Abstract

In this study, the effect of coir fiber reinforcement on the mechanical properties of vulcanized natural rubber composite has been studied. An attempt has been made to predict the effect on tensile strength, maximum load, and elongation at break (%) of coir fiber-reinforced vulcanized natural rubber composites under cold, heat, and water aging tests. The natural rubber was vulcanized at 150°C. The fibers were soaked in a 5% solution of NaOH for 48 h at room temperature. At different temperatures, cold, heat, and water aging resistance tests were conducted to understand the behavior of the composite under different environment. The properties recorded after aging tests were compared with initial properties to investigate the effect of fiber reinforcement. The results revealed that the samples containing coir fiber showed better performance after each aging test. The specimens showed the highest properties in case of water aging resistance.

1 Introduction

Philippines, Indonesia, India, and Sri Lanka account for 78% of coconut production. It is a renewable resource and CO2-neutral material. It is a nontoxic, biodegradable, low-density, and low-cost fiber, which is abundant in nature. The fiber has a high degree of water retention and is rich in micronutrients.

Generally, natural rubber (NR) is used as a base material for such products where flexibility and elasticity are of greater importance. On its normal life span, NR products can face various atmospheric and temperature variations. In certain cases, it is required that the product should have a specific stiffness in a particular direction. A high level of reinforcement cannot be achieved using short fiber, but they can exhibit soft, stiff, and stronger properties. In this article, an attempt has been made to understand the effect on tensile strength (MPa), maximum load (N), and elongation at break (%) of coir fiber reinforced vulcanized NR composites under cold, heat, and water aging tests. Because rubber products have a very wide area of application, it becomes very important to understand the behavior of NR under such conditions. The coir fibers are short and coarse in nature; thus, they can be used as reinforcement in NR. They can alter the strength and can make rubber a little stronger, although it is nearly impossible to obtain enhanced toughness because of the steepness in its stress-strain curve. Geethamma et al. [1] studied the dynamic mechanical analysis of short coir fiber-reinforced NR composites. The results suggested that fibers increased the value of the modulus.

Nam et al. [2] investigated the effect of alkali treatment on the interface and mechanical properties of coir fiber-reinforced poly(butylene succinate) biodegradable composites. The results suggested that the alkali-treated composites showed better properties as compared with that of untreated. In this study, the fibers were soaked in 5% of NaOH solution for 48 h. This treatment removed the undesired coir pith from the fiber and made the fiber suitable to enhance fiber/rubber adhesion. Geethamma et al. [3] treated the fiber with alkali solution, and the results showed improved properties than untreated fibers. Karthikeyan and Balamurugan [4] investigated the effect of alkali-treated coir fibers on polyester composite. In their experiment, different volume fractions were taken and results revealed that the volume fraction ranging from 10% to 30% showed optimum properties. The treated fiber showed better results as compared with untreated fibers. The flexural strength of such composites was found out to be lower than the pure polyester.

Rattanasom and Prasertsri [5] studied the relationship between mechanical properties, heat aging resistance, cut growth behavior, and morphology in NR. The results showed that the elongation at break % and the tensile strength were reduced after thermal aging, whereas the modulus was increased by thermal aging. Wang et al. [6] studied the weather aging resistance of different rubber modified asphalts. Dynamic shear rheometer and dynamic mechanical analysis showed that the chemical and rheological properties were significantly altered by weather aging.

Table 1 summarizes important studies related to coir fiber/NR composites.

Summary of important studies based on coir/NR composites.

| References | Approach used | Material used | Properties studied | Remarks |

|---|---|---|---|---|

| Geethamma et al. [1] | Experimental approach, dynamic mechanical analyzer machine | Coir fiber, NR ISNR 5 (light color) grade | Loss modulus, glass transition temperature, mechanical damping | Effect of frequency, effect of fiber incorporation |

| Nam et al. [2] | Experimental study, two-roll laboratory mill | Poly(butylene succinate) pellets, coir fibers | Interfacial bonding, tensile modulus, tensile strength, and tear strength | Effect on mechanical properties of composite |

| Geethamma et al. [3] | Experimental approach, two roll mill | Coir fiber, ISNR 5 (light color) grade NR | Tensile properties, stress-strain curve | Effect of transverse and longitudinal loading |

| Cholachagudda et al. [7] | Experimental approach, fabrication of composite, universal machine testing, SEM | Coconut coir, rice husk, Mylar sheet | Ultimate tensile strength, flexural strength | Effect on mechanical properties |

| Barbosa et al. [8] | Experimental analysis, DMTA dynamic mechanical, and thermal analysis | Tannin-phenolic polymers, coir fiber bundles | Water diffusion rate, izod impact strength, loss modulus | Effect on mechanical properties and absorption properties |

2 Materials and methods

2.1 Materials

The coir fiber used as reinforcement was supplied by Shri Balaji Pressing Unit, Bhosari MIDC, local industry in Pune, Maharashtra, India. The NR used in this investigation was obtained from Balaji Rubber Lining Industry Bhosari MIDC, local industry in Pune, Maharashtra, India. All the materials used were of commercial grade. Figure 1 shows the structures of coir fiber and vulcanized NR. Initial properties of the vulcanized NR are shown in Table 2.

Optical micrograph of: (A) Raw coir fiber. (B) Raw vulcanized NR.

Initial properties of vulcanized NR.

| Sr. no. | Sample name | Max load (N) | Tensile strength (MPa) | Elongation at break (%) | Stress vs. strain plot |

|---|---|---|---|---|---|

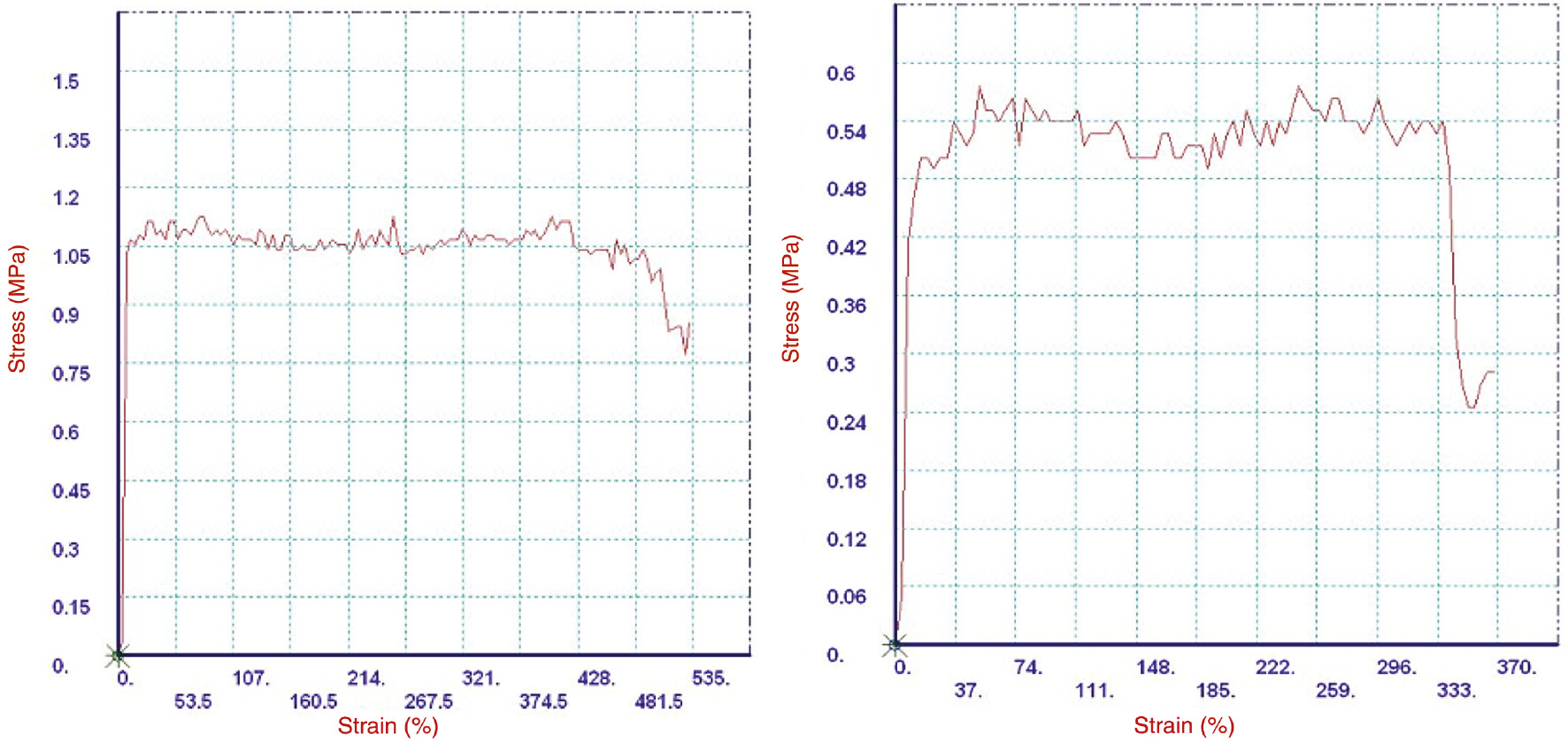

| 1 | Vulcanized NR (specimen no. 1) | 6.86 | 1.127 | 532 | Figure 4 |

| 2 | Vulcanized NR (specimen no. 2) | 4.606 | 0.576 | 368 | |

| Average values | 5.733 | 0.852 | 450 | ||

2.2 Fiber preparation

Coir pith present in the fibers was removed before alkali treatment. The fibers were chopped into approximately 10 mm length and then soaked in 5% NaOH for 48 h. The fibers absorbed most of the solution. The fibers were taken out and washed rapidly under tap water several times and allowed to dry out in air. Figure 2 shows the coir fibers soaked in 5% NaOH solution.

Coir fibers soaked in 5% NaOH solution.

2.3 Preparation of composites

The composites were prepared on two roll laboratory mill shown in Figure 3. All the machine parameters were kept same for both NR and coir fiber-reinforced NR. The nip gap was maintained at 2 mm. The NR was milled and passed through the roller several times to ensure no air was present in the rubber. The following chemicals were added during the milling of vulcanized NR:

Zinc, 10 g

Mercaptobenzodithiazole, 10 g

Tetramethylthiurum, 5 g

Sulfur, 5 g

Two roll laboratory mill.

The fibers were mixed at the last of the milling process for better fiber alignment. Two different types of sheets were made of the mill. One with reinforcement and the other without reinforcement, then the samples were made of sheets (150×150×2 mm3). The samples were then allowed to cure at room temperature. Initial properties of coir fiber-reinforced vulcanized NR composites are shown in Table 3.

Initial properties of coir fiber-reinforced vulcanized NR composite.

| Sr. no. | Sample name | Max load (N) | Tensile strength (MPa) | Elongation at break (%) | Stress vs. strain plot |

|---|---|---|---|---|---|

| 1 | Coir fiber-reinforced vulcanized NR (specimen no. 1) | 12.25 | 1.332 | 156 | Figure 5 |

| 2 | Coir fiber-reinforced vulcanized NR (specimen no. 2) | 12.152 | 1.321 | 644 | |

| 3 | Coir fiber-reinforced vulcanized NR (specimen no. 3) | 7.154 | 0.778 | 664 | |

| Average values | 10.519 | 1.144 | 488 | ||

3 Results and discussion

The samples were investigated under different temperature and atmospheric conditions for understanding the response of the material under such working conditions. Initial mechanical properties such as maximum load (N), elongation at break (%), and tensile strength for both kinds of samples were investigated. It was then compared with the properties obtained after the aging tests.

3.1 Initial tensile strength and elongation at break (%)

Mechanical properties such as maximum load, tensile strength, and elongation at break (%) were investigated for both samples without any kind of aging. The specimens were cut into dog bone shape for tensile strength investigation. Both types of samples were analyzed in the same universal testing machine (UTM) according to ATSMD 3039 standard.

The stress-strain variation was recorded by an extensometer. The specimens with coir fiber showed better performance. The tensile strength was increased by 34.70%. Geethamma et al. [3] studied the effect of coir fiber reinforcement on NR composite and calculated various mechanical properties. Elongation at break (%) was analyzed for different mixtures of fiber/rubber. The increase in maximum load was recorded to be 83.32%. Figure 4 shows the initial mechanical properties of vulcanized NR, and Figure 5 shows the initial properties of coir fiber-reinforced vulcanized NR composite. From Tables 2 and 3, it can be concluded that the elongation at break increased because of better fiber/rubber adhesion. The increase in elongation at break (%) was calculated as 8.44%, whereas the percentage increase in the tensile strength was recorded as 34.70 (%).

Initial mechanical properties of vulcanized NR.

Initial properties of coir fiber-reinforced vulcanized NR composite.

3.2 Effect of cold resistance at −60°C for 8 h

Multiple samples were made for a better understanding of the behavior of the composite material in different working conditions. Three samples of vulcanized NR and two samples of coir fiber-reinforced vulcanized NR composites were analyzed in cold resistance test. The samples were kept at −60°C for 8 h. Curing was conducted at room temperature. The samples were hardened a little by cold temperature. All the samples were tested in UTM.

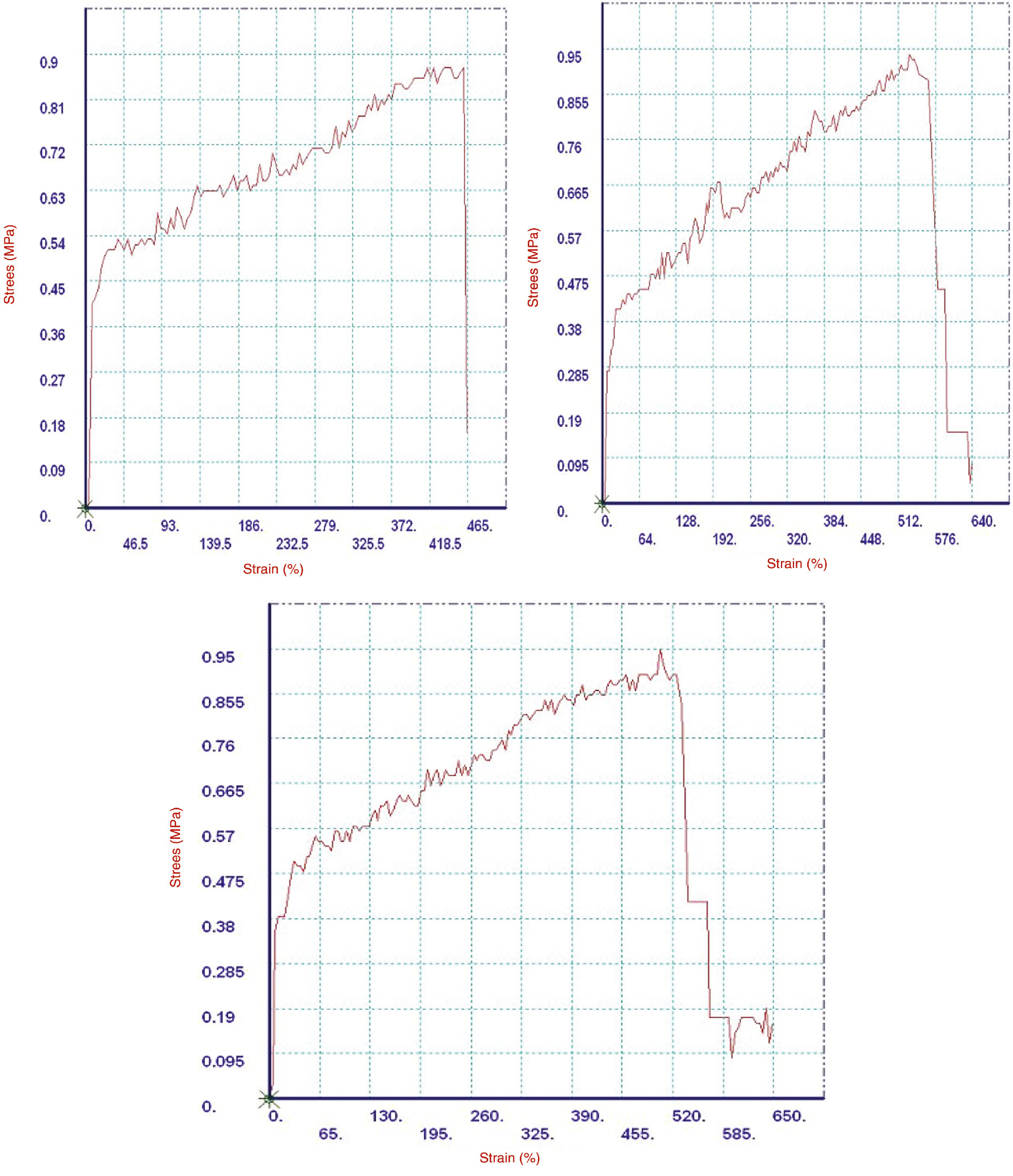

Maximum load (N), tensile strength (MPa), and elongation at break (%) were recorded during the test. The stress-strain curve depicts the behavior of material under maximum load (N). Reinforced NR specimens showed higher mechanical properties as compared with raw NR samples. The maximum load was increased by 121.162%, tensile strength by 90.06%, and elongation at break by 84.65%. The coir fiber enhanced the properties of NR for working under cold temperature. The mechanical properties of vulcanized NR after cold resistance at −60°C for 8 h are shown in Table 4. Figure 6 shows the stress-strain curve of vulcanized NR after cold resistance at −60°C for 8 h. Table 5 shows the mechanical properties of coir fiber-reinforced vulcanized NR composite after cold resistance at −60°C for 8 h. Figure 7 displays the stress-strain curve of coir fiber-reinforced vulcanized NR composite after cold resistance at −60°C for 8 h. On comparing these parameters with initial parameters given in Tables 2 and 3, it can be concluded that because of cold resistance, the properties were reduced.

Mechanical properties of vulcanized NR after cold resistance at −60°C for 8 h.

| Sr. no. | Sample name | Max load (N) | Tensile strength (MPa) | Elongation at break (%) | Stress vs. strain plot |

|---|---|---|---|---|---|

| 1 | Vulcanized NR (specimen no. 1) | 4.116 | 0.515 | 512 | Figure 6 |

| 2 | Vulcanized NR (specimen no. 2) | 3.724 | 0.466 | 304 | |

| 3 | Vulcanized NR (specimen no. 3) | 3.234 | 0.404 | 292 | |

| Average values | 3.691 | 0.462 | 369.34 | ||

Stress-strain curve of vulcanized NR after cold resistance at −60°C for 8 h.

Mechanical properties of coir fiber-reinforced vulcanized NR composite after cold resistance at −60°C for 8 h.

| Sr. no. | Sample name | Max load (N) | Tensile strength (MPa) | Elongation at break (%) | Stress vs. strain plot |

|---|---|---|---|---|---|

| 1 | Coir fiber-reinforced vulcanized NR (specimen no. 1) | 7.644 | 0.831 | 592 | Figure 7 |

| 2 | Coir fiber-reinforced vulcanized NR (specimen no. 2) | 8.722 | 0.948 | 772 | |

| Average values | 8.183 | 0.889 | 682 | ||

Stress-strain curve of coir fiber-reinforced vulcanized NR composite after cold resistance at −60°C for 8 h.

3.3 Effect of water resistance at ambient temperature for 8 h

To study the effect of water on fibers, the specimens of both types were kept in water for 8 h at ambient temperature. The graphs of both samples were analyzed. Table 6 shows the mechanical properties of vulcanized NR after water resistance at ambient temperature for 8 h. Table 7 highlights the mechanical properties of coir fiber-reinforced vulcanized NR composite after water resistance at ambient temperature for 8 h. Figure 8 shows the stress-strain curve of vulcanized NR after water resistance at ambient temperature for 8 h, and Figure 9 displays the stress-strain curve of coir fiber-reinforced vulcanized NR composite after water resistance at ambient temperature for 8 h.

Mechanical properties of vulcanized NR after water resistance at ambient temperature for 8 h.

| Sr. no. | Sample name | Max load (N) | Tensile strength (MPa) | Elongation at break (%) | Stress vs. strain plot |

|---|---|---|---|---|---|

| 1 | Vulcanized NR (specimen no. 1) | 4.90 | 0.613 | 276 | Table 8 |

| 2 | Vulcanized NR (specimen no. 2) | 6.37 | 0.796 | 308 | |

| Average values | 5.64 | 0.705 | 292 | ||

Mechanical properties of coir fiber-reinforced vulcanized NR composite after water resistance at ambient temperature for 8 h.

| Sr. no. | Sample name | Max load (N) | Tensile strength (MPa) | Elongation at break (%) | Stress vs. strain plot |

|---|---|---|---|---|---|

| 1 | Coir fiber-reinforced vulcanized NR (specimen no. 1) | 8.036 | 0.873 | 460 | Figure 9 |

| 2 | Coir fiber-reinforced vulcanized NR (specimen no. 2) | 8.624 | 0.937 | 592 | |

| 3 | Coir fiber-reinforced vulcanized NR (specimen no. 3) | 8.722 | 0.948 | 648 | |

| Average values | 8.461 | 0.919 | 566.67 | ||

Stress-strain curve of vulcanized NR after water resistance at ambient temperature for 8 h.

Stress-strain curve of coir fiber-reinforced vulcanized NR composite after water resistance at ambient temperature for 8 h.

The results suggested that the reinforced specimens showed higher properties as compared with raw vulcanized NR specimens. For raw vulcanized NR, the maximum load was found out to be 5.635 N (average). For coir fiber-reinforced composite, the maximum load recorded was 8.46 N (average). Thus, it can be concluded that the coir fiber act as a reinforcement for water-based application. The maximum load was increased by 50.13%, tensile strength by 31.428%, and elongation at break by 94.065%. It can be seen that these values of maximum loads are still smaller than the values shown in Tables 2 and 3. Hence, water soaking reduced the fiber/rubber adhesion and decreased the amount of maximum load (N) in both samples. Still, after the effect of water resistance, the reinforced samples showed better results. The coir fiber also has high lignin content.

3.4 Effect of heat resistance at 80°C for 4 h

Three specimens of both NR and coir fiber-reinforced vulcanized NR were examined under this test. NR on its typical application can face temperature variations. It is important to understand its behavior after the heat aging process. After heat aging, the specimens were tested on UTM, and their stress-strain relationship was analyzed. It can be seen that after heat aging, the performance is reduced. Rattanasom and Prasertsri [5] studied the effect of thermal aging on different NR vulcanizates. The strength of samples was decreased after heat aging. Table 8 shows the mechanical properties of vulcanized NR after heat resistance at 80°C for 4 h, and Table 9 displays the mechanical properties of coir fiber-reinforced vulcanized NR composite after heat resistance at 80°C for 4 h. Figure 10 shows the stress-strain curve of vulcanized NR after heat resistance at 80°C for 4 h. Figure 11 shows the stress-strain curve of coir fiber-reinforced vulcanized NR composite after heat resistance at 80°C for 4 h.

Mechanical properties of vulcanized NR after heat resistance at 80°C for 4 h.

| Sr. no. | Sample name | Max load (N) | Tensile strength (MPa) | Elongation at break (%) | Stress vs. strain plot |

|---|---|---|---|---|---|

| 1 | Vulcanized NR (specimen no. 1) | 2.842 | 0.355 | 340 | Figure 10 |

| 2 | Vulcanized NR (specimen no. 2) | 7.644 | 1.274 | 212 | |

| 3 | Vulcanized NR (specimen no. 3) | 1.078 | 0.466 | 192 | |

| Average values | 3.854 | 0.698 | 248 | ||

Mechanical properties of coir fiber-reinforced vulcanized NR composite after heat resistance at 80°C for 4 h.

| Sr. no. | Sample name | Max load (N) | Tensile strength (MPa) | Elongation at break (%) | Stress vs. strain plot |

|---|---|---|---|---|---|

| 1 | Coir fiber-reinforced vulcanized NR (specimen no. 1) | 6.762 | 0.845 | 376 | Figure 11 |

| 2 | Coir fiber-reinforced vulcanized NR (specimen no. 2) | 6.468 | 0.845 | 392 | |

| 3 | Coir fiber-reinforced vulcanized NR (specimen no. 3) | 7.644 | 0.956 | 652 | |

| Average values | 6.958 | 0.882 | 473.33 | ||

Stress-strain curve of vulcanized NR after heat resistance at 80°C for 4 h.

Stress-strain curve of coir fiber-reinforced vulcanized NR composite after heat resistance at 80°C for 4 h.

Comparing the results of Tables 8 and 9 with the initial properties given in Tables 2 and 3, it can be concluded that the performance of specimens was reduced because of heat aging. It made the fiber/rubber adhesion weaker. The reinforced samples showed better performance after the heat aging. The maximum load was increased by 80.53%, tensile strength by 26%, and elongation at break by 90.85%. Tensile strength was recorded least in this case. It can be concluded that the behavior of composites was least in this case and optimum in the case of cold aging resistance tests. For the quantitative analysis of reinforcement, the percentage increase has been calculated. Table 10 shows the percentage increase in each property of the composite.

Percentage increase in properties of coir fiber-reinforced vulcanized NR composites.

| Sr. no. | Aging tests | Maximum load (N) | Tensile strength (MPa) | Elongation at break (%) |

|---|---|---|---|---|

| 1 | Initial properties | 83.32 | 34.70 | 8.44 |

| 2 | Cold aging | 121.16 | 90.06 | 84.65 |

| 3 | Water aging | 50.13 | 31.43 | 94.06 |

| 4 | Heat aging | 80.53 | 26 | 90.85 |

4 Conclusions

The mechanical properties of coir fiber-reinforced vulcanized NR composites were studied. Alkali treatment (5% of NaOH solution) removed the undesired coir pith from the fiber. Tensile strength, maximum load, and elongation at break were recorded during each test to understand the response of composites under different conditions. After conducting all three tests, an attempt has been made to analyze the behavior of the composite under such conditions. The initial properties showed that the incorporation of coir fiber in vulcanized NR improved the properties of the composite significantly. The stress-strain curve for both specimens suggested that the coir fiber reinforcement has made the NR stronger. On cold resistance aging test, both the reinforced and the raw vulcanized NR specimens showed a relatively lower performance as compared with the initial properties. The coir fiber-reinforced specimens showed better properties.

After aging both specimens under water resistance test, the elongation at break (%) for raw vulcanized NR specimens was found out to be too lower than that of the initial value. The reinforced specimens showed higher performance. Same behavior was observed after heat aging. From the experiment, it can be concluded that the coir fiber-reinforced vulcanized NR composites showed better mechanical properties in comparison with raw vulcanized NR composites. From Table 9, it can be concluded that the coir fiber reinforcement made the NR withstand different temperatures for different intervals of time. The tensile strength of all vulcanizates tends to decrease after treatment at high temperature. This is because the degree of cross-linking after aging exceeds an optimum value and the networks become too dense, leading to the decrease in tensile strength while the moduli increase. A reduction in elongation at break is observed for all aged samples. This is simply attributed to the formation of additional cross-links for the optimum cured samples, which is well known as the postcuring effect. The increase in the cross-link density via the postcuring reduces the mobility of rubber chains.

The coir fiber-reinforced vulcanized rubber composite can be used in insulations, mattresses, and toys. It can also be used in automobile tires. Different weight percentages can also result in significant changes in the properties of the material. Further investigation can be performed on fiber length, volume fraction, and diameter. The response of the composite for different volume fractions can be studied. Curing properties can be studied for better reinforcement. Scanning electron microscopy (SEM) and X-ray diffraction test can be performed for understanding the morphological properties and structure of the composite. Synthetic rubber can be used in place of NR because they have better mechanical properties. More research can be done for making the material more resistive against increasing temperature. The duration of each test can be altered for understanding the change in behavior of the composite under varying parameters.

References

[1] Geethamma VG, Kalaprasad G, Groeninckx G, Thomas S. Compos. Part A. Appl. Sci. Manuf. 2005, 36, 1499–1506.10.1016/j.compositesa.2005.03.004Search in Google Scholar

[2] Nam T, Ogihara S, Tung N, Kobayashi S. Compos. Part B. 2011, 42, 1648–1656.10.1016/j.compositesb.2011.04.001Search in Google Scholar

[3] Geethamma VG, Mathew T, Lakshminarayanan R, Thomas S. Polymer 1997, 39, 1483–1491.10.1016/S0032-3861(97)00422-9Search in Google Scholar

[4] Karthikeyan A, Balamurugan K. J. Sci. Ind. Res. 2012, 71, 627–631.Search in Google Scholar

[5] Rattanasom N, Prasertsri S. Polym. Test. 2009, 28, 270–276.10.1016/j.polymertesting.2008.12.010Search in Google Scholar

[6] Wang Q, Li S, Wu X, Wang S, Ouyang C. Constr. Build. Mater. 2016, 106, 443–448.10.1016/j.conbuildmat.2015.12.138Search in Google Scholar

[7] Cholachagudda V, Udayakumar PA, Ramalingaiah. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 3779–3785.Search in Google Scholar

[8] Barbosa V, Ramires EC, Razera I, Frollini E. Ind. Crops Prod. 2010, 32, 305–312.10.1016/j.indcrop.2010.05.007Search in Google Scholar

©2018 Walter de Gruyter GmbH, Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Original articles

- Review of the mechanical performance of variable stiffness design fiber-reinforced composites

- Exact solution for bending analysis of functionally graded micro-plates based on strain gradient theory

- Synthesis, microstructure, and mechanical properties of in situ TiB2/Al-4.5Cu composites

- Microstructure and properties of W-Cu/1Cr18Ni9 steel brazed joint with different Ni-based filler metals

- Drilling studies on the prepared aluminum metal matrix composite from wet grinder stone dust particles

- Studies on mechanical properties of thermoplastic composites prepared from flax-polypropylene needle punched nonwovens

- Design of and with thin-ply non-crimp fabric as building blocks for composites

- Effect of coir fiber reinforcement on mechanical properties of vulcanized natural rubber composites

- Investigation and analysis of glass fabric/PVC composite laminates processing parameters

- Abrasive wear behavior of silane treated nanoalumina filled dental composite under food slurry and distilled water condition

- Finite element study into the effects of fiber orientations and stacking sequence on drilling induced delamination in CFRP/Al stack

- Preparation of PAA/WO3 composite films with enhanced electrochromism via layer-by-layer method

- Effect of alkali treatment on hair fiber as reinforcement of HDPE composites: mechanical properties and water absorption behavior

- Integration of nano-Al with one-step synthesis of MoO3 nanobelts to realize high exothermic nanothermite

- A time-of-flight revising approach to improve the image quality of Lamb wave tomography for the detection of defects in composite panels

- The simulation of the warpage rule of the thin-walled part of polypropylene composite based on the coupling effect of mold deformation and injection molding process

- Novel preparation method and the characterization of polyurethane-acrylate/ nano-SiO2 emulsions

- Microwave properties of natural rubber based composites containing carbon black-magnetite hybrid fillers

- Simulation on impact response of FMLs: effect of fiber stacking sequence, thickness, and incident angle

Articles in the same Issue

- Frontmatter

- Original articles

- Review of the mechanical performance of variable stiffness design fiber-reinforced composites

- Exact solution for bending analysis of functionally graded micro-plates based on strain gradient theory

- Synthesis, microstructure, and mechanical properties of in situ TiB2/Al-4.5Cu composites

- Microstructure and properties of W-Cu/1Cr18Ni9 steel brazed joint with different Ni-based filler metals

- Drilling studies on the prepared aluminum metal matrix composite from wet grinder stone dust particles

- Studies on mechanical properties of thermoplastic composites prepared from flax-polypropylene needle punched nonwovens

- Design of and with thin-ply non-crimp fabric as building blocks for composites

- Effect of coir fiber reinforcement on mechanical properties of vulcanized natural rubber composites

- Investigation and analysis of glass fabric/PVC composite laminates processing parameters

- Abrasive wear behavior of silane treated nanoalumina filled dental composite under food slurry and distilled water condition

- Finite element study into the effects of fiber orientations and stacking sequence on drilling induced delamination in CFRP/Al stack

- Preparation of PAA/WO3 composite films with enhanced electrochromism via layer-by-layer method

- Effect of alkali treatment on hair fiber as reinforcement of HDPE composites: mechanical properties and water absorption behavior

- Integration of nano-Al with one-step synthesis of MoO3 nanobelts to realize high exothermic nanothermite

- A time-of-flight revising approach to improve the image quality of Lamb wave tomography for the detection of defects in composite panels

- The simulation of the warpage rule of the thin-walled part of polypropylene composite based on the coupling effect of mold deformation and injection molding process

- Novel preparation method and the characterization of polyurethane-acrylate/ nano-SiO2 emulsions

- Microwave properties of natural rubber based composites containing carbon black-magnetite hybrid fillers

- Simulation on impact response of FMLs: effect of fiber stacking sequence, thickness, and incident angle