Abstract

In this paper, the experimental paradigm of cognitive behaviors to study the cognitive activities in the contiguous sense cognition of the tested linen clothing is introduced. The experimental program is written with E-Prime 2.0, while the expression of experimental stimulus material is realized with the developed dressing contiguous sense measurement device, which output the senses of urtication, roughness and smoothness among the fabric contiguous sense. Changing the relative force for the contact between fabric and human skin, the dressing contiguous sense is tested in different contiguous force conditions. The result shows that, with the increase of relative contiguous force, the evaluation value for the sense of urtication is increase, the value for the roughness sense is also increase, but that for the smoothness sense is decrease.

1 Introduction

During the process of dressing, the physiological features of human body, such as surface temperature of skin, humidity of skin surface, and sweating velocity variation at all times, which are easy to cause varieties of new stimulus. During this period, the motion status of human body will cause the constant slippage of fabric on skin, and is easy to cause new mechanical stimulus.

The sense of urtication arising from fabrics has been proven as one of the most discomforting contiguous senses [1]. The sense of roughness, also known as granular sense [2], refers to the sense experienced when skin contacts fabric surface, which is a kind of physiological and psychic combined reaction arising from the stimulation formed by the surface topography and texture features of the fabric. The sense of smoothness is used for representing the ability of skin deformation along with tangential motion between fabric and skin. When under high pressure or sweating condition, the actual contact area between fabric and human skin increases, and the tangential motion of fabric will cause deformation of skin.

Contiguous cool-warm sense refers to the judgment of cool and warm formed by the brain when clothing contacts with human skin, causes the increase or decrease of skin temperature at the contiguous part, and makes the skin temperature at the contiguous part different with that of other part because of the heat transfer between them caused by temperature difference [3].

Perception on cold and warm means the cognition instantly completed via cold receptor and warm receptor, which existing large difference in perception mechanism with other senses, such as urtication, roughness and smoothness. According to the previous research achievements on clothing comfort and cognitive psychology, the dressing contiguous senses discussed in this paper includes the sense of urtication, roughness and smoothness [4].

When human skin contacts with fabric of clothing, the surface hairiness causes mechanical stimulation and emerges the sense of urtication in the case of the fiber end of the surface hairiness of the fabric can resist the bending load greater than 0.75mN, and the stimulus of the fiber end meeting the requirement of density [5, 6].

By changing the contact force between fingers or human skin and the object surface, it has been proven in the studies of Sripati et al. that the sense of roughness may vary with the variation of force; the increase of contact force may cause the increase of the response strength of SAI receptor [7]. However, as far as fine surface is concerned, the roughness sense is not fully strengthened with the increase of contact force, because the receptor perceiving the fine surface cannot be changed. Meanwhile, as shown in the research results of Louw, when the contact force within the range of 0.4-4N, the difference of acting force applied by the different subjects on the contacted object surface is not vary the psychophysical threshold value of the sense of roughness [8]. Employing UST surface tester, Hu et al. [9] tested the sense of roughness on the fabric surface under different pressures, and found that the roughness sense on the fabric surface intensifies with the increase of contact pressure.

In this paper, the experimental paradigm of cognitive behaviors is introduced to study cognitive activities in the contiguous sense cognition of the tested linen clothing. The experimental program is written with E-Prime 2.0, while the expression of experimental stimulus material is realized with the developed dressing contiguous sense measurement device, which output the senses of urtication, roughness and smoothness. Changing the relative force for the contact between fabric and human skin, the dressing contiguous sense is tested in different contiguous force conditions to explore the influence of force towards dressing cognition sense.

2 Experiment methods

2.1 Subjects

In each set of experiments, 64 young female college students with relevant specialized knowledge are selected randomly as subjects, aged from 20 to 23 years. The reason to choose female undergraduate is that the study of Garnsworth [10] shows that females are much more sensitive than males. All the subjects are normal in vision or normal after correction, and are right hander. All the subjects are separately measured, and have not done any similar experiment.

Garnsworth, et al. firstly proposed utilizing forearm test method for the experiment, and discovered that arm skin shows excellent sensitiveness against external stimulus, such as mechanical stress, hairiness puncture and temperature irritation. Because the freedom degree of shoulder joints, elbow joints and wrist joints is high, and arms can also flexibly bend to conveniently accomplish the contact between fabric and skin during the experiment process. Furthermore, because only bared forearm is required for experiment, the selected subject is willing to participate in the experiment [10, 11]. Naylor, et al. also adopted forearm test method, and the experiment result further validated the scientific nature and reasonability of the method [12]. Hence, the forearm is selected as tested part in this paper.

2.2 Design of dressing contiguous sense measurement device

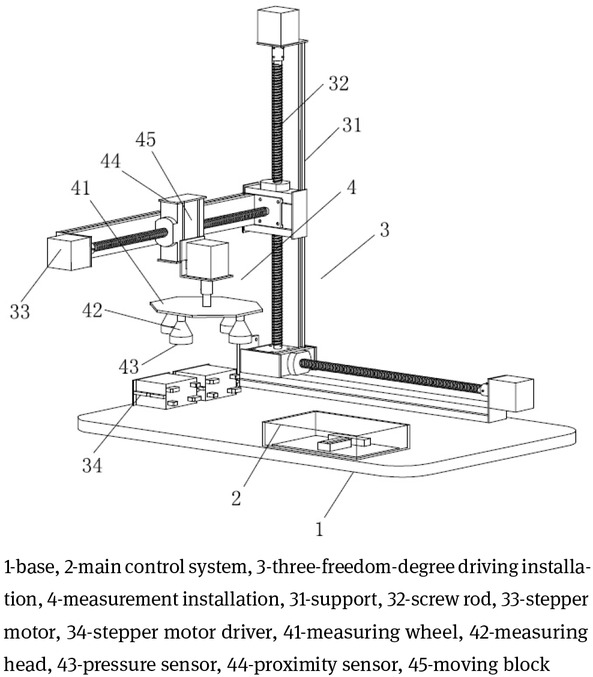

The developed device comprises the base, main control system, and three-freedom-degree driving installation fixed on the base, the measurement installation set on the driving installation, whose location can be adjusted in X, Y and Z coordinate space. Through the driving of the installation, the displacement with different speeds or forces can be realized, as shown in Figure 1.

The developed measurement device

The main control system adopts a 51 single chip micro-computer (open edition) integrated with A/ D converter.

The stepper motor is a two-phase four-wire stepper motor, which controls the mechanical movement of the screw rod at three directions of X, Y and Z. The measurement installation is connected to the screw rod of the driving installation on Y direction, and drives the rotation of the screw rod with the operation of the stepper motor, thus transforming rotation of the screw rod to the rectilinear motion of the measurement installation, so as to adjust moving distance, moving speed and acting force of the measurement installation relative to the body contact position.

