Abstract

In this study, the efficiency of flexible composites consisting of viscous silicone rubber as matrix and micro- and nanoparticles of Bi2O3 and SnO2 as fillers was investigated. Four composites with a matrix/filler at 50:50 were prepared. The four samples are the liquid silicone rubber (LSR) materials with micro-Bi2O3, micro-Bi2O3, and nano-SnO, nano-Bi2O3, and nano-SnO, and both nano-Bi2O3 and nano-SnO are labeled as LSR-Micro, LSR-Micro/Nano, LSR-Nano/Micro, and LSR-Nano/Nano, respectively. The morphologies and the homogeny of the nanoparticles and the prepared composites were checked by scanning electron microscopy. The efficiency of shielding characteristics was investigated experimentally by the narrow-beam technique using a lead collimator, different gamma-point sources, and a semiconductor detector. The results showed that at both energies, the composites that contain a combination of micro- and nanoparticles have higher linear attenuation coefficient (LAC) values than the composites with only micro- or nanoparticles. For example, at 0.060 MeV, the LACs are 5.592, 6.391, 6.412, and 6.202 cm−1 for LSR-Micro, LSR-Micro/Nano, LSR-Nano/Micro, and LSR-Nano/Nano, respectively, while at 0.662 MeV, they are, respectively, 0.185, 0.204, 0.210, and 0.199 cm−1. The prepared composites were compared with commercial lead aprons of different thicknesses, and the results demonstrated the efficiency of the prepared flexible composites against gamma radiation, in addition to their lightweight and environmental safety.

1 Introduction

Radiation-based applications have become a growing trend in recent decades. Are we familiar with the many uses of gamma and X-rays, including ionizing radiation in nuclear energy production, medical imaging, and healthcare treatment, being just some of the endless applications of radiation? Today, in the healthcare industry, radiation is an important tool for diagnosing and treating diseases. Techniques like X-ray, MRI, and radiotherapy are widely adopted to enhance the quality of health care. The use of radiation in industries for inspections and analysis has also improved several safety and quality standards of many industries (1,2,3,4).

According to previous studies, expert opinion, and experience, it is well recognized that prolonged exposure to radiation can adversely affect the health of not only humans but also other living beings and the entire environment. Also, due to the increased number of radiation applications, there is a need to develop effective means to protect professionals and patients from unnecessary adverse effects of radiation. Most scientists believe that high atomic number and high density are important radiation shielding properties of a shielding material. Researchers are developing new materials like polymers, concrete, glass, ceramics, and alloys that have excellent ionizing radiation shielding capabilities. New protective materials could be manufactured by changing the composition of the existing materials (5,6,7,8,9,10,11).

Radiation aprons are generally considered personal protective equipment in medical fields and research centres, where professionals deal with the source of radiation. Due to continuous developments in the material and design, these aprons continue to develop to enhance radiation protection without affecting comfort. For standard protection against radiation, the aprons use lead- or Pb-based materials due to their high density (11.29 g·cm−3) and high atomic number (Z = 82) (12,13).

Lead aprons are often used at research and medical facilities to shield people from radiation, but they have many shortcomings. It is one of the most critical issues; lead is a heavy material that makes it uncomfortable and tiring to wear these aprons for an extended period, especially for orthopedic professionals who have to wear the aprons for an extended time during surgeries (14,15,16,17). Furthermore, wearing them for a long period can cause structural and muscular problems for healthcare professionals, making them reluctant to wear them, which places them in great danger. Also, lead is considered a toxic material that is harmful to health when not handled properly. It is also a major problem to dispose of lead aprons because of the further necessities of hygiene protocols after their use, and waste management, as lead waste is expensive to recycle with severe environmental restrictions to prevent pollution. Moreover, wearers of lead aprons often have to obtain a properly fitting apron before engaging in any activity. The need of the hour is more research to find out safer and more comfortable alternatives to radiation protection (18,19,20).

Currently, scientists are considering using materials like nanoparticles of bismuth oxides (Bi2O3) (21) and tin oxides (SnO) (22) that will merge with cheap polymer material to provide lead-like behavior. Recent research revealed that the radiation shielding of metal oxide nanoparticles is better than bulk metal oxide. The materials are great candidates because they have a high atomic number and can absorb gamma rays more effectively; hence, they can provide protection similar to that of lead with lower weight. Moreover, these substances are less toxic than lead, reducing the health and environmental risks associated with their use and promoting environmental safety (21,22,23). These materials are a good choice because of their high melting points and ability to be stable at high temperatures. They are cheaper than other materials used in radiation attenuation techniques and can be used for multiple applications. In order to achieve this goal, the present work aims to evolve materials that are effective and realistic. The research will test the radiation qualities of these materials and enhance their radiation absorption efficiency. The flexibility of these materials would also be enhanced for ease of use. This opens up the possibility of replacing lead with these materials in radiation shielding applications (24,25,26,27,28,29,30).

This research aims to develop new composite materials based on mixing heavy metal oxides and polymers in a safe and low-cost manner, which can be used as an alternative to lead-containing radiation shielding aprons. Furthermore, comparative studies involving Bi₂O₃ and SnO₃ fillers under identical conditions are still rare in the scientific literature. Therefore, the primary objective of this study is to investigate and compare the gamma-ray blocking efficiency of silicone rubber materials reinforced with micro- and nano-sized Bi₂O₃ and SnO particles. This approach aims to improve the safety and comfort of professionals in radiation environments using highly efficient and flexible shielding materials, enhancing the user experience while mitigating some of the major drawbacks associated with lead and reducing environmental impacts.

