Preparation of in situ polymerized polypyrrole-modified braided cord and its electrical conductivity investigation under varied mechanical conditions

-

Jinzhao Zhang

, Haonan Cheng

, Xiaokang Wang

Abstract

With the advancement of flexible electronic textiles, electronic braided cords have garnered significant attention in smart wearable fields by integrating electronic functionalities while preserving textile characteristics such as softness, breathability, and comfort. However, their electrical conductivity suffers varying degrees of degradation under mechanical conditions including friction, stretching, and flexure. This study employed polyester braided cord as a substrate and optimized the preparation of polypyrrole (PPy)-modified braided cord through in situ polymerization combined with orthogonal experimental design. The degradation mechanisms of conductivity under different mechanical conditions were systematically investigated. Experimental results demonstrate that the optimal conductivity (63 S·m−1) was achieved when the pyrrole monomer concentration, FeCl₃·6H₂O concentration, pre-immersion time, and polymerization time were set to 0.2, 0.2 mol·L−1, 4 h, and 9 h, respectively. Although external forces can damage PPy conductive pathways on the cord surface, leading to conductivity loss, the modified cord exhibits excellent friction resistance, stretch tolerance, flexural durability, and stable conductivity under low-load conditions. This research provides critical scientific insights for prolonging the service life of electronic braided cords and their integrated smart textiles.

Graphical abstract

1 Introduction

In the current era of rapid technological advancement, traditional textile products struggle to meet people’s increasingly diversified and sophisticated demands. The emergence of smart wearable devices, particularly driven by recent developments in Internet of Things, big data, humanoid robotics, and artificial intelligence, has accelerated the evolution of fiber-based wearable electronics. Consumers are no longer confined to conventional smart wearables (1,2). Flexible sensors characterized by flexibility, foldability, and wearability have become pivotal components in this transformation (3). As a key innovation, intelligent electronic textiles (e-textiles) integrate cutting-edge weaving techniques with nanotechnology, materials science, and electronic engineering. This convergence facilitates the seamless incorporation of conductivity and flexible electronic components into fabrics, not only enabling novel applications in wearable devices and health monitoring systems but also expanding into diverse fields including smart apparel, flexible sensors, energy harvesting, and storage technologies (4,5,6,7).

The core of smart electronic braided cord lies in its ability to endow textiles with additional electronic functions, such as sensing, luminescence, heating, and communication, while maintaining their natural softness, breathability, and comfort (8). The realization of these functions is attributed to the development and application of conductive materials, semiconductor materials, nanomaterials, etc., which can be coated or modified by electrostatic spinning (9,10), solution impregnation, in situ polymerization (11,12), or weaving, braiding, knitting, or felting to introduce metal or metal-coated fibers and yarns (13). Compared with other preparation methods, flexible e-textiles made by coating or modification processes have shown more excellent performance in terms of electrical conductivity, mechanical properties, and service life (14,15,16,17). Polypyrrole (PPy), as a type of conductive polymer, has a pure monomer that is a colorless, oily liquid at room temperature, with a high boiling point and a low density. In addition, the material has the advantages of simple synthesis, high electrical conductivity, low cost, light weight, and good environmental stability. In recent years, PPy has been widely used in smart textiles and flexible electronic devices due to its excellent biocompatibility, favorable environmental and thermal stability, and simple synthesis method. PPy preparation is usually carried out using chemical oxidizers or electrochemical reactions, and the common chemical oxidizers include ferric chloride, ammonium persulfate, etc. (18,19). For example, Zhang (20) prepared carbon nanotubes (CNTs)/iron oxide/PPy/carbon composites by in situ polymerization, which possessed magnetic loss and dielectric loss properties. Wang (21) prepared PPy/CNTs composite cotton fabric by in situ polymerization, and it was found that the composite fabrics exhibited specific capacitive properties, good thermal conductivity, and antimicrobial properties. Gu (22) prepared graphite oxide (GO)/PPy composites with high electrical conductivity by in situ polymerization, which was four orders of magnitude higher than the pristine GO. Mahesh Parit (23) adopted two new methods to synthesize PPy and cellulose nanofiber (CNF) based conductive composite films: in situ polymerization of pyrrole on cellulose nanopaper (PPy/CNP) and polyvinyl alcohol coated cellulose nanopaper (PPy/PVA-CNP), which showed significant improvements in electrical conductivity, tensile strength, water resistance and electromagnetic shielding (SE). The electrical conductivity of PPy is influenced by parameters such as the type of oxidizing agents and dopants, molar concentration, reaction temperature, and polymerization duration (24,25,26,27). Consequently, these parameters can be modulated to enhance the conductive performance of smart electronic textile yarns. Although wearable electronics based on smart electronic textile-based cords are theoretically expected to exhibit multifunctionality, low power consumption, and advantages including resource abundance, material accessibility, and environmental sustainability, this field still faces significant challenges in practical applications. Current limitations include poor conductive performance, inadequate durability, insufficient reliability, and incompatibility with electronic components in electronic textile cords (28,29). For instance, PPy-modified textiles (e.g., braided cords) experience delamination of the PPy layer under mechanical stress induced by external forces (friction, stretching, or flexure), which severely influences their electrical conductivity.

In this work, polyester braided cords were selected as the substrate for fabricating PPy-modified braided cords through in situ polymerization. A four-factor, four-level orthogonal experimental design was implemented to systematically investigate the effects of pyrrole monomer concentration, iron(iii) chloride hexahydrate (FeCl₃·6H₂O) concentration, pre-immersion time and polymerization time on the electrical conductivity of PPy-modified braided cords, thereby optimizing the preparation process. Structural characterization and analysis of the optimized PPy-modified braided cords were conducted using scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and X-ray diffraction (XRD). Furthermore, the conductive performance evolution under various mechanical loading conditions was thoroughly investigated, accompanied by a mechanistic analysis of the corresponding conductivity degradation phenomena. This investigation aims to establish a critical scientific foundation for prolonging the service life of conductive braided cords and their resultant smart textile systems.

