silicone polymer cement and (b) after aging of the silicone polymer cement.

4 Conclusion

In this article, CF powder and CB were used as conductive fillers and silicone polymers as the matrix to prepare a UHV transmission line to suppress corona noise and prevent shedding. When the content of conductive filler CF and CB in conductive silicone cement reaches a ratio of 2:1 mixed, the conductivity of the cement reaches a maximum value. Specifically, the conductivity of the gel with 70% organic silicone polymer was measured to be 0.73 S/cm, while the gel with 80% organic silicone polymer exhibited a conductivity of 1.17 S/cm. Additionally, the gel with 70% organic silicone polymer demonstrated a tensile strength of 678.6 MPa, a Young’s modulus of 1.3 MPa, and a fracture elongation of 15.22%. On the other hand, the gel with 80% organic silicone polymer exhibited a tensile strength of 129.9 MPa, a Young’s modulus of 1.6 MPa, and a fracture elongation of 55.89%.

In conclusion, based on the experimental results, the conductive silicone gel prepared in this study meets the requirements for tensile performance, conductivity, and prevention of detachment in ultra-high-voltage transmission lines. This research provides significant support for the reliability and stability of such transmission lines and offers valuable insights for further studies and developments in related fields.

-

Funding information: This work was financially supported by State Grid Shandong Electric Power Company.

-

Conflict of interest: The authors have no conflict of interest to declare.

References

[1] Emelyanenko KA, Domantovsky AG, Platonov PS, Kochenkov PS, Emelyanenko AM, Boinovich LB. The durability of superhydrophobic and slippery liquid infused porous surface coatings under corona discharge characteristic of the operation of high voltage power transmission lines. Energy Rep. 2022;8:6837–44.10.1016/j.egyr.2022.05.035Suche in Google Scholar

[2] Li Y, Xu F, Lin Z, Sun X, Peng Q, Yuan Y, et al. Electrically and thermally conductive underwater acoustically absorptive graphene/rubber nanocomposites for multifunctional applications. Nanoscale. 2017;9(38):14476–85.10.1039/C7NR05189ASuche in Google Scholar

[3] Wang Y, Cao R, Wang M, Liu X, Zhao X, Lu Y, et al. Design and synthesis of phenyl silicone rubber with functional epoxy groups through anionic copolymerization and subsequent epoxidation. Polymer. 2020;186:122077.10.1016/j.polymer.2019.122077Suche in Google Scholar

[4] Jiang B, Shi X, Zhang T, Huang Y. Recent advances in UV/thermal curing silicone polymers. Chem Eng J. 2022;435(1):134843.10.1016/j.cej.2022.134843Suche in Google Scholar

[5] Kargarfard N, Simon F, Schlenstedt K, Ulischberger L, Voit B, Gedan-Smolka M, et al. Self-stratifying powder coatings based on eco-friendly, solvent-free epoxy/silicone technology for simultaneous corrosion and weather protection. Prog Org Coat. 2021;161:106443.10.1016/j.porgcoat.2021.106443Suche in Google Scholar

[6] Pawar SS, Naik RB, Billa S, Rath SK, Mahato TK, Kandasubramanian B. The effect of pigment volume concentration on self-stratification and physico-mechanical properties of solvent-free silicone/epoxy coating systems. Polym Bulletin. 2023;80(2):2045–67.10.1007/s00289-022-04138-wSuche in Google Scholar

[7] Zhang J, Kong G, Li S, Le Y, Che C, Zhang S, et al. Graphene-reinforced epoxy powder coating to achieve high performance wear and corrosion resistance. J Mater Res Technol. 2022;20:4148–60.10.1016/j.jmrt.2022.08.156Suche in Google Scholar

[8] Adin MŞ, Kılıçkap E. Strength of double-reinforced adhesive joints. Mater Test. 2021;63(2):176–81.10.1515/mt-2020-0024Suche in Google Scholar

[9] Adin H, Adin MŞ. Effect of particles on tensile and bending properties of jute epoxy composites. Mater Test. 2022;64(3):401–11.10.1515/mt-2021-2038Suche in Google Scholar

[10] Ma Z, Zhang K, Yang S, Zhang Y, Chen X, Fu Q, et al. High-performance capacitive pressure sensors Fabricated by introducing dielectric filler and conductive filler into a porous dielectric layer through a Biomimic strategy. Compos Sci Technol. 2022;227:109595.10.1016/j.compscitech.2022.109595Suche in Google Scholar

