Abstract

Polymers are widely used as replacements for machined metal components in engineering applications. To withstand extreme contact conditions, reinforcing materials are often introduced into polymers to improve their mechanical and wear properties. This paper investigates the applicability of basalt fibres as reinforcing materials to enhance the mechanical and wear properties of polyetheretherketone (PEEK). The weight percentage of short basalt fibres in PEEK composites was 0-10% based on the injection moulding method. The mechanical properties and tribological behaviours of the resulting composites were investigated. The results showed that the composites filled with basalt fibres exhibit significant improvements in strength, anti-indentation creep and hardness. Meanwhile, the friction coefficient and wear rate of the composites decreased obviously due to basalt fibres on the top of the worn surface bearing the dynamic load under sliding. The morphology of the worn surface indicates that fibre pull-out and fibre breakage both contribute to energy dissipation. However, the mechanical properties of the composites did not increase linearly with increasing fibre content because of the decreasing bonding force between the fibres and the matrix. These results are significant for the application of PEEK in engineering.

1 Introduction

Polyetheretherketone (PEEK) is a semi-crystalline thermoplastic polymer with high strength, corrosion resistance, high-temperature resistance, wear resistance and high plastic performance [1, 2]. PEEK is widely used as a replacement for machined metal components in the fields of aviation, aerospace, petrochemicals, mechanical manufacturing and biological materials [3, 4, 5, 6]. To withstand extreme contact conditions, engineering polymers with high performance for use in these fields have been investigated. Modifying an existing special engineering polymer by composite methods is an effective way to meet extreme contact requirements [7, 8].

Fibres are ideal carriers due to their high strength and modulus. A good combination of fibres and a matrix has the advantages of both components and achieves the best structural design with excellent properties [9, 10]. The mechanical and wear properties of PEEK and its composites have been widely studied. Early research by X.X. Chu et al. [11] showed that the tensile strength, tensile modulus, flexural modulus and impact strength of glass fibre (GF)/PEEK prepared by injection moulding at cryogenic temperatures are higher than those at room temperature, and GF/PEEK has better ductility at room temperature than cryogenic temperatures. J.R.Vail et al. [8] found that the wear rate of expanded polytetrafluoroethylene (PTFE) filaments was 84% lower than conventional PTFE-PEEK composites and maintained a stable low coefficient below 0.125 for over 2 million cycles under test conditions. Mohit Sharma et al. [12] found that plasma-treated carbon fibres (CFs) could significantly improve the mechanical and wear properties of CF/PEEK composites, with a friction coefficient of 0.2 and a wear rate of 1×10−15 m3/Nmexhibited by the treated composite. The study of Guodong Huang et al. [13] showed that graphene the wear rate of ultra-high molecular weight polyethylene (UHMWPE)/graphene oxide(GO) decreased by 25% compared to UHMWPE under dry friction condition. The UHMWPE/GO composite presented better friction and wear properties with bovine serum albumin (BSA) lubrication than with deionized water and dry friction.

Basalt fibre (BF) is a natural material with a melting temperature between 1500∘C and 1700∘C, and it is cheaper than glass and carbon fibre [14]. BF is a kind of environmentally friendly material with unique mechanical strength properties, high modulus of elasticity, excellent heat resistance, good chemical stability and superior wear resistance. In particularly, the adhesion and tensile strength of BF are higher than the glass fibres and comparable to carbon fibres. It proved the acid resistance of BF is greater than the one of glass fibres, and the alkali resistance is similar [15]. BF technology has been developed for creating excellent high-performance composites. Shoufan Cao et al. [16] investigated the mechanical and tribological behaviours of UHMWPE composites filled with 5–20 wt.% of BF. The max hardness, strength increased by 68%, 32%, respectively. The minimum indentation depth of UHMWPE composite was 60 of that of pure UHMWPE. The wear loss was only 0.01% of the wear loss of pure UHMWPE when the content of BFs was 20%. The study of SV Panin [17] showed that the strength properties of UHMWPE composites filled with basalt fibre content (0-20 wt.%) do not substantially change with increasing filler content, and the wear rate of the composites with a fibre content of 5 wt.% was three times smaller than that of the composite with a fibre 20 wt.%. Yatao Wang et al. [18] studied the effect of long basalt fibre content on the mechanical and tribological properties of polyoxymethylene (POM). The minimum friction coefficients and wear rates of POM composites decreased by 41.67% and 43.48%, respectively. Researchers have shown that the mechanical and wear properties of basalt fibre-reinforced polymers depend on the content of basalt fibres, applied load and lubrication conditions [19, 20]. They suggested that fibre pull-out and breakage lead to energy dissipation via tensile fracture of the composites. Matrix binds fibres and transmits the compressional and shear forces to the fibres when the composite sliding against metal.

There are many studies on fibre-reinforced PEEK composites [21, 22, 23].However, few studies have been performed on how basalt fibre content contributes to the mechanical and wear properties of PEEK polymers [24]. In this paper, PEEK/short cut basalt fibre (SBF) composites were made by injection moulding. The strength, anti-indentation creep and hardness of these composites were tested. In addition, the friction coefficient and wear rate of composites with different SBF contents were studied.Wear mechanisms involved in friction are discussed based on the worn surface morphology.

