Abstract

With the depletion of energy and the increasing awareness of environmental protection, bio-polymer films will become a possible alternative to plastic packaging in the future. However, further improvement is needed in the mechanical, waterproof, anti-ultraviolet (UV), and antioxidant properties of bio-polymer films. In this work, a novel bio-polymer film consisting of gelatin, chitosan, and carnauba wax was developed by crosslinking reactions and exhibited excellent performance with appropriate mechanical strength (tensile strength 10 MPa, breaking elongation 38%), excellent water resistance properties (the contact angle reached 124°), and 2,2-diphenyl-1-picrylhydrazyl scavenging ability (69.1%) and can completely block UV rays. Consequently, carnauba wax/chitosan/gelatin film, as a new type of versatile film with excellent performance, will broaden the application of biobased polymer films in the packaging field.

1 Introduction

Traditional petroleum-based plastic film as packaging materials has resulted in increasingly severe environmental pollution due to their non-degradable properties (1,2). Bio-polymer films, known for their non-toxic, biodegradable, and renewable characteristics, have gained more interest as a substitute for conventional plastics derived from petroleum (3,4,5). These bio-polymer films are usually composed of one or several polysaccharides and proteins, e.g., starch, glycogen, carrageenan, chitosan, and gelatin (6,7). However, their performance in mechanical properties, waterproofing, and UV resistance is still lower than that of petroleum-based films, which seriously restricts the application in food and agriculture fields as packaging films (8).

Multi-component blending, the formation of crosslinked structures, and the addition of functional monomer are common strategies to enhance properties of bio-polymer films (9). Chitosan has characteristics of being fragile and easily soluble in water. Adding gelatin with triple helical structure can form a crosslinked structure, effectively reduce the crystallinity of chitosan, and improve the flexibility (10). Early research mainly focused on blending studies; introducing gelatin into chitosan could enhance tensile strength (TS), forming capacity, and thermal stability, and decrease sensitiveness of gelatin to humidity (11). Hence, as an important member of bio-polymer films, chitosan/gelatin (CG) has become an early research hotspot (12). As research deepens, researchers have found that crosslinking is an effective method for enhancing the performance of bio-polymer films (13). The development of CG films has mainly focused on new non-toxic and environmentally friendly bio-crosslinking agents in recent years. Due to its low toxicity, natural substances such as vanillin, salicylaldehyde, nitrosalicylaldehyde, and tannic acid have become frequently used crosslinking agents in bio-polymer research (14,15,16).

In the research on properties of CG, the focus has shifted from early physical and mechanical properties to functional studies such as waterproofing, antioxidant, and UV resistance (17,18). Compared with other lipids, the exceptional hydrophobic properties of wax, linked to the presence of long-chain alkane and fatty alcohol structures, contribute to its superior ability to act as a water barrier. Carnauba wax is derived from Brazilian carnauba leaves, and it is composed of long-chain saturated fatty acids, mainly as carnaubaitic acid and oleic acid, with good hydrophobic ability. In addition, the melting point of carnauba wax was approximately 82–86°C, surpassing the melting points of carnauba wax (58–60°C), candlestick wax (69–73°C), and bees wax (62–66°C) (19). Carnauba wax can promote the crosslinking reaction between chitosan and other substances, forming a more stable three-dimensional network structure. This structure can maintain the integrity of the film better at high temperatures, thus improving thermal stability of the material (20). In addition, the significant proportion of saturated compounds in its chemical composition makes it less prone to typical self-oxidation processes, which is beneficial to maintain the oxidation stability of the material.

The objective of this research was to prepare versatile bio-polymer packaging film with excellent mechanical properties, thermal stability, hydrophobicity, UV resistance, and antioxidant through hydrogen bonding interactions and the formation of double crosslinking structure. The study of film structure, multi-component interactions, and the influence of carnauba wax on film properties will provide theoretical references and scientific basis for the development of environmental-friendly packaging films.

2 Materials and methods

2.1 Materials

The Carnauba wax (melting point: >83°C) was purchased from Macklin Co., Ltd. Chitosan was purchased from Shanghai Sigma-Aldrich Biochemical Technology Co., Ltd. The deacety-lation degree of chitosan ≥ 95%. Vanillin (melting point: 81°C, assay: 99.5%,) was purchased from Macklin Co., Ltd. Glycerol, tween 80, acetic acid and absolute ethanol (all analytical grade) were derived from Macklin Co., Ltd. Gelatin (glue strength ∼250 g Bloom) were purchased from Macklin (Shanghai) Co., Ltd.

2.2 Preparation of carnauba wax/chitosan/gelatin (CGVC) films

The CGV film (carnauba wax content is zero) was prepared by our previous work (21). Similarly, versatile carnauba wax/chitosan/gelatin bio-polymer film (CGVC) was prepared by solution blending method. Briefly, 0.212 g of chitosan was dissolved in a 1.5% v/v acetic acid aqueous solution and stirred in a water bath at 60°C to form a 20 wt% chitosan solution. It stood overnight at room temperature until the bubble disappeared. 0.100 g of carnauba wax and 5 mL of ethanol were mixed in a magnetic mixer for 3 h. 0.848 g of gelatin and 10 mL of deionized water were stirred for 30 min using a water bath set at 60°C to obtain a gelatin solution. The aforementioned chitosan solution, carnauba wax, gelatin solution, and tween-80 as surfactant (2 wt% of total mass) were added to a 100 mL triple neck flask and continuously stirred at 60°C for 1 h; then, the solution of vanillin and glycerol (10 and 30 wt% of total mass, respectively) was mixed, and the reaction was conducted for 3 h at 60°C at 200 rpm. The mixture was placed in a silicone mold measuring 140 × 20 mm and dried naturally for 48 h, until the weight of the film showed a minimal change. The CGVC films with different carnauba wax contents 5, 10, 15, and 20 wt% were successfully prepared and designated as CGVC5, CGVC10, CGVC15, and CGVC20, respectively.

2.3 Characterization of films

The prepared sample underwent complete drying at ambient temperature. An attenuated total reflectance infrared reflector was employed in the infrared spectroscopy analysis, using a Fourier transform infrared spectroscopy (FTIR) spectrophotometer (IRTracer-100, USA). The absorbance was recorded over a spectral range of 600–4,000 cm−1, with 32 scans performed at a resolution of 0.09 cm−1. Subsequently, an X-ray diffraction (XRD) analysis was performed using a SmartLab apparatus from Japan, which utilized nickel-filtered Cu-Kα radiation (λ = 1.5406 Å). The scanning range occurred from 5° to 90° at a rate of 10° per min. Finally, the cross-sections of CGV and CGVC films were observed with a scanning electron microscope (SEM) (FEI Magellan 400, USA). The surface of films was gold-coated with a sputtering tool at a current of 10 mA for 30 s.

2.4 Performance test

Detailed information about the performance testing in this study is given in the Supporting Information (S1).

3 Results and discussion

3.1 Fabrication and characterization of CGVC bio-polymer film

Carnauba wax is insoluble in water, but dissolved in a hot ethanol solution. Hence, a homogenous system can be achieved through co-mixing at 60°C. However, in the cooling stage of film formation, carnauba wax is easy to migrate from the matrix phase to the surface layer and undergo secondary agglomeration, which has positive effects on the surface hydrophobic effect of film materials. However, the uniformity of the formed film was poor when the content of carnauba wax in the system exceeded 20 wt%. In addition, vanillin, as a crosslinking agent, can facilitate the formation of a three-dimensional network structure in films, stabilize carnauba wax, and significantly enhance the properties of CGVC bio-polymer films. The schematic diagram of film preparation is shown in Figure 1.

