Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

-

M.J. Shen

Abstract

The present work aims to research the treatment processing of magnesium reinforced with 1 μmsilicon carbide particle (SiCp) using stir casting combined by ultrasonic vibration. Present studies have been done on six different materials: (a) AZ31B alloy without particles, (b) 5 vol.% SiCp/AZ31B composites fabricated with different semi-solid stirring time (5 min, 10 min, 15 min and 20 min), (c) composite with 20 vol.% SiCp. The effects of 1 μm/SiCp pretreatment and stirring time on microstructure and interfacial wettability as well as mechanical properties of the materials were confirmed. Both short and long stirring time for the particle dispersion brought particle agglomeration. Results of SEM microstructure and tensile properties exhibited that the optimal stirring parameters of 625 °C/1500 rpm/15 min are exploited, and 20 vol.% SiCp/AZ31B composite was fabricated by the optimal stirring parameters. The application of optimal stirring parameters for the treatment resulted in homogeneous particle distribution. The addition of SiCp leads to a reduced matrix grain, and 20 vol.% SiCp/AZ31B composite showed smaller grain size than. 5 vol.% SiCp/AZ31B composite. The interface between SiCp and matrix is clear and interfacial wettability well. Tensile test results show that with increasing SiCp content, strengths increase while ductility decreases.

1 Introduction

Magnesium alloys have long been taken as promising materials in the automotive, aerospace and 3C industries due to their light weight, high specific-strength good damping, recyclability and machinability [1]. Magnesium with its density of 1.74 g/cm3 is about 2/3 of the density of aluminum and 1/5 of the density of steel [2, 3]. Meanwhile, its density is the lightest among all the metallic structural materials. However, compared with steel and aluminum alloys, potential engineering applications of magnesium alloys are limited. This is because of its hexagonal close-packed(HCP) crystal structure and limited number of slip systems, these reasons result in low strength and poor formability [4]. Moreover, stiffness, wear resistance and yield asymmetry are also disappointed. Reinforcing the magnesium matrix composites(MMCs) with hard and thermally stable particles often improves the wear resistance, stiffness and strength of magnesium alloys [5, 6]. At present, a large number of research works, such as powder metallurgy [7], stir casting[8], disintegrated melt deposition [9], mechanical alloying [10] etc., were made to prepare MMCs, but stir casting is superior among these preparation methods. The reasons are attributed to its simple process flow, easy operation, high yields and low cost, and is considered to be the best choice for fabrication of composites with high content SiCp.

It is well known that many factors influence microstructure and mechanical properties of particle reinforced MMCs. B.N. Sahoo et al. [11] synthesized fine (TiC-TiB2) reinforced magnesium matrix in-situ composites through novel stir casting process. Their works indicate that the strength of composite is related to homogeneous distribution of (TiC-TiB2) hybrid reinforcements. G.Q. Han et al. [12] discussed the factors related to good interfacial bonding between the CNTs and the matrix, which is essential to mechanical properties of composite. Moreover, when composite is fabricated by stirring technique, stirring parameters are also very important factors. Therefore, process parameters need to be optimized in the production

of MMCs with homogeneous particle distribution and remarkable mechanical properties.

There are studies about MMCs fabricated by semi-solid stir casting combined by ultrasonic vibration. However, compared to conventional stir-casting technique, there are limited studies using stir casting combined by ultrasonic vibration to fabricate submicron SiCp reinforced MMCs. In this study, an optimized stirring time for producing 5 vol.% SiCp/AZ31B composite was confirmed to obtain MMCs with homogeneous microstructure and good mechanical properties. The main aims in this process are synthesizing the composite with high content SiCp and understanding the influences of particles parameters on microstructure and mechanical properties.