2 Materials and methods

2.1 Experimental materials

The polyester braided cords used in this study exhibited a diameter of 0.8 mm with a 16-strand braided structure. The polymerization monomer, pyrrole (CAS: 109-97-7, purity ≥99%), was procured from Shanghai Aladdin Biochemical Technology Co., Ltd. The oxidant and dopant, iron(iii) chloride hexahydrate (FeCl₃·6H₂O, CAS: 10025-77-1, purity ≥98%), was supplied by Sinopharm Chemical Reagent Co., Ltd. Absolute ethanol (CAS: 64-17-5, purity 99.7%) was obtained from Tianjin Kemiou Chemical Reagent Co., Ltd. Deionized water was prepared in-house using laboratory purification systems.

2.2 Preparation of PPy-modified braided cords

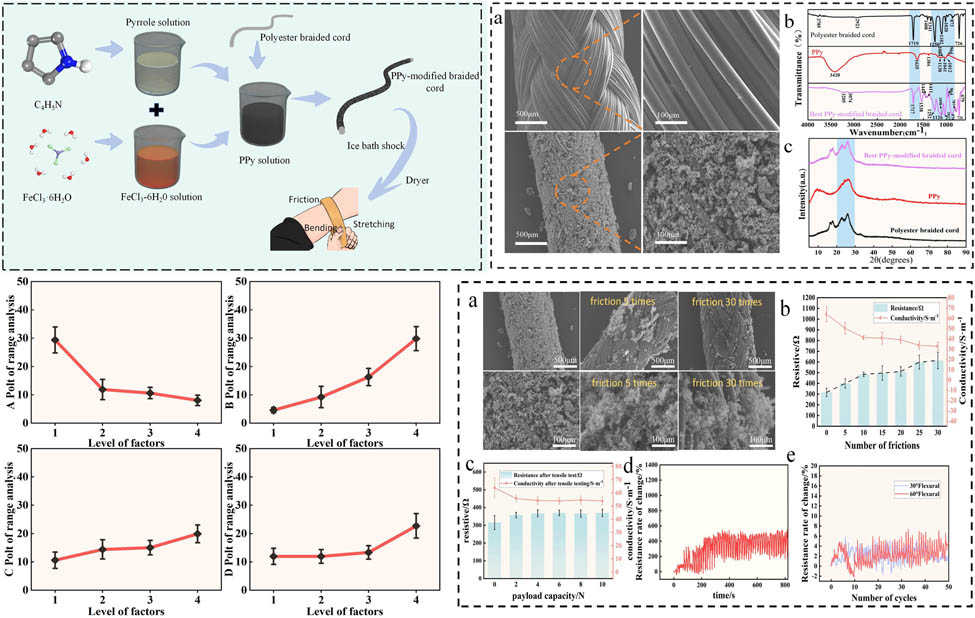

The PPy-modified braided cord was prepared using an in situ polymerization method, and its preparation process is illustrated in Figure 1. First, polyester braided cord was immersed in 75% ethanol solution and cleaned for 2 h in an ultrasonic cleaner (80°C, 120 kHz frequency, 500 W power) to remove surface oils, followed by rinsing with deionized water and drying in an oven at 60°C. Second, 0.2–0.8 mol·L−1 pyrrole monomer was dispersed in a 100 mL aqueous solution in a beaker, and a 30 cm-long braided cord was immersed in the pyrrole solution for 1–4 h. Third, 0.05–0.2 mol·L−1 FeCl₃·6H₂O was dissolved in 10 mL aqueous solution and slowly added to the pyrrole solution. Oxidative polymerization was conducted for 6–9 h at 0–6°C and 140 rpm using a refrigerated water bath constant temperature shaker (Changzhou Runhua Electric Co., Ltd., China) to prepare a PPy-modified braided cord. Finally, the modified cord was sequentially washed with anhydrous ethanol and deionized water several times and then dried in an oven at 80°C.

Schematic diagram of the process flow for the preparation of PPy-modified braided cord.

2.3 Experimental program

A four-factor, four-level orthogonal experimental design (as shown in Table 1) was developed, with Factor A as pyrrole monomer concentration (mol·L−1), Factor B as FeCl₃·6H₂O concentration (mol·L−1), Factor C as pre-immersion time (h), and Factor D as polymerization time (h). Without considering interaction effects and under unreplicated experimental conditions, the L₁₆(4⁵) orthogonal array (as shown in Table 2) was selected, with the unassigned column designated as Factor E.

Factor-level table for the orthogonal experimental design

| Levels/factors | A (mol·L−1) | B (mol·L−1) | C (h) | D (h) |

|---|---|---|---|---|

| 1 | 0.2 | 0.05 | 1 | 6 |

| 2 | 0.4 | 0.1 | 2 | 7 |

| 3 | 0.6 | 0.15 | 3 | 8 |

| 4 | 0.8 | 0.2 | 4 | 9 |

L₁₆(4⁵) orthogonal array

| Test number | A (mol·L−1) | B (mol·L−1) | C (h) | D (h) | E |

|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 | 3 |

| 4 | 1 | 4 | 4 | 4 | 4 |

| 5 | 2 | 1 | 2 | 3 | 4 |

| 6 | 2 | 2 | 1 | 4 | 3 |

| 7 | 2 | 3 | 4 | 1 | 2 |

| 8 | 2 | 4 | 3 | 2 | 1 |

| 9 | 3 | 1 | 3 | 4 | 2 |

| 10 | 3 | 2 | 4 | 3 | 1 |

| 11 | 3 | 3 | 1 | 2 | 4 |

| 12 | 3 | 4 | 2 | 1 | 3 |

| 13 | 4 | 1 | 4 | 2 | 3 |

| 14 | 4 | 2 | 3 | 1 | 4 |

| 15 | 4 | 3 | 2 | 4 | 1 |

| 16 | 4 | 4 | 1 | 3 | 2 |

2.4 Property characterization

2.4.1 Morphology observation

The apparent morphology of the PPy-coated braided cord was observed by an SEM model SU3500 (Hitachi, Japan). The accelerating voltage was 15 kV. To avoid charge-build-up problems, the 1 cm long sample was previously coated with a thin layer of gold by employing a sputter coater.