Schematic diagram of the film preparation.

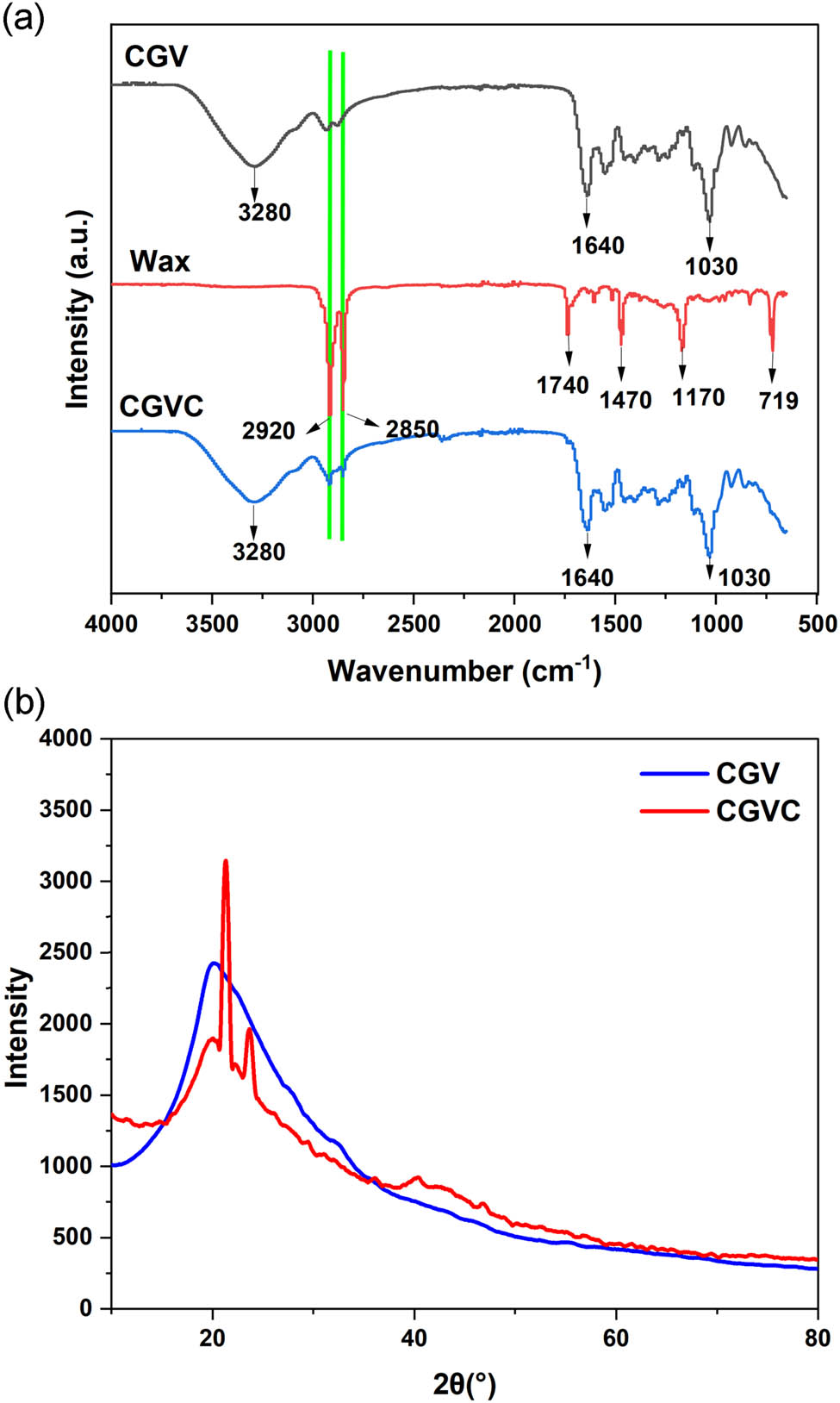

According to the infrared spectrum of the CGV film (Figure 2a), the obvious absorption peak observed at 3,280 cm−1 is attributed to the stretching vibration of −OH, and the peak at 1,640 cm−1 is attributed to the stretching vibration of C═O (22), and the absorption peak at 1,030 cm−1 is related to the interaction between the −OH component in glycerol and the functional groups present in chitosan and gelatin (23). From the infrared spectrum of the wax, it can be inferred that the peaks formed at 2,920 and 2,850 cm−1 are attributed to the methylene asymmetry and symmetric stretching vibration of the fatty acid chain, respectively. Compared with the CGVC film, only two new peaks were added, located at 2,920 and 2,850 cm−1, respectively, while the remaining peaks aligned with the absorption peak of CGV. This indicates that the addition of carnauba wax did not affect the hydrogen bonding interaction between gelatin and chitosan, as well as the formation of Schiff bonds between vanillin and gelatin/chitosan (24).

(a) FTIR and (b) XRD spectra.

It can be seen from the XRD spectra of CGV and CGVC films (Figure 2b) that CGV showed a broad diffraction peak at 20.3°, which is related to the lower crystallinity of CG. The CGVC film, on the other hand, exhibits new sharp and strong peaks at 21.2° and 23.6°, respectively, based on retaining the broad diffraction peak at 20.3°, which is related to carnauba wax (25). This indicates that the crystal structure of the film was not destroyed after adding carnauba wax, which was further confirmed by SEM analysis results.