The measurement installation comprises a measuring wheel, and the measuring heads equally set below the measuring wheel, which are equally distributed on a circle surrounding the center of the wheel, and a pressure sensor set on the surface below the measuring heads. The testing board could achieve intermittent rotation and the angle it rotated for each time was 360∘/n. Four testing heads were evenly distributed at the bottom of the testing board. The fabric is packed over the measuring heads, and the measuring wheel can realize an intermittent rotation with an angle of 90∘ for each time.

2.3 Design of force parameter

Essick [13] set different forces in the two groups of experiment respectively, as shown in Table 1. When Experiment 1 set the range of force contacting with velvet fabric as 0.19-0.73N, the result showed that the subjects had greater evaluation on the contiguous sense of the velvet fabric when contacting with relative smaller force. When Experiment 2 set the range of force contacting with the denim fabric as 0.64-0.92N, the result showed that greater force has significant influence on the contiguous sense evaluation of denim fabric.

Stimulus conditions for experiment

| Experiment 1 Essick (2010) | Experiment 2 Essick (2010) | Essick (1999) | |

|---|---|---|---|

| participants textured materials body sites |

12 females, 11 males cosmetic brush, velvet, burlap, velcro dorsal forearm |

10females, 10 males cupro, cotton interlock, terry toweling, denim forehead, dorsal forearm, hand, thigh, calf |

10 females velvet, cotton, plastic mesh face(cheek), ventral forearm |

| force (N) | 0.19 (small), 0.73(great) | 0.46 (small), 0.92 (great) |

In the absence of external force, the weight of clothing has certain stimulation to the human body, which is also the biggest stimulus. The female summer shirts are selected as objects, gram weighting about 250-350 per each piece of clothing, for which selecting the average value of 300g. Accordingly, G = mg = 0.3Kg * 10N/Kg = 3N

That is to say, the maximum force applied by each shirt on human body is 3N. During the process of dressing, the double shoulders of human body serve as the important supporting points of weight of the clothing, for which the force of each location is calculated as 1.5N, thus the maximum force for each action point is 1.5N. In order to fully explore the cognition law of dressing contiguous sense, the force for the contact between fabric and human skin is set as 0.1-1.5N.

Human skin receptor can accurately perceive the external tactile information. According to the theories of biomechanics and bioinformatics, the elasticity relation model for skin and subcutaneous tissues is as follow.

Where, a, b denotes constant, F means stress, λ is extension ratio, F * and λ* denotes reference value. Hypothesis, there is function relationship between tactile perception S and relative deformation of contact area of human skin (λ − 1).

Where, θ is constant. According to Equation 1 and 2, equation 3 can be deduced.

The research results indicate that the subjects have generated corresponding psychological perception for tactile sense under the external stimulation. This psychological perception has interrelation with the degree difference of stimulation perceived. Therefore, when external stimulation conditions change, the minimum feeling difference able to be generated for subjects is referred to as just noticeable difference (JND) [14]. The core concept of Weber’s law is that the quantity of stimulation changes required for perceiving a minimum noticeable sense difference has certain function relationship with the quantity of stimulations applied during the process of external stimulation.

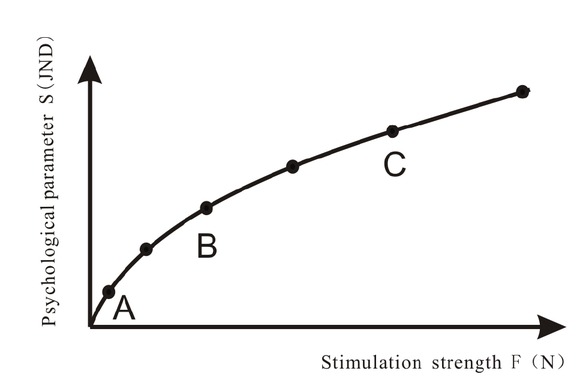

German psychologist Gustav Fechner further expounded the theory, and concluded the core concept of Fechner’s law: JND is the minimum noticeable stimulation, which can be used as the basic unit for the measurement of psychological variation. When external stimulation gradually intensifies, the stimulation variation required for the generation of JND is also increase correspondingly. This is mainly because when the physical variation constantly increases, the change of psychological value decreases gradually. It means that when the physical stimulation increases, much more mechanical stimulations requires under the same stimulation difference perceived by the subjects. Following mathematical theories, the opinion can be expressed as that the quantity of perception from subjects is the logarithm product of K value in the corresponding sensory system by the stimulation quantity, as shown in Figure 2.

The law of Gustav Fechner

As shown in Figure 2, as for the stimulation difference quantity, the difference between A and B is different with that between B and C, which yet causes the same psychological quantity. In mathematical linguistics: if the psychological stimulation increase amplitude conforms to arithmetic progression, then the stimulation energy increase amplification can be calculated in geometrical progression. That is to say, the psychological perception of the subjects has logarithmic function relationship with the mechanical stimulation strength.

Considering the nonlinear stimulation applied by the force on human body receptor when the female summer shirt contact with human skin during the process of dressing, and combining the meaning of Figure 2, the force of point A, C is set as 0.1N, 1N respectively, then the force of point B can be calculated as follow.

Therefore, the force ranges is set as large, medium and small in this paper. Specifically speaking, there are small force range (0.1-0.3N), medium force range (0.316-0.9N) and large force range (1-1.5N).

2.4 Experiment materials

8 kinds of linen fabrics popular in the market are selected as experiment materials, which are suitable for making female summer shirts. The warp and weft density of the fabrics is measured by using DW512A digital fabric count tester. The linear density of the warp and weft yarn and the areal density of fabrics are measured and calculated in weighting method with BSA224S electronic scale [15, 16, 17, 18]. The specification parameters of each fabric are shown in Table 2.

Specification parameters of linen fabrics

| No. | Fabric weave | Ingredient | Linear density of warp yarn | Linear density of weft yarn | Warp density | Weft density | Areal density |

|---|---|---|---|---|---|---|---|

| 1# | Plain weave | L55/V45 | 29.53 tex×1 | 42.18 tex×1 | 59 | 52 | 156 |

| 2# | Plain weave | L100% | 42.18 tex×1 | 42.18 tex×1 | 54 | 52 | 165 |

| 3# | Plain weave | L55/C45 | 28.12 tex×1 | 42.18 tex×1 | 54 | 50 | 156 |

| 4# | Plain weave | L55/V45 | 59.05 tex×1 | 59.05 tex×1 | 44 | 38 | 192 |

| 5# | Plain weave | L55/C45 | 53.68 tex×1 | 53.68 tex×1 | 51 | 47 | 195 |

| 6# | Plain weave | L100% | 42.18 tex×1 | 42.18 tex×1 | 54 | 54 | 165 |

| 7# | Plain weave | L55/C45 | 39.37 tex×1 | 39.37 tex×1 | 54 | 52 | 165 |

| 8# | Plain weave | L55/V45 | 19.68 tex×2 | 42.18 tex×1 | 52 | 51 | 175 |

Unit: warp density, weft density (root/cm); areal density (g/m2)

2.5 Experiment program

When using the device, open the power switch of the main control system, and press the start button on the main control system, so as to transmit the order to the stepper motor through the stepper motor driver, and regulate the mechanical movement of the screw rod at three directions of X, Y, Z, and conduct the zero correction of the measuring wheel.

