Abstract

Many risks have adverse consequences for construction projects’ objectives such as quality, schedule, and cost. As engineering procurement construction (EPC) contracts gradually become one of the most common types used in implementing major large-scale construction projects, identifying common risk types and analyzing their root causes is important for developing measures to decrease and eliminate future risks in these types of contracts. The information about the main causes of risks was collected via well-structured questionnaires addressed to construction sector professionals and preparing lists of main potential risks in EPC/construction projects through reviewing literature studies, books, and articles related to this topic. The findings indicate that several causes of risks are more critical for the project including causes related to contract, design and execution, subcontractors, systems, and equipment. The study’s results revealed that the absence of risk management implementation in the EPC construction project is a root cause of the lack of planning and control of the project.

1 Introduction

Every construction project requires effective contract risk management. The risks in construction projects vary depending on the type of contract, because each contract type has its project life cycle. If contract risk management is not adequately managed and controlled, the project as a whole may not achieve its objectives. The processes of performing project risk management encompass risk management planning, identification, analysis, response planning, and risk control on a project. The cause of implementing risk management in projects is to enhance the possibility of positive occurrences and their impact while decreasing the probability and impact of negative events [1]. Due to various intrinsic factors (complication, scope, organization, renovation, lifecycle duration, and magnitude of changes), every project has its ambiguity which is related to risk, which is likely to affect the project’s success and applicable consequence unless they are managed appropriately. A risk is an unexpected event or a sequence of events that, if they occur, will have an impact on achieving its objectives. It is composed of the likelihood of a possible threat or opportunity occurring, as well as the magnitude of the impact on its objectives [2].

The goal of project risk management is to lower the chances of the project and its stakeholders failing to reach its objectives. It allows project managers to set priorities, allocate resources, and implement actions and processes that lessen the chances of the project failing to meet its objectives [3]. For this uncertainty, these risks should be managed as control risks, and the project’s overall management should adjust for the uncertainty associated with these various types of risks. It would be impractical for the project manager to simply focus on the disadvantages of the ground conditions. Moreover, the project manager should not expect that things will turn out better than predicted just because he or she wants them to [4]. Only the project manager has the authority to decide which risks are desirable [5]. Under an engineering procurement construction (EPC) approach, the owners have to deal with one general Contractor. This major Contractor, on the other hand, could be a set of companies that engage with the Employer as “one Entity.” The Employers’ obligations, for example allowing access to the site and paying the agreed-upon amount, are reduced to a minimum level under the EPC contract, the contractor undertakes all other responsibilities and risks connected with project construction, design, erection, and commissioning as well as the associated interface risks [6]. EPC contracts entail a substantial shift in responsibility from the client to the contractor [7].

2 Methodology

2.1 Collecting data methods

There are two parts to the data collection method utilized in this study:

Review literature studies, books, and articles related to this topic.

Surveys: a combination of two methods, including in-person meetings and questionnaires, were utilized to collect the information needed. The purpose of the questionnaire was to present potential hazards identified through a literature analysis to experts and get their feedback on specific risks connected to the project under consideration. For this purpose, a specialist briefing session was arranged to discuss project risks and questionnaire items. The demographic sample method was used among project managers from several departments. Finally, 66 professionals completed the questionnaire, as well as provided feedback and suggestions on how to identify relevant risks.

2.2 Reviewing previous studies to identify potential risks in EPC projects

Risk identification in EPC projects was divided into three phases according to the life cycle for this contract type, and these phases are engineering, procurement, and construction as shown in Tables 1–3. It can be managed project risks, if it is possible to identify the important sources of risk and taking proactive actions to minimize failure modes and improve project success [8–10].

Potential risks in the engineering phase

| No. | Risks | Supporting research studies |

|---|---|---|

| 1 | Inaccurate cost estimation for the engineering phase | [11,12] |

| 2 | Inaccurate time estimation for the engineering phase | [13,14] |

| 3 | Lack of management and trained personnel | [15,16] |

| 4 | Design errors | [17,18] |

| 5 | Technical drawings that are inappropriate and inadequate | [19] |

| 6 | Reduced design time and a faster transition to the execution stage | [20] |

| 7 | Delay in receiving the project’s initial permits | [21] |

| 8 | Insufficient feasibility studies | [22] |

| 9 | Inexperienced project managers | [23] |

| 10 | Changes resulting from political events | [24] |

| 11 | Internal policy changes in the organization | [25] |

| 12 | Changes to the scope of the project’s work | [26] |

| 13 | A shortage of necessary resources | [27] |

| 14 | Changes in the requirements of the employer | [28] |

Potential risks in the procurement phase

| No. | Risks | Supporting research studies |

|---|---|---|

| 1 | Inaccurate cost estimation for the procurement phase | [11,12] |

| 2 | Inaccurate time estimation for the procurement phase | [13,14] |

| 3 | Supplying poor quality equipment and materials | [29] |

| 4 | Variation in the cost of materials and equipment | [30] |

| 5 | A delay in the delivery time of some materials and equipment | [31] |

| 6 | Manufacturers’ selection of equipment and materials is inappropriate | [32] |

| 7 | Lack of project planning and control in the procurement phase | [33] |

| 8 | Bureaucracy and lack of collaboration exist in the procurement department | [34] |

| 9 | Changes resulting from political events | [24] |

| 10 | Delay in technical inspection | [35] |

| 11 | Poor international communication | [36] |

| 12 | Equipment and construction materials have poor quality control | [37] |

| 13 | Damage to equipment during transportation | [38] |

| 14 | Financial issues associated with the contractors in the procurement and supplying phase | [39] |

| 15 | Lack of data and documentation | [40] |

| 16 | Changes to rules regulating insurance, taxation, and other matters | [41] |

Potential risks in the construction phase

| No. | Risks | Supporting research studies |

|---|---|---|

| 1 | Inaccurate cost estimation for the procurement phase | [11,12] |

| 2 | Inaccurate time estimation for the engineering phase | [13,14] |

| 3 | Delays caused by the long process of obtaining permits required | [31] |

| 4 | Incompetent subcontractors | [15] |

| 5 | Lack of skills and technical workers | [16] |

| 6 | Poor planning and management in the construction phase | [33] |

| 7 | Unexpected disasters such as floods, earthquakes, etc. | [42] |

| 8 | Changes resulting from governmental and political developments | [24] |

| 9 | Errors in testing materials and equipment | [43] |

| 10 | Poor inspection process, quality control, and quality assurance | [44] |

| 11 | Employing unskilled engineers in monitoring | [16] |

| 12 | The project manager’s performance was poor | [33] |

2.3 Potential risks in the EPC projects

The importance of several risks highlighted by experts was validated when the results of tests performed on data obtained from the surveys were assessed. This indicates that these are the most important risks in this study, while “risks irrelevant to the project” and “less important risks” were not recognized as shown in Table 4.

Risks that have been highlighted by the experts

| Engineering phase | Procurement phase | Construction phase |

|---|---|---|

| Inaccurate cost estimation for the engineering phase | Inaccurate cost estimation for the procurement phase | Inaccurate cost estimation for the procurement phase |

| Inaccurate time estimation for the engineering phase | Inaccurate time estimation for the procurement phase | Inaccurate time estimation for the engineering phase |

| Management and staff with qualified skills are in short supply | Financial issues associated with the contractors in the procurement and supplying phase | Delays caused by the long process of obtaining permits required |

| Design errors (weaknesses or cover design) | Lack of data and documentation | Incompetent subcontractors |

| Technical drawings that are inappropriate and inadequate | Lack of project planning and control in the procurement phase | Lack of skills and technical workers |

| Delay in receiving the project’s initial permits | Delay in technical inspection | Employing unskilled engineers in monitoring |

| Inexperienced project managers | ||

| Insufficient feasibility studies | Poor performance of the project site manager | |

| Internal policy changes in the organization |

3 Techniques for root cause analysis

3.1 Fishbone diagram (Ishikawa)

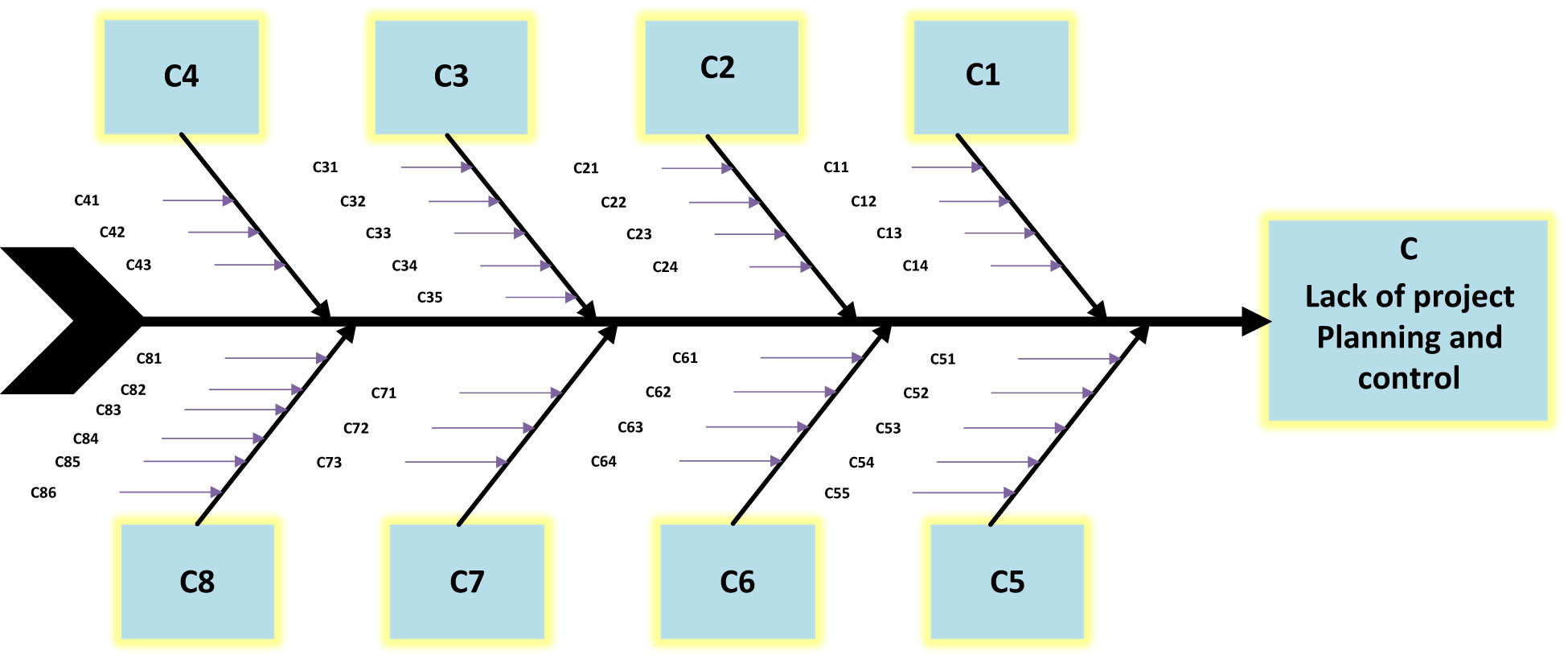

Ishikawa diagrams, cause and effect tests, and fishbone diagrams are all terms for diagrams that simulate a skeleton of a fish when viewed as a whole. The fishbone diagram helps the team identify and focus on root cause analysis by describing potential causes of problems in a structured manner. Cause-and-effect analysis sequence can be a simple analysis that relates to a large number of causes and their order, but it can also be supplemented with other representation and hierarchical aspects for risk management. This diagram type identifies all possible contributing factors to a problem (Figure 1). This can aid in finding resolutions after the fishbone diagram has gathered and displayed all the desired information [45].