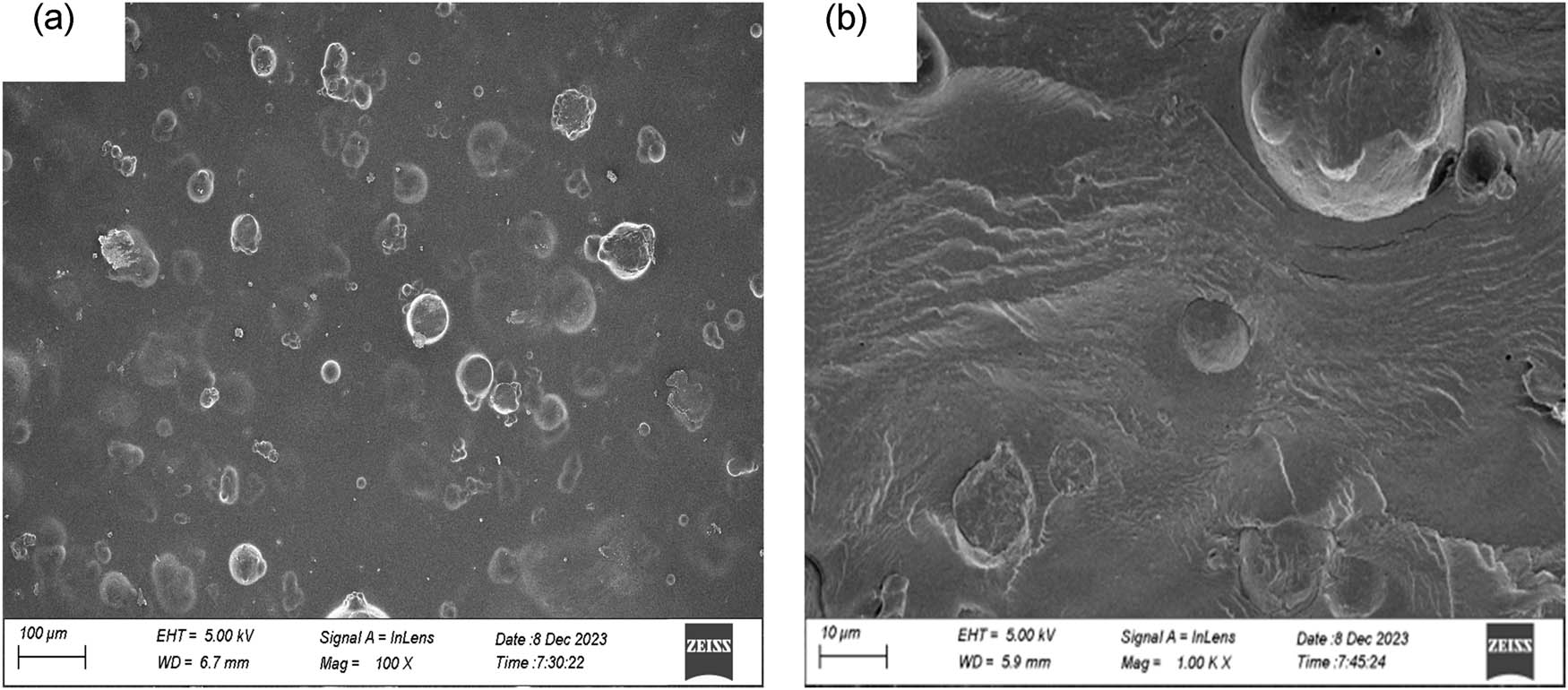

From the image of the surface of CGVC film, a large number of uniformly dispersed spherical structures were observed, indicating that carnauba wax is evenly distributed on the surface of CG matrix (Figure 3a). The cross-sectional images showed that the carnauba wax left a pore structure in the diameter range of 10–80 μm (Figure 3b). These results explain from a microscopic perspective that the particle size and distribution of wax affect hydrophobicity and mechanical properties of the film.

(a) SEM images of the surface of CGVC film and (b) the cross-section of CGVC film.

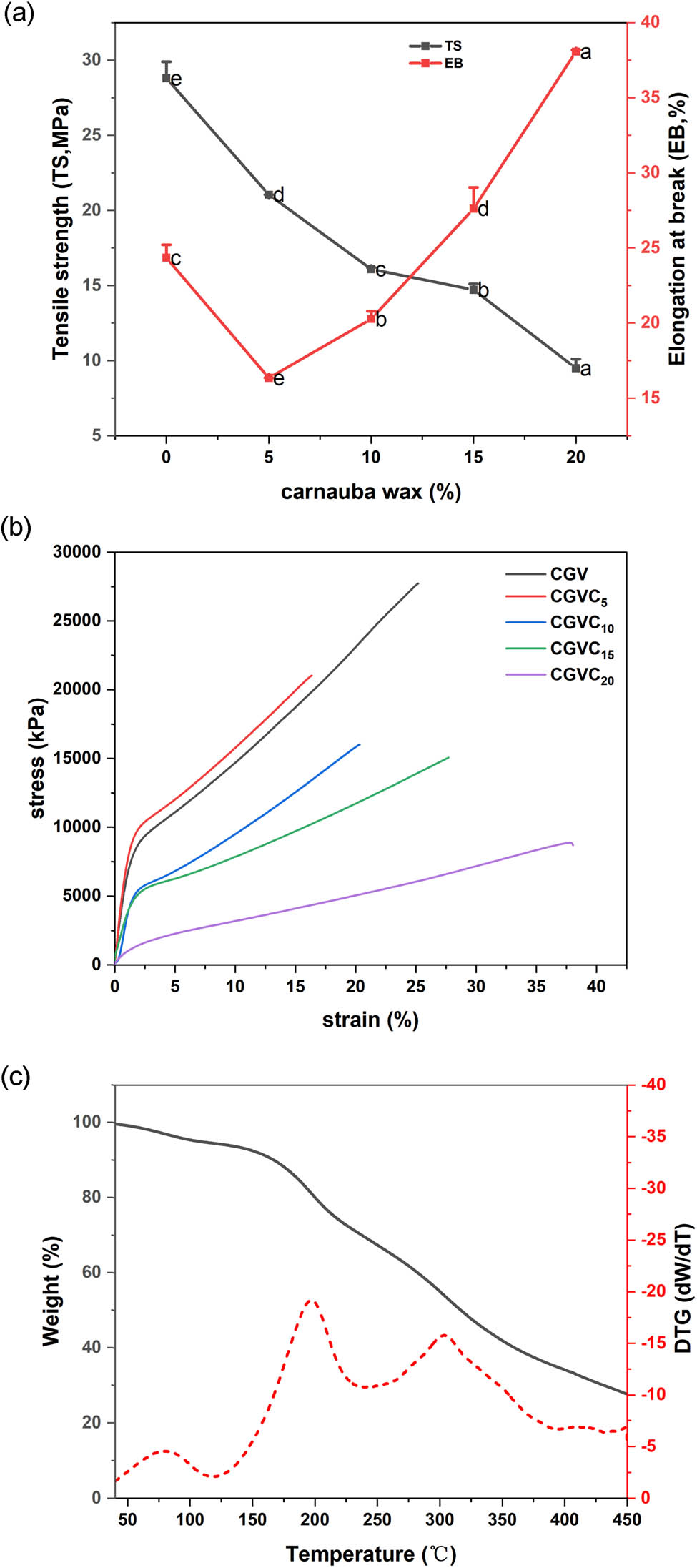

3.2 Mechanical and thermal performance

Although CG has good film formation, its toughness is poor. In order to enhance its toughness, plasticizer is often added to the system or other bio-polymer materials for the formation of the composite film. In this study, TS and breaking elongation (EB) of the film were tested according to international organization for standardization 527-2 (26). TS values reduced from 29 to 10 MPa as the amount of carnauba wax increased, while EB continued to increase significantly from 16% to 38% (Figure 4a and b). This strength and toughness can meet the requirements for materials used as packaging films. The reason for this phenomenon is mainly attributed to wax plasticity (27). Carnauba wax mainly contains more than 80% aliphatic esters and cassia bark acid diesters, which improves the flexibility of the film. It is also possible that the presence of carnauba wax weakens the intermolecular forces, especially hydrogen bonds, thereby reducing the TS.

(a) TS and EB of CGVC films, (b) stress–strain plot of CGVC films, and (c) TGA and DTG thermograms of the CGVC film.

Thermogravimetric analysis (TGA) of CGVC and thermogravimetric differential curve (DTG) show the multistep weight loss (Figure 4c). The initial stage of weight change in the film takes place between 80°C and 120°C, primarily resulting from the evaporation of unbound water. The loss in the second stage is in the range from 180°C to 220°C. At this stage, the weight loss of the film is due to the decomposition of plasticizer (glycerol) (28,29). The reduction of weight in the third stage occurs between 270°C and 400°C, which corresponds to the thermal degradation of chitosan, gelatin, and wax (30). The thermal decomposition temperature of chitosan and gelatin is 270–320°C and 280–370°C, respectively. The improvement in thermal stability includes two reasons: the improvement of crosslinking on thermal stability and the influence of carnauba wax. Carnauba wax can promote the crosslinking reaction between chitosan and gelatin, forming a more stable three-dimensional network structure, thus improving the thermal stability of the film.

