Abstract

Dough moulding compound (DMC) reinforced polymerized styrene butadiene rubber (SBR) / methyl vinyl silicone rubber (MVQ) composites were prepared, in which MVQ was matrix, DMC was a reinforcement phase and SBR was a compatibilizer. Dynamic thermomechanical analysis (DMA), infrared spectrum analysis (IR) and the effect of SBR and DMC content on mechanical properties, electrical insulating property and compatibility of the composites were investigated. The results showd that the morphology and thermal properties of the composites were improved when dough moulding compound was used as a reinforcement, and styrene butadiene rubber was compatibilizer, and had excellent insulating property with volume resistivity above 4.8×1012 Ω·m.

1 Introduction

The various abilities and power in human production and life are provided by the energy sources. From this view, the energy is the important material foundation of national economy, and depends on its control in the future world [1]. However, the existing energy shortage is becoming more and more serious, and the energy waste is also very serious, thus it has become the focus topic problem [2]. Based on this background, the use of nuclear power to generate energy has become one of the important ways to solve this problem [3, 4]. The development of nuclear power brings

a broad development space for the cable materials of distributing the electricity produced by the nuclear power; actively researching and developing cable materials for nuclear power plants are of great significance for the use of nuclear energy [5]. As a material of nuclear power cables, silicone rubber is a kind of cable insulating material with high quality [6]. The thermal degradation resistance of silicone rubber is the best in all kinds of rubbers [7, 8]; silicone rubber also has excellent weather resistance, aging resistance and good electrical insulating properties, which make it irreplaceable by other materials [9]. However, the mechanical properties of silicone rubber are poor [10, 11]; the addition of inorganic filler, such as silica, to reinforce rubber composite systems has been researched for several decades [12, 13, 14, 15], thus the need for further research. On the other hand, in recent years scholars at home and abroad have been focusing attention on the research of fiber reinforced rubber composites [16, 17, 18, 19]. Therefore, a dough moulding compound (DMC), of which is a uniform mixture mainly made of glass fibers and unsaturated polyester with the excellent mechanical properties and electrical insulation properties [20], was adopted to reinforce methyl vinyl silicone rubber (MVQ) in this work. In addition, polymerized styrene butadiene rubber (SBR) has many branched chains, as a result, the space between the molecular backbones was large, which makes the compatibility between MVQ and DMC is good; and SBR with MVQ and unsaturated polyester in the DMC are all organic compounds, according to the similar chemical materials dissolve mutually theory, thus the SBR was added to improve the compatibility of DMC and MVQ, and the influencing factors on the properties of the DMC / SBR / MVQ composites were investigated.

2 Materials and methods

2.1 Materials

Polymerized styrene butadiene rubber (SBR 1500, styrene and butadiene copolymer in the emulsion polymerization, styrene content is 23%, ML1001+4 viscosity is 51), as a result of our research is the insulation material, so we choose a non-oil-extended rubber SBR 1500 of excellent mechanical properties. The methyl vinyl silicone rubber (MVQ, the number average molecular weight is 5.8×106 and the vinyl content is 0.09 wt%) was supplied by DC Chejue Organic Silicon Aggregation Group (China). Dough moulding compound (DMC), as an industry product, was obtained from Harbin Insulated Material Factory (China); it was a uniform mixture made up of 21% (mass percentage) unsaturated polyester (UP), 8% ethyl methyl ketone peroxide, 1% styrolene, 50% calcium carbonate, and 20% short glass fibres. Butadiene rubber (BR 9000, 1,4-cis-content 96%, ML1001+4 viscosity is 45, number-average molecular weight 6.0 ×105) was purchased from Shanghai Yuda Petroleum Chemical Industry Co., LTD. (China). Ethylene propylene diene monomer (EPDM Z3080P, ethylene/propylene is 80/20, a ethylene propylene diene tripolymer) was supplied by Jilin Chemical Industrial LTD (China). Butadiene acrylonitrile rubber (NBR 230, a acrylonitrile butadiene copolymer, ML1001+4 viscosity is 56, acrylonitrile content is 35%, prepared by emulsion polymerization) were supplied by China National Petroleum Corporation (China). Silica (383) was obtained from Qingdao Sweet Silica Co., LTD (China). Acrylate rubber (ACM200,ML1001+4 viscosity is 40, a ethyl acrylate copolymer) was supplied by Suining Qinglong Poryacrylate Rubber Manufactory (China). The other agents are all common commercially available materials and were obtained in the market (China).