[11] Orozco F, Salvatore A, Sakulmankongsuk A, Gomes DR, Pei Y, Araya-Hermosilla E, et al. Electroactive performance and cost evaluation of carbon nanotubes and carbon black as conductive fillers in self-healing shape memory polymers and other composites. Polymer. 2022;260:125365.10.1016/j.polymer.2022.125365Suche in Google Scholar

[12] Untila G, Kost T, Chebotareva A. F-In-codoped ZnO (FIZO) films produced by corona-discharge-assisted ultrasonic spray pyrolysis and hydrogenation as electron-selective contacts in FIZO/SiOx/p-Si heterojunction crystalline silicon solar cells with 10.5% efficiency. Sol Energy. 2019;181:148–60.10.1016/j.solener.2019.01.080Suche in Google Scholar

[13] Li L, Ji H, Yang H, Zhang L, Zhou X, Wang R. Itaconate based elastomer as a green alternative to styrene–butadiene rubber for engineering applications: Performance comparison. Processes. 2020;8(12):1527.10.3390/pr8121527Suche in Google Scholar

[14] Song J, Zhang Y. Vertically aligned silicon carbide nanowires/reduced graphene oxide networks for enhancing the thermal conductivity of silicone rubber composites. Compos Part A Appl Sci Manuf. 2020;133:105873.10.1016/j.compositesa.2020.105873Suche in Google Scholar

[15] Gul S, Arican S, Cansever M, Beylergil B, Yildiz M, Saner Okan B. Design of highly thermally conductive hexagonal boron nitride-reinforced PEEK composites with tailored heat conduction through-plane and rheological behaviors by a scalable extrusion. ACS Appl Polym Mater. 2022;5(1):329–41.10.1021/acsapm.2c01534Suche in Google Scholar

[16] Durukan SN, Beylergil B, Dulgerbaki C. Effects of silane-modified nano-CaCO3 particles on the mechanical properties of carbon fiber/epoxy (CF/EP) composites. Polym Compos. 2023;44(3):1805–21.10.1002/pc.27206Suche in Google Scholar

[17] Yang H, Gong LH, Zheng Z, Yao XF. Highly stretchable and sensitive conductive rubber composites with tunable piezoresistivity for motion detection and flexible electrodes. Carbon. 2020;158:893–903.10.1016/j.carbon.2019.11.079Suche in Google Scholar

[18] Megala V, Karpagam R, Sathishkumar G, Gopinath B, Kumar PM, Brindha MD. Investigation on corona performance of conductors using fabricated indoor corona cage. Mater Today Proc. 2021;44:3652–6.10.1016/j.matpr.2020.10.682Suche in Google Scholar

[19] Adin MŞ, Okumuş M. Investigation of microstructural and mechanical properties of dissimilar metal weld between AISI 420 and AISI 1018 STEELS. Arab J Sci Eng. 2022;47(7):8341–50.10.1007/s13369-021-06243-wSuche in Google Scholar

[20] JISR 7608-2007. Carbon fiber-determination of tensile properties of resin impregnated yarn. 2021.Suche in Google Scholar

[21] Hamit A, Sağlam Z, Adin MŞ. Numerical investigation of fatigue behavior of non-patched and patched aluminum/composite plates. Eur Mech Sci. 2021;5(4):168–76.10.26701/ems.923798Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Effects of cellulose nanofibers on flexural behavior of carbon-fiber-reinforced polymer composites with delamination

- Damage mechanisms of bismaleimide matrix composites under transverse loading via quasi-static indentation

- Experimental study on hydraulic fracture behavior of concrete with wedge-splitting testing

- The assessment of color adjustment potentials for monoshade universal composites

- Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property

- The effect of temperature on the tensile properties and failure mechanisms of two-dimensional braided composites

- The influence of preparation of nano-ZrO2/α-Al2O3 gradient coating on the corrosion resistance of 316L stainless steel substrate

- A numerical study on the spatial orientation of aligning fibrous particles in composites considering the wall effect

- A simulative study on the effect of friction coefficient and angle on failure behaviors of GLARE subjected to low-velocity impact