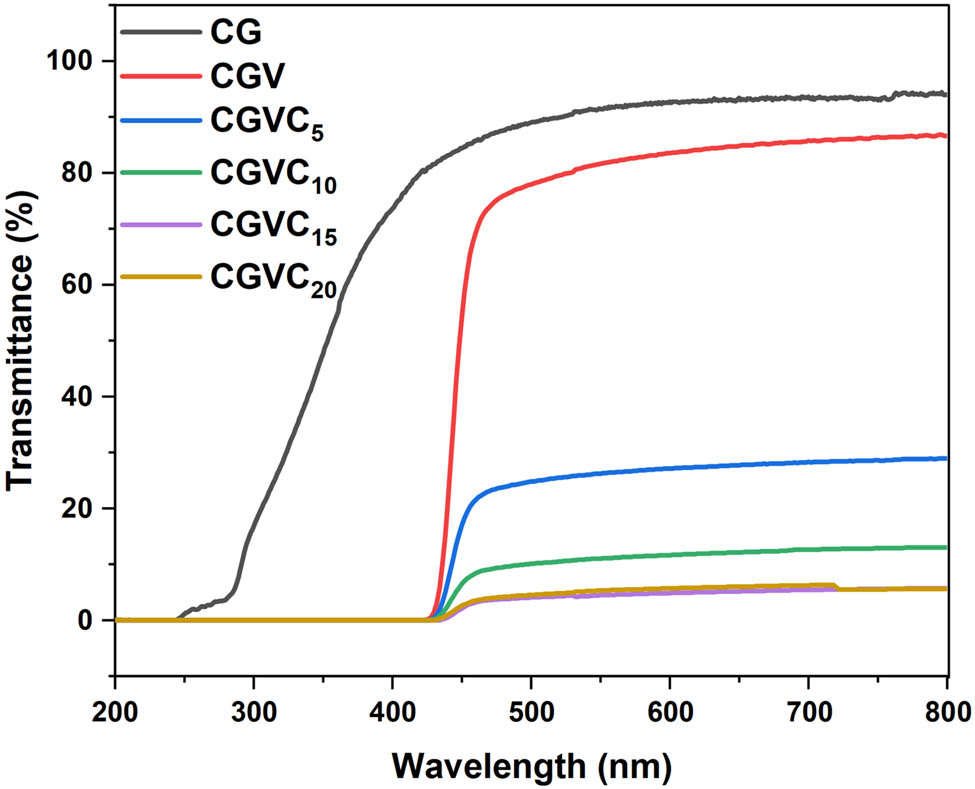

3.3 UV–visible light transmittance

Packaging materials outdoors need to have significant UV rays protection capabilities to avoid excessive UV damage to fruits or food. As shown in the results (Figure 5), the transmittance of CG film is low in the range of 200–300 nm, but high in the range of 300–400 nm. For CGV films, the introduction of vanillin significantly reduces the UV transmittance of the film (31). Furthermore, the introduction of carnauba wax did not weaken the UV-blocking performance of the film, and all CGVC films have zero UV transmittance in the range of 200–400 nm. It is worth noting that CGVC films completely prevent short wavelength blue light at 410 nm from harming human health (32). Meanwhile, carnauba wax is dispersed inside the matrix as a ball, greatly reducing the transmittance to visible light. This value of CG film reduced at 600 nm from about 82–28% with the introduction of 5 wt% carnauba wax.

UV and visible light transmittance.

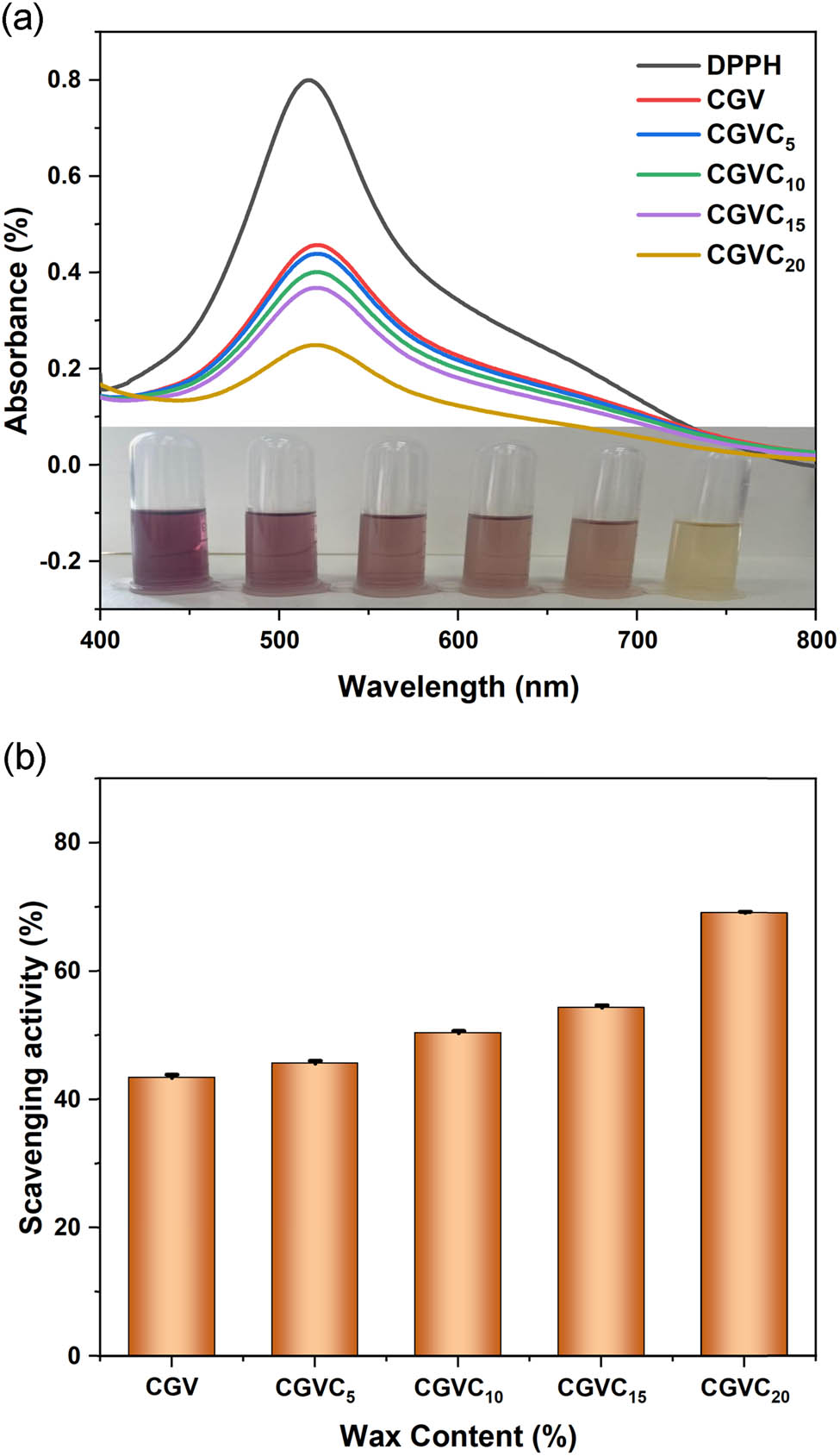

3.4 Antioxidant activity

One of the important features of high-quality packaging film is their ability to antioxidant activity. Owing to the fact that a large portion of the chemical composition of carnauba wax is saturated compounds, they are less susceptible to traditional self-oxidation reactions that primarily attacks double bonds, and therefore, they often maintain their oxidative stability. In the experiment, the absorbance of 2,2-diphenyl-1-picrylhydrazyl (DPPH) stock solution, as well as solutions soaked in CGV and CGVC films, was tested separately using the method described in the previous study (33), and the results are shown in Figure 6a. As the carnauba wax content increases, the absorbance at 517 nm shows a decreasing trend. Subsequently, Figure 6b shows the results of further evaluating the antioxidant capacity of CGVC in terms of changes in absorbance at 517 nm. Due to unsaturated bonds in the CGV film being attacked by free radicals to form more stable radicals, its ability to scavenge DPPH free radicals is relatively low (34). With the increase of a large amount of saturated components in carnauba wax, the antioxidant capacity against DPPH is enhanced. The maximum scavenging activity can reach 69.07%. The carnauba wax contains natural antioxidant components such as gallic acid, catechin, and chlorogenic acid, which is the main reason for improving antioxidant performance of the film (35).

