Abstract

This research work investigated the effect of fiber loading and alkali treatment on hair fiber (HF)-reinforced high-density polyethylene (HDPE) composites in terms of mechanical properties and water absorption behavior. The mechanical stability of the composite material was studied by Universal Testing Machine. The alkali treatment of HF-reinforced HDPE composites was responsible for the investigation of the mechanical and water absorption properties. Fourier transform infrared (FTIR) spectroscopy and scanning electron microscopy (SEM) analysis were also done for the study of the reinforced polymer composites. The results of the SEM analysis were very helpful for the study of the morphology of the fiber-matrix interface for better/optimum mechanical properties.

1 Introduction

In recent years, the use of polymer base natural fiber-reinforced composites has increased dramatically in our society due to environmental and economical reasons. Various types of natural fibers (plant and animal hair) are used for developing ecofriendly and more effective reinforced composites. However, some disadvantages (variable quality, water sensitivity, etc.) are associated with natural fibers, which can decrease the adhesion between the matrix and the fiber. Therefore, physical and chemical treatments are used to improve the bonding between the matrix and the fiber. Hair fiber (HF) can be treated as animal fiber under the category of natural fiber or other fibrous materials, which offer the advantages of lightweight, ecofriendly, and low-energy production [1]. HF is a natural fiber considered useless in most societies. Therefore, it is found in municipal waste streams in almost all cities and towns of the world. In rural areas or areas with low population density, hair is thrown away in nature, where it slowly decomposes over several years, eventually returning to the constituent elements, namely, carbon, nitrogen, and sulfur. In urban area or areas with high population density, it often accumulates in large amounts in the solid waste streams and chokes the drainage systems, posing a multifaceted problem [2]. Human hair is a natural fiber formed by keratin, a protein containing high concentrations of sulfur coming from the amino acid cysteine. HF is mainly composed of 65%–95% proteins, remaining water, and lipid pigment. HF is the combination of cuticle, cortex, and medulla. The cuticle is the most valuable component of human hair, which covers the hair from the scalp to the ends. The cortex occupies most of the hair area (75%). The cross-links of cysteine and the cell membrane complex (CMC) are filled with cortex cells. Each cortex cell has a spindle shape, which is 50–100 μm long and has a 3 μm diameter. The thin cylindrical layer of the medulla is the middle part of human hair, which contains high lipid rate concentration and poor cysteine. Dehydrated hair may be affected for color and shine. The cortex (keratin) is responsible for this propriety. The long chains of the cortex (keratin) are compressed to form a regular structure, which provides the strength in HF [3]. Usually, the hair diameter ranges between 50 and 80 μm, the density is about 1.32 g/cm3, tensile strength is from 150 to 350 MPa, and the elongation at break is approximately 216.9% [3], [4].

HF is conventionally used for the manufacturing of natural fiber-reinforced composites due to their large availability in municipal waste and their low density and inexpensiveness; also, it contains good mechanical and water absorption properties. Reduction of waste fiber is the key factor for economy. As a potential material resource, HF/high-density polyethylene (HDPE)-reinforced composite has the advantage of being completely biodegradable, renewable, and available in every locality [5]. HF-reinforced HDPE composites can be used in dashboards, door panels and frames, railings, and mobile and laptop cases due to their good mechanical properties, low moisture absorption, and chemical and corrosion resistance properties [5], [6], [7]. The passing of stress load from the matrix to the fiber and the adhesion between the matrix and the fiber are the key aspects for increasing the performance of reinforced composites. Surface modification is used to develop the additional reactive sites on the surface and improve the bonding between the fiber and the polymer. Indeed, several works have done for the study of the mechanical properties and water absorption behavior of natural fiber (plant and animal hair)-reinforced polymer composites [8], [9], [10], [11], [12]. Velasco et al. [2] have characterized the physical and mechanical properties of HF. Zheng et al. [3] have investigated the interfacial shear strength with the help of microbond test in between hair and water-based polyurethane. Xu and Chen [7] studied the mechanical stress of the curly pattern of hair due to the growth force exerted by hair follicles. Oladele et al. [12] have investigated the mechanical behavior of animal fiber composites. Choudhry and Pandey [13] have studied the mechanical behavior of HF polypropylene composites. Senthilnathan et al. [14] have analyzed the mechanical behavior of hybrid composites of glass, coir, and hair. Mittal and Sinha [15] did a review of natural fiber composites. Mittal and Sinha [16] have studied the effect of the chemical treatment of bagasse fiber-reinforced epoxy composites in terms of mechanical and water absorption properties. They analyzed the optimum value of fiber treatment to improve the mechanical behavior as well as to reduce the water absorption behavior. Furthermore, in another study, Mittal et al. [17] studied the effect of the chemical treatment of wheat straw fiber-reinforced epoxy composites in terms of mechanical and water absorption properties. Prasad et al. [18] have investigated the mechanical properties of Coir fiber/LDPE composites. They have analyzed the optimum value of fiber in composites for maximum mechanical properties.

These researchers have shown that the mechanical and water absorption behaviors are improved with the help of fiber treatment as well as surface modification. Accordingly, this article deals with the effect of alkali treatment of HF as reinforcement of HDPE composites on mechanical properties and water absorption behavior with various fiber loadings (0, 5, 10, 15, 20, and 25 wt%) in composites.

2 Materials and characterization

2.1 Materials and preparation of composites

Waste HF is purchased from Kayak alp salon (Roorkee, India). HF is taken from the 25 to 30 age group persons for the better strength, and the thickness is about 50–80 μm and the length is 5–10 mm. Natural HDPE is purchased from Rapid Coat Powder Coatings Pvt. Ltd. (Ghaziabad, India). HDPE matrix has good strength, toughness, and better bonding property. HF/HDPE-reinforced composites have an outstanding resistance to moisture and chemical attacks. Absolute ethanol (assay-min 96.4%) was purchased from Taj Pharmaceuticals Ltd. (Gujarat, India). Sodium hydroxide (assay-min 98.0%) was purchased from Leonid chemicals Pvt. Ltd. (Bengaluru, India).

Waste HF is used directly as a natural fiber after different treatments. Preliminarily, hair was washed with hot water to remove its oil and other impurities then washed with absolute ethanol to remove the organic components that adhered to HF. This HF sample was washed several times with distilled water to remove the alcohol residues. These fibers were dried in hot oven for 48 h to remove the water. Three types of human hair samples were used: untreated and treated with 0.25 and 0.5 N NaOH. Untreated fiber is used for sample preparation directly, but treated fiber is used after the caustic treatment with 0.25 and 0.5 N NaOH at room temperature for 1 h [12], [13].

HDPE-based HF-reinforced composites were prepared by hot compression molding techniques. HF and matrix (HDPE) were mixed uniformly using stirrers for 10–15 min at 1800 rpm rotation speed. HF and HDPE were mixed according to fiber loading (0, 5, 10, 15, 20, and 25 wt%) in composite samples using an electric mixer. This uniform sample was fed in mold and the temperature was raised up to 180°C of the molding machine with a specific load of 25 to 30 kg. Then, the prepared composites (300×300×4 mm3) were cooled to 120°C and removed from the molding. The mold was coated with a Teflon sheet to avoid the sticking problem of polymer composites. The specimens of the composites were prepared according to the ASTM standards [19], [20], [21] for various analyses, which are shown in Figure 1A–D [16], [22].

Diagrams of the experimental facility.

(A) Treatment of hair fiber, (B) Uniform mixing of HF/HDPE, (C) Mold for composites, and (D) Hot compress molding machine.

2.2 Characterization

2.2.1 Fourier transform infrared (FTIR) spectroscopy

An FTIR spectrometer (Nicolet 6700 series) was used for examining the spectrum analysis of untreated and treated human HF as well as the prepared composites. Potassium bromide (KBr) was used to develop the pellets of the samples as a reference substance. The spectrum resolution of 4 cm−1 was used for the analysis of samples with a range of 4000–6000 cm−1 [15], [16], [17].

2.2.2 Test for mechanical properties

The flat specimen samples were used for the analysis of the mechanical properties using the computerized Universal Testing Machine (UTM; Instron model 5982). Tensile and flexural analyses of the specimens were done as per ASTM D3039 [22] and ASTM D790 [19] standards, respectively. A constant crosshead speed of 2 mm/min is applied during the material testing for better study. The values of the analyses were taken as the average of four same types of samples of each composition [8], [9], [10], [11], [12].

2.2.3 Scanning electron microscopy (SEM) analysis

The morphological study of untreated and alkali-treated HF composites were done by SEM (model LEO-435 VP) with an acceleration voltage of 0–30 kV. In this analysis, fractured surfaces of the composite samples were used to examine the failure mode of composites after the tensile test. A thin layer coating of gold was used for the SEM analysis of fractured surfaces [15], [16], [17], [18].

2.2.4 Water absorption test

ASTM D570 [20] standards were used for the moisture absorption test of composite samples. The prepared samples were dried in a hot air oven at 50°C for 48 h or until a constant weight was obtained. The samples were taken out from the oven, and the weight with high precision balance was measured (Voyager Analytical Balances CPA225D). Then, the samples were dipped in distilled water and weighed at a specific time period followed by wiping with tissue paper. The gain weight difference was used for the estimation of water absorption test of the samples. The percent gain of water absorption was calculated using the following formula:

where Wt represents the wet weight specimen and Wi represents the oven-dried specimen at t time interval.

3 Results and discussion

3.1 FTIR analysis of HF-reinforced composites

FTIR spectroscopy was used for the spectral analysis of untreated and treated HF as well as untreated and treated HF-reinforced composites. The investigated spectra results are shown in Figure 2A. The FTIR spectra show the strong absorbance band at 3425.40 cm−1 corresponding to the O-H stretching vibration of free and hydrogen-bonded -OH group present in the fiber components [15]. The peaks at 2922.04 and 2851 cm−1 are associated with the medium C-H stretch of fibers [17]. The absorbance peak at 2257.72 cm−1 is observed due to the -CN stretch, which is the protein component of the fibers. The spectrum at 1633.31 cm−1 is present due to the presence of medium N-H bend in the fiber and that at 1436.52 cm−1 is observed as the C-C stretch (in-ring) bonding due to aromatic components. The spectrum at 1093.96 cm−1 is associated with the C-N stretch bonding due to the presence of aliphatic amines in the fibers. The band spectrum at 597.62 cm−1 shows the medium C-Br stretch bonding in the fiber. However, the C-Br stretch is removed due to the alkali treatment of the fibers.

(A) FTIR spectra of the untreated and alkali-treated HFs and (B) FTIR spectra of the untreated and alkali-treated composites.

The investigated results of untreated and 0.25 N alkali-treated fiber-reinforced composites are shown in Figure 2B. The strong absorbance band of O-H stretching vibration is observed at 3615.76 cm−1 due to the moisture present in composites. The presence of spectra at 2919.01 and 2850.47 cm−1 is attributed to the presence of C-H stretch bonding in the composites. Then, 0.25 N alkali treatment is improved by the bonding between the matrix and the fiber. The absorbance peaks are observed at 2237.67 cm−1 due to the nitrile group in the composites. The spectrum at 2121.75 cm−1 shows the alkyne group in the composite due to carbon content. The absorbance peaks at 1466.77 cm−1 are observed due to the C-H bend in the composites. Thus, C-H bonding is improved due to the alkali treatment of fibers. The spectra peaks at 1363.87 and 1362.14 cm−1 are observed for the carbon-hydrogen bonding in the composites. The above absorbances of spectra show the effect of 0.25 N alkali treatment of HF in HF/HDPE-reinforced composites.

3.2 Mechanical properties of HF-reinforced composites

The effects of fiber loading (5, 10, 15, 20, and 25 wt%) on different mechanical properties (tensile strength, tensile modulus, flexural strength, flexural modulus, load force vs. extension, and elongation at break) of HF/HDPE-reinforced composites are shown in Figures 3–8 . The average values of the experimental results are taken for different mechanical tests. The experimental results show that the tensile and flexural properties of treated and untreated HF base reinforcement of HF/HDPE composites are increased with the increases in fiber loading from 0 to 15 wt%. It was found that, beyond 15 wt% of fibers, the mechanical properties are substantially decreased. At 15 wt% fibers, the optimum value of the mechanical properties of HF/HDPE-reinforced composites is observed. The value of tensile and flexural strength is 19.2% and 33.06% lesser than virgin HDPE matrix, respectively, but the tensile and flexural moduli are found to be 42.25% and 33.8%, which is more than the virgin HDPE matrix. Beyond 15 wt% fiber loading, the properties are decreased with higher fiber contents and poor bonding between the matrix and the fiber. The fiber-pullout voids, poor interlocking, and nonuniform stress transfer are responsible for the decrease in tensile properties [12], [17].

Effect of fiber loading on the tensile strength of HF/HDPE-reinforced composites.

Effect of fiber loading on the tensile modulus of HF/HDPE-reinforced composites.

Effect of fiber loading on the flexural strength of HF/HDPE-reinforced composites.

Effect of fiber loading on the flexural modulus of HF/HDPE-reinforced composites.

(A) Effect of fiber loading on applied load vs. extension of untreated HF/HDPE-reinforced composites and (B) effect of fiber loading on applied load vs. extension of alkali-treated HF/HDPE-reinforced composites.

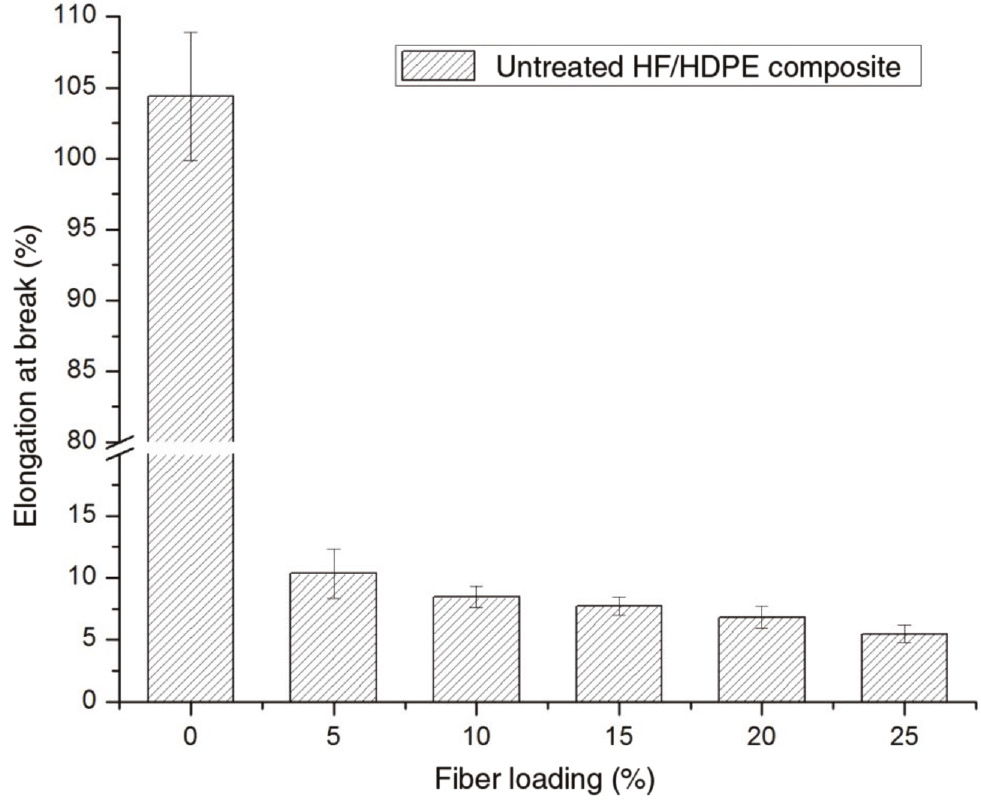

Effect of fiber loading on the elongation at break of untreated HF/HDPE-reinforced composites.

The surface modification (0.25 and 0.5 N alkali treatment) of fibers also effected the tensile and flexural properties. However, the strength of HFs is reduced beyond the 0.25 N alkali treatment because of fiber surface damage. The tensile and flexural properties are slightly increased after the 0.25 N alkali treatment. Tensile and flexural strength reached 15.487 and 23.456 MPa, which are increased in comparison to untreated fiber-reinforced composites. The modulus of tensile and flexural strength is 45.7% and 48.98% greater than the virgin matrix, respectively, which also improved the Young’s modulus of composites compared to untreated fiber/matrix composites. The chemical treatment is the most important fiber modification technique, which increases the surface roughness of fiber due to its hydrophilic character [2].

The characterization of applied load and their extension of untreated and alkali-treated fiber/matrix-reinforced composites are shown in Figure 7A and B. The load behavior strength depends on the interlocking between the matrix and the fiber. The load strength is found to be maximum at 15 wt% fiber loading in composites, which is lesser than the virgin matrix. However, alkali-treated fiber-reinforced composites shows a slightly higher load-bearing strength. The elongation at break of HF-reinforced HDPE composites is shown in Figure 8. The elongation at break is decreased from 104.4% to 5.46% due to the increase in fiber loading, which is in matrix form. Because the higher value of fibers in a matrix form decreased the interlocking between the matrix and the fiber, fiber loading has also increased the ductility of composites.

3.3 SEM analysis of HF-reinforced composites

The morphology of the treated and untreated HFs and composites is assessed by SEM. SEM micrographs show the morphology of untreated HF as presented in Figure 9A. The surface of the fiber is smooth due to the presence of amino acids and cuticles. The alkali-treated HF surface is shown in Figure 9B and C. The surface of the fiber is more porous and the roughness is up to a certain limit of alkali treatment at 0.25 N. Further treatment (0.5 N alkali) promotes the formation of fractures on the fiber surface, which causes a decrease in the fiber strength [9]. Pits are shown on the fiber surface to increase the bonding between the matrix and the fiber. The SEM micrographs of the untreated and alkali-treated HF-reinforced composites are shown in Figure 10A and B. Normally, fiber-pullouts, fiber breakage, bonding between the matrix and the fiber, gaps, and voids can be investigated after the fracture test of composites. The morphology of the samples is taken from the tensile fractured surface in both figures. In Figure 10A, the SEM micrograph shows the typical fracture surface of untreated 15% HF-reinforced HDPE composite. Gaps, fiber-pullouts, and poor bonding between the matrix and the fiber are shown in the figure due to the presence of a smooth surface of the fiber and poor interlocking of the matrix-fiber. Due to the above reasons, the mechanical properties and water absorption behavior of composites are decreased. The alkali-treated HF-reinforced composite is shown in Figure 10B. Fiber-pullouts, fiber breakage, and strong bonding between the matrix and the fiber are shown in the figure attributed to the alkali treatment of fiber. Alkali treatment increases the pits on the fiber surface and therefore increases the fiber locking with the matrix to enhance the mechanical property of the composites [15], [16], [17], [18].

(A) SEM micrographs of untreated HF, (B) SEM micrographs of 0.25 N alkali-treated HF, and (C) SEM micrographs of 0.5 N alkali-treated HF.

(A) SEM micrographs of untreated HF and (B) SEM micrographs of 0.25 N alkali-treated HF-reinforced composites.

3.4 Water absorption behavior of HF-reinforced composites

The water absorption behavior of untreated and alkali-treated HF-reinforced composites is shown in Figure 11. The absorption of water increases with the increase in the fiber loading in composites and can increase with an increase in the time period. The water absorption of composites depends on the fiber surface and the bonding between the matrix and the fiber. In HF/HDPE composites, the absorption percentage is lesser in comparison to that in other natural fibers due to their hydrophobic nature. The percent gain of water absorption is increased with the alkali treatment of fiber, because alkali treatment increases the pits/roughness on the fiber surface, as shown in SEM analysis [16], [17], [18].

Water absorption behavior of untreated and treated HF/HDPE composites.

4 Conclusion

The effect of fiber loading on the mechanical properties and water absorption of HF-reinforced HDPE composites was investigated. The mechanical properties (maximum tensile and flexural strength, modulus, etc.) are increased with the surface modification of fibers at 0.25 N alkali treatment. If further treatments (0.5 N alkali) are applied on HF, the properties of fiber are decreased due to the fracture of the fiber surface. However, the experimental results show that the tensile and flexural properties of treated and untreated HF base reinforcement of HF/HDPE composites increase with the increase in fiber loading from 0 to 15 wt%. Beyond 15 wt%, the mechanical properties are relatively decreased. At 15 wt%, the optimum value of the mechanical properties of HF/HDPE-reinforced composites is observed. The water absorption of composites depends on the fiber surface and the bonding between the matrix and the fiber. In HF/HDPE composites, the water absorption percentage is lesser compared to that in other natural fibers due to their hydrophobic nature [2], [3]. The percent gain of water absorption is increased with the alkali treatment of fiber, because alkali treatment increases the pits/roughness on the fiber surface [16]. An SEM morphological study can easily verify the effect of chemical treatment and fiber modification and also improve the interlocking between the matrix and the fiber. Waste HF can be used as resources for the development of HF-reinforced polymer composites.

Acknowledgments

This study was supported by the Indian Institute of Technology Roorkee (India) and the Ministry of Human Resources and Development (MHRD; India).

References

[1] Gupta A. J. Waste Manag. 2014. Article ID 498018. DOI: http://dx.doi.org/10.1155/2014/498018.10.1155/2014/498018Search in Google Scholar

[2] Velasco MVR, Dias TCS, Freitas AZ, Junior NDV, Pinto CASO, Kaneko TM, Baby AR. Braz. J. Pharm. Sci. 2009, 45, 153.10.1590/S1984-82502009000100019Search in Google Scholar

[3] Robbins CR. Chemical and Physical Behavior of Human Hair. Springer-Verlag: Berlin, Heidelberg, 2012, 537.10.1007/978-3-642-25611-0_9Search in Google Scholar

[4] Zheng L, Jones FR, Liu Y, Jiang B. Int. J. Adhes. Adhes. 2014, 48, 14.10.1016/j.ijadhadh.2013.09.004Search in Google Scholar

[5] Faruka O, Bledzkia AK, Fink HP, Sain M. Prog. Polym. Sci. 2012, 37, 1552.10.1016/j.progpolymsci.2012.04.003Search in Google Scholar

[6] Abraham E, Deepa B, Pothen LA, Cintil J, Thomasc S, Johnd MJ, Anandjiwala R, Narine SS. Carbohydr. Polym. 2013, 92, 1477.10.1016/j.carbpol.2012.10.056Search in Google Scholar PubMed

[7] Xu B, Chen X. J. Mech. Behav. Bio Med. Mater. 2011, 4, 212.10.1016/j.jmbbm.2010.06.009Search in Google Scholar PubMed

[8] Monteiro SN, Terrones LAH, Almeida JRMD. Polym. Test. 2008, 27, 591.10.1016/j.polymertesting.2008.03.003Search in Google Scholar

[9] Haque MM, Hasan M, Islam MS, Ali ME. Bioresour. Technol. 2009, 100, 4903.10.1016/j.biortech.2009.04.072Search in Google Scholar PubMed

[10] Trana LQN, Minh TN, Fuentes CA, Chic TT, Vuure AWV, Verpoest I. Ind. Crops Prod. 2015, 65, 437.10.1016/j.indcrop.2014.10.064Search in Google Scholar

[11] Venkateshwaran N, Perumal AE, Alavudeen A, Thiruchitrambalam M. Mater. Des. 2011, 32, 4017.10.1016/j.matdes.2011.03.002Search in Google Scholar

[12] Oladele IO, Olajide JL, Ogunbadejo AS. Am. J. Eng. Res. 2015, 4, 19.Search in Google Scholar

[13] Choudhry S, Pandey B. IJMIE 2012, 2, 118.Search in Google Scholar

[14] Senthilnathan D, Babu AG, Bhaskar GB, Gopinath KGS. IJET 2014, 6, 75.Search in Google Scholar

[15] Mittal V, Sinha S. J. Polym. Eng. 2015, 35, 545–550.10.1515/polyeng-2014-0270Search in Google Scholar

[16] Mittal V, Sinha S. Sci. Eng. Compos. Mater. 2017, 24, 731–738.10.1515/secm-2015-0441Search in Google Scholar

[17] Mittal V, Saini R, Sinha S. J. Compos. Pt. B Eng. 2016, 99, 425–435.10.1016/j.compositesb.2016.06.051Search in Google Scholar

[18] Prasad N, Agarwal VK, Sinha S. Kor. J. Chem. Eng. 2015, 32, 122534–122541.10.1007/s11814-015-0069-zSearch in Google Scholar

[19] ASTM D3039. Standard test method for tensile properties of polymer matrix composite materials.Search in Google Scholar

[20] ASTM D790. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials.Search in Google Scholar

[21] ASTM D570. Standard test method for water absorption of plastics.Search in Google Scholar

[22] Prasad N, Agarwal VK, Sinha S. Iran Polym. J. 2016, 25, 229–241.10.1007/s13726-016-0416-xSearch in Google Scholar

©2018 Walter de Gruyter GmbH, Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Original articles

- Review of the mechanical performance of variable stiffness design fiber-reinforced composites

- Exact solution for bending analysis of functionally graded micro-plates based on strain gradient theory

- Synthesis, microstructure, and mechanical properties of in situ TiB2/Al-4.5Cu composites

- Microstructure and properties of W-Cu/1Cr18Ni9 steel brazed joint with different Ni-based filler metals

- Drilling studies on the prepared aluminum metal matrix composite from wet grinder stone dust particles

- Studies on mechanical properties of thermoplastic composites prepared from flax-polypropylene needle punched nonwovens

- Design of and with thin-ply non-crimp fabric as building blocks for composites

- Effect of coir fiber reinforcement on mechanical properties of vulcanized natural rubber composites

- Investigation and analysis of glass fabric/PVC composite laminates processing parameters

- Abrasive wear behavior of silane treated nanoalumina filled dental composite under food slurry and distilled water condition

- Finite element study into the effects of fiber orientations and stacking sequence on drilling induced delamination in CFRP/Al stack

- Preparation of PAA/WO3 composite films with enhanced electrochromism via layer-by-layer method

- Effect of alkali treatment on hair fiber as reinforcement of HDPE composites: mechanical properties and water absorption behavior

- Integration of nano-Al with one-step synthesis of MoO3 nanobelts to realize high exothermic nanothermite

- A time-of-flight revising approach to improve the image quality of Lamb wave tomography for the detection of defects in composite panels

- The simulation of the warpage rule of the thin-walled part of polypropylene composite based on the coupling effect of mold deformation and injection molding process

- Novel preparation method and the characterization of polyurethane-acrylate/ nano-SiO2 emulsions

- Microwave properties of natural rubber based composites containing carbon black-magnetite hybrid fillers

- Simulation on impact response of FMLs: effect of fiber stacking sequence, thickness, and incident angle

Articles in the same Issue

- Frontmatter

- Original articles

- Review of the mechanical performance of variable stiffness design fiber-reinforced composites

- Exact solution for bending analysis of functionally graded micro-plates based on strain gradient theory

- Synthesis, microstructure, and mechanical properties of in situ TiB2/Al-4.5Cu composites

- Microstructure and properties of W-Cu/1Cr18Ni9 steel brazed joint with different Ni-based filler metals

- Drilling studies on the prepared aluminum metal matrix composite from wet grinder stone dust particles

- Studies on mechanical properties of thermoplastic composites prepared from flax-polypropylene needle punched nonwovens

- Design of and with thin-ply non-crimp fabric as building blocks for composites

- Effect of coir fiber reinforcement on mechanical properties of vulcanized natural rubber composites

- Investigation and analysis of glass fabric/PVC composite laminates processing parameters

- Abrasive wear behavior of silane treated nanoalumina filled dental composite under food slurry and distilled water condition

- Finite element study into the effects of fiber orientations and stacking sequence on drilling induced delamination in CFRP/Al stack

- Preparation of PAA/WO3 composite films with enhanced electrochromism via layer-by-layer method

- Effect of alkali treatment on hair fiber as reinforcement of HDPE composites: mechanical properties and water absorption behavior

- Integration of nano-Al with one-step synthesis of MoO3 nanobelts to realize high exothermic nanothermite

- A time-of-flight revising approach to improve the image quality of Lamb wave tomography for the detection of defects in composite panels

- The simulation of the warpage rule of the thin-walled part of polypropylene composite based on the coupling effect of mold deformation and injection molding process

- Novel preparation method and the characterization of polyurethane-acrylate/ nano-SiO2 emulsions

- Microwave properties of natural rubber based composites containing carbon black-magnetite hybrid fillers

- Simulation on impact response of FMLs: effect of fiber stacking sequence, thickness, and incident angle