Abstract

In countries where volcanic activity is widespread, fly ash (FA) formation can represent both a waste to be disposed of and a resource of inorganic substances that can be utilized. Among the technologies able to incorporate FA, geopolymers (GP) or inorganic aluminosilicate amorphous materials are very suitable for this purpose. In this study, GP are realized using metakaolin (MK), sodium hydroxide solution (NaOH 8 M), sodium silicate solution (Na2SiO3), and FA as filler (20 wt% with respect to MK content). The samples were cured at 25 or 40°C for 24 h and the physicochemical, thermal, and antibacterial properties of this material through the integrity test, weight loss test, Fourier-transform infra-red spectroscopy (FT-IR), thermogravimetric analysis (TGA), and Kirby-Bauer assay were assessed. Integrity and weight loss tests indirectly revealed the stability of the macroscopic 3D networks and that the curing at 40°C led to more stable GP. The shift of the Si–O–T absorption band (from 1,090 cm−1 of the MK to 1,017–1,012 cm−1 of the specimens with and without FA) in FT-IR spectra suggested the occurrence of the geopolymerizazion reactions, while TGA study confirmed the higher stability of samples cured at 40°C (with a mass loss equal to 7–13% at 800°C under nitrogen atmosphere). Finally, the antimicrobial activity shed light on the ability of the synthesized GP with the filler and treated at 40°C to have a great effect against Escherichia coli and Pseudomonas aeruginosa.

1 Introduction

Over the past decades, significant research efforts have been focused on the development of inorganic geopolymers (GP) [1,2,3,4]. GP represent a new eco-friendly material not only because they can be synthesized by the addition of waste material [5,6,7], but also thanks to the low temperature needed for their synthesis and the wide range of possible applications they have [8,9,10,11]. First synthesized by Joseph Davidovits in 1978, GP are inorganic, non-combustible, heat-resistant, aluminosilicate materials [12,13]. GP are formed via geopolymerization reactions, which refer to a formation of aluminosilicate covalently bonded 3D network consisting of [–Si–O–Al–O–] bonds in an alkaline environment [14]. First, once the precursors have contact with the alkaline activator, there is the dissolution of the amorphous components, aluminates, and silicates, in the solution. Next, aluminate and silicate interact to form an aluminosilicate gel that, since aluminium dissolves faster than silicon, is richer in aluminium. When more silicon dissolves at a later stage, the gel structure is rearranged to form another type of gel that is more stable. The stability of the second gel is due to the formation of new Si–O bonds that are stronger than Al–O bonds. During this time this reorganization process led to the formation of a GP [15]. Aluminosilicate compounds are the most common compounds in the crust of the Earth, and for this reason, there are many starting materials rich in silica and alumina that can be used as precursors in the geopolymerization process [16]. Among these materials, both calcined kaolin (metakaolin [MK]) and fly ash (FA) are considered solid starting materials containing sufficient amounts of reactive alumina and silica [17,18,19], the latter is also used as the main additive for cement-based concretes [20,21], for quaternary blended cements [22,23,24] with and without nano-additives [25]. Among FA, volcanic FAs, that derive from volcanic eruptions, are considered natural waste materials because some volcanoes can generate huge amounts of FA that need to be disposed of [26,27,28]. One of these volcanoes available in the world, known as Etna, is located in the South part of Italy and was selected for FA production [29]. Normally, the size and the thickness of the FA particles decrease exponentially with increasing distance from the volcano and they can differ from volcano to volcano [30]. Despite the presence of the literature of studies regarding FA inside the GP matrix [31,32,33,34,35], there is still a lack of knowledge. This study aims to enrich the knowledge on the use of FA in MK-based GP. To this aim, FA were collected very close to the Etna volcano and were grounded and roughly sieved (125 µm < d < 250 µm) before being used as filler in MK-based GP. The GP pastes after alkali activation with NaOH 8 M and sodium silicate solution were cured at 25 or 40°C for 24 h after the moulding procedure and then aged to 56 days. The physicochemical properties of the synthesized GP were ascertained by evaluating: pH, ionic conductivity (IC), integrity and weight loss tests, Fourier-transform infra-red spectroscopy (FT-IR), thermogravimetric analysis (TGA), and differential scanning calorimetry (DSC). Moreover, X-ray fluorescence spectroscopy was carried out to obtain information about the chemical composition of the used filler. All the analyses were made after 7, 14, 28, and 56 days of the samples stored at room temperature (RT), investigating the changing properties of these materials during the hardening time. Finally, the possible antimicrobial activity of the synthesized materials has been investigated after 56 days of aging.

2 Materials and methods

2.1 Raw material preparation and characterization

MK (Argical™-M 1000, Imerys, France) was used as a GP precursor. Its chemical oxide composition and granulometry are reported elsewhere in (efficient addition). FAs were taken from Etna Volcano (Sicily, Italy) and used as filler in MK-based GP. The chemical oxide composition (Table 1) of FA was obtained by X-ray fluorescence analysis performed with a Shimadzu Spectrometer EDX-720 (GmbH, Duisburg, Germany) equipped with a 50 W Rh target X-ray tube, a high-energy resolution Si (Li) detector, and five primary X-ray filters. The measurement was performed in the ranges of Na-Sc and Ti-U. The composition suggests that FA belong to Class F because of the higher content of silica and alumina with respect to calcium oxide [36,37]. Before their addition as filler (20 wt% with respect to MK content) in GP pastes, sodium hydroxide 8 M (NaOH) and sodium silicate (Na2SiO3, with SiO2 = 2% and Na2O = 8%, ρ = 1.346 g/ml, and pH = 11.0–11.5) were used as alkali activator solutions, while acetone (C3H6O), KBr, both of analytical grade, and MilliQ water were used for the sample analyses. All the reagents were purchased from Sigma Aldrich (Merck KGaA, Darmstadt, Germany).

FA oxides’ composition

| Compound (wt%) | Fe2O3 | SiO2 | CaO | Al2O3 | TiO2 | K2O | Other oxides |

|---|---|---|---|---|---|---|---|

| Fly ashes | 34.8 | 26.6 | 18.0 | 11.7 | 4.2 | 3.9 | 0.8 |

Results are expressed as mean ±0.5.

2.2 GP syntheses

Table 2 reports the sample formulations, whereas Figure 1 reports the scheme of the GP syntheses without (GP0 25 and 40°C samples) and with the FA filler (GP20FA 25 and 40°C samples). Initially, NaOH 8 M and Na2SiO3 solutions were mixed with MK powder under mechanical stirring (ca 10 min) until the mixture became viscous. Then, the fresh pastes were poured into the plastic cubic and cylinder moulds, and after the mechanical removal of the bubbles, the moulds were carefully closed and the samples were cured at fixed temperatures (25 or 40°C) for 24 h. After the curing, the samples (GP0 25 and GP0 40°C) were stored at RT and analysed at different ageing times. The GP samples with FA filler (GP20FA 25 and 40°C) were synthesized following the same procedure and mixing the FA powder with the fresh GP paste for 5 min.

Geopolymer sample composition

| GP0 | GP20FA | |

|---|---|---|

| MK | 100 g | 80 g |

| FA | — | 20 g |

| NaOH 8M | 30 ml | 24 ml |

| Na 2 SiO 3 | 30 ml | 24 ml |

Flow chart showing the procedure of the GP synthesis without (a) and with (b) FA filler.

2.3 GP characterization

Indirect measurements of the aluminosilicate 3D reticulation proposed in the literature [38,39] were used to test the chemical stability of the consolidated paste. To determine the efficiency of 3D reticulation, powders from the consolidated samples were immersed in water as described in the Supplementary Materials. In addition, weight loss was measured over 56 days after the preparation of the final GP at different curing times (see Supplementary Materials for more details on the experimental procedures).