2.4.2 FTIR spectroscopy analysis

The FTIR spectra of the PPy-coated braided cord were recorded on a spectrometer model TENSOR27 (Bruker, German) in the range of 400–4,000 cm−1. The PPy-coated braided cord spectra were obtained using KBr pellets at room temperature.

2.4.3 XRD tests

The crystal structures of uncoated and PPy-coated braided cord were determined using an Aeris benchtop X-ray diffractometer (Panalytical, The Netherlands). The tests were carried out using Cu-targeted Kα radiation at a voltage and current of 40 kV and 30 mA, respectively, in a sequential scanning mode with a scanning rate of 5°/min and a scanning angle (2θ) in the range of 5°–80°.

2.4.4 Conductivity

The resistance of PPy-modified braided cord was tested using a DMM6500 six-and-a-half digit multimeter (Tektronix, USA) with a length of 1 cm between the test points and its conductivity was calculated using Eq. 1:

where σ is the electrical conductivity (S·m−1); R is the sample resistance (Ω); L is the sample length (m); and S is the cross-sectional area of the sample (m²).

2.4.5 Friction properties tests

The friction resistance of PPy-modified braided cords was tested according to the standard FZ/T 01058-1999, using a YG109 yarn abrasion tester (Ningbo Textile Instrument Factory, China). The testing conditions were as follows: 3000-grit sandpaper, 0.1 N load, 60 cycles/min in friction speed, and 30 total friction cycles. After every 5 friction cycles, the resistance of a 1-cm-long abraded sample was measured using a digital multimeter, and the corresponding electrical conductivity was calculated. Post-friction, the wear morphology of the samples was observed via SEM.

2.4.6 Tensile properties tests

With reference to the standard FZ/T 01034-2008, the performance of PPy-modified braided cord was tested by using YG (B) 026HC-500 fabric strength machine (Darong Textile Instrument, China) for constant load stretching (2, 4, 6, 8, and 10 N) and constant load cyclic stretching (20 N, 50 times of cycling), and the real-time resistance of the 1-cm-long stretching specimens was tested by using multimeter and conductivity was calculated. The test interval was 20 cm, the speed was 100 mm·min−1, and each group of tests was tested three times.

2.4.7 Flexural properties tests

The flexural performance of the PPy-modified braided cord was tested using a homemade device (shown in Figure 2). The specimen was positioned on the operation table for testing. The tail end of the specimen was secured by Fixture 1, which was routed around an 8 mm diameter cylinder to prevent slippage of the specimen. The first end was then clamped by Fixture 2 at the initial position. Fixture 2 was mounted on a linkage mechanism, which was controlled by a stepper motor to perform flexural tests at angles of 30° and 60°. The specimen underwent 50 flexural cycles. During flexural testing, a multimeter was employed to measure real-time resistance by clamping the electrodes to the ends of a 5 cm segment of the specimen.

Schematic diagram of PPy-modified braided cord flexural performance test.

3 Results and discussion

3.1 Range analysis of orthogonal experiment

The conductivity of PPy-modified braided cord was used as an index to measure the optimal preparation process, and the data of orthogonal experiments were processed statistically and analytically using the range analysis method, and the results are shown in Table 3. Where R is the range, which indicates the magnitude of the conductivity of 1 cm long PPy-modified braided cord under different factors and levels, and K indicates the sum of experimental results at each level. The range analysis of conductivity under the conditions of each reaction factor is shown in Figure 3.

Range analysis results of the L₁₆(4⁵) orthogonal experiment

| Factor | A (mol·L−1) | B (mol·L−1) | C (h) | D (h) | E | Conductivity (S·m−1) |

|---|---|---|---|---|---|---|

| 1 | 1(0.2) | 1(0.05) | 1(1) | 1(6) | 1 | 8.03 |

| 2 | 1(0.2) | 2(0.1) | 2(2) | 2(7) | 2 | 14.51 |

| 3 | 1(0.2) | 3(0.15) | 3(3) | 3(8) | 3 | 31.92 |

| 4 | 1(0.2) | 4(0.2) | 4(4) | 4(9) | 4 | 63.03 |

| 5 | 2(0.4) | 1(0.05) | 2(2) | 3(8) | 4 | 5.39 |

| 6 | 2(0.4) | 2(0.1) | 1(1) | 4(9) | 3 | 12.31 |

| 7 | 2(0.4) | 3(0.15) | 4(4) | 1(6) | 2 | 9.66 |

| 8 | 2(0.4) | 4(0.2) | 3(3) | 2(7) | 1 | 20.20 |

| 9 | 3(0.6) | 1(0.05) | 3(3) | 4(9) | 2 | 2.58 |

| 10 | 3(0.6) | 2(0.1) | 4(4) | 3(8) | 1 | 4.63 |

| 11 | 3(0.6) | 3(0.15) | 1(1) | 2(7) | 4 | 10.67 |

| 12 | 3(0.6) | 4(0.2) | 2(2) | 1(6) | 3 | 24.77 |

| 13 | 4(0.8) | 1(0.05) | 4(4) | 2(7) | 3 | 2.42 |

| 14 | 4(0.8) | 2(0.1) | 3(3) | 1(6) | 4 | 5.44 |

| 15 | 4(0.8) | 3(0.15) | 2(2) | 4(9) | 1 | 13.00 |

| 16 | 4(0.8) | 4(0.2) | 1(1) | 3(8) | 2 | 11.43 |

| k1 | 29.37 | 4.61 | 10.61 | 11.97 | 11.46 | |

| k2 | 11.89 | 9.22 | 14.42 | 11.95 | 9.55 | |

| k3 | 10.66 | 16.31 | 15.04 | 13.35 | 17.86 | |

| k4 | 8.07 | 29.86 | 19.94 | 22.73 | 21.13 | |

| R | 21.30 | 25.25 | 9.33 | 10.78 | 11.59 |

Plot of range analysis of conductivity under each factor condition.