2 Experimental methods

2.1 Sample preparation

The PEEK powder used in the experiment, supplied by Victrex Plc, UK, is 1000 mesh. The parameters of the PEEK powder are shown in Table 1. The average diameter of BF was 12 μm, and the length was approximately 2 mm. The mechanical properties of the basalt fibre are shown in Table 2. In this paper, the weight percentages of the SBFs were 0%, 2.5%, 5%, 7.5% and 10%. Injection moulding is the main method of producing short fibre-reinforced plastics due to its low cost and convenient operation. The samples used in this experiment were all injection moulded. Prior to injection moulding, the raw PEEK powder was dried under vacuum at 60∘C for 12 h to ensure an extremely low amount of water in the powder. A film was formed on the surface of basalt fibre, which was treated with a silane coupling agent, and increased the roughness and mechanical strength of the basalt fibre [25, 26]. The film is helpful in improving the interfacial bonding between basalt fibres and organic polymers. Therefore, the BFs used in this experiment were treated with 0.75 wt.% KH550 saline coupling agent [27]. The PEEK powder and SBFs were mixed thoroughly through a high-speed mixing machine to ensure that the SBFs were distributed evenly in the matrix [28]. Then, a furnace was heated to a temperature of 360∘C, and the mould cavity was heated to 300∘C. The mixture was placed into the furnace. The molten material was then injected into the mould cavity, and the temperature was maintained at 360∘C. The packing time was 30 min.

Parameters of PEEK powder

| Density (g/cm3) | Shrinkage (%) | Water absorption capacity (%) | Tensile modulus (MPa) | Linearexpansion coeflcient (cm/cm/∘C) | |

|---|---|---|---|---|---|

| 1.30 | <2.0 | 0.04 | 2400 | 0.000047 | |

Mechanical properties of basalt fibres

| Tensile strength (MPa) | Elastic modulus (MPa) | Elongation at failure (%) | |

|---|---|---|---|

| Basalt fibre | 1250 | 40 | 75 |

2.2 Compression test

The wear resistance of the material is closely related to its compressive property. The compression test was performed according to ISO604-2002. The size of the sam-pleswas 10×10×5mm3. Compression tests were carried out using an electronic universal testing machine (UTM5305, SUNS Technology Stock Co., LTD, Shenzhen, China) at room temperature. The test pressure was 20±3 KPa, and the test speed was 5 mm/min.

2.3 Ball indentation hardness test

The hardness of PEEK/SBF composites was obtained by ball indentation hardness testing. Taking ISO2093-73 as a reference, the experiment was performed on a UMT-II tribometer. A ZrO2 ball with a diameter of 5 mm was selected as the indenter. The preload was 9.8 N, and the test load was 49 N. The ball indentation hardness of the composites is defined as follows:

where Pmax is the test load (N), D is the diameter of the ball indenter (mm), and hmax is the depth of impression (mm).

2.4 Indentation creep test

PEEK/SBF composite creep refers to its deformation under constant stress at a constant temperature. The gradual change in material deformation with time is a manifestation of the viscoelasticity of polymers and the relaxation process of materials under stress. The indentation creep properties of PEEK/SBF composites were tested on a UMT-II tribometer. The indenter is a ZrO2 ball with a diameter of 5±0.05 mm. The test load was 49 N, and the pressure holding time was 3600 s. During the test, when the load reached 49 N, the indentation depthwas set to 0, and then, the real-time change of the ceramic ball press depth with time was obtained by computer.

2.5 Tribological test

Tribological tests were performed using a block-on-ring and an M-2000 wear tester as shown in Figure 1. The size of the block was 20×10×6mm3, which was composed of PEEK and PEEK/SBF composite reinforced with SBF. The friction surface was sanded with 600, 800, 1000, 1500, and 2000 mesh sandpaper and finally ground to Ra = 0.3 μm. The counterface was an AISI-1045 ring with a diameter of 40 mm and a width of 10 mm. The roughness of the friction surface of the ring was equal to 0.8 μm. Prior to testing, all specimens were cleaned ultrasonically three times in alcohol baths and then dried in a vacuum drying box for 1 h. The applied load of the test was 200 N under dry friction conditions for 120 min. The rotation speed was 200 r/min [16, 29]. Three independent tests were performed repeatedly for each group of specimens.

3 Results

3.1 Effects of the BFs on the hardness and compressive strength

Figure 2 shows the ball indentation hardness of the PEEK/SBF composite with different basalt fibre contents. As expected, the ball indentation hardness of the PEEK/SBF composite increased with increasing content of basalt fibres. The ball hardness of pure PEEK is 58.15 MPa, and a small amount of SBFs added in PEEK, at 2.5 wt.%, can increase the hardness by 7%. When the content of SBF reached up to 5 wt.%, the increase in the ball indentation hardness of the PEEK/SBF composite was approximately 14.48%, which is 66.57. Compared to the hardness at 5 wt.%, the ball indentation hardness of the PEEK/SBF composite increased slightly when the content of SBF was 7.5 wt.% and 10 wt.%.

The Stress-displacement curve of PEEK/SBF composites is shown in Figure 3. There is a significant elastic deformation zone and yield point in the compression curve.

Block-on-ring wear test

Ball indentation hardness of PEEK/SBF composites

Stress-displacement curve of the PEEK/SBF composites

As shown in Figure 4, the compression test indicated that there was a significant yield point in the compression curve. The compressive strength of pure PEEK is the lowest, which was 133.66 MPa. The compressive strength of the PEEK/SBF composites increases dramatically. However, the compressive strength did not increase as the content of SBFs increased. The increase in strength is very close. With the content of SBFs increasing from 0 wt.% to 5 wt.%, the compressive strength of the PEEK/SBF composites increased. Compared with pure PEEK, the compressive strength of the PEEK/SBF composites increased by 18.7% with 2.5 wt.% SBF to 158.64 When the content of SBFs increased to 5 wt.%, the compressive strength of the PEEK/SBF composite reached 176.45 MPa, which was 32% larger than that of pure PEEK. Then, the compressive strength decreased slightly when the content of SBFs increased to 7.5 wt.% and 10 wt.%.

Variation in the compressive strength of the PEEK/SBF composites

3.2 Effects of SBF on indentation creep

It can be seen from Figure 5 that the indentation depths of pure PEEK and PEEK/SBF composites increased sharply at the beginning of the indentation creep test, and then, the depth growth slowed down to a stable level. The indentation depth decreased with increasing SBF content from 0 wt.% to 7.5 wt.%. When the content of SBFs was 7.5 wt.%, the indentation depth of the PEEK/SBF composite was 0.008 mm, 80% smaller than that of pure PEEK (0.042 mm). When the content of SBFs increased to 10 wt.%, the indentation depth of the PEEK/SBF composite did not decrease further (0.0165 mm) and was equivalent to that of the PEEK/SBF composite with a content of 5 wt.% SBFs.

Variation in indentation depth of PEEK/SBF composites

3.3 Friction coefficient and wear loss

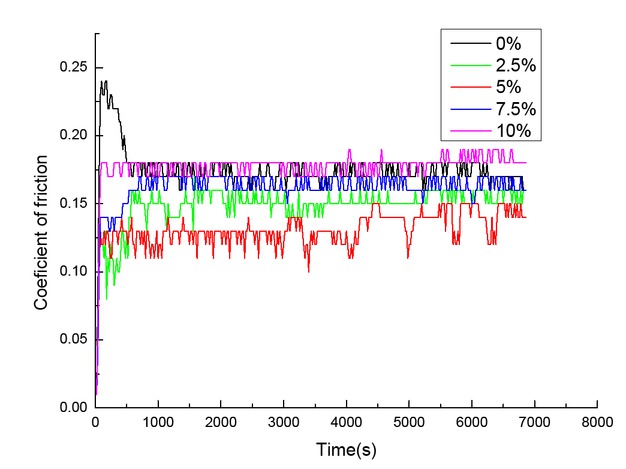

Figure 6 presents the time-dependent friction coefficients of pure PEEK and PEEK/SBF composites in the test. The composites exhibit a sharp increase in the initial period and then maintain a relatively stable value. The friction coefficient decreases gradually from 0 wt.% to 5 wt.%. The composite filled with 5 wt.% SBFs had a friction coefficient of μ = 0.12, which is 29% smaller than that of pure PEEK. The addition of 7.5 wt.% SBFs increased the friction coefficient to an average value of μ = 0.16. The friction coefficient of the composite filled with 10 wt.% SBF was μ = 0.18, i.e., the same friction coefficient as pure PEEK. The friction coefficients of the composites with different weight percentages of SBFs were similar. Compared to pure PEEK, the friction coefficient of composites filled with SBFs did not decrease significantly.

Variation in the time-dependent friction coefficients of PEEK/SBF composites

Figure 7(a) presents the variation in wear loss for PEEK and PEEK/SBF composites in the tribology test. As expected, a small amount of SBFs can reduce the wear loss sharply. The wear loss of pure PEEK was 3.61 mg. The wear loss of the composites filled with 2.5 wt.% and 5 wt.% SBFs decreased to 1.57 mg and 1.33 mg, respectively. The wear loss of PEEK filled with 7.5 wt.% SBFs was 66.7 %lower than that of pure PEEK, which was 1.2 mg. For PEEK filled with 10 wt.% SBFs, the wear loss of the composite increased to 2.56 mg. The wear loss of PEEK/SBF composites did not decrease with increasing SBF content. Figure 7(b)shows the section contour of PEEK/SBF composites with laser scanning. The wear width and wear depth of PEEK/SBF composites are shown in Table 3. The width and depth of pure PEEK are 5.35 mm and 175.66 μm, respectively, which are larger than those of the other samples. The width and depth of the composites with 5 wt.% are 4.31 mm and 97.20 μm, respectively, which are the smallest of the samples.

Variation in the wear loss and shape of the section for PEEK and PEEK/ SBF composites (a) wear loss of PEEK/SBF composites (b) section contours of PEEK/SBF composites