(a) Absorbance of the solutions soaked in CGV and CGVC film and (b) DPPH scavenging capacity of CGVC films.

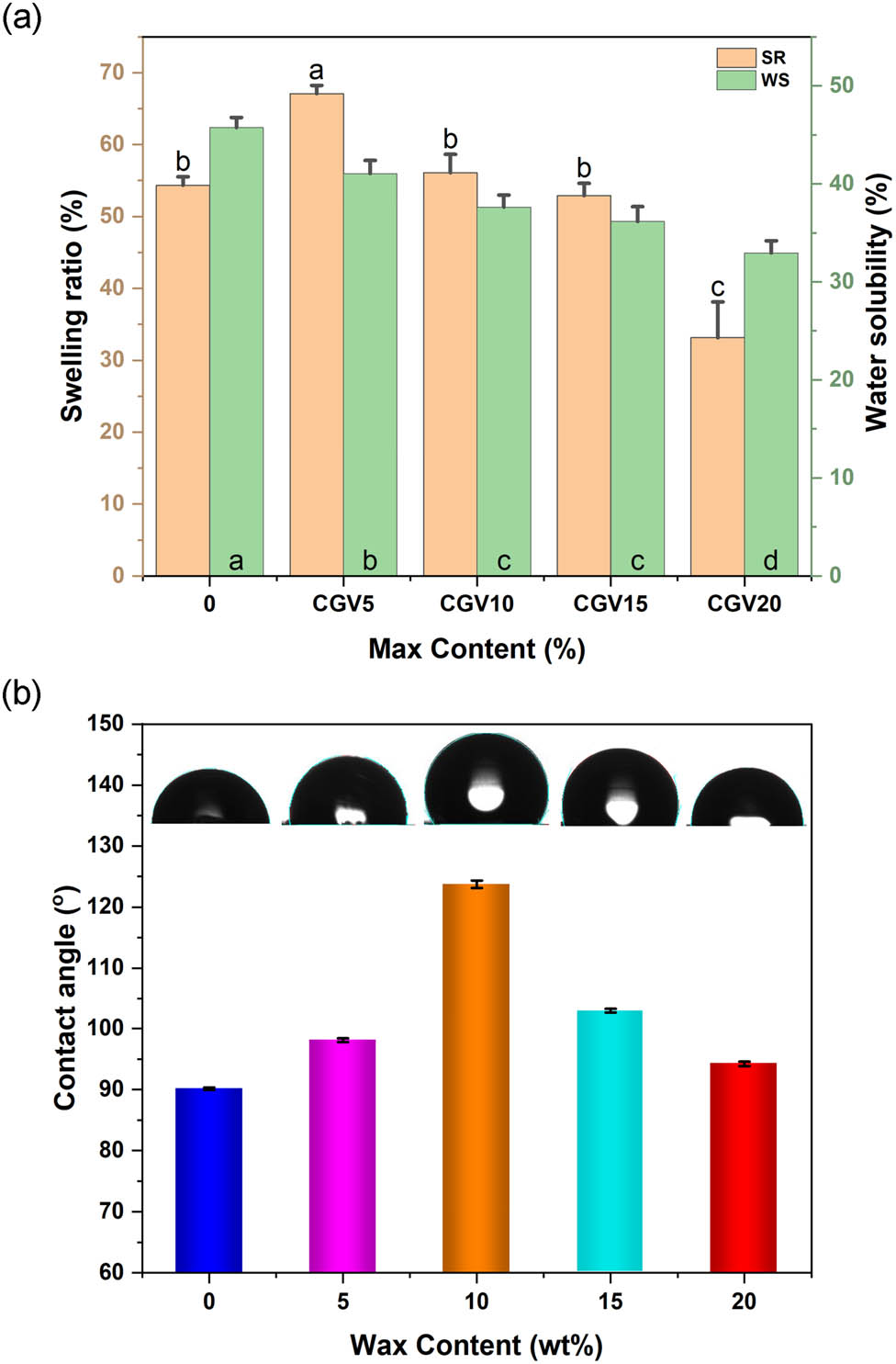

3.5 Water resistance

Low expansion rate, water solubility (WS), and excellent waterproofing have always been the goals pursued in the research and development of biopolymer films. The determination of WS reflects the ability of the film to maintain its integrity when in contact with wet food, which is related to the durability of the film and the safety of food. However, the vast majority of bio-polymers are highly soluble in water (36), which restricts their waterproof properties and is an important factor limiting the application of bio-polymer films. The prepared CGVC film did not dissolve visibly in water after 24 h, which may be responsible for the formation of stable crosslinking network. Moreover, the swelling ratio (SR) of the film reduced significantly with carnauba wax increasing from 5 to 20 wt% (Figure 7a). As the carnauba wax content increases, the WS of the film has a slightly decreasing trend, which may be due to the hydrophobicity of wax molecules (37).

(a) SR and WS (b) WCA of CGVC films.

Wet-proof and waterproof resistance are the most important properties of packaging film. The waterproof properties of the CG film are inadequate because of the presence of numerous hydrophilic groups (38). As shown in Figure 7b, the water contact angle (WCA) of CGVC films was improved to different degrees compared with that of CGV films, indicating that the carnauba wax improved the hydrophobic capacity of the films. With the increasing contents of carnauba wax, the WCA exhibited a trend of rising at first and then decreasing. WCA was increased to 124° when 10 wt% carnauba wax was added to the system. The improvement in hydrophobicity is mainly related to the hydrophobicity of wax components, while the three-dimensional network formed by crosslinking reduces the interaction between bio-polymers and water molecules. And further increasing the amount of carnauba wax, the WCA began to decrease. The reason for this phenomenon may be that the excess carnauba wax is not evenly dispersed in the matrix, leading to the decrease in hydrophobicity caused by agglomeration (2).

Obtaining packaging films with excellent performance is currently the focus of research and development for bio-polymer films. Table 1 lists the relevant research works on CG films, some of which have obtained excellent results in terms of antioxidant and anti-UV properties, but have poor waterproof performance. Some studies mainly focus on waterproofing, but there is room for improvement in terms of UV resistance performance. Here, a novel and simple preparation method has been developed, which can obtain carnauba wax/chitosan/gelatin films with good hydrophobicity, excellent UV barrier, and antioxidant properties. However, after adding carnauba wax to films, although the hydrophobicity was improved, it did not achieve the superhydrophobic effect. This may be related to the distribution and morphology of carnauba wax. According to SEM images, on the surface of the film, wax particles did not form a uniform protrusion structure similar to lotus leaves. Moreover, the presence of wax particles inside the film may also affect the hydrophobic effect of the film to some extent due to compatibility issues.