As evidenced by the range analysis in Table 3, the factors influencing the electrical conductivity of PPy-modified braided cords follow a descending order of significance: B (FeCl₃·6H₂O dopant concentration) > A (pyrrole monomer concentration) > D (polymerization time) > C (pre-immersion time). Figure 3 further reveals distinct trends: the conductivity exhibited an inverse correlation with pyrrole monomer concentration, whereas it demonstrated a positive dependence on FeCl₃·6H₂O dopant concentration, pre-immersion time and polymerization time.

The comprehensive analysis shows that the PPy-modified braided cord has the best electrical conductivity with a resistance of 316 Ω and a conductivity of 63 S·m−1 when the concentration of pyrrole monomer is 0.2 mol·L−1, the concentration of FeCl3 ·6H2O is 0.2 mol·L−1, the presoaking time is 4 h, and the polymerization reaction time is 9 h.

3.2 Variance analysis of orthogonal experiment

To assess the statistical significance of pyrrole monomer concentration, FeCl₃·6H₂O concentration, pre-immersion time, and polymerization time on the electrical conductivity of PPy-modified braided cords, and to validate the rationality of the range analysis, an analysis of variance (ANOVA) was performed on the orthogonal experimental results, as summarized in Table 4. The ANOVA results demonstrated that: Pyrrole monomer concentration (Factor A) and FeCl₃·6H₂O dopant concentration (Factor B) exhibited statistically significant effects on conductivity (P ≤ 0.05), with their primary-secondary order aligned with the range analysis results (B > A). Pre-immersion time (Factor C) and polymerization time (Factor D) showed no significant impact (P > 0.1). Therefore, considering practical production efficiency and process requirements, the pre-immersion time and polymerization time can be appropriately reduced to optimize the preparation process of PPy-modified braided cords without compromising their conductivity performance.

ANOVA table for the L₁₆(4⁵) orthogonal experimental results

| Factor | Sum of squares | Degrees of freedom | Mean square | F-value | P-value | Significance |

|---|---|---|---|---|---|---|

| A | 1,132.09 | 3.00 | 377.36 | 3.99 | 0.05 | * |

| B | 1,455.75 | 3.00 | 485.25 | 5.13 | 0.02 | * |

| C | 176.03 | 3.00 | 58.68 | |||

| D | 323.78 | 3.00 | 107.93 | |||

| E(error) | 352.07 | 3.00 | 117.36 | |||

| eΔ(new error) | 851.87 | 9.00 | 94.65 | 1.00 |

Note: Confidence interval (P ≤ 0.05).

* indicates that the factor has a significant effect on the test results.

3.3 Structural analysis

The apparent morphology and microstructure of polyester braided cord before and after PPy modification were analyzed using an SU3500 SEM, as illustrated in Figure 4a. The unmodified polyester braided cord exhibited a compact structure with tightly interlaced strands, smooth and uniform fiber surfaces, and orderly fiber alignment. Following PPy modification, the cord surface was uniformly coated with granular deposits. Further examination of individual fibers revealed that the fiber surfaces were also covered with particulate matter. Additionally, these granular deposits formed interconnected networks, demonstrating intimate bonding at the fiber surfaces, inter-fiber interfaces, and interstitial gaps between strands.

(a) Structural morphology of polyester braided cord and PPy-modified braided cord. (b) FTIR spectra of PPy, polyester braided cord, and PPy-modified braided cord. (c) XRD curves of PPy, polyester braided cord, and PPy-modified braided cord.

Figure 4b displays the FTIR spectra of PPy, unmodified polyester braided cord and PPy-modified cord. As shown in Figure 4b, the FTIR spectrum of the unmodified polyester braided cord exhibits characteristic peaks: A peak at 1,719 cm⁻¹ is assigned to the stretching vibration of the carbonyl group (C═O). A peak at 1,250 cm⁻¹ corresponds to the asymmetric stretching vibration of the C–O bond adjacent to the carbonyl group in the ester moiety. A peak at 1,102 cm⁻¹ arises from the stretching vibration of C–OH. A peak at 1,020 cm⁻¹ is attributed to the symmetric stretching vibration of the C–O bond linked to the alkyl group in the ester moiety. A peak at 726 cm⁻¹ originates from the in-plane rocking vibration of CH₂ groups in long-chain aliphatic segments (n > 4). In the FTIR spectrum of PPy: A broad absorption band at 3,420 cm⁻¹ is observed, attributed to the stretching vibration of N–H bonds in pyrrole rings. A strong peak at 1,635 cm⁻¹ is assigned to the stretching vibration of conjugated C═C bonds in the PPy backbone. A peak at 1,384 cm⁻¹ corresponds to the stretching vibration of C–N bonds in pyrrole rings, confirming the PPy structure. Peaks near 1,084 cm⁻¹ and 964 cm⁻¹ are associated with the breathing vibrations of pyrrole rings, further supporting the presence of PPy. For the PPy-modified cord: a peak at 3,074 cm⁻¹ is attributed to the stretching vibration of C–H bonds on pyrrole rings. Compared to pure PPy, the position and intensity of this peak shifted due to hydrogen bonding interactions between PPy and the polyester cord. A prominent peak at 1,538 cm⁻¹, characteristic of the stretching vibration of C═C double bonds within pyrrole rings, aligns with the PPy spectrum, confirming the retention of PPy structure. A peak at 1,252 cm⁻¹ corresponds to the stretching vibration of C–N single bonds in pyrrole rings, consistent with PPy’s spectral features. A peak at 1,037 cm⁻¹ is related to the bending or deformation vibrations of C–H bonds on the pyrrole ring. A peak at 878 cm⁻¹ represents the out-of-plane bending vibration of C–H bonds on pyrrole rings. Notably, the FTIR spectrum of the PPy-modified cord exhibits new absorption peaks and significant shifts in peak positions and intensities compared to both unmodified polyester cord and pure PPy. These changes confirm the successful polymerization of PPy on the polyester cord surface, driven by interactions between the modifier and the PPy structure.