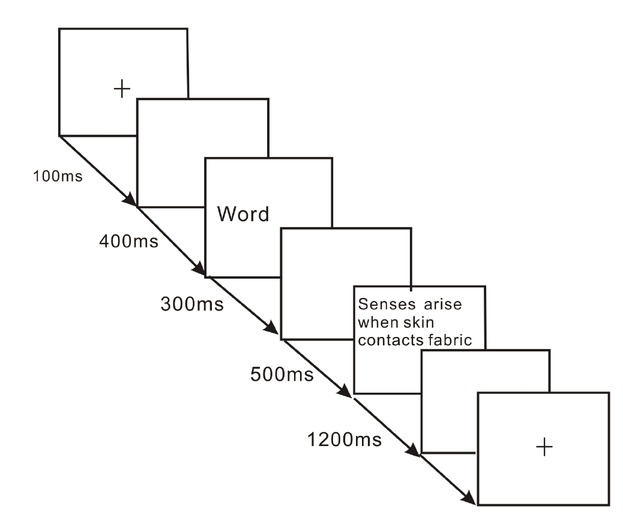

In the behavioral experiment mode, the expression program of the experimental paradigm, the expression of experimental stimulation materials, the random display of evaluation indexes, and the storage program of the evaluation results is designed firstly. The experiment program is shown in Figure 3. The experiment is conducted on computer, and its program is written with E-Prime 2.0.

A schematic illustration of the trial

After the evaluation indexes show, the measuring wheel loading fabric starts to contact human skin. When the contact is detected by the pressure sensor, the sensor will send the information to the main control system, which will send the order to control the stepper motor to run, and the fabric will start to have movement relative to the skin; when the proximity sensor detects the specified route mark, it will give an information feedback to the main control system, which will send an order to stop the measuring wheel. During this process, the subjects perceive the contiguous sense with the fabric, and makes quantization judgment. The continuous evaluation results are saved in the storage system.

After completion of one measurement, press the button on the main control system, then the measuring wheel will automatically rotate for 1/4 circle, and the measuring wheel will move to the initial position, i.e., zero position, where the next fabric will contact the skin.

The reaction data will be generated by the subjects through pressing buttons. If the subject feels that the fabric contiguous sense and the meaning of sensory word is same and the sense is quite strong, press button “/”; if the subject feels the sense is common, press button “X”; if the subject feels that the fabric contiguous sense and the meaning of sensory word is different, press button “Z”.

During the process of experiment, subjects could be given time to rest and everyone participated once in the same experiment to prevent memory mechanism disturbing subjects’ cognitive processes.

2.6 Evaluation scale

In order to conduct a quantitative evaluation on contiguous senses, three-point system is employed to assign each evaluation index. If the subject feels that the fabric contiguous sense and the meaning of sensory word is same and the sense is quite strong, the evaluation value will be 2 points; if the sense is quite common, the evaluation value will be 1 point; if the subject feels that the fabric contiguous sense is different from the meaning of sensory word, the evaluation value will be 0 point.

3 Results and discussion

In order to explore the influences of force variation on the dressing contiguous sense, the medium speed is selected in this paper, by changing the relative contiguous force of fabrics and human skin, the dressing contiguous senses under different force conditions are measured, and the obtained dressing contiguous sense is analyzed comparatively.

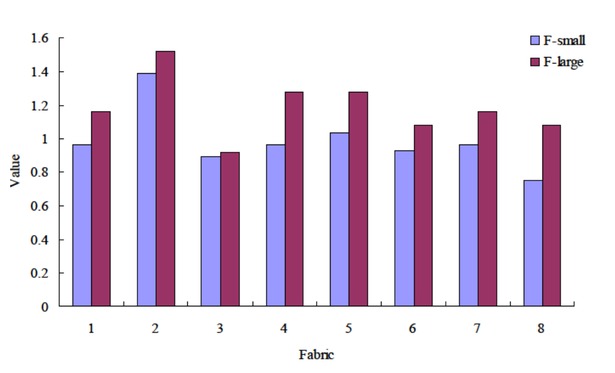

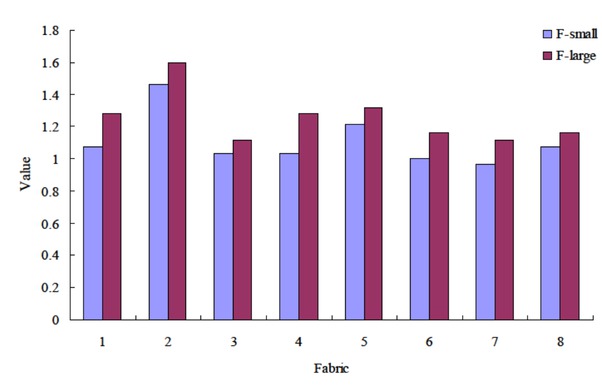

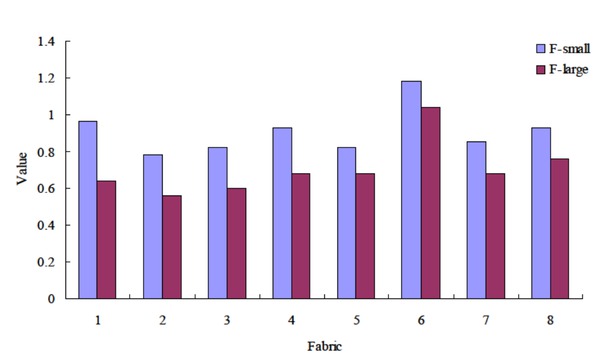

3.1 Comparative Analysis on V-medium-F-small and V-medium-F-large

The dressing contiguous senses of 8 kinds of linen fabrics under two kinds of different stimulus conditions are measured And the average value of dressing contiguous senses from different fabrics under different stimulus conditions are shown in Figure 4, Figure 5 and Figure 6.

Comparison of urtication sense

Comparison of roughness sense

Comparison of smoothness sense

As shown in Figure 4, with the increase of contiguous force between fabrics and human skin, the sense of urtication perceived by human body for each fabric is intensified. When the fabrics contact with human skin, the protuberant hairiness or hard fiber ends on the surface of fabrics energize together. When the fabric gets close to human skin, the force is increased, and the protuberant fibers start to bend and induce receptors to certain extent, which consequently increases the perception intensity of urtication sense. Therefore, with the increase of force, the urtication sensory intensity perceived by subject is much more than that under the slighter force stimulation.

The amplitude of the urtication sense of 3# fabric is less intensified along with the increase of force. This is mainly because 3# fabric is a kind of interweaved fabric, which warp is cotton yarn. With the increase of force, the quantity of cotton fiber hairiness on the surface of the fabric increases due to the mutual friction between fabric and human skin, reducing the perception intensity of the subject towards the urtication sense consequently.

The results of Figure 5 show that the roughness sense intensity perceived by human for each type of fabric is intensified with the increase of the contiguous force between fabric and human skin. Studies show that, when perceiving the roughness of fabrics under general circumstances, the force applied by fingers on the fabric should not exceed 1.0N. When the force for the contact between the fingertips and fabrics increases, the subject cognizes much more sense of roughness [19]. During the research on the surface with embossing texture, Blake et al. [20] found that SAI receptor is very sensitive to the variations of height and diameter of the point, which is super to RA receptor. Matching with the spatial variation pattern of peripheral nerve coding, variability of induction discharge space of SAI receptors is emerged to some degree and consequently impact on the perception of sense organ with the variation of contiguous force. Moreover, the induction discharge ratio of SAI receptor also intensifies with the increase of the local contact force applied on skin surface [21, 22].

There is more or less hairiness on the surface of linen fabric. When certain force is applied on fabric, the deformation of surface hairiness is appeared, because the subsidence of hairiness passivates the surface texture of linen fabric. In addition, the yarns at the intersection points of the fabric slips to some extent under the function of external force, increasing the gap among yarns, which increase the roughness sense intensity perceived by wearer.

Figure 6 indicates that, with the increase of contiguous force between fabrics and skin, the smoothness sense intensity perceived for each kind of fabric is reduced. This is consistent with the evaluation result on the sense of roughness, meeting the perception law when human skin contact with fabrics.

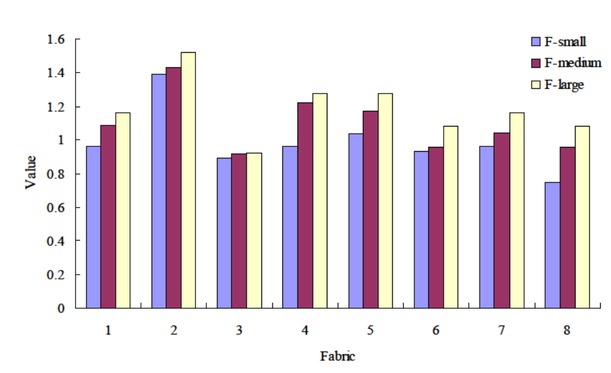

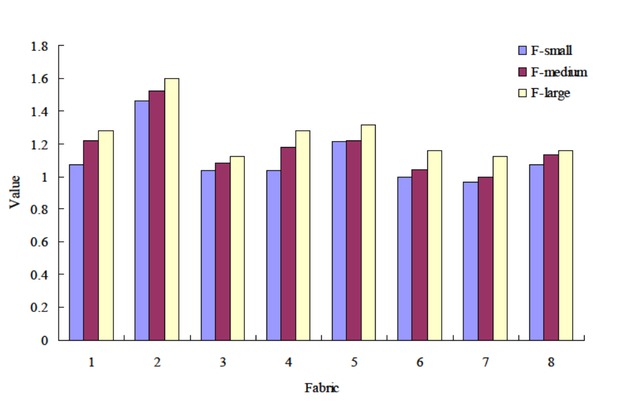

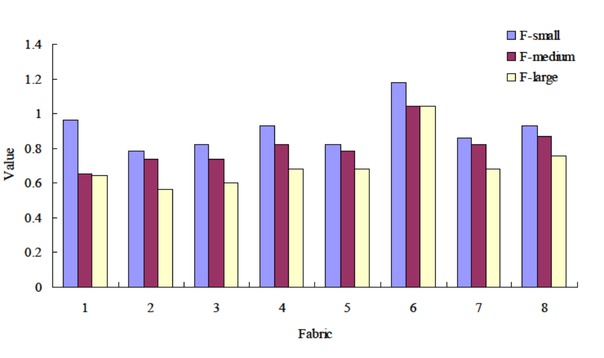

3.2 Comparative Analysis on V-medium-F-small, V-medium-F-medium and V-medium-F-large

As shown in Figure 4, Figure 5 and Figure 6, under the small and large force conditions, the dressing senses of urtication, roughness and smoothness present the consistent variation law, that is, with the increase of contiguous force, the evaluation value of the sense of urtication is increase, and that of roughness sense is also increase, but that of the smoothness sense is decrease. In order to further analyze the influences of the contiguous force variation between fabrics and human skin on the evaluation value of dressing contiguous sense, the experimental stimulation condition of V-medium-F-medium is introduced. Under the three experimental stimulation conditions of V-medium-F-small, V-medium-F-medium and V-medium-F-large, the variation of average value of dressing sense such as the sense of urtication, roughness and smoothness is shown in Figure 7, Figure 8 and Figure 9.

Comparison of urtication sense

Comparison of roughness sense

Comparison of smoothness sense

As shown in Figure 7, under the experimental stimulations of small, medium and large force, the perception intensity of urtication sense of the subjects to different fabrics is intensify with the increase of force, not following the linear variation law. It means that the intensification degree for the perception of urtication sense is not balanced with the non-linear increase of force.

The form of hairiness has impacts on the form of urtication during the process of puncture. When the fabric contacts with human skin, if the pressure is small, the supporting surface mainly provided by hairiness with certain hardness; when the pressure is large, the supporting surface is constituted by the fabric texture because of hairiness lodging. If hard hairiness is act as the contact or supporting surface, the contact forms include positive pressure puncture and tangential friction or scrapping.

Positive pressure puncture is divided into moving right towards skin from fiber end and bending end. For the former, the fibers is compressed and deformed, whose reaction force act on skin through the end. Because of the small area of contact point and greater pressure, the sense of puncture is strong. While for the latter, although skin moves right towards the principal axis of fibers, the pressure generated by pressing on skin is slight, and the urtication sense is slighter than that of the former because of the increased contact area from the bending of the fiber end. The vertical friction-type and bending friction-type fibers move tangentially towards skin and generate tangential stress on skin. Although the pressure generated is small, it generates vibration slippage and forms continuous scrapping and puncture actions within large area due to the rebound and recovery property of fibers. Its effect depends on the dimension of included angles between the fiber axle and motion direction. Therefore, with the increase of contiguous force between linen fabric and human skin, the overall urtication sensation value of the subjects to the different fabrics is also gradually intensified.

With the increase of force stimulation, the urtication sense of 3# fabric is intensifies relatively slow. This is mainly because 3# fabric is a kind of interweaved fabric, whose warp is cotton yarn. With the increase of force, the quantity of cotton fiber hairiness on the surface of the fabric is increased due to the friction between fabric and human skin, which reduce the perception intensity of urtication sense.

The results of Figure 8 indicates that under the experimental stimulation of small, medium and large force, the overall feeling intensity of the subjects for the roughness sense of different fabrics is increased with the increase of force, not following the linear variation law. With the non-linear increase of force, the increase degree for the perception of roughness sense is unbalanced.

There is more or less hairiness on the surface of linen fabric. When certain force is applied on fabric, the deformation of surface hairiness is appeared, because the subsidence of hairiness passivates the surface texture of linen fabric. The friction parameter on the surface of the fabric increases with the increase of force, so do the sense of roughness perceived by the subjects. In addition, the yarns at the intersection points of the fabric slips to some extent under the function of external force, increasing the gap among yarns, which increase the roughness sense intensity perceived by wearer consequently [23, 24, 25].

As shown in Figure 9, under the experimental stimulation of small, medium and large force, the overall feeling intensity of the subjects for the smoothness sense of different fabrics is decreased along with the increase of force, which yet not follows the linear variation law [26, 27, 28, 29]. This is consistent with the evaluation result on the roughness sense, meeting the perception law for the contact between human skin and fabrics.

4 Conclusions

In this paper, the experimental paradigm of cognitive behaviors is introduced to study cognitive activities in the contiguous sense cognition of the tested linen clothing. The expression of the experimental stimulus material is realized with the developed dressing contiguous sense measurement device. Changing the relative force for the contact between fabric and human skin, the dressing contiguous sense is tested. Some conclusions can be obtained as follow:

Employing behavioral experiment paradigm into dressing cognition psychology field, and combining it with the developed equipment, it guarantees the orderly proceeding of experiment stimulus sequence and the synchronism of experiment time.

When the acting velocity keeps constant, the variation laws of the perception intensity for the sense of urtication, roughness and smoothness of the subjects toward different fabrics are consistent under the three experiment conditions. That is to say, with the increase of relative contiguous force, the evaluation value for the sense intensity of urtication is increase, the value for roughness sense is also increase, but that for smoothness sense is decrease.

Through the analysis on the dressing contiguous sense of urtication, roughness and smoothness, the contiguous cognition laws of dressing contiguous perception under different velocity conditions is tested, which will provide scientific references for the establishment of psychological models of dressing contiguous sense information integration.

In the actual dressing process, the direction of the applied force is not fixed, and the applied force direction of 45 degrees should be focused on, which is of great research value. Future studies will focus on the influences of force direction on contact sensation evaluation.

Acknowledgement

This paper is sponsored by Science and Technology Guidance Projects of China National Textile and Apparel Council (2016060), Qing Lan Project and project of Zhejiang Sci-Tech University (Engineering Research Center of Clothing of Zhejiang Province) (No. 2018FZKF06).

References

[1] Li Y., Comfort of clothing and product design, 1st ed., China Textile & Apparel Press, Beijing, 2002Search in Google Scholar

[2] Freyberger F.K., Farber B., Psychophysics and perceiving granularity, In: Proceeding Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems (22-25 April 2006), 2006, 387-393.10.1109/HAPTIC.2006.1627105Search in Google Scholar

[3] Chen D.S., Clothing hygiene, 1st ed., China Textile& Apparel Press, Beijing, 2000Search in Google Scholar

[4] Kuang C.Y., Research on measurement method of dressing contiguous sense based on tactile perception, Suzhou: Soochow University, 2015.Search in Google Scholar

[5] Naylor G.R.S., Phillips D.G., Veitch C.J., Fabric-evoked prickle in worsted spun single-jersey fabrics Part1: the role of fiber end diameter characteristic, Text. Res. J., 1997, 67, 288-295.10.1177/004051759706700408Search in Google Scholar

[6] Naylor G.R.S., Phillips D.G., Veitch C.J. et al., Fabric-evoked prickle in worsted spun single-jersey fabrics Part2: the role of fiber end diameter characteristic, Text. Res. J., 1997, 67, 354-358.10.1177/004051759706700508Search in Google Scholar

[7] Arun P.S., Sliman J.B., Kenneth O.J., A continuum mechanical model of mechanoreceptive afferent responses to indented spatial patterns, J. Neurosci., 2006, 95(6), 3852-3864.10.1152/jn.01240.2005Search in Google Scholar PubMed PubMed Central

[8] Louw S., Kappers A.M.L., Koenderink J.J., Haptic detection of sine-wave gratings, Perception, 2005, 34(7), 869-885.10.1068/p5425Search in Google Scholar PubMed

[9] Hu J.Y., Study on the fabric tactile textures from the principle of human cognition, Shanghai: Donghua University, 2008.Search in Google Scholar

[10] Garnsworthy R.K., Gully R.L., Kenins P., Westerman, R. A., Transcutaneous electrical stimulation and the sensation of prickle, J. Neurophysiol., 1988, 59, 1116-1127.10.1152/jn.1988.59.4.1116Search in Google Scholar PubMed

[11] Garnsworthy R.K., Gully R.L., Kandiah R.P., Understanding the causes of prickle and itch from the skin contact of fabrics, Australian Text., 1988, 8, 26-29.Search in Google Scholar

[12] Naylor G.R., The coarse fiber component and fiber end diameter characteristics of Australian wool tops, Wool Technol Sheep Breed, 1992, 40(3/4), 14-18.Search in Google Scholar

[13] Essick G.K., James A., Mcglone F.P., Psychophysical assessment of the affective components of non-painful touch, Neuroreport, 1999, 10, 2083-2087.10.1097/00001756-199907130-00017Search in Google Scholar PubMed

[14] Shen C.S., Nie Y.M., Ge Y.J., Research on psychological state measuring of touch for robot sensor, J. Transducer Technol., 2005, 24(4), 11-12.Search in Google Scholar

[15] Les M.S., Armand V.C., Carole W., Identification of the most significant comfort factors for textiles from processing mechanical, handfeel, fabric construction, and perceived tactile comfort data, Text. Res. J., 2013, 83(1), 34-43.10.1177/0040517512438121Search in Google Scholar

[16] Kamalha E., Zeng Y.C., Mwasiagi J.I., The comfort dimension: a review of perception in clothing, J. Sens Stud., 2013, 28, 423-444.10.1111/joss.12070Search in Google Scholar

[17] Bertaux, E., Lewandowski, M., Derler, S., Relationship between friction and tactile properties for woven and knitted fabrics, Text. Res. J., 2007, 77(6), 387-396.10.1177/0040517507074165Search in Google Scholar

[18] Bacci, L., Camilli, F., Drago, S., Sensory evaluation and instrumental measurements to determine tactile properties of wool fabrics, Text. Res. J., 2012, 82(14), 1430-1441.10.1177/0040517512438125Search in Google Scholar

[19] Yoshioka T., Gibb B., Dorsch A.K., Hsiao S.S., Neural coding mechanisms underlying perceived roughness of finely textured surfaces, J. Neurosci., 2001, 21(17), 6905-6916.10.1523/JNEUROSCI.21-17-06905.2001Search in Google Scholar

[20] Blake D.T., Hsiao S.S., Johnson K.O., Neural coding mechanism in tactile pattern recognition: the relative contributions of slowly and rapidly adapting mechanoreceptors to perceived roughness, J. Neurosci., 1997, 17(19), 7480-7489.10.1523/JNEUROSCI.17-19-07480.1997Search in Google Scholar

[21] Philips J.R., Johnson K.O., Tactile spatial resolution III: A continuum mechanics model of skin predicting mechanoreceptor response to bars, edges, gratings, J. Neurophysiol., 1981, 46(6), 1204-1225.10.1152/jn.1981.46.6.1204Search in Google Scholar PubMed

[22] Arun P.S., Bensmaia S.J., Johnson K.O., A continuum mechanical model of mechanoreceptive afferent responses to indented spatial patterns, J. Neurophysiol., 2006, 95(6), 3852-3864.10.1152/jn.01240.2005Search in Google Scholar PubMed PubMed Central

[23] Murray J.D., Demirtaş M., Anticevic A., Biophysical modeling of large-scale brain dynamics and applications for computational psychiatry, Biol Psychiatry Cogn Neurosci Neuroimaging, 2018, 3(9), 777-787.10.1016/j.bpsc.2018.07.004Search in Google Scholar PubMed PubMed Central

[24] Gao W., Zhu L., Guo Y., Wang K., Ontology learning algorithm for similarity measuring and ontology mapping using linear programming, J. Intell Fuzzy Syst., 2017, 33, 3153-3163.10.3233/JIFS-169367Search in Google Scholar

[25] Gao W., Wang W.F., The fifth geometric-arithmetic index of bridge graph and carbon nanocones, J. Differ Equ Appl., 2017, 23, 100-109.10.1080/10236198.2016.1197214Search in Google Scholar

[26] Malviya P.S., Yadav N., Ghosh S., Acousto-optic modulation in ion implanted semiconductor plasmas having SDDC, Appl Math Nonli Sci., 2018, 3, 303-310.10.21042/AMNS.2018.1.00023Search in Google Scholar

[27] Nizami A.R., Perveen A., Nazeer W., Baqir M., Walk Polynomial: a new graph invariant, Appl Math Nonli Sci., 2018, 3, 321-330.10.21042/AMNS.2018.1.00025Search in Google Scholar

[28] Pandey P.K., Jaboob S.S.A., A finite difference method for a numerical solution of elliptic boundary value problems, Appl Math Nonli Sci., 2018, 3, 311-320.10.21042/AMNS.2018.1.00024Search in Google Scholar

[29] Vajravelu K., Li R., Dewasurendra M., Benarroch J., Ossi N., Zhang Y., Sammarco M., Prasad K. V., Effects of second-order slip and drag reduction in boundary layer flows, Appl Math Nonli Sci., 2018, 3, 291-302.10.21042/AMNS.2018.1.00022Search in Google Scholar

© 2019 C. Kuang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Non-equilibrium Phase Transitions in 2D Small-World Networks: Competing Dynamics

- Harmonic waves solution in dual-phase-lag magneto-thermoelasticity

- Multiplicative topological indices of honeycomb derived networks

- Zagreb Polynomials and redefined Zagreb indices of nanostar dendrimers

- Solar concentrators manufacture and automation

- Idea of multi cohesive areas - foundation, current status and perspective

- Derivation method of numerous dynamics in the Special Theory of Relativity

- An application of Nwogu’s Boussinesq model to analyze the head-on collision process between hydroelastic solitary waves

- Competing Risks Model with Partially Step-Stress Accelerate Life Tests in Analyses Lifetime Chen Data under Type-II Censoring Scheme

- Group velocity mismatch at ultrashort electromagnetic pulse propagation in nonlinear metamaterials

- Investigating the impact of dissolved natural gas on the flow characteristics of multicomponent fluid in pipelines

- Analysis of impact load on tubing and shock absorption during perforating

- Energy characteristics of a nonlinear layer at resonant frequencies of wave scattering and generation

- Ion charge separation with new generation of nuclear emulsion films

- On the influence of water on fragmentation of the amino acid L-threonine

- Formulation of heat conduction and thermal conductivity of metals

- Displacement Reliability Analysis of Submerged Multi-body Structure’s Floating Body for Connection Gaps

- Deposits of iron oxides in the human globus pallidus

- Integrability, exact solutions and nonlinear dynamics of a nonisospectral integral-differential system

- Bounds for partition dimension of M-wheels

- Visual Analysis of Cylindrically Polarized Light Beams’ Focal Characteristics by Path Integral

- Analysis of repulsive central universal force field on solar and galactic dynamics

- Solitary Wave Solution of Nonlinear PDEs Arising in Mathematical Physics

- Understanding quantum mechanics: a review and synthesis in precise language

- Plane Wave Reflection in a Compressible Half Space with Initial Stress

- Evaluation of the realism of a full-color reflection H2 analog hologram recorded on ultra-fine-grain silver-halide material

- Graph cutting and its application to biological data

- Time fractional modified KdV-type equations: Lie symmetries, exact solutions and conservation laws

- Exact solutions of equal-width equation and its conservation laws

- MHD and Slip Effect on Two-immiscible Third Grade Fluid on Thin Film Flow over a Vertical Moving Belt

- Vibration Analysis of a Three-Layered FGM Cylindrical Shell Including the Effect Of Ring Support

- Hybrid censoring samples in assessment the lifetime performance index of Chen distributed products

- Study on the law of coal resistivity variation in the process of gas adsorption/desorption

- Mapping of Lineament Structures from Aeromagnetic and Landsat Data Over Ankpa Area of Lower Benue Trough, Nigeria

- Beta Generalized Exponentiated Frechet Distribution with Applications

- INS/gravity gradient aided navigation based on gravitation field particle filter

- Electrodynamics in Euclidean Space Time Geometries

- Dynamics and Wear Analysis of Hydraulic Turbines in Solid-liquid Two-phase Flow

- On Numerical Solution Of The Time Fractional Advection-Diffusion Equation Involving Atangana-Baleanu-Caputo Derivative

- New Complex Solutions to the Nonlinear Electrical Transmission Line Model

- The effects of quantum spectrum of 4 + n-dimensional water around a DNA on pure water in four dimensional universe

- Quantum Phase Estimation Algorithm for Finding Polynomial Roots

- Vibration Equation of Fractional Order Describing Viscoelasticity and Viscous Inertia

- The Errors Recognition and Compensation for the Numerical Control Machine Tools Based on Laser Testing Technology

- Evaluation and Decision Making of Organization Quality Specific Immunity Based on MGDM-IPLAO Method

- Key Frame Extraction of Multi-Resolution Remote Sensing Images Under Quality Constraint

- Influences of Contact Force towards Dressing Contiguous Sense of Linen Clothing

- Modeling and optimization of urban rail transit scheduling with adaptive fruit fly optimization algorithm

- The pseudo-limit problem existing in electromagnetic radiation transmission and its mathematical physics principle analysis

- Chaos synchronization of fractional–order discrete–time systems with different dimensions using two scaling matrices

- Stress Characteristics and Overload Failure Analysis of Cemented Sand and Gravel Dam in Naheng Reservoir

- A Big Data Analysis Method Based on Modified Collaborative Filtering Recommendation Algorithms

- Semi-supervised Classification Based Mixed Sampling for Imbalanced Data

- The Influence of Trading Volume, Market Trend, and Monetary Policy on Characteristics of the Chinese Stock Exchange: An Econophysics Perspective

- Estimation of sand water content using GPR combined time-frequency analysis in the Ordos Basin, China

- Special Issue Applications of Nonlinear Dynamics

- Discrete approximate iterative method for fuzzy investment portfolio based on transaction cost threshold constraint

- Multi-objective performance optimization of ORC cycle based on improved ant colony algorithm

- Information retrieval algorithm of industrial cluster based on vector space

- Parametric model updating with frequency and MAC combined objective function of port crane structure based on operational modal analysis

- Evacuation simulation of different flow ratios in low-density state

- A pointer location algorithm for computer visionbased automatic reading recognition of pointer gauges

- A cloud computing separation model based on information flow

- Optimizing model and algorithm for railway freight loading problem

- Denoising data acquisition algorithm for array pixelated CdZnTe nuclear detector

- Radiation effects of nuclear physics rays on hepatoma cells

- Special issue: XXVth Symposium on Electromagnetic Phenomena in Nonlinear Circuits (EPNC2018)

- A study on numerical integration methods for rendering atmospheric scattering phenomenon

- Wave propagation time optimization for geodesic distances calculation using the Heat Method

- Analysis of electricity generation efficiency in photovoltaic building systems made of HIT-IBC cells for multi-family residential buildings

- A structural quality evaluation model for three-dimensional simulations

- WiFi Electromagnetic Field Modelling for Indoor Localization

- Modeling Human Pupil Dilation to Decouple the Pupillary Light Reflex

- Principal Component Analysis based on data characteristics for dimensionality reduction of ECG recordings in arrhythmia classification

- Blinking Extraction in Eye gaze System for Stereoscopy Movies

- Optimization of screen-space directional occlusion algorithms

- Heuristic based real-time hybrid rendering with the use of rasterization and ray tracing method

- Review of muscle modelling methods from the point of view of motion biomechanics with particular emphasis on the shoulder

- The use of segmented-shifted grain-oriented sheets in magnetic circuits of small AC motors

- High Temperature Permanent Magnet Synchronous Machine Analysis of Thermal Field

- Inverse approach for concentrated winding surface permanent magnet synchronous machines noiseless design

- An enameled wire with a semi-conductive layer: A solution for a better distibution of the voltage stresses in motor windings

- High temperature machines: topologies and preliminary design

- Aging monitoring of electrical machines using winding high frequency equivalent circuits

- Design of inorganic coils for high temperature electrical machines

- A New Concept for Deeper Integration of Converters and Drives in Electrical Machines: Simulation and Experimental Investigations

- Special Issue on Energetic Materials and Processes

- Investigations into the mechanisms of electrohydrodynamic instability in free surface electrospinning

- Effect of Pressure Distribution on the Energy Dissipation of Lap Joints under Equal Pre-tension Force

- Research on microstructure and forming mechanism of TiC/1Cr12Ni3Mo2V composite based on laser solid forming

- Crystallization of Nano-TiO2 Films based on Glass Fiber Fabric Substrate and Its Impact on Catalytic Performance

- Effect of Adding Rare Earth Elements Er and Gd on the Corrosion Residual Strength of Magnesium Alloy

- Closed-die Forging Technology and Numerical Simulation of Aluminum Alloy Connecting Rod

- Numerical Simulation and Experimental Research on Material Parameters Solution and Shape Control of Sandwich Panels with Aluminum Honeycomb

- Research and Analysis of the Effect of Heat Treatment on Damping Properties of Ductile Iron

- Effect of austenitising heat treatment on microstructure and properties of a nitrogen bearing martensitic stainless steel

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical simulation of welding distortions in large structures with a simplified engineering approach

- Investigation on the effect of electrode tip on formation of metal droplets and temperature profile in a vibrating electrode electroslag remelting process

- Effect of North Wall Materials on the Thermal Environment in Chinese Solar Greenhouse (Part A: Experimental Researches)

- Three-dimensional optimal design of a cooled turbine considering the coolant-requirement change

- Theoretical analysis of particle size re-distribution due to Ostwald ripening in the fuel cell catalyst layer

- Effect of phase change materials on heat dissipation of a multiple heat source system

- Wetting properties and performance of modified composite collectors in a membrane-based wet electrostatic precipitator

- Implementation of the Semi Empirical Kinetic Soot Model Within Chemistry Tabulation Framework for Efficient Emissions Predictions in Diesel Engines

- Comparison and analyses of two thermal performance evaluation models for a public building

- A Novel Evaluation Method For Particle Deposition Measurement

- Effect of the two-phase hybrid mode of effervescent atomizer on the atomization characteristics

- Erratum

- Integrability analysis of the partial differential equation describing the classical bond-pricing model of mathematical finance

- Erratum to: Energy converting layers for thin-film flexible photovoltaic structures

Articles in the same Issue

- Regular Articles

- Non-equilibrium Phase Transitions in 2D Small-World Networks: Competing Dynamics

- Harmonic waves solution in dual-phase-lag magneto-thermoelasticity

- Multiplicative topological indices of honeycomb derived networks

- Zagreb Polynomials and redefined Zagreb indices of nanostar dendrimers

- Solar concentrators manufacture and automation

- Idea of multi cohesive areas - foundation, current status and perspective

- Derivation method of numerous dynamics in the Special Theory of Relativity

- An application of Nwogu’s Boussinesq model to analyze the head-on collision process between hydroelastic solitary waves

- Competing Risks Model with Partially Step-Stress Accelerate Life Tests in Analyses Lifetime Chen Data under Type-II Censoring Scheme

- Group velocity mismatch at ultrashort electromagnetic pulse propagation in nonlinear metamaterials

- Investigating the impact of dissolved natural gas on the flow characteristics of multicomponent fluid in pipelines

- Analysis of impact load on tubing and shock absorption during perforating

- Energy characteristics of a nonlinear layer at resonant frequencies of wave scattering and generation

- Ion charge separation with new generation of nuclear emulsion films

- On the influence of water on fragmentation of the amino acid L-threonine

- Formulation of heat conduction and thermal conductivity of metals

- Displacement Reliability Analysis of Submerged Multi-body Structure’s Floating Body for Connection Gaps

- Deposits of iron oxides in the human globus pallidus

- Integrability, exact solutions and nonlinear dynamics of a nonisospectral integral-differential system

- Bounds for partition dimension of M-wheels

- Visual Analysis of Cylindrically Polarized Light Beams’ Focal Characteristics by Path Integral

- Analysis of repulsive central universal force field on solar and galactic dynamics

- Solitary Wave Solution of Nonlinear PDEs Arising in Mathematical Physics

- Understanding quantum mechanics: a review and synthesis in precise language

- Plane Wave Reflection in a Compressible Half Space with Initial Stress

- Evaluation of the realism of a full-color reflection H2 analog hologram recorded on ultra-fine-grain silver-halide material

- Graph cutting and its application to biological data

- Time fractional modified KdV-type equations: Lie symmetries, exact solutions and conservation laws

- Exact solutions of equal-width equation and its conservation laws

- MHD and Slip Effect on Two-immiscible Third Grade Fluid on Thin Film Flow over a Vertical Moving Belt

- Vibration Analysis of a Three-Layered FGM Cylindrical Shell Including the Effect Of Ring Support

- Hybrid censoring samples in assessment the lifetime performance index of Chen distributed products

- Study on the law of coal resistivity variation in the process of gas adsorption/desorption

- Mapping of Lineament Structures from Aeromagnetic and Landsat Data Over Ankpa Area of Lower Benue Trough, Nigeria

- Beta Generalized Exponentiated Frechet Distribution with Applications

- INS/gravity gradient aided navigation based on gravitation field particle filter

- Electrodynamics in Euclidean Space Time Geometries

- Dynamics and Wear Analysis of Hydraulic Turbines in Solid-liquid Two-phase Flow

- On Numerical Solution Of The Time Fractional Advection-Diffusion Equation Involving Atangana-Baleanu-Caputo Derivative

- New Complex Solutions to the Nonlinear Electrical Transmission Line Model

- The effects of quantum spectrum of 4 + n-dimensional water around a DNA on pure water in four dimensional universe

- Quantum Phase Estimation Algorithm for Finding Polynomial Roots

- Vibration Equation of Fractional Order Describing Viscoelasticity and Viscous Inertia

- The Errors Recognition and Compensation for the Numerical Control Machine Tools Based on Laser Testing Technology

- Evaluation and Decision Making of Organization Quality Specific Immunity Based on MGDM-IPLAO Method

- Key Frame Extraction of Multi-Resolution Remote Sensing Images Under Quality Constraint

- Influences of Contact Force towards Dressing Contiguous Sense of Linen Clothing

- Modeling and optimization of urban rail transit scheduling with adaptive fruit fly optimization algorithm

- The pseudo-limit problem existing in electromagnetic radiation transmission and its mathematical physics principle analysis

- Chaos synchronization of fractional–order discrete–time systems with different dimensions using two scaling matrices

- Stress Characteristics and Overload Failure Analysis of Cemented Sand and Gravel Dam in Naheng Reservoir

- A Big Data Analysis Method Based on Modified Collaborative Filtering Recommendation Algorithms

- Semi-supervised Classification Based Mixed Sampling for Imbalanced Data

- The Influence of Trading Volume, Market Trend, and Monetary Policy on Characteristics of the Chinese Stock Exchange: An Econophysics Perspective

- Estimation of sand water content using GPR combined time-frequency analysis in the Ordos Basin, China

- Special Issue Applications of Nonlinear Dynamics

- Discrete approximate iterative method for fuzzy investment portfolio based on transaction cost threshold constraint

- Multi-objective performance optimization of ORC cycle based on improved ant colony algorithm

- Information retrieval algorithm of industrial cluster based on vector space

- Parametric model updating with frequency and MAC combined objective function of port crane structure based on operational modal analysis

- Evacuation simulation of different flow ratios in low-density state

- A pointer location algorithm for computer visionbased automatic reading recognition of pointer gauges

- A cloud computing separation model based on information flow

- Optimizing model and algorithm for railway freight loading problem

- Denoising data acquisition algorithm for array pixelated CdZnTe nuclear detector

- Radiation effects of nuclear physics rays on hepatoma cells

- Special issue: XXVth Symposium on Electromagnetic Phenomena in Nonlinear Circuits (EPNC2018)

- A study on numerical integration methods for rendering atmospheric scattering phenomenon

- Wave propagation time optimization for geodesic distances calculation using the Heat Method

- Analysis of electricity generation efficiency in photovoltaic building systems made of HIT-IBC cells for multi-family residential buildings

- A structural quality evaluation model for three-dimensional simulations

- WiFi Electromagnetic Field Modelling for Indoor Localization

- Modeling Human Pupil Dilation to Decouple the Pupillary Light Reflex

- Principal Component Analysis based on data characteristics for dimensionality reduction of ECG recordings in arrhythmia classification

- Blinking Extraction in Eye gaze System for Stereoscopy Movies

- Optimization of screen-space directional occlusion algorithms

- Heuristic based real-time hybrid rendering with the use of rasterization and ray tracing method

- Review of muscle modelling methods from the point of view of motion biomechanics with particular emphasis on the shoulder

- The use of segmented-shifted grain-oriented sheets in magnetic circuits of small AC motors

- High Temperature Permanent Magnet Synchronous Machine Analysis of Thermal Field

- Inverse approach for concentrated winding surface permanent magnet synchronous machines noiseless design

- An enameled wire with a semi-conductive layer: A solution for a better distibution of the voltage stresses in motor windings

- High temperature machines: topologies and preliminary design

- Aging monitoring of electrical machines using winding high frequency equivalent circuits

- Design of inorganic coils for high temperature electrical machines

- A New Concept for Deeper Integration of Converters and Drives in Electrical Machines: Simulation and Experimental Investigations

- Special Issue on Energetic Materials and Processes

- Investigations into the mechanisms of electrohydrodynamic instability in free surface electrospinning

- Effect of Pressure Distribution on the Energy Dissipation of Lap Joints under Equal Pre-tension Force

- Research on microstructure and forming mechanism of TiC/1Cr12Ni3Mo2V composite based on laser solid forming

- Crystallization of Nano-TiO2 Films based on Glass Fiber Fabric Substrate and Its Impact on Catalytic Performance

- Effect of Adding Rare Earth Elements Er and Gd on the Corrosion Residual Strength of Magnesium Alloy

- Closed-die Forging Technology and Numerical Simulation of Aluminum Alloy Connecting Rod

- Numerical Simulation and Experimental Research on Material Parameters Solution and Shape Control of Sandwich Panels with Aluminum Honeycomb

- Research and Analysis of the Effect of Heat Treatment on Damping Properties of Ductile Iron

- Effect of austenitising heat treatment on microstructure and properties of a nitrogen bearing martensitic stainless steel

- Special Issue on Fundamental Physics of Thermal Transports and Energy Conversions

- Numerical simulation of welding distortions in large structures with a simplified engineering approach

- Investigation on the effect of electrode tip on formation of metal droplets and temperature profile in a vibrating electrode electroslag remelting process

- Effect of North Wall Materials on the Thermal Environment in Chinese Solar Greenhouse (Part A: Experimental Researches)

- Three-dimensional optimal design of a cooled turbine considering the coolant-requirement change

- Theoretical analysis of particle size re-distribution due to Ostwald ripening in the fuel cell catalyst layer

- Effect of phase change materials on heat dissipation of a multiple heat source system

- Wetting properties and performance of modified composite collectors in a membrane-based wet electrostatic precipitator

- Implementation of the Semi Empirical Kinetic Soot Model Within Chemistry Tabulation Framework for Efficient Emissions Predictions in Diesel Engines

- Comparison and analyses of two thermal performance evaluation models for a public building

- A Novel Evaluation Method For Particle Deposition Measurement

- Effect of the two-phase hybrid mode of effervescent atomizer on the atomization characteristics

- Erratum

- Integrability analysis of the partial differential equation describing the classical bond-pricing model of mathematical finance

- Erratum to: Energy converting layers for thin-film flexible photovoltaic structures