Contrast of the main properties of CG films

| Bio-polymer film | WCA (°) | Scavenging capacity (%) | UV transmittance (%) | TS (MPa) | EB (%) | References | |

|---|---|---|---|---|---|---|---|

| CG | 73.6 | — | 280 nm | 14.6 | 52.1 | 6.1 | (39) |

| CG-TA | — | 89.3 | 300–400 nm | <50 | 48.5 | 2.7 | (40) |

| CG@S-Chitin | 67.8 | 98.0 | 280 nm | 0.05 | 55.3 | 6.4 | (41) |

| CG-PC | — | 69.85 | 300–400 nm | <53 | 27.2 | 33.4 | (42) |

| CG/nanofiber/ZnO-NPs/B-NLPs | 92.5 | 53.0 | — | — | 19.6 | 8,5 | (43) |

| CG-Rut | 52.4 | 92 | 280 nm | 0.4 | 63.1 | 4.8 | (44) |

| CG/Wax/TA | 98 | 69.1 | 200–400 nm | 0 | 9.5 | 38.1 | This work |

4 Conclusions

The present study successfully prepared carnauba wax/chitosan/gelatin multifunctional films. The formation of the crosslinking network structure gives the film proper strength, low swelling rate, and WS. The addition of carnauba wax improves flexibility and hydrophobicity of the film, resulting in a maximum contact angle of 124° for carnauba wax/chitosan/gelatin film. Moreover, the film has good thermal stability and certain DPPH scavenging ability (69.1%) and can completely block UV rays. CGVC film will broaden the application of bio-polymer films in packaging field.

-

Funding information: This research was funded by the Scientific Research Program of Jilin Provincial Department of Education, Grant Number JJKH20230331KJ; Project of Jilin Provincial Department of Education, Grant Number JJKH20220695SK; Project of Jilin Provincial Science and Technology Department, Grant Number 20230601013FG and 2023 China Scholarship Council Grant.

-

Author contributions: Xueying Yang: writing – review and editing, investigation, conceptualization, validation; Weiyu Tian: writing – original draft, formal analysis, data curation; Huanyang Yu: methodology, funding acquisition, project administration, resources, supervision; all authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

References

(1) Etxabide A, Uranga J, Guerrero P, De la Caba K. Development of active gelatin films by means of valorisation of food processing waste: A review. Food Hydrocoll. 2017;68:192–8.10.1016/j.foodhyd.2016.08.021Search in Google Scholar

(2) Syahida SN, Ismail-Fitry MR, Ainun ZM, Hanani ZA. Effects of palm wax on the physical, mechanical and water barrier properties of fish gelatin films for food packaging application. Food Packag Shelf Life. 2020;23:100437.10.1016/j.fpsl.2019.100437Search in Google Scholar

(3) Beikzadeh S, Khezerlou A, Jafari SM, Pilevar Z, Mortazavian AM. Seed mucilages as the functional ingredients for biodegradable films and edible coatings in the food industry. Adv Colloid Interface Sci. 2020;280:102164.10.1016/j.cis.2020.102164Search in Google Scholar PubMed

(4) Sutipanwihan N, Kitsawat V, Sintharm P, Phisalaphong M. Natural rubber films reinforced with cellulose and chitosan prepared by latex aqueous microdispersion. Polymers. 2024;16:2652.10.3390/polym16182652Search in Google Scholar PubMed PubMed Central

(5) Vanaraj R, Suresh Kumar SM, Kumar S, Mayakrishnan G, Rathinam B, Kim SC. A current trend in efficient biopolymer coatings for edible fruits to enhance shelf life. Polymers. 2024;16:2639.10.3390/polym16182639Search in Google Scholar PubMed PubMed Central

(6) Zhang W, Roy S, Ezati P, Yang D, Rhin JW. Tannic acid: A green crosslinker for biopolymer-based food packaging films. Trends Food Sci Technol. 2023;136:11–23.10.1016/j.tifs.2023.04.004Search in Google Scholar

(7) Sajjan AM, Premakshi HG, Kariduraganavar MY. Synthesis and characterization of polyelectrolyte complex membranes for the pervaporation separation of water-isopropanol mixtures using sodium alginate and gelatin. Polym Bull. 2018;75:851–75.10.1007/s00289-017-2062-7Search in Google Scholar

(8) Bakouri H, Ziane A, Guemra K. Development of multifunctional packaging films based on arginine-modified chitosan/gelatin matrix and betacyanins from weed amaranth (A. hybridus). Int J Biol Macromol. 2023;230:123181.10.1016/j.ijbiomac.2023.123181Search in Google Scholar PubMed

(9) Fu B, Liu Q, Liu M, Chen X, Lin H, Zheng Z, et al. Carbon dots enhanced gelatin/chitosan bio-nanocomposite packaging film for perishable foods. Chin Chem Lett. 2022;33(10):4577–82.10.1016/j.cclet.2022.03.048Search in Google Scholar

(10) Ahammed S, Liu F, Khin MN, Yokoyama WH, Zhong F. Improvement of the water resistance and ductility of gelatin film by zein. Food Hydrocoll. 2020;105:105804.10.1016/j.foodhyd.2020.105804Search in Google Scholar

(11) Fiallos-Núñez J, Cardero Y, Cabrera-Barjas G. Eco-friendly design of chitosan-based films with biodegradable properties as an alternative to low-density polyethylene packaging. Polymers. 2024;16:2471.10.3390/polym16172471Search in Google Scholar PubMed PubMed Central

(12) Xiong Y, Chen M, Warner RD, Fang Z. Incorporating nisin and grape seed extract in chitosan-gelatine edible coating and its effect on cold storage of fresh pork. Food Control. 2020;110:107018.10.1016/j.foodcont.2019.107018Search in Google Scholar

(13) Skopinska-Wisniewska J, Tuszynska M, Kaźmierski Ł, Bartniak M, Bajck A. Gelatin–sodium alginate hydrogels cross-linked by squaric acid and dialdehyde starch as a potential bio-ink. Polymers. 2024;16:2560.10.3390/polym16182560Search in Google Scholar PubMed PubMed Central

(14) Gavrilović-Grmuša I, Rančić M, Tešić T, Stupar S, Milošević M, Gržetić J. Bio-epoxy resins based on lignin and tannic acids as wood adhesives – characterization and bonding properties. Polymers. 2024;16:2602.10.3390/polym16182602Search in Google Scholar PubMed PubMed Central

(15) Hu J, Wang Z, Miszuk M, Zhu M, Lansakara TI, Tivanski A, et al. Vanillin-bioglass cross-linked 3D porous chitosan scaffolds with strong osteopromotive and antibacterial abilities for bone tissue engineering. Carbohydr Polym. 2021;271:118440.10.1016/j.carbpol.2021.118440Search in Google Scholar PubMed PubMed Central

(16) Craciun AM, Tartau LM, Pinteala M, Marin L. Nitrosalicyl-imine chitosan hydrogels based drug delivery systems for long term sustained release in local therapy. J Colloid Interface Sci. 2019;536:196–207.10.1016/j.jcis.2018.10.048Search in Google Scholar PubMed

(17) Figueroa-Lopez KJ, Andrade-Mahecha MM, Torres-Vargas OL. Development of antimicrobial biocomposite films to preserve the quality of bread. Molecules. 2018;23(1):212.10.3390/molecules23010212Search in Google Scholar PubMed PubMed Central

(18) Wu J, Sun X, Guo X, Ge S, Zhang Q. Physicochemical properties, antimicrobial activity and oil release of fish gelatin films incorporated with cinnamon essential oil. Aquacult Fish. 2017;2(4):185–92.10.1016/j.aaf.2017.06.004Search in Google Scholar