FT-IR analysis was performed in the range of 400–4,000 cm−1 using the Prestige21 Shimadzu system, equipped with a DTGS KBr (deuterated tri-glycine sulphate with potassium bromide windows) detector, resolution of 2 cm−1 (60 scans). The analysis procedure uses KBr discs realized weighing 2 mg of sample and 198 mg of KBr. FT-IR spectra were elaborated by IR solution and Origin software. The analyses were performed on the samples aged at 7, 14 28, and 56 days at room temperature.

The thermal characterization of the prepared GP was carried out in a Mettler Thermogravimetric Analyzer TGA 1 Star System. A roughly amount of 6 × 10−3 g of GP was placed inside an open alumina crucible and degraded from 25 up to 800°C, by using a heating rate of 10°C min−1. Thermogravimetric (TG) experiments were carried out in both inert (nitrogen with a flowing rate of 0.06 l min−1) and oxidative (static air) atmospheres. TG equipment was calibrated following the suggestion of the company, by exploiting the magnetic properties change of three metal standards (Isatherm, Nickel-alloy, and Trafoperm 86) at their Curie points (148, 355, and 750°C, respectively). Furthermore, following the recommendations of the ICTAC kinetics committee [40], we provided to correct the error in the mass determination due to the reduction of the buoyancy force on increasing temperature, by performing a blank TG run with an empty pan and then subtracting it from those of samples, so obtaining corrected degradation TG curves. TG data were thus reported graphically, by plotting the percentage of undegraded sample, (1 − D)%, as a function of temperature, where D = (W o − W)/W o, and W o and W were the masses at the starting point and during scanning.

The calorimetric behaviour of the prepared GP was evaluated by using a Mettler DSC 1 Star System (Mettler Instrument, Greifensee, Swizterland). DSC scans were carried out in the range 25–500°C, by employing roughly 6.0 × 10−3 g of GP and a scanning rate of 10°C min−1. The characteristic DSC parameters were determined by performing three scanning for each GP and reporting the averaged value, the deviation remain within ±0.5%. Before the experiments, DSC equipment was calibrated, in both enthalpy and temperature, following the company’s suggestions consolidated by our previous study [41].

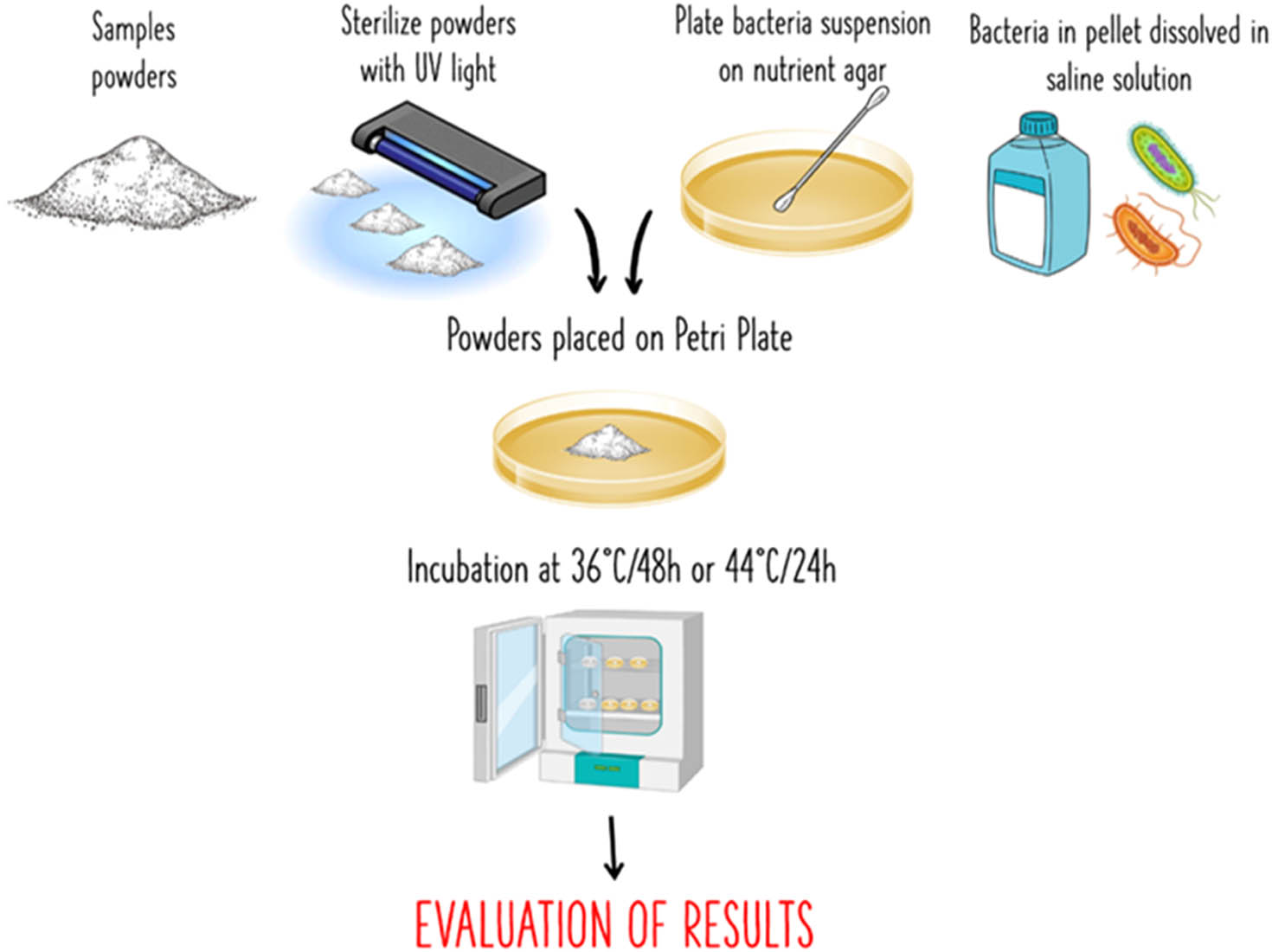

The antibacterial properties of the GP were assessed against Escherichia coli (ATCC 25922) and Pseudomonas aeruginosa (ATCC27853) as Gram-negative bacteria, Staphylococcus aureus (ATCC 25923) and Enterococcus faecalis (ATTC29212) as Gram-positive bacteria performing the Kirby-Baure method [42]. The whole procedure follows the one reported in [43] and it is summarized in Figure 2. After the incubation times, the diameter of inhibition halos (IDs) in relation to Petri plate diameter (D) (6 cm) was calculated. Four measures for each sample were carried out to determine the mean standard deviation. Results were expressed as bacterial viability (%):

Flowchart procedure for the evaluation of the antibacterial properties.

Bacteria viabilities without samples are expressed as 100% bacterial viability. The mean Standard Deviation is expressed as relative standard deviation.

3 Results and discussion

3.1 Sample observations

GP0 and GP20FA were removed from the moulds at RT after 7, 14, 28, and 56 days (Figure 3). From 7 to 56 days of aging time, GP0 at 25°C changes its colour from dark beige to light beige, suggesting the occurrence of the efflorescence phenomenon [44,45]. However, the samples were hard under finger pressure, and smooth with only a few bubbles visible on their surfaces. GP0 samples cured at 40°C were similar to GP = samples cured at 25°C, but with dryer surfaces. GP20FA cured at 25 and 40°C was dried and smooth. All these samples at different ageing times possess few bubbles and black dots on their surfaces due to the presence of the filler. The presence of white colour on GP specimens suggests the setting of the efflorescence phenomenon also for these samples. This phenomenon was also observed for GP samples prepared via alkali activation of FA and MK in [46].

Images of the samples after extraction at different ageing times.

IC and pH analyses were conducted on GP0 25°C, GP0 40°C, GP20FA 25°C, and GP20FA 40°C samples to obtain indirect information about the stability of the synthesized samples [47]. All these samples showed a similar trend over time, as shown in Figure S1a–d. For all samples, within 48 h, there is an increase in pH and IC. pH values were stable at 11.5 for all the samples aged up to 56 days, whereas regarding the IC values, GP0 25 and 40°C possess values at 150–170 mS/m after 56 days of ageing times, while GP20FA 25 and 40°C possess values at 200 mS/m.

The integrity test was carried out on the samples after 7, 14, 28, and 56 days. The sample images after the test, reported in Figure S2, show that all the samples overcame the test. Indeed, none of them released their pieces in the waters, which appeared always very clean and transparent. The pH values of the water in which the samples were immersed slightly differ based on the ageing time of the samples. The values ranged from 10.73–10.95 (samples aged 7 days) to 10.10–9.93 (samples aged 56 days).

Figure S3 reports the weight loss test on the GP samples. The addition of 20 wt% of FA results in a reduction of weight loss at 7 days, indeed both GP20FA 25 and 40°C values are lower than the values of the sample obtained without the FA. Moreover, Figure S3 points out that the thermal treatment had an effect in terms of stability, indeed during the ageing times, the weight loss values of samples treated at 40°C are slightly lower than the ones obtained from the samples cured at 25°C.

3.2 FT-IR analysis

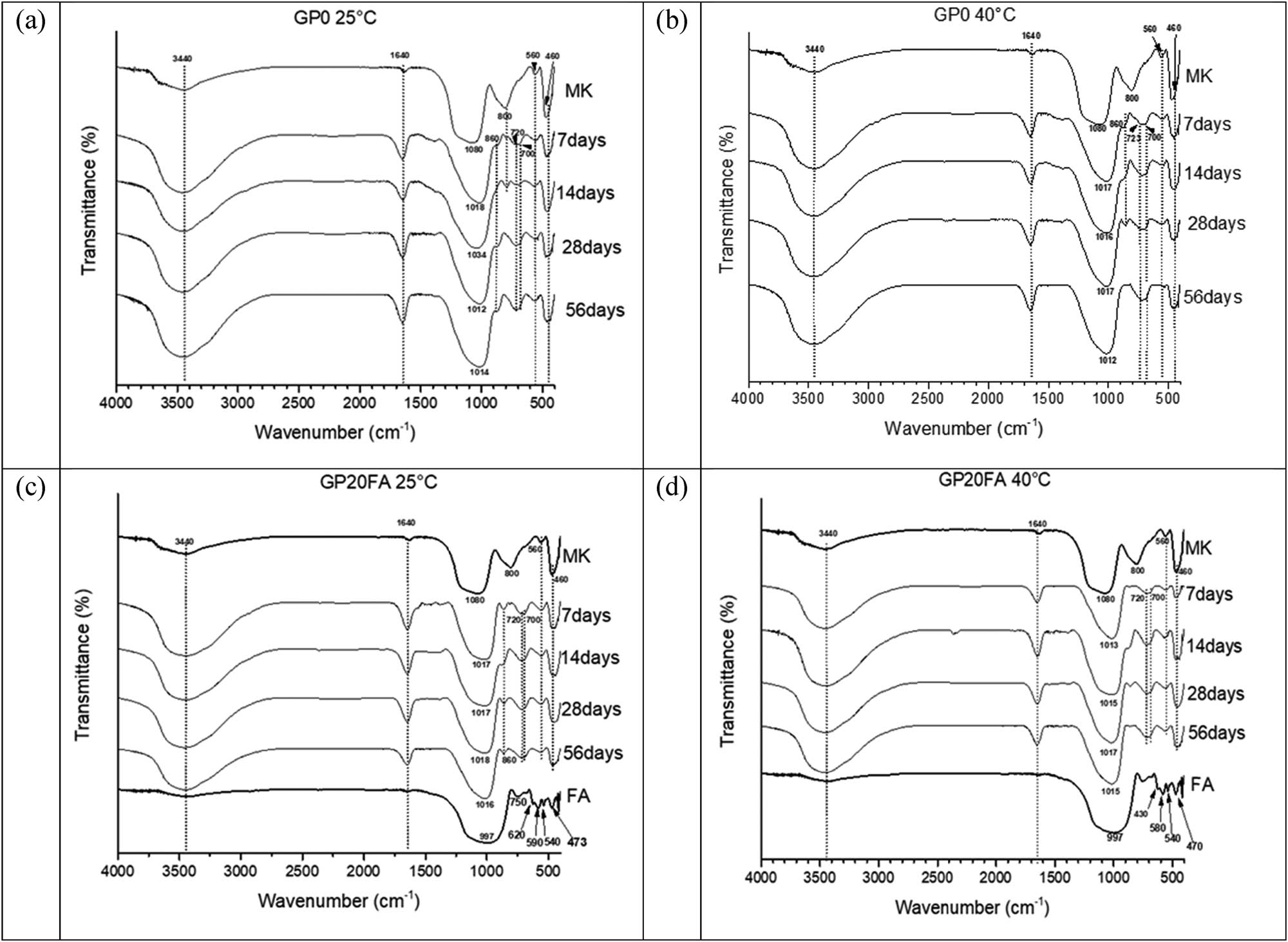

Figure 4a and b show the FT-IR spectra of GP0 cured at 25 and 40°C compared at different ageing times from 7 up to 56 days, while Figure 4c and d shows the FT-IR spectra of GP20FA cured at 25 and 40°C. In MK, GP0 and GP20FA spectra are present the bands at 3,450 cm−1 (strong) and 1,650 cm−1 (medium) are due to hydration water [16].

FT-IR spectra (a) GP0 at 25°C, (b) GP0 at 40°C, (c) GP20FA at 25°C, and (d) GP20FA at 40°C at different ageing times.

MK shows a typical strong band at 1,080 cm−1 due to asymmetric stretching vibration of Si–T–O (T = Al or Si). Moreover, the band at 460 and around 800 cm−1 was assigned to the symmetric bending of T–O and Al(iv)–O, respectively [48,49,50,51].

All the GP spectra cured at 25 or 40°C and aged up to 56 days reveal the increase of the bands at 720 and 870–860 cm−1 due to the formation of new AlOX polyhedral species formed during the synthesis [52]. Indeed, the band at 870 cm−1 is due to the high amount of Al(v)–O species [49,52]. In addition, in the GP samples aged from 7 to 56 days, the strong band at 1,080 cm−1 of MK is displaced up to 1,016–1,012 cm−1, suggesting a new aluminosilicate network formation due to the increased substitution of Al in the tetrahedral silicate network [50]. This displacement was also observed in [31] by in situ attenuated total reflectance FT-IR on GP flash pastes made up of volcanic FA and MK. The broad bands in the range 1,435–1,385 cm−1 could be related to the efflorescence phenomenon (formation of sodium carbonate on GP surfaces) mainly for the GP0 samples and also for the calcium presence in GP20FA samples [53].

3.3 Thermal analysis

GP20FA samples cured at 25 and 40°C were degraded in a thermobalance, in dynamic heating conditions (RT – 800°C), to verify how the presence of volcanic ash and the different conditioning post-preparation affect their thermal behaviour. GP0, cured at 25 and 40°C, was also degraded in the same conditions for comparison. TG curves for the prepared GP are reported in Figures 5 and 6, in inert and oxidative atmosphere, respectively. TG curves, as expected, show the highest mass loss for the GP without volcanic ash added and treated at 25°C, while both the experiment in inert and oxidative environments clearly show a reduction in the mass loss when the volcanic ash is added in the GP formulation. If the oxidative atmosphere seems to flatten the influence of preventive heat treatment on the GP mass loss (Figure 5), the degradations (Figure 6) in an inert environment restore hierarchies, confirming that the presence of volcanic ash has a positive effect on the GP stabilization and that the curing treatment at 40°C reduces the weight loss. At 800°C, all the studied GP showed a stable solid residue ranging from 81 to 87% in static air atmosphere and 83 to 94% in nitrogen flow.

TG degradation curves, in static air atmosphere, for GP0 at 25°C, GP0 at 40°C, GP20FA at 25°C, and GP20FA at 40°C.

TG degradation curves, in nitrogen flow, for GP0 at 25°C, GP0 at 40°C, GP20FA at 25°C, and GP20FA at 40°C.

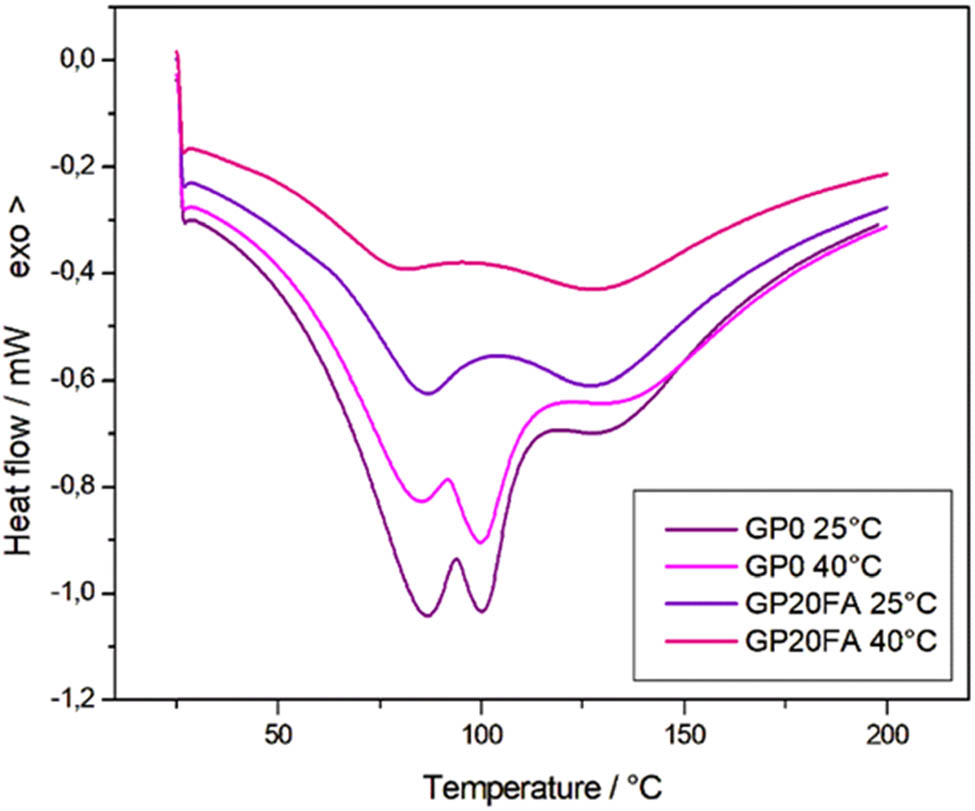

GP, thermally treated and not, were calorimetrically characterized by first carrying out DSC scans from 25 to 200°C, to investigate the temperature range of TG mass loss and then from room temperature up to 500°C. DSC curves for GP0 and GP20FA samples cured at 25 and 40°C are shown in Figures 7 and 8, respectively. DSC traces of the GP without volcanic ash are completely different with respect to those regarding GP20FA. GP0 samples, independently of the thermal treatment post-preparation, show a main double endothermic peak, with peak temperatures at about 75 and 105°C, followed by a less intense one at about 130°C (Figure 7). For the samples with volcanic ash, namely GP20FA 25 and GP20FA 40, only one endothermic peak is detectable at about 75°C, followed only by the other one at 130°C. Looking at the curing effect on the calorimetric behaviour, we noticed that the sample treated at 40°C, independently of the presence of volcanic ash, showed a lower value of enthalpy related to the endothermic phenomena (Figure 7).

DSC curves, from room temperature up to 250°C, for GP0 at 25°C, GP0 at 40°C, GP20FA at 25°C, and GP20FA at 40°C.

DSC curves, from room temperature up to 500°C, for GP0 at 25°C, GP0 at 40°C, GP20FA at 25°C, and GP20FA at 40°C.

Figure 8 reports DSC scans of all four GP from room temperature up to 500°C. We observed a shift of the endothermic peak for all the studied GP, with and without volcanic ash. From Figure 8, we also noticed a slight reduction in the enthalpy of melting for the GP containing volcanic ash. The calorimetric traces proceed in the same way for all GP up to 500°C, without highlighting other differences.