- Impact resistance capacity and degradation law of epoxy-coated steel strand under the impact load

- Analytical solutions of coupled functionally graded conical shells of revolution

- The influence of water vapor on the structural response of asphalt pavement

- A non-invasive method of glucose monitoring using FR4 material based microwave antenna sensor

- Chloride ion transport and service life prediction of aeolian sand concrete under dry–wet cycles

- Micro-damage analysis and numerical simulation of composite solid propellant based on in situ tensile test

- Experimental study on the influence of high-frequency vibratory mixing on concrete performance

- Effects of microstructure characteristics on the transverse moisture diffusivity of unidirectional composite

- Gradient-distributed ZTAp-VCp/Fe45 as new anti-wear composite material and its bonding properties during composite casting

- Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field

- Mechanical and tribological properties of C/C–SiC ceramic composites with different preforms

- Mechanical property improvement of oil palm empty fruit bunch composites by hybridization using ramie fibers on epoxy–CNT matrices

- Research and analysis on low-velocity impact of composite materials

- Optimizing curing agent ratios for high-performance thermosetting phthalonitrile-based glass fibers

- Method for deriving twisting process parameters of large package E-glass yarn by measuring physical properties of bobbin yarn

- A probability characteristic of crack intersecting with embedded microcapsules in capsule-based self-healing materials

- An investigation into the effect of cross-ply on energy storage and vibration characteristics of carbon fiber lattice sandwich structure bionic prosthetic foot

- Preparation and application of corona noise-suppressing anti-shedding materials for UHV transmission lines

- XRD analysis determined crystal cage occupying number n of carbon anion substituted mayenite-type cage compound C12A7: nC

- Optimizing bending strength of laminated bamboo using confined bamboo with softwoods

- Hydrogels loaded with atenolol drug metal–organic framework showing biological activity

- Creep analysis of the flax fiber-reinforced polymer composites based on the time–temperature superposition principle

- A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously

- Effect of aggregate characteristics on properties of cemented sand and gravel

- An integrated structure of air spring for ships and its strength characteristics

- Modeling and dynamic analysis of functionally graded porous spherical shell based on Chebyshev–Ritz approach

- Failure analysis of sandwich beams under three-point bending based on theoretical and numerical models

- Study and prediction analysis on road performance of basalt fiber permeable concrete

- Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method

- Study on properties of recycled mixed polyester/nylon/spandex modified by hydrogenated petroleum resin

- Effect of particle size distribution on microstructure and chloride permeability of blended cement with supplementary cementitious materials

- In situ ligand synthesis affording a new Co(ii) MOF for photocatalytic application

- Fracture research of adhesive-bonded joints for GFRP laminates under mixed-mode loading condition

- Influence of temperature and humidity coupling on rutting deformation of asphalt pavement

- Review Articles

- Sustainable concrete with partial substitution of paper pulp ash: A review

- Durability and microstructure study on concrete made with sewage sludge ash: A review (Part Ⅱ)

- Mechanical performance of concrete made with sewage sludge ash: A review (Part Ⅰ)

- Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II)

- Communication

- Calculation of specific surface area for tight rock characterization through high-pressure mercury intrusion

- Special Issue: MDA 2022

- Vibration response of functionally graded material sandwich plates with elliptical cutouts and geometric imperfections under the mixed boundary conditions

- Analysis of material removal process when scratching unidirectional fibers reinforced polyester composites

- Tailoring the optical and UV reflectivity of CFRP-epoxy composites: Approaches and selected results

- Fiber orientation in continuous fiber-reinforced thermoplastics/metal hybrid joining via multi-pin arrays

- Development of Mg-based metal matrix biomedical composites for acicular cruciate ligament fixation by reinforcing with rare earth oxide and hydroxyapatite – A mechanical, corrosion, and microstructural perspective

- Special Issue: CACMSE

- Preparation and application of foamed ceramic panels in interior design

Artikel in diesem Heft

- Regular Articles

- Effects of cellulose nanofibers on flexural behavior of carbon-fiber-reinforced polymer composites with delamination

- Damage mechanisms of bismaleimide matrix composites under transverse loading via quasi-static indentation

- Experimental study on hydraulic fracture behavior of concrete with wedge-splitting testing

- The assessment of color adjustment potentials for monoshade universal composites

- Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property

- The effect of temperature on the tensile properties and failure mechanisms of two-dimensional braided composites

- The influence of preparation of nano-ZrO2/α-Al2O3 gradient coating on the corrosion resistance of 316L stainless steel substrate

- A numerical study on the spatial orientation of aligning fibrous particles in composites considering the wall effect

- A simulative study on the effect of friction coefficient and angle on failure behaviors of GLARE subjected to low-velocity impact

- Impact resistance capacity and degradation law of epoxy-coated steel strand under the impact load

- Analytical solutions of coupled functionally graded conical shells of revolution

- The influence of water vapor on the structural response of asphalt pavement

- A non-invasive method of glucose monitoring using FR4 material based microwave antenna sensor

- Chloride ion transport and service life prediction of aeolian sand concrete under dry–wet cycles

- Micro-damage analysis and numerical simulation of composite solid propellant based on in situ tensile test

- Experimental study on the influence of high-frequency vibratory mixing on concrete performance

- Effects of microstructure characteristics on the transverse moisture diffusivity of unidirectional composite

- Gradient-distributed ZTAp-VCp/Fe45 as new anti-wear composite material and its bonding properties during composite casting

- Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field

- Mechanical and tribological properties of C/C–SiC ceramic composites with different preforms

- Mechanical property improvement of oil palm empty fruit bunch composites by hybridization using ramie fibers on epoxy–CNT matrices

- Research and analysis on low-velocity impact of composite materials

- Optimizing curing agent ratios for high-performance thermosetting phthalonitrile-based glass fibers

- Method for deriving twisting process parameters of large package E-glass yarn by measuring physical properties of bobbin yarn

- A probability characteristic of crack intersecting with embedded microcapsules in capsule-based self-healing materials

- An investigation into the effect of cross-ply on energy storage and vibration characteristics of carbon fiber lattice sandwich structure bionic prosthetic foot

- Preparation and application of corona noise-suppressing anti-shedding materials for UHV transmission lines

- XRD analysis determined crystal cage occupying number n of carbon anion substituted mayenite-type cage compound C12A7: nC

- Optimizing bending strength of laminated bamboo using confined bamboo with softwoods

- Hydrogels loaded with atenolol drug metal–organic framework showing biological activity

- Creep analysis of the flax fiber-reinforced polymer composites based on the time–temperature superposition principle

- A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously

- Effect of aggregate characteristics on properties of cemented sand and gravel

- An integrated structure of air spring for ships and its strength characteristics

- Modeling and dynamic analysis of functionally graded porous spherical shell based on Chebyshev–Ritz approach

- Failure analysis of sandwich beams under three-point bending based on theoretical and numerical models

- Study and prediction analysis on road performance of basalt fiber permeable concrete

- Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method

- Study on properties of recycled mixed polyester/nylon/spandex modified by hydrogenated petroleum resin

- Effect of particle size distribution on microstructure and chloride permeability of blended cement with supplementary cementitious materials

- In situ ligand synthesis affording a new Co(ii) MOF for photocatalytic application

- Fracture research of adhesive-bonded joints for GFRP laminates under mixed-mode loading condition

- Influence of temperature and humidity coupling on rutting deformation of asphalt pavement

- Review Articles

- Sustainable concrete with partial substitution of paper pulp ash: A review

- Durability and microstructure study on concrete made with sewage sludge ash: A review (Part Ⅱ)

- Mechanical performance of concrete made with sewage sludge ash: A review (Part Ⅰ)

- Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II)

- Communication

- Calculation of specific surface area for tight rock characterization through high-pressure mercury intrusion

- Special Issue: MDA 2022

- Vibration response of functionally graded material sandwich plates with elliptical cutouts and geometric imperfections under the mixed boundary conditions

- Analysis of material removal process when scratching unidirectional fibers reinforced polyester composites

- Tailoring the optical and UV reflectivity of CFRP-epoxy composites: Approaches and selected results

- Fiber orientation in continuous fiber-reinforced thermoplastics/metal hybrid joining via multi-pin arrays

- Development of Mg-based metal matrix biomedical composites for acicular cruciate ligament fixation by reinforcing with rare earth oxide and hydroxyapatite – A mechanical, corrosion, and microstructural perspective

- Special Issue: CACMSE

- Preparation and application of foamed ceramic panels in interior design