(19) Zhang Y, Simpson BK, Dumont MJ. Effect of beeswax and carnauba wax addition on properties of gelatin films: A comparative study. Food Biosci. 2018;26:88–95.10.1016/j.fbio.2018.09.011Search in Google Scholar

(20) Xu X, Deng S, Essawy H, Lee SH, Lum WC, Zhou X, et al. Chitosan-casein blended with condensed tannin and carnauba wax for the fabrication of antibacterial and antioxidant food packing films. Int J Biol Macromol. 2024;277:133784.10.1016/j.ijbiomac.2024.133784Search in Google Scholar PubMed

(21) Yu H, Ge Y, Ding H, Yan Y, Wang L. Vanillin cross-linked chitosan/gelatin bio-polymer film with antioxidant, water resistance and ultraviolet-proof properties. Int J Biol Macromol. 2023;253:126726.10.1016/j.ijbiomac.2023.126726Search in Google Scholar PubMed

(22) Carneiro J, Tedim J, Ferreira MGS. Chitosan as a smart coating for corrosion protection of aluminum alloy 2024: A review. Prog Org Coat. 2015;89:348–56.10.1016/j.porgcoat.2015.03.008Search in Google Scholar

(23) Liu F, Avena-Bustillos RJ, Zhong F, Chiou BS, Zhang Y, Li Y, et al. Study of combined effects of glycerol and transglutaminase on properties of gelatin films. Food Hydrocoll. 2017;65:1–9.10.1016/j.foodhyd.2016.10.004Search in Google Scholar

(24) Yu H, Wang Y, Wang R, Ge Y, Wang L. Tannic acid crosslinked chitosan/gelatin/SiO2 biopolymer film with superhydrophobic, antioxidant and UV resistance properties for prematuring fruit packaging. Int J Biol Macromol. 2024;275:133368.10.1016/j.ijbiomac.2024.133368Search in Google Scholar PubMed

(25) Romani VP, Olsen B, Collares MP, Oliveira JRM, Prentice C, Martins VG. Cold plasma and carnauba wax as strategies to produce improved bi-layer films for sustainable food packaging. Food Hydrocoll. 2020;108:106087.10.1016/j.foodhyd.2020.106087Search in Google Scholar

(26) Roy S, Rhim JW. Carrageenan-based antimicrobial bionanocomposite films incorporated with ZnO nanoparticles stabilized by melanin. Food Hydrocoll. 2019;90:500–7.10.1016/j.foodhyd.2018.12.056Search in Google Scholar

(27) Hajji S, Kchaou H, Bkhairia I, Salem RB, Boufi S, Debeaufort F, et al. Conception of active food packaging films based on crab chitosan and gelatin enriched with crustacean protein hydrolysates with improved functional and biological properties. Food Hydrocoll. 2021;116:106639.10.1016/j.foodhyd.2021.106639Search in Google Scholar

(28) Yadav S, Mehrotra GK, Bhartiya P, Singh A, Dutta PK. Preparation, physicochemical and biological evaluation of quercetin based chitosan-gelatin film for food packaging. Carbohydr Polym. 2020;227:115348.10.1016/j.carbpol.2019.115348Search in Google Scholar PubMed

(29) Roy S, Rhim JW. Fabrication of pectin/agar blended functional film: effect of reinforcement of melanin nanoparticles and grapefruit seed extract. Food Hydrocoll. 2021;118:106823.10.1016/j.foodhyd.2021.106823Search in Google Scholar

(30) Roy S, Rhim JW. Preparation of antimicrobial and antioxidant gelatin/curcumin composite films for active food packaging application. Colloids Surf B. 2020;188:110761.10.1016/j.colsurfb.2019.110761Search in Google Scholar PubMed

(31) Zheng GQ, Liu BW, Yuan L, Chen L, Wang XL, Zhao HB, et al. Natural polyphenol-inspired polymer towards multifunction and high performance. Chem Eng J. 2023;462:142212.10.1016/j.cej.2023.142212Search in Google Scholar

(32) Yang W, Zhang Y, Zhang YJ, Deng W, Fang X. Transparent schottky photodiode based on AgNi NWs/SrTiO3 contact with an ultrafast photoresponse to short‐wavelength blue light and UV‐shielding effect. Adv Funct Mater. 2019;29(46):1905923.10.1002/adfm.201905923Search in Google Scholar

(33) Siripatrawan U, Harte BR. Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocoll. 2010;24(8):770–5.10.1016/j.foodhyd.2010.04.003Search in Google Scholar

(34) Bonilla J, Poloni T, Lourenço RV, Sobral PJ. Antioxidant potential of eugenol and ginger essential oils with gelatin/chitosan films. Food Biosci. 2018;23:107–14.10.1016/j.fbio.2018.03.007Search in Google Scholar

(35) da Silva Andrade LB, da Silva Julião MS, Cruz RCV, Rodrigues THS, dos Santos Fontenelle RO, da Silva ALC. Antioxidant and antifungal activity of carnauba wax powder extracts. Ind Crop Prod. 2018;125:220–7.10.1016/j.indcrop.2018.09.004Search in Google Scholar

(36) Xiong S, Li R, Ye S, Ni P, Shan J, Yuan T, et al. Vanillin enhances the antibacterial and antioxidant properties of polyvinyl alcohol-chitosan hydrogel dressings. Int J Biol Macromol. 2022;220:109–16.10.1016/j.ijbiomac.2022.08.052Search in Google Scholar PubMed

(37) de Oliveira Filho JG, Albiero BR, Cipriano L, de Oliveira Nobre Bezerra CC, Oldoni FCA, Egea MB, et al. Arrowroot starch-based films incorporated with a carnauba wax nanoemulsion, cellulose nanocrystals, and essential oils: A new functional material for food packaging applications. Cellulose. 2021;28(10):6499–511.10.1007/s10570-021-03945-0Search in Google Scholar

(38) Nisar T, Wang ZC, Yang X, Tian Y, Iqbal M, Guo Y. Characterization of citrus pectin films integrated with clove bud essential oil: Physical, thermal, barrier, antioxidant and antibacterial properties. Int J Biol Macromol. 2018;106:670–80.10.1016/j.ijbiomac.2017.08.068Search in Google Scholar PubMed

(39) Sul Y, Ezati P, Rhim JW. Preparation of chitosan/gelatin-based functional films integrated with carbon dots from banana peel for active packaging application. Int J Biol Macromol. 2023;246:125600.10.1016/j.ijbiomac.2023.125600Search in Google Scholar PubMed

(40) Zhang C, Yang Z, Shi J, Zou X, Zhai X, Huang X. Physical properties and bioactivities of chitosan/gelatin-based films loaded with tannic acid and its application on the preservation of fresh-cut apples. LWT Food Sci Technol. 2021;144:111223.10.1016/j.lwt.2021.111223Search in Google Scholar

(41) Khan A, Riahi Z, Kim JT, Rhim JW. Chitosan/gelatin-based multifunctional films integrated with sulfur-functionalized chitin for active packaging applications. Food Hydrocoll. 2024;149:109537.10.1016/j.foodhyd.2023.109537Search in Google Scholar

(42) Ramziia S, Ma H, Yao Y, Wei K, Huang Y. Enhanced antioxidant activity of fish gelatin-chitosan edible films incorporated with procyanidin. J Appl Polym Sci. 2018;135(10):45781.10.1002/app.45781Search in Google Scholar