3.4 Antibacterial properties

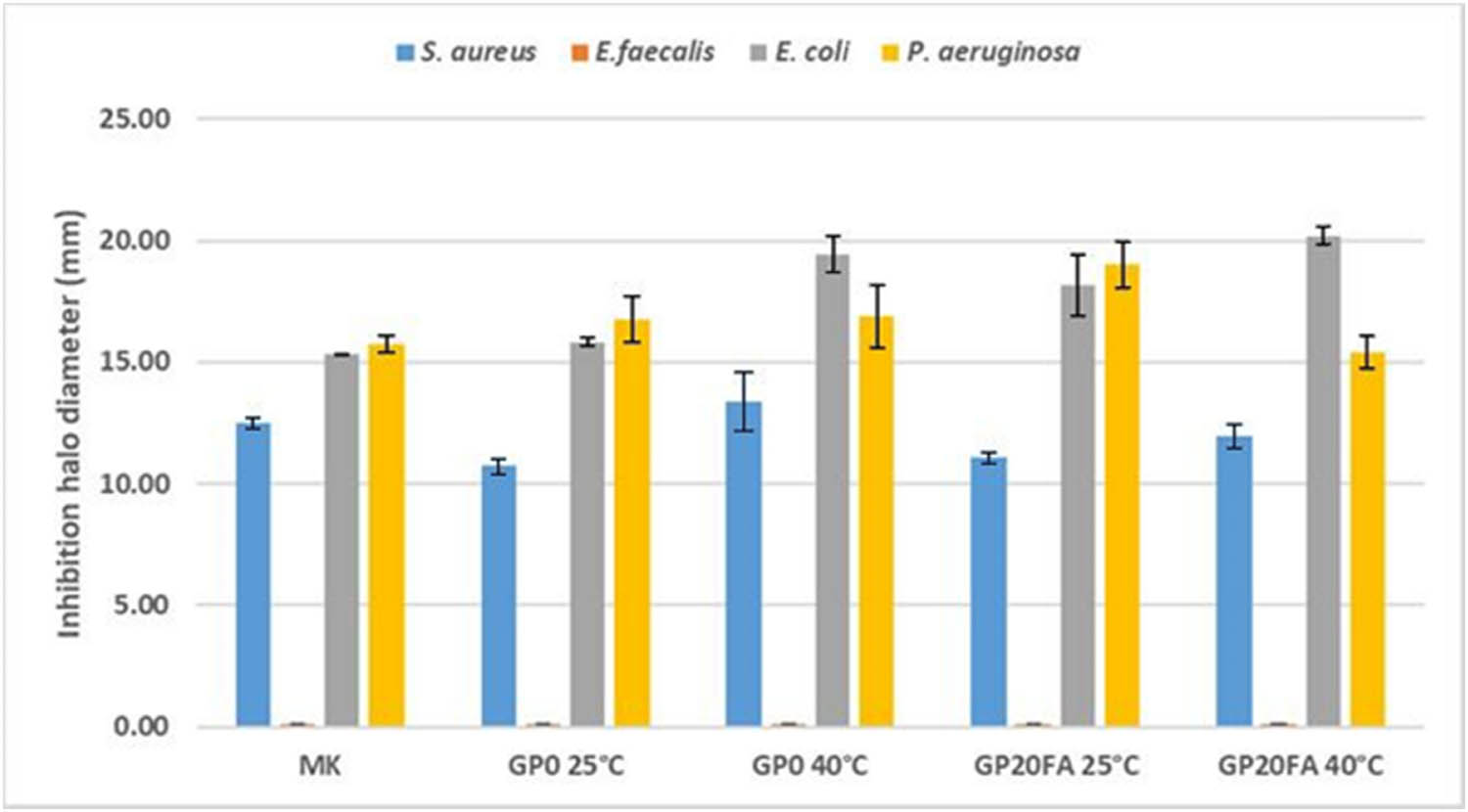

The antibacterial properties of all samples were investigated at 56 days (Figures 9 and 10). Based on the observation of the plates, not all the bacteria assayed were sensitive to the presence of the samples. In particular, the inhibition halos were present only on the Petri plates with S. aureus, E. coli, and P. aeruginosa (Figure 9). Moreover, the inhibition halos values were more extensive against E. coli and P. aeruginosa, which are both Gram-negative bacteria, than S. aureus which is a Gram-positive bacterium. This behaviour is also confirmed by the value of the bacterial viability shown in Figure 10. A more accurate analysis of the IDs reveals that GP0 40°C and GP20FA 25 and 40°C in the presence of E. coli have increased antimicrobial activity. In comparison with the MK response, it can be noticed that the presence of FA as well as the heat treatment led to a slight increment in the antimicrobial activity. The reason why the heat treatment led to an increment of the antibacterial activity may be related to the fact that, as also demonstrated with the TGA analysis, this causes the water inside the geopolymeric system to be less. In addition, it is known that adding FA reduces the water demand in cementitious materials [54], leading to the samples containing FA, even less free water than the FA-free samples. This does not help the bacteria growth, thus leading to an increase in antibacterial activity of both the materials that underwent heat treatment and contained FA. Furthermore, another explanation of the antimicrobial activity of the GP20FA samples is related to the presence of FA. FA, as demonstrated by EDX analysis, are mainly composed of Fe2O3, SiO2, and CaO. In literature, it is reported that Fe2O3 and SiO2 have bactericidal and bacteriostatic activities against most Gram-positive and -negative bacteria [55]; however, the reason why no inhibition halos were present against E. faecalis is related to the fact that, to have a bacteriostatic effect, a minimum concentration of Fe2O3 is needed to be reached. Therefore, the use of only 20 wt% of FA suggests that it is not enough to reach this scope [56]. In addition, CaO could contribute, together with the GP environment itself, to form an alkaline environment that can successfully prevent the growth of both Gram-positive and -negative bacteria through inactivating ATP synthesis and generating oxidative stress [57]. However, comparing the result between GP0 40°C and GP20FA 25°C, it is possible to notice that the thermic treatment led to the same result of the addition of 20 wt% of FA without the thermal treatment.

Inhibition halo diameter for the investigated composites.

Bacterial viability for the investigated composites.

4 Conclusion

The feasibility to use FA from volcanic activity as filler in MK-based GP has been demonstrated. In particular, 20 wt% of FA has been added inside the GP formulations and the samples were cured at 25 or 40°C and aged up to 56 days at RT. The results proved that the used FA belongs to Class F and the samples cured at 40°C are more stable than those cured at 25°C. The efflorescence phenomenon was observed on the sample surface and confirmed by the presence of the C–O absorption band in FT-IR spectra. These also revealed the geopolymerization occurrences because of the shift of the main Si–O–T signal, detected at 1,080 cm−1 in the MK spectrum, to lower wavenumbers (1,017–1,012 cm−1) in sample spectra. TGA curves of the synthesized GP revealed that samples treated at 40°C are more stable than those treated at 25°C. Moreover, independently from the curing temperature, GP0 samples showed two endothermic peaks at 75 and 105°C followed by a less endothermic peak at 130°C, while GP20FA samples showed only two endothermic phenomena at 75 and 130°C. In addition, GP20FA samples revealed a slight reduction of melting enthalpy with respect to the GP0 samples.

Finally, all the samples showed antibacterial properties against S. aureus and in particular against E. coli and P. aeruginosa strains where the inhibition halos were larger. Furthermore, the heat treatment and the presence of FA seemed to enhance the antibacterial power. The antimicrobial properties of the synthesized material suggest their use for indoor applications (e.g., cover for hospital surface furniture). Even though the results are promising, deep investigation into the reduction of FA dimension and an increase in their use both as filler and precursor for the GP syntheses will be done in the next future.

Acknowledgments

This work was supported in part by “SCAVENGE” financed by Università degli Studi della Campania Luigi Vanvitelli in the framework of “Piano Strategico di Ateneo 2021-2023 - Azione strategica R1.S2”. The authors thank Prochin Italia Prodotti Chimici Industriali Srl for the kind donation of the sodium silicate used in this work.

-

Conflict of interest: The authors declare no conflict of interest.

References

[1] Silva PD, Sagoe-Crenstil K, Sirivivatnanon V. Kinetics of geopolymerization: Role of Al2O3 and SiO2. Cem Concr Res. 2007;37:512–8.10.1016/j.cemconres.2007.01.003Suche in Google Scholar

[2] Lloyd NA, Rangan BV. Geopolymer concrete: A review of development and opportunities. 35th Conference on Our World in Concrete & Structures. Singapore; 25–27 August 2010. Article Online Id: 100035037. http://cipremier.com/100035037.Suche in Google Scholar

[3] Zakka WP, Lim NHAS, Khun MC. A scientometric review of geopolymer concrete. J Clean Prod. 2021;280(1):124353.10.1016/j.jclepro.2020.124353Suche in Google Scholar

[4] Fan X. A brief introduction on the research status and future prospects on geopolymer concrete. IOP Conf Ser Earth Environ Sci. 2020;508(1):012124.10.1088/1755-1315/508/1/012124Suche in Google Scholar

[5] Gou M, Zhou L, Then N. Utilization of tailings in cement and concrete: A review. Sci Eng Compos Mater. 2019;26(1):449–64.10.1515/secm-2019-0029Suche in Google Scholar

[6] Le V, Szczypinski M, Hájková P, Kovacic V, Bakalova T, Volesky L, et al. Mechanical properties of geopolymer foam at high temperature. Sci Eng Compos Mater. 2020;27(1):129–38.10.1515/secm-2020-0013Suche in Google Scholar

[7] Luhar S, Luhar I. Valorisation of waste glasses for the development of geopolymer mortar—Properties and applications: An appraisal. J Compos Sci. 2022;6:30.10.3390/jcs6010030Suche in Google Scholar

[8] Mohajerani A, Suter D, Jeffrey-Bailey T, Song T, Arulrajah A, Horpibulsuk S, et al. Recycling waste materials in geopolymer concrete. Clean Techn Env Policy. 2019;21:493–515.10.1007/s10098-018-01660-2Suche in Google Scholar

[9] Podolsky Z, Liu J, Dinh H, Doh JH, Guerrieri M, Fragomeni S. State of the art on the application of waste materials in geopolymer concrete. Case Stud Constr Mater. 2021;15:e00637.10.1016/j.cscm.2021.e00637Suche in Google Scholar

[10] Mohd Mortar NA, Abdullah MMAB, Abdul Razak R, Abd Rahim SZ, Aziz IH, Nabiałek M, et al. Geopolymer ceramic application: A review on mix design, properties and reinforcement enhancement. Materials. 2022;15:7567.10.3390/ma15217567Suche in Google Scholar PubMed PubMed Central

[11] Zhong H, Zhang M. Engineered geopolymer composites: A state-of-the-art review. Cem Concr Compos. 2023;135:104850.10.1016/j.cemconcomp.2022.104850Suche in Google Scholar

[12] Davidovits J. Geopolymers. J Therm Anal. 1991;37:1633–56.10.1007/BF01912193Suche in Google Scholar

[13] Cong P, Cheng Y. Advances in geopolymer materials: A comprehensive Review. J Traffic Transport Eng (Engl Ed). 2021;8:283–314.10.1016/j.jtte.2021.03.004Suche in Google Scholar

[14] Sitaram Amritphale S, Bhardwaj P, Gupta R. Advanced Geopolymerization Technology. In: Alshaaer M, Jeon H-Y, editors. Geopolymers and other geosynthetics. London, UK: IntechOpen; 2020. ISBN 978-1-78985-176-2.10.5772/intechopen.87250Suche in Google Scholar

[15] Duxson P, Fernández-Jiménez A, Provis JL, Lukey GC, Palomo A, van Deventer JSJ. Geopolymer technology: The current state of the art. J Mater Sci. 2007;42:2917–33.10.1007/s10853-006-0637-zSuche in Google Scholar

[16] Tchakoute HK, Elimbi A, Yanne E, Djangang CN. Utilization of volcanic ashes for the production of geopolymers cured at ambient temperature. Cem Concr Compos. 2013;38:75–81.10.1016/j.cemconcomp.2013.03.010Suche in Google Scholar

[17] Lemougna PN, MacKenzie KJD, Melo UFC. Synthesis and thermal properties of inorganic polymers (geopolymers) for structural and refractory applications from volcanic ash. Ceram Int. 2011;37:3011–8.10.1016/j.ceramint.2011.05.002Suche in Google Scholar

[18] Zhuang XY, Chen L, Komarneni S, Zhou CH, Tong DS, Yang HM, et al. Fly ash-based geopolymer: Clean production, properties and applications. J Clean Prod. 2016;125:253–67.10.1016/j.jclepro.2016.03.019Suche in Google Scholar

[19] Olivia M, Nikraz H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater Des. 2012;36:191–8.10.1016/j.matdes.2011.10.036Suche in Google Scholar

[20] Golewski GL, Szostak B. Strength and microstructure of composites with cement matrixes modified by fly ash and active seeds of C-S-H phase. Struct Eng Mech. 2022;82(4):543–56.Suche in Google Scholar

[21] Golewski GL. Combined effect of coal fly ash (CFA) and nanosilica (nS) on the strength parameters and microstructural properties of eco-friendly concrete. Energies. 2023;16(1):452.10.3390/en16010452Suche in Google Scholar

[22] Golewski GL. Fracture performance of cementitious composites based on quaternary blended cements. Materials. 2022;15(17):6023.10.3390/ma15176023Suche in Google Scholar PubMed PubMed Central

[23] Golewski GL. An extensive investigations on fracture parameters of concretes based on quaternary binders (QBC) by means of the DIC technique. Constr Build Mater. 2022;351:128823.10.1016/j.conbuildmat.2022.128823Suche in Google Scholar

[24] Golewski GL. Comparative measurements of fracture toughness combined with visual analysis of cracks propagation using the DIC technique of concretes based on cement matrix with a highly diversified composition. Theor Appl Fract Mech. 2022;121:103553.10.1016/j.tafmec.2022.103553Suche in Google Scholar

[25] Zhang P, Han S, Golewski GL, Wang X. Nanoparticle-reinforced building materials with applications in civil engineering. Adv Mech Eng. 2014;12:10.10.1177/1687814020965438Suche in Google Scholar

[26] Yankwa Djobo JN, Elimbi A, Tchakouté HK, Kumar S. Mechanical activation of volcanic ash for geopolymer synthesis: Effect on reaction kinetics, gel characteristics, physical and mechanical properties. RSC Adv. 2016;6:39106–17.10.1039/C6RA03667HSuche in Google Scholar

[27] Belfiore CM, Amato C, Pezzino A, Viccaro M. An end of waste alternative for volcanic ash: A resource in the manufacture of ceramic tiles. Constr Build Mater. 2020;263:120118.10.1016/j.conbuildmat.2020.120118Suche in Google Scholar

[28] Alqarni AS. A comprehensive review on properties of sustainable concrete using volcanic pumice powder ash as a supplementary cementitious material. Constr Build Mater. 2022;323:126533.10.1016/j.conbuildmat.2022.126533Suche in Google Scholar

[29] Contrafatto L. Recycled etna volcanic ash for cement, mortar and concrete manufacturing. Constr Build Mater. 2017;151:704–13.10.1016/j.conbuildmat.2017.06.125Suche in Google Scholar

[30] Smithsonian Institution; Venzke, E. Volcanoes of the World, v. 4.3.4 2013.Suche in Google Scholar

[31] Finocchiaro C. Evaluation of new uses of volcanic ashes and paleo-soils coming from Mt. Etna volcano in the geopolymer production. Plinius. 2021;47:26–30. (01004).Suche in Google Scholar

[32] Finocchiaro C, Barone G, Mazzoleni P, Leonelli C, Gharzouni A, Rossignol S. FT-IR study of early stages of alkali activated materials based on pyroclastic deposits (Mt. Etna, Sicily, Italy) using two different alkaline solutions. Constr Build Mater. 2020;262:120095.10.1016/j.conbuildmat.2020.120095Suche in Google Scholar

[33] Karolina R, Tarigan J, Megat JMA, Mijarsh MJA, Hardjasaputra H. Synthesis of volcanic ash-based geopolymer mortar designed by the Taguchi method. Civ Eng. 2022;8:2585–97.10.28991/CEJ-2022-08-11-016Suche in Google Scholar

[34] Tchakoute KH, Mbey JA, Elimbi A, Kenne DBB, Njopwouo D. Synthesis of volcanic ash-based geopolymer mortars by fusion method: Effects of adding metakaolin to fused volcanic ash. Ceram Int. 2013;39:1613–21.10.1016/j.ceramint.2012.08.003Suche in Google Scholar

[35] Djobo YJN, Elimbi A, Tchakouté KH, Kumar S. Mechanical properties and durability of volcanic ash based geopolymer mortars. Constr Build Mater. 2016;124:606–14.10.1016/j.conbuildmat.2016.07.141Suche in Google Scholar

[36] Khan A. Microstructure investigation of fly ash f and fly ash c geopolymer concrete using synergy of recycle aggregates. JMCMS. 2020;15(9):344–54.10.26782/jmcms.2020.09.00027Suche in Google Scholar

[37] Klima KM, Schollbach K, Brouwers HJH, Yu Q. Thermal and fire resistance of class F fly ash based geopolymers – A review. Constr Build Mater. 2022;323:126529.10.1016/j.conbuildmat.2022.126529Suche in Google Scholar

