Abstract

The paper presents the design of a machine that can work at high temperature. The impact of various topologies and materials on electromagnetic field distribution and losses was analyzed. Two and three-dimensional simulations were carried out. The results obtained were discussed.

1 Introduction

The general trend in the aircraft industry is to replace hydraulic and pneumatic actuators with electrical machines (more electric aircraft concept). The aircraft industry could derive an interesting profit from powerful and compact generators able to operate in the vicinity of the propulsion turbines. In recent years, many works have been carried out [1, 2, 3, 4, 5, 6] regarding compact systems containing electrical machines and electronic components. The project presented in this paper concerns the design of the machine

that can work at an ambient temperature higher than 200∘C. Permanent Magnet Synchronous Machine (PMSM) who can work in the ambient temperature of about 200∘C, will have a hottest points of order 450-500∘C. For high power densities and high ambient temperature, the hottest points of the machine, is much over the capabilities of best polymers that are able to work up to of more or less 240∘C during 2000h. So we decide to replace the polymer by inorganic insulation [7, 8, 9]. The inorganic insulation materials have no mechanical flexibility; therefore, it is impossible to build classical distributed stator windings. The only option is to design concentrated windings with rigid coils placed on the stator teeth. The windings must be made of simple-shaped coils which are rigid objects encapsulated with a high temperature cement. The fractional number of teeth per pole topology requires a specific electromagnetic design for limiting the cogging torque and the additional losses due to eddy currents. With such a winding structure, only Permanent Magnet Synchronous Machine (PMSM) and Doubly Salient Reluctance Machines (DSRM) structures are possible. The paper focuses on PMSMs. For this type of machine special attention to the right selection of magnets must be pay. The best magnets are magnets built with SmCo. This material have unfortunately a higher electric conductivity [10, 11, 12, 13, 14, 15, 16, 17] than other permanent magnets materials. This fact should be considered when designing the machine. To properly adjust the machine parameters, various designs and materials were verified. Two structures are available for rotor: the magnets can be placed on the external surface of the rotor or buried in the soft magnetic part of the rotor. The first option is easier to achieve but it places the magnets near the stator coils that is in the high temperature. The second places the magnets inside the rotor core. The flux is concentrated towards the air-gap by the more complex shape of the soft magnetic rotor poles. The opened slots of the stator create flux density harmonics in the air-gap of the machine that influence additional losses due to eddy currents. To avoid this problem, wedges closing the stator slots are used. The influence of wedges on field distribution and losses for various wedges materials were analysed. To compute thelosses and verify the influence of design and materials the time-stepping 2D simulation was made. To verify the eddy currents and their impact on losses, the 3D calculations are necessary, because the 2D model assuming the infinite length of the machine for eddy currents generates significant errors. Because the paper concerns material verification and machine construction, in the first row we will discuss the topologies of the machine and the existing possibilities that can be checked at high temperatures. Next, the simulation by the finite elements method will be carried out and the different options of the rotor will be examined. Then the influence of wedges closing the slots on the machine parameters will be verified.

2 Topologies of high temperature machine

In this section, we will discuss the particular materials used to construct electrical machine capable to operating at high temperature. Working at a temperature of 500∘C requires exact checking of all materials such as for example glues and welds.

2.1 Magnetic sheets

The magnetic circuit of the alternating currents power machines is built with sheets insulated between them. Some sheets available as "fully processed" are coated with an organic layer. It is not advisable to use these products for machines operating at high temperatures. The sheets based on FeCo or FeSi are naturally overlap with an iron oxide layer during the manufacturing process. The overlap of iron oxide ensure insulation preventing the eddy currents. The behavior of non oriented magnetic sheets in the high temperature were examined by the team of University of Okayama [18, 19]. The measurements were made on 0.35mm thickness, naturally isolated with iron oxide. The iron losses in function of temperature naturally decrease. This is due to the fact that the resistivity increase with temperature. Similar results as for anisotropic sheets were obtained for isotropic sheets making a stator with sheets shifted by ninety degrees [20]. The soft magnetic circuit can be also build with cobalt and iron alloys. Likewise the several alloys offer a good solutions. It is clear therefore that the selection of sheet does not represent a crucial problem.

2.2 Permanent magnets

The documentation of the manufacturers summarizes the technologies available in HT∘. The excellent magnets made of neodymium alloys, iron, and boron usually used to build synchronous machines do not support very high temperatures. AlNiCo,which accepts temperatures of 450∘C, cannot be used to build synchronous machines because it requires in situ magnetization. This is due to its very low coercive field. Only Cobalt’s Samarium-based alloys maintain reasonable inductions, with high coercive fields, down to just over 300∘C. The magnet is therefore a critical element that constitutes a technological lock to reach very high temperatures. For this reason, emphasis should be put on the analysis of hot spots around the permanent magnets.

2.3 Insulated wires for windings

Two types of metals are used for the construction of the windings: copper and aluminum. Aluminum has a relatively low melting temperature and its electrical characteristics are not very good at high temperatures because its resistivity increases much with temperature. For copper, the oxidation problem is preponderant [21, 22]. Copper must be protected if we want to use it at high temperature. Nickel-plated copper wires are commercially available. The protective nickel layer is thicker the higher is the nominal temperature of the product.

2.4 The connections between the wires

The connections between wires are critical points. The solders made from lead and tin, typically used are only able to fulfill their role up to 200∘C. Beyond this temperature, alloys with high melting points resistant to oxidation are needed. These alloys are solders based on copper (Cu), nickel (Ni), silver (Ag) or manganese (Mn), which are resistant to oxidation, but whose implementation is carried out at higher temperatures.

2.5 Inter-turn insulation

Insulations between coils operating at high temperature must be characterized by high resistance to voltage, the ability to withstand temperature gradients and mechanical stress with acceptable degradation of dielectric properties.

There are several technologies for isolating the turns of a machine:

The conventional polymeric isolations that are temperature limited. Polymers are insulating materials composed of carbon-based macromolecules. Machines operating at temperatures of 240∘C are isolated with Polyimide (PI) [23]). The yarns are impregnated with varnishes of the same type to guarantee a good solidity and an effective barrier against pollutants. Polymeric varnishes also have good mechanical flexibility which makes possible winding operations. They are also able to absorb internal and external vibrations during the operation of the machine.

Mica is also a good insulation solution for high temperature machines. It is widely used for the insulation of very high power and high voltage machines (power plants). On the market, laminated mica is found on a fiberglass ribbon which allows for some flexibility, and is also available in the form of sheets. This type of insulation can be used up to 450∘C-600∘C [27, 28].

In a high temperature electric machine it is essential to use a fully inorganic EIS. For the design of the high temperature coil, materials that resist up to 500∘C must be used.

2.6 Inorganic bottom insulators

In the case of bottom insulation several solutions are available:

Tapes made with glass fiber are particularly suitable for insulating coils. These tapes can withstand temperatures of 450∘C [29]. Very thin organic layers are often added to facilitate their implementation. These organic layers are expected to disappear during the first thermal cycle.

Ceramic fabric tapes are products that have high thermal and mechanical performance. It retains its strength and flexibility up to a temperature of 1370∘C [30].

Ceramic paper which is made of high strength, high purity fibers (75% alumina fiber and silica mixed). These materials withstand temperatures up to 1400∘C [31].

The mica is deposited on a glass fabric to ensure a certain mechanical flexibility during winding operations. This product withstands temperatures of 1200 to 1300∘C [32].

Muscovite mica refers to a mineral that has a laminated structure and that has excellent electrical properties at elevated temperatures. Muscovite mica is available in a variety of thicknesses from 0.2 mm. It is a fragile and highly flexible material that is difficult to handle. For low thicknesses, it is associated with thin organic coatings which disappear during the first thermal cycle.

2.7 Bearings for high temperature machines

Conventional bearings made of steel and using organic lubricants will need to be replaced by high temperature resistant elements. The mechanical structure of an electric motor remains fairly simple and up to average speeds, the bearings are the most complex parts. HT∘ bearings have been developed a long time ago [33, 34]. This technology is now mature up to 300∘C. This limit can be used to define a reasonable maximum ambient temperature for HT∘ motors, taking into account the thermal resistance of the mechanical housing and the mechanical losses in the bearings. Another solution is to use ceramic bearings [35]. These bearings available on the market are capable of operating up to 450∘C. They use a treatment of steel parts with manganese phosphate and / or ceramic. They are very resistant [36]. The lubricant HT∘ is replaced by a solid lubricant such as molybdenum disulfide which withstands up to 400∘C [37] or tungsten disulfide [38] up to 650∘C.

2.8 Rotor topology

In synchronous permanent magnet machines, two magnet mounting technologies are possible: surface mounting and mounting inside the rotor. The first offer is easier to assemble. The negative aspect is that the magnets are close to the stator coils, i.e. at high temperature. In the second case, the temperature of the permanent magnets is clearly lower. This is due to the fact that the flux, for the magnets placed inside the rotor, closes through the air gap by the magnetic circuit. The permanent magnets are made of a solid conductor, which causes the induction of eddy currents, heating them up. It should be remembered that the heat produced in the magnets must be carried away outside. In any case, the rotor must be constructed in such a way as to ensure direct heat dissipation. One way to dissipate heat is to fill free volumes with a material that absorbs heat.

3 Choice of topology for HT∘ machines

We wanted to analyze different aspects of the design of an electric machine with a power supply that can work permanently in a hot environment. The basic elements are the right selection of materials from which the active parts of the machine are built. It is advisable to avoid machines with brushes for which the winding rotor is powered by a sliding contact system. The problem that these machines make is faster wear and oxidation of the involved parts due to heat. The second problem concerns the presence of a rotor winding made of rigid inorganic materials that would undergo mechanical stress and vibration in addition to temperature constraints. The asynchronous machine with cage or even with solid rotor is discarded because of the need to use distributed windings that require some flexibility of the coils.

We decided to investigate initially a synchronous machine with permanent magnets. The same stator with winding can be used with two different structures of architecture and materials of rotor. The main objective being the study of the feasibility; the external dimensions of the machine as well as its performances (power, torque ...). It is necessary to study a practical case of electrical installations, it is therefore essential to dimension this machine for a voltage level similar to that frequently used in the avionics: either a DC 540V bus. The other aspect is that it is essential to maintain orders of rotational speed magnitudes, frequencies standard power supply and cutting in aeronautics (of the order of 5000 rpm, a few hundred Hz and a few kilo-Hertz respectively). The mechanical power, the torque and the current value are limited by the current rating of the power components, the power transducer used, the current density according to the motor, pulsed or steady state operation [39, 40, 41, 42, 43, 44, 45, 46].

The first step is to choose the fundamental quantities such as the number of poles, the number of stator slots, the winding topology, and the supply frequencies in relation to the desired mechanical speed. Different combinations of number of poles and teeth are possible. On the side of the permanent magnet rotor topology, several possibilities can be envisaged so that for the same number of slots of stator. There is a wide choice of number of pole pairs. The electromotive force quality, the coefficient of the winding, the expansion torque, the radial forces and the rate of the harmonics of the magnetomotive force are the criteria which must be examined in order to find the choice. The 12 teeth - 10 poles structure is known for its low torque and performance in terms of EMF quality. Ultimately, we decided to choose 24 teeth and 20 poles machine, which makes it possible to reduce the height of the rotor and stator yokes and consequently the resistance of heat exchange between the winding and the crankcase. The choice of a 24-tooth and 20-pole machine leads to elementary coils with many smaller volumes. Finally, the parameters of the machine are following: Ns = 24 coils, Nr = 2p = 20 poles and f = 833 Hz, 5000 rpm (maximum speed).

4 Simulation using the finite element method

The study of the influence of the location and dimensions of magnets is possible due to the use of the field-circuit modeling with the use of 2D finite element method. It was assumed that both machine versions: with embedded magnets and magnets mounted on the surface, will use the same stator. Of course, the type of rotor will have a significant impact on the machine parameters. Unfortunately conductivity of SmCo magnets is much higher than others, which causes higher eddy current losses due to pulsating flux on the magnets surface. Therefore, it is necessary to use methods that reduce these losses. The simplest method was chosen, consisting of laminating the core on the division of magnets into mutually isolated parts. The number of divisions (two by two) was chosen as a compromise between limiting losses and not increasing the workload [47, 48].

In addition, magnetic wedges, closing the stator slots, can be used to reduce the eddy currents losses and torque ripple. Three types of wedge construction were taken into consideration: wedges made from magnetic material - steel(M), wedges made of composite material (SM) and non-magnetic wedges (NM). Field-circuit simulation was unfortunately time-consuming due to transient state that arises at the beginning of calculations. Therefore it was necessary perform simulation during approximately twenty periods before the effect of transient can be eliminated. The results of simulation for 3 different wedges material are shown in Figure 1. All figures show distribution of magnitude of magnetic flux density for the selected time moment after reaching the steady state. These results refer to the case of the unloaded generator.

Flux density distribution for 3 design option for the stator wedges at no-load.

Comparing the three presented magnetic flux density distributions we see that the wedges of the magnetic material are strongly saturated. The magnetic flux partially closes through the wedge causing saturation. In the case of non-magnetic wedge, saturation take place near the tooth’s head, where there are notches to the wedges (here the cross-section is reduced), so there is local saturation.

The impact of the wedges on the loaded machine was then examined. For the analysis of the impact of wedges, the work of the machine as a generator was considered, which was loaded with a resistance of value of 24.3 per phase. As an example of the impact of the load on the magnetic flux density distribution, in Figure 2, a comparison of the flux density distribution for the case with wedges from magnetic material is shown for no-load and load. As can be seen the influence of leakage flux, caused from stator

Repartition of the flux density in the stator of the machine with magnetic wedges a) at no-load, b) at full-load.

winding current, on the level of saturation of the wedges is not significant. The reason for this is the high value of the coercive field of permanent magnet in comparison to the equivalent slot total current.

The presence of wedges has some influence on the torque ripple. Comparison between torque ripple for different wedges materials (from wedge made from magnetic steel through wedge made from composite material up to nonmagnetic) have been shown in Figure 3. In this case, the best result is obtained for composite (semi-magnetic) wedges.

Relative values of the torque ripple for 3 options (NM): no magnetic wedge; (M): magnetic wedges; (SM): semi-magnetic wedges.

In the Table 1 the RMS value of the phase to Neutral voltage of the generator at no-load and the average torque ripple computed on one period is presented. As can be seen from the results presented, the use of magnetic wedges decrease the output RMS voltage and a slightly increase the average torque ripple. However, the biggest impact on the choice of the type of wedges on the losses in magnets will be considered in the 3D simulation chapter.

RMS value of the stator voltage at no-load and average torque ripple.

| Stator wedge | Output voltage | Average torque ripple |

|---|---|---|

| - | v | Nm |

| NM | 267.6 | 0.38 |

| M | 228.6 | 0.42 |

| SM | 270.0 | 0.31 |

The coefficients of temperature TC(HcJ) for the coercivity , TC(Br), for the remanent polarization, and the line B/μ0H of the permanent magnet determine continuous operating maximum temperature of permanent magnets. As generally known [46], the maximum temperature at which a permanent magnet can work is related to the Curie temperature (loss of ferromagnetic properties) as shown in Figure 3b and therefore for HT machines magnets with high Curie temperature should be used. Hence, from available permanent magnets materials our choice was Vacomax Sm2Co17, unfortunately material with relative high electrical conductivity compared to ferrites. The properties of available materials are shown in the Table 2.

Physical properties of Vacodym and Vacomax.

| material | Curie temp. [∘C] | Thermal Conduct. [W(m*K)] | Specific Electrical Resistance [Ohm*mm2 /m] | Coef. Of Thermal Expansion 10−6/K | Maximal Operating Temp. [∘C] |

|---|---|---|---|---|---|

| VACODYM | 310-370 | 5-15 | A*1,4-1,6 | A* 4-9 | 250 |

| B* 1,2-1,4 | B* -2-0 | ||||

| VACOMAX | 800-850 | 5-15 | 0,65-0,95 | A* 8-12 | 450 |

| Sm2Co17 | B* 10-14 | ||||

| VACOMAX | 700-750 | 5-15 | 0,4-0,7 | A* 4-10 | 350 |

| SmCo5 | B*10-16 |

A* parallel to the preferred magnetic direction; B* perpendicular to the preferred magnetic direction

The use of two-dimensional models is always preferred, especially for optimization, due to the considerably lower computational cost than for fully three-dimensional models. However, the two-dimensional model assumes an infinite length of the model in the direction of the axis, which especially in the case of induced currents causes significant differences in comparison with the physical model. This is particularly important for magnets divided in parts with isolated segments because eddy currents must close within each of the magnet segments. Modeling of eddy currents and losses caused by them is therefore possible with the use of full three-dimensional models. Because the distribution of field and eddy currents within the magnets is strongly uneven due to the effect of currents and open stator slots, a large number of mesh elements (61000) were already required for the 2D model. The more significant calculation cost is characterized by the use of a three-dimensional model due to the significant density of the mesh. The reduction of eddy current losses and the cogging torque can be achieved by using magnetic wedges closing the stator grooves, which reduces the flow pulsation.

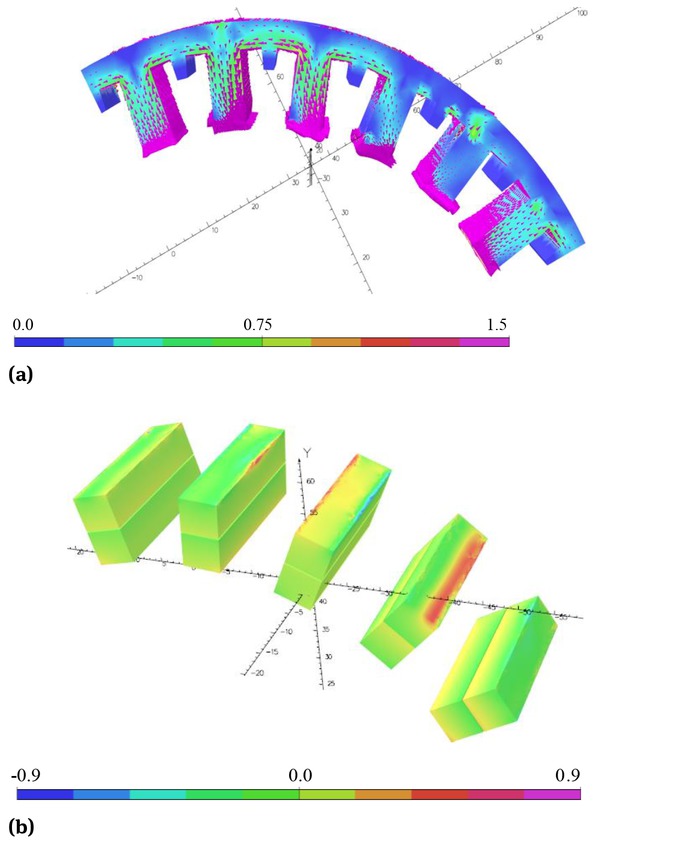

5 3D simulation

In order to minimize the calculation area for the 3D model, the symmetries of the object were used, thanks to which the analysis could be limited to one quarter of the machine. A field-circuit model was used in which the windings of the machine are connected to external resistances constituting a load for generator work. The time stepping solution is carried out similarly to the 2D model assuming constant speed. In order to obtain the appropriate accuracy of the 3D model in the conductive areas, the principle of determining the size of the element smaller than one-third of the equivalent depth of penetration was guided. The constructed mesh consists of 4.274778 million elements, thanks to which it allows the imaging of phenomena related to the rotation of the rotor with an excess. The results of the simulation of the magnetic induction distribution on the rotor and stator surfaces are shown in Figure 4a. The next figure (Figure 4b) shows the distribution of induced eddy currents, the distribution of which, as you can see, is very uneven. In spite of significant values of the current density on the surface of the magnet, it is strongly damped into the magnet, therefore the losses are not as large as the surface values would indicate. The correct calculation of losses in magnets is very important due to the possibility of overheating of the magnet resulting in the loss of magnetic properties. The design of the rotor limits the possibility of heat emission from magnets, which intensifies the problem.

![Figure 4 a) The flux density [T] distribution on the surfaces of the stator and the rotor. b) : Current density distribution [A/mm2] on the surface of PM.](/document/doi/10.1515/phys-2019-0068/asset/graphic/j_phys-2019-0068_fig_004.jpg)

a) The flux density [T] distribution on the surfaces of the stator and the rotor. b) : Current density distribution [A/mm2] on the surface of PM.

As mentioned earlier and in [47, 48], reduction of losses in permanent magnets from eddy currents can be obtained by dividing the magnet into insulated segments. Figure 5 shows the effect of magnet division on segments for distribution of eddy current density. The beneficial effect of the division into decreasing the current density amplitude and thus the value of eddy current losses is visible.

![Figure 5 a) Current density distribution [A/mm2] on the surface of a magnet split in the axial direction. b): Cross section of interior magnets machine.](/document/doi/10.1515/phys-2019-0068/asset/graphic/j_phys-2019-0068_fig_005.jpg)

a) Current density distribution [A/mm2] on the surface of a magnet split in the axial direction. b): Cross section of interior magnets machine.

6 Comparison of the structure with magnets mounted on the surface of the rotor (sm) with the structure with magnets placed inside the rotor core (im)

The selected material for permanent magnets Vacomax Sm2Co17 is characterized by high temperature resistance due to the addition of cobalt, but at the same time cobalt increases the electrical conductivity. The high electrical conductivity combined with the change of flux caused by the rotor movement results in significant eddy currents and related losses. Moving the magnets from the surface to the center of the rotor core in the IM construction due to the reduction of the field variability on the surface of the magnets results in a significant reduction of the eddy current losses. In order to maintain proper mechanical stiffness of the rotor structure, it was necessary to leave the bridge over the magnet of the thickness resulting from the strength requirements of the structure. The bridge should have the smallest dimensions, so as not to limit the flux of magnets closing by the stator. Of course, this helps in the phenomenon of saturation of the bridge. Despite the saturation, however, the bridge causes an increase in the leakage flux, and thus the operating flux decreases, and thus the phase voltage is less than for a magnet of similar dimensions placed on the surface of the rotor (SM).

In Figure 6a phase voltages for internal magnets construction (IM) versus the surface construction (SM) have been shown. In that figure one can see comparison of relative torque ripple values (relative to the average torque value) for 1 – embedded magnets (IM), 2 – surface magnets (SM) for no-load conditions. The benefits of the embedded structure (as shown in Figure 6a) are the voltage without disruption and lower value of cogging torque even for case of wedges from nonmagnetic material. In the case of a loaded generator, the structure of the internal magnetsalso has significantly lower torque ripple. Figure 7a shows

a) Phase voltages for internal magnets construction (1) versus the surface construction (2); b) the cogging torque for internal magnets construction (1) versus the surface construction (2).

a) torque instantaneous value for both cases b) comparison of relative torque ripple values (relative to the average torque value) for 1 – embedded magnets (IM), 2 – surface magnets (SM).

the torque value versus time for that two cases and for the same resistance. Figure 7b shows the torque ripple associated with its average value. The permanent magnet is protected against pulsating fields by means of a rotor iron. As a result, eddy currents in the case of embedded magnets appear mainly on the surface of the magnet and on its upper corners. Figure 8a shows the distribution of the induction in the core of the machine. Visible is the very deep saturation of the bridge left over magnets. In Figure 8b vectors of magnetic flux density on the surface of the magnets have been shown. One can see that the corners of the magnets are the area where these vectors changed their direction. Therefore the corners of the magnets were the area of bigger value of induced eddy currents. To avoid that phenomenon small additional air hole was added in the immediate vicinity of the corner of the magnet.

![Figure 8 Magnitude of magnetic flux density [T] a) in the stator core b) on the magnet surface.](/document/doi/10.1515/phys-2019-0068/asset/graphic/j_phys-2019-0068_fig_008.jpg)

Magnitude of magnetic flux density [T] a) in the stator core b) on the magnet surface.

The source of cogging torque is the change of reluctivity due to slotted structure of the stator and distribution of the magnets for surface placed construction. Magnetic flux density concentrate in stator teeth as can be seen in Figure 9a.

a) Vectors of magnetic induction on stator core surface, b) Magnitude of current density (A/mm2).

The following figures show the effect of using wedges made of martensitic steel with good magnetic properties, but at the same time with relatively high electrical conductivity. Thanks to the use of magnetic wedges, it was possible to reduce the pulsation of the magnetic flux near the gap zone, thus reducing the eddy current losses for structures with magnets placed on the surface up to 22.9 W, when for structures with magnets built into the rotor core, these losses were only 0.72 W (with a loss size of 1.07 W for a case without wedges). Figure 9b shows how the current flowing along the machine axis for the machine with the used magnetic wedges. A series of simulations were carried out that made it possible to dimensioning the machine. During simulation we paid particular attention to the effect of introducing magnetic wedges as well as the previously described division of magnets into segments for the obtained machine parameters. The effect of using different types of materials on wedges closing stator slots and the influence of the method of dividing permanent magnets on segments on the power losses generated from eddy currents as well as uniformity of torque are examined in detail.

7 Realization of prototypes

Based on simulation results, two prototypes of high internal temperature machines have been built. Although the simulations showed the superiority of internal magnets on the surface mounted magnets, we decided to build two prototypes. The stators are identical. The first machine uses a rotor with surface-mounted magnet, the second one with interior magnet. During tests, a prototype will work as an inverter-fed motor and the second one as a synchronous generator connected to a 3-phase load resistance. A part of the experiments will be performed in an oven able to impose an ambient temperature up to 200∘C.

The stator inner diameter is determined considering the slot number and the coil width, which depends on the minimum bending radius of the ceramic coated HT∘ wire. For both prototypes the inner diameter is 122 mm. The magnetic core is placed in the motor housing. The thermal expansion of the iron core and of the housing must be as close as possible for avoiding thermo-mechanical stresses. The housing is made of stainless steel because its thermal expansion coefficient is close to the iron-cobalt soft magnetic core one. For HT∘, the classical aluminum housing must be prohibited because of large differences of the thermal expansions. The 24 inorganic coils are placed on the stator teeth. (Figure 10a), the stator slots are closed with metallic wedges of a low permeability. Electric connections between coils are made using silver brazing. Figure 10b presents a picture of the rotor placed inside the stator. The buried magnet topology do not use any glue, the magnet are inside the rotor. The interior-magnet structure is a better solution, for practical reasons and because

a) HT∘ stator in the stainless steel housing b). Stator with a surface-mounted magnet rotor c) Whole instrumented motor.

The temperature values obtained from four thermocouples.

a significant reduction of losses in the magnets. This solution provides also a smoother voltage, a much smaller cogging torque, which have proven simulations. The embedded magnets structure needs a special design of the flux barriers to reduce flux leakages. The good mechanical fixing of the soft iron between the magnets is made with a nonmagnetic stainless steel shaft that have a complex shape. It yields the rotor rigidity. Figure 10c is a picture of the whole machine.

Several thermocouples type K are placed in stator slots, between the inorganic coil and the magnetic core. A large hole is drilled in the rear flange in order to get a rotor temperature measurement using an infrared camera. The measurements were taken on a moving machine (speed of 2000 turn per minute). The results of measurements obtained from individual thermocouples were recorded. They are shown on picture 11. The following results were obtained:

thermocouple in the surroundings of the machine – 202∘C

housing surface – 216∘C,

center of wedges – 228∘C,

center of the coil – 234∘C

Comparing the measurement results with simulation, we can see that the difference is less than 1∘C. We have obtained good consistency of measurement and simulation.

First, measurements were made for the no-load. We stated that they are heating mainly in the wedges and in the core. Losses result mainly from eddy currents, i.e. mainly in metallic wedges. It is a zone in which there are significant changes in the flux caused by permanent magnets. The increase of the temperature after half an hour is about 6 degrees. In the second order, a load test was carried out. The machine was loaded with a three-phase resistor. It was observed that the temperature in the coils increased significantly. This is due to Joule’s losses. On the basis of the measurement and simulation, the winding and wedges were found to be the most strongly heated element. Machine parts that must be protected from excessive overheating are magnets. Their temperature increases by about 20∘C for an ambient temperature of 200∘C.

8 Conclusions

In order to design a machine that is capable of long-term operation at HT environment, a number of aspects should be considered:

Coil insulation must be inorganic,

the prepared coils are rigid, allowing only one coil to be placed in the slots

the stator slots must be open,

the teeth should be rectangular,

from the previously given limitations, result the fact that slotting effect is much bigger than in a conventional machine

this in turn causes the larger eddy currents and losses in the machine

two options for magnet assembly were tested; magnets placed on the surface and magnets built into the rotor magnetic core

it was found that the option with built-in magnets gives better results; the torque ripple, power losses were compared; the permanent magnet is protected from pulsating fields by the iron of the rotor; eddy currents are induced mainly on the surface of the magnet

the magnet is a critical element that constitutes a technological lock to reach very high temperatures, only Cobalt’s Samarium-based alloys maintain reasonable inductions, with high coercive fields, down to just over 300∘C; these magnets unfortunately have a high conductivity,

to take into account the high conductivity of permanent magnets, use of magnetic wedges to close the stator slots are necessary,

through the use of magnetic wedges made of martensitic steel it was possible to reduce the losses in the structure with the surface magnet to a value of 22.9 W, and for the structure with embedded magnets to 0.72 W(1.07Wfor the structure without the wedges),

we have found that synchronous motors with permanent magnets can be used in the case of an ambient temperature of not more than 300∘C, for temperatures above 300∘C it is advisable to use the variable reluctance machine.

Simulations have shown improved characteristics of operation of the machines with internal magnets. Implementation of such a machine is complicated and therefore we decided to build two prototypes. Experimental thermal and electric measurements performed on the prototypes of two different designs will allow a deep verification of the numerical models. Experimental studies allow only the comparison of global quantities (losses, torque, temperature in the coils, magnetomotive force at no-load); but the proposed numerical models, after a verification for these global quantities will be an interesting tool for further optimization of HT∘ motors that are very different of classical ones.

References

[1] Robutel R., Passive components for high temperature power electronics: application to the EMI input filter, PhD Theses, INSA de Lyon, France, 2011Search in Google Scholar

[2] Robutel R.,Martin C., Buttay C., Morel H.,Matavelli P., Boroyevich D., et al., Design and Implementation of Integrated Common Mode Capacitors for SiC JFET Inverters, IEEE Transactions on Power Electronics, 2014, 29, 7, 3625–363610.1109/TPEL.2013.2279772Search in Google Scholar

[3] Podlejski A.-S., Bréard A., Buttay C., Rondon-Pinilla E., Morel F., Vollaire C., Layout modelling to predict compliance with EMC standards of power electronic converters, in EMC 2015, ser. Proc. of the IEEE International Symposium on Electromagnetic Compatibility, (August 2015, Dresden, Germany), 2015, 779–78410.1109/ISEMC.2015.7256262Search in Google Scholar

[4] Funaki T., Balda J., Junghans J., Kashyap A., Mantooth H., Barlow F., Kimoto T., Hikihara T., Power conversion with SiC devices at extremely high ambient temperatures, IEEE Trans. Power Electron., Jul. 2007, 22, 4, 1321–132910.1109/PESC.2005.1581911Search in Google Scholar

[5] Bergogne D., Morel H., Planson D., Tournier D., Bevilacqua P., Allard B., et al., Towards an airborne high temperature SiC inverter, in Proceedings of the Power Electronics Specialists Conference(PESC). IEEE, 200810.1109/PESC.2008.4592442Search in Google Scholar

[6] Buttay C., Ouaida R., Morel H., Bergogne D., Raynaud C., Morel F., Thermal Stability of Silicon Carbide Power JFETs, IEEE Transactions on Electron Devices, 2013, 60, 12, 4191–419810.1109/TED.2013.2287714Search in Google Scholar

[7] Hamieh Y., Caractérisation et modélisation du transistor JFET en SiC à haute température, PhD Thesis, Institut National des Sciences Appliquées (INSA), Lyon, France, 2011Search in Google Scholar

[8] Liu J. and Walmer M., Thermal stability and performance data for SmCo 2:17 high-temperature magnets on ppm focusing structures, IEEE Transactions on Electron Devices, 2005, 52, 5, 899–90210.1109/TED.2005.845868Search in Google Scholar

[9] Cozonac D., Lecointe J.-P., Duchesne S., Velu G., Materials characterization and geometry of a high temperature induction machine, 2014 International Conference on Electrical Machines (ICEM), 2014, 2499–250510.1109/ICELMACH.2014.6960538Search in Google Scholar

[10] Hooker M., Hazelton C., Kano K., Tupper M., High-temperature electrical insulation for egs downhole equipment, in Thirty-Fifth Workshop on Geothermal Reservoir Engineering Stanford University, Stanford, California, 2010Search in Google Scholar

[11] Nair S. S., Wang J., Chen L., Chin R., Manolas I., Svechkarenko D., Computationally Efficient 3-D Eddy Current Loss Prediction in Magnets of Interior Permanent Magnet Machines, IEEE Transactions on Magnetics 2016, 52, 1-1010.1109/TMAG.2016.2582145Search in Google Scholar

[12] Yamazaki K., Kitayuguchi K., Teeth shape optimization of surface and interior permanent-magnet motors with concentrated windings to reduce magnet eddy current losses, Proc. Int. Conf. Elect. Mach. Syst. (ICEMS), 2010, 990–99510.1109/ECCE.2009.5316114Search in Google Scholar

[13] Kawase Y., Ota T., Fukunaga H., 3-D eddy current analysis in permanent magnet of interior permanent magnet motors, IEEE Trans. Magn., 2000, 36, 4, 1863–186610.1109/20.877808Search in Google Scholar

[14] Zhang P., Sizov G. Y., He J., Ionel D. M., Demerdash N. A. O., Calculation of Magnet Losses in Concentrated-Winding Permanent-Magnet Synchronous Machines Using a Computationally Efficient Finite-Element Method, IEEE Transactions on Industry Applications, 2013, 49, 6, 2524–253210.1109/ECCE.2012.6342331Search in Google Scholar

[15] Ionel D. M., Popescu M., Finite element surrogate model for electric machines with revolving field—Application to IPM motors, IEEE Trans. Ind. Appl., 2010, 46, 6, 2424–243310.1109/ECCE.2009.5316184Search in Google Scholar

[16] Bianchi N., Durello D., Fasolo A., Relationship Between Rotor Losses and Size of Permanent-Magnet Machines, IEEE Transactions on Industry Applications 2013, 49, 2015–202310.1109/DEMPED.2011.6063632Search in Google Scholar

[17] Ponomarev P., Petrov I., Pyrhonen J., Influence of Travelling Current Linkage Harmonics on Inductance Variation Torque Ripple and Sensorless Capability of Tooth-Coil Permanent-Magnet Synchronous Machines, IEEE Transactions on Magnetics 2014, 50, 1–810.1109/TMAG.2013.2283067Search in Google Scholar

[18] Takahashi N., Morishita M., Miyagi D., Nakano M., Examination of magnetic properties of magnetic materials at high temperature using a ring specimen, IEEE Transactions on Magnetics, 2010, 46, 2, 548–55110.1109/TMAG.2009.2033122Search in Google Scholar

[19] Takahashi N., Morishita M., Miyagi D., Nakano M., Comparison of magnetic properties of magnetic materials at high temperature, IEEE Transactions on Magnetics, 2011, 47, 10, 4352–435510.1109/TMAG.2011.2158517Search in Google Scholar

[20] Cozonac D., Lecointe J., Duchesne S., Velu G., Materials characterization and geometry of a high temperature induction machine, International Conference on Electrical Machines (ICEM), 201410.1109/ICELMACH.2014.6960538Search in Google Scholar

[21] Aymonino F., Lebey T., Malec D., Petit C., Saint Michel J., Anton A., Dielectrics measurements of rotating machines insulation at high temperature (200-400∘C), IEEE International Conference on Solid Dielectrics. Winchester, UK : IEEE, 2007, 130–13310.1109/ICSD.2007.4290770Search in Google Scholar

[22] Zhu K., Mimura Y., Lim J., Isshiki M., Jiang Q., Brief review of oxidation kinetics of copper at 350 c to 1050 c, Metallurgical and Materials Transaction, 2006, 37A, 1231–123710.1007/s11661-006-1074-ySearch in Google Scholar

[23] Emery J., Smith F., Next generation insulation for high operating stress, in Proceedings Electrical Insulation Conference and Electrical Manufacturing & Coil Winding Conference, 2001, 209–21210.1109/EEIC.2001.965612Search in Google Scholar

[24] Sawada K., Yamada S., Method of manufacturing a coil of insulated wire, in United States Patent US005105531A1, 1992Search in Google Scholar

[25] Owate R., Freer O., AC breakdown characteristics of ceramic materials, in Journal of Applied Physics, 1992, 72, 2418–242210.1063/1.351586Search in Google Scholar

[26] Jumonji S., Senoo J., Ueda K., Chabata S., Amano S., Ono A., Super heat resistant ceramic insulatedwire, in Electrical Electronics Insulation Conference, and Electrical Manufacturing Coil Winding Conference Proceedings, (1995 Rosemont), 1995, 557–56310.1109/EEIC.1995.482493Search in Google Scholar

[27] Vondracek E., Croop C., New inorganic insulation for 500C electric equipment, in Transactions of the American Institute of Electrical Engineers Power Apparatus and Systems, PartIII, 1958, 77, 1463–146710.1109/AIEEPAS.1958.4500182Search in Google Scholar

[28] Mizutani I., Tatsuki Y., Kumazawa O., Investigation of deterioration mechanism of inorganic insulation under high temperature, Annual Report Conference on Electrical Insulation and Dielectric Phenomena, 2000, 1, 29-3210.1109/CEIDP.2000.885220Search in Google Scholar

[29] Bourgois E., Cetaver R., http://www.e-bourgeois.com/Search in Google Scholar

[30] F. Materials, Fibres textiles haute temperature, http://www.final-materials.comSearch in Google Scholar

[31] Cotronics, Papier céramique 1400-1700∘C, https://www.cotronics.com/vo/cotr/Search in Google Scholar

[32] V. Roll, Mica products for electrical insulation, Von Roll, Tech. Rep., www.vonroll.comSearch in Google Scholar

[33] Dalzell L., Jan J., Wyk W., US Patent 3,206,264, 1960Search in Google Scholar

[34] Sliney H., Solid lubricant materials for high temperatures are view, Tribology International, 1982, 15, 5, 303–31510.1016/0301-679X(82)90089-5Search in Google Scholar

[35] Roulement, Beijingrkf mechanical & electrical equipment, Beijing RKF Mechanical & Electrical Equipment Co., Ltd. Beijing , ChinaSearch in Google Scholar

[36] Roulements hautes temperatures 450∘C, http://www.roulement-ceramique.frSearch in Google Scholar

[37] Bearings for high-temperature environments, http://www.nsk.com/Search in Google Scholar

[38] Disulfure de tungstène ws2., http://traitements-preparationsmoteurs.aquitaine-racing-service.frSearch in Google Scholar

[39] El-Refaie A. M., Fractional-Slot Concentrated-Windings Synchronous Permanent Magnet Machines: Opportunities and Challenges, IEEE Transactions on Industrial Electronics, 2010, 57, 1, 107–12110.1109/TIE.2009.2030211Search in Google Scholar

[40] El-Refaie, A.M., T.. M. Jahns, Optimal flux weakening in surface PM machines using fractional-slot concentrated windings, IEEE Transactions on Industry Applications, 2005, 41, 310.1109/TIA.2005.847312Search in Google Scholar

[41] Tang C., SoongW. L., Jahns T. M., Ertugrul N., Analysis of Iron Loss in Interior PM Machines With Distributed Windings Under Deep Field Weakening, IEEE Transactions on Industry Applications, 2015, 51, 5, 3761–377210.1109/ECCE.2014.6953969Search in Google Scholar

[42] Pfister P.-D., Yin X, Fang Y., Slotted Permanent-MagnetMachines: General Analytical Model of Magnetic Fields, Torque, Eddy Currents, and Permanent-Magnet Power Losses Including the Diffusion Effect, IEEE Transactions on Magnetics, 2016, 52, 510.1109/TMAG.2015.2512528Search in Google Scholar

[43] Wrobel R., Staton D., Lock, R. Booker J., Drury D.,Winding Design for Minimum Power Loss and Low-Cost Manufacture in Application to Fixed-Speed PM Generator, IEEE Transactions on Industry Applications, 2015, 51, 5, 3773–378210.1109/ECCE.2014.6953637Search in Google Scholar

[44] Ruoho S., Haavisto M., Takala E., Santa-Nokki T., Paju M., Temperature Dependence of Resistivity of Sintered Rare-Earth Permanent-Magnet Materials, IEEE Transactions on Magnetics, 2010, 46, 1, 15 – 2010.1109/TMAG.2009.2027815Search in Google Scholar

[45] Arkkio A., Jokinen T., Lantto E., Induction and permanent-magnet synchronousmachines for high-speed applications, Proceedings of the 8th International Conference on Electrical Machines and Systems ICEMS 2005, 2005, 871–87610.1109/ICEMS.2005.202668Search in Google Scholar

[46] Rodewald W., Wall B., Katter M., Uesteuner K., Topology of Nd-F-B magnets with a high energy density. IEEE Transactions on Magnetics, 2003, 39, 5, 2932–293410.1109/INTMAG.2003.1230547Search in Google Scholar

[47] Huang W-Y., Bettayeb A., Kaczmarek R., Vannier J.-C., Optimization of Magnet Segmentation for Reduction of Eddy-CurrentLosses in Permanent Magnet Synchronous Machine, IEEE Transactions on Energy Conversion, 2010, 25, 2, 381–38710.1109/TEC.2009.2036250Search in Google Scholar

[48] Iosif V., Takorabet N., Duchesne S., Meibody-Tabar F., Technological assessments for designing machines able to work at very high internal temperatures (450–500∘C), 2016 XXII International Conference on Electrical Machines (ICEM), 2016, 2682-268710.1109/ICELMACH.2016.7732900Search in Google Scholar

© 2019 M. Lefik et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Non-equilibrium Phase Transitions in 2D Small-World Networks: Competing Dynamics

- Harmonic waves solution in dual-phase-lag magneto-thermoelasticity

- Multiplicative topological indices of honeycomb derived networks

- Zagreb Polynomials and redefined Zagreb indices of nanostar dendrimers

- Solar concentrators manufacture and automation

- Idea of multi cohesive areas - foundation, current status and perspective

- Derivation method of numerous dynamics in the Special Theory of Relativity

- An application of Nwogu’s Boussinesq model to analyze the head-on collision process between hydroelastic solitary waves

- Competing Risks Model with Partially Step-Stress Accelerate Life Tests in Analyses Lifetime Chen Data under Type-II Censoring Scheme

- Group velocity mismatch at ultrashort electromagnetic pulse propagation in nonlinear metamaterials

- Investigating the impact of dissolved natural gas on the flow characteristics of multicomponent fluid in pipelines

- Analysis of impact load on tubing and shock absorption during perforating

- Energy characteristics of a nonlinear layer at resonant frequencies of wave scattering and generation

- Ion charge separation with new generation of nuclear emulsion films

- On the influence of water on fragmentation of the amino acid L-threonine

- Formulation of heat conduction and thermal conductivity of metals

- Displacement Reliability Analysis of Submerged Multi-body Structure’s Floating Body for Connection Gaps

- Deposits of iron oxides in the human globus pallidus

- Integrability, exact solutions and nonlinear dynamics of a nonisospectral integral-differential system

- Bounds for partition dimension of M-wheels

- Visual Analysis of Cylindrically Polarized Light Beams’ Focal Characteristics by Path Integral

- Analysis of repulsive central universal force field on solar and galactic dynamics

- Solitary Wave Solution of Nonlinear PDEs Arising in Mathematical Physics

- Understanding quantum mechanics: a review and synthesis in precise language

- Plane Wave Reflection in a Compressible Half Space with Initial Stress

- Evaluation of the realism of a full-color reflection H2 analog hologram recorded on ultra-fine-grain silver-halide material

- Graph cutting and its application to biological data

- Time fractional modified KdV-type equations: Lie symmetries, exact solutions and conservation laws

- Exact solutions of equal-width equation and its conservation laws

- MHD and Slip Effect on Two-immiscible Third Grade Fluid on Thin Film Flow over a Vertical Moving Belt

- Vibration Analysis of a Three-Layered FGM Cylindrical Shell Including the Effect Of Ring Support

- Hybrid censoring samples in assessment the lifetime performance index of Chen distributed products

- Study on the law of coal resistivity variation in the process of gas adsorption/desorption

- Mapping of Lineament Structures from Aeromagnetic and Landsat Data Over Ankpa Area of Lower Benue Trough, Nigeria

- Beta Generalized Exponentiated Frechet Distribution with Applications

- INS/gravity gradient aided navigation based on gravitation field particle filter

- Electrodynamics in Euclidean Space Time Geometries

- Dynamics and Wear Analysis of Hydraulic Turbines in Solid-liquid Two-phase Flow

- On Numerical Solution Of The Time Fractional Advection-Diffusion Equation Involving Atangana-Baleanu-Caputo Derivative

- New Complex Solutions to the Nonlinear Electrical Transmission Line Model

- The effects of quantum spectrum of 4 + n-dimensional water around a DNA on pure water in four dimensional universe

- Quantum Phase Estimation Algorithm for Finding Polynomial Roots

- Vibration Equation of Fractional Order Describing Viscoelasticity and Viscous Inertia

- The Errors Recognition and Compensation for the Numerical Control Machine Tools Based on Laser Testing Technology

- Evaluation and Decision Making of Organization Quality Specific Immunity Based on MGDM-IPLAO Method

- Key Frame Extraction of Multi-Resolution Remote Sensing Images Under Quality Constraint

- Influences of Contact Force towards Dressing Contiguous Sense of Linen Clothing

- Modeling and optimization of urban rail transit scheduling with adaptive fruit fly optimization algorithm

- The pseudo-limit problem existing in electromagnetic radiation transmission and its mathematical physics principle analysis

- Chaos synchronization of fractional–order discrete–time systems with different dimensions using two scaling matrices

- Stress Characteristics and Overload Failure Analysis of Cemented Sand and Gravel Dam in Naheng Reservoir

- A Big Data Analysis Method Based on Modified Collaborative Filtering Recommendation Algorithms

- Semi-supervised Classification Based Mixed Sampling for Imbalanced Data

- The Influence of Trading Volume, Market Trend, and Monetary Policy on Characteristics of the Chinese Stock Exchange: An Econophysics Perspective

- Estimation of sand water content using GPR combined time-frequency analysis in the Ordos Basin, China

- Special Issue Applications of Nonlinear Dynamics

- Discrete approximate iterative method for fuzzy investment portfolio based on transaction cost threshold constraint

- Multi-objective performance optimization of ORC cycle based on improved ant colony algorithm

- Information retrieval algorithm of industrial cluster based on vector space

- Parametric model updating with frequency and MAC combined objective function of port crane structure based on operational modal analysis

- Evacuation simulation of different flow ratios in low-density state

- A pointer location algorithm for computer visionbased automatic reading recognition of pointer gauges

- A cloud computing separation model based on information flow

- Optimizing model and algorithm for railway freight loading problem

- Denoising data acquisition algorithm for array pixelated CdZnTe nuclear detector

- Radiation effects of nuclear physics rays on hepatoma cells

- Special issue: XXVth Symposium on Electromagnetic Phenomena in Nonlinear Circuits (EPNC2018)

- A study on numerical integration methods for rendering atmospheric scattering phenomenon

- Wave propagation time optimization for geodesic distances calculation using the Heat Method

- Analysis of electricity generation efficiency in photovoltaic building systems made of HIT-IBC cells for multi-family residential buildings

- A structural quality evaluation model for three-dimensional simulations

- WiFi Electromagnetic Field Modelling for Indoor Localization

- Modeling Human Pupil Dilation to Decouple the Pupillary Light Reflex

- Principal Component Analysis based on data characteristics for dimensionality reduction of ECG recordings in arrhythmia classification

- Blinking Extraction in Eye gaze System for Stereoscopy Movies

- Optimization of screen-space directional occlusion algorithms

- Heuristic based real-time hybrid rendering with the use of rasterization and ray tracing method

- Review of muscle modelling methods from the point of view of motion biomechanics with particular emphasis on the shoulder

- The use of segmented-shifted grain-oriented sheets in magnetic circuits of small AC motors

- High Temperature Permanent Magnet Synchronous Machine Analysis of Thermal Field

- Inverse approach for concentrated winding surface permanent magnet synchronous machines noiseless design

- An enameled wire with a semi-conductive layer: A solution for a better distibution of the voltage stresses in motor windings

- High temperature machines: topologies and preliminary design

- Aging monitoring of electrical machines using winding high frequency equivalent circuits

- Design of inorganic coils for high temperature electrical machines

- A New Concept for Deeper Integration of Converters and Drives in Electrical Machines: Simulation and Experimental Investigations

- Special Issue on Energetic Materials and Processes

- Investigations into the mechanisms of electrohydrodynamic instability in free surface electrospinning

- Effect of Pressure Distribution on the Energy Dissipation of Lap Joints under Equal Pre-tension Force

- Research on microstructure and forming mechanism of TiC/1Cr12Ni3Mo2V composite based on laser solid forming

- Crystallization of Nano-TiO2 Films based on Glass Fiber Fabric Substrate and Its Impact on Catalytic Performance

- Effect of Adding Rare Earth Elements Er and Gd on the Corrosion Residual Strength of Magnesium Alloy

- Closed-die Forging Technology and Numerical Simulation of Aluminum Alloy Connecting Rod

- Numerical Simulation and Experimental Research on Material Parameters Solution and Shape Control of Sandwich Panels with Aluminum Honeycomb

- Research and Analysis of the Effect of Heat Treatment on Damping Properties of Ductile Iron

- Effect of austenitising heat treatment on microstructure and properties of a nitrogen bearing martensitic stainless steel

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical simulation of welding distortions in large structures with a simplified engineering approach

- Investigation on the effect of electrode tip on formation of metal droplets and temperature profile in a vibrating electrode electroslag remelting process

- Effect of North Wall Materials on the Thermal Environment in Chinese Solar Greenhouse (Part A: Experimental Researches)

- Three-dimensional optimal design of a cooled turbine considering the coolant-requirement change

- Theoretical analysis of particle size re-distribution due to Ostwald ripening in the fuel cell catalyst layer

- Effect of phase change materials on heat dissipation of a multiple heat source system

- Wetting properties and performance of modified composite collectors in a membrane-based wet electrostatic precipitator

- Implementation of the Semi Empirical Kinetic Soot Model Within Chemistry Tabulation Framework for Efficient Emissions Predictions in Diesel Engines

- Comparison and analyses of two thermal performance evaluation models for a public building

- A Novel Evaluation Method For Particle Deposition Measurement

- Effect of the two-phase hybrid mode of effervescent atomizer on the atomization characteristics

- Erratum

- Integrability analysis of the partial differential equation describing the classical bond-pricing model of mathematical finance

- Erratum to: Energy converting layers for thin-film flexible photovoltaic structures

Articles in the same Issue

- Regular Articles

- Non-equilibrium Phase Transitions in 2D Small-World Networks: Competing Dynamics

- Harmonic waves solution in dual-phase-lag magneto-thermoelasticity

- Multiplicative topological indices of honeycomb derived networks

- Zagreb Polynomials and redefined Zagreb indices of nanostar dendrimers

- Solar concentrators manufacture and automation

- Idea of multi cohesive areas - foundation, current status and perspective

- Derivation method of numerous dynamics in the Special Theory of Relativity

- An application of Nwogu’s Boussinesq model to analyze the head-on collision process between hydroelastic solitary waves

- Competing Risks Model with Partially Step-Stress Accelerate Life Tests in Analyses Lifetime Chen Data under Type-II Censoring Scheme

- Group velocity mismatch at ultrashort electromagnetic pulse propagation in nonlinear metamaterials

- Investigating the impact of dissolved natural gas on the flow characteristics of multicomponent fluid in pipelines

- Analysis of impact load on tubing and shock absorption during perforating

- Energy characteristics of a nonlinear layer at resonant frequencies of wave scattering and generation

- Ion charge separation with new generation of nuclear emulsion films

- On the influence of water on fragmentation of the amino acid L-threonine

- Formulation of heat conduction and thermal conductivity of metals

- Displacement Reliability Analysis of Submerged Multi-body Structure’s Floating Body for Connection Gaps

- Deposits of iron oxides in the human globus pallidus

- Integrability, exact solutions and nonlinear dynamics of a nonisospectral integral-differential system

- Bounds for partition dimension of M-wheels

- Visual Analysis of Cylindrically Polarized Light Beams’ Focal Characteristics by Path Integral

- Analysis of repulsive central universal force field on solar and galactic dynamics

- Solitary Wave Solution of Nonlinear PDEs Arising in Mathematical Physics

- Understanding quantum mechanics: a review and synthesis in precise language

- Plane Wave Reflection in a Compressible Half Space with Initial Stress

- Evaluation of the realism of a full-color reflection H2 analog hologram recorded on ultra-fine-grain silver-halide material

- Graph cutting and its application to biological data

- Time fractional modified KdV-type equations: Lie symmetries, exact solutions and conservation laws

- Exact solutions of equal-width equation and its conservation laws

- MHD and Slip Effect on Two-immiscible Third Grade Fluid on Thin Film Flow over a Vertical Moving Belt

- Vibration Analysis of a Three-Layered FGM Cylindrical Shell Including the Effect Of Ring Support

- Hybrid censoring samples in assessment the lifetime performance index of Chen distributed products

- Study on the law of coal resistivity variation in the process of gas adsorption/desorption

- Mapping of Lineament Structures from Aeromagnetic and Landsat Data Over Ankpa Area of Lower Benue Trough, Nigeria

- Beta Generalized Exponentiated Frechet Distribution with Applications

- INS/gravity gradient aided navigation based on gravitation field particle filter

- Electrodynamics in Euclidean Space Time Geometries

- Dynamics and Wear Analysis of Hydraulic Turbines in Solid-liquid Two-phase Flow

- On Numerical Solution Of The Time Fractional Advection-Diffusion Equation Involving Atangana-Baleanu-Caputo Derivative

- New Complex Solutions to the Nonlinear Electrical Transmission Line Model

- The effects of quantum spectrum of 4 + n-dimensional water around a DNA on pure water in four dimensional universe

- Quantum Phase Estimation Algorithm for Finding Polynomial Roots

- Vibration Equation of Fractional Order Describing Viscoelasticity and Viscous Inertia

- The Errors Recognition and Compensation for the Numerical Control Machine Tools Based on Laser Testing Technology

- Evaluation and Decision Making of Organization Quality Specific Immunity Based on MGDM-IPLAO Method

- Key Frame Extraction of Multi-Resolution Remote Sensing Images Under Quality Constraint

- Influences of Contact Force towards Dressing Contiguous Sense of Linen Clothing

- Modeling and optimization of urban rail transit scheduling with adaptive fruit fly optimization algorithm

- The pseudo-limit problem existing in electromagnetic radiation transmission and its mathematical physics principle analysis

- Chaos synchronization of fractional–order discrete–time systems with different dimensions using two scaling matrices

- Stress Characteristics and Overload Failure Analysis of Cemented Sand and Gravel Dam in Naheng Reservoir

- A Big Data Analysis Method Based on Modified Collaborative Filtering Recommendation Algorithms

- Semi-supervised Classification Based Mixed Sampling for Imbalanced Data

- The Influence of Trading Volume, Market Trend, and Monetary Policy on Characteristics of the Chinese Stock Exchange: An Econophysics Perspective

- Estimation of sand water content using GPR combined time-frequency analysis in the Ordos Basin, China

- Special Issue Applications of Nonlinear Dynamics

- Discrete approximate iterative method for fuzzy investment portfolio based on transaction cost threshold constraint

- Multi-objective performance optimization of ORC cycle based on improved ant colony algorithm

- Information retrieval algorithm of industrial cluster based on vector space

- Parametric model updating with frequency and MAC combined objective function of port crane structure based on operational modal analysis

- Evacuation simulation of different flow ratios in low-density state

- A pointer location algorithm for computer visionbased automatic reading recognition of pointer gauges

- A cloud computing separation model based on information flow

- Optimizing model and algorithm for railway freight loading problem

- Denoising data acquisition algorithm for array pixelated CdZnTe nuclear detector

- Radiation effects of nuclear physics rays on hepatoma cells

- Special issue: XXVth Symposium on Electromagnetic Phenomena in Nonlinear Circuits (EPNC2018)

- A study on numerical integration methods for rendering atmospheric scattering phenomenon

- Wave propagation time optimization for geodesic distances calculation using the Heat Method

- Analysis of electricity generation efficiency in photovoltaic building systems made of HIT-IBC cells for multi-family residential buildings

- A structural quality evaluation model for three-dimensional simulations

- WiFi Electromagnetic Field Modelling for Indoor Localization

- Modeling Human Pupil Dilation to Decouple the Pupillary Light Reflex

- Principal Component Analysis based on data characteristics for dimensionality reduction of ECG recordings in arrhythmia classification

- Blinking Extraction in Eye gaze System for Stereoscopy Movies

- Optimization of screen-space directional occlusion algorithms

- Heuristic based real-time hybrid rendering with the use of rasterization and ray tracing method

- Review of muscle modelling methods from the point of view of motion biomechanics with particular emphasis on the shoulder

- The use of segmented-shifted grain-oriented sheets in magnetic circuits of small AC motors

- High Temperature Permanent Magnet Synchronous Machine Analysis of Thermal Field

- Inverse approach for concentrated winding surface permanent magnet synchronous machines noiseless design

- An enameled wire with a semi-conductive layer: A solution for a better distibution of the voltage stresses in motor windings

- High temperature machines: topologies and preliminary design

- Aging monitoring of electrical machines using winding high frequency equivalent circuits

- Design of inorganic coils for high temperature electrical machines

- A New Concept for Deeper Integration of Converters and Drives in Electrical Machines: Simulation and Experimental Investigations

- Special Issue on Energetic Materials and Processes

- Investigations into the mechanisms of electrohydrodynamic instability in free surface electrospinning

- Effect of Pressure Distribution on the Energy Dissipation of Lap Joints under Equal Pre-tension Force

- Research on microstructure and forming mechanism of TiC/1Cr12Ni3Mo2V composite based on laser solid forming

- Crystallization of Nano-TiO2 Films based on Glass Fiber Fabric Substrate and Its Impact on Catalytic Performance

- Effect of Adding Rare Earth Elements Er and Gd on the Corrosion Residual Strength of Magnesium Alloy

- Closed-die Forging Technology and Numerical Simulation of Aluminum Alloy Connecting Rod

- Numerical Simulation and Experimental Research on Material Parameters Solution and Shape Control of Sandwich Panels with Aluminum Honeycomb

- Research and Analysis of the Effect of Heat Treatment on Damping Properties of Ductile Iron

- Effect of austenitising heat treatment on microstructure and properties of a nitrogen bearing martensitic stainless steel

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical simulation of welding distortions in large structures with a simplified engineering approach

- Investigation on the effect of electrode tip on formation of metal droplets and temperature profile in a vibrating electrode electroslag remelting process

- Effect of North Wall Materials on the Thermal Environment in Chinese Solar Greenhouse (Part A: Experimental Researches)

- Three-dimensional optimal design of a cooled turbine considering the coolant-requirement change

- Theoretical analysis of particle size re-distribution due to Ostwald ripening in the fuel cell catalyst layer

- Effect of phase change materials on heat dissipation of a multiple heat source system

- Wetting properties and performance of modified composite collectors in a membrane-based wet electrostatic precipitator

- Implementation of the Semi Empirical Kinetic Soot Model Within Chemistry Tabulation Framework for Efficient Emissions Predictions in Diesel Engines

- Comparison and analyses of two thermal performance evaluation models for a public building

- A Novel Evaluation Method For Particle Deposition Measurement

- Effect of the two-phase hybrid mode of effervescent atomizer on the atomization characteristics

- Erratum

- Integrability analysis of the partial differential equation describing the classical bond-pricing model of mathematical finance

- Erratum to: Energy converting layers for thin-film flexible photovoltaic structures