Figure 4c presents the XRD curves of PPy, unmodified polyester braided cord and PPy-modified cord. The XRD curve of the unmodified polyester braided cord (Figure 4c) displays characteristic diffraction peaks at 17, 22.5, and 25.5°, corresponding to the diffraction from specific crystallographic planes with defined interplanar spacings in the crystalline structure of polyester. The intensity of these peaks reflects the diffraction efficiency of distinct crystallographic planes (30). In the XRD curve of PPy (Figure 4c), two broad diffraction peaks are observed at 9.5° (low intensity) and 25.5° (higher intensity). For the PPy-modified cord, the XRD curve retains similarities to both components: No new diffraction peaks emerge, indicating that the crystalline structures of polyester and PPy remain largely intact without significant structural disruption or peak shifts (31). The curve combines characteristic peaks of the polyester cord (e.g., at 17° and 22.5°) with those of PPy (e.g., at 25.5°), confirming the successful modification of the cord with PPy. Notably, the intensity of the 25.5° peak differs from both the unmodified cord and pure PPy, likely due to altered intercrystalline interactions and spatial distribution of PPy within the modified cord. Collectively, the XRD curves of the three samples demonstrate that a minimal amount of PPy is uniformly dispersed on the surface of the modified cord, without inducing substantial crystallographic distortion.

3.4 Conductivity analysis under different mechanical working conditions

Figure 5a illustrates the apparent morphology of the PPy-modified braided cord after friction testing. As shown in Figure 5a, the unabraded sample exhibits uniform polymerization of PPy on individual fibers within the cord. However, after five cycles of friction with 3000-grit sandpaper, partial detachment of PPy from the fiber surfaces was observed under mechanical friction. Following thirty cycles of friction, a more pronounced removal of PPy and significant alterations in apparent morphology were evident. This phenomenon is attributed to the weak interfacial adhesion between PPy and polyester fibers, as the pyrrole monomer was solely deposited on the cord via in situ polymerization without additional bonding agents. Even under mild frictional forces, PPy tends to delaminate from the cord surface. Progressive accumulation of friction cycles exacerbates the detachment, leading to an incremental loss of PPy coating.

(a) Apparent morphology of PPy-modified braided cord after friction property test. (b) Electrical conductivity of PPy-modified braided cord under friction test condition (3000 grit sandpaper, 0.1 N load). (c) Electrical conductivity of PPy-modified braided cord under constant load tensile test condition. (d) Electrical conductivity of PPy-modified braided cord under constant load cyclic tensile test condition of 20 N. (e) Electrical conductivity of PPy-modified braided cord under flexural test condition.

Figure 5b illustrates the relationship between the electrical conductivity of the PPy-modified braided cord (prepared under optimal conditions) and the number of friction cycles. As shown, the conductivity gradually decreases with increasing friction cycles. After 5 cycles of friction with 3000-grit sandpaper, the conductivity decreased from 63 to 50 S·m−1 (a 20.63% reduction), indicating relatively good friction resistance and electrical stability under low friction and limited cycles. After 30 cycles, the conductivity further dropped to 32.82 S·m−1 (a 30.21% reduction). This decline is attributed to the progressive and uneven detachment of PPy from the cord surface under repeated friction, which disrupts the conductive pathways formed by PPy, increases resistance, and leads to cumulative degradation of electrical performance.

Figure 5c depicts the correlation between the electrical conductivity of the PPy-modified cord and applied constant tensile loads. The conductivity decreases gradually with increasing load. At 2 N, the conductivity declined from 63 to 56 S·m−1 (11.11% reduction), while at 10 N, it further decreased to 54 S·m−1 (14.29% reduction). This behavior arises from the structural elongation of the cord under tensile stress. Since PPy is deposited on the cord surface via in situ polymerization and cannot elongate synchronously with the substrate, the increased spacing between PPy particles reduces conductive pathways, elevating resistance and degrading conductivity. Notably, the conductivity reduction between 2 and 10 N was only an additional 2.76%, demonstrating excellent tensile resistance and electrical stability under low loads.

Figure 5d presents the real-time resistivity variation rate of the PPy-modified cord during cyclic tensile testing under a 20 N constant load. The resistivity fluctuates reciprocally with increasing cycles, showing a larger initial amplitude and an overall trend of rising followed by stabilization. During cyclic loading, the cord undergoes elongation, reducing conductive pathways and increasing resistance. Upon load release, partial recovery of the cord’s structure restores some pathways, lowering resistance. However, due to the cord’s limited elasticity, incomplete recovery after repeated cycles causes irreversible conductive pathway damage, leading to an upward trend in resistivity variation during initial cycles. After 220 s, the resistivity stabilizes as the cord adapts to the test conditions. After 800 s, the resistivity variation rate increased by 474.46%, indicating fairly good electrical stability under prolonged cyclic loading.

Figure 5(e) shows the resistivity variation of the PPy-modified cord during cyclic flexural tests at 30° and 60°. Under both conditions, the resistivity fluctuates with increasing cycles, exhibiting larger initial amplitudes and stabilizing over time. After 50 cycles, the resistivity variation rates increased by 1% (30°) and 4% (60°), respectively. These results confirm the cord’s robust electrical stability under flexural cyclic. During flexural test, the outer side of the cord experiences tensile stress, while the inner side undergoes compression. The tensile-induced resistance increase follows the same mechanism as cyclic tensile testing, with higher flexural angles amplifying tensile stress and resistivity variation. Conversely, the compressive side maintains stable conductivity due to minimal structural deformation, ensuring sustained contact between PPy particles and intact conductive pathways.

4 Conclusion

In this article, the in situ polymerization method was adopted, and an orthogonal experiment was designed to optimize the preparation of a PPy-modified braided cord. When the pyrrole monomer concentration, FeCl₃·6H₂O concentration, pre-immersion time, and polymerization time were 0.2, 0.2 mol·L−1, 4 h, and 9 h, respectively, the PPy-modified braided cord exhibited the best electrical conductivity with a conductivity of 63 S·m−1. Pyrrole can uniformly polymerize on the surface of the braided cord, forming conductive pathways that endow the braided cord with excellent electrical conductivity. Under friction (3000-grit sandpaper, 0.1 N, 5 times) and constant load (2 N) tensile test conditions, the retention rates of the electrical conductivity of the PPy-modified braided cord were 79.72% and 88.32%, respectively; under the flexural test condition of 30°, the resistance change rate increased by only 1% after 50 cycles. This indicates that although external forces can damage the PPy conductive pathways formed on the surface of the PPy-modified braided cord, resulting in conductive loss, it still exhibits excellent friction resistance, stretch tolerance, flexural durability and stable conductivity under low-load conditions. In addition, if a very diluted solution of PDMS or PU is used to coat the PPy-modified braided cord to protect the conductive pathways formed by PPy and improve its ability to resist external forces, this will provide more possibilities for extending the service life of electronic braided cord and the intelligent textiles constructed from it.

Acknowledgments

The authors gratefully acknowledge the financial support from the Youth Program of Hunan Provincial Education Department (Grant No. 22B0729), Regional Joint Fund of Hunan Provincial Department of Science and Technology (Grant No. 2024JJ7106 and Grant No. 2024JJ7111).

-

Author contributions: Jinzhao Zhang: writing & original draft, investigation, data curation, software; Kaifang Xie: conceptualization, supervision, funding acquisition; Haonan Cheng: writing – review & editing, project administration; Xiaokang Wang: data curation; Jiao Li: methodology, validation; Changwei Liu: formal analysis; Guangbiao Xu: resources.

-

Conflict of interest: Authors state no conflict of interest.

References

(1) Liu X, Miao J, Fan Q, Zhang W, Zuo X, Tian M, et al. Recent progress on smart fiber and textile based wearable strain sensors: materials, fabrications and applications. Adv Fiber Mater. 2022;4(3):361–8. 10.1007/s42765-022-00155-6.Search in Google Scholar

(2) Yin Y, Guo C, Li H, Yang H, Xiong F, Chen D. The progress of research into flexible sensors in the field of smart wearables. Sensors. 2022;22(14):5089. 10.3390/s22145089.Search in Google Scholar PubMed PubMed Central

(3) Wang K, Lou Z, Wang L, Zhao L, Zhao S, Wang D, et al. Bioinspired interlocked structure-induced high deformability for two-dimensional titanium carbide (mxene)/natural microcapsule-based flexible pressure sensors. ACS Nano. 2019;13(9):9139–47. 10.1021/acsnano.9b03454.Search in Google Scholar PubMed

(4) Shekhar R, Choudhry NA, Islam S, Ahnood A, Pirogova E, Troynikov O. A novel elastic conductive yarn for smart textile applications. Adv Eng Mater. 2023;25(22):2300572. 10.1002/adem.202300572.Search in Google Scholar

(5) Wu J, Jiao W, Guo Y, Guo Y, Wu Y, Zhu C, et al. Recent progress on yarn-based electronics: From material and device design to multifunctional applications. Adv Electron Mater. 2023;9(8):2300219. 10.1002/aelm.202300219.Search in Google Scholar

(6) Chen M, Liu J, Li P, Gharavi H, Hao Y, Ouyang J, et al. Fabric computing:Concepts, opportunities, and challenges. Innovation. 2022;3(6):100340. 10.1016/j.xinn.2022.100340.Search in Google Scholar PubMed PubMed Central

(7) Chen M, Ouyang J, Jian A, Liu J, Li P, Hao Y, et al. Imperceptible, designable, and scalable braided electronic cord. Nat Commun. 2022;13(1):7097. 10.1038/s41467-022-34918-x.Search in Google Scholar PubMed PubMed Central

(8) Azani MR, Hassanpour A. Electronic textiles (E-Textiles): types, fabrication methods, and recent strategies to overcome durability challenges (washability & flexibility). J Mater Sci: Mater Electron. 2024;35(29):1897. 10.1007/s10854-024-13747-2.Search in Google Scholar

(9) Liu J, Pan CT, Lin LW, Huang J, Ou ZY. Direct-write PVDF nonwoven fiber fabric energy harvesters via the hollow cylindrical near-field electrospinning process. Smart Mater Struct. 2013;23(2):025003. 10.1088/0964-1726/23/2/025003.Search in Google Scholar

(10) Inagaki M, Yang Y, Kang F. Carbon nanofibers prepared via electrospinning. Adv Mater. 2012;24(19):2547–66. 10.1002/adma.201104940.Search in Google Scholar PubMed

(11) Bhat VN, Seshadri DT, Nate MM, Gore AV. Development of conductive cotton fabrics for heating devices. J Appl Polym Sci. 2006;102(5):4690–5. 10.1002/app.24708.Search in Google Scholar

(12) Hamdani ST, Potluri P, Fernando A. Thermo-mechanical behavior of textile heating fabric based on silver coated polymeric yarn. Materials. 2013;6(3):1072–89. 10.3390/ma6031072.Search in Google Scholar PubMed PubMed Central

(13) Pragya A, Singh H, Kumar B, Gupta H, Shankar P. Designing and investigation of braided-cum-woven structure for wearable heating textile. Eng Res Express. 2020;2(1):015003. 10.1088/2631-8695/ab63f3.Search in Google Scholar

(14) Liu Y, Wang Y. Preparation of polypyrrole/polyester-cotton composites and a study of their dielectric properties and conductivity. Text Res J. 2021;91(9–10):973–83. 10.1177/0040517520965696.Search in Google Scholar