(43) Amjadi S, Nazari M, Alizadeh SA, Hamishehkar H. Multifunctional betanin nanoliposomes-incorporated gelatin/chitosan nanofiber/ZnO nanoparticles nanocomposite film for fresh beef preservation. Meat Sci. 2020;167:108161.10.1016/j.meatsci.2020.108161Search in Google Scholar PubMed

(44) Roy S, Rhim JW. Fabrication of bioactive binary composite film based on gelatin/chitosan incorporated with cinnamon essential oil and rutin. Colloids Surf B. 2021;204:111830.10.1016/j.colsurfb.2021.111830Search in Google Scholar PubMed

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Flow-induced fiber orientation in gas-powered projectile-assisted injection molded parts

- Research on thermal aging characteristics of silicone rubber composite materials for dry-type distribution transformers

- Kinetics of acryloyloxyethyl trimethyl ammonium chloride polymerization in aqueous solutions

- Influence of siloxane content on the material performance and functional properties of polydimethylsiloxane copolymers containing naphthalene moieties

- Enhancement effect of electron beam irradiation on acrylonitrile–butadiene–styrene (ABS) copolymers from waste electrical and electronic equipment by adding 1,3-PBO: A potential way for waste ABS reuse

- Model construction and property study of poly(ether-ether-ketone) by molecular dynamics simulation with meta-modeling methods

- Zinc–gallic acid–polylysine nanocomplexes with enhanced bactericidal activity for the treatment of bacterial keratitis

- Effect of pyrogallol compounds dosage on mechanical properties of epoxy coating

- Preparation of in situ polymerized polypyrrole-modified braided cord and its electrical conductivity investigation under varied mechanical conditions

- Hydrophobicity, UV resistance, and antioxidant properties of carnauba wax-reinforced CG bio-polymer film

- Janus nanofiber membrane films loading with bioactive calcium silicate for the promotion of burn wound healing

- Synthesis of migration-resistant antioxidant and its application in natural rubber composites

- Influence of the flow rate on the die swell for polymer micro coextrusion process

- Fatty acid filled polyaniline nanofibres with dual electrical conductivity and thermo-regulatory characteristics: Futuristic material for thermal energy storage

- Hydrolytic depolymerization of major fibrous wastes

- Performance of epoxy hexagonal boron nitrate underfill materials: Single and mixed systems

- Blend electrospinning of citronella or thyme oil-loaded polyurethane nanofibers and evaluating their release behaviors

- Efficiency of flexible shielding materials against gamma rays: Silicon rubber with different sizes of Bi2O3 and SnO

- A comprehensive approach for the production of carbon fibre-reinforced polylactic acid filaments with enhanced wear and mechanical behaviour

- Electret melt-blown nonwovens with charge stability for high-performance PM0.3 purification under extreme environmental conditions

- Study on the failure mechanism of suture CFRP T-joints under/after the low-velocity impact loading

- Experimental testing and finite element analysis of polyurethane adhesive joints under Mode I loading and degradation conditions

- Optimizing recycled PET 3D printing using Taguchi method for improved mechanical properties and dimensional precision

- Effect of stacking sequence of the hybrid composite armor on ballistic performance and damage mechanism

- Bending crack propagation and delamination damage behavior of orthogonal ply laminates under positive and negative loads

- Molecular dynamics simulation of thermodynamic properties of Al2O3-modified silicone rubber under silane coupling agent modification

- Precision injection molding method based on V/P switchover point optimization and pressure field balancing

- Heparin and zwitterion functionalized small-diameter vascular grafts for thrombogenesis prevention

- Metal-free N, S-co-doped carbon materials derived from calcined aromatic co-poly(urea-thiourea)s as efficient alkaline oxygen reduction catalysts

- Influence of stitching parameters on the tensile performance and failure mechanisms of CFRP T-joints

- Synthesis of PEGylated polypeptides bearing thioether pendants for injectable ROS-responsive hydrogels

- Rapid Communication

- RAFT-mediated polymerization-induced self-assembly of poly(ionic liquid) block copolymers in a green solvent

- Corrigendum

- Corrigendum to “High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing”

Articles in the same Issue

- Research Articles

- Flow-induced fiber orientation in gas-powered projectile-assisted injection molded parts

- Research on thermal aging characteristics of silicone rubber composite materials for dry-type distribution transformers

- Kinetics of acryloyloxyethyl trimethyl ammonium chloride polymerization in aqueous solutions

- Influence of siloxane content on the material performance and functional properties of polydimethylsiloxane copolymers containing naphthalene moieties

- Enhancement effect of electron beam irradiation on acrylonitrile–butadiene–styrene (ABS) copolymers from waste electrical and electronic equipment by adding 1,3-PBO: A potential way for waste ABS reuse

- Model construction and property study of poly(ether-ether-ketone) by molecular dynamics simulation with meta-modeling methods

- Zinc–gallic acid–polylysine nanocomplexes with enhanced bactericidal activity for the treatment of bacterial keratitis

- Effect of pyrogallol compounds dosage on mechanical properties of epoxy coating

- Preparation of in situ polymerized polypyrrole-modified braided cord and its electrical conductivity investigation under varied mechanical conditions

- Hydrophobicity, UV resistance, and antioxidant properties of carnauba wax-reinforced CG bio-polymer film

- Janus nanofiber membrane films loading with bioactive calcium silicate for the promotion of burn wound healing

- Synthesis of migration-resistant antioxidant and its application in natural rubber composites

- Influence of the flow rate on the die swell for polymer micro coextrusion process

- Fatty acid filled polyaniline nanofibres with dual electrical conductivity and thermo-regulatory characteristics: Futuristic material for thermal energy storage

- Hydrolytic depolymerization of major fibrous wastes

- Performance of epoxy hexagonal boron nitrate underfill materials: Single and mixed systems

- Blend electrospinning of citronella or thyme oil-loaded polyurethane nanofibers and evaluating their release behaviors

- Efficiency of flexible shielding materials against gamma rays: Silicon rubber with different sizes of Bi2O3 and SnO

- A comprehensive approach for the production of carbon fibre-reinforced polylactic acid filaments with enhanced wear and mechanical behaviour

- Electret melt-blown nonwovens with charge stability for high-performance PM0.3 purification under extreme environmental conditions

- Study on the failure mechanism of suture CFRP T-joints under/after the low-velocity impact loading

- Experimental testing and finite element analysis of polyurethane adhesive joints under Mode I loading and degradation conditions

- Optimizing recycled PET 3D printing using Taguchi method for improved mechanical properties and dimensional precision

- Effect of stacking sequence of the hybrid composite armor on ballistic performance and damage mechanism

- Bending crack propagation and delamination damage behavior of orthogonal ply laminates under positive and negative loads

- Molecular dynamics simulation of thermodynamic properties of Al2O3-modified silicone rubber under silane coupling agent modification

- Precision injection molding method based on V/P switchover point optimization and pressure field balancing

- Heparin and zwitterion functionalized small-diameter vascular grafts for thrombogenesis prevention

- Metal-free N, S-co-doped carbon materials derived from calcined aromatic co-poly(urea-thiourea)s as efficient alkaline oxygen reduction catalysts

- Influence of stitching parameters on the tensile performance and failure mechanisms of CFRP T-joints

- Synthesis of PEGylated polypeptides bearing thioether pendants for injectable ROS-responsive hydrogels

- Rapid Communication

- RAFT-mediated polymerization-induced self-assembly of poly(ionic liquid) block copolymers in a green solvent

- Corrigendum

- Corrigendum to “High-strength polyvinyl alcohol-based hydrogel by vermiculite and lignocellulosic nanofibrils for electronic sensing”