[38] Sgarlata C, Formia A, Ferrari F, Leonelli C. Effect of the introduction of reactive fillers and metakaolin in waste clay-based materials for geopolymerization processes. Molecules. 2021;26:1325.10.3390/molecules26051325Suche in Google Scholar PubMed PubMed Central

[39] D’Angelo A, Dal Poggetto G, Piccolella S, Leonelli C, Catauro M. Characterisation of white metakaolin-based geopolymers doped with synthetic organic dyes. Polymers. 2022;14:3380.10.3390/polym14163380Suche in Google Scholar PubMed PubMed Central

[40] Vyazovkin S, Chrissafis K, Di Lorenzo ML, Koga N, Pijolat M, Roduit B, et al. ICTAC kinetics committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim Acta. 2014;590:1–23.10.1016/j.tca.2014.05.036Suche in Google Scholar

[41] Abate L, Badea E, Blanco I, Della Gatta G. Heat capacities and enthalpies of solid−solid transitions and fusion of a series of eleven primary alkylamides by differential scanning calorimetry. J Chem Eng Data. 2008;53:959–65.10.1021/je700662aSuche in Google Scholar

[42] Hudzicki J. Kirby-bauer disk diffusion susceptibility test protocol. Washington, DC: American Society for Microbiology; 2009.Suche in Google Scholar

[43] Dal Poggetto G, D’Angelo A, Catauro M, Barbieri L, Leonelli C. Recycling of waste corundum abrasive powder in MK-based geopolymers. Polymers. 2022;14:2173.10.3390/polym14112173Suche in Google Scholar PubMed PubMed Central

[44] Simão L, Fernandes E, Hotza D, Ribeiro MJ, Montedo ORK, Raupp-Pereira F. Controlling efflorescence in geopolymers: A new approach. Case Stud Constr Mater. 2021;15:e00740.10.1016/j.cscm.2021.e00740Suche in Google Scholar

[45] Liang K, Cui K, Sabri MMS, Huang J. Influence factors in the wide application of alkali-activated materials: A critical review about efflorescence. Materials. 2022;15:6436.10.3390/ma15186436Suche in Google Scholar PubMed PubMed Central

[46] Barone G, Finocchiaro C, Lancellotti I, Leonelli C, Mazzoleni P, Sgarlata C, et al. Potentiality of the use of pyroclastic volcanic residues in the production of alkali activated material. Waste Biomass Valor. 2021;12:1075–94.10.1007/s12649-020-01004-6Suche in Google Scholar

[47] Dal Poggetto G, Catauro M, Crescente G, Leonelli C. Efficient addition of waste glass in MK-based geopolymers: Microstructure, antibacterial and cytotoxicity investigation. Polymers. 2021;13:1493.10.3390/polym13091493Suche in Google Scholar PubMed PubMed Central

[48] Diaz EI, Allouche EN, Eklund S. Factors affecting the suitability of fly ash as source material for geopolymers. Fuel. 2010;89:992–6.10.1016/j.fuel.2009.09.012Suche in Google Scholar

[49] Lamanna G, Soprano A, Bollino F, Catauro M. Mechanical characterization of hybrid (organic-inorganic) geopolymers. KEM. 2013;569–570:119–25.10.4028/www.scientific.net/KEM.569-570.119Suche in Google Scholar

[50] Sitarz M, Handke M, Mozgawa W. Identification of silicooxygen rings in SiO2 based on IR spectra. Spectrochim Acta Part A. 2000;56:1819–23.10.1016/S1386-1425(00)00241-9Suche in Google Scholar

[51] Djobo JNY, Tchadjié LN, Tchakoute HK, Kenne BBD, Elimbi A, Njopwouo D. Synthesis of geopolymer composites from a mixture of volcanic scoria and metakaolin. J Asian Ceram Soc. 2014;2:387–98.10.1016/j.jascer.2014.08.003Suche in Google Scholar

[52] Catauro M, Dal Poggetto G, Sgarlata C, Vecchio Ciprioti S, Pacifico S, Leonelli C. Thermal and microbiological performance of metakaolin-based geopolymers cement with waste glass. Appl Clay Sci. 2020;197:105763.10.1016/j.clay.2020.105763Suche in Google Scholar

[53] Nickolov ZhS, Ozcan O, Miller JD. FTIR analysis of water structure and its significance in the flotation of sodium carbonate and sodium bicarbonate salts. Colloids Surf A. 2003;224:231–9.10.1016/S0927-7757(03)00317-0Suche in Google Scholar

[54] Vimonsatit S, Chindaprasirt P, Ruangsiriyakul S, Sata V. Influence of fly ash fineness on water requirement and shrinkage of blended cement mortars. KKU Eng J. 2015;42(4):311–6.Suche in Google Scholar

[55] Azam A, Ahmed AS, Oves M, Khan MS, Habib SS, Memic A. Antimicrobial activity of metal oxide nanoparticles against Gram-positive and Gram-negative bacteria: a comparative study. Int J Nanomed. 2012;7:6003–9.10.2147/IJN.S35347Suche in Google Scholar PubMed PubMed Central

[56] Shahbazi E, Morshedzadeh F, Zaeifi D. Bacteriostatic potency of Fe2O3 against enterococcus faecalis in synergy with antibiotics by DDST method. Avicenna J Med Biotechnol. 2019;11(2):176–9.Suche in Google Scholar

[57] Tan J, Wang D, Cao H, Qiao Y, Zhu H, Liu X. Effect of local alkaline microenvironment on the behaviors of bacteria and osteogenic cells. ACS Appl Mater Interfaces. 2018;10(49):42018–29.10.1021/acsami.8b15724Suche in Google Scholar PubMed

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Effects of cellulose nanofibers on flexural behavior of carbon-fiber-reinforced polymer composites with delamination

- Damage mechanisms of bismaleimide matrix composites under transverse loading via quasi-static indentation

- Experimental study on hydraulic fracture behavior of concrete with wedge-splitting testing

- The assessment of color adjustment potentials for monoshade universal composites

- Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property

- The effect of temperature on the tensile properties and failure mechanisms of two-dimensional braided composites

- The influence of preparation of nano-ZrO2/α-Al2O3 gradient coating on the corrosion resistance of 316L stainless steel substrate

- A numerical study on the spatial orientation of aligning fibrous particles in composites considering the wall effect

- A simulative study on the effect of friction coefficient and angle on failure behaviors of GLARE subjected to low-velocity impact

- Impact resistance capacity and degradation law of epoxy-coated steel strand under the impact load

- Analytical solutions of coupled functionally graded conical shells of revolution

- The influence of water vapor on the structural response of asphalt pavement

- A non-invasive method of glucose monitoring using FR4 material based microwave antenna sensor

- Chloride ion transport and service life prediction of aeolian sand concrete under dry–wet cycles

- Micro-damage analysis and numerical simulation of composite solid propellant based on in situ tensile test

- Experimental study on the influence of high-frequency vibratory mixing on concrete performance

- Effects of microstructure characteristics on the transverse moisture diffusivity of unidirectional composite

- Gradient-distributed ZTAp-VCp/Fe45 as new anti-wear composite material and its bonding properties during composite casting

- Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field

- Mechanical and tribological properties of C/C–SiC ceramic composites with different preforms

- Mechanical property improvement of oil palm empty fruit bunch composites by hybridization using ramie fibers on epoxy–CNT matrices

- Research and analysis on low-velocity impact of composite materials

- Optimizing curing agent ratios for high-performance thermosetting phthalonitrile-based glass fibers