Wear width and wear depth of PEEK/SBF composites

| 0 wt.% | 2.5 wt.% | 5 wt.% | 7.5 wt.% | 10 wt.% | |

|---|---|---|---|---|---|

| Width | 5.35 | 4.37 | 4.31 | 4.48 | 4.06 |

| (mm) | |||||

| Depth | 175.66 | 148.83 | 97.20 | 155.74 | 162.00 |

| (μm) |

3.4 Morphologies of worn surfaces

The worn surfaces were observed by scanning electron microscopy (SEM) at 400x magnification, to find evidence of different friction mechanisms. Figure 7 illustrates the worn surfaces of pure PEEK and PEEK/SBF composites with different contents of SBFs after the tribology test. There are obvious ploughing furrows on the worn surfaces of pure PEEK and the PEEK/SBF composites. There are marked differences in the worn surfaces of the different composites. The worn surface of pure PEEK is shown in Figure 8(a). The position of visible furrows was observed in the sliding direction. Slight peeling on the worn surface can be found mainly at the edges of furrows. Particles, ranging from several microns to over ten microns, are attached to the worn surface. Figure 8(b) shows the worn surface of the PEEK/SBF composite filled with 2.5 wt.% SBFs. In addition to the furrows on the surface, there were some cavities caused by shed fibres. Very few fibre fractures were observed in the sliding direction. In addition, particles adhered to the worn surface. The worn surfaces of the PEEK/SBF composite filled with 5 wt.% SBFs are depicted in Figure 8(c). It can be seen that there were more grooves due to shedding fibres and more fractured fibres on the worn surface. There were some large flakes peeling off of the worn surface. When the content of SBFs was increased to 7.5 wt.%, the number of larger grooves increased on the worn surface where fractured fibres were positioned in the sliding direction, as shown in Figure 8(d). It can be seen from Figure 8(e) that there are more grooves and fractured fibres on the worn surface of the PEEK/SBF composite with 10 wt.% SBFs than the other samples. In addition, there are more grooves relative to the composites mentioned above on the surface due to the shed fibres.

Scanning electron microscopy (SEM) micrographs taken of worn surfaces of (a) pure PEEK,(b) PEEK/ SBF composite with 2.5 wt.% SBFs, (c) PEEK/ SBF composite with 5 wt.% SBFs, (d) PEEK/ SBF composite with 7.5 wt.% SBFs and (e)PEEK/ SBF composite with 10 wt.% SBFs

4 Discussion

It was found from the results that the hardness and compressive strength of PEEK/SBF composites increase compared with those of pure PEEK. The main reasons for the reinforcing effect are as follows: the strength and hardness of the SBFs were much higher than those of PEEK. The SBFs support the composites when they are compressed, and the load acts first and mainly on the SBFs. When a certain quantity of basalt fibres was added to the matrix, the hardness and compressive strength of the PEEK/ SBF composites increased significantly. However, the molecular continuity of the PEEK matrix was broken, and the microfractures increased when the content of SBF was high [17]. Therefore, the hardness and compressive strength may decrease as the content of SBF increases. The hardness of the PEEK composites increased to their greatest value when 7.5 wt.% SBFs was added, and the compressive strength of the PEEK composites when 5 wt.% SBFs was added was the greatest.

The creep of PEEK material is a synergistic response of the materials to external forces under certain conditions. The short cut basalt fibres were distributed randomly in PEEK composites, hindering the sliding of the molecular chain when the matrix was filled with SBFs. As a result, the coordinated response of PEEK composites becomes difficult. The creep resistance of PEEK filled with SBFs increases. However, a high content of SBFs in the composite leads to porosity and cracks. The inadequate adhesion of the fibres with the resin matrix leads to insufficient stress transfer. Therefore, the creep resistance of composites does not increase linearly with increasing SBF content.

In terms of interface forces, in general, a strong interaction between interfaces facilitates the transfer of external loads between the fibres and the matrix. When the weight content of SBFs was low, the distance between the fibres and the matrix was greater, which was not conductive to the transfer of the load between the matrix and the fibres. An excessive quantity of fibres leads to an increase in the processing viscosity of the composite and local fibre aggregation. Research shows that the fibres are evenly distributed in the direction of flow of the composite material and that the fibres have a strong interface with the matrix. Therefore, the addition of basalt fibres to PEEK can improve its mechanical properties, and the mechanical properties of PEEK/SBF composites filled with 7.5 wt.% SBFs were superior to those of the other composites.

It is believed that ridges are formed on the surface of polymers and polymer composites during the running-in period. During the steady-state period, these ridges disappear, and wear debris covers the surface, leading to a low friction coefficient and steady-state friction values. The friction coefficient of PEEK/SBF composites is 50% lower than that of PEEK/GF and comparable to PEEK/CF composites. The lowest friction coefficient of PEEK/SBF filled with 5wt.% SBFs is lower than PEEK/CF composites [30, 31]. When PEEK sliding against the metal ring, a low friction coefficient was obtained due to the transfer film on the counterface.Onthe one hand, under dry friction conditions, the softening of the matrix of the PEEK/SBF composites due to its temperature increase reduced the strength and stiffness of the composites. At the same time, the softened part adheres between the two grinding surfaces, increasing the frictional resistance of the composite material and increasing the friction coefficient of the composite material. On the other hand, the friction contact area and the surface shear strength determine the coefficient of friction of the material. As the friction progresses, the frictional heat generated on the worn surface will melt the matrix and form a low-shear lubricating layer on the worn surface. Basalt fibres are gradually exposed on the wear surface. The fibres and matrix can interlock with each other on the wear surface to reinforce the transfer film, which significantly reduces the friction coefficient. Given the above, the friction coefficient of the composites is lower than that of pure PEEK.

In general, the material, which has a high elastic modulus and high hardness, has good wear resistance. The hardness and the ability to resist deformation of the composite improves obviously due to the addition of SBFs. The basalt fibres in the composites can bear, transmit and distribute loads. Therefore, the contact area between the composite material and the ring decreases, and fibre reinforcers can reduce wear, such as ploughing and tears. Therefore, the wear loss of PEEK/ SBF was much lower than the PEEK/GF and PEEK/CF composites [30]. The wear loss of PEEK/ SBF increased slightly due to the strength and hardness increase when the weight content was 10%. It is consistent with the width and depth of the worn section.

It can be seen from the worn surface that there are different wear mechanisms involved in the friction progress based on the surface morphologies revealed in SEM micrographs. There is abrasive wear and a small amount of tearing on the surface of pure PEEK due to adhesive wear, as shown in Figure 9(a). The asperities on the surface of the stainless-steel ring cut the surface of the PEEK, which leads to considerable furrows in the worn surface. For PEEK reinforced with SBFs, matrix wear and fibre thinning, cracking, and debonding are important mechanisms contributing to the tribological performance of the composite [32]. The matrix plays a role in dispersing and transmitting a load between fibres and increases the fibre carrying capacity along the fibre direction. Due to the interaction enhancement between the SBFs and matrix, the stress of the worn surface can be better transferred between the matrix and the SBFs. Its high modulus can reduce the shear effects of the matrix (Figure 9(b)). Repeated compression-tension stresses at the fibre/matrix interface lead to fibre debonding phenomena [1, 32]. At the same time, fibre fracture occurs due to high compression stress at their rear edges [24, 33]. When the quantity of fibres was small, only a few fibres supported the matrix materials. Abrasive wear due to the asperities on the counterface and particles is still the main wear mechanism. Additionally, there are a few fractured fibres and a large number of furrows on the surface. As the content of SBFs increases, the fibres in the composites bear most of the load because the stress is concentrated on the top of the fibres. The stress concentration dissipates as the fibres break and shed. When the content of BFs increased to 10 wt.%, interlocking between the fibres and matrix decreased due to the decreasing bonding force. There are more fibres broken and pulled out due to the shearing action. Therefore, there are more grooves on the worn surface of the PEEK/ SBF composite with 10 wt.% SBFs compared to those of the other composites.

Wear mechanisms of pure PEEK and PEEK/ SBF; (a) wear mechanism of PEEK; red label is abrasive wear, blue label is adhesive wear; (b)wear mechanism of PEEK/ SBF; red and blue labels are abrasive and adhesive wear, respectively; red arrows indicate the stress transfer between matrix/BFs

5 Conclusions

The mechanical properties, such as the hardness, compressive strength and creep resistance, improved when the composite was reinforced with SBFs. The maximum hardness and compressive strength of PEEK/SBF were obtained when the content of SBFs was 5 wt.%. In the creep test, the minimum indentation depth of PEEK/SBF composites when the content of SBFs was 7.5 wt.%. SBF reinforcement broadened the application area of PEEK as a structural material significantly.

A low friction coefficient is obtained due to the transfer film of a solid lubricant on the friction surface. The fibres and matrix can interlock with each other on the wear surface to reinforce the transfer film, which significantly reduces the friction coefficient. The friction coefficient of the composites filled with 5 wt.% SBFs is lowest. A certain amount of basalt fibre can further reduce the friction coefficient of PEEK.

During the sliding process, asperities on the surface of the stainless-steel ring cut the surface of the PEEK, which leads to considerable furrows on the worn surface of pure PEEK. There is a small amount of tearing on the surface of pure PEEK due to adhesive wear. When the quantity of fibres is small, a few fibres support the matrix materials. The main wear mechanisms change to fatigue wear in addition to abrasive wear when the polymer is filled with SBFs. The fibres in the composites mainly bear the load because the stress is concentrated on the top of the fibres. The stress concentration dissipates as the fibres break and shed due to shearing action. When the content of SBFs is too high, the bonding force between fibres and the matrix decreases and there are more fibres shedding. A PEEK composite with a certain content of SBFs possesses a low friction coefficient and excellent wear resistance.

The PEEK/SBF composites will have advanced engineering applications such as bolt gear, plate and special parts to overcome significant weight, corrosion, hard machining. Finally, the role of SBF in different conditions, such as lubrication, load, velocity, were not discussed in the present work, which will be investigated by future work.

Acknowledgement

The study reported in this article was supported by the Fundamental Research Funds for the Central Universities (No. 2017XKZD08) and Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

References

[1] Czigány T, Vad J, Pölöskei K., Basalt fiber as a reinforcement of polymer composites, Periodica Polytechnica Mechanical Engineering, 2005, 49, 3-14.Search in Google Scholar

[2] Monich P. R., Henriques B., Novaes de O.A.P., Souza Júlio C. M., Mechanical and biological behavior of biomedical PEEK matrix composites: a focused review, Materials Letters, 2016, 185, 593-597.10.1016/j.matlet.2016.09.005Search in Google Scholar

[3] Laux K. A., Jean-Fulcrand A., Sue H. J., Pechociakova M., Noman M.T., The influence of surface properties on sliding contact temperature and friction for polyetheretherketone (PEEK), Polymer, 2016, 103,397-404.10.1016/j.polymer.2016.09.064Search in Google Scholar

[4] Garcia-Gonzalez D., Rusinek A., Jankowiak T., Arial A., Mechanical impact behavior of polyether–ether–ketone (PEEK), Composite Structures, 2015, 124,88-99.10.1016/j.compstruct.2014.12.061Search in Google Scholar

[5] Greco A. C., Erck R., Ajayi O, Fenske G., Effect of reinforcement morphology on high-speed sliding friction and wear of PEEK polymers, Wear, 2011, 271, 2222-2229.10.1016/j.wear.2011.01.065Search in Google Scholar