Fishbone diagram for causes of lack of project planning and control.

3.2 Pareto analysis

A Pareto chart is a graphical tool used in Pareto analysis. A Pareto chart is a bar chart that displays the relative importance of issues in an easy-to-understand format. The tallest bar reflects the most significant difficulty (e.g., the one with the largest cost, frequency, or another metric), followed by the next tallest bar, and so on. To collect data for Pareto charts, a check sheet might be used [46].

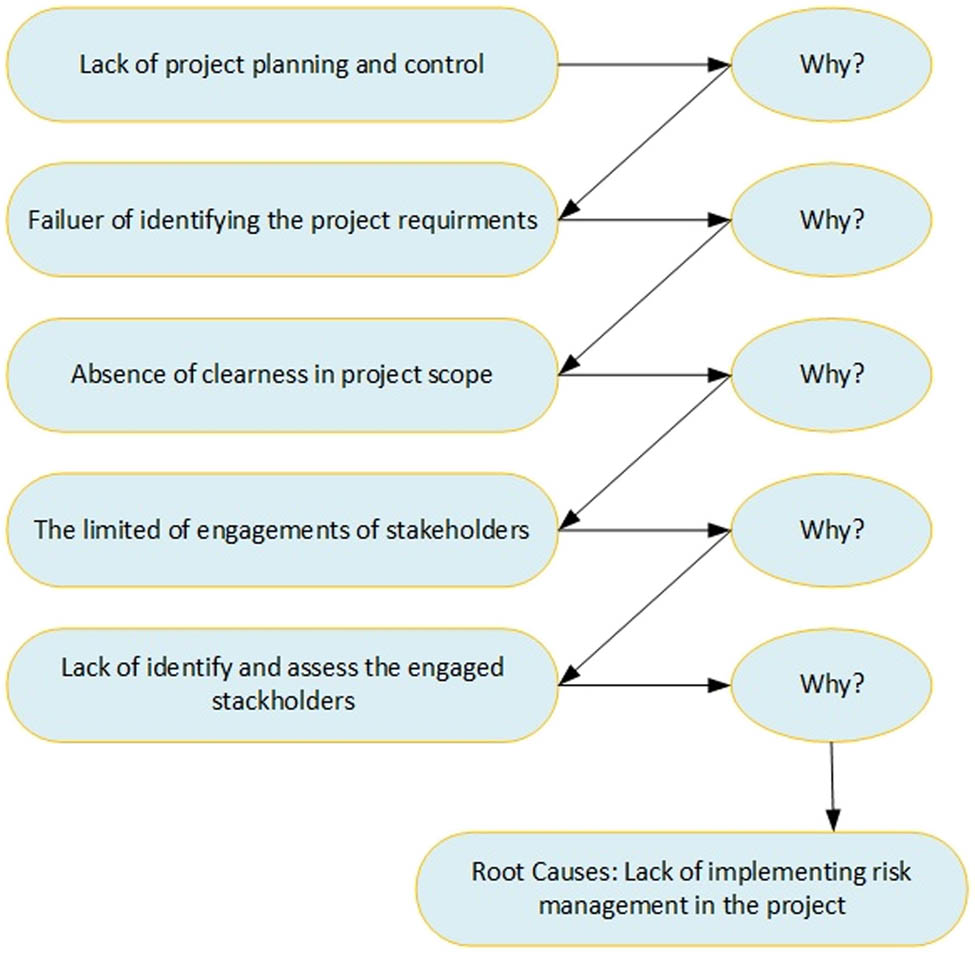

3.3 5-Whys for root cause analysis

The 5-why method aids in the identification of cause-and-effect relationships in a problem or failure event. It is useful when the true source of a problem or situation is not obvious. The 5-why method aids in the identification of cause-and-effect links in a problem or failure event. It is useful when the true source of an issue or situation is not obvious. Using the 5-whys is a quick and easy technique to try to solve a problem without having to conduct a lengthy, resource-intensive inquiry [47]. A case study of analyzing the risk causes in an EPC construction project implemented in Iraq, by using the 5-why technique to find the root causes of lack of planning and control in the project and showing the relationships between these causes are illustrated in Figure 2.

The relationships between these causes.

4 Diagnosing lack of project planning in Iraq

To identify and analyze root causes for the lack of project planning and control in Iraqi construction projects, a survey analytic approach was used which is important for root cause analysis. In this study, the researcher also used a literature review, an expert questionnaire, and personal interviews with people who were chosen for their expertise and qualifications. Various groups were engaged to determine the causes for the lack of project planning and control in construction projects in Iraq (contract causes, labor causes, system causes, material causes, design and execution causes, subcontractors’ causes, site staff causes, and equipment causes) as shown in Table 5.

Main causes of risks with their codes

| Main cause | Code | Secondary cause | Code |

|---|---|---|---|

| Equipment | C1 | Lack of a mechanism to manage the equipment | C11 |

| The inability for evaluating the equipment’s productivity | C12 | ||

| Equipment was overused | C13 | ||

| Lack of equipment maintenance | C14 | ||

| Labors | C2 | Using inexperienced or incompetent operator staff | C21 |

| Labor income and salaries are at a low level | C22 | ||

| Lack of worker coordination | C23 | ||

| Lack of an active labor management system | C24 | ||

| Systems | C3 | Failure to implement a safety program | C31 |

| Modern management practices and computer programs are not utilized | C32 | ||

| Insufficient quality control and inspection | C33 | ||

| Failure to adhere to a cost-management strategy | C34 | ||

| Managing a large number of projects at the same time | C35 | ||

| Improper material selection and utilization by contract standards | C41 | ||

| Improper inspection and testing of materials before usage | C42 | ||

| Lack of coordination between contractors and suppliers | C43 | ||

| Design and execution | C 5 | The owner’s design criteria are unclear | C51 |

| Designers with insufficient experience and knowledge | C52 | ||

| Lack of compliance with specifications cited in the working report | C53 | ||

| Lack of collaboration between the designer and the owners | C54 | ||

| Financial issues arising during execution | C55 | ||

| Subcontractors | C6 | Improper supervision of subcontractors | C61 |

| Unexperienced subcontractors | C62 | ||

| Lack of coordination between general contractor and subcontractor | C63 | ||

| Lack of evaluation for subcontractor performance | C64 | ||

| Site staff | C7 | Lack of coordination between contractor’s personnel and supervisors | C71 |

| The contractor’s personnel have a low level of skill and experience | C72 | ||

| Supervisory staff with little experience and ineptitude | C73 | ||

| Contract | C8 | Lack of collaboration between contracting parties | C81 |

| The contractor’s personnel have a low level of skill and experience | C82 | ||

| Lack of familiarity with the regulations to implement governmental contracts no. 2 of 2014 and attachments to these regulations | C83 | ||

| Lack of knowledge of any official instruction issued from the Ministry of Planning of Iraq | C84 | ||

| Insufficient experience in the use of (EPC) standard bid documents which are considered the best solution to implement governmental contracts, assure stability of procedures, and reduce administrative and financial corruption | C85 | ||

| Inadequate management contract disputes | C86 |

To get an idea of the importance of each risk cause groups, the Pareto analysis was used after making a survey consisting of 80 distributed forms. After collecting and analyzing the frequencies by using the frequency procedures in SPSS, only 66 forms were considered while the others were neglected because of the lack of the information provided.

Table 6 demonstrates the number of occurrences of each risk cause groups with their relative accumulative values to present the Pareto chart (Figure 2) for the main causes of risks and their weight of effects.

Main groups of risk issues with their frequencies

| Main cause | Frequency | Relative frequency (%) | Cumulative relative frequency (%) |

|---|---|---|---|

| Contract causes (C8) | 16 | 24.24 | 24.24 |

| Design and execution causes (C5) | 14 | 21.21 | 45.45 |

| Subcontractors’ causes (C6) | 11 | 16.67 | 62.12 |

| Systems causes (C3) | 9 | 13.64 | 75.76 |

| Equipment causes (C1) | 7 | 10.7 | 86.36 |

| Labors causes (C2) | 4 | 6.06 | 92.42 |

| Materials causes (C4) | 3 | 4.55 | 96.97 |

| Site staff causes (C7) | 2 | 3.03 | 100 |

| Total | 66 |

As mentioned above, the main causes for lack of planning and control in EPC construction projects in Iraq were grouped into eight groups, contract causes (C8) and design and execution causes (C5) are the principal triggers, followed by subcontractors’ causes (C6), system causes (C3), equipment causes (C1), labor cause (C2), material causes (C4), and site staff cause (C7). The contract group causes (C8), design and execution cause group (C5), group of subcontractor causes (C6), group of system causes (C3), and group of equipment causes (C1) are considered to account for 75.76% of the problem in the Pareto chart (Figure 3). By focusing on these five main triggers, 75.76% of the issue (lack of planning and control in projects) will be resolved.

Pareto chart for main risk causes in EPC projects.

5 Conclusion

The main causes of risk in EPC construction projects in Iraq have been identified and diagnosed and then represented in group lists that demonstrated these main risks. Each group of risks had secondary causes that contributed to the major risks which need more tracking and observation. Pareto analysis revealed that only 75.76% of the main causes are related to contract causes, design and execution causes, subcontractors’ causes, the system causes, and equipment causes, while minimal reasons in labor causes, material causes, and site staff cause categories.

The results of using the 5-why analysis on a case study of the Iraqi EPC construction project revealed that the absence of risk management implementation in the EPC construction project is a root cause for the lack of planning and control of the project.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Project Management Institute, Inc. A guide to project management body of knowledge, (PMBOK). 5th ed. 2013.10.1002/pmj.21345Search in Google Scholar

[2] Massimo P. Project life cycle economics cost estimation, management, and effectiveness in construction projects. Farnham, UK: Ashgate Publishing; 2015.Search in Google Scholar

[3] Cooper DF, Grey S, Raymond G, Walker P. Project Risk Management Guidelines: Managing Risk in Large Projects and Complex Procurements. Hoboken (NJ), USA: John Wiley & Sons; 2005.Search in Google Scholar

[4] Hopkin P. Fundamentals of risk management, understanding, evaluating, and implementing effective risk management. 4th ed. Lodon: Kogan Page Ltd; 2017.Search in Google Scholar

[5] Morris PWG, Pinto JK. The Wiley Guide to Managing Projects. Hoboken (NJ), USA: John Wiley & Sons; 2004.10.1002/9780470172391Search in Google Scholar

[6] Hagner M. Engineering, Procurement and Construction Contracts for Large Scale Projects: A Practical Guide to EPC Contracting and Claim Management. Bonn: Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ); 2013.Search in Google Scholar

[7] Cova B, Chauri PN, Salle R. Project marketing: beyond competitive bidding. Chichester: John Wiley & Sons; 2002.Search in Google Scholar

[8] Wenger A, Mauer V, Cavelty MD. International handbook on risk analysis and management. Center for Security Studies at ETH Zurich. Swiss Federal Institute of Technology; 2008.Search in Google Scholar

[9] Kendrick T. Identifying and managing project risk, essential tools for failure-proofing your project. 2nd ed. Hoboken, New Jersey: Prentice Hall; 2000.Search in Google Scholar

[10] Nurdiana A, Susanti R. Assessing risk on the engineering procurement construction (EPC) project from the perspective of the owner: a case study. JIC-CEGE 2019. 2020;506:012040.10.1088/1755-1315/506/1/012040Search in Google Scholar

[11] Gransberg DD, Riemer C. Impact of inaccurate engineer’s estimated quantities on unit price contracts. J Const Eng Manag ASCE. November 2009;135(11):1138–45.10.1061/(ASCE)CO.1943-7862.0000084Search in Google Scholar

[12] Christensen P, Dysert LR, Bates J, Burton D, Creese RC, Hollmann J. Cost estimate classification system – as applied in engineering, procurement, and construction for the process industries. AACE International Recommended Practices; 2005.Search in Google Scholar

[13] Dysert L, Elliott BG. The estimate review and validation process. AACE International Annual Meeting and 2nd World Congress of Cost Engineering, Project Management, and Quantity Surveying at Calgary, Alberta, Canada; 2000.Search in Google Scholar

[14] Simushi S, Wium J. Time and cost overruns on large projects: understanding the root cause. J Const Devel Countries Time Cost Overruns Large Projects. 2020;25(1):129–46.10.21315/jcdc2020.25.1.7Search in Google Scholar

[15] Auwalin I, Nyasulu A, Kittayaapinant S. Labour Supply and Skills Shortage in Australia. KnE Soc Sci. 2019;3(13):1249–1265.10.18502/kss.v3i13.4281Search in Google Scholar

[16] Horbach J, Rammer C. Labor shortage and innovation. Germany: ZEW - Leibniz Centre for European Economic Research. 2020.10.2139/ssrn.3545776Search in Google Scholar

[17] Vashishtha U, Bawaniya V, Paul VK. Design errors in building construction projects. Int Res J Eng Technol (IRJET). July 2020;7(7):3850.Search in Google Scholar

[18] Peansupapa V, Ly R. Evaluating the impact level of design errors in structural and other building components in building construction projects in Cambodia. Proc Eng. 2015;123:370–8.10.1016/j.proeng.2015.10.049Search in Google Scholar

[19] Abdullah WS, Ali Qaradaghi AM. Measurable mistakes in architecture the effect of designer’s experience on the propagation of mistakes in architectural design – residential buildings in Al Sulaymaniyah city as a case study. J Eng. January 2021;27(1):89–111.10.31026/j.eng.2021.01.07Search in Google Scholar

[20] Mejlænder-Larsen Ø. Improving transition from engineering to construction using a project execution model and BIM. ITcon. 2018;23:324–339.Search in Google Scholar

[21] Muhammed TA. Delay in construction projects [dissertation]. Sulaymaniyah: The American University of Iraq, Sulaimani; 2015.Search in Google Scholar

[22] Mohammed SR, Naji HI, Hussein Ali R. Impact of the feasibility study on the construction projects. 2nd International Conference on Sustainable Engineering Techniques (ICSET); 2019 Mar 6–7; Baghdad, Iraq.10.1088/1757-899X/518/2/022074Search in Google Scholar

[23] Pollack J, Algeo C. Project managers and change managers contribution to success. Int J Manag Proj Business. 2016;9(2):3.10.1108/IJMPB-09-2015-0085Search in Google Scholar

[24] Akwei C, Damoah IS, Amankwah-Amoah J. The effects of politics on the implementation of government programs/projects: insights from a developing economy. P&P. 2020;48(6):1161–1201.10.1111/polp.12384Search in Google Scholar

[25] Aronsson F, Huusko A, Wansulin V. Internal and external forces of organizational change in project management a case study on a collaborative project [dissertation]. Västerås: Mälardalen University; 2021.Search in Google Scholar

[26] Nahod M-M. Scope control through managing changes in construction projects. Organ Technol Manag Constr. 2021;4(1):438–447.10.5592/otmcj.2012.1.9Search in Google Scholar

[27] Irugal Bandara IBMMS. Effects of resource planning on construction project delays in Sri Lanka. A Research Project Submitted in Partial Fulfillment of the Requirements for the Higher National Diploma in Civil Engineering; 2018.Search in Google Scholar

[28] Bojesson C. Improving project performance in product development [dissertation]. Västerås: Mälardalen University; 2015.Search in Google Scholar

[29] Danso H. Poor workmanship and lack of plant/equipment problems in the construction industry in Kumasi, Ghana. GE-IJMR. 2014;2(3):60–70.Search in Google Scholar

[30] Kincannon L, Franchet Y. Sources and methods construction price indices. Luxembourg: Statistical Office of the European Community.Search in Google Scholar

[31] Rahman MM, Yap YH, Ramli NR, Dullah MA, Shamsuddin MSW. Causes of shortage and delay in material supply: a preliminary study. Mater Sci Eng. 2017;271.10.1088/1757-899X/271/1/012037Search in Google Scholar

[32] Shahbazi S. Material efficiency management in manufacturing [dissertation]. Västerås: Mälardalen University; 2015.Search in Google Scholar

[33] Khalid FJ. The impact of poor planning and management on the duration of construction projects: a review. MECSJ. 2017;2:161–81.Search in Google Scholar

[34] Decarolis F, Giuffrida LM, Iossa E, Mollisi V, Spagnolo G. Bureaucratic competence and procurement outcomes. ZEW – Centre for European Economic Research Discussion Paper No. 19-057; 2019.10.3386/w24201Search in Google Scholar

[35] Jodejko-Pietruczuk A, Nowakowski T, Webińska-Wojciechowska S. Time between inspections optimization for technical object with time delay. J Polish Saf Reliab Assoc. 2013;4(1):35–42.Search in Google Scholar

[36] Hendrith M. The effects culture and communication have on business [dissertation]. Murray (KY), USA: Murray State University; 2018.Search in Google Scholar

[37] Albert I, Shakantu W, Ibrahim S. The effect of poor materials management in the construction industry: a case study of Abuja, Nigeria. Acta Structilia. 2021;28(1):142–167.10.18820/24150487/as28i1.6Search in Google Scholar

[38] Anholcer M, Hinc T, Kawa A. Losses in transportation – importance. In Kawa A, Maryniak A, editors. SMART Supply Network. Cham: Springer; 2019. p. 111–128.10.1007/978-3-319-91668-2_6Search in Google Scholar

[39] Buzzettoa RR, Baulia MR, de Carvalhoa MM. The key aspects of procurement in project management: investigating the effects of selection criteria, supplier integration, and dynamics of acquisitions. Production. 2020;30(7):e20190112.10.1590/0103-6513.20190112Search in Google Scholar

[40] Xu S, Luo H. The information-related time loss on construction sites: a case study on two sites. Int J Adv Robotic Syst. 2014 Aug 22;11(8):128.10.5772/58444Search in Google Scholar

[41] Organization for Economic Co-Operation and Development. Guidance note compliance risk management: managing and improving tax compliance; 2004.Search in Google Scholar

[42] Chaudhary MT, Piracha A. Natural disasters – origins, impacts, management. Encyclopedia. 2021;1(4):1101–1131.10.3390/encyclopedia1040084Search in Google Scholar

[43] Zou PX, Guomin Z, Jiayuan W. Understanding the key risks in construction projects in China. Int J Project Manag. 2007;25:601–14.10.1016/j.ijproman.2007.03.001Search in Google Scholar

[44] Bassiony MS, Abd El-Karim A, El Nawawy OAM, Abdel-Alim AM. Identification and assessment of risk factors acting construction projects. HBRC J. 2017;13(2):203–216.10.1016/j.hbrcj.2015.05.001Search in Google Scholar

[45] Slameto. The application of fishbone diagram analysis to improve school quality. Dinamika Ilmu. 2016;16(1):59–74.10.21093/di.v16i1.262Search in Google Scholar

[46] Enesi Y, Salawu OOA, Ajayi AI, Afolalu SA, Samson O. Pareto analysis of product quality failures and cost effects in bottling machines – a lean thinking solution for the alcohol industry. Int J Mech Eng Technol (IJMET). 2018;9(11):2380–8.Search in Google Scholar

[47] Serrat O. The five whys technique. ADB Asian Development Bank; 2009.Search in Google Scholar

© 2022 Noor Hussein Khairullah et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Calcium carbonate nanoparticles of quail’s egg shells: Synthesis and characterizations

- Effect of welding consumables on shielded metal arc welded ultra high hard armour steel joints

- Stress-strain characteristics and service life of conventional and asphaltic underlayment track under heavy load Babaranjang trains traffic

- Corrigendum to: Statistical mechanics of cell decision-making: the cell migration force distribution

- Prediction of bearing capacity of driven piles for Basrah governatore using SPT and MATLAB

- Investigation on microstructural features and tensile shear fracture properties of resistance spot welded advanced high strength dual phase steel sheets in lap joint configuration for automotive frame applications

- Experimental and numerical investigation of drop weight impact of aramid and UHMWPE reinforced epoxy

- An experimental study and finite element analysis of the parametric of circular honeycomb core

- The study of the particle size effect on the physical properties of TiO2/cellulose acetate composite films

- Hybrid material performance assessment for rocket propulsion

- Design of ER damper for recoil length minimization: A case study on gun recoil system

- Forecasting technical performance and cost estimation of designed rim wheels based on variations of geometrical parameters

- Enhancing the machinability of SKD61 die steel in power-mixed EDM process with TGRA-based multi criteria decision making

- Effect of boron carbide reinforcement on properties of stainless-steel metal matrix composite for nuclear applications

- Energy absorption behaviors of designed metallic square tubes under axial loading: Experiment-based benchmarking and finite element calculation

- Synthesis and study of magnesium complexes derived from polyacrylate and polyvinyl alcohol and their applications as superabsorbent polymers

- Artificial neural network for predicting the mechanical performance of additive manufacturing thermoset carbon fiber composite materials

- Shock and impact reliability of electronic assemblies with perimeter vs full array layouts: A numerical comparative study

- Influences of pre-bending load and corrosion degree of reinforcement on the loading capacity of concrete beams

- Assessment of ballistic impact damage on aluminum and magnesium alloys against high velocity bullets by dynamic FE simulations

- On the applicability of Cu–17Zn–7Al–0.3Ni shape memory alloy particles as reinforcement in aluminium-based composites: Structural and mechanical behaviour considerations

- Mechanical properties of laminated bamboo composite as a sustainable green material for fishing vessel: Correlation of layer configuration in various mechanical tests

- Singularities at interface corners of piezoelectric-brass unimorphs

- Evaluation of the wettability of prepared anti-wetting nanocoating on different construction surfaces

- Review Article

- An overview of cold spray coating in additive manufacturing, component repairing and other engineering applications

- Special Issue: Sustainability and Development in Civil Engineering - Part I

- Risk assessment process for the Iraqi petroleum sector

- Evaluation of a fire safety risk prediction model for an existing building

- The slenderness ratio effect on the response of closed-end pipe piles in liquefied and non-liquefied soil layers under coupled static-seismic loading

- Experimental and numerical study of the bulb's location effect on the behavior of under-reamed pile in expansive soil

- Procurement challenges analysis of Iraqi construction projects

- Deformability of non-prismatic prestressed concrete beams with multiple openings of different configurations

- Response of composite steel-concrete cellular beams of different concrete deck types under harmonic loads

- The effect of using different fibres on the impact-resistance of slurry infiltrated fibrous concrete (SIFCON)

- Effect of microbial-induced calcite precipitation (MICP) on the strength of soil contaminated with lead nitrate

- The effect of using polyolefin fiber on some properties of slurry-infiltrated fibrous concrete

- Typical strength of asphalt mixtures compacted by gyratory compactor

- Modeling and simulation sedimentation process using finite difference method

- Residual strength and strengthening capacity of reinforced concrete columns subjected to fire exposure by numerical analysis

- Effect of magnetization of saline irrigation water of Almasab Alam on some physical properties of soil

- Behavior of reactive powder concrete containing recycled glass powder reinforced by steel fiber

- Reducing settlement of soft clay using different grouting materials

- Sustainability in the design of liquefied petroleum gas systems used in buildings

- Utilization of serial tendering to reduce the value project

- Time and finance optimization model for multiple construction projects using genetic algorithm

- Identification of the main causes of risks in engineering procurement construction projects

- Identifying the selection criteria of design consultant for Iraqi construction projects

- Calibration and analysis of the potable water network in the Al-Yarmouk region employing WaterGEMS and GIS

- Enhancing gypseous soil behavior using casein from milk wastes

- Structural behavior of tree-like steel columns subjected to combined axial and lateral loads

- Prospect of using geotextile reinforcement within flexible pavement layers to reduce the effects of rutting in the middle and southern parts of Iraq

- Ultimate bearing capacity of eccentrically loaded square footing over geogrid-reinforced cohesive soil

- Influence of water-absorbent polymer balls on the structural performance of reinforced concrete beam: An experimental investigation

- A spherical fuzzy AHP model for contractor assessment during project life cycle

- Performance of reinforced concrete non-prismatic beams having multiple openings configurations

- Finite element analysis of the soil and foundations of the Al-Kufa Mosque

- Flexural behavior of concrete beams with horizontal and vertical openings reinforced by glass-fiber-reinforced polymer (GFRP) bars

- Studying the effect of shear stud distribution on the behavior of steel–reactive powder concrete composite beams using ABAQUS software

- The behavior of piled rafts in soft clay: Numerical investigation

- The impact of evaluation and qualification criteria on Iraqi electromechanical power plants in construction contracts

- Performance of concrete thrust block at several burial conditions under the influence of thrust forces generated in the water distribution networks

- Geotechnical characterization of sustainable geopolymer improved soil

- Effect of the covariance matrix type on the CPT based soil stratification utilizing the Gaussian mixture model

- Impact of eccentricity and depth-to-breadth ratio on the behavior of skirt foundation rested on dry gypseous soil

- Concrete strength development by using magnetized water in normal and self-compacted concrete

- The effect of dosage nanosilica and the particle size of porcelanite aggregate concrete on mechanical and microstructure properties

- Comparison of time extension provisions between the Joint Contracts Tribunal and Iraqi Standard Bidding Document

- Numerical modeling of single closed and open-ended pipe pile embedded in dry soil layers under coupled static and dynamic loadings

- Mechanical properties of sustainable reactive powder concrete made with low cement content and high amount of fly ash and silica fume

- Deformation of unsaturated collapsible soils under suction control

- Mitigation of collapse characteristics of gypseous soils by activated carbon, sodium metasilicate, and cement dust: An experimental study

- Behavior of group piles under combined loadings after improvement of liquefiable soil with nanomaterials

- Using papyrus fiber ash as a sustainable filler modifier in preparing low moisture sensitivity HMA mixtures

- Study of some properties of colored geopolymer concrete consisting of slag

- GIS implementation and statistical analysis for significant characteristics of Kirkuk soil

- Improving the flexural behavior of RC beams strengthening by near-surface mounting

- The effect of materials and curing system on the behavior of self-compacting geopolymer concrete

- The temporal rhythm of scenes and the safety in educational space

- Numerical simulation to the effect of applying rationing system on the stability of the Earth canal: Birmana canal in Iraq as a case study

- Assessing the vibration response of foundation embedment in gypseous soil

- Analysis of concrete beams reinforced by GFRP bars with varying parameters

- One dimensional normal consolidation line equation

Articles in the same Issue

- Research Articles

- Calcium carbonate nanoparticles of quail’s egg shells: Synthesis and characterizations

- Effect of welding consumables on shielded metal arc welded ultra high hard armour steel joints

- Stress-strain characteristics and service life of conventional and asphaltic underlayment track under heavy load Babaranjang trains traffic

- Corrigendum to: Statistical mechanics of cell decision-making: the cell migration force distribution

- Prediction of bearing capacity of driven piles for Basrah governatore using SPT and MATLAB

- Investigation on microstructural features and tensile shear fracture properties of resistance spot welded advanced high strength dual phase steel sheets in lap joint configuration for automotive frame applications

- Experimental and numerical investigation of drop weight impact of aramid and UHMWPE reinforced epoxy

- An experimental study and finite element analysis of the parametric of circular honeycomb core

- The study of the particle size effect on the physical properties of TiO2/cellulose acetate composite films

- Hybrid material performance assessment for rocket propulsion

- Design of ER damper for recoil length minimization: A case study on gun recoil system

- Forecasting technical performance and cost estimation of designed rim wheels based on variations of geometrical parameters

- Enhancing the machinability of SKD61 die steel in power-mixed EDM process with TGRA-based multi criteria decision making

- Effect of boron carbide reinforcement on properties of stainless-steel metal matrix composite for nuclear applications

- Energy absorption behaviors of designed metallic square tubes under axial loading: Experiment-based benchmarking and finite element calculation

- Synthesis and study of magnesium complexes derived from polyacrylate and polyvinyl alcohol and their applications as superabsorbent polymers

- Artificial neural network for predicting the mechanical performance of additive manufacturing thermoset carbon fiber composite materials

- Shock and impact reliability of electronic assemblies with perimeter vs full array layouts: A numerical comparative study

- Influences of pre-bending load and corrosion degree of reinforcement on the loading capacity of concrete beams

- Assessment of ballistic impact damage on aluminum and magnesium alloys against high velocity bullets by dynamic FE simulations

- On the applicability of Cu–17Zn–7Al–0.3Ni shape memory alloy particles as reinforcement in aluminium-based composites: Structural and mechanical behaviour considerations

- Mechanical properties of laminated bamboo composite as a sustainable green material for fishing vessel: Correlation of layer configuration in various mechanical tests

- Singularities at interface corners of piezoelectric-brass unimorphs

- Evaluation of the wettability of prepared anti-wetting nanocoating on different construction surfaces

- Review Article

- An overview of cold spray coating in additive manufacturing, component repairing and other engineering applications

- Special Issue: Sustainability and Development in Civil Engineering - Part I

- Risk assessment process for the Iraqi petroleum sector

- Evaluation of a fire safety risk prediction model for an existing building

- The slenderness ratio effect on the response of closed-end pipe piles in liquefied and non-liquefied soil layers under coupled static-seismic loading

- Experimental and numerical study of the bulb's location effect on the behavior of under-reamed pile in expansive soil

- Procurement challenges analysis of Iraqi construction projects

- Deformability of non-prismatic prestressed concrete beams with multiple openings of different configurations

- Response of composite steel-concrete cellular beams of different concrete deck types under harmonic loads

- The effect of using different fibres on the impact-resistance of slurry infiltrated fibrous concrete (SIFCON)

- Effect of microbial-induced calcite precipitation (MICP) on the strength of soil contaminated with lead nitrate

- The effect of using polyolefin fiber on some properties of slurry-infiltrated fibrous concrete

- Typical strength of asphalt mixtures compacted by gyratory compactor

- Modeling and simulation sedimentation process using finite difference method

- Residual strength and strengthening capacity of reinforced concrete columns subjected to fire exposure by numerical analysis

- Effect of magnetization of saline irrigation water of Almasab Alam on some physical properties of soil

- Behavior of reactive powder concrete containing recycled glass powder reinforced by steel fiber

- Reducing settlement of soft clay using different grouting materials

- Sustainability in the design of liquefied petroleum gas systems used in buildings

- Utilization of serial tendering to reduce the value project

- Time and finance optimization model for multiple construction projects using genetic algorithm

- Identification of the main causes of risks in engineering procurement construction projects

- Identifying the selection criteria of design consultant for Iraqi construction projects

- Calibration and analysis of the potable water network in the Al-Yarmouk region employing WaterGEMS and GIS

- Enhancing gypseous soil behavior using casein from milk wastes

- Structural behavior of tree-like steel columns subjected to combined axial and lateral loads

- Prospect of using geotextile reinforcement within flexible pavement layers to reduce the effects of rutting in the middle and southern parts of Iraq

- Ultimate bearing capacity of eccentrically loaded square footing over geogrid-reinforced cohesive soil

- Influence of water-absorbent polymer balls on the structural performance of reinforced concrete beam: An experimental investigation

- A spherical fuzzy AHP model for contractor assessment during project life cycle

- Performance of reinforced concrete non-prismatic beams having multiple openings configurations

- Finite element analysis of the soil and foundations of the Al-Kufa Mosque

- Flexural behavior of concrete beams with horizontal and vertical openings reinforced by glass-fiber-reinforced polymer (GFRP) bars

- Studying the effect of shear stud distribution on the behavior of steel–reactive powder concrete composite beams using ABAQUS software

- The behavior of piled rafts in soft clay: Numerical investigation

- The impact of evaluation and qualification criteria on Iraqi electromechanical power plants in construction contracts

- Performance of concrete thrust block at several burial conditions under the influence of thrust forces generated in the water distribution networks

- Geotechnical characterization of sustainable geopolymer improved soil

- Effect of the covariance matrix type on the CPT based soil stratification utilizing the Gaussian mixture model

- Impact of eccentricity and depth-to-breadth ratio on the behavior of skirt foundation rested on dry gypseous soil

- Concrete strength development by using magnetized water in normal and self-compacted concrete

- The effect of dosage nanosilica and the particle size of porcelanite aggregate concrete on mechanical and microstructure properties

- Comparison of time extension provisions between the Joint Contracts Tribunal and Iraqi Standard Bidding Document

- Numerical modeling of single closed and open-ended pipe pile embedded in dry soil layers under coupled static and dynamic loadings

- Mechanical properties of sustainable reactive powder concrete made with low cement content and high amount of fly ash and silica fume

- Deformation of unsaturated collapsible soils under suction control

- Mitigation of collapse characteristics of gypseous soils by activated carbon, sodium metasilicate, and cement dust: An experimental study

- Behavior of group piles under combined loadings after improvement of liquefiable soil with nanomaterials

- Using papyrus fiber ash as a sustainable filler modifier in preparing low moisture sensitivity HMA mixtures

- Study of some properties of colored geopolymer concrete consisting of slag

- GIS implementation and statistical analysis for significant characteristics of Kirkuk soil

- Improving the flexural behavior of RC beams strengthening by near-surface mounting

- The effect of materials and curing system on the behavior of self-compacting geopolymer concrete

- The temporal rhythm of scenes and the safety in educational space

- Numerical simulation to the effect of applying rationing system on the stability of the Earth canal: Birmana canal in Iraq as a case study

- Assessing the vibration response of foundation embedment in gypseous soil

- Analysis of concrete beams reinforced by GFRP bars with varying parameters

- One dimensional normal consolidation line equation