(15) Liu S, Liu Y, Li L. The impact of different proportions of knitting elements on the resistive properties of conductive fabrics. Text Res J. 2019;89(5):881–90. 10.1177/0040517518758003.Search in Google Scholar

(16) Ashayer-Soltani R, Hunt C, Thomas O. Fabrication of highly conductive stretchable textile with silver nano-particles. Text Res J. 2016;86:1041–9. 10.1177/0040517515603813.Search in Google Scholar

(17) Dhineshbabu NR, Sekhar Behera S, Bose S. Smart textile fabrics for screening millimeter wavelength radiations: challenges and future perspectives. ChemistrySelect. 2018;3(22):6087–101. 10.1002/slct.201801125.Search in Google Scholar

(18) Caringella R, Patrucco A, Simionati M, Gavignano S, Montarsolo A, Mossotti R, et al. Electrically conducting linen fabrics for technical applications. Text Res J. 2018;88(2):144–54. 10.1177/0040517516676067.Search in Google Scholar

(19) Wang B, Cheng H, Zhu J, Yuan Y, Wang C. A flexible and stretchable polypyrrole- coated cotton for electrothermal heater. Org Electron. 2020;85:105819. 10.1016/j.orgel.2020.105819.Search in Google Scholar

(20) Zhang K, Chen X, Gao X, Chen L, Ma S, Xie C, et al. Preparation and microwave absorption properties of carbon nanotubes/iron oxide/polypyrrole/carbon composites. Synth Metals. 2020;260:116282. 10.1016/j.synthmet.2019.116282.Search in Google Scholar

(21) Wang Y, Kong Q, Liu Q, Li R, Zhou C, Li Z. Preparation of polypyrrole/carbon nanotubes composite cotton fabric through in situ polymerization and its conductive property. ACS Appl Electron Mater. 2024;6(5):3563–73. 10.1021/acsaelm.4c00311.Search in Google Scholar

(22) Gu Z, Zhang L, Li C. Preparation of highly conductive polypyrrole/graphite oxide composites via in situ polymerization. J Macromol Sci Part B. 2009;48(6):1093–102. 10.1080/00222340903035576.Search in Google Scholar

(23) Parit M, Du H, Zhang X, Prather C, Adams M, Jiang Z. Polypyrrole and cellulose nanofiber based composite films with improved physical and electrical properties for electromagnetic shielding applications. Carbohydr Polym. 2020;240:116304. 10.1016/j.carbpol.2020.116304.Search in Google Scholar PubMed

(24) Kaynak A, Zolfagharian A, Featherby T, Bodaghi M, Mahmud MP, Kouzani AZ. Electrothermal modeling and analysis of polypyrrole-coated wearable E-Textiles. Materials. 2021;14(3):550. 10.3390/ma14030550.Search in Google Scholar PubMed PubMed Central

(25) Wang L, Li X, Yang Y. Preparation, properties and applications of polypyrroles. React Funct Polym. 2001;47(2):125–39. 10.1016/S1381-5148(00)00079-1.Search in Google Scholar

(26) Wei C, Fan L, Rao W, Bai Z, Xu W, Bao H, et al. Electrothermochromic paper fabricated by depositing polypyrrole on one side. Cellulose. 2017;24(11):5187–96. 10.1007/s10570-017-1481-9.Search in Google Scholar

(27) Sarojini G, Venkateshbabu S, Rajasimman M. Facile synthesis and characterization of polypyrrole-iron oxide-seaweed (PPy-Fe3O4-SW) nanocomposite and its exploration for adsorptive removal of Pb(II) from heavy metal bearing water. Chemosphere. 2021;278:130400. 10.1016/j.chemosphere.2021.130400.Search in Google Scholar PubMed

(28) Wang Y, Chen L, Cheng H, Wang B, Feng X, Mao Z, et al. Mechanically flexible, waterproof, breathable cellulose/polypyrrole/polyurethane composite aerogels as wearable heaters for personal thermal management. Chem Eng J. 2020;402:126235. 10.1016/j.cej.2020.126222.Search in Google Scholar

(29) Yun S, Niu X, Yu Z, Hu W, Brochu P, Pei Q. Compliant silver nanowire-polymer composite electrodes for bistable large strain actuation. Adv Mater. 2012;24(10):1321–7. 10.1002/adma.201104101.Search in Google Scholar PubMed

(30) Kamel MM, El Zawahry MM, Helmy H, Eid MA. Improvements in the dyeability of polyester fabrics by atmospheric pressure oxygen plasma treatment. J Text Inst. 2011;102(3):220–31. 10.1080/00405001003672366.Search in Google Scholar

(31) Xie J, Pan W, Guo Z, Jiao SS, Yang LP. In situ polymerization of polypyrrole on cotton fabrics as flexible electrothermal materials. J Eng Fibers Fabr. 2019;14:1558925019827447. 10.1177/1558925019827447.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Flow-induced fiber orientation in gas-powered projectile-assisted injection molded parts

- Research on thermal aging characteristics of silicone rubber composite materials for dry-type distribution transformers

- Kinetics of acryloyloxyethyl trimethyl ammonium chloride polymerization in aqueous solutions

- Influence of siloxane content on the material performance and functional properties of polydimethylsiloxane copolymers containing naphthalene moieties

- Enhancement effect of electron beam irradiation on acrylonitrile–butadiene–styrene (ABS) copolymers from waste electrical and electronic equipment by adding 1,3-PBO: A potential way for waste ABS reuse

- Model construction and property study of poly(ether-ether-ketone) by molecular dynamics simulation with meta-modeling methods

- Zinc–gallic acid–polylysine nanocomplexes with enhanced bactericidal activity for the treatment of bacterial keratitis

- Effect of pyrogallol compounds dosage on mechanical properties of epoxy coating

- Preparation of in situ polymerized polypyrrole-modified braided cord and its electrical conductivity investigation under varied mechanical conditions

- Hydrophobicity, UV resistance, and antioxidant properties of carnauba wax-reinforced CG bio-polymer film

- Janus nanofiber membrane films loading with bioactive calcium silicate for the promotion of burn wound healing

- Synthesis of migration-resistant antioxidant and its application in natural rubber composites

- Influence of the flow rate on the die swell for polymer micro coextrusion process

- Fatty acid filled polyaniline nanofibres with dual electrical conductivity and thermo-regulatory characteristics: Futuristic material for thermal energy storage

- Hydrolytic depolymerization of major fibrous wastes

- Performance of epoxy hexagonal boron nitrate underfill materials: Single and mixed systems

- Blend electrospinning of citronella or thyme oil-loaded polyurethane nanofibers and evaluating their release behaviors

- Efficiency of flexible shielding materials against gamma rays: Silicon rubber with different sizes of Bi2O3 and SnO

- A comprehensive approach for the production of carbon fibre-reinforced polylactic acid filaments with enhanced wear and mechanical behaviour

- Electret melt-blown nonwovens with charge stability for high-performance PM0.3 purification under extreme environmental conditions

- Study on the failure mechanism of suture CFRP T-joints under/after the low-velocity impact loading

- Experimental testing and finite element analysis of polyurethane adhesive joints under Mode I loading and degradation conditions

- Optimizing recycled PET 3D printing using Taguchi method for improved mechanical properties and dimensional precision

- Effect of stacking sequence of the hybrid composite armor on ballistic performance and damage mechanism

- Bending crack propagation and delamination damage behavior of orthogonal ply laminates under positive and negative loads

- Molecular dynamics simulation of thermodynamic properties of Al2O3-modified silicone rubber under silane coupling agent modification

- Precision injection molding method based on V/P switchover point optimization and pressure field balancing

- Heparin and zwitterion functionalized small-diameter vascular grafts for thrombogenesis prevention

- Metal-free N, S-co-doped carbon materials derived from calcined aromatic co-poly(urea-thiourea)s as efficient alkaline oxygen reduction catalysts

- Influence of stitching parameters on the tensile performance and failure mechanisms of CFRP T-joints

- Synthesis of PEGylated polypeptides bearing thioether pendants for injectable ROS-responsive hydrogels

- Rapid Communication

- RAFT-mediated polymerization-induced self-assembly of poly(ionic liquid) block copolymers in a green solvent

- Corrigendum

- Corrigendum to “High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing”

Articles in the same Issue

- Research Articles

- Flow-induced fiber orientation in gas-powered projectile-assisted injection molded parts

- Research on thermal aging characteristics of silicone rubber composite materials for dry-type distribution transformers

- Kinetics of acryloyloxyethyl trimethyl ammonium chloride polymerization in aqueous solutions

- Influence of siloxane content on the material performance and functional properties of polydimethylsiloxane copolymers containing naphthalene moieties

- Enhancement effect of electron beam irradiation on acrylonitrile–butadiene–styrene (ABS) copolymers from waste electrical and electronic equipment by adding 1,3-PBO: A potential way for waste ABS reuse

- Model construction and property study of poly(ether-ether-ketone) by molecular dynamics simulation with meta-modeling methods

- Zinc–gallic acid–polylysine nanocomplexes with enhanced bactericidal activity for the treatment of bacterial keratitis

- Effect of pyrogallol compounds dosage on mechanical properties of epoxy coating

- Preparation of in situ polymerized polypyrrole-modified braided cord and its electrical conductivity investigation under varied mechanical conditions

- Hydrophobicity, UV resistance, and antioxidant properties of carnauba wax-reinforced CG bio-polymer film

- Janus nanofiber membrane films loading with bioactive calcium silicate for the promotion of burn wound healing

- Synthesis of migration-resistant antioxidant and its application in natural rubber composites

- Influence of the flow rate on the die swell for polymer micro coextrusion process

- Fatty acid filled polyaniline nanofibres with dual electrical conductivity and thermo-regulatory characteristics: Futuristic material for thermal energy storage

- Hydrolytic depolymerization of major fibrous wastes

- Performance of epoxy hexagonal boron nitrate underfill materials: Single and mixed systems

- Blend electrospinning of citronella or thyme oil-loaded polyurethane nanofibers and evaluating their release behaviors

- Efficiency of flexible shielding materials against gamma rays: Silicon rubber with different sizes of Bi2O3 and SnO

- A comprehensive approach for the production of carbon fibre-reinforced polylactic acid filaments with enhanced wear and mechanical behaviour

- Electret melt-blown nonwovens with charge stability for high-performance PM0.3 purification under extreme environmental conditions

- Study on the failure mechanism of suture CFRP T-joints under/after the low-velocity impact loading

- Experimental testing and finite element analysis of polyurethane adhesive joints under Mode I loading and degradation conditions

- Optimizing recycled PET 3D printing using Taguchi method for improved mechanical properties and dimensional precision

- Effect of stacking sequence of the hybrid composite armor on ballistic performance and damage mechanism

- Bending crack propagation and delamination damage behavior of orthogonal ply laminates under positive and negative loads

- Molecular dynamics simulation of thermodynamic properties of Al2O3-modified silicone rubber under silane coupling agent modification

- Precision injection molding method based on V/P switchover point optimization and pressure field balancing

- Heparin and zwitterion functionalized small-diameter vascular grafts for thrombogenesis prevention

- Metal-free N, S-co-doped carbon materials derived from calcined aromatic co-poly(urea-thiourea)s as efficient alkaline oxygen reduction catalysts

- Influence of stitching parameters on the tensile performance and failure mechanisms of CFRP T-joints

- Synthesis of PEGylated polypeptides bearing thioether pendants for injectable ROS-responsive hydrogels

- Rapid Communication

- RAFT-mediated polymerization-induced self-assembly of poly(ionic liquid) block copolymers in a green solvent

- Corrigendum

- Corrigendum to “High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing”