Abstract

To improve the accuracy of numerical control machine tools error, this paper studies the application of laser testing technology in numerical control machine tool, and put forward a laser interferometer automatic aiming system which can conduct space error measurement. The system, in the process of the NC machine tool operating, can measure the machine tool space curve through changing the direction of the laser. The principle of laser interferometer and matlab analysis are adopted, through the experiment of laser interference technology in the numerical control machine tool, the law curve of error in NC machine tools is obtained, getting the method of error of NC machine tools. When conducting laser testing error experiment in NC machine tool, the results show that the laser testing can measure aggregated error and thermal error of NC machine tool better, with small control of environment and high accuracy of measurement.

1 Introduction

The current NC machine tools develop very rapidly, and the accuracy of NC machining also increases significantly. But the positioning error of NC machine tools will also affected by scale error and geometric error, impacting on products processed by NC machining. In order to make NC workshop produce high quality products, and also improve the productivity, it is urgent that realizing efficient and fast control on the error of machine tool in the production of NC machine tool, so we can get products with small error and high precision, achieving no error production. This has relatively high requirements on instruments and technical that measuring error.

The dual-frequency laser interferometer is high precise equipment measuring NC machine tools in contemporary. In the actual operation, the measuring technology of laser interference can accurately measure the actual position and ideal location in the process of operation, achieving the error measurement and the function of error compensation [1, 2, 3, 4].

Professor Yang Jianguo, through the cooperation of foreign NC enterprises, has found a method using body diagonals to measure spatial position error in the process of NC machine tool operation, which is based on laser Doppler technique and multi-step measurement, error control in NC machine tool operation can be realized by using a simple laser, creating conditions for error compensation [5].

Mark A. V. Chapman has analyzed the measurement precision of laser vector diagonal from the principle of NC machine tool error forming, and measured the size of error accurately, also pointed out that the test data by using this method for error compensation may have some deficiencies.

H. Schwenke and others have proposed the laser tracking method based on the measurement of single laser tracking interferometer, this method cannot be influenced by external environment, namely, there has no direct relation with the run length of the NC machine tool, and the reference object is static, and this method can reduce the inaccuracy of measurement [6].

A team from Shanghai Jiaotong University, through the analysis of three-axis NC machine tool error, has proposed a measuring method of three-axis NC machine tool based on the raster, through detecting the linear motion trajectory precision in the three coordinate planes, the linearity error has been obtained, then through the three co-ordinate plane, the trajectory accuracy of circular motion is detected. The aggregate error of NC machine has been got effective control [7].

In the actual production of the NC machine tool, due to the limitation of machine itself and the work environment, NC machine tool will produce positioning error and straightness error, etc., influencing the products processed, especially for precision processing parts, small error will affect the precious parts, the automatic aiming test system studied can obtain the error in the process of operation, implementing the compensation of NC machine tool [8].

Therefore, this paper puts forward the error identification and compensation of CNC machine tools based on laser detection technology.

2 Material and Methods

As for all parts composing NC machine tool, they will produce error inevitable in the operation, and that each part will also produce error. Through analyzing the aspects of error generation in the processing, it has been found that when the machine tools in manufacturing the coordination of various assemblies will produce geometric error. Due to the high speed and high temperature, and if cooling is not timely, produce thermal error will be produced; the weight of NC machine tool is much heavier, in the process of cutting, it will produce vibration, and also cause the deformation in cutting; Servo system of machine tool, in the process of producing power, will also under the influence of voltage and current, causing errors; In addition. NC machine will also be affected by external factors. In the previous production, usually the direct measurement error is adopted, and the positioning error is taken as an example to show its principle [9, 10, 11, 12].

2.1 The direct measurement of positioning error in machine tool space

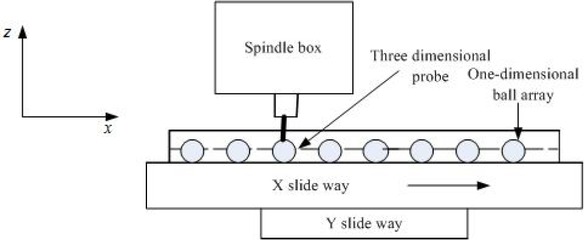

Because the existing methods cannot directly measure error vector, the traditional method is a one-dimensional ball array measuring the error of single unit in NC machine tool, the analysis conducted also needs subsequent calculation and other studies, and the work needed to be done is very large. As shown in Figure 1, the one-dimensional ball sequence is neatly ranked above the machine tool, and then the position of one-dimensional sequence is adjusted parallel to the position of the X axis. Through the three-dimensional camera on the principal axis of machine tool [13], the coordinates location of centre of each ball in ball series can be measured, the positioning of machine tools is the difference value, the formula used is shown as follows:

The structure diagram of one-dimensional ball measuring method

Of which, Xi refers to the center of ball distance value in the machine tool, Li refers to the reference value of distance between the balls, δx(Xi) refers to the positioning error values of X coordinate axis in the location of i.

2.2 The measurement principle of laser testing

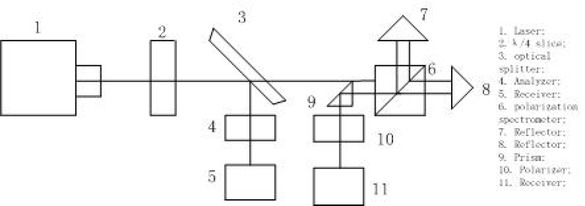

The measuring principle of laser interferometer is as shown in Figure 2. The principle of laser interferometer is achieved using the interference principle of light principle, and also combining with the Doppler Effect [14, 15, 16]. The two laser beams in Figure 2 have equal amplitude and different frequency, the specific working process is as follows: the laser 1 located in right sends out the light, and goes through λ/4 slice in Figure 2, then the light changes into different linear polarized light. Using the optical splitter 3, part of the light is reflected, therefore through analyzer 4, the light will form different frequency signals, and then the signals are accepted by the receiver 5; This part of signal is known as the reference signal [17, 18]. In the figure, the number 3 represents the optical splitter, and the rest of beam can be spread to polarization spectrometer 6 through the beam splitter, so the two beams, through their respective reflector 7 and 8, finally converge to the polarization spectrometer. Through the reflection of prism 9, transfer to the polarizer 10, finally received by receiver, this is the final measuring signal.

The measuring principle diagram of the laser interference

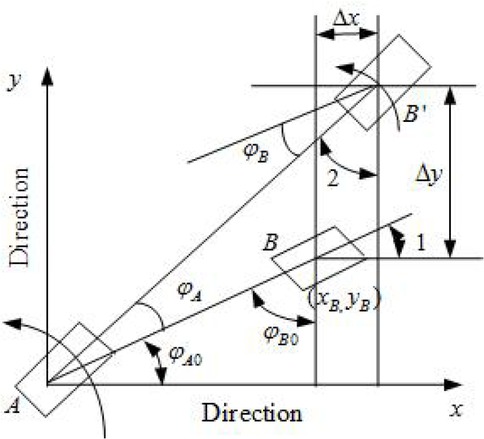

On the basis of the above laser interference, the alignment settings is increased, as for the working principle, it is as follows: the alignment principle of xy plane is as shown in Figure 3. A stands for interferoscope, B represents reflector, and B can be expressed as (xB, yB), when the reflector B rotating to B’, the values in the direction x, y increases Δx and Δy, when rotating B, the light beam occurs deflection, and the interferoscope should go around z rotating a certain angle to keep the position of the beam, the reflector should rotate to keep balance. In the figure, the rotating angle of interferoscope A at the beginning is as follows:

The reflection principle of xy plane

The initial angle of the reflector B is as follows:

The interferoscope should rotate the following angle:

It can be seen from the figure that:

From the above formula, it can be concluded that the angle of reflector is equal to that of interferoscope. The angle that the reflector should rotate can be obtained as follows:

3 Results

3.1 The error measurement of NC machine tool

The experiment, adopting model XL-80 laser interferometer system, carries out direct measurement and also analysis on positioning error in coordinate axis and the error in the vertical direction of 3-axis NC machine tool. Due to the limited experimental conditions, the other errors are not analyzed. The positioning error is the difference between the actual position and target position, and it is an important index of machine tool accuracy, reflecting comprehensively the manufacturing assembly accuracy of mechanical part, feedback control accuracy of numerical control system and the thermal and mechanical coupling properties between the machine tool and environment.

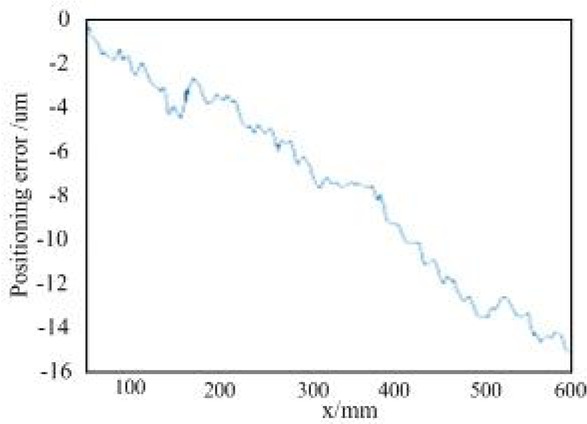

The positioning error in X axis is as shown in Figure 4, the positioning error turns a downward trend as a whole, in the process of falling, the fluctuation is much smaller, and the overall trend is relatively stable, the maximum error is 15.1μm, occurring in the location x = 600 mm.

The positioning error in x axis

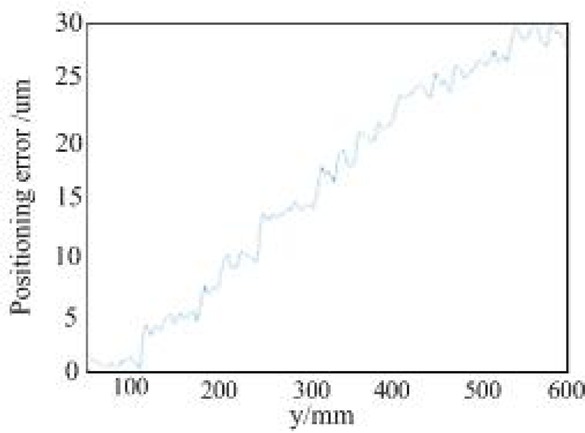

As shown in Figure 5, compared with the positioning error in X axis, the change trend of the positioning error in Y axis presents the overall upward trend, though in the middle there is a relatively small fluctuations, the overall increasing state is relatively stable. Observing the error values, it can be found that the obtained value is relatively high, the maximum error is about 28.56μm, lying in the location y = 445 mm approximately. Because the gap existing between ball screws causes the error, so the error value will turn a rising trend with the increasing of y value.

The positioning error in y axis

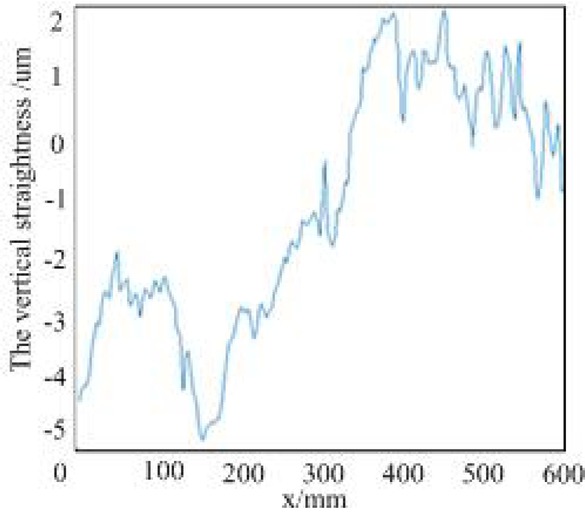

Unlike the above positioning error, the straightness error in X axis shows very small. As shown in Figure 6, the straightness error in vertical direction of X axis shows a trend of increase first and then decrease during the route 0-130 mm, afterward it increase dramatically during the route 130-280 mm, it can be seen that the image start to fluctuate in the location 1.8μm, and in the location about x = 400 mm, the error produced by slide way in the location 400-600 mm is the largest, because products are often processed on the slide way, generating larger error. In general, it can be seen that if the value of x is larger, the error generated shows a rising trend.

The error in vertical direction of x axis

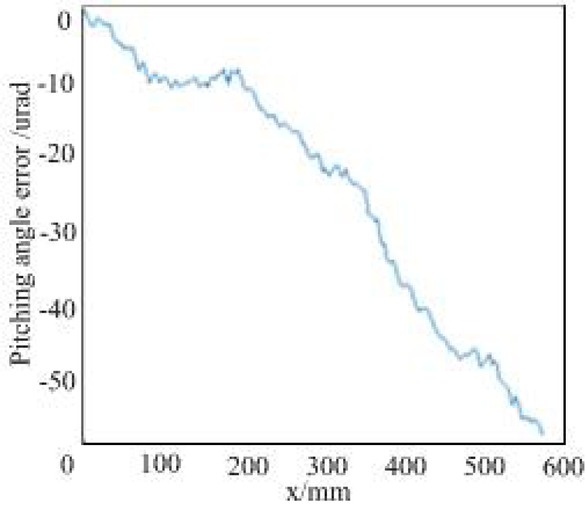

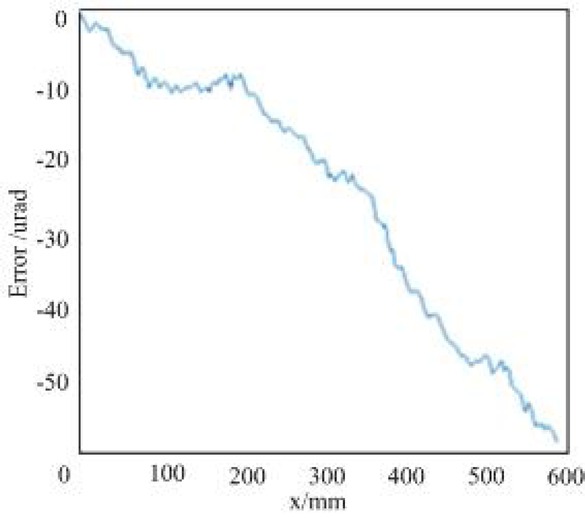

In the pitching angle error of NC machine tool, as for the X axis, the pitching angle error in the process of route increasing presents a downward trend, due to the error has nothing to do with the positive and negative, it can be seen that the error becomes larger with the increase of route, and the maximum lies in the location about −56 um. It is as shown in Figure 7:

The pitching angle error in x axis

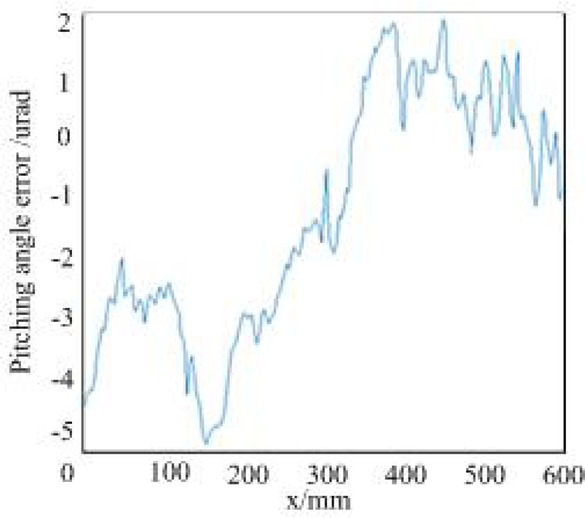

In the process of y axis movement, as shown in Figure 8, the pitching angle error becomes larger with the increase of route y, the maximum is about 12um, far less than the error in X axis,what’s more it fluctuate more noticeable in the middle.

The pitching angle error in y axis

3.2 The error compensation of NC machine tool

Though the error of NC machine tool caused by many reasons, through a lot of experiments it can be seen that the error has its regularity, and the value of error will maintain relative stability in the position of machine tool movement. Therefore the error can be simple measured, getting the rule and obtaining the compensated values. As for the error of NC machine tool, the most fundamental thing is to realize the error detection in the process of machine tool movement, get the size of the deviation and find the rule, then conduct effective compensation of NC machine tools.

The laser measurement technology not only measures the error of NC machine tool with high precision but also its automatic aiming system can realize error compensation.

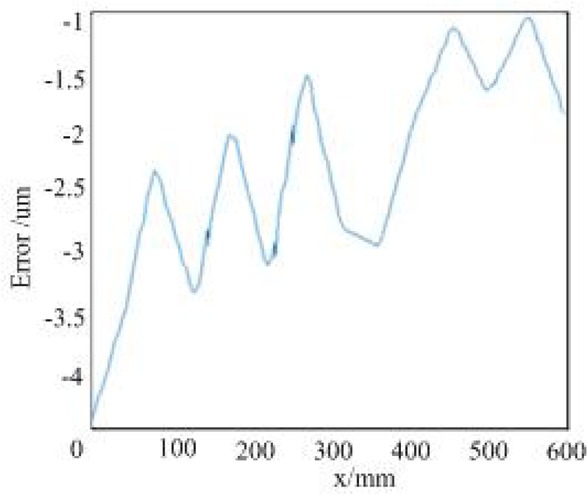

The effect of compensation can be proved through experiment, and Figure 9 shows that before the compensation, the error range of laser interferometer measurement is between −15 and 10, it also can be seen that its error becomes larger with the increase of the route, the change trend is very obvious. In Figure 10, after the compensation of laser interferometer measurement error, it can be seen that the error range is between −4 and −1, although the fluctuation in the middle is more noticeable, the amplitude value is very small, realizing the processing compensation of NC machine tools. The error effect is very obvious.

The error before compensation in x axis

The error after ompensation in x axis

In the current error detection of NC machine tool, thermal error is also existed. The forming reason of thermal error of NC machine tool is complex temperature field. In the process of machine tool movement the generated lots of heat and deformation make the machine tool produce thermal error. Measuring the temperature of machine tool at different time can get the changing rule of thermal error of machine tool, so the error amount can be obtained. In the aspect of thermal error, the sensor is installed to get the wanted value. The laser testing technology can measure the thermal error, and mathematical model is also needed to establish.

4 Conclusion

Laser testing technology, as the method measuring the machine tool error, has a good effect. The principle of automatic aiming of laser testing in the NC machine tool is studied, and the feasibility of automatic aiming system is proved. Based on the technology of laser testing, the error in the operation of the machine tool can be got, obtaining the deviation of NC machine tool more simple and accurate, and also conducting compensation effectively. The laser testing technology, as the high accuracy measuring technology, gets rid of traditional direct measurement shortcomings and improves the error precision of the NC machine tools. It has larger significance for the production of NC machine tools. But good feedback design isn’t achieved in this study, worthy to be studied continuous in the future.

Acknowledgement

This research was supported by Ministry of education: Beijing Bai Ke Rong Chuang Production-study Cooperation and Collaborative Education Project (No. 20160211006); Science and Technology Project of Henan Province Science and Technology Department (182102110301); Henan Education Department Project (18A210014).

References

[1] Peng W., Li D., Zhang M., et al., Characteristics of antibacterial molecular activities in poplar wood extractives, Saudi Journal of Biological Sciences, 2017, 24(2), 399-404.10.1016/j.sjbs.2015.10.026Suche in Google Scholar PubMed PubMed Central

[2] Yang Y., Zhong M., et al., Postolache, Internet of things for smart ports: Technologies and challenges, Ieee Instrumentation & Measurement Magazine, 2018, 21(1), 34-43.10.1016/j.iot.2018.08.011Suche in Google Scholar

[3] Aladadi W.M., Moustafa M.F., et al., Genetic variability among seven cultivars of date palm (&ITPhoenix dactylifera &ITL.) based on embryonic DNA of old fruit, Kuwait Journal of Science, 2018, 45(1), 108-114.Suche in Google Scholar

[4] Kalaivani N., El-Maghrabi A.I., et al., Operation-compact spaces, regular spaces and normal spaces with –open sets in topological spaces, Journal of Interdisciplinary Mathematics, 2017, 20(2), 427-441.10.1080/09720502.2015.1104945Suche in Google Scholar

[5] Ben Taher R., Naassi N., et al., On the Leslie matrices, Fibonacci sequences and population dynamics, Journal of Discrete Mathematical Sciences and Cryptography, 2017, 20(2), 565-594.10.1080/09720529.2016.1241545Suche in Google Scholar

[6] Bonanno G., D’Agui G., et al., One-dimensional nonlinear boundary value problems with variable exponent, Discrete and Continuous Dynamical Systems-Series S, 2018, 11(2SI), 179-191.10.3934/dcdss.2018011Suche in Google Scholar

[7] Iannizzotto A., Papageorgiou N.S., Existence and multiplicity results for resonant fractional boundary value problems, Discrete and Continuous Dynamical Systems-Series S, 2018, 11(3SI), 511-532.10.3934/dcdss.2018028Suche in Google Scholar

[8] Li R., Taylor M.M., The first zagreb index and some hamiltonian properties of the line graph of a graph, Journal of Discrete Mathematical Sciences and Cryptography, 2017, 20(2), 445-451.10.1080/09720529.2015.1103009Suche in Google Scholar

[9] Hou J., Wen Z., Lai J., A constrained optimization reformulation of the generalized Nash equilibrium problem, Journal of Interdisciplinary Mathematics, 2017, 20(1), 27-34.10.1080/09720502.2016.1258833Suche in Google Scholar

[10] Adiyaman M.E., Oger V., A residual method using Bezier curves for singular nonlinear equations of Lane-Emden type, Kuwait Journal of Science, 2017, 44(4), 9-18.Suche in Google Scholar

[11] Yang A., Han Y., Li S., Xing H., Pan Y., Liu W., Synthesis and comparison of photocatalytic properties for Bi2WO6 nanofibers and hierarchical microspheres, Journal of Alloys and Compounds, 2017, 695, 915-921.10.1016/j.jallcom.2016.10.188Suche in Google Scholar

[12] Shen Y., Zhao N., Xia M., Du X., A deep q-learning network for ship stowage planning problem, Polish Maritime Research, 2017, 24(SI), 102-109.10.1515/pomr-2017-0111Suche in Google Scholar

[13] Gao W.,Wang W.F., The fifth geometric-arithmetic index of bridge graph and carbon nanocones, Journal of Difference Equations and Applications, 2017, 23, 100-109.10.1080/10236198.2016.1197214Suche in Google Scholar

[14] Malviya P.S., Yadav N., Ghosh S., Acousto-Optic modulation in ion implanted semiconductor plasmas having SDDC, Applied Mathematics & Nonlinear Sciences, 2018, 3, 303-310.10.21042/AMNS.2018.1.00023Suche in Google Scholar

[15] Mi C., Shen Y., Mi W.J., Huang Y.F., Ship identification algorithm based on 3D point cloud for automated ship loaders, Journal of Coastal Research, 2015, (73), 28-34.10.2112/SI73-006.1Suche in Google Scholar

[16] Nizami A.R., Perveen A., Nazeer W., Baqir M., WALK POLYNOMIAL: a new graph invariant, Applied Mathematics & Nonlinear Sciences, 2018, 3, 321-330.10.21042/AMNS.2018.1.00025Suche in Google Scholar

[17] Pandey P.K., Jaboob S.S.A., A finite difference method for a numerical solution of elliptic boundary value problems, Applied Mathematics & Nonlinear Sciences, 2018, 3, 311-320.10.21042/AMNS.2018.1.00024Suche in Google Scholar

[18] Vajravelu K., Li R., Dewasurendra M., Benarroch J., Ossi N., Zhang Y., Sammarco M., Prasad K.V., Effects of second-order slip and drag reduction in boundary layer flows, Applied Mathematics & Nonlinear Sciences, 2018, 3, 291-302.10.21042/AMNS.2018.1.00022Suche in Google Scholar

© 2019 Q. Gao and P. Zhang, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Non-equilibrium Phase Transitions in 2D Small-World Networks: Competing Dynamics

- Harmonic waves solution in dual-phase-lag magneto-thermoelasticity

- Multiplicative topological indices of honeycomb derived networks

- Zagreb Polynomials and redefined Zagreb indices of nanostar dendrimers

- Solar concentrators manufacture and automation

- Idea of multi cohesive areas - foundation, current status and perspective

- Derivation method of numerous dynamics in the Special Theory of Relativity

- An application of Nwogu’s Boussinesq model to analyze the head-on collision process between hydroelastic solitary waves

- Competing Risks Model with Partially Step-Stress Accelerate Life Tests in Analyses Lifetime Chen Data under Type-II Censoring Scheme

- Group velocity mismatch at ultrashort electromagnetic pulse propagation in nonlinear metamaterials

- Investigating the impact of dissolved natural gas on the flow characteristics of multicomponent fluid in pipelines

- Analysis of impact load on tubing and shock absorption during perforating

- Energy characteristics of a nonlinear layer at resonant frequencies of wave scattering and generation

- Ion charge separation with new generation of nuclear emulsion films

- On the influence of water on fragmentation of the amino acid L-threonine

- Formulation of heat conduction and thermal conductivity of metals

- Displacement Reliability Analysis of Submerged Multi-body Structure’s Floating Body for Connection Gaps

- Deposits of iron oxides in the human globus pallidus

- Integrability, exact solutions and nonlinear dynamics of a nonisospectral integral-differential system

- Bounds for partition dimension of M-wheels

- Visual Analysis of Cylindrically Polarized Light Beams’ Focal Characteristics by Path Integral

- Analysis of repulsive central universal force field on solar and galactic dynamics

- Solitary Wave Solution of Nonlinear PDEs Arising in Mathematical Physics

- Understanding quantum mechanics: a review and synthesis in precise language

- Plane Wave Reflection in a Compressible Half Space with Initial Stress

- Evaluation of the realism of a full-color reflection H2 analog hologram recorded on ultra-fine-grain silver-halide material

- Graph cutting and its application to biological data

- Time fractional modified KdV-type equations: Lie symmetries, exact solutions and conservation laws

- Exact solutions of equal-width equation and its conservation laws

- MHD and Slip Effect on Two-immiscible Third Grade Fluid on Thin Film Flow over a Vertical Moving Belt

- Vibration Analysis of a Three-Layered FGM Cylindrical Shell Including the Effect Of Ring Support

- Hybrid censoring samples in assessment the lifetime performance index of Chen distributed products

- Study on the law of coal resistivity variation in the process of gas adsorption/desorption

- Mapping of Lineament Structures from Aeromagnetic and Landsat Data Over Ankpa Area of Lower Benue Trough, Nigeria

- Beta Generalized Exponentiated Frechet Distribution with Applications

- INS/gravity gradient aided navigation based on gravitation field particle filter

- Electrodynamics in Euclidean Space Time Geometries

- Dynamics and Wear Analysis of Hydraulic Turbines in Solid-liquid Two-phase Flow

- On Numerical Solution Of The Time Fractional Advection-Diffusion Equation Involving Atangana-Baleanu-Caputo Derivative

- New Complex Solutions to the Nonlinear Electrical Transmission Line Model

- The effects of quantum spectrum of 4 + n-dimensional water around a DNA on pure water in four dimensional universe

- Quantum Phase Estimation Algorithm for Finding Polynomial Roots

- Vibration Equation of Fractional Order Describing Viscoelasticity and Viscous Inertia

- The Errors Recognition and Compensation for the Numerical Control Machine Tools Based on Laser Testing Technology

- Evaluation and Decision Making of Organization Quality Specific Immunity Based on MGDM-IPLAO Method

- Key Frame Extraction of Multi-Resolution Remote Sensing Images Under Quality Constraint

- Influences of Contact Force towards Dressing Contiguous Sense of Linen Clothing

- Modeling and optimization of urban rail transit scheduling with adaptive fruit fly optimization algorithm

- The pseudo-limit problem existing in electromagnetic radiation transmission and its mathematical physics principle analysis

- Chaos synchronization of fractional–order discrete–time systems with different dimensions using two scaling matrices

- Stress Characteristics and Overload Failure Analysis of Cemented Sand and Gravel Dam in Naheng Reservoir

- A Big Data Analysis Method Based on Modified Collaborative Filtering Recommendation Algorithms

- Semi-supervised Classification Based Mixed Sampling for Imbalanced Data

- The Influence of Trading Volume, Market Trend, and Monetary Policy on Characteristics of the Chinese Stock Exchange: An Econophysics Perspective

- Estimation of sand water content using GPR combined time-frequency analysis in the Ordos Basin, China

- Special Issue Applications of Nonlinear Dynamics

- Discrete approximate iterative method for fuzzy investment portfolio based on transaction cost threshold constraint

- Multi-objective performance optimization of ORC cycle based on improved ant colony algorithm

- Information retrieval algorithm of industrial cluster based on vector space

- Parametric model updating with frequency and MAC combined objective function of port crane structure based on operational modal analysis

- Evacuation simulation of different flow ratios in low-density state

- A pointer location algorithm for computer visionbased automatic reading recognition of pointer gauges

- A cloud computing separation model based on information flow

- Optimizing model and algorithm for railway freight loading problem

- Denoising data acquisition algorithm for array pixelated CdZnTe nuclear detector

- Radiation effects of nuclear physics rays on hepatoma cells

- Special issue: XXVth Symposium on Electromagnetic Phenomena in Nonlinear Circuits (EPNC2018)

- A study on numerical integration methods for rendering atmospheric scattering phenomenon

- Wave propagation time optimization for geodesic distances calculation using the Heat Method

- Analysis of electricity generation efficiency in photovoltaic building systems made of HIT-IBC cells for multi-family residential buildings

- A structural quality evaluation model for three-dimensional simulations

- WiFi Electromagnetic Field Modelling for Indoor Localization

- Modeling Human Pupil Dilation to Decouple the Pupillary Light Reflex

- Principal Component Analysis based on data characteristics for dimensionality reduction of ECG recordings in arrhythmia classification

- Blinking Extraction in Eye gaze System for Stereoscopy Movies

- Optimization of screen-space directional occlusion algorithms

- Heuristic based real-time hybrid rendering with the use of rasterization and ray tracing method

- Review of muscle modelling methods from the point of view of motion biomechanics with particular emphasis on the shoulder

- The use of segmented-shifted grain-oriented sheets in magnetic circuits of small AC motors

- High Temperature Permanent Magnet Synchronous Machine Analysis of Thermal Field

- Inverse approach for concentrated winding surface permanent magnet synchronous machines noiseless design

- An enameled wire with a semi-conductive layer: A solution for a better distibution of the voltage stresses in motor windings

- High temperature machines: topologies and preliminary design

- Aging monitoring of electrical machines using winding high frequency equivalent circuits

- Design of inorganic coils for high temperature electrical machines

- A New Concept for Deeper Integration of Converters and Drives in Electrical Machines: Simulation and Experimental Investigations

- Special Issue on Energetic Materials and Processes

- Investigations into the mechanisms of electrohydrodynamic instability in free surface electrospinning

- Effect of Pressure Distribution on the Energy Dissipation of Lap Joints under Equal Pre-tension Force

- Research on microstructure and forming mechanism of TiC/1Cr12Ni3Mo2V composite based on laser solid forming

- Crystallization of Nano-TiO2 Films based on Glass Fiber Fabric Substrate and Its Impact on Catalytic Performance

- Effect of Adding Rare Earth Elements Er and Gd on the Corrosion Residual Strength of Magnesium Alloy

- Closed-die Forging Technology and Numerical Simulation of Aluminum Alloy Connecting Rod

- Numerical Simulation and Experimental Research on Material Parameters Solution and Shape Control of Sandwich Panels with Aluminum Honeycomb

- Research and Analysis of the Effect of Heat Treatment on Damping Properties of Ductile Iron

- Effect of austenitising heat treatment on microstructure and properties of a nitrogen bearing martensitic stainless steel

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical simulation of welding distortions in large structures with a simplified engineering approach

- Investigation on the effect of electrode tip on formation of metal droplets and temperature profile in a vibrating electrode electroslag remelting process

- Effect of North Wall Materials on the Thermal Environment in Chinese Solar Greenhouse (Part A: Experimental Researches)

- Three-dimensional optimal design of a cooled turbine considering the coolant-requirement change

- Theoretical analysis of particle size re-distribution due to Ostwald ripening in the fuel cell catalyst layer

- Effect of phase change materials on heat dissipation of a multiple heat source system

- Wetting properties and performance of modified composite collectors in a membrane-based wet electrostatic precipitator

- Implementation of the Semi Empirical Kinetic Soot Model Within Chemistry Tabulation Framework for Efficient Emissions Predictions in Diesel Engines

- Comparison and analyses of two thermal performance evaluation models for a public building

- A Novel Evaluation Method For Particle Deposition Measurement

- Effect of the two-phase hybrid mode of effervescent atomizer on the atomization characteristics

- Erratum

- Integrability analysis of the partial differential equation describing the classical bond-pricing model of mathematical finance

- Erratum to: Energy converting layers for thin-film flexible photovoltaic structures

Artikel in diesem Heft

- Regular Articles

- Non-equilibrium Phase Transitions in 2D Small-World Networks: Competing Dynamics

- Harmonic waves solution in dual-phase-lag magneto-thermoelasticity

- Multiplicative topological indices of honeycomb derived networks

- Zagreb Polynomials and redefined Zagreb indices of nanostar dendrimers

- Solar concentrators manufacture and automation

- Idea of multi cohesive areas - foundation, current status and perspective

- Derivation method of numerous dynamics in the Special Theory of Relativity

- An application of Nwogu’s Boussinesq model to analyze the head-on collision process between hydroelastic solitary waves

- Competing Risks Model with Partially Step-Stress Accelerate Life Tests in Analyses Lifetime Chen Data under Type-II Censoring Scheme

- Group velocity mismatch at ultrashort electromagnetic pulse propagation in nonlinear metamaterials

- Investigating the impact of dissolved natural gas on the flow characteristics of multicomponent fluid in pipelines

- Analysis of impact load on tubing and shock absorption during perforating

- Energy characteristics of a nonlinear layer at resonant frequencies of wave scattering and generation

- Ion charge separation with new generation of nuclear emulsion films

- On the influence of water on fragmentation of the amino acid L-threonine

- Formulation of heat conduction and thermal conductivity of metals

- Displacement Reliability Analysis of Submerged Multi-body Structure’s Floating Body for Connection Gaps

- Deposits of iron oxides in the human globus pallidus

- Integrability, exact solutions and nonlinear dynamics of a nonisospectral integral-differential system

- Bounds for partition dimension of M-wheels

- Visual Analysis of Cylindrically Polarized Light Beams’ Focal Characteristics by Path Integral

- Analysis of repulsive central universal force field on solar and galactic dynamics

- Solitary Wave Solution of Nonlinear PDEs Arising in Mathematical Physics

- Understanding quantum mechanics: a review and synthesis in precise language

- Plane Wave Reflection in a Compressible Half Space with Initial Stress

- Evaluation of the realism of a full-color reflection H2 analog hologram recorded on ultra-fine-grain silver-halide material

- Graph cutting and its application to biological data

- Time fractional modified KdV-type equations: Lie symmetries, exact solutions and conservation laws

- Exact solutions of equal-width equation and its conservation laws

- MHD and Slip Effect on Two-immiscible Third Grade Fluid on Thin Film Flow over a Vertical Moving Belt

- Vibration Analysis of a Three-Layered FGM Cylindrical Shell Including the Effect Of Ring Support

- Hybrid censoring samples in assessment the lifetime performance index of Chen distributed products

- Study on the law of coal resistivity variation in the process of gas adsorption/desorption

- Mapping of Lineament Structures from Aeromagnetic and Landsat Data Over Ankpa Area of Lower Benue Trough, Nigeria

- Beta Generalized Exponentiated Frechet Distribution with Applications

- INS/gravity gradient aided navigation based on gravitation field particle filter

- Electrodynamics in Euclidean Space Time Geometries

- Dynamics and Wear Analysis of Hydraulic Turbines in Solid-liquid Two-phase Flow

- On Numerical Solution Of The Time Fractional Advection-Diffusion Equation Involving Atangana-Baleanu-Caputo Derivative

- New Complex Solutions to the Nonlinear Electrical Transmission Line Model

- The effects of quantum spectrum of 4 + n-dimensional water around a DNA on pure water in four dimensional universe

- Quantum Phase Estimation Algorithm for Finding Polynomial Roots

- Vibration Equation of Fractional Order Describing Viscoelasticity and Viscous Inertia

- The Errors Recognition and Compensation for the Numerical Control Machine Tools Based on Laser Testing Technology

- Evaluation and Decision Making of Organization Quality Specific Immunity Based on MGDM-IPLAO Method

- Key Frame Extraction of Multi-Resolution Remote Sensing Images Under Quality Constraint

- Influences of Contact Force towards Dressing Contiguous Sense of Linen Clothing

- Modeling and optimization of urban rail transit scheduling with adaptive fruit fly optimization algorithm

- The pseudo-limit problem existing in electromagnetic radiation transmission and its mathematical physics principle analysis

- Chaos synchronization of fractional–order discrete–time systems with different dimensions using two scaling matrices

- Stress Characteristics and Overload Failure Analysis of Cemented Sand and Gravel Dam in Naheng Reservoir

- A Big Data Analysis Method Based on Modified Collaborative Filtering Recommendation Algorithms

- Semi-supervised Classification Based Mixed Sampling for Imbalanced Data

- The Influence of Trading Volume, Market Trend, and Monetary Policy on Characteristics of the Chinese Stock Exchange: An Econophysics Perspective

- Estimation of sand water content using GPR combined time-frequency analysis in the Ordos Basin, China

- Special Issue Applications of Nonlinear Dynamics

- Discrete approximate iterative method for fuzzy investment portfolio based on transaction cost threshold constraint

- Multi-objective performance optimization of ORC cycle based on improved ant colony algorithm

- Information retrieval algorithm of industrial cluster based on vector space

- Parametric model updating with frequency and MAC combined objective function of port crane structure based on operational modal analysis

- Evacuation simulation of different flow ratios in low-density state

- A pointer location algorithm for computer visionbased automatic reading recognition of pointer gauges

- A cloud computing separation model based on information flow

- Optimizing model and algorithm for railway freight loading problem

- Denoising data acquisition algorithm for array pixelated CdZnTe nuclear detector

- Radiation effects of nuclear physics rays on hepatoma cells

- Special issue: XXVth Symposium on Electromagnetic Phenomena in Nonlinear Circuits (EPNC2018)

- A study on numerical integration methods for rendering atmospheric scattering phenomenon

- Wave propagation time optimization for geodesic distances calculation using the Heat Method

- Analysis of electricity generation efficiency in photovoltaic building systems made of HIT-IBC cells for multi-family residential buildings

- A structural quality evaluation model for three-dimensional simulations

- WiFi Electromagnetic Field Modelling for Indoor Localization

- Modeling Human Pupil Dilation to Decouple the Pupillary Light Reflex

- Principal Component Analysis based on data characteristics for dimensionality reduction of ECG recordings in arrhythmia classification

- Blinking Extraction in Eye gaze System for Stereoscopy Movies

- Optimization of screen-space directional occlusion algorithms

- Heuristic based real-time hybrid rendering with the use of rasterization and ray tracing method

- Review of muscle modelling methods from the point of view of motion biomechanics with particular emphasis on the shoulder

- The use of segmented-shifted grain-oriented sheets in magnetic circuits of small AC motors

- High Temperature Permanent Magnet Synchronous Machine Analysis of Thermal Field

- Inverse approach for concentrated winding surface permanent magnet synchronous machines noiseless design

- An enameled wire with a semi-conductive layer: A solution for a better distibution of the voltage stresses in motor windings

- High temperature machines: topologies and preliminary design

- Aging monitoring of electrical machines using winding high frequency equivalent circuits

- Design of inorganic coils for high temperature electrical machines

- A New Concept for Deeper Integration of Converters and Drives in Electrical Machines: Simulation and Experimental Investigations

- Special Issue on Energetic Materials and Processes

- Investigations into the mechanisms of electrohydrodynamic instability in free surface electrospinning

- Effect of Pressure Distribution on the Energy Dissipation of Lap Joints under Equal Pre-tension Force

- Research on microstructure and forming mechanism of TiC/1Cr12Ni3Mo2V composite based on laser solid forming

- Crystallization of Nano-TiO2 Films based on Glass Fiber Fabric Substrate and Its Impact on Catalytic Performance

- Effect of Adding Rare Earth Elements Er and Gd on the Corrosion Residual Strength of Magnesium Alloy

- Closed-die Forging Technology and Numerical Simulation of Aluminum Alloy Connecting Rod

- Numerical Simulation and Experimental Research on Material Parameters Solution and Shape Control of Sandwich Panels with Aluminum Honeycomb

- Research and Analysis of the Effect of Heat Treatment on Damping Properties of Ductile Iron

- Effect of austenitising heat treatment on microstructure and properties of a nitrogen bearing martensitic stainless steel

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical simulation of welding distortions in large structures with a simplified engineering approach

- Investigation on the effect of electrode tip on formation of metal droplets and temperature profile in a vibrating electrode electroslag remelting process

- Effect of North Wall Materials on the Thermal Environment in Chinese Solar Greenhouse (Part A: Experimental Researches)

- Three-dimensional optimal design of a cooled turbine considering the coolant-requirement change

- Theoretical analysis of particle size re-distribution due to Ostwald ripening in the fuel cell catalyst layer

- Effect of phase change materials on heat dissipation of a multiple heat source system

- Wetting properties and performance of modified composite collectors in a membrane-based wet electrostatic precipitator

- Implementation of the Semi Empirical Kinetic Soot Model Within Chemistry Tabulation Framework for Efficient Emissions Predictions in Diesel Engines

- Comparison and analyses of two thermal performance evaluation models for a public building

- A Novel Evaluation Method For Particle Deposition Measurement

- Effect of the two-phase hybrid mode of effervescent atomizer on the atomization characteristics

- Erratum

- Integrability analysis of the partial differential equation describing the classical bond-pricing model of mathematical finance

- Erratum to: Energy converting layers for thin-film flexible photovoltaic structures