[6] Jamshaid H., Mishra R., Militky J., Pechociakova M., Mechanical, thermal and interfacial properties of green composites from basalt and hybrid woven fabrics, Fibers & Polymers, 2016, 17, 1675-1686.10.1007/s12221-016-6563-zSearch in Google Scholar

[7] Kern M, Lehmann F., Influence of surface conditioning on bonding to polyetheretherketon (PEEK), Dental Materials, 2012, 28(12),1280-1283.10.1016/j.dental.2012.09.010Search in Google Scholar PubMed

[8] Vail J R, B.A. Krick, Marchman K R, Sawyer W. G., Polytetrafluoroethylene (PTFE) fiber reinforced polyetheretherketone (PEEK) composites, Wear, 2011, 270, 737-741.10.1016/j.wear.2010.12.003Search in Google Scholar

[9] Gu T., Blends and short glass fiber reinforced composite of Poly(arylether)s containing phthalazinone moieties(PhD thesis), 2010, Dalian, Dalian university of technology.Search in Google Scholar

[10] Sun Z., Progress in the research and applications of natural fiber-reinforced polymer matrix composites, Science and Engineering of Composite Materials, 2017, 25,835-846.10.1515/secm-2016-0072Search in Google Scholar

[11] Chu X.,Wu Z., Huang R., Mechanical and thermal expansion properties of glass fibers reinforced PEEK composites at cryogenic temperatures, Cryogenics, 2010, 50,84-88.10.1016/j.cryogenics.2009.12.003Search in Google Scholar

[12] Sharma M, Bijwe J, Mitschang P. Wear performance of PEEK– carbon fabric composites with strengthened fiber–matrix interface, Wear, 2011, 27, 2261-2268.10.1016/j.wear.2010.11.055Search in Google Scholar

[13] Huang G., Ni Z., Chen G., Huang H., The Investigation of Friction and Wear Properties of UHMWPE/GO in Different Lubrication Conditions, China Plastics Industry, 2015.Search in Google Scholar

[14] Fiore V., Scalici T., Bella G. D., Valexenko A., A review on basalt fibre and its composites, Composites Part B, 2015, 74, 74-94.10.1016/j.compositesb.2014.12.034Search in Google Scholar

[15] Monaldo E., Nerilli F., Vairo G., Basalt-based fiber-reinforced materials and structural applications in civil engineering, Composites Structures, 2019,214,246-263.10.1016/j.compstruct.2019.02.002Search in Google Scholar

[16] Cao S., Liu H., Ge S., Wu G. Mechanical and tribological behaviors of UHMWPE composites filled with basalt fibers, Journal of Reinforced Plastics & Composites, 2011, 30, 347-355.10.1177/0731684410394698Search in Google Scholar

[17] Panin S. V., Kornienko L. A., Alexenko V. O., Huang Q., Ivannova L.R., Comparison of mechanical and tribotechnical properties of UHMWPE reinforced with basalt fibers and particles, IOP Conference Series, Materials Science and Engineering, 2016, 156, 012026.10.1088/1757-899X/156/1/012026Search in Google Scholar

[18] Wang Y., Wang X., Wu D., Mechanical and tribological enhancement of polyoxymethylene-based composites with long basalt fiber through melt pultrusion, Composite Interfaces, 2016, 1-19.10.1080/09276440.2016.1168124Search in Google Scholar

[19] Liu N., Wang J., Chen B., Sen U., Effect of UHMWPE Microparticles on the Tribological Performances of High-Strength Glass Fabric/Phenolic Laminate Composites Under Water Lubrication, Tribology Letters, 2014, 55, 253-260.10.1007/s11249-014-0354-8Search in Google Scholar

[20] Akinci A., Yilmaz S., Sen U., Wear Behavior of Basalt Filled Low Density Polyethylene Composites [J]. Applied Composite Materials, 2012, 19,499-511.10.1007/s10443-011-9208-9Search in Google Scholar

[21] Wang H., Preparation and properties of long basalt fiber-reinforced polyamide 6 composite (PhD), Taiyuan, North University of China, 2017.Search in Google Scholar

[22] Wang Q, Wu J, Unsworth A, Briscoe A., Smith M., Lowry C., Simpson D., Collins S., Biotribological study of large diameter ceramic-on-CFR-PEEK hip joint including fluid uptake, wear and frictional heating, Journal of Materials Science: Materials in Medicine, 2012, 23(6), 1533-1542.10.1007/s10856-012-4617-3Search in Google Scholar PubMed

[23] Kalin M., Zalaznik M., Novak S, Wear and friction behaviour of poly-ether-ether-ketone (PEEK) filled with graphene, WS2 and CNT nanoparticle, Wear, 2015, 332-333, 855-862.10.1016/j.wear.2014.12.036Search in Google Scholar

[24] Monaldo Elisabetta, Nerilli Francesca, Vairo Giuseppe, Basalt-based fiber-reinforced materials and structural applications in civil, Composite Structures, 2019,214, 246-263.10.1016/j.compstruct.2019.02.002Search in Google Scholar

[25] Li G, Qi H, Zhang G, Zhao F., Wang T. Wang Q., Significant friction and wear reduction by assembling two individual PEEK composites with specific functionalities, Materials & Design, 2017, 116, 152-159.10.1016/j.matdes.2016.11.100Search in Google Scholar

[26] Guo Z., Zhang Z., The effect of silane coupling agent treatment on the tensile property of basalt fiber fabric, Shanghai Textile Science & Technology, 2012, 40, 25-27.Search in Google Scholar

[27] Liu T., Yu X., et al. Study on preparation and properties of basalt fiber reinforced nyloon66, Engineering Plastics Application, 2010, 38, 5-9.Search in Google Scholar

[28] Li W, Xu J., Mechanical properties of basalt fiber reinforced geopolymeric concrete under impact loading, Materials Science & Engineering A, 2009, 505, 178-186.10.1016/j.msea.2008.11.063Search in Google Scholar

[29] Davim J., Rosária C., Effect of the reinforcement (carbon or glass fibres) on friction and wear behaviour of the PEEK against steel surface at long dry sliding, Wear, 2009, 266(7), 795-799.10.1016/j.wear.2008.11.003Search in Google Scholar

[30] Sharma M., Bijwe J., MäDer E., Klaus K., Strengthening of CF/PEEK interface to improve the tribological performance in low amplitude oscillating wear mode, Wear, 2013, 301(1-2), 735-739.10.1016/j.wear.2012.12.006Search in Google Scholar

[31] Zhang G., Rasheva Z, Schlarb A K., Friction and wear variations of short carbon fiber (SCF)/PTFE/graphite (10 vol.%) filled PEEK: Effects of fiber orientation and nominal contact pressure, Wear, 2010, 268, 893-899.10.1016/j.wear.2009.12.001Search in Google Scholar

[32] Friedrich K., Varadi K., Goda T, Giertzsch H., Finite element analysis of a polymer composite subjected to a sliding steel asperity Part I Normal fibre orientation, Journal of Materials Science, 2002, 37(16), 3497-3507.10.1023/A:1016571324836Search in Google Scholar

[33] Francesca N., Vairo G., Experimenta investigation on the debonding failure mode of basalt-based FRP Sheet from concrete, Composite Part B, 2018,153,205-216.10.1016/j.compositesb.2018.07.002Search in Google Scholar

© 2019 T. Zhang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Articles in the same Issue

- Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation

- Artificial neural network for predicting the flexural bond strength of FRP bars in concrete

- Cyclic behavior of GFRP strengthened infilled RC frames with low and normal strength concrete

- Durability of basalt fiber-reinforced polymer bars in wet-dry cycles alkali-salt corrosion

- Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite

- Enhanced dielectric properties of BaTiO3 ceramics with cerium doping, manganese doping and Ce-Mn co-doping

- Free and forced vibration analysis of rectangular/circular/annular plates made of carbon fiber-carbon nanotube-polymer hybrid composites

- Influence of nano-SiO2 on the bonding strength and wear resistance properties of polyurethane coating

- Investigation of wear behavior of nanoalumina and marble dust-reinforced dental composites

- Negative effect of clay fillers on the polyvinyl alcohol biodegradation: technical note

- Photocatalytic activity of Cu2O/ZnO nanocomposite for the decomposition of methyl orange under visible light irradiation

- Sub-surface mechanical properties and sub-surface creep behavior of wood-plastic composites reinforced by organoclay

- Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3

- The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level: FEM based study

- Vibration-damping characterization of the basalt/epoxy composite laminates containing graphene nanopellets

- A review on nanocomposite hydrogels and their biomedical applications

- Optimization and simulation analysis of structure parameters of OPCM ultrasonic longitudinal wave actuating element

- Research Article

- Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings

- Research on preload relaxation for composite pre-tightened tooth connections

- Dough moulding compound reinforced silicone rubber insulating composites using polymerized styrene butadiene rubber as a compatibilizer

- Hydration And Microstructure Of Astm Type I Cement Paste

- Effects of NiO content on the microstructure and mechanical properties of AgSnO2NiO composites

- Overall buckling behaviour of laminated CFRP tubes with off-axis ply orientation in axial compression

- UV sensing optode for composite materials environment monitoring

- On crushing characteristics of hybrid sandwich aluminum-cardboard panels reinforced with glass fiber composite rods

- Preparation and characterization of Ni-Cu composite nanoparticles for conductive paints

- A research on the preparation of oil-adsorbing hydrophobic porous resins by high internal phase emulsions (HIPEs) template

- Material characteristics of random glass-mat-reinforced thermoplastic under cryogenic thermal cycles

- Differentiation of non-black fillers in rubber composites using linear discriminant analysis of principal components

- Research Article

- Efficiency of TiO2 catalyst supported by modified waste fly ash during photodegradation of RR45 dye

- Synthesis and performance of polyurethane/silicon oxide nano-composite coatings

- Study on preparation of magnesium-rich composite coating and performance enhancement by graft modification of epoxy resin

- Research Article

- Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres

- Mechanical Properties of Al 25 wt.% Cu Functionally Graded Material

- Research Article

- Weight reduction of a carbon fibre composite wheel

- Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/ polyvinyl alcohol - magnetite nanocomposites film

- Seismic Behaviour of TRC-Strengthened RC Columns under Different Constraint Conditions

- Characterization of neat and modified asphalt binders and mixtures in relation to permanent deformation

- Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

- Research Article

- Effect of Cutting Temperature on Bending Properties of Carbon Fibre Reinforced Plastics

- Mechanical and tribological properties of B-C-N coatings sliding against different wood balls

- Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix

- Effects of Waste Eggshells addition on Microstructures, Mechanical and Tribological Properties of Green Metal Matrix Composite