2 Experimental

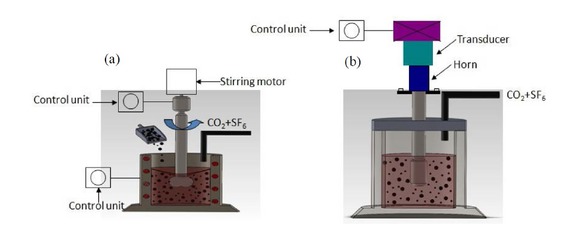

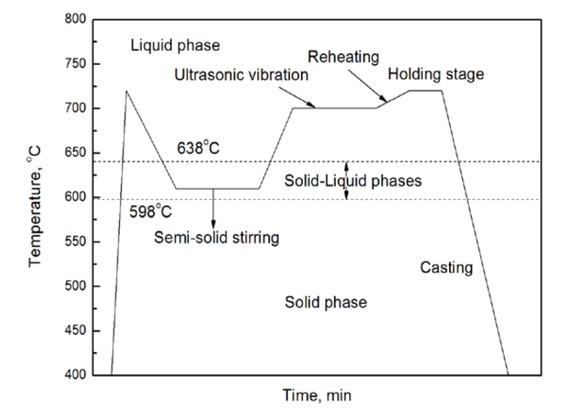

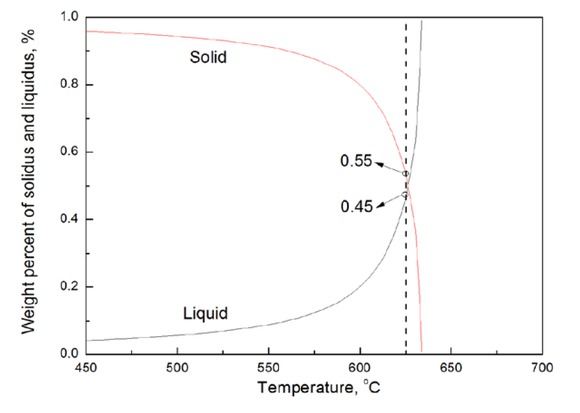

The AZ31B with chemical composition of 2.7Al-0.8Zn-Mg(wt.%) was used in the experiment. The reinforcements, 1 μm-SiCp are purchased from white Dove Co., Ltd. Zhengzhou, China. The fabrication of composites with high content SiCp included two parts: optimization of stir parameters of 5 vol.% SiCp/AZ31B composites and the stirring cast of 20 vol.% SiCp/AZ31B composite. The schematic diagram in Fig. 1 illustrates the fabrication equipment of composite. Firstly, about 1 kg of AZ31B alloy was loaded in a mild steel crucible, kept in an electric resistance furnace, under the protective atmosphere (CO2+SF6). The temperature-time sequence for the stir casting assisted by ultrasonic treatment was shown in Fig. 2. The alloy ingot was first melted at 720 ∘C and held at this temperature for 10min. After that, melt was cooling down to the ~625 ∘C. Fig. 3 shows the solid-liquid weight fraction in the semi solid slurry. Solid fractions was increased to about 45 wt.% ( ~625 ∘C) to keep the semi-solid condition. Preheated (up to 650 ∘C) SiCp were added into the vortex of the magnesium melt during stirring. The composite slurry was stirred at temperatures of 625 ∘C with stirring speeds of 1500 rpm for 5, 10, 15 and 20 min, respectively. The designations of composites fabricated by four fabrication parameters are listed in Table 1. After semi-solid stirring, the semi solid mixture was reheated up to 720 ∘C and ultrasonic treated at 50 Hz at 500 W power for 20 min. Finally, the melt was transferred into a preheated steel mold (450 ∘C) and solidified under about 100 MPa. Based on the optimized process parameters of 5vol.% SiCp/AZ31B composites, 20 vol.% SiCp/AZ31B composite was also fabricated under same stirring parameters.

Schematic diagram to fabrication of MMC by using stirring cast. (a) stirring apparatus, (b) ultrasonic-vibration apparatus.

The temperature–time sequence in fabricating composites with the method of stir casting assisted by ultrasonic vibration.

Solid-liquid weight fraction in the semi-solid slurry.

Composites designations

| stirring speed (rpm) | Stirring temperature(°C) | Stirring time(min) | designation |

|---|---|---|---|

| 1500 | 625 | 5 | ST-5 |

| 1500 | 625 | 10 | ST-10 |

| 1500 | 625 | 15 | ST-15 |

| 1500 | 625 | 20 | ST-20 |

Microstructures of the different materials were observed by optical microscopy (OM) and scanning electron microscopy (SEM). A mixture solution of 100 ml pure water and 4 g oxalic acid was used for etching. Image-Pro Plus (IPP) software was used to reveal matrix grain sizes. Tensile tests of specimens were performed with an Instron5569 material test machine with a crosshead speed of 0.5 mm/min at room temperature.

3 Results and Discussions

3.1 Optimization of stirring time

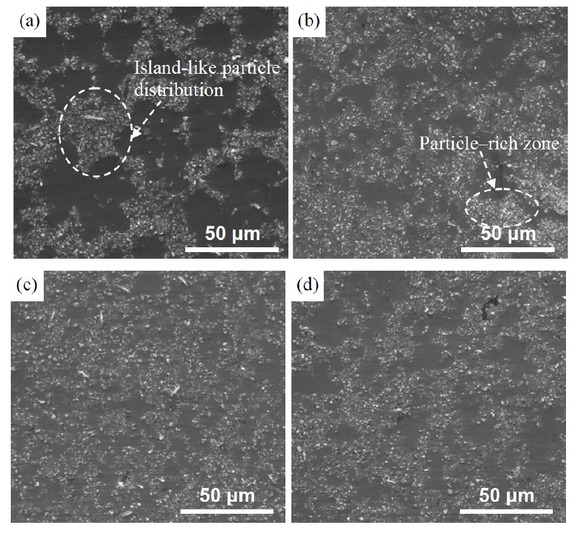

Fig. 4 shows the SEM micrographs of the composite fabricated with different stirring time(ST-5, ST-10, ST-15, ST-20). Compared with ST-5, the particles distribution of ST-10 more homogeneously with increasing stirring time. It especially eliminated some island-like particle distribution zones and broken local cluster of particles. However, some particle-rich zones still appear in composite fabricated with stirring time of 10 min. Compared with ST-5 and ST-10, ST-15 indicates that SiCp agglomeration does not ex-

SEM graphs of SiCp/AZ31B composites fabricated by semi-solid stirring assisted ultrasonic vibration with different stirring time.

ist in macroscopic regions of ST-15 sample. It means that further increasing stirring time longer than 10min is practicable. The reason is that gas absorption and oxidation of the prepared composites did not exist in ST-15, as shown in Fig. 4(c). Therefore, SiCp distribution can be improved with increasing stirring time. Further long stirring time will increase the agglomerate of SiCp, as show in Fig. 4(d). Increasing stirring time certainly increases viscosity of Mg melt, which can distinctly weaken the effect of ultrasonic cavitation [13]. In addition, long time stir would result in the gas absorption and material oxidation. Therefore, a optimized stirring time of 15min is considered good for 5vol.% SiCp/AZ31B composite.

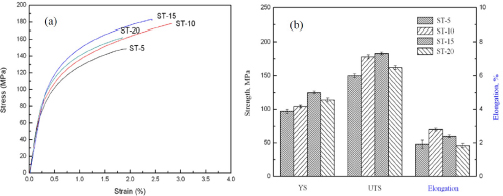

The tensile strength of SiCp/AZ31B composites fabricated by semi-solid stirring assisted ultrasonic vibration with different semi-solid stirring time are shown in Fig. 5. Moreover, with the stirring time increasing, the tensile strengths of 5 vol.% SiCp/AZ31B composites firstly increases and then decreases. By comparison the ultimate strength of composite fabricated at different stirring time, ST-15 is 33 MPa, 5 MPa, and 21 MPa higher than that the of composites produced at 5 min, 10 min and 20 min, re-

Tensile strength of SiCp/AZ31B composites fabricated by semi-solid stirring assisted ultrasonic vibration with different stirring time.

spectively. As expected, the application of ST-15 stirring parameters enhanced yield strength (YS) and ultimate tensile strength (UTS), mainly due to the uniform particle distribution. In addition, enhanced strength of composite made at ST-15 is maybe attributed to the reduced oxidation at a modest stirring time of 15 min, and controlled interfacial reactions, as shown in Fig. 4(c).

3.2 Stirring cast of SiCp/AZ31B composite with high content

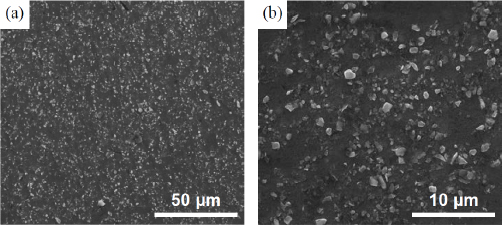

According to the above analysis results, used stirring parameters were 625 ∘C/1500 rpm/15 min for 20 vol.% SiCp/AZ31B composite fabricated by stir casting. Figs. 6a and b show the SEM images of the 20 vol.% SiCp/AZ31B composite. It has been found that addition of high content SiCp leads to increase significantly of number SiCp. Meanwhile, SiCp were distributed in magnesium matrix homogenously, and particle clusters were not observed. It means that optimal stirring parameters were reasonable and practicable because of good particle distribution, which makes 625 ∘C/1500 rpm/15 min possible for semisolid stirring process of the 20 vol.% SiCp/AZ31B composite. High magnification micrograph of the 20 vol.% SiCp/AZ31B composite is shown in Fig. 6b. It can be observed that the SiCp were well dispersed in the metal matrix, and there is no direct contact between them, which ensures the good wettability between SiCp and matrix. In addition, a continuous interface without any inclusions was observed. This reason can be attributed to the chemical inertness of SiCp and the good synthesis process of the composite, there was no interfacial reaction between the SiCp and the magnesium. The good interfacial structure is helpful to improvement of mechanical properties.

SEM graphs of SiCp/AZ31B composites fabricated by semisolid stirring assisted ultrasonic vibration with 20vol.% SiCp.

3.3 Microstructure of SiCp/AZ31B composite reinforced with different SiCp content

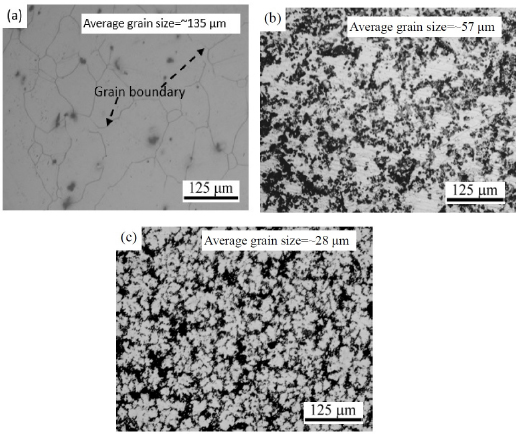

Fig. 7 show the optical micrographs of the cast monolithic AZ31 and the SiCp/AZ31 composite fabricated by different SiCp content, respectively. It can be observed that the average grain size of composite is significantly refined compared with the monolithic alloy, and the average grain size of composite is found to be reduced with increasing particle content. The uniformly distributed SiCp in field of view play a role of particle stimulation on nucleation of magnesium. According to heterogeneous nucleation theory [14], SiCp may be used as effectively heterogeneous nucleation sites for the initial nuclei formation, resulting in a more refined microstructure. Moreover, it is observed that the SiCp are mainly distributed along grain boundaries, like network. The network-like of particle distribution was determined by theparticles and the solid/liquid interface of Mg during solidification. particle near the solidification front will either be captured or pushed due to quickly move forward of solid/liquid interface front during magnesium melt containing good dispersed ceramic particles [15, 16]. Therefore, compared with particle distribution in magnesium melt, solidified composites would have the new changes. As is known, if the freezing front captured SiCp, the solidified composites can keep the particle distribution in the magnesium melt. If the freezing front pushed the particles, particles tended to aggregate in some regions especially in the last solidified regions, such as grain boundaries. The research paper of the interaction between SiCp and the solid/liquid interface of Mg matrix was firstly published by Omenyi et al. [17]. It’s study works indicate that the SiCp were pushed by the solidification front during solidification with slow speed. In the present work, the cast temperature of the melt was 720 ∘C, and the preheating temperature of steel mold was 450 ∘C. This indicates that the movement speed of solid/liquid interface is slower than the critical speed. As a result, the particles tended to segregate in the grain boundaries, as shown in Fig. 7. The grain refinement of magnesium matrix material may have resulted from the presence of the SiCp. Mean while, the grain refinement of magnesium matrix material may have resulted from the inhibition effect of the SiCp on the growth of magnesium matrix grains. In conclusion, SiCp not only acts as heterogeneous nucleus of the primary magnesium, but also distributes around grain boundaries to restrain the growth of grain, so that addition of SiCp can form uniform microstructure and refined grain. In addition, particle stimulated nucleation and grain-growth inhibition effects of SiCp enhanced with the increase of the SiCp content. Therefore, the addition of SiCp with high content leads to the decrease of grain size.

The OM micrographs of the composites. (a) AZ31B alloy, (b) 5 vol.% SiCp/AZ31B, (c) 20 vol.% SiCp/AZ31B

3.4 Mechanical properties

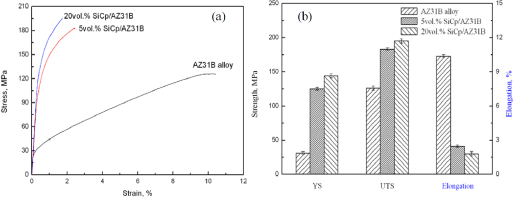

Fig. 8 illustrates mechanical properties diagrams for produced composites. As expected, the incorporation of SiCp enhanced yield strength in tension. Compared with monolithic alloy, an increase of 350% (from 32 MPa to 144 MPa) and 54.8% (from 126 MPa to 195 MPa) in yield strength and ultimate tensile strength of 20 vol.% SiCp was found respectively. It also can be seen that the tensile strength are enhanced with an increase in SiCp content. The mechanical properties reported by other authors are listed in Tables 2. By combining Table 2 and Fig. 8, it can be found that the present composite has good yield strength and ultimate tensile strength. This improvement can be attributed to the following reasons: (i) Uniform distributed and harder SiCp may play a significant role to enhance the load transfer effect. With the increase of the particle contents, the load transfer effect increased. Dependence of strength on particle contents is generally well-established, which may be described by the calculating formula Eq. (1) for yield strength [22].

The mechanical properties of as-cast composite and monolithic AZ31B alloy. (a) tensile stain–stress curves, (b) ultimate tensile strength, yield strength and elongation.

Comparison of tensile properties of magnesium based materials

| Material | 0.2% YS(MPa) | UTS(MPa) | Elongation(%) |

|---|---|---|---|

| AZ31B/SiCp(Present work) | 144 | 195 | 1.75 |

| AZ91/10 vol.% SiC[18] | 135 | 152 | 0.8 |

| Mg/0.22B4C[19] | 110 | 159 | 9.9 |

| Mg/0.66B4C[19] | 120 | 164 | 10 |

| Mg/1.11B4C[19] | 82 | 119 | 5.5 |

| Mg/9.3SiCp[20] | 115 | 180 | 3.4 |

| AZ91D/15 SiCp[21] | 119 | 193 | 0.9 |

In which σLoad is the yield strength of composite, σm is the yield strength of matrix alloy and Vp is the particle volume fraction. Therefore, the yield strength increases with the increase of particle volume fraction. (ii) The increase of particle contents would generate geometrically necessary dislocations at the interface due to the difference between elastic modulus and coefficients of thermal expansion (CTE) of SiCp and magnesium [23]. Thus, composites yield strength increased as the particle contents increase from 5vol.% to 20vol.%. (iii) The grain size was decreased as the particle contents increased, as shown in Fig. 7. The well-known Hall–Petch relation Eq. (2) indicates the effect of grain size on the strength of a material [24].

where σ is flow stress, σ0 and K were constants, D is a grain size. Therefore, according to Hall–Petch strengthening mechanism, the yield strength increased with the decrease of grain size. As a result, tensile properties of SiCp/AZ31B composites increase with increasing SiCp content. Moreover, Fig. 8 also can be seen that the elongation of the composite decrease as the increase of SiCp contents. From Fig. 7, it can be seen that the particles segregated at grain boundaries could cause the stress concentrations during tensile test. Meanwhile, stress concentrations increase with increasing SiCp content. Therefore, as the SiCp content increased, the elongation of the composite decreased.

4 Conclusions

The effects of stirring process and particle parameters on microstructure and mechanical properties of SiCp/AZ31Bcomposites were investigated, and the main conclusions can be drawn as follows:

Both too short and too long stirring time for the SiCp/AZ31B composite fabricated by stirring cast method resulted in nonhomogeneous particle distribution. According to homogeneous degree of particle distribution, a optimal stirring parameters of 625 °C/1500 rpm/15 min are considered better for composites reinforced with high content SiCp.

Present composite fabrication processing significantly improves the wettability between SiCp and magnesium matrix, which helps in achieving uniform particle distribution.

Composites reinforced by SiCp display a superior grain-refinement effect compared with the monolithic alloy. With increasing SiCp contents, it is reasonable to expect that grain size also decreases.

Compared with monolithic alloy, the ultimate tensile strength and yield strength at room temperature of 20 vol.% SiCp/AZ31B composite were increased by 54.8 % and 350 %, respectively.

Acknowledgments

This work was supported by “Chinese National Natural Science Foundation (No. 51701108).

References

[1] Zhang L, Wang QD, Liao WJ, Guo W, Li WZ, Jiang HY, Ding WJ. Mater. Sci. Eng. A 2017, 689, 427-434.10.1016/j.msea.2017.02.076Search in Google Scholar

[2] Tunde Kingsley A, Oscar Marcelo S. Sci. Eng. Compos. Mater 2010, 17, 155-172.10.1515/SECM.2010.17.3.155Search in Google Scholar

[3] Turan ME, Sun YV, Akgul YS. J. Alloys Compd 2018, 740, 1149-1158.10.1016/j.jallcom.2018.01.103Search in Google Scholar

[4] Yang XL, Wang F, Fan ZY. J. Alloys Compd 2017, 706, 430-437.10.1016/j.jallcom.2017.02.246Search in Google Scholar

[5] Wang QL. Sci. Eng. Compos. Mater 2014, 21, 309-314.10.1515/secm-2013-0155Search in Google Scholar

[6] Huang SJ, Ali AN, Mater. Sci. Eng. A 2018, 711, 670-682.10.1016/j.msea.2017.11.020Search in Google Scholar

[7] Hassan SF, Gupta M. Mater. Sci. Eng. A 2005, 392, 163–168.10.1016/j.msea.2004.09.047Search in Google Scholar

[8] Wang SJ,Wu GQ, Ling ZH, Huang Z.Mater. Sci. Eng. A 2009, 518, 158–161.10.1016/j.msea.2009.04.031Search in Google Scholar

[9] Lim CYH, Leo DK, Ang JJS, Gupta M. Wear 2005, 259, 620–625.10.1016/j.wear.2005.02.006Search in Google Scholar

[10] Lu L, Thong KK, Gupta M. Compos. Sci. Technol 2003, 63, 627-632.10.1016/S0266-3538(02)00203-8Search in Google Scholar

[11] Sahoo BN, Panigrahi SK. Mater. Des 2016, 109, 300-313.10.1016/j.matdes.2016.07.024Search in Google Scholar

[12] Han GQ, Wang ZH, Liu K, Li SB, Du X, Du WB. Mater. Sci. Eng. A 2015, 628, 350-357.10.1016/j.msea.2015.01.039Search in Google Scholar

[13] Lan J, Yang Y, Li XC. Mater. Sci. Eng. A 2004, 386, 284-290.10.1016/S0921-5093(04)00936-0Search in Google Scholar

[14] Turnbull D, Fisher JC. J. Chem. Phys 1949, 17, 71–73.10.1063/1.1747055Search in Google Scholar

[15] Shen M.J. Ying T, Chen FY, Hou JM. InterMetalcast 2017, 11, 266-273.10.1007/s40962-016-0050-6Search in Google Scholar

[16] Shen MJ, Wang XJ, Li CD, Zhang MF, Hu XS, Zheng MY, Wu K. Mater. Des 2014, 54, 436-442.10.1016/j.matdes.2013.08.078Search in Google Scholar

[17] Omenyi SN. J. Appl. Phys 1976, 47, 3956-3962.10.1063/1.323217Search in Google Scholar

[18] Luo A. Metall. Mater. Trans. A 1995, 26A, 2445–2455.10.1007/BF02671259Search in Google Scholar

[19] Habibi MK, Hamouda AS, Gupta M. J. Alloys Compd. 2013, 550, 83-93.10.1016/j.jallcom.2012.09.128Search in Google Scholar

[20] Han SF, Gupta M. J. Alloys Compd. 2007, 429, 176-183.10.1016/j.jallcom.2006.04.033Search in Google Scholar

[21] Poddar P, Srivastava VC, De PK, Sahoo KL. Mater. Sci. Eng. A 2007, 460-461, 357-364.10.1016/j.msea.2006.01.180Search in Google Scholar

[22] Deng KK, Wang XJ, Gan WM, Wu YW, Nie KB, Wu K, Zheng MY, Brokmeier HG. Mater. Sci. Eng. A 2011, 528, 1707-1712.10.1016/j.msea.2010.10.091Search in Google Scholar

[23] Xiao P, Gao YM, Yang CC, Liu ZW, Li YF, Xu FX. Mater. Sci. Eng. A 2018, 710, 251-259.10.1016/j.msea.2017.10.107Search in Google Scholar

[24] Xiao P, Gao YM, Yang CC, Liu ZW, Li YF, Xu FX. Mater. Sci. Eng. A 2018, 710, 251-259.10.1016/j.msea.2017.10.107Search in Google Scholar

© 2019 M.J. Shen et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Articles in the same Issue

- Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation

- Artificial neural network for predicting the flexural bond strength of FRP bars in concrete

- Cyclic behavior of GFRP strengthened infilled RC frames with low and normal strength concrete

- Durability of basalt fiber-reinforced polymer bars in wet-dry cycles alkali-salt corrosion

- Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite

- Enhanced dielectric properties of BaTiO3 ceramics with cerium doping, manganese doping and Ce-Mn co-doping

- Free and forced vibration analysis of rectangular/circular/annular plates made of carbon fiber-carbon nanotube-polymer hybrid composites

- Influence of nano-SiO2 on the bonding strength and wear resistance properties of polyurethane coating

- Investigation of wear behavior of nanoalumina and marble dust-reinforced dental composites

- Negative effect of clay fillers on the polyvinyl alcohol biodegradation: technical note

- Photocatalytic activity of Cu2O/ZnO nanocomposite for the decomposition of methyl orange under visible light irradiation

- Sub-surface mechanical properties and sub-surface creep behavior of wood-plastic composites reinforced by organoclay

- Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3

- The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level: FEM based study

- Vibration-damping characterization of the basalt/epoxy composite laminates containing graphene nanopellets

- A review on nanocomposite hydrogels and their biomedical applications

- Optimization and simulation analysis of structure parameters of OPCM ultrasonic longitudinal wave actuating element

- Research Article

- Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings

- Research on preload relaxation for composite pre-tightened tooth connections

- Dough moulding compound reinforced silicone rubber insulating composites using polymerized styrene butadiene rubber as a compatibilizer

- Hydration And Microstructure Of Astm Type I Cement Paste

- Effects of NiO content on the microstructure and mechanical properties of AgSnO2NiO composites

- Overall buckling behaviour of laminated CFRP tubes with off-axis ply orientation in axial compression

- UV sensing optode for composite materials environment monitoring

- On crushing characteristics of hybrid sandwich aluminum-cardboard panels reinforced with glass fiber composite rods

- Preparation and characterization of Ni-Cu composite nanoparticles for conductive paints

- A research on the preparation of oil-adsorbing hydrophobic porous resins by high internal phase emulsions (HIPEs) template

- Material characteristics of random glass-mat-reinforced thermoplastic under cryogenic thermal cycles

- Differentiation of non-black fillers in rubber composites using linear discriminant analysis of principal components

- Research Article

- Efficiency of TiO2 catalyst supported by modified waste fly ash during photodegradation of RR45 dye

- Synthesis and performance of polyurethane/silicon oxide nano-composite coatings

- Study on preparation of magnesium-rich composite coating and performance enhancement by graft modification of epoxy resin

- Research Article

- Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres

- Mechanical Properties of Al 25 wt.% Cu Functionally Graded Material

- Research Article

- Weight reduction of a carbon fibre composite wheel

- Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/ polyvinyl alcohol - magnetite nanocomposites film

- Seismic Behaviour of TRC-Strengthened RC Columns under Different Constraint Conditions

- Characterization of neat and modified asphalt binders and mixtures in relation to permanent deformation

- Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

- Research Article

- Effect of Cutting Temperature on Bending Properties of Carbon Fibre Reinforced Plastics

- Mechanical and tribological properties of B-C-N coatings sliding against different wood balls

- Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix

- Effects of Waste Eggshells addition on Microstructures, Mechanical and Tribological Properties of Green Metal Matrix Composite

- Investigation of porosity effect on flexural analysis of doubly curved FGM conoids

- Review Article

- Utilization of tailings in cement and concrete: A review

- Research Article

- Equivalent stiffness prediction and global buckling analysis using refined analytical model of composite laminated box beam

- Mechanochemical synthesis of zincite doped with cadmium in various amounts

- Size-dependent vibration analysis of graphene-PMMA lamina based on non-classical continuum theory

- Automated, Quality Assured and High Volume Oriented Production of Fiber Metal Laminates (FML) for the Next Generation of Passenger Aircraft Fuselage Shells

- Research Article

- An investigation of the stitching effect on single lap shear joints in laminated composites

- The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Effect of granulometric distribution on electromagnetic shielding effectiveness for polymeric composite based on natural graphite

- The enhancement of filament winding in marine launching rubber gasbag

- Research on ELID Grinding Mechanism and Process Parameter Optimization of Aluminum-Based Diamond Composites for Electronic Packaging

Articles in the same Issue

- Analysis on the impact response of fiber-reinforced composite laminates: an emphasis on the FEM simulation

- Artificial neural network for predicting the flexural bond strength of FRP bars in concrete

- Cyclic behavior of GFRP strengthened infilled RC frames with low and normal strength concrete

- Durability of basalt fiber-reinforced polymer bars in wet-dry cycles alkali-salt corrosion

- Effect of B4C particle size on the mechanical properties of B4C reinforced aluminum matrix layered composite

- Enhanced dielectric properties of BaTiO3 ceramics with cerium doping, manganese doping and Ce-Mn co-doping

- Free and forced vibration analysis of rectangular/circular/annular plates made of carbon fiber-carbon nanotube-polymer hybrid composites

- Influence of nano-SiO2 on the bonding strength and wear resistance properties of polyurethane coating

- Investigation of wear behavior of nanoalumina and marble dust-reinforced dental composites

- Negative effect of clay fillers on the polyvinyl alcohol biodegradation: technical note

- Photocatalytic activity of Cu2O/ZnO nanocomposite for the decomposition of methyl orange under visible light irradiation

- Sub-surface mechanical properties and sub-surface creep behavior of wood-plastic composites reinforced by organoclay

- Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3

- The influence of the WC-Co composite microstructure model on stress field heterogeneity at the microstructure level: FEM based study

- Vibration-damping characterization of the basalt/epoxy composite laminates containing graphene nanopellets

- A review on nanocomposite hydrogels and their biomedical applications

- Optimization and simulation analysis of structure parameters of OPCM ultrasonic longitudinal wave actuating element

- Research Article

- Preparation of POSS-triol/wollastonite composite particles by Liquid phase mechanochemical method and its application in UV curable coatings

- Research on preload relaxation for composite pre-tightened tooth connections

- Dough moulding compound reinforced silicone rubber insulating composites using polymerized styrene butadiene rubber as a compatibilizer

- Hydration And Microstructure Of Astm Type I Cement Paste

- Effects of NiO content on the microstructure and mechanical properties of AgSnO2NiO composites

- Overall buckling behaviour of laminated CFRP tubes with off-axis ply orientation in axial compression

- UV sensing optode for composite materials environment monitoring

- On crushing characteristics of hybrid sandwich aluminum-cardboard panels reinforced with glass fiber composite rods

- Preparation and characterization of Ni-Cu composite nanoparticles for conductive paints

- A research on the preparation of oil-adsorbing hydrophobic porous resins by high internal phase emulsions (HIPEs) template

- Material characteristics of random glass-mat-reinforced thermoplastic under cryogenic thermal cycles

- Differentiation of non-black fillers in rubber composites using linear discriminant analysis of principal components

- Research Article

- Efficiency of TiO2 catalyst supported by modified waste fly ash during photodegradation of RR45 dye

- Synthesis and performance of polyurethane/silicon oxide nano-composite coatings

- Study on preparation of magnesium-rich composite coating and performance enhancement by graft modification of epoxy resin

- Research Article

- Mechanical and wear properties of polyetheretherketone composites filled with basalt fibres

- Mechanical Properties of Al 25 wt.% Cu Functionally Graded Material

- Research Article

- Weight reduction of a carbon fibre composite wheel

- Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/ polyvinyl alcohol - magnetite nanocomposites film

- Seismic Behaviour of TRC-Strengthened RC Columns under Different Constraint Conditions

- Characterization of neat and modified asphalt binders and mixtures in relation to permanent deformation

- Microstructures, interface structure and room temperature tensile properties of magnesium materials reinforced by high content submicron SiCp

- Research Article

- Effect of Cutting Temperature on Bending Properties of Carbon Fibre Reinforced Plastics

- Mechanical and tribological properties of B-C-N coatings sliding against different wood balls

- Thermal conductivity of unidirectional composites consisting of randomly dispersed glass fibers and temperature-dependent polyethylene matrix

- Effects of Waste Eggshells addition on Microstructures, Mechanical and Tribological Properties of Green Metal Matrix Composite

- Investigation of porosity effect on flexural analysis of doubly curved FGM conoids

- Review Article

- Utilization of tailings in cement and concrete: A review

- Research Article

- Equivalent stiffness prediction and global buckling analysis using refined analytical model of composite laminated box beam

- Mechanochemical synthesis of zincite doped with cadmium in various amounts

- Size-dependent vibration analysis of graphene-PMMA lamina based on non-classical continuum theory

- Automated, Quality Assured and High Volume Oriented Production of Fiber Metal Laminates (FML) for the Next Generation of Passenger Aircraft Fuselage Shells

- Research Article

- An investigation of the stitching effect on single lap shear joints in laminated composites

- The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets

- Effect of granulometric distribution on electromagnetic shielding effectiveness for polymeric composite based on natural graphite

- The enhancement of filament winding in marine launching rubber gasbag

- Research on ELID Grinding Mechanism and Process Parameter Optimization of Aluminum-Based Diamond Composites for Electronic Packaging