2 Materials and methods

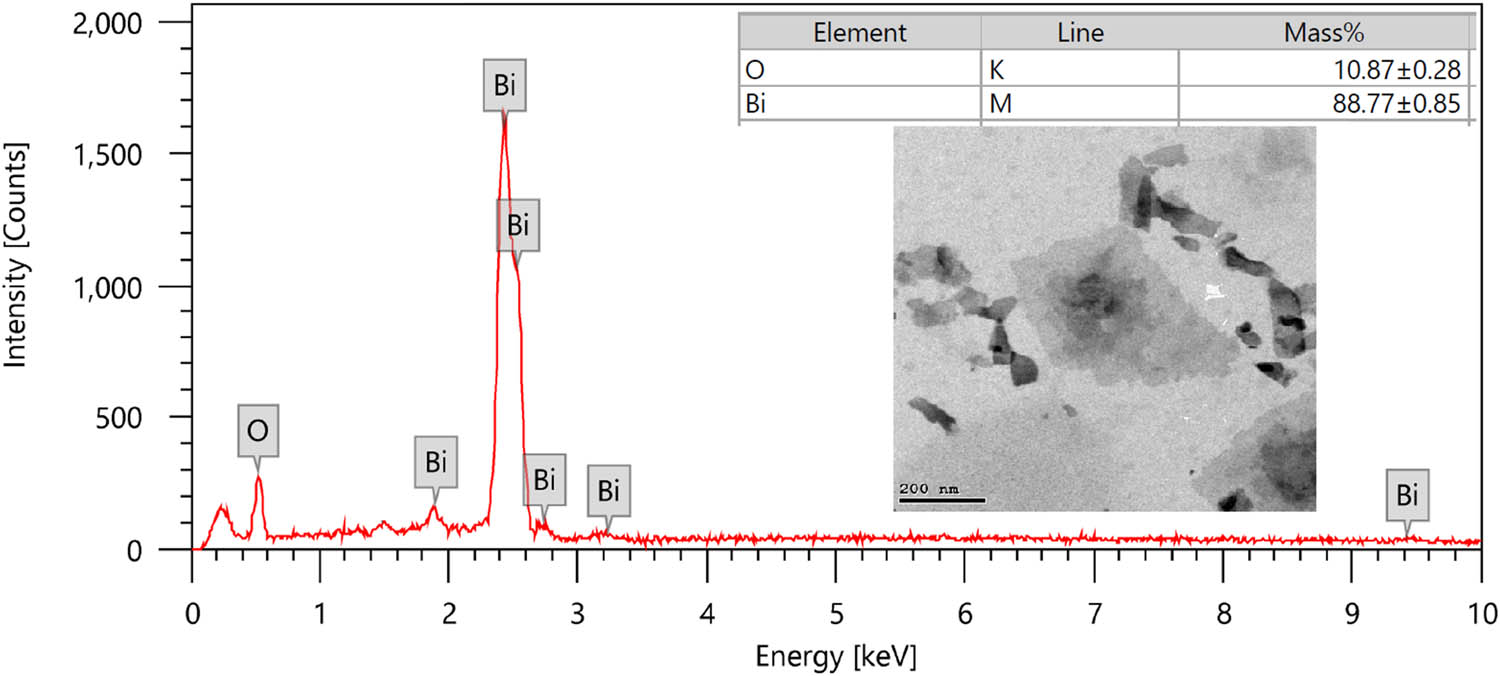

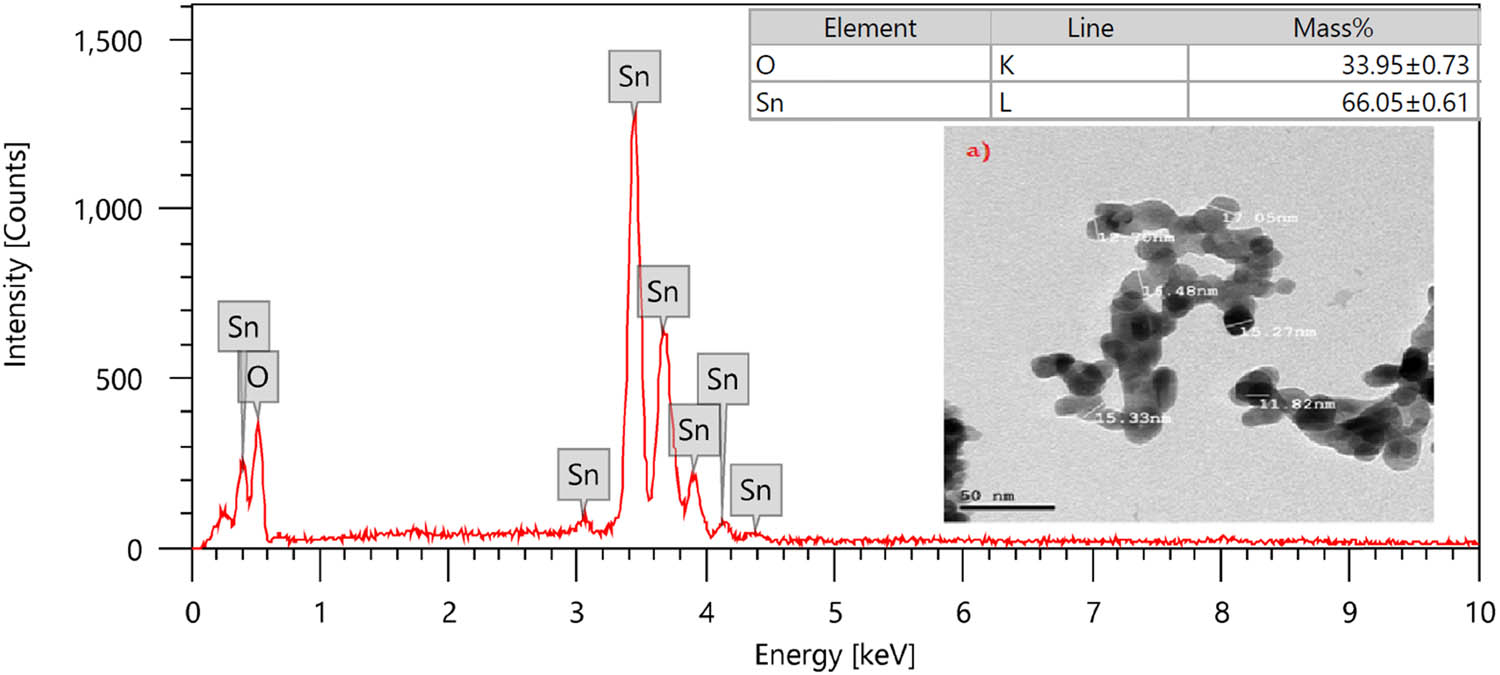

For this work, the matrix material was liquid silicone rubber (LSR), which was bought from a commercial store with its hardener mixed in a 10:1 weight ratio. The main component of silicone rubber, an elastomer, is a chain of molecules called a siloxane bond (–Si–O–Si–). The mechanical characteristics of this silicone rubber, according to the manufacturer, are as follows: density: 1.25 g·cm−3, tensile strength: 6.8 MPa, hardness number: 50 ha, elongation ratio: 290%, and elastic modulus: 2 MPa. LSR-doped filler oxides of different sizes (nano- and micro-sized) Bi2O3 and SnO, were purchased from Nano-Gate Co. (Cairo, Egypt). Transmission electron microscopy (TEM) and energy dispersive X-ray (EDX) with a scanning electron microscope were used to investigate the structure, shape, and average size of the nano- and micro-sized particles under study, as illustrated in Figures 1 and 2. The mean particle size was 30 ± 20 nm for Bi2O3-NPs, 80 ± 30 µm for Bi2O3-MPs, 40 ± 15 nm for SnO-NPs, and 100 ± 20 µm for SnO-MPs, with purity percentages of 99.3% and 99.1%, respectively.

EDX and TEM results of Bi2O3-NPs.

EDX and TEM results of SnO-NPs.

To create new rubber composites using the proportions listed in Table 1, a cylindrical container was filled with a proportion of LSR (with a 10% silicone rubber hardener), and glass beakers labeled LSR-Micro, LSR-Micro/Nano, LSR-Micro/Nano, and LSR-Nano were filled with metal oxides (Bi2O3 and SnO), as illustrated in Figure 3. The composites were then stirred constantly in an electric mixer for 20 min to achieve homogeneity. Then, they were carefully placed inside the mold boxes to prevent bubbles, and they were left in the laboratory for a day and a half to dry. By measuring the mass of the composite with a digital balance that is extremely sensitive (0.001 g), its thickness and radius were calculated. The weight-to-volume ratio was used in experiments to determine the density of the formed composites using the equation V = πr 2 t, where r and t are the radius and thickness of the prepared flexible composite, respectively.

Weight ratio and the determined density of the prepared flexible composites

| SR code | LSR | Bi2O3 | SnO | Density (g·cm−3) | ||

|---|---|---|---|---|---|---|

| Micro | Nano | Micro | Nano | |||

| LSR-Micro | 50 | 25 | — | 25 | 2.201 | |

| LSR-Micro/Nano | 50 | 25 | — | — | 25 | 2.210 |

| LSR-Nano/Micro | 50 | — | 25 | 25 | — | 2.212 |

| LSR-Nano | 50 | — | 25 | ̶ | 25 | 2.208 |

The steps of the prepared composites.

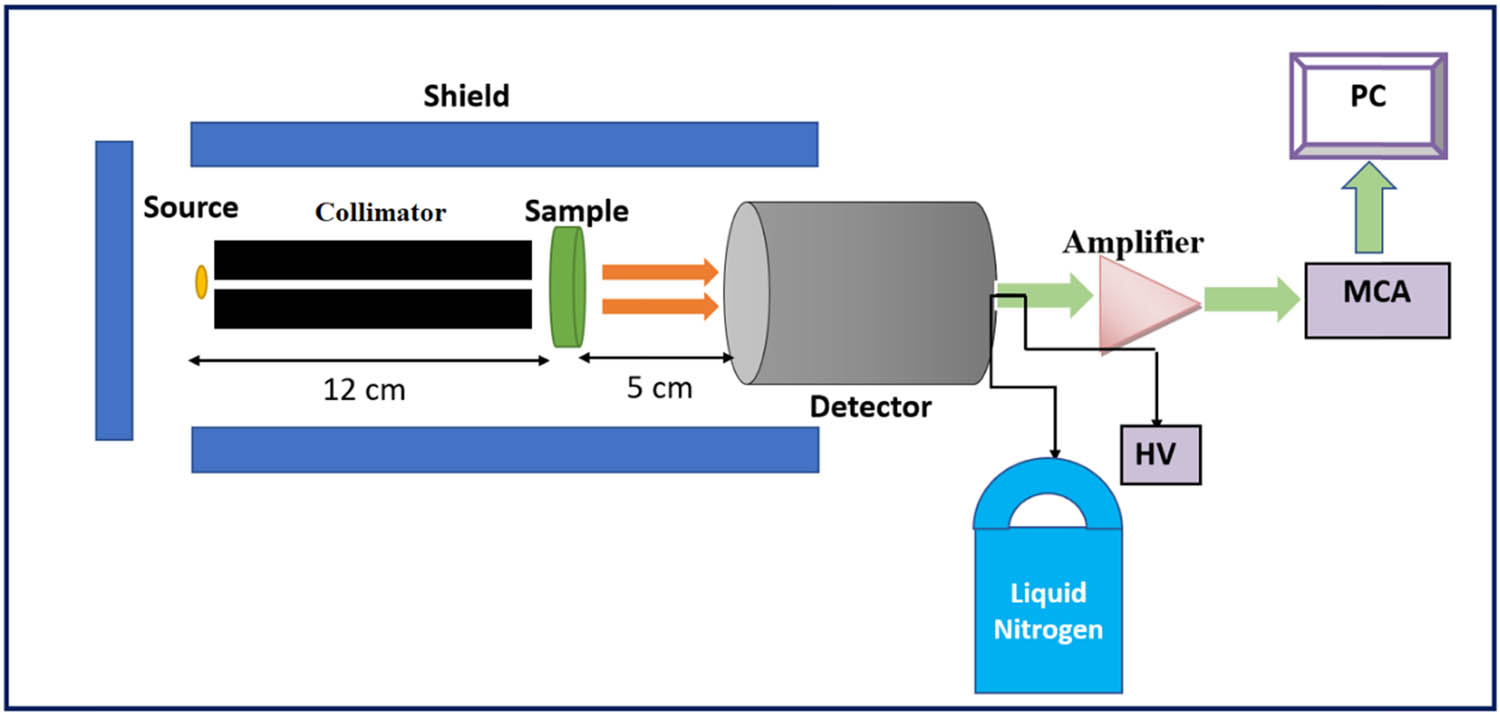

Three radioactive gamma sources were used to measure the attenuation properties of the flexible samples: Cs-137 (decayed with a gamma energy of 0.662 MeV), Co-60 (decayed with gamma energies of 1.173 and 1.333 MeV), and Am-241 (decayed with an energy of 0.060 MeV). A high pure germanium (HPGe) detector was used to pick up the sources, as shown in Figure 4. The lead collimator was utilized between the detector and source to achieve a narrow beam line. The detector was calibrated, and the geometry was fixed during the measurements in the presence and absence of a flexible absorber sample. The source, collimator, and gamma detector were positioned coaxially, and the count rate was calculated in both cases to determine the photon intensity I and I 0 at different energies according to the gamma sources. The rubber sample linear attenuation coefficient (LAC) was estimated from the intensity values depending on the sample thickness (x) (31,32,33,34,35,36,37,38,39):

Experimental setup to determine attenuation coefficients for different samples.

