Abstract

This paper studies the free vibration of polymer nanocomposite reinforced by graphene sheet. In this work, the new size dependent formulation is presented for nanocomposites based on couple stress theory. For this purpose, the first shear deformation theory is applied. The effect of scale parameter is investigated based on anisotropic couple stress theory. Vibration equations of the composite lamina are extracted using Hamilton’s principle. Numerical results are provided for Poly methyl methacrylate/graphene composite.Mechanical properties of the composite are obtained from molecular dynamics simulation. Based on eigenvalue procedure, an analytical solution is obtained for the natural frequency of composite lamina. In the results section, the effect of dimensional and physical parameters are investigated on lamina natural frequency. It is observed that graphene defects caused to diminish the lamina frequency. Furthermore, it is revealed that the increase in graphene volume fraction leads to natural frequency be greater.

1 Introduction

Today, composite materials have improved the performance in various mechanisms. Additionally, by exploiting the low volume fraction of the reinforcement, the mechanical properties of structures have been greatly improved and lead to the ideal efficiency of consumables [1, 2, 3, 4]. Basically, designers are eager to build the structures with high strength to weightratio. Depend on the applications, there are various applicable types of reinforcements and matrixes. Among the most widely used composites, one can be mentioned to metal-metal, metal-ceramics and polymer composites [5, 6]. Including the nanoscale reinforcements, it can be noted to the graphene sheet, carbon nanotube, and fullerene which the second and third elements made from twisting and rounding the graphene sheets, respectively [7]. Graphene is one of the thinner known materials in the nature that is about 0.34 nanometers thick. Graphene has special properties compared to other nano-reinforcements. Because the top and bottom surfaces of the graphene sheet surrounded in the matrix, it has an excellent surface contacts. Moreover, the price of graphene is reasonable [8, 9].

Thus far, several studies have been conducted on polymer composite reinforced by nanoparticles [10, 11, 12, 13]. Shen et al. [14, 15] investigated vibration and buckling of functionally graded composite reinforced by graphene and carbon nanotube (CNT). Mirzaei and Kiani [16] studied vibration of functionally graded CNT reinforced composite cylindrical panels. Zhang et al. [17] investigated the vibration of triangle composite plate reinforced by CNT.

In addition to macro, Composites are also used in micro and nano scales. For instance, nano-scale composites utilize in the production of nanoelectromechanical systems (NEMS) and microelectromechanical systems (MEMS) [18]. In the nanoscale, due to certain physical conditions and the low ratio of molecular distance to the structural dimensions, the material scale parameter affects the mechanical behavior of the structure [19]. As a result, the size effect must be applied in constitutive equations. There are several size dependent continuum theories. In some of these theories, the scale parameter has a softening effect on the results, such as nonlocal Eringen’s theories [20, 21, 22]. Barretta et al. [23] presented nonlocal integral model for Timoshenko beam model. Romano et al. [24] studied constitutive boundary condition of nano-beam based on non-local theory. Higher order nonlocal Euler Bernoulli beam model presented by Barretta et al. [25]. Acierno et al. [26] measured mechanical properties of polymer nano composite based on both nonlocal theory and experimental approach. Also, the nonlocal elastoplastic model presented by De sciara [27]. In some other theories, the scale parameter has a hardening effect on the results, such as the strain gradient and couple stress theories [28, 29, 30]. Aifanties [31] presented update of scale dependent gradient theories. Reviewed study was conducted on the stress gradient theory for size-dependent response of structures by Askes and Gitman [32]. Furthermore, some studies conducted based on nonlocal strain gradient theory [33, 35]. Barretta and Sciarra [36] investigated constitutive boundary conditions of nano- beams according to nonlocal strain gradient theory. Vibration analysis of elastic beam was studied by Apuzzu et al. [37] based on nonlocal gradient theory. Canadija et al. [38] extended nonlocal gradient formulation for beam model.

For the first time, couple stress theory was presented by Mindlin in 1962 [39]. So far, many scientists have studied the behavior of nanoscale elements using this theory [40, 41, 42, 43, 44]. Chen and Yang [45] developed the couple stress theory for anisotropic behavior. Some scholars using the anisotropic couple stress theory have studied the mechanical behavior of anisotropic structures. Tadi et al. [46, 47] studied free vibration and buckling of CNT based on anisotropic size dependent shell model. Gao et al. [48] benefitting anisotropic couple stress model studied the static deformation of layered magneto electro-elastic plates under surface loading. Buckling analysis of orthotropic protein microtubules investigated by Tadi et al. [49]. Yang and He [50] investigated static analysis of orthotropic microplate based on modified couple stress theory. Tsiatas and Yiotis [51] studied the static, dynamic and buckling of the anisotropic skew plate. It should be noted that conventional size dependent models have been challenged in some new studies [52, 53, 54]. The kinematics of generalized micro-morphic continua is presented by Romano et al. [52]. They proposed the simplest non-redundant model by dropping the micro-curvature term from the Mindlin theory. Furthermore, Barbagallo et al. [53] showed that a general formula is not applicable for the standard Mindlin-Eringen-format of the anisotropic micro-morphic model. Furthermore, Neff et al. [54] presented the relaxed micro-morphic model and derive the set of appropriate conditions that have to be imposed on the constitutive parameters. While, some researchers used nonlocal and gradient based size dependent theories [55].

Given that mechanical testing and control of its process are very costly and complex, molecular simulation is a suitable method for determining the materials properties. Some researchers calculated mechanical properties of nanocomposites by molecular dynamics simulations (MD). Han an Eliot [56] calculated mechanical properties of polymer composite reinforced by CNT using MD simulation. Lin et al. [57] using MD obtained mechanical properties of graphene-reinforced polymer composites. Moreover, Yunlong et al. [58] studied the mechanical properties of polymer composite reinforced by CNT and graphene sheet.

In this paper, new size dependent formulation is presented for the vibrational behavior of nano-composite. For sake of this aim, the anisotropic motion equations are extracted using Hamilton’s principle. These equations are developed for the first shear deformation plate model (FSDT). Furthermore, the size effect is involved according to the couple stress theory. It is noted the present vibrational equations are reduced to different states in certain conditions:

If the mechanical properties of the plate are identical in various directions, vibration equations of the size-dependent isotropic plate are obtained.

If the scale parameter is ignored, vibration equations of the orthotropic plate are extracted for classical continuum mechanic.

By combining the two above assumptions, vibration equations are derived for an isotropic macro plate.

Indeed, current work presents the new formulation for orthotropic composite plates which considers orthotropic and size sensitivity behavior of composite plates, simultaneously. Mechanical properties are also evaluated based on the molecular simulation. For the case study, the vibration of all edges simply supported (SSSS) Poly methyl methacrylate (PMMA) lamina reinforced by graphene sheet are investigated. Elastic properties of lamina reinforced by defected graphene are gained by molecular dynamics simulation. In the results section, the effect of physical and geometric parameters on the natural frequency of lamina has been investigated. Also, different vibrational mode shapes of lamina have been shown.

2 Size-dependent formulation for composite plate

In this work, the lamina is modeled as FSDT plate. The displacement components of this model are defined as follows:

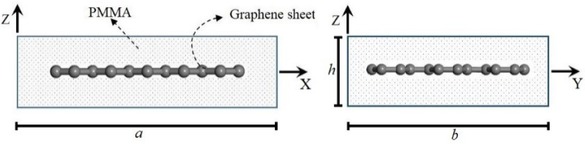

In the above equation u, v and w are total displacements related to x, y and z directions, respectively. u0, v0, and w0 indicate the in-plane displacements (at the z=0). Also, ϕx and ϕy represent a rotation around y and x-axes. Schematic of the lamina is illustrated in Figure 1. Based on energy methods, Hamilton’s principle is used to develop the motion equations. According to this theory, the variation of the system energy in a period of time is equal to zero as follows:

Schematic of the X-Z and Y-Z views of Graphene reinforced lamina.

In the above equation, U expresses lamina strain energy, and T indicates the lamina kinetic energy. Based on the couple stress theory, the strain energy of a body is obtained through the following integration:

Where ϵ, σ, χ and m represent strain tensor, Cauchy’s stress tensor, rotation gradient tensor, and higher order stress tensor, respectively. Based on the couple stress formulation, the strain and rotation gradient tensors are defined as follows:

In the following sections, the calculation process of classic and higher-order stresses using ϵ and χ values is explained. For orthotropic materials, the relationship between stress and strain is expressed as follows:

Besides, the relationship between higher-order stress and rotation gradient is defined as follows [45, 46, 47]:

In the above equation, li represents the material length scale parameter. By substituted Eq. (1) into Eq. (4), components of lamina strain are derived as follows:

As well as, by substituting Eq. (1) into Eq. (5), components of lamina rotation gradient tensor are obtained as follows:

According to Eqs. (3), (6) and (7), and by using components of strain and rotation gradient tensors which were obtained in the Eqs. (8) to (18), the strain energy of composite is obtained as follows:

After determining the lamina strain energy, the kinetic energy of composite is calculated. Using the time derivative on the FSDT displacement vector, the plate kinetic energy is computed as follows:

By substituting Eqs. (19) and (20) into Eq. (2), and using calculus of variation approach, the size-dependent vibration equations of the orthotropic lamina are developed as follows:

In the above equations, Cij’s are reliant on the mechanical properties of the lamina which provided in appendix A.

3 Molecular dynamics simulation

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation as well as the experimental conclusions that can be drawn. As mentioned in the introduction section, use of the experimental procedure for extract the mechanical properties of nanoscale composites are very complicated and difficult, and one of the most suitable methods is use of molecular dynamics. The molecular dynamics method is one of the powerful methods of molecular mechanics which is designed based on numerical integration of Newton’s equations on the molecular domain of a body. In order to perform molecular dynamics simulation, first, the initial conditions of the system including the speed and the primary location of the particles are determined. Then, by selecting a suitable time interval, the new atomic positions will be predicted according to the previous position and initial velocity. Intermolecular interactions using a function the potential is expressed. In fact, the potential function is the main input in the molecular dynamics simulation. The potential function of N-particle systems is given by the following equation:

Where ϕi is represented the various kind of interactions for individual particles. The force applied to each particle is calculated from the following equation:

Also, according to Newton’s second law, the following basic relation is extracted for each particle

Using the above equation, we can calculate the acceleration of each particle and then using numerical integration, in a very small time interval, the new position and speed of the particles have been achieved. In the present work, the mechanical properties of the composite are calculated using Material Studio software and effects of vacancy (VD) and stone wales (SW) defects of graphene are explored on the stiffness of lamina. The stone wales and vacancy defects along the molecular model of the lamina are shown in Figure 2. Composite is modeled based on COMPASS forcefield. In the beginning, the molecular model of the lamina is subjected to NVT ensemble in 450∘K. Then, it is exposed to NPT ensemble by 0.1 GPa pressure. In the end, by applying finite strain, mechanical properties of the lamina are determined according to Table 1.

(a) Stone Walls defect (SW), (b) Vacancy Defect (VD), (c) molecular model of the lamina.