- Method for deriving twisting process parameters of large package E-glass yarn by measuring physical properties of bobbin yarn

- A probability characteristic of crack intersecting with embedded microcapsules in capsule-based self-healing materials

- An investigation into the effect of cross-ply on energy storage and vibration characteristics of carbon fiber lattice sandwich structure bionic prosthetic foot

- Preparation and application of corona noise-suppressing anti-shedding materials for UHV transmission lines

- XRD analysis determined crystal cage occupying number n of carbon anion substituted mayenite-type cage compound C12A7: nC

- Optimizing bending strength of laminated bamboo using confined bamboo with softwoods

- Hydrogels loaded with atenolol drug metal–organic framework showing biological activity

- Creep analysis of the flax fiber-reinforced polymer composites based on the time–temperature superposition principle

- A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously

- Effect of aggregate characteristics on properties of cemented sand and gravel

- An integrated structure of air spring for ships and its strength characteristics

- Modeling and dynamic analysis of functionally graded porous spherical shell based on Chebyshev–Ritz approach

- Failure analysis of sandwich beams under three-point bending based on theoretical and numerical models

- Study and prediction analysis on road performance of basalt fiber permeable concrete

- Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method

- Study on properties of recycled mixed polyester/nylon/spandex modified by hydrogenated petroleum resin

- Effect of particle size distribution on microstructure and chloride permeability of blended cement with supplementary cementitious materials

- In situ ligand synthesis affording a new Co(ii) MOF for photocatalytic application

- Fracture research of adhesive-bonded joints for GFRP laminates under mixed-mode loading condition

- Influence of temperature and humidity coupling on rutting deformation of asphalt pavement

- Review Articles

- Sustainable concrete with partial substitution of paper pulp ash: A review

- Durability and microstructure study on concrete made with sewage sludge ash: A review (Part Ⅱ)

- Mechanical performance of concrete made with sewage sludge ash: A review (Part Ⅰ)

- Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II)

- Communication

- Calculation of specific surface area for tight rock characterization through high-pressure mercury intrusion

- Special Issue: MDA 2022

- Vibration response of functionally graded material sandwich plates with elliptical cutouts and geometric imperfections under the mixed boundary conditions

- Analysis of material removal process when scratching unidirectional fibers reinforced polyester composites

- Tailoring the optical and UV reflectivity of CFRP-epoxy composites: Approaches and selected results

- Fiber orientation in continuous fiber-reinforced thermoplastics/metal hybrid joining via multi-pin arrays

- Development of Mg-based metal matrix biomedical composites for acicular cruciate ligament fixation by reinforcing with rare earth oxide and hydroxyapatite – A mechanical, corrosion, and microstructural perspective

- Special Issue: CACMSE

- Preparation and application of foamed ceramic panels in interior design

Artikel in diesem Heft

- Regular Articles

- Effects of cellulose nanofibers on flexural behavior of carbon-fiber-reinforced polymer composites with delamination

- Damage mechanisms of bismaleimide matrix composites under transverse loading via quasi-static indentation

- Experimental study on hydraulic fracture behavior of concrete with wedge-splitting testing

- The assessment of color adjustment potentials for monoshade universal composites

- Metakaolin-based geopolymers filled with volcanic fly ashes: FT-IR, thermal characterization, and antibacterial property

- The effect of temperature on the tensile properties and failure mechanisms of two-dimensional braided composites

- The influence of preparation of nano-ZrO2/α-Al2O3 gradient coating on the corrosion resistance of 316L stainless steel substrate

- A numerical study on the spatial orientation of aligning fibrous particles in composites considering the wall effect

- A simulative study on the effect of friction coefficient and angle on failure behaviors of GLARE subjected to low-velocity impact

- Impact resistance capacity and degradation law of epoxy-coated steel strand under the impact load

- Analytical solutions of coupled functionally graded conical shells of revolution

- The influence of water vapor on the structural response of asphalt pavement

- A non-invasive method of glucose monitoring using FR4 material based microwave antenna sensor

- Chloride ion transport and service life prediction of aeolian sand concrete under dry–wet cycles

- Micro-damage analysis and numerical simulation of composite solid propellant based on in situ tensile test

- Experimental study on the influence of high-frequency vibratory mixing on concrete performance

- Effects of microstructure characteristics on the transverse moisture diffusivity of unidirectional composite

- Gradient-distributed ZTAp-VCp/Fe45 as new anti-wear composite material and its bonding properties during composite casting

- Experimental evaluation of velocity sensitivity for conglomerate reservoir rock in Karamay oil field

- Mechanical and tribological properties of C/C–SiC ceramic composites with different preforms

- Mechanical property improvement of oil palm empty fruit bunch composites by hybridization using ramie fibers on epoxy–CNT matrices

- Research and analysis on low-velocity impact of composite materials

- Optimizing curing agent ratios for high-performance thermosetting phthalonitrile-based glass fibers

- Method for deriving twisting process parameters of large package E-glass yarn by measuring physical properties of bobbin yarn

- A probability characteristic of crack intersecting with embedded microcapsules in capsule-based self-healing materials

- An investigation into the effect of cross-ply on energy storage and vibration characteristics of carbon fiber lattice sandwich structure bionic prosthetic foot

- Preparation and application of corona noise-suppressing anti-shedding materials for UHV transmission lines

- XRD analysis determined crystal cage occupying number n of carbon anion substituted mayenite-type cage compound C12A7: nC

- Optimizing bending strength of laminated bamboo using confined bamboo with softwoods

- Hydrogels loaded with atenolol drug metal–organic framework showing biological activity

- Creep analysis of the flax fiber-reinforced polymer composites based on the time–temperature superposition principle

- A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously

- Effect of aggregate characteristics on properties of cemented sand and gravel

- An integrated structure of air spring for ships and its strength characteristics

- Modeling and dynamic analysis of functionally graded porous spherical shell based on Chebyshev–Ritz approach

- Failure analysis of sandwich beams under three-point bending based on theoretical and numerical models

- Study and prediction analysis on road performance of basalt fiber permeable concrete

- Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method

- Study on properties of recycled mixed polyester/nylon/spandex modified by hydrogenated petroleum resin

- Effect of particle size distribution on microstructure and chloride permeability of blended cement with supplementary cementitious materials

- In situ ligand synthesis affording a new Co(ii) MOF for photocatalytic application

- Fracture research of adhesive-bonded joints for GFRP laminates under mixed-mode loading condition

- Influence of temperature and humidity coupling on rutting deformation of asphalt pavement

- Review Articles

- Sustainable concrete with partial substitution of paper pulp ash: A review

- Durability and microstructure study on concrete made with sewage sludge ash: A review (Part Ⅱ)

- Mechanical performance of concrete made with sewage sludge ash: A review (Part Ⅰ)

- Durability and microstructure analysis of concrete made with volcanic ash: A review (Part II)

- Communication

- Calculation of specific surface area for tight rock characterization through high-pressure mercury intrusion

- Special Issue: MDA 2022

- Vibration response of functionally graded material sandwich plates with elliptical cutouts and geometric imperfections under the mixed boundary conditions

- Analysis of material removal process when scratching unidirectional fibers reinforced polyester composites

- Tailoring the optical and UV reflectivity of CFRP-epoxy composites: Approaches and selected results

- Fiber orientation in continuous fiber-reinforced thermoplastics/metal hybrid joining via multi-pin arrays

- Development of Mg-based metal matrix biomedical composites for acicular cruciate ligament fixation by reinforcing with rare earth oxide and hydroxyapatite – A mechanical, corrosion, and microstructural perspective

- Special Issue: CACMSE

- Preparation and application of foamed ceramic panels in interior design