- Investigation of porosity effect on flexural analysis of doubly curved FGM conoids

- Review Article

- Utilization of tailings in cement and concrete: A review

- Research Article

- Equivalent stiffness prediction and global buckling analysis using refined analytical model of composite laminated box beam

- Mechanochemical synthesis of zincite doped with cadmium in various amounts

- Size-dependent vibration analysis of graphene-PMMA lamina based on non-classical continuum theory

- Automated, Quality Assured and High Volume Oriented Production of Fiber Metal Laminates (FML) for the Next Generation of Passenger Aircraft Fuselage Shells

- Research Article

- An investigation of the stitching effect on single lap shear joints in laminated composites

- The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Effect of granulometric distribution on electromagnetic shielding effectiveness for polymeric composite based on natural graphite

- The enhancement of filament winding in marine launching rubber gasbag

- Research on ELID Grinding Mechanism and Process Parameter Optimization of Aluminum-Based Diamond Composites for Electronic Packaging

Articles in the same Issue

- Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation

- Artificial neural network for predicting the flexural bond strength of FRP bars in concrete

- Cyclic behavior of GFRP strengthened infilled RC frames with low and normal strength concrete

- Durability of basalt fiber-reinforced polymer bars in wet-dry cycles alkali-salt corrosion

- Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite

- Enhanced dielectric properties of BaTiO3 ceramics with cerium doping, manganese doping and Ce-Mn co-doping

- Free and forced vibration analysis of rectangular/circular/annular plates made of carbon fiber-carbon nanotube-polymer hybrid composites

- Influence of nano-SiO2 on the bonding strength and wear resistance properties of polyurethane coating

- Investigation of wear behavior of nanoalumina and marble dust-reinforced dental composites

- Negative effect of clay fillers on the polyvinyl alcohol biodegradation: technical note

- Photocatalytic activity of Cu2O/ZnO nanocomposite for the decomposition of methyl orange under visible light irradiation

- Sub-surface mechanical properties and sub-surface creep behavior of wood-plastic composites reinforced by organoclay

- Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3

- The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level: FEM based study

- Vibration-damping characterization of the basalt/epoxy composite laminates containing graphene nanopellets

- A review on nanocomposite hydrogels and their biomedical applications

- Optimization and simulation analysis of structure parameters of OPCM ultrasonic longitudinal wave actuating element

- Research Article

- Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings

- Research on preload relaxation for composite pre-tightened tooth connections

- Dough moulding compound reinforced silicone rubber insulating composites using polymerized styrene butadiene rubber as a compatibilizer

- Hydration And Microstructure Of Astm Type I Cement Paste

- Effects of NiO content on the microstructure and mechanical properties of AgSnO2NiO composites

- Overall buckling behaviour of laminated CFRP tubes with off-axis ply orientation in axial compression

- UV sensing optode for composite materials environment monitoring

- On crushing characteristics of hybrid sandwich aluminum-cardboard panels reinforced with glass fiber composite rods

- Preparation and characterization of Ni-Cu composite nanoparticles for conductive paints

- A research on the preparation of oil-adsorbing hydrophobic porous resins by high internal phase emulsions (HIPEs) template

- Material characteristics of random glass-mat-reinforced thermoplastic under cryogenic thermal cycles

- Differentiation of non-black fillers in rubber composites using linear discriminant analysis of principal components

- Research Article

- Efficiency of TiO2 catalyst supported by modified waste fly ash during photodegradation of RR45 dye

- Synthesis and performance of polyurethane/silicon oxide nano-composite coatings

- Study on preparation of magnesium-rich composite coating and performance enhancement by graft modification of epoxy resin

- Research Article

- Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres

- Mechanical Properties of Al 25 wt.% Cu Functionally Graded Material

- Research Article

- Weight reduction of a carbon fibre composite wheel

- Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/ polyvinyl alcohol - magnetite nanocomposites film

- Seismic Behaviour of TRC-Strengthened RC Columns under Different Constraint Conditions

- Characterization of neat and modified asphalt binders and mixtures in relation to permanent deformation

- Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

- Research Article

- Effect of Cutting Temperature on Bending Properties of Carbon Fibre Reinforced Plastics

- Mechanical and tribological properties of B-C-N coatings sliding against different wood balls

- Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix

- Effects of Waste Eggshells addition on Microstructures, Mechanical and Tribological Properties of Green Metal Matrix Composite

- Investigation of porosity effect on flexural analysis of doubly curved FGM conoids

- Review Article

- Utilization of tailings in cement and concrete: A review

- Research Article

- Equivalent stiffness prediction and global buckling analysis using refined analytical model of composite laminated box beam

- Mechanochemical synthesis of zincite doped with cadmium in various amounts

- Size-dependent vibration analysis of graphene-PMMA lamina based on non-classical continuum theory

- Automated, Quality Assured and High Volume Oriented Production of Fiber Metal Laminates (FML) for the Next Generation of Passenger Aircraft Fuselage Shells

- Research Article

- An investigation of the stitching effect on single lap shear joints in laminated composites

- The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Effect of granulometric distribution on electromagnetic shielding effectiveness for polymeric composite based on natural graphite

- The enhancement of filament winding in marine launching rubber gasbag

- Research on ELID Grinding Mechanism and Process Parameter Optimization of Aluminum-Based Diamond Composites for Electronic Packaging