Additional attenuator factors deemed essential, namely, the half/tenth value layer (HVL/TVL), and the radiation shielding efficiency (RSE), is obtained using the following equations (40,41,42,43,44,45,46,47,48,49,50,51,52):

3 Results and discussion

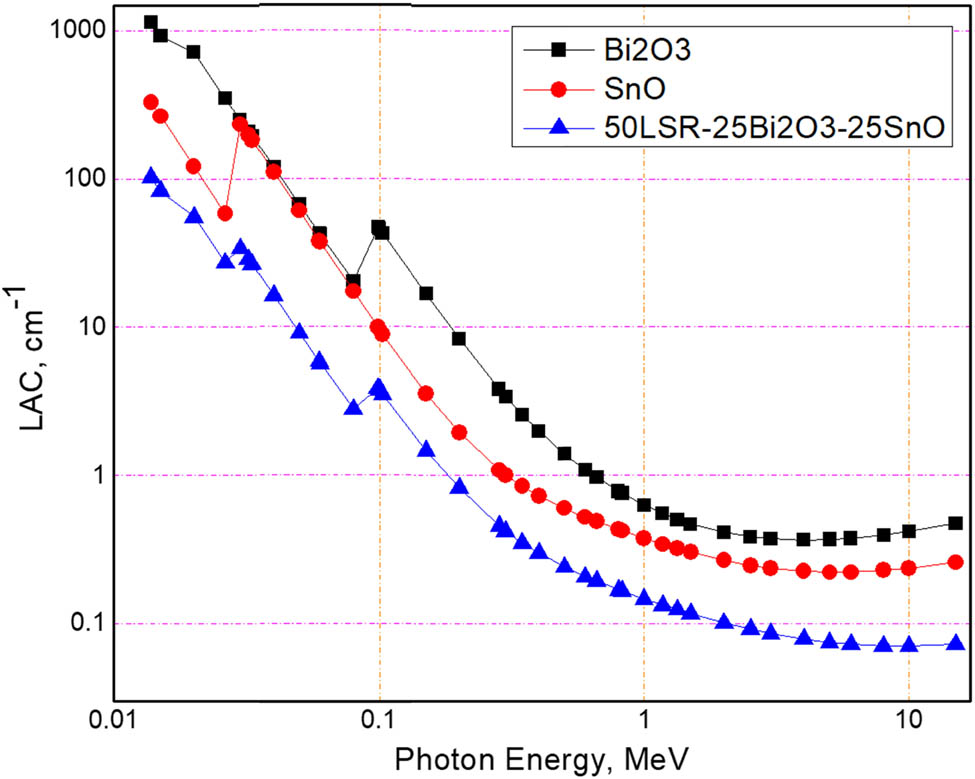

Figure 5 shows the theoretical LAC of the pure Bi2O3 and SnO samples, as well as the 50LSR–25Bi2O3–25SnO sample using the Phy-x software (53). The 50LSR–25Bi2O3–25SnO sample has the lowest LAC out of the three materials at all energies. This trend occurs because the density of this sample is lower than that of Bi2O3 and SnO, resulting in a lower LAC. Nevertheless, because the sample contains both Bi2O3 and SnO, it was found that at 0.04 and 0.1 MeV, the LAC of the sample is relatively high, with a much smaller difference between its LAC and that of the pure samples. Therefore, near these two energies, which correspond to the two k-absorption edges of Sn and Bi, this material is an effective shield at protecting incoming photons.

Theoretical LAC as a function of gamma energies for Bi2O3, SnO as well as the 50LSR–25Bi2O3–25SnO composite.

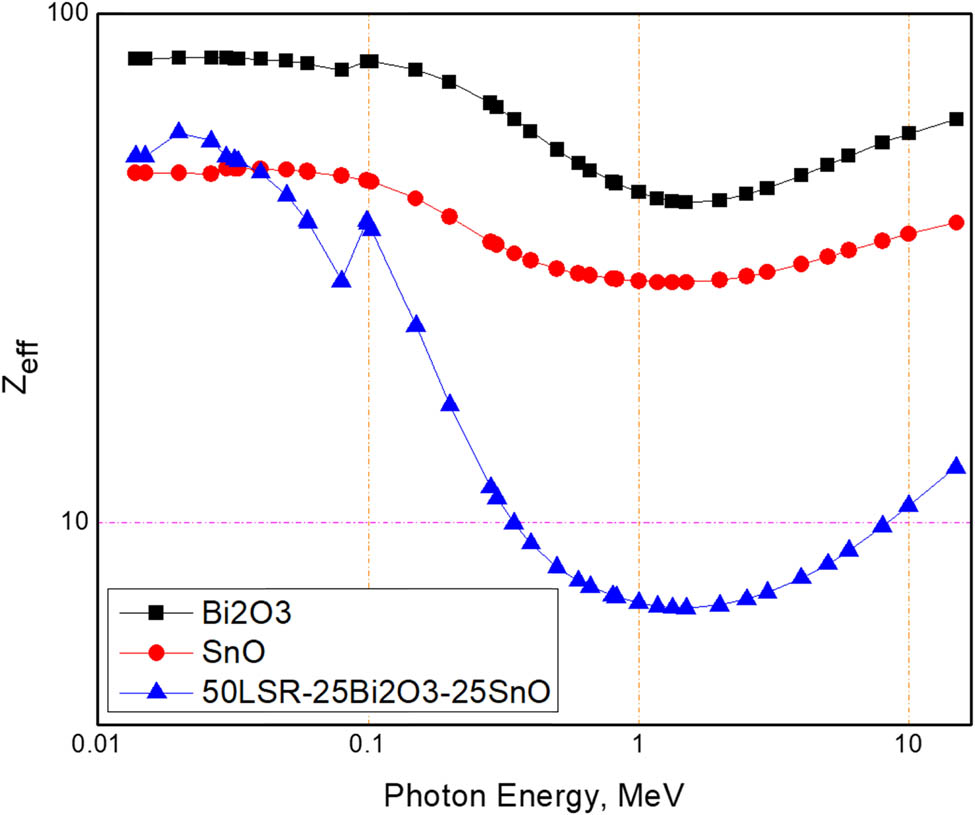

Figure 6 shows the Z eff values of the pure Bi2O3 and SnO samples along with those of the 50LSR–25Bi2O3–25SnO sample. The Z eff of the 50LSR–25Bi2O3–25SnO sample is much lower than that of the two other materials in the low energy range, namely, below 0.05 MeV. At these energies, however, its Z eff is higher than that of the SnO compound. It is also close to the Z eff of the SnO material at 0.1 MeV, with the difference increasing above this energy. This difference can be attributed to the lower Z materials of the LSR compared to Bi and Sn.

The Z eff LAC as a function of gamma energies for Bi2O3, SnO as well as the 50LSR–25Bi2O3–25SnO composite.