2.2 Sample preparation

The fundamental formulation of the blends was 100 phr (parts per hundred rubber) reletive to total rubber components (MVQ + other rubber), 45 phr silica, 50 phr DMC, 1.5 phr sulfur accelerant M, 4 phr dicumyl peroxide (DCP), 2 phr zinc oxide (ZnO), 2 phr ferric oxide (Fe2O3), and 1 phr antioxidant D.

The MVQ and SBR were masticated on a XK-160 two-roll mill (Tianjin Electrical Machinery Plant, China) with the nip gap about 0.5 mm, at 45∘C for 5 min. After that, adjusting roll temperature to 55∘C and nip gap to 1.0 ~ 2.0 mm, various other ingredients (silica, Fe2O3, DCP, sulphur accelerant M, antioxidant D and ZnO) were added and mixed for 20 min. Then the mixture was mixed with the masticated-DMC about 5 min. Finally the mixture was cured in an electrically heated hydraulic press (XLB-D350 × 350, Shanghai First Rubber Machinery Co., LTD, China) at 175∘C under pressure of 1.2 MPa for 10 min. Heat aging test samples were obtained by putting samples in an aging box (401B, Jiangdu True Power Machinery Co., LTD, China) at 200∘C under normal pressure for 2 hours.

2.3 Physical and mechanical analysis

The mechanical properties of the blends, such as tensile strength and elongation at break, were determined by a universal testing instrument (model CSS-2200, Zhongji Application Technical Institute, China) with a strain rate of 100 mm/min according to the ASTMD638 method. Heat aging of the samples was measured according to ISO 188-1998. For each of the measurements, with the average reported at least five readings were taken, errors in the measurement of mechanical properties were within 10%.

The oxygen index refers to the minimum oxygen concentration required for flame burning in an oxygen-nitrogen mixed gas stream under specified conditions, expressed as a percentage of the volume of oxygen. The oxygen index is high indicates that the material is not easy to burn, on the contrary, the low oxygen index means that the material is easy to burn. The oxygen index of the samples was measured with an oxygen index apparatus (model HC-2, Jiangning County Analysis Instrument Factory, China) according to ISO 4589.1-1996.

The electrical volume resistivity, the current impedance of the material per unit volume, was used to characterize the electrical properties of the material. Generally, the higher the volume resistivity is, the better the electrical insulation properties of the material are. In this test, the electrical volume resistivity of the samples was conducted according to IEC 93-1980.

2.4 Dynamic thermomechanical analysis

The dynamic thermomechanical analysis was performed using a dynamic mechanical analyzer (model Q800, TA Instrument Co., USA). The temperatures of the tests ranged from −150 to 100∘C, with a 3∘C/min heating rate. The frequency was 1 Hz and the oscillation amplitude was 15 μm. The measurement was carried out using the single cantilever clamp mode on a rectangular sample of size 30 × 12 × 1 mm3.

2.5 Morphological analysis

The infrared spectra of the samples were recorded by using Fourier transform infrared spectrometer (FTIR; model Spectrum One, PEKINElMER Co. Ltd., USA), FTIR spectra were collected after 256 scans at 2 cm−1 resolution among the region of 4000-500 cm−1 at room temperature.

The samples were fractured in liquid nitrogen, then the fracture surface was sputtered with gold and the fracture morphology of the sampleswas observed by scanning electron microscopy (SEM, model S-4300, Hitachi Limited, Japan).

3 Results and discussion

3.1 Effect of various rubbers on the mechanical and oxygen index of the composites

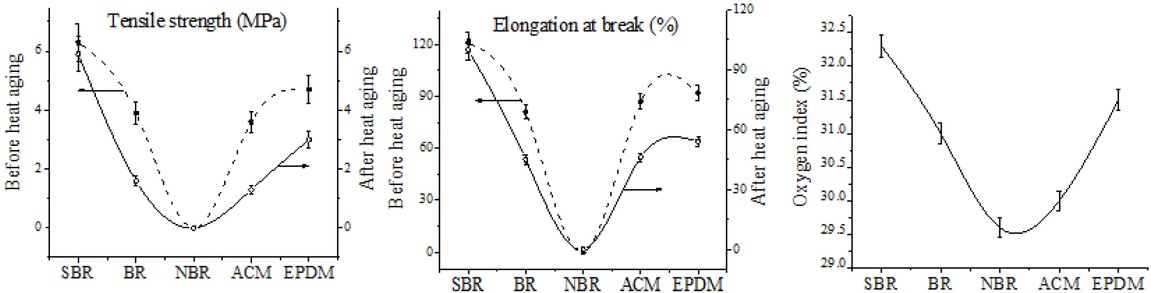

The methyl group on silicone rubber can revolve around the -Si-O- bond axis; the spacing of Si and O on neighboring molecules is large and the inter-molecular forces are small, which leads to the poor mechanical properties of silicone rubber. The performance of silicone rubber can be significantly improved by adding silica and DMC, but it is not sufficient. Silicone rubber possesses chemical inertness, according to the chemical materials similar dissolve mutually theory, various rubbers with good mechanical properties were used as a compatibilizer between the DMC and MVQ to improve the mechanical properties of MVQ and the comprehensive performance of the composites, and the blends of MVQ and the various rubbers were the matrices. The effect of the various rubbers on the mechanical properties and the oxygen index of the composites are shown in Figure 1 (DMC / rubber / MVQ = 50 / 20 / 80, the heat aging was done at 200∘C for 24 hours in air).

Mechanical properties and the oxygen index of various rubber filled DMC/MVQ composites (DMC/rubber/MVQ = 50/20/80).

The mechanical properties of the DMC reinforced MVQ composites were best when SBR was selected as the compatibilizer in the Figure 1, followed by EPDM, and no test data were obtained due to poor compatibility between NBR and MVQ, resulting in no prepared rubber sheet. The mechanical properties of the composites were poor when the BR or ACM was used as a compatibilizer. It is interpreted as MVQ and SBR are both non-polar rubber, they can combine together well according to the chemical materials similar dissolve mutually theory; in addition, the relative molecular weight of MVQ was smaller than that of SBR, and the SBR has many branched chains, as a result, the space between the molecular backbones was large, which makes the compatibility between MVQ and SBR good; thus the addition of SBR improved the mechanical properties of the composites. And the oxygen index of the sample with the SBR as the compatibilizer was the largest, so the comprehensive properties of the proposed electrical insulating materials were best when the compatibilizer of DMC/MVQ was SBR.

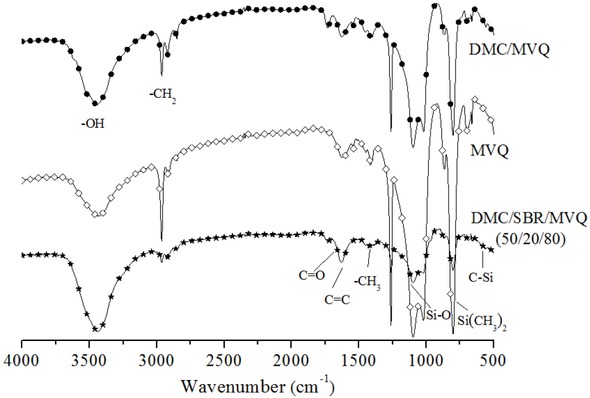

Furthermore, it could be seen from Figure 2 that the curve of DMC / SBR / MVQ retained the absorption peaks of C-H of CH2 (2920 cm−1) or CH3 (1430 cm−1), C=C (1630 cm−1), and Si-O (1131 cm−1) characteristic peak formed by MVQ and silica. Compared with the MVQ curve, new absorption peak of C=O bond at 1730 cm−1 appeared in the DMC/SBR/MVQ curve, it was caused by C=O bond of the unsaturated polyester in the DMC, and the absorption peak of Si(CH3)2 at 802 cm−1 decreased with the addition of SBR and/or DMC, and the absorption peak of C-Si bond appeared in the curve of DMC/ SBR /MVQ; it was due to the MVQ reacted with the C=C bond of SBR and generated C-Si bond, it further explained that MVQ and SBR had cross-linked reaction, and thus proved the inevitability of the results in Figure 1.

FTIR spectra of DMC/SBR/MVQ composites.

3.2 Effect of SBR content on the mechanical and oxygen index of the composites

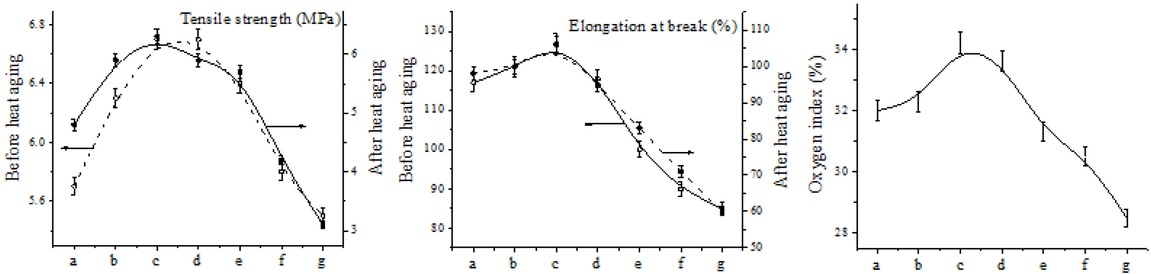

It could be seen from Figure 3 that with the addition of the SBR, the tensile strength, elongation at break and the oxygen index of all samples increased first and then decreased. Compared with the mechanical properties of all samples before and after heat aging, it is obviously observed that the tensile strength, elongation at break and oxygen index of the DMC / SBR / MVQ composites were best when the SBR / MVQ mass ratio was 25 / 75. It can be interpreted that a small quantity of SBR can not affect the properties of the composites, whereas too much SBR will increase the rigidity of the blends, the SBR is major component when SBR content is 50, 60 phr, the bending and tearing of the SBR is poor, so the properties of the DMC/SBR/MVQcomposites get worse.

Mechanical properties and the oxygen index of DMC/SBR/MVQ composites.(a:50/0/100, b:50/20/80, c:50/25/75, d:50/30/70, e:50/40/60, f:50/50/50, g:50/60/40).

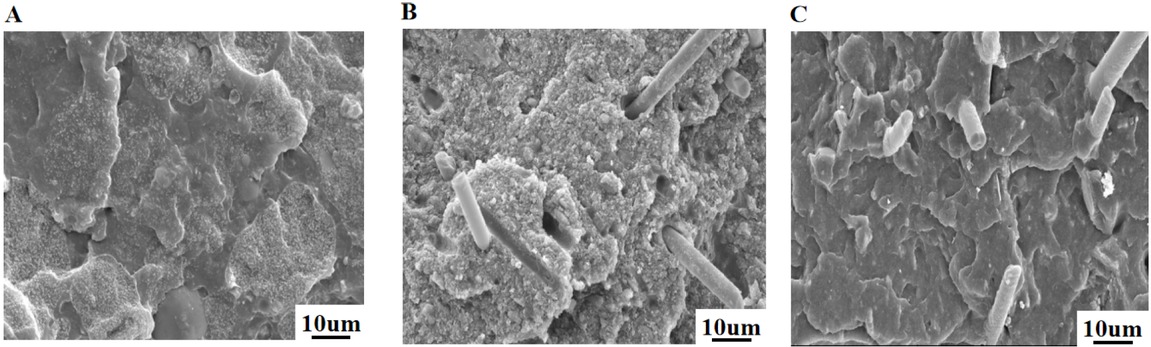

In addition, compared with Figure 4A, Figure 4B existed obvious separation phenomenon between DMC and MVQ; the fracture surface was rough on a local scale, it showed that the compatibility between DMC and MVQ was poor. However, the DMC dispersed in the rubber evenly in Figure 4C, the fracture surface of the sample was flat and smooth, it indicated that the rubber and DMC combined tightly. It suggested that the addition of SBR improved the compatibility between DMC and MVQ, and the mechanical properties of the composites were improved, too. Therefore, we concluded that the best mass ratio of SBR / MVQ was 25 / 75 when DMC content was 50.

SEM images of (A) DMC/SBR/MVQ (0/0/100), (B) DMC/SBR/MVQ (60/0/100) and (C) DMC/SBR/MVQ (60/25/75).

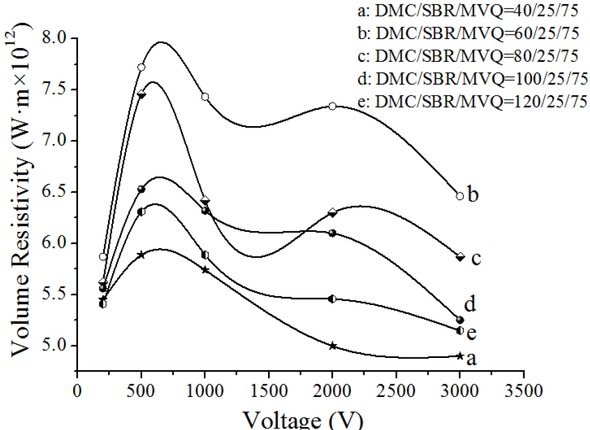

3.3 Effect of DMC content on electrical volume resistivity of the composites

In order to prevent the insulating materials occurring current leakage or breakdown in the process of use, the insulating materials must possess and retain excellent electrical insulating properties. The volume resistivity was used in this experiment to characterize the electrical insulating properties of the blends. DMC has better electrical insulation than rubber matrix, so the addition of DMC can enhance the electrical insulating property of the composites. The effect of DMC content on the volume resistivity of the composites was characterized. It can be seen from Figure 5 that with the increase of voltage, the volume resistivity of all samples increased first and then decreased. The volume resistivity of DMC / SBR / MVQ composites with various mass ratio were all above 4.8×1012 Ω·m; for 500 V applied voltage, the volume resistivity was largest when the mass ratio of DMC / SBR / MVQ was 60 / 25 / 75, it illustrates that the composites have excellent electrical insulating property. But the electrical insulating property decreased when the DMC content was less than or more than 60. It might be due to too small an amount of DMC were not enough to improve the insulating effect, whereas too much DMC could not disperse homogeneously and even aggregate together, which led to some flaws appearing in the matrix, as a result, the electrical insulating property of the composites decreased.

Volume resistivity of DMC/SBR/MVQ composites.

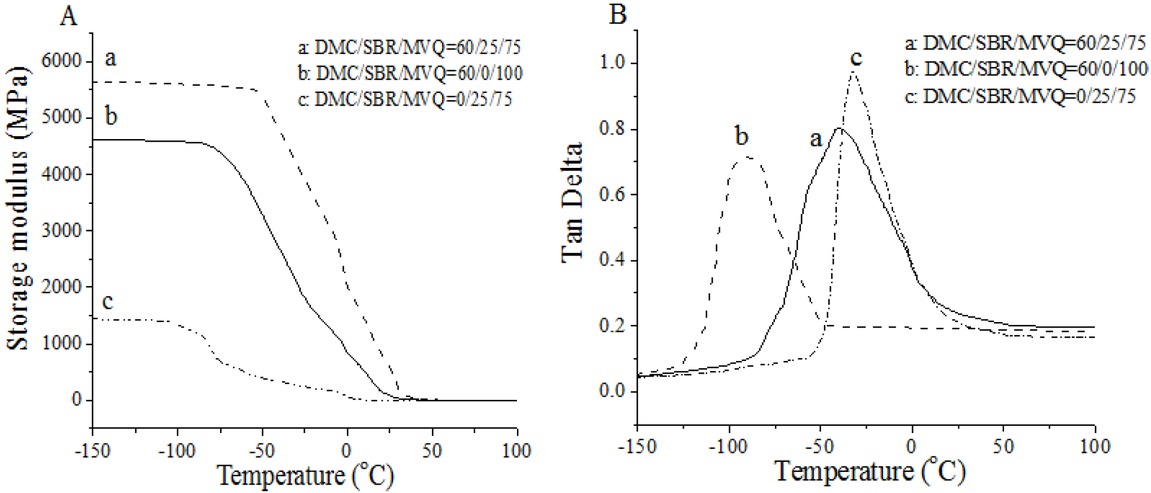

3.4 DMA analysis of DMC/SBR/MVQ composites

It can be seen from Figure 6A that at the same temperature, the storage modulus (E′) of the DMC / SBR / MVQ composites were in the order 60 / 25 / 75 (mass ratio) & 60 / 0 / 100 & 0 / 25 / 75; the E′ of the sample with DMC was obviously higher than those without DMC. It can be assumed that the E′ represents the elasticity of the materials; the DMC was more rigid than rubber no matter whether in the glass state or high elastic state; the DMC in the matrix could generate chemical cross-linking or physical tangles with the molecular chains of rubbers, on one hand, it could load part of the mechanical stress when the samples were stretched or compressed in the test, on the other hand, it could limit the movement of the molecular chains of rubbers. Therefore, the E′ of DMC reinforced composites were significantly higher than those without DMC below Tg. In addition, the E′ of the DMC / SBR / MVQ (60 / 0 / 100) was lower than that of the DMC/ SBR /MVQ (60 / 25 / 75), it was probably due to the poor compatibility between DMC and MVQ. Moreover, The glass fiber in the DMC, playing a stiffening role, can be well-distributed in rubber blends of SBR /MVQ, the unsaturated polyester in the DMC can cross-link with SBR / MVQ and form a large number of across-link; thus the addition of DMC blocked the motion of molecular chain segments of SBR / MVQ blend rubbers, and therefore the thermal stability of the composites was improved as well. Figure 6A also showed that the turning points in the curves, with the addition of the DMC, gradually moved in the direction of high temperature; it suggests that the addition of the DMC can increase the Tg of the composites.

Storage modulus–temperature curves and Tan δ–temperature curves of DMC/SBR/MVQ composites.

It can be seen from Figure 6B that there was only a glass transition temperature (Tg) for the DMC / SBR / MVQ composites with various mass ratio; the area of the tan δ peak was widest when the mass ratio of DMC / SBR / MVQ was 60 / 25 / 75; it suggests this was due to limited miscibility of the various components; the SBR and MVQ were only partially miscible. On the other hand, the DMC can fully disperse in rubbers, improving the interface action between components, limiting the movement of the chain segments of rubbers. So, the Tg of DMC / SBR / MVQ (60 / 25 / 75) was higher than that of DMC / SBR / MVQ (0 / 25 / 75).

4 Conclusions

The compatibility and mechanical properties of the DMC / MVQ composites were improved by the SBR as a compatibilizer, and the best mass ratio of DMC / SBR / MVQ was 60 / 25 / 75. The electrical volume resistivities of the composites were all above 4.8×1012 Ω·m, when the mass ratio of DMC / SBR / MVQ was determined as 60 / 25 / 75, the composites had the largest volume resistivity value and excellent electrical insulating property. Compared with the DMC/MVQor SBR /MVQcomposites, the E′ of DMC/ SBR / MVQ was the largest and the area of the tan δ peak was the widest. MVQ reacted with SBR and generated C-Si bond, the glass fiber in the DMC, playing a stiffening role, can be well-distributed in the DMA/ SBR / MVQ and improve the thermal property of the composites.

Acknowledgement

This work was financially supported by Fundamental Research Funds in Heilongjiang Provincial Universities of China (No. YSTSXK201864).

References

[1] Van Leeuwen RP, De Wit JB, Smit GJM. Energ. Convers. Manage. 2017, 150, 941-948.10.1016/j.enconman.2017.05.081Search in Google Scholar

[2] Olabi AG. Energy 2017, 136, 1-6.10.1016/j.energy.2017.07.054Search in Google Scholar

[3] Vidadili N, Suleymanov E, Bulut C, Mahmudlu C. Renew. Sust. Energ. Rev. 2017, 80, 1153-1161.10.1016/j.rser.2017.05.168Search in Google Scholar

[4] Gielen D, Boshell F, Saygin D, Bazilian MD, Wagner N, Gorini R. Energy Strateg. Rev. 2019, 24, 38-50.10.1016/j.esr.2019.01.006Search in Google Scholar

[5] Thellufsen JZ, Lund H. Appl. Energ. 2016, 183, 419-429.10.1016/j.apenergy.2016.09.005Search in Google Scholar

[6] Samakosh JD, Mirzaie M. Int. J. Elec. Power. 2019, 108, 382-391. [7] Patil Y, Sharma S. Sci. Eng. Compos. Mater. 2018, 25, 517–528.10.1016/j.ijepes.2019.01.028Search in Google Scholar

[7] Patil Y, Sharma S. Sci. Eng. Compos. Mater. 2018, 25, 517–528.10.1515/secm-2016-0167Search in Google Scholar

[8] Matsuura K, Saito H. J. Appl. Polym. Sci. 2018, 135, 46192.10.1002/app.46192Search in Google Scholar

[9] Aouabed F, Bayadi A, Boudissa R. Electr. Pow. Syst. Res. 2017, 143, 66-72.10.1016/j.epsr.2016.10.025Search in Google Scholar

[10] Terrab H, Kara A. Electr. Pow. Syst. Res. 2018.163. 782-788.10.1016/j.epsr.2017.06.002Search in Google Scholar

[11] Rezazadeh N, Rezazadeh J. J. Magn. Magn. Mater. 2019, 475, 201-204.10.1016/j.jmmm.2018.11.117Search in Google Scholar

[12] Esmizadeh E, Naderi G, Arezoomand S, Mazinani S. Sci. Eng. Compos. Mater. 2018, 25, 31–39.10.1515/secm-2015-0406Search in Google Scholar

[13] Kumar V, Lee DJ. Chem. Phys. Lett. 2019. 715. 195-203.10.1016/j.cplett.2018.11.042Search in Google Scholar

[14] Kong JH, Sun JT, Tong YJ, Dou QQ, He CB. Compos. Sci. Technol. 2019. 169. 232-241.10.1016/j.compscitech.2018.11.006Search in Google Scholar

[15] Khattak A, Iqbal M, Amin M. Sci. Eng. Compos. Mater. 2017, 24, 679-689.10.1515/secm-2015-0327Search in Google Scholar

[16] Park HW, Park JW, Lee JH, Kim HJ, Shin S. Eur. Polym. J. 2019, 112, 320-327.10.1016/j.eurpolymj.2019.01.021Search in Google Scholar

[17] Bui R, Brook MA. Polymer 2019, 160, 282-290.10.1016/j.polymer.2018.11.043Search in Google Scholar

[18] Wu WL, Cai JY. Adv. Mater. Res. 2013, 800, 383-386.10.4028/www.scientific.net/AMR.800.383Search in Google Scholar

[19] Lipińska M, Imiela M. Polym. Test. 2019, 75, 26-37.10.1016/j.polymertesting.2019.01.020Search in Google Scholar

[20] Moni Ribeiro Filho SL, Oliveira PR, Panzera TH, Scarpa F. Compos. Part B-Eng. 2019, 159, 157-164.10.1016/j.compositesb.2018.09.054Search in Google Scholar

© 2019 W. Wu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Articles in the same Issue

- Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation

- Artificial neural network for predicting the flexural bond strength of FRP bars in concrete

- Cyclic behavior of GFRP strengthened infilled RC frames with low and normal strength concrete

- Durability of basalt fiber-reinforced polymer bars in wet-dry cycles alkali-salt corrosion

- Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite

- Enhanced dielectric properties of BaTiO3 ceramics with cerium doping, manganese doping and Ce-Mn co-doping

- Free and forced vibration analysis of rectangular/circular/annular plates made of carbon fiber-carbon nanotube-polymer hybrid composites

- Influence of nano-SiO2 on the bonding strength and wear resistance properties of polyurethane coating

- Investigation of wear behavior of nanoalumina and marble dust-reinforced dental composites

- Negative effect of clay fillers on the polyvinyl alcohol biodegradation: technical note

- Photocatalytic activity of Cu2O/ZnO nanocomposite for the decomposition of methyl orange under visible light irradiation

- Sub-surface mechanical properties and sub-surface creep behavior of wood-plastic composites reinforced by organoclay

- Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3

- The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level: FEM based study

- Vibration-damping characterization of the basalt/epoxy composite laminates containing graphene nanopellets

- A review on nanocomposite hydrogels and their biomedical applications

- Optimization and simulation analysis of structure parameters of OPCM ultrasonic longitudinal wave actuating element

- Research Article

- Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings

- Research on preload relaxation for composite pre-tightened tooth connections

- Dough moulding compound reinforced silicone rubber insulating composites using polymerized styrene butadiene rubber as a compatibilizer

- Hydration And Microstructure Of Astm Type I Cement Paste

- Effects of NiO content on the microstructure and mechanical properties of AgSnO2NiO composites

- Overall buckling behaviour of laminated CFRP tubes with off-axis ply orientation in axial compression

- UV sensing optode for composite materials environment monitoring

- On crushing characteristics of hybrid sandwich aluminum-cardboard panels reinforced with glass fiber composite rods

- Preparation and characterization of Ni-Cu composite nanoparticles for conductive paints

- A research on the preparation of oil-adsorbing hydrophobic porous resins by high internal phase emulsions (HIPEs) template

- Material characteristics of random glass-mat-reinforced thermoplastic under cryogenic thermal cycles

- Differentiation of non-black fillers in rubber composites using linear discriminant analysis of principal components

- Research Article

- Efficiency of TiO2 catalyst supported by modified waste fly ash during photodegradation of RR45 dye

- Synthesis and performance of polyurethane/silicon oxide nano-composite coatings

- Study on preparation of magnesium-rich composite coating and performance enhancement by graft modification of epoxy resin

- Research Article

- Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres

- Mechanical Properties of Al 25 wt.% Cu Functionally Graded Material

- Research Article

- Weight reduction of a carbon fibre composite wheel

- Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/ polyvinyl alcohol - magnetite nanocomposites film

- Seismic Behaviour of TRC-Strengthened RC Columns under Different Constraint Conditions

- Characterization of neat and modified asphalt binders and mixtures in relation to permanent deformation

- Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

- Research Article

- Effect of Cutting Temperature on Bending Properties of Carbon Fibre Reinforced Plastics

- Mechanical and tribological properties of B-C-N coatings sliding against different wood balls

- Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix

- Effects of Waste Eggshells addition on Microstructures, Mechanical and Tribological Properties of Green Metal Matrix Composite

- Investigation of porosity effect on flexural analysis of doubly curved FGM conoids

- Review Article

- Utilization of tailings in cement and concrete: A review

- Research Article

- Equivalent stiffness prediction and global buckling analysis using refined analytical model of composite laminated box beam

- Mechanochemical synthesis of zincite doped with cadmium in various amounts

- Size-dependent vibration analysis of graphene-PMMA lamina based on non-classical continuum theory

- Automated, Quality Assured and High Volume Oriented Production of Fiber Metal Laminates (FML) for the Next Generation of Passenger Aircraft Fuselage Shells

- Research Article

- An investigation of the stitching effect on single lap shear joints in laminated composites

- The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Effect of granulometric distribution on electromagnetic shielding effectiveness for polymeric composite based on natural graphite

- The enhancement of filament winding in marine launching rubber gasbag

- Research on ELID Grinding Mechanism and Process Parameter Optimization of Aluminum-Based Diamond Composites for Electronic Packaging

Articles in the same Issue

- Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation

- Artificial neural network for predicting the flexural bond strength of FRP bars in concrete

- Cyclic behavior of GFRP strengthened infilled RC frames with low and normal strength concrete

- Durability of basalt fiber-reinforced polymer bars in wet-dry cycles alkali-salt corrosion

- Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite

- Enhanced dielectric properties of BaTiO3 ceramics with cerium doping, manganese doping and Ce-Mn co-doping

- Free and forced vibration analysis of rectangular/circular/annular plates made of carbon fiber-carbon nanotube-polymer hybrid composites

- Influence of nano-SiO2 on the bonding strength and wear resistance properties of polyurethane coating

- Investigation of wear behavior of nanoalumina and marble dust-reinforced dental composites

- Negative effect of clay fillers on the polyvinyl alcohol biodegradation: technical note

- Photocatalytic activity of Cu2O/ZnO nanocomposite for the decomposition of methyl orange under visible light irradiation

- Sub-surface mechanical properties and sub-surface creep behavior of wood-plastic composites reinforced by organoclay

- Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3

- The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level: FEM based study

- Vibration-damping characterization of the basalt/epoxy composite laminates containing graphene nanopellets

- A review on nanocomposite hydrogels and their biomedical applications

- Optimization and simulation analysis of structure parameters of OPCM ultrasonic longitudinal wave actuating element

- Research Article

- Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings

- Research on preload relaxation for composite pre-tightened tooth connections

- Dough moulding compound reinforced silicone rubber insulating composites using polymerized styrene butadiene rubber as a compatibilizer

- Hydration And Microstructure Of Astm Type I Cement Paste

- Effects of NiO content on the microstructure and mechanical properties of AgSnO2NiO composites

- Overall buckling behaviour of laminated CFRP tubes with off-axis ply orientation in axial compression

- UV sensing optode for composite materials environment monitoring

- On crushing characteristics of hybrid sandwich aluminum-cardboard panels reinforced with glass fiber composite rods

- Preparation and characterization of Ni-Cu composite nanoparticles for conductive paints

- A research on the preparation of oil-adsorbing hydrophobic porous resins by high internal phase emulsions (HIPEs) template

- Material characteristics of random glass-mat-reinforced thermoplastic under cryogenic thermal cycles

- Differentiation of non-black fillers in rubber composites using linear discriminant analysis of principal components

- Research Article

- Efficiency of TiO2 catalyst supported by modified waste fly ash during photodegradation of RR45 dye

- Synthesis and performance of polyurethane/silicon oxide nano-composite coatings

- Study on preparation of magnesium-rich composite coating and performance enhancement by graft modification of epoxy resin

- Research Article

- Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres

- Mechanical Properties of Al 25 wt.% Cu Functionally Graded Material

- Research Article

- Weight reduction of a carbon fibre composite wheel

- Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/ polyvinyl alcohol - magnetite nanocomposites film

- Seismic Behaviour of TRC-Strengthened RC Columns under Different Constraint Conditions

- Characterization of neat and modified asphalt binders and mixtures in relation to permanent deformation

- Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

- Research Article

- Effect of Cutting Temperature on Bending Properties of Carbon Fibre Reinforced Plastics

- Mechanical and tribological properties of B-C-N coatings sliding against different wood balls

- Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix

- Effects of Waste Eggshells addition on Microstructures, Mechanical and Tribological Properties of Green Metal Matrix Composite

- Investigation of porosity effect on flexural analysis of doubly curved FGM conoids

- Review Article

- Utilization of tailings in cement and concrete: A review

- Research Article

- Equivalent stiffness prediction and global buckling analysis using refined analytical model of composite laminated box beam

- Mechanochemical synthesis of zincite doped with cadmium in various amounts

- Size-dependent vibration analysis of graphene-PMMA lamina based on non-classical continuum theory

- Automated, Quality Assured and High Volume Oriented Production of Fiber Metal Laminates (FML) for the Next Generation of Passenger Aircraft Fuselage Shells

- Research Article

- An investigation of the stitching effect on single lap shear joints in laminated composites

- The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Effect of granulometric distribution on electromagnetic shielding effectiveness for polymeric composite based on natural graphite

- The enhancement of filament winding in marine launching rubber gasbag

- Research on ELID Grinding Mechanism and Process Parameter Optimization of Aluminum-Based Diamond Composites for Electronic Packaging