Mechanical properties of the composite with 0.19 volume fraction for various graphene defects.

| Type of graphene-reinforced in PMMA | E11(GPa) | E22(GPa) | G12(GPa) |

|---|---|---|---|

| Perfect graphene | 104.1 | 107.7 | 22.7 |

| Graphene with 1.6% vacancy | 98.1 | 100.5 | 20.8 |

| Graphene with 5% vacancy | 93.2 | 92.6 | 18.8 |

| Graphene with 1.6% stone wales | 103.5 | 97 | 21.4 |

| Graphene with 5% stone wales | 91.9 | 86.9 | 19.7 |

4 Solution method

Based on Navier’s solution method, for simply supported lamina, the displacement components are considered as follows:

In the above equation, ω is the lamina natural frequency. Also, A1, A2, A3, A4, and A5 represent the vibration amplitude for each of the variables. Moreover, m and n represent the longitudinal mode number and circumferential mode number, respectively. By substituting Eq. (29) into the motion equations, the resulted equations are converted to following eigenvalue problem:

In the above equation, K and M are stiffness and mass matrixes. After solving Eq. (30), the lamina natural frequency is obtained, which will be discussed in detail in the results section.

5 Results and discussions

The aim beyond of the present work is to study the free vibration of Graphene-reinforced lamina. Predict the oscillation behavior of nano-structures can be useful for the control of their performance. Polymeric composites reinforced by graphene sheets have a good physical properties and can be used in nanoelectromechanical systems. In this section, according to the procedure that presented before, the vibration of simply supported lamina composite is investigated using the orthotropic FSDT model. Various numerical examples are proposed to investigate the influence of geometrical and material properties on the vibration behavior of lamina. In order to study the vibrational behavior of current composite model, natural frequencies are presented for the various geometrical parameters, α parameter represents ratio of length to lamina thickness (a/h). β parameter also signifies width to lamina thickness (b/h). Furthermore, λ parameter is defined as a non-dimensional length scale parameter (l/h). Besides, the material length scale parameter is assumed as l1 = l2 = l3 = l. By literature review, the value of length scale l is calibrated for graphene sheet by 2.46 nm length and width. Arash and Wang [59] using MD simulation demonstrated that the natural frequency of the aforementioned graphene is equal to 77.6 GHz. By comparison this frequency with the solution of equation (30), length scale parameter is calibrated in 0.118 nm.

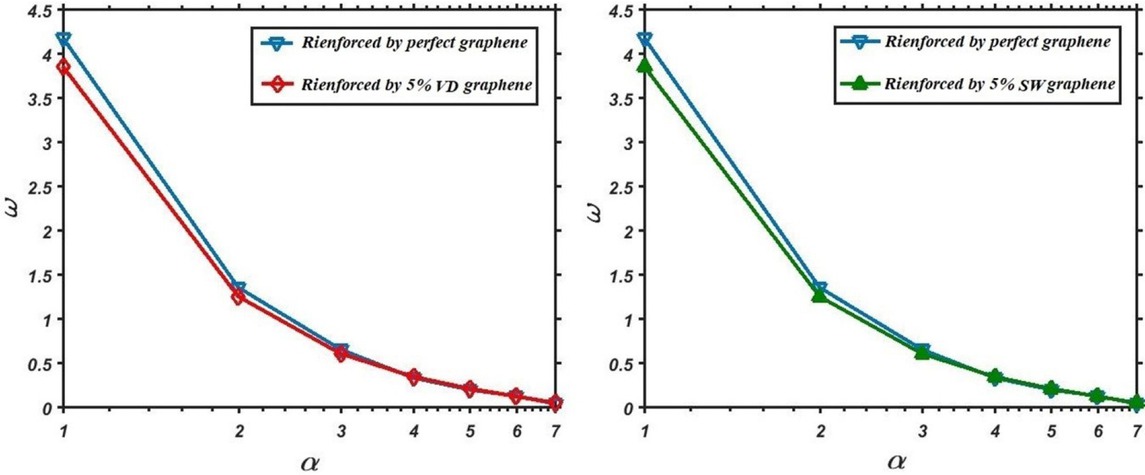

In the Figure 3, influences of graphene defects on lamina natural frequency are studied. The mechanical properties of the composites reinforced by defected graphene are given in Table 1. According to the following graphs, it is clear that vacancy (VD) and stone wales (SW) defects lead to decrease lamina frequency. Furthermore, it is obvious that the impact of graphene defects is more severe for lower α parameter.

Variation of lamina frequency with α parameter: a) vacancy defect b) stone wales defect.

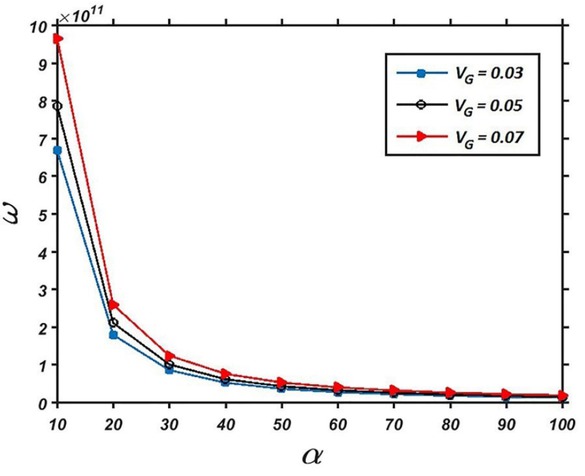

In Figure 4, the variation of the lamina frequency related to α parameter is shown. As seen in this figure, by increasing of α parameter lamina natural frequency is reduced. It is also clear that by increasing the volume fraction of graphene, the natural frequency of lamina has grown that for α smaller than 60 this increase is more significant. It should be noted mechanical properties for the various volume fraction of reinforcement have been used from Shen study [40].

Variation of lamina natural frequency with α parameter for different graphene volume fraction.

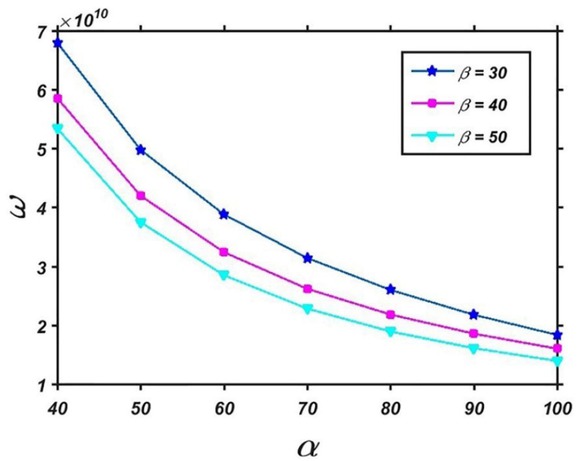

In Figure 5 the simultaneous effects of α and β dimensionless parameters are illustrated. According to this figure,

Variation of the natural frequency with α for different β parameters.

the highest lamina natural frequency has been obtained for smaller α and β parameters.

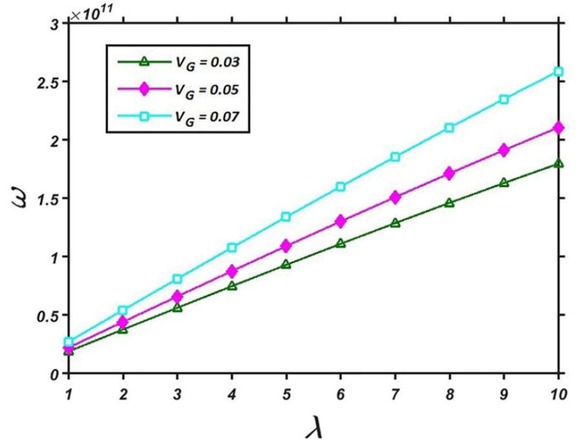

In Figure 6, the effect of the material length scale parameter is investigated on the results. It is observed that by increasing in λ parameter vibrational frequency of lamina increases which this result confirms the hardening effect of couple stress scale parameter. In addition, it is observed that the rate of frequency increase is more severe for composites with higher volume fractions of the graphene. Figure 7, provides the various vibration mode shapes of the lamina. In this figure, different mode shapes along with their corresponding frequencies are observed which α = 50, β = 50, λ = 1 and VG =0.03 are considered.

Variation of the natural frequency with λ for different graphene volume fraction.

Various vibrational mode shapes of the lamina.

6 Conclusion

In this paper, a new model was presented for nanoscale composites. For this purpose, the composite was modeled as FSDT plate model. Scale sensitivity was considered according to couple stress theory. Using the variations principles governing equations of anisotropic plate were derived. In order to a case study, free vibration of graphene-reinforced polymer lamina was examined. Mechanical properties of lamina reinforced by defected graphene were obtained by molecular dynamic simulation.

After solving the lamina free vibration equations, the results demonstrated that the increase in graphene volume fraction leads to increase in lamina frequency. Furthermore, it was determined that although the graphene volume fraction increases composite frequency, the intensity of the effect of this parameter for lamina with α > 0.01 condition is stronger. In addition, it was founded that the impact of raising the scale parameter on the lamina frequency is stronger for higher graphene volume fraction.

References

[1] Kaw, Autar K. mechanic of composite materials. s.l. : CRC Press, 2006.10.1201/9781420058291Search in Google Scholar

[2] Globus, A., Bailey, D., Han, J., Jaffe, R., Levit, C., Merkle, R.Srivastava, D. Nasa applications of molecular nanotechnology, 1998.Search in Google Scholar

[3] Silvia G. Prolongo, Adam D. Printz, Nicholas Rolston, Brian L. Watson, Reinhold H. Dauskardt, Poly(triarylamine) composites with carbon nanomaterials for highly transparent and conductive coatings, Thin Solid Films, 646, Pages 61-66, 2018.10.1016/j.tsf.2017.11.025Search in Google Scholar

[4] Paula, D.R, Robeson, L.M.Polymer nanotechnology: Nanocomposites, Polymer, Vol. 49, pp. 3187–3204, 2008.10.1016/j.polymer.2008.04.017Search in Google Scholar

[5] Roghayeh Ghasempour, Hamid Narei, CNT Basics and Characteristics, Carbon Nanotube-Reinforced Polymers, 1-24, 2018.10.1016/B978-0-323-48221-9.00001-7Search in Google Scholar

[6] Zeynel Ozturk, Cengiz Baykasoglu, Mesut Kirca, Sandwiched graphene-fullerene composite: A novel 3-D nanostructured material for hydrogen storage, International Journal of Hydrogen Energy, Volume 41, 6403-6411, 2016.10.1016/j.ijhydene.2016.03.042Search in Google Scholar

[7] Kuilla, T, Bhadra, S. Recent advances in graphene based polymer composites, Progress in Polymer Science, Vol. 35, pp. 1350–1375, 2010.10.1016/j.progpolymsci.2010.07.005Search in Google Scholar

[8] Vijay Ponraj, N, Azhagurajan, A. Graphene nanosheet as reinforcement agent in copper matrix composite by using powder metallurgy method, Surfaces, and Interfaces, Vol. 6, pp. 190–196, 2017.10.1016/j.surfin.2017.01.010Search in Google Scholar

[9] Lin, F, Xiang, Y, Shen, H.S. Temperature dependent mechanical properties of graphene-reinforced polymer nanocomposites – a molecular dynamics simulation. 2017, Compos. Part B, Vol. 111, pp. 261-269.10.1016/j.compositesb.2016.12.004Search in Google Scholar

[10] Anisha Christy, Rajesh Purohit, R.S. Rana, Swadesh Kumar Singh, Saraswati Rana, Development and Analysis of Epoxy/nano SiO2 Polymer Matrix Composite fabricated by Ultrasonic Vibration assisted Processing, Materials Today: Proceedings, Volume 4, Part A, 2748-2754, 2017.10.1016/j.matpr.2017.02.152Search in Google Scholar

[11] Yuanliang Zhao, Xiaowen Qi, Yu Dong, Jian Ma, Qingxiang Yang, Mechanical, thermal and tribological properties of polyimide/nano-SiO2 composites synthesized using an in-situ polymerization, Tribology International, Volume 103, 599-608, 2016.10.1016/j.triboint.2016.08.018Search in Google Scholar

[12] Mitao Song, Jie Yang, Sritawat Kitipornchai, Bending and buckling analyses of functionally graded polymer composite plates reinforced with graphene nanoplatelets, Composites Part B: Engineering, Volume 134, 106-113, 2018.10.1016/j.compositesb.2017.09.043Search in Google Scholar

[13] Alireza Gharib, Mohammad Saeed Karimi, Ali Ghorbanpour Arani, Vibration analysis of the embedded piezoelectric polymeric nano-composite panels in the elastic substrate, Composites Part B: Engineering, Volume 101, 64-76, 2016.10.1016/j.compositesb.2016.06.077Search in Google Scholar

[14] Hui-Shen Shen, Y. Xiang, Feng Lin, D. Hui, Buckling and post-buckling of functionally graded graphene-reinforced composite laminated plates in thermal environments, Composites Part B: Engineering, Volume 119, 67-78, 2017.10.1016/j.compositesb.2017.03.020Search in Google Scholar

[15] Hui-Shen Shen, Y. Xiang, Feng Lin, Nonlinear vibration of functionally graded graphene-reinforced composite laminated plates in thermal environments, Computer Methods in Applied Mechanics and Engineering, Volume 319,175-193, 2017.10.1016/j.cma.2017.02.029Search in Google Scholar

[16] M. Mirzaei, Y. Kiani, Free vibration of functionally graded carbon nanotube reinforced composite cylindrical panels, Composite Structures, Volume 142, 45-56, 2016.10.1016/j.compstruct.2015.12.071Search in Google Scholar

[17] L.W. Zhang, Z.X. Lei, K.M. Liew, Free vibration analysis of functionally graded carbon nanotube reinforced composite triangular plates using the FSDT and element-free IMLS Ritz method, Composite Structures, Volume 120, 189-199, 2015.10.1016/j.compstruct.2014.10.009Search in Google Scholar

[18] Dongzhi Zhang, Tianhong Cui, Tunable mechanical properties of layer-by-layer self-assembled carbon nanotube/polymer nanocomposite membranes for M/NEMS, Sensors and Actuators A: Physical, Volume 185, 101-108, 2012.10.1016/j.sna.2012.05.050Search in Google Scholar

[19] Tadi Beni, Y., Karimi Zeverdejani, M. Free vibration of microtubules as elastic shell model based on modified couple stress theory. Journal of Mechanics in Medicine and Biology, 15, 1550037, 2015.10.1142/S0219519415500372Search in Google Scholar

[20] Y. Gao, L. An, A nonlocal elastic anisotropic shell model for microtubule buckling behaviors in cytoplasm, Physica E, 42, 2406-2415, 2010.10.1016/j.physe.2010.05.022Search in Google Scholar

[21] Shen HS, Nonlocal shear deformable shell model for bending buckling of microtubules embedded in an elastic medium, Phys Lett A. 374, 4030-4039, 2010.10.1016/j.physleta.2010.08.006Search in Google Scholar

[22] Zeighampour, Hamid, Yaghoub Tadi Beni, and Iman Karimipour. "Material Length Scale and Nonlocal Effects on the Wave Propagation of Composite Laminated Cylindrical Micro/Nanoshells." The European Physical Journal Plus 132, no. 12, 503, 2017.10.1140/epjp/i2017-11770-7Search in Google Scholar

[23] Barretta, R., Luciano, R., Marotti de Sciarra, F., & Ruta, G. Stress-driven nonlocal integral model for Timoshenko elastic nano-beams. European Journal of Mechanics - A/Solids, 72, 275-286, 2018.10.1016/j.euromechsol.2018.04.012Search in Google Scholar

[24] Romano, G., Barretta, R., Diaco, M., & Marotti de Sciarra, F. Constitutive boundary conditions and paradoxes in nonlocal elastic nanobeams. International Journal of Mechanical Sciences, 121, 2017.10.1016/j.ijmecsci.2016.10.036Search in Google Scholar

[25] Barretta, Raffaele, Marko Čanadija, and Francesco Marotti de Sciarra. "A Higher-Order Eringen Model for Bernoulli–Euler Nanobeams." Archive of Applied Mechanics 86, no. 3, 483-495, 2016.10.1007/s00419-015-1037-0Search in Google Scholar

[26] Acierno, S., Barretta, R., Luciano, R., Marotti de Sciarra, F., & Russo, P. Experimental evaluations and modeling of the tensile behavior of polypropylene/single-walled carbon nanotubes fibers. Composite Structures, 174, 12-18, 2017.10.1016/j.compstruct.2017.04.049Search in Google Scholar

[27] Marotti de Sciarra, F. Novel variational formulations for nonlocal plasticity. International Journal of Plasticity, 25(2), 302-331, 2009.10.1016/j.ijplas.2008.02.002Search in Google Scholar

[28] Shengqi Yang, Wanji Chen, On hypotheses of composite laminated plates based on new modified couple stress theory, Composite Structures 133, 46–53, 2015.10.1016/j.compstruct.2015.07.050Search in Google Scholar

[29] Hamid Zeighampour, Yaghoub Tadi Beni, A shear deformable cylindrical shell model based on couple stress theory, Arch Appl Mech. 85, 539–553, 2015.10.1007/s00419-014-0929-8Search in Google Scholar

[30] Zeverdejani MK, Tadi Beni Y, The nano scale vibration of protein microtubules based on modified strain gradient theory, Current Appl Phys 13:1566–1576, 2013.10.1016/j.cap.2013.05.019Search in Google Scholar

[31] Aifantis, E. Update on a Class of Gradient Theories. Vol. 35, 2003.10.1016/S0167-6636(02)00278-8Search in Google Scholar

[32] Askes, Harm, and Inna M. Gitman. "Review and Critique of the Stress Gradient Elasticity Theories of Eringen and Aifantis." In Mechanics of Generalized Continua: One Hundred Years after the Cosserats, edited by Gérard A. Maugin and Andrei V. Metrikine, 203-10. New York, NY: Springer New York, 201010.1007/978-1-4419-5695-8_21Search in Google Scholar

[33] Mehralian, Fahimeh, Yaghoub Tadi Beni, and Mehran Karimi Zeverdejani. "Calibration of Nonlocal Strain Gradient Shell Model for Buckling Analysis of Nanotubes Using Molecular Dynamics Simulations." Physica B: Condensed Matter 521, 102-11, 2017.10.1016/j.physb.2017.06.058Search in Google Scholar

[34] Mehralian, Fahimeh, Yaghoub Tadi Beni, and Mehran Karimi Zeverdejani. "Nonlocal Strain Gradient Theory Calibration Using Molecular Dynamics Simulation Based on Small Scale Vibration of Nanotubes." Physica B: Condensed Matter 514, 61-69, 2017.10.1016/j.physb.2017.03.030Search in Google Scholar

[35] Yaghoub Tadi Beni , Fahimeh Mehralian, A Nonlocal Strain Gradient Shell Model for Free Vibration Analysis of Functionally Graded Shear Deformable Nanotubes, International Journal Of Engineering & Applied Sciences, 9 , 88-102, 201710.24107/ijeas.309818Search in Google Scholar

[36] Barretta, Raffaele, and Francesco Marotti de Sciarra. "Constitutive Boundary Conditions for Nonlocal Strain Gradient Elastic Nano-Beams." International Journal of Engineering Science 130, 187-198, 2018.10.1016/j.ijengsci.2018.05.009Search in Google Scholar

[37] Apuzzo, A., R. Barretta, S. A. Faghidian, R. Luciano, and F.Marotti de Sciarra. "Free Vibrations of Elastic Beams by Modified Nonlocal Strain Gradient Theory." International Journal of EngineeringScience 133, 99-108, 2018.10.1016/j.ijengsci.2018.09.002Search in Google Scholar

[38] Čanađija, Marko, Raffaele Barretta, and Francesco Marotti de Sciarra. "A Gradient Elasticity Model of Bernoulli–Euler Nanobeams in Non-Isothermal Environments." European Journal of Mechanics - A/Solids 55, 243-255, 2016.10.1016/j.euromechsol.2015.09.008Search in Google Scholar

[39] Mindlin RD and Tiersten HF. Effects of couple-stresses in linear elasticity. Arch Ration Mech Anal; 11: 415–448, 1962.10.1007/BF00253946Search in Google Scholar

[40] Hamed Razavi, Asghar Faramarzi Babadi, Yaghoub Tadi Beni, Free vibration analysis of functionally graded piezoelectric cylindrical nanoshell based on consistent couple stress theory, Composite Structures, Volume 160, 1299-1309, 2017.10.1016/j.compstruct.2016.10.056Search in Google Scholar

[41] Zeighampour H and Tadi Beni Y. A shear deformable conical shell formulation in the framework of couple stress theory, Acta Mech. 226: 2607–2629, 2015.10.1007/s00707-015-1318-2Search in Google Scholar

[42] Tadi Beni Y, Koochi A, and Abadyan M. Using modified couple stress theory for modeling the size dependent pull-in instability of torsional nano-mirror under Casimir force. Int J Optomechatronics 2014; 8: 47–7110.1080/15599612.2014.893595Search in Google Scholar

[43] Al-Basyouni KS, Tounsi A and Mahmoud SR. Size dependent bending and vibration analysis of functionally graded micro beams based on modified couple stress theory and neutral surface position. Compos Struct 2015; 125: 621–630.10.1016/j.compstruct.2014.12.070Search in Google Scholar

[44] Jianshi Fang, Jianping Gu, Hongwei Wang Size-dependent three-dimensional free vibration of rotating functionally graded microbeams based on a modified couple stress theory, International Journal of Mechanical Sciences, Volume 136, Pages 188-199, 2018.10.1016/j.ijmecsci.2017.12.028Search in Google Scholar

[45] Shengqi Yang, Wanji Chen, On hypotheses of composite laminated plates based on new modified couple stress theory, Composite Structures 133, 46–53, 2015.10.1016/j.compstruct.2015.07.050Search in Google Scholar

[46] Y Tadi Beni, F Mehralian, M Karimi Zeverdejani, Free vibration of anisotropic single-walled carbon nanotube based on couple stress theory for different chirality, Journal of Low Frequency Noise, Vibration and Active Control 36 (3), 277-293, 2017.10.1177/0263092317700153Search in Google Scholar

[47] YT Beni, F Mehralian, MK Zeverdejani, Size-dependent buckling analysis of different chirality SWCNT under combined axial and radial loading based on orthotropic model, Materials Research Express 4 (6), 065004, 2017.10.1088/2053-1591/aa7318Search in Google Scholar

[48] Junhong Guo, Jiangyi Chen, Ernian Pan, Static deformation of anisotropic layered magnetoelectroelastic plates based on modified couple-stress theory, Composites Part B: Engineering, Volume 107, 84-96, 2016.10.1016/j.compositesb.2016.09.044Search in Google Scholar

[49] YT Beni, MK Zeverdejani, F Mehralian, Buckling analysis of orthotropic protein microtubules under axial and radial compression based on couple stress theory, Mathematical Biosciences 292, 18-29, 2017.10.1016/j.mbs.2017.07.002Search in Google Scholar PubMed

[50] Zihao Yang, Dan He, Vibration and buckling of orthotropic functionally graded micro-plates on the basis of a re-modified couple stress theory, Results in Physics, Volume 7, 3778-3787, 2017.10.1016/j.rinp.2017.09.026Search in Google Scholar

[51] George C. Tsiatas, Aristophanes J. Yiotis, Size effect on the static, dynamic and buckling analysis of orthotropic Kirchhoff-type skew micro-plates based on a modified couple stress theory: comparison with the nonlocal elasticity theory, Acta Mechanica, 226, pp 1267–1281, 2015.10.1007/s00707-014-1249-3Search in Google Scholar

[52] Romano, Giovanni, Raffaele Barretta, and Marina Diaco. "Micromorphic Continua: Non-Redundant Formulations." Continuum Mechanics and Thermodynamics 28, no. 6, 1659-1670, 2016.10.1007/s00161-016-0502-5Search in Google Scholar

[53] Barbagallo, Gabriele, Angela Madeo, Marco Valerio d’Agostino, Rafael Abreu, Ionel-Dumitrel Ghiba, and Patrizio Neff. "Transparent Anisotropy for the Relaxed Micromorphic Model: Macroscopic Consistency Conditions and Long Wave Length Asymptotics." International Journal of Solids and Structures 120, 7-30, 2017.10.1016/j.ijsolstr.2017.01.030Search in Google Scholar

[54] Neff, Patrizio et al. “Real wave propagation in the isotropic-relaxed micromorphic model”Proceedings. Mathematical, physical, and engineering sciences, 473,2197, 20160790, 2017.10.1098/rspa.2016.0790Search in Google Scholar PubMed PubMed Central

[55] Sourki, R., and S. A. Hosseini. "Coupling Effects of Nonlocal and Modified Couple Stress Theories Incorporating Surface Energy on Analytical Transverse Vibration of a Weakened Nanobeam." The European Physical Journal Plus 132, no. 4, 184, 2017.10.1140/epjp/i2017-11458-0Search in Google Scholar

[56] Han, Y, Elliott, J., Molecular dynamics simulations of the elastic properties of polymer/carbon nanotube composites, Computational Materials Science, Vol. 39, pp. 315–323. 2007.10.1016/j.commatsci.2006.06.011Search in Google Scholar

[57] Lin, F, Xiang, Y, Shen, H.S. Temperature dependent mechanical properties of graphene reinforced polymer nanocomposites – a molecular dynamics simulation. 2017, Compos. Part B, Vol. 111, pp. 261-269.10.1016/j.compositesb.2016.12.004Search in Google Scholar

[58] Yunlong Li, Shijie Wang, Quan Wang, Malcolm Xing, A comparison study on mechanical properties of polymer composites reinforced by carbon nanotubes and graphene sheet, Composites Part B: Engineering, Volume 133, Pages 35-41, 2018.10.1016/j.compositesb.2017.09.024Search in Google Scholar

[59] Behrouz Arash, Quan Wang, Vibration of Single-and Double-Layered Graphene Sheets, J. Nanotechnol. Eng.Med, 2(1), 011012, 2011.10.1115/1.4003353Search in Google Scholar

© 2019 M. K. Zeverdejani and Y. T. Beni, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Articles in the same Issue

- Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation

- Artificial neural network for predicting the flexural bond strength of FRP bars in concrete

- Cyclic behavior of GFRP strengthened infilled RC frames with low and normal strength concrete

- Durability of basalt fiber-reinforced polymer bars in wet-dry cycles alkali-salt corrosion

- Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite

- Enhanced dielectric properties of BaTiO3 ceramics with cerium doping, manganese doping and Ce-Mn co-doping

- Free and forced vibration analysis of rectangular/circular/annular plates made of carbon fiber-carbon nanotube-polymer hybrid composites

- Influence of nano-SiO2 on the bonding strength and wear resistance properties of polyurethane coating

- Investigation of wear behavior of nanoalumina and marble dust-reinforced dental composites

- Negative effect of clay fillers on the polyvinyl alcohol biodegradation: technical note

- Photocatalytic activity of Cu2O/ZnO nanocomposite for the decomposition of methyl orange under visible light irradiation

- Sub-surface mechanical properties and sub-surface creep behavior of wood-plastic composites reinforced by organoclay

- Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3

- The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level: FEM based study

- Vibration-damping characterization of the basalt/epoxy composite laminates containing graphene nanopellets

- A review on nanocomposite hydrogels and their biomedical applications

- Optimization and simulation analysis of structure parameters of OPCM ultrasonic longitudinal wave actuating element

- Research Article

- Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings

- Research on preload relaxation for composite pre-tightened tooth connections

- Dough moulding compound reinforced silicone rubber insulating composites using polymerized styrene butadiene rubber as a compatibilizer

- Hydration And Microstructure Of Astm Type I Cement Paste

- Effects of NiO content on the microstructure and mechanical properties of AgSnO2NiO composites

- Overall buckling behaviour of laminated CFRP tubes with off-axis ply orientation in axial compression

- UV sensing optode for composite materials environment monitoring

- On crushing characteristics of hybrid sandwich aluminum-cardboard panels reinforced with glass fiber composite rods

- Preparation and characterization of Ni-Cu composite nanoparticles for conductive paints

- A research on the preparation of oil-adsorbing hydrophobic porous resins by high internal phase emulsions (HIPEs) template

- Material characteristics of random glass-mat-reinforced thermoplastic under cryogenic thermal cycles

- Differentiation of non-black fillers in rubber composites using linear discriminant analysis of principal components

- Research Article

- Efficiency of TiO2 catalyst supported by modified waste fly ash during photodegradation of RR45 dye

- Synthesis and performance of polyurethane/silicon oxide nano-composite coatings

- Study on preparation of magnesium-rich composite coating and performance enhancement by graft modification of epoxy resin

- Research Article

- Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres

- Mechanical Properties of Al 25 wt.% Cu Functionally Graded Material

- Research Article

- Weight reduction of a carbon fibre composite wheel

- Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/ polyvinyl alcohol - magnetite nanocomposites film

- Seismic Behaviour of TRC-Strengthened RC Columns under Different Constraint Conditions

- Characterization of neat and modified asphalt binders and mixtures in relation to permanent deformation

- Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

- Research Article

- Effect of Cutting Temperature on Bending Properties of Carbon Fibre Reinforced Plastics

- Mechanical and tribological properties of B-C-N coatings sliding against different wood balls

- Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix

- Effects of Waste Eggshells addition on Microstructures, Mechanical and Tribological Properties of Green Metal Matrix Composite

- Investigation of porosity effect on flexural analysis of doubly curved FGM conoids

- Review Article

- Utilization of tailings in cement and concrete: A review

- Research Article

- Equivalent stiffness prediction and global buckling analysis using refined analytical model of composite laminated box beam

- Mechanochemical synthesis of zincite doped with cadmium in various amounts

- Size-dependent vibration analysis of graphene-PMMA lamina based on non-classical continuum theory

- Automated, Quality Assured and High Volume Oriented Production of Fiber Metal Laminates (FML) for the Next Generation of Passenger Aircraft Fuselage Shells

- Research Article

- An investigation of the stitching effect on single lap shear joints in laminated composites

- The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Effect of granulometric distribution on electromagnetic shielding effectiveness for polymeric composite based on natural graphite

- The enhancement of filament winding in marine launching rubber gasbag

- Research on ELID Grinding Mechanism and Process Parameter Optimization of Aluminum-Based Diamond Composites for Electronic Packaging

Articles in the same Issue

- Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation

- Artificial neural network for predicting the flexural bond strength of FRP bars in concrete

- Cyclic behavior of GFRP strengthened infilled RC frames with low and normal strength concrete

- Durability of basalt fiber-reinforced polymer bars in wet-dry cycles alkali-salt corrosion

- Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite

- Enhanced dielectric properties of BaTiO3 ceramics with cerium doping, manganese doping and Ce-Mn co-doping

- Free and forced vibration analysis of rectangular/circular/annular plates made of carbon fiber-carbon nanotube-polymer hybrid composites

- Influence of nano-SiO2 on the bonding strength and wear resistance properties of polyurethane coating

- Investigation of wear behavior of nanoalumina and marble dust-reinforced dental composites

- Negative effect of clay fillers on the polyvinyl alcohol biodegradation: technical note

- Photocatalytic activity of Cu2O/ZnO nanocomposite for the decomposition of methyl orange under visible light irradiation

- Sub-surface mechanical properties and sub-surface creep behavior of wood-plastic composites reinforced by organoclay

- Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3

- The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level: FEM based study

- Vibration-damping characterization of the basalt/epoxy composite laminates containing graphene nanopellets

- A review on nanocomposite hydrogels and their biomedical applications

- Optimization and simulation analysis of structure parameters of OPCM ultrasonic longitudinal wave actuating element

- Research Article

- Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings

- Research on preload relaxation for composite pre-tightened tooth connections

- Dough moulding compound reinforced silicone rubber insulating composites using polymerized styrene butadiene rubber as a compatibilizer

- Hydration And Microstructure Of Astm Type I Cement Paste

- Effects of NiO content on the microstructure and mechanical properties of AgSnO2NiO composites

- Overall buckling behaviour of laminated CFRP tubes with off-axis ply orientation in axial compression

- UV sensing optode for composite materials environment monitoring

- On crushing characteristics of hybrid sandwich aluminum-cardboard panels reinforced with glass fiber composite rods

- Preparation and characterization of Ni-Cu composite nanoparticles for conductive paints

- A research on the preparation of oil-adsorbing hydrophobic porous resins by high internal phase emulsions (HIPEs) template

- Material characteristics of random glass-mat-reinforced thermoplastic under cryogenic thermal cycles

- Differentiation of non-black fillers in rubber composites using linear discriminant analysis of principal components

- Research Article

- Efficiency of TiO2 catalyst supported by modified waste fly ash during photodegradation of RR45 dye

- Synthesis and performance of polyurethane/silicon oxide nano-composite coatings

- Study on preparation of magnesium-rich composite coating and performance enhancement by graft modification of epoxy resin

- Research Article

- Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres

- Mechanical Properties of Al 25 wt.% Cu Functionally Graded Material

- Research Article

- Weight reduction of a carbon fibre composite wheel

- Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/ polyvinyl alcohol - magnetite nanocomposites film

- Seismic Behaviour of TRC-Strengthened RC Columns under Different Constraint Conditions

- Characterization of neat and modified asphalt binders and mixtures in relation to permanent deformation

- Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

- Research Article

- Effect of Cutting Temperature on Bending Properties of Carbon Fibre Reinforced Plastics

- Mechanical and tribological properties of B-C-N coatings sliding against different wood balls

- Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix

- Effects of Waste Eggshells addition on Microstructures, Mechanical and Tribological Properties of Green Metal Matrix Composite

- Investigation of porosity effect on flexural analysis of doubly curved FGM conoids

- Review Article

- Utilization of tailings in cement and concrete: A review

- Research Article

- Equivalent stiffness prediction and global buckling analysis using refined analytical model of composite laminated box beam

- Mechanochemical synthesis of zincite doped with cadmium in various amounts

- Size-dependent vibration analysis of graphene-PMMA lamina based on non-classical continuum theory

- Automated, Quality Assured and High Volume Oriented Production of Fiber Metal Laminates (FML) for the Next Generation of Passenger Aircraft Fuselage Shells

- Research Article

- An investigation of the stitching effect on single lap shear joints in laminated composites

- The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Effect of granulometric distribution on electromagnetic shielding effectiveness for polymeric composite based on natural graphite

- The enhancement of filament winding in marine launching rubber gasbag

- Research on ELID Grinding Mechanism and Process Parameter Optimization of Aluminum-Based Diamond Composites for Electronic Packaging