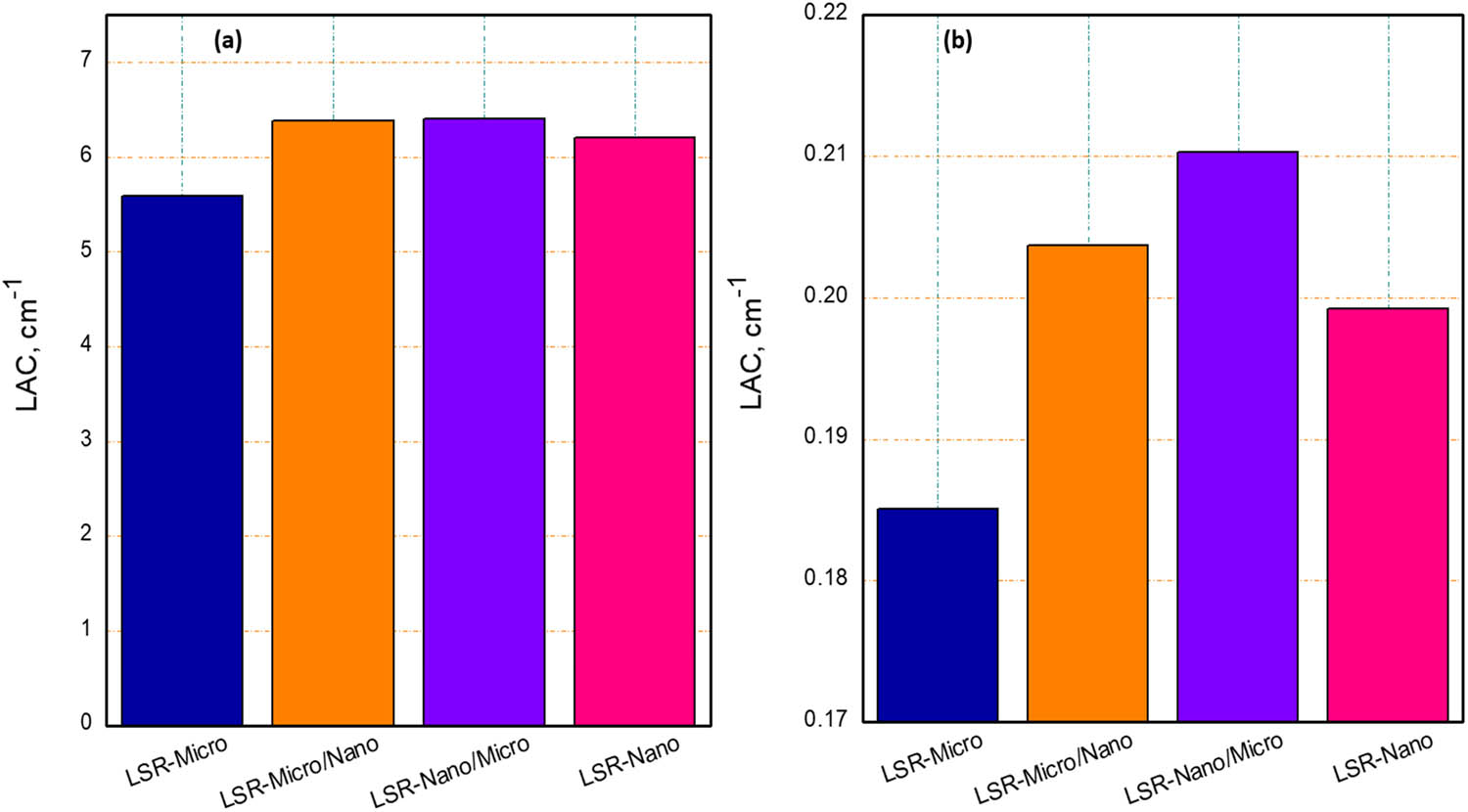

The LAC of the LSR samples is shown at 0.060 and 0.662 MeV in Figure 7(a) and (b), respectively. The four samples shown are the LSR materials with micro-Bi2O3, micro-Bi2O3 and nano-SnO, nano-Bi2O3, and nano-SnO, and both nano-Bi2O3 and nano-SnO, labeled as LSR-Micro, LSR-Micro/Nano, LSR-Nano/Micro, and LSR-Nano/Nano, respectively. The figures show that at both energies, the composites that contain a combination of micro- and nanoparticles have higher LACs than the composites with micro- or nanoparticles only. For example, at 0.060 MeV, the LACs are 5.592, 6.391, 6.412, and 6.202 cm−1 for LSR-Micro, LSR-Micro/Nano, LSR-Nano/Micro, and LSR-Nano/Nano, respectively, while at 0.662 MeV, they, respectively, are 0.185, 0.204, 0.210, and 0.199 cm−1. The reason that the mixture of particle sizes results in the highest LAC is that when combining the two, the nanoparticles fill up the spaces within the microparticles, leading to a larger number of interactions when photons try to penetrate the sample. Between the two samples that have mixed particle sizes, the LSR-Nano/Micro sample has the highest density, resulting in its higher LAC.

LAC values of the four prepared composites at (a) 0.060 MeV and (b) 0.662 MeV.

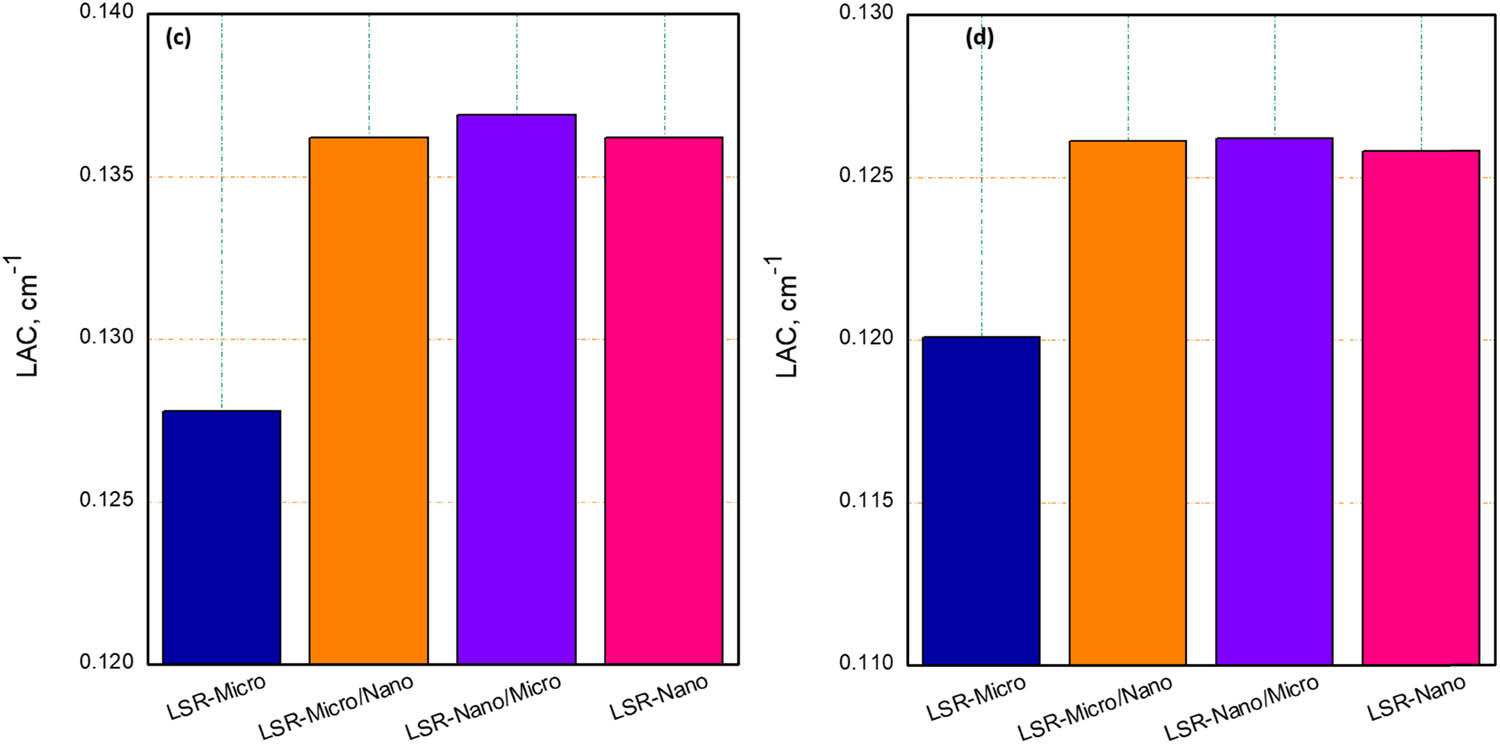

Figure 8 shows the LAC of the four LSR samples, but at 1.173 and 1.333 MeV. Even at these higher energies, a similar trend can be observed where the combined micro- and nanoparticle samples have the highest LACs. For instance, at 1.173 MeV, the LACs are 0.1278, 0.1362, 0.1369, and 0.1362 cm−1 for LSR-Micro, LSR-Micro/Nano, LSR-Nano/Micro, and LSR-Nano/Nano, respectively, while they are, respectively, 0.1201, 0.1261, 0.1262, and 0.1258 cm−1 at 1.333 MeV. Thus, combining both particle sizes leads to an overall more effective shield, although its effect decreases at higher energies.

LAC values of the four prepared composites at (c) 1.173 MeV and (d) 1.333 MeV.

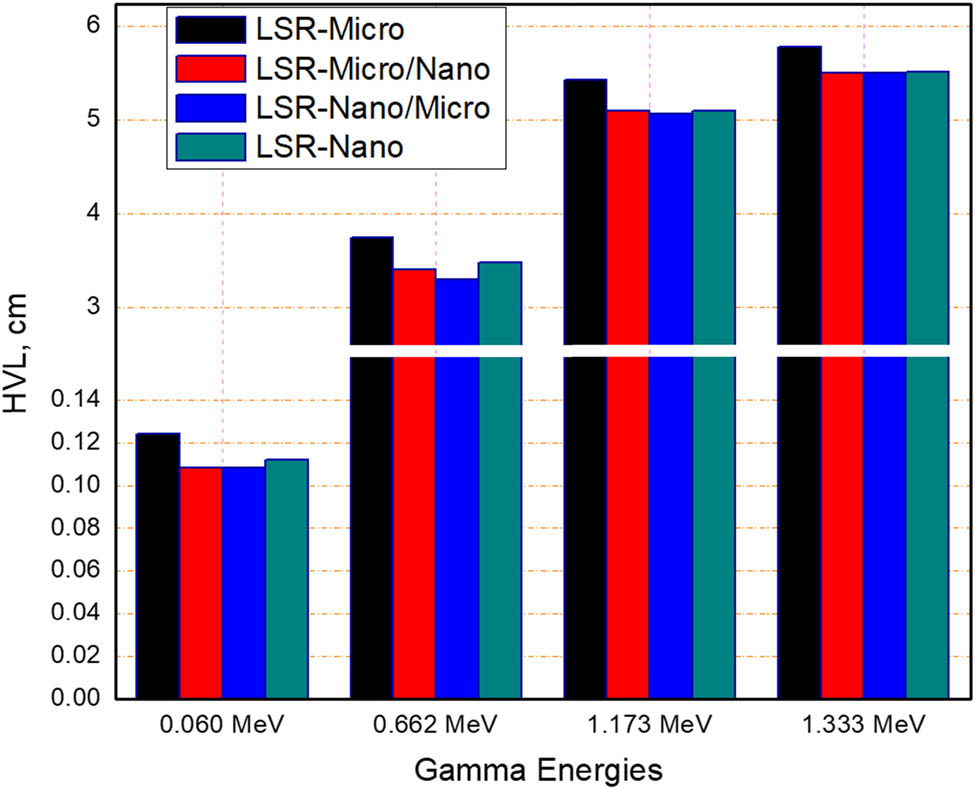

The HVL values of the four LSR samples are shown at four selected energies in Figure 9. At all four energies, the LSR-Micro sample has the highest HVL, followed by the LSR-Nano sample, the LSR-Micro/Nano sample, and finally, the LSR-Nano/Micro sample. For instance, at 0.662 MeV, the HVLs are 3.745, 3.403, 3.296, and 3.480 cm for LSR-Micro, LSR-Micro/Nano, LSR-Nano/Micro, and LSR-Nano/Nano, respectively, while at 1.333 MeV, they are, respectively, equal to 5.771, 5.497, 5.492, and 5.510 cm. This result reinforces the conclusion that mixing both the micro- and nanoparticles leads to a better shield, as the LSR-Micro/Nano and LSR-Nano/Micro materials have the smallest HVLs across all energies. At higher energies, the LSR-Nano sample has an HVL very close to that of the other samples, closer than the LSR-Micro sample, but there still exists a large difference to conclude that the mixture of particle sizes has a clear advantage across radiation energies.

HVL values of the four prepared composites at different gamma energies studied.

Table 2 presents the TF of the four prepared samples with thicknesses of 1 and 2 cm. At low energies, such as 0.060 MeV, the samples with a thickness of 1 cm all have a good shielding ability against incoming photons, with TF values varying from 0.16 to 0.37. However, as the photon energies increase, the TF values also largely increase. At 1.173 MeV, the TFs vary from 87.21 to 88.80, and at 1.333 MeV, they are between 88.14 and 88.68. Therefore, most of the photons can penetrate through the samples at higher energies, resulting in a less-than-ideal performance. To improve the shielding performance at higher energies, the thickness of the samples can be increased. At a thickness of 2 cm, all TF values decrease with increasing thickness. At 0.060 MeV, all the TF values are 0.00, and at the highest energy, they are between 77.69 and 78.65. This improvement occurs because when the thickness of the samples is increased, there are atoms within the sample to interact with the incoming photons, leading to more collisions and thus more attenuation.

TF values of the four prepared samples with thicknesses of 1 and 2 cm

| Energy (MeV) | LSR-BiMSnM | LSR-BiMSnN | LSR-BiNSnM | LSR-BiNSnN | |

|---|---|---|---|---|---|

| TF, 1 cm | 0.060 | 0.37 | 0.17 | 0.16 | 0.20 |

| 0.662 | 83.10 | 81.57 | 81.03 | 81.94 | |

| 1.173 | 88.00 | 87.27 | 87.21 | 87.27 | |

| 1.333 | 88.68 | 88.15 | 88.14 | 88.18 | |

| TF, 2 cm | 0.060 | 0.00 | 0.00 | 0.00 | 0.00 |

| 0.662 | 69.06 | 66.54 | 65.67 | 67.14 | |

| 1.173 | 77.45 | 76.15 | 76.05 | 76.15 | |

| 1.333 | 78.65 | 77.71 | 77.69 | 77.76 |

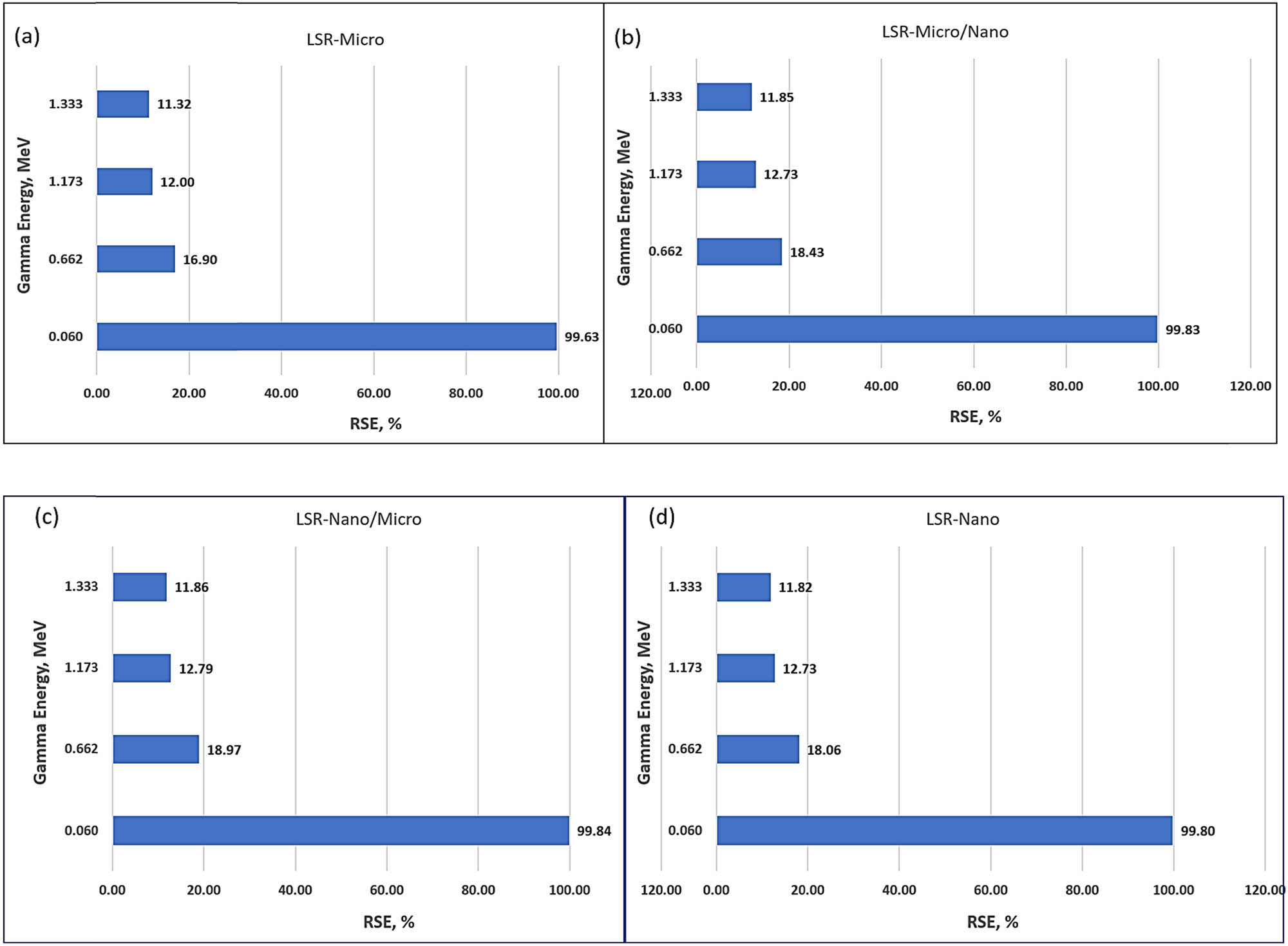

Figure 10(a)–(d) shows the RSE of all four LSR samples at the four tested energies. Figure 10(a) and (b) shows the RSE of LSR-Micro and LSR-Micro/Nano samples. For the LSR-Micro sample, its RSE is very high (0.060 MeV), being equal to 99.63%. As the gamma energy increases, the RSE decreases to 16.90% at 0.662 MeV, 12.00% at 1.173 MeV, and 11.32% at 1.333 MeV. The LSR-Micro/Nano sample shows a similar trend, with RSE values equal to 99.83%, 18.43%, 12.73%, and 11.85% at 0.060, 0.662, 1.173, and 1.333 MeV, respectively. These results indicate that RSE decreases with gamma energy because of the larger penetration power of the photons with higher radiation energies, preventing the materials from absorbing as much as possible. Figure 10(c) and (d) shows a similar pattern for the LSR-Nano/Micro and LSR-Nano samples. The LSR-Nano/Micro sample has its highest RSE at 0.060 MeV, being equal to 99.84%, and its lowest at 1.333 MeV, equal to 11.86%. Meanwhile, the LSR-Nano sample has RSEs equal to 99.80% and 11.82% at 0.060 and 1.333 MeV, respectively. Therefore, the lower the incoming photon energy, the greater protection ability the materials have, and the more effective they are as radiation shields.

RSE values of the four prepared composites at different gamma energies studied, (a) LSR-Micro, (b) LSR-Micro/Nano, (c) LSR-Nano/Micro and (d) LSR-Nano.

In Table 3, four SR-aprons were tested for their shielding abilities and compared against lead aprons. Each apron contains three layers: two neoprene layers that are 2 mm wide, and between them a layer that varies between the samples. Four aprons contain the four investigated samples, which are 2 cm thick, and four of the aprons contain lead, with varying thicknesses from 2 to 5 mm. Analyzing the RSE values between these aprons, it can be observed that for all the aprons at 0.060 MeV, they all reach an RSE of 100. At 0.662 MeV, the aprons with the investigated materials have RSEs that vary between 33.76 and 26.62, while the lead aprons vary between 24.18 and 40.07. At the highest energy of 1.333 MeV, the investigated aprons have RSEs between 23.66 and 24.87, and the lead aprons have RSEs between 14.22 and 24.20. Therefore, at most energies, the SR aprons, especially the one containing LSR-BiNSnM, have higher RSEs than even the lead apron with 5 mm of lead. Therefore, these results highlight the ability to make aprons with better attenuation performance that are less toxic while also being lightweight.

Comparison between the prepared SR apron and commercial lead apron of different thicknesses

| SR apron | Lead apron | ||||||

|---|---|---|---|---|---|---|---|

| Energy (MeV) | Neoprene (2 mm) | LSR-BiMSnM (2 cm) | Neoprene (2 mm) | RSE | RSE (%) | ||

| LAC | 0.060 | 0.343 | 5.5918 | 0.343 | 100.00 | Lead apron – 2 mm | 100.00 |

| 0.662 | 0.104 | 0.1851 | 0.104 | 33.76 | 24.18 | ||

| 1.173 | 0.079 | 0.1278 | 0.079 | 24.98 | 15.39 | ||

| 1.333 | 0.074 | 0.1201 | 0.074 | 23.66 | 14.22 | ||

| LAC | 0.060 | 0.343 | 6.3911 | 0.343 | 100.00 | Lead apron – 3 mm | 100.00 |

| 0.662 | 0.104 | 0.2037 | 0.104 | 36.18 | 32.59 | ||

| 1.173 | 0.079 | 0.1362 | 0.079 | 26.23 | 20.93 | ||

| 1.333 | 0.074 | 0.1261 | 0.074 | 24.57 | 19.37 | ||

| LAC | 0.060 | 0.343 | 6.4122 | 0.343 | 100.00 | Lead apron – 4 mm | 100.00 |

| 0.662 | 0.104 | 0.2103 | 0.104 | 37.67 | 40.07 | ||

| 1.173 | 0.079 | 0.1369 | 0.079 | 26.91 | 26.10 | ||

| 1.333 | 0.074 | 0.1262 | 0.074 | 25.15 | 24.20 | ||

| LAC | 0.060 | 0.343 | 6.2021 | 0.343 | 100.00 | Lead apron – 5 mm | 100.00 |

| 0.662 | 0.104 | 0.1992 | 0.104 | 35.60 | 46.72 | ||

| 1.173 | 0.079 | 0.1362 | 0.079 | 26.23 | 30.94 | ||

| 1.333 | 0.074 | 0.1258 | 0.074 | 24.53 | 28.75 | ||

4 Conclusion

The present study demonstrated the high efficiency of flexible silicone rubber (LSR)-based composites reinforced with micro- and nanoparticles of Bi₂O₃ and SnO₂ in reducing gamma-ray transmittance. The results demonstrated that integrating micro- and nano-fillers into a single matrix achieves superior performance, with hybrid samples such as LSR-Micro/Nano and LSR-Nano/Micro exhibiting LAC values compared to conventional components and materials containing only one type of particle. At 0.662 MeV, the LACs were 0.185, 0.204, 0.210, and 0.199 cm−1 for LSR-Micro, LSR-Micro/Nano, LSR-Nano/Micro, and LSR-Nano/Nano, respectively. Furthermore, these composites exhibited ideal properties such as lightweight and environmental compatibility, making them a promising alternative to conventional lead aprons, especially in medical and industrial applications that require radiation protection without sacrificing flexibility or safety. Based on these results, these composites can be recommended for use in the design of flexible protective shields, opening new horizons in the development of safer and more sustainable radiation-shielding materials.

Acknowledgments

The authors express their gratitude to Princess Nourah bint Abdulrahman University Researchers, Supporting Project Number (PNURSP2025R2), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia.

-

Funding information: Authors state no funding involved.

-

Author contributions: MIS: investigation, data curation, visualization, and funding acquisition; AHA: software, formal analysis and visualization; SMA: investigation, data curation, and resources; AH: formal analysis, and visualization; writing – original draft, ME: conceptualization, methodology, writing – review and editing and supervision. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All relevant data are provided within this article.

References

(1) Tijani SA, Al-Hadeethi Y. The use of isophthalic-bismuth polymer composites as radiation shielding barriers in nuclear medicine. Mater Res Express. 2019;6:055323. 10.1088/2053-1591/ab0578.Suche in Google Scholar

(2) Pedro V. Radiological protection, safety and security issues in the industrial and medical applications of radiation sources. Radiat Phys Chem. 2015;116:48–55.10.1016/j.radphyschem.2015.05.012Suche in Google Scholar

(3) Kaewjaeng S, Kothan S, Chaiphaksa W, Chanthima N, Rajaramakrishna R, Kim HJ, et al. High transparency La2O3-CaO-B2O3-SiO2 glass for diagnosis x-rays shielding material application. Radiat Phys Chem. 2019;160:41–7.10.1016/j.radphyschem.2019.03.018Suche in Google Scholar

(4) Araz A, Kavaz E, Durak R. Neutron and photon shielding competences of aluminum open-cell foams filled with different epoxy mixtures: An experimental study. Radiant Phys Chem. 2021;182:109382.10.1016/j.radphyschem.2021.109382Suche in Google Scholar

(5) Sayyed MI, Al-Ghamdi H, Almuqrin AH, Yasmin S, Elsafi M. A study on the gamma radiation protection effectiveness of nano/micro-MgO-reinforced novel silicon rubber for medical applications. Polymers. 2022;14:2867.10.3390/polym14142867Suche in Google Scholar PubMed PubMed Central

(6) Elsafi M, Hedaya AM, Abdel-Gawad EH, Rashad M, Sayyed MI, Saleh IH. Experimental investigation of the radiation shielding performance of a newly developed silicon-epoxy resin doped with WO3 micro/nanoparticles. Silicon. 2024;16:5439–46.10.1007/s12633-024-03088-4Suche in Google Scholar

(7) Ali MAEM, Hafez MAY, Nagy NM, Abed NS. Radiation shielding properties of sustainable concrete with novel plastering techniques. Ann Nucl Energy. 2025;211:110958. 10.1016/j.anucene.2024.110958.Suche in Google Scholar

(8) Elsafi M, Hedaya AM, Sayyed MI. Study the impact of MgO, Al2O3, MoO3, BaO, ZnO and PbO on the radiation shielding performance of Borate glasses. Nucl Eng Technol. 2025;57:103475. 10.1016/j.net.2025.103475.Suche in Google Scholar

(9) Elsafi M, Sayyed MI, Hanafy TA, More CV, Hedaya A. Experimental study of gamma-ray attenuation capability of B2O3-ZnO-Na2O-Fe2O3 glass system. Sci Rep. 2024;14:19141.10.1038/s41598-024-68941-3Suche in Google Scholar PubMed PubMed Central

(10) Alshahrani B, Olarinoye I, Mutuwong C, Sriwunkum C, Yakout H, Tekin H, et al. Amorphous alloys with high Fe content for radiation shielding applications. Radiat Phys Chem. 2021;183:109386.10.1016/j.radphyschem.2021.109386Suche in Google Scholar

(11) Al-Saleh WM, Dahi MRH, Sayyed MI, Almutairi HM, Saleh IH, Elsafi. M. Comprehensive study of the radiation shielding feature of polyester polymers impregnated with iron filings. e-Polymers. 2023;23(1):20230096. 10.1515/epoly-2023-0096.Suche in Google Scholar

(12) Verdipoor K, Alemi A, Mesbahi A. Photon mass attenuation coefficients of a silicon resin loaded with WO3, PbO, and Bi2O3 Micro and Nanoparticles for radiation shielding. Radiat Phys Chem. 2018;147:85–90.10.1016/j.radphyschem.2018.02.017Suche in Google Scholar

(13) Lakhwani OP, Dalal V, Jindal M, Nagala A. Radiation protection and standardization. J Clin Orthop Trauma. 2019;10(4):738–43.10.1016/j.jcot.2018.08.010Suche in Google Scholar PubMed PubMed Central

(14) Hout JD, Ryu JH. The association between musculoskeletal disorders and lead apron use in healthcare workers: A systematic review and meta-analysis. Saf Sci. 2025;181:106669.10.1016/j.ssci.2024.106669Suche in Google Scholar

(15) Aral N, Banu Nergis F, Candan C. An alternative X-ray shielding material based on coated textiles. Text Res J. 2015;86(8):803–11.10.1177/0040517515590409Suche in Google Scholar

(16) Ferrari P, Venturi G, Campani L, Mariotti F, Becker F, Jansen J, et al. Medical staff monitoring in interventional cardiology: over apron dosemeter placement based on measurements and simulations. Radiat Prot Dosimetry. June 2024;200(8):802–7.10.1093/rpd/ncae125Suche in Google Scholar PubMed

(17) Dubey KA, Chaudhari CV, Suman SK, Raje N, Mondal RK, Grover V, et al. Synthesis of flexible polymeric shielding materials for soft gamma rays: Physicomechanical and attenuation characteristics of radiation crosslinked polydimethylsiloxane/Bi2O3 composites. Polym Compos. 2016;37(3):756–62.10.1002/pc.23232Suche in Google Scholar

(18) Fetterly KA, Magnuson DJ, Tannahill GM, Hindal MD, Mathew V. Effective use of radiation shields to minimize operator dose during invasive cardiology procedures. JACC. 2011;4(10):1133–9.10.1016/j.jcin.2011.05.027Suche in Google Scholar PubMed

(19) Badawy MK, Deb P, Chan R, Farouque O. A review of radiation protection solutions for the staff in the cardiac catheterisation laboratory. Heart Lung Circ. 2016;25(10):961–7.10.1016/j.hlc.2016.02.021Suche in Google Scholar PubMed

(20) Rizik DG, Riley RD, Burke RF, Klassen SR, Nigoghosian AM, Gosselin KP, et al. Comprehensive radiation shield minimizes operator radiation exposure and obviates need for lead aprons. J Soc Cardiovasc Angiogr Interv. 2023;2(3):100603.10.1016/j.jscai.2023.100603Suche in Google Scholar PubMed PubMed Central

(21) Hedaya A, Elsafi M, Al-Saleh WM, Saleh IH. Effect of Bi2O3 particle size on the radiation-shielding performance of free-lead epoxide materials against ionizing radiation. Polymers. 2024;16:2125.10.3390/polym16152125Suche in Google Scholar PubMed PubMed Central

(22) Elsafi M, Abdel-Gawad EH, El-Nahal MA, Sayyed MI. Effect of tin oxide particle size on epoxy resin to form new composites against gamma radiation. Sci Rep. 2024;14:27901.10.1038/s41598-024-78608-8Suche in Google Scholar PubMed PubMed Central

(23) De Coninck V, Hendrickx L, Mortiers X, Somani B, Emiliani E, Sener ET, et al. Radiation exposure of urologists during endourological procedures: a systematic review. World J Urol. 2024;42:310.10.1007/s00345-024-05023-zSuche in Google Scholar PubMed

(24) Katsarou M, Zwiebel B, Chowdhury RP, Shames M, Berger T, Przybyla B, et al. Experimental analysis of radiation protection offered by a novel exoskeleton-based radiation protection system versus conventional lead aprons. J Vasc Interventional Radiol. 2023;34(8):1345–52.10.1016/j.jvir.2023.03.033Suche in Google Scholar PubMed

(25) Nuñez-Briones AG, Benavides R, Bolaina-Lorenzo ED, Martínez-Pardo ME, Kotzian-Pereira-Benavides C, Mendoza-Mendoza E, et al. Nontoxic fexible PVC nanocomposites with Ta2O5 and Bi2O3 nanoparticles for shielding diagnostic X-rays. Radiat Phys Chem. 2023;202:110512.10.1016/j.radphyschem.2022.110512Suche in Google Scholar

(26) Al-Saleh WM, Almutairi HM, Sayyed MI, Elsafi M. Multilayer radiation shielding system with advanced composites containing heavy metal oxide nanoparticles: a free-lead solution. Sci Rep. 2023;13(1):18429.10.1038/s41598-023-45621-2Suche in Google Scholar PubMed PubMed Central

(27) Atashi P, Rahmani S, Ahadi B, Rahmati A. Efficient, flexible and lead-free composite based on room temperature vulcanizing silicone rubber/W/Bi2O3 for gamma ray shielding application. J Mater Sci: Mater Electron. 2018;29:12306–22.10.1007/s10854-018-9344-1Suche in Google Scholar

(28) Peng M, Cai X, Fu Y, Yu X, Liu S, Deng B, et al. Facial synthesis of SnO2 nanoparticle film for efficient fiber-shaped dye-sensitized solar cells. J Power Sources. 2014;247:249–55.10.1016/j.jpowsour.2013.08.075Suche in Google Scholar

(29) Bagheri Mohagheghi M, Tabatabai Yazdi S, Mousavi M. Magneto-transport and magneto-optical studies on SnO2 transparent semiconducting thin films alloyed with mn over a wide range of concentration. Appl Phys A. 2018;124:1–6.10.1007/s00339-018-1685-3Suche in Google Scholar

(30) Lu G, Huebner KL, Ocola LE, Gajdardziska-Josifovska M, Chen J. Gas sensors based on tin oxide nanoparticles synthesized from a mini-arc plasma source. J Nanomater. 2006;2006(1):1–7.10.1155/JNM/2006/60828Suche in Google Scholar

(31) Aljohani FS, Elsafi M, Ghoneim NI, Khandaker MU, El-Khatib M. Water treatment from MB using Zn-Ag MWCNT synthesized by double arc discharge. Materials. 2021;14(23):7205.10.3390/ma14237205Suche in Google Scholar PubMed PubMed Central

(32) Guntu RK. EPR-TL correlation, in radiation shielding Ba(10-x)MnxLa30Si60 glasses. Prog J Mol Struct. 2022;1248:131533.10.1016/j.molstruc.2021.131533Suche in Google Scholar

(33) Sayyed MI, Abdel-Gawad EH, Hanafy TA, Elsafi M. Experimental evaluation of radiation shielding characteristics of borate-based-glass system reinforced with titanium oxide. Opt Mater. 2024;154:115738.10.1016/j.optmat.2024.115738Suche in Google Scholar

(34) Elsafi M, Almousa N, Almasoud FI, Alyahyawi AR, Sayyed MI. A novel epoxy resin-based composite with zirconium and boron oxides: an investigation of photon attenuation. Crystals. 2022;12(10):1370.10.3390/cryst12101370Suche in Google Scholar

(35) Sayyed MI, Yasmin S, Almousa N, Elsafi M. Shielding properties of epoxy matrix composites reinforced with MgO micro- and nanoparticles. Materials. 2022;15(18):6201.10.3390/ma15186201Suche in Google Scholar PubMed PubMed Central

(36) Zakaly HMH, Issa SAM, Tekin HO, Badawi A, Saudi HA, Henaish AMA, et al. An experimental evaluation of CdO/PbO-B2O3 glasses containing neodymium oxide: Structure, electrical conductivity, and gamma-ray resistance. Mater Res Bull. 2022;151:111828. 10.1016/j.materresbull.2022.111828.Suche in Google Scholar

(37) Zakaly HMH, Issa SAM, Saudi HA, Alharshan GA, Uosif MAM, Henaish AMA. Structure, Mössbauer, electrical, and γ-ray attenuation-properties of magnesium zinc ferrite synthesized co-precipitation method. Sci Rep. 2022;12:15495. 10.1038/s41598-022-17311-y.Suche in Google Scholar PubMed PubMed Central

(38) Zakaly HMH, Issa SAM, Saudi HA, Soliman TS. Decoding the role of bismuth oxide in advancing structural, thermal, and nuclear properties of [B2O3–Li2O–SiO2]-Nb2O5 glass systems. Radiat Phys Chem. 2024;223:111984. 10.1016/j.radphyschem.2024.111984.Suche in Google Scholar

(39) Alanazi S, Mahmoud KA, Marashdeh M, Aljaafreh MJ, El-Soad AA, Hanfi M. Impacts of the calcinated clay on structure and gamma-ray shielding capacity of epoxy-based composites. e-Polymers. 2024;24(1):1–12. 10.1515/epoly-2024-0017.Suche in Google Scholar

(40) Almuqrin AH, ALasali HJ, Sayyed MI, Mahmoud KG. Preparation and experimental estimation of radiation shielding properties of novel epoxy reinforced with Sb2O3 and PbO. e-Polymers. 2023;23(1):20230019. 10.1515/epoly-2023-0019.Suche in Google Scholar

(41) Alorain DA, Almuqrin AH, Sayyed MI, Elsafi M. Impact of WO3 and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites. e-Polymers. 2023;23(1):20230037. 10.1515/epoly-2023-0037.Suche in Google Scholar

(42) Alorain DA, Sayyed MI, Almuqrin AH, Mahmoud KG. Impacts of micro-size PbO on the gamma-ray shielding performance of polyepoxide resin. e-Polymers. 2023;23(1):20230032. 10.1515/epoly-2023-0032.Suche in Google Scholar

(43) Aloraini DA, Almuqrin AH, Kaky KM, Sayyed MI, Elsafi M. Radiation shielding capability and exposure buildup factor of cerium(iv) oxide-reinforced polyester resins. e-Polymers. 2023;23(1):20230128. 10.1515/epoly-2023-0128.Suche in Google Scholar

(44) Al-Saleh WM, Almutairi HM, Alsafi K, Nabil IM, Elsafi M. Gamma-ray shielding investigation of nano- and microstructures of SnO on polyester resin composites: Experimental and theoretical study. e-Polymers. 2024;24(1):20240039. 10.1515/epoly-2024-0039.Suche in Google Scholar

(45) Elsafi M, Almuqrin AH, Yasmin S, Sayyed MI. The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding. e-Polymers. 2023;23(1):1–14. 10.1515/epoly-2023-0011.Suche in Google Scholar

(46) Kaky KM, Sayyed MI. The radiation shielding parameters of a standard silica glass system. Silicon. 2023;16(3):1197–203. 10.1007/s12633-023-02750-7.Suche in Google Scholar

(47) Mahmoud KA, Binmujlli MM, Marashdeh MW, Aljaafreh MJ, Saleh A, Hanfi MY. Gamma-ray shielding analysis using the experimental measurements for copper(ii) sulfate-doped polyepoxide resins. e-Polymers. 2023;23(1):14–21. 10.1515/epoly-2023-0142.Suche in Google Scholar

(48) Sayyed MI, Kaky KM, Mhareb MHA, Al-Keisy A, Baki SO. Impact of CuO on TeO2–GeO2–ZnO–Al2O3–MgO glass system for ionizing shielding applications. J Mater Sci Mater Electron. 2023;34(36):2277. 10.1007/s10854-023-11727-6.Suche in Google Scholar

(49) Sayyed MI, Mhareb MHA, Kaky KM. Characterization of mechanical and radiation shielding features of borosilicate glasses doped with MoO3. Silicon. 2023;16(5):1955–65. 10.1007/s12633-023-02801-z.Suche in Google Scholar

(50) Sayyed M, Mahmoud K, Mohammed FQ, Kaky KM. A comprehensive evaluation of Mg-Ni based alloys radiation shielding features for nuclear protection applications. Nucl Eng Technol. 2023;56(5):1830–5. 10.1016/j.net.2023.12.040.Suche in Google Scholar

(51) Al-Ghamdi H, Sayyed MI, Kumar A, Yasmin S, Elbashir BO, Almuqrin AH. Effect of PbO and B2O3 on the physical, structural, and radiation shielding properties of PbO-TeO2-MgO-Na2O-B2O3 glasses. Sustainability. 2022;14(15):9695. 10.3390/su14159695.Suche in Google Scholar

(52) Almuqrin A, Abualsayed M. Effect of dysprosium on the radiation-shielding features of SiO2–PbO–B2O3 glasses. Open Phys. 2023;21(1):20220250. 10.1515/phys-2022-0250.Suche in Google Scholar

(53) Sakar E, Özpolat F, Alım B, Sayyed M, Kurudirek M. Phy-X/PSD: development of a user friendly online software for calculation of parameters relevant to radiation shielding and dosimetry. Radiat Phys Chem. 2020;166:108496.10.1016/j.radphyschem.2019.108496Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Flow-induced fiber orientation in gas-powered projectile-assisted injection molded parts

- Research on thermal aging characteristics of silicone rubber composite materials for dry-type distribution transformers

- Kinetics of acryloyloxyethyl trimethyl ammonium chloride polymerization in aqueous solutions

- Influence of siloxane content on the material performance and functional properties of polydimethylsiloxane copolymers containing naphthalene moieties

- Enhancement effect of electron beam irradiation on acrylonitrile–butadiene–styrene (ABS) copolymers from waste electrical and electronic equipment by adding 1,3-PBO: A potential way for waste ABS reuse

- Model construction and property study of poly(ether-ether-ketone) by molecular dynamics simulation with meta-modeling methods

- Zinc–gallic acid–polylysine nanocomplexes with enhanced bactericidal activity for the treatment of bacterial keratitis

- Effect of pyrogallol compounds dosage on mechanical properties of epoxy coating

- Preparation of in situ polymerized polypyrrole-modified braided cord and its electrical conductivity investigation under varied mechanical conditions

- Hydrophobicity, UV resistance, and antioxidant properties of carnauba wax-reinforced CG bio-polymer film

- Janus nanofiber membrane films loading with bioactive calcium silicate for the promotion of burn wound healing

- Synthesis of migration-resistant antioxidant and its application in natural rubber composites

- Influence of the flow rate on the die swell for polymer micro coextrusion process

- Fatty acid filled polyaniline nanofibres with dual electrical conductivity and thermo-regulatory characteristics: Futuristic material for thermal energy storage

- Hydrolytic depolymerization of major fibrous wastes

- Performance of epoxy hexagonal boron nitrate underfill materials: Single and mixed systems

- Blend electrospinning of citronella or thyme oil-loaded polyurethane nanofibers and evaluating their release behaviors

- Efficiency of flexible shielding materials against gamma rays: Silicon rubber with different sizes of Bi2O3 and SnO

- A comprehensive approach for the production of carbon fibre-reinforced polylactic acid filaments with enhanced wear and mechanical behaviour

- Electret melt-blown nonwovens with charge stability for high-performance PM0.3 purification under extreme environmental conditions

- Study on the failure mechanism of suture CFRP T-joints under/after the low-velocity impact loading

- Experimental testing and finite element analysis of polyurethane adhesive joints under Mode I loading and degradation conditions

- Optimizing recycled PET 3D printing using Taguchi method for improved mechanical properties and dimensional precision

- Effect of stacking sequence of the hybrid composite armor on ballistic performance and damage mechanism

- Bending crack propagation and delamination damage behavior of orthogonal ply laminates under positive and negative loads

- Molecular dynamics simulation of thermodynamic properties of Al2O3-modified silicone rubber under silane coupling agent modification

- Precision injection molding method based on V/P switchover point optimization and pressure field balancing

- Heparin and zwitterion functionalized small-diameter vascular grafts for thrombogenesis prevention

- Metal-free N, S-co-doped carbon materials derived from calcined aromatic co-poly(urea-thiourea)s as efficient alkaline oxygen reduction catalysts

- Influence of stitching parameters on the tensile performance and failure mechanisms of CFRP T-joints

- Synthesis of PEGylated polypeptides bearing thioether pendants for injectable ROS-responsive hydrogels

- Rapid Communication

- RAFT-mediated polymerization-induced self-assembly of poly(ionic liquid) block copolymers in a green solvent

- Corrigendum

- Corrigendum to “High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing”

Artikel in diesem Heft

- Research Articles

- Flow-induced fiber orientation in gas-powered projectile-assisted injection molded parts

- Research on thermal aging characteristics of silicone rubber composite materials for dry-type distribution transformers

- Kinetics of acryloyloxyethyl trimethyl ammonium chloride polymerization in aqueous solutions

- Influence of siloxane content on the material performance and functional properties of polydimethylsiloxane copolymers containing naphthalene moieties

- Enhancement effect of electron beam irradiation on acrylonitrile–butadiene–styrene (ABS) copolymers from waste electrical and electronic equipment by adding 1,3-PBO: A potential way for waste ABS reuse

- Model construction and property study of poly(ether-ether-ketone) by molecular dynamics simulation with meta-modeling methods

- Zinc–gallic acid–polylysine nanocomplexes with enhanced bactericidal activity for the treatment of bacterial keratitis

- Effect of pyrogallol compounds dosage on mechanical properties of epoxy coating

- Preparation of in situ polymerized polypyrrole-modified braided cord and its electrical conductivity investigation under varied mechanical conditions

- Hydrophobicity, UV resistance, and antioxidant properties of carnauba wax-reinforced CG bio-polymer film

- Janus nanofiber membrane films loading with bioactive calcium silicate for the promotion of burn wound healing

- Synthesis of migration-resistant antioxidant and its application in natural rubber composites

- Influence of the flow rate on the die swell for polymer micro coextrusion process

- Fatty acid filled polyaniline nanofibres with dual electrical conductivity and thermo-regulatory characteristics: Futuristic material for thermal energy storage

- Hydrolytic depolymerization of major fibrous wastes

- Performance of epoxy hexagonal boron nitrate underfill materials: Single and mixed systems

- Blend electrospinning of citronella or thyme oil-loaded polyurethane nanofibers and evaluating their release behaviors

- Efficiency of flexible shielding materials against gamma rays: Silicon rubber with different sizes of Bi2O3 and SnO

- A comprehensive approach for the production of carbon fibre-reinforced polylactic acid filaments with enhanced wear and mechanical behaviour

- Electret melt-blown nonwovens with charge stability for high-performance PM0.3 purification under extreme environmental conditions

- Study on the failure mechanism of suture CFRP T-joints under/after the low-velocity impact loading

- Experimental testing and finite element analysis of polyurethane adhesive joints under Mode I loading and degradation conditions

- Optimizing recycled PET 3D printing using Taguchi method for improved mechanical properties and dimensional precision

- Effect of stacking sequence of the hybrid composite armor on ballistic performance and damage mechanism

- Bending crack propagation and delamination damage behavior of orthogonal ply laminates under positive and negative loads

- Molecular dynamics simulation of thermodynamic properties of Al2O3-modified silicone rubber under silane coupling agent modification

- Precision injection molding method based on V/P switchover point optimization and pressure field balancing

- Heparin and zwitterion functionalized small-diameter vascular grafts for thrombogenesis prevention

- Metal-free N, S-co-doped carbon materials derived from calcined aromatic co-poly(urea-thiourea)s as efficient alkaline oxygen reduction catalysts

- Influence of stitching parameters on the tensile performance and failure mechanisms of CFRP T-joints

- Synthesis of PEGylated polypeptides bearing thioether pendants for injectable ROS-responsive hydrogels

- Rapid Communication

- RAFT-mediated polymerization-induced self-assembly of poly(ionic liquid) block copolymers in a green solvent

- Corrigendum

- Corrigendum to “High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing”