Abstract

In the world of modern industry, which is constantly evolving, the manufacturing sector is intricately connected to the revolutionary currents of the digital economy. Considering the on-going digital revolutions, this study aims to evaluate the robustness of supply chains in the industrial sector. This result was reached by conducting in-depth interviews and analyzing the resilience performance of business systems in the manufacturing industry. The findings indicated that redundancy is the most significant component of resilience. The major purpose is to ascertain how these chains can hold up amid constantly shifting digital dynamics. Utilizing an innovative index contribution technique, our approach uniquely measures the manufacturing sector’s resilience in the ever-changing digital economy. An index contribution model driven by digital economy measurements is included in this case study, focusing primarily on a particular manufacturing company. This research aims to build a comprehensive framework for measuring the resilience of industrial chains. Identifying important indications of resilience, particularly for the case study company, is the first phase of the technique. These indicators include the robustness of the digital infrastructure, the supply chain’s flexibility, and the technology’s adaptation. During the research, the strengths and weaknesses of the manufacturing industry chains are investigated, which leads to the discovery of nuanced insights. Stakeholders can utilize the one-of-a-kind model’s actionable insights to navigate and enhance their resilience in the constantly shifting industrial sector. Considering the dynamic nature of the manufacturing industry, it is of the utmost importance to adopt preventative measures to guarantee the firm’s ongoing development and adaptability. By providing a fresh analytical framework, this study contributes to a better understanding of the complexities of contemporary industrial resilience.

1 Introduction

In response to the advent of the digital economy, the industrial sector, a primary driver of economic expansion, is going through a profound transformation. The purpose of this investigation is to get an understanding of the degree to which the chains of the manufacturing industry can withstand the digital era. The most recent article that we have produced (Le et al., 2023) is where we set the basis for an all-encompassing evaluation framework. In this publication, we provide a model for index contribution that combines many different resilience characteristics.

In addition to being a leading indicator of economic success, the digital economy is redefining conventional production principles, which is causing the existing environment of the manufacturing industry to undergo significant transformation.

This contrasts with big firms, who can generally obtain the funds to construct infrastructure. One of the most prevalent resource-related challenges organizations have faced recently is the inability to obtain and keep internet access (Liu et al., 2023).

Since most companies depend on suppliers for guidance and support and lack the resources to establish their security procedures, information security is an essential concern for many sectors. This, along with other concerns about online privacy and security, is the most significant barrier to the widespread use of shopping online.

1.1 Research Background or Problem Statement

By encapsulating the multifaceted nature of resilience, our model provides a structured and systematic means of analysis. It lays the foundation for a holistic evaluation framework that accommodates the complexities and nuances inherent in the contemporary manufacturing landscape. This index contribution model (ICM) research is a testament to the imperative need for an adaptive understanding of resilience in evolving technological landscapes. As a crucible of innovation and economic growth, the manufacturing industry stands to benefit significantly from insights gleaned through this study. Adding to the existing body of knowledge in the field is the first objective of this investigation. The second objective is to supply academics, policymakers, and practitioners in the business world with the resources they require to confront the challenges and seize the opportunities that have arisen as a result of the paradigm shift that has been brought about by the digital economy (Le et al., 2023). Further highlighting the need to enhance manufacturing’s resilience is that the difficulties presented by the digital economy are becoming more evident. The fast obsolescence of technology, the risks posed by cybersecurity, the difficulty of managing digital supply networks, and the need for resilient ways to respond to unexpected interruptions are some of the problems that are now being faced.

The change in the industrial sector that the growth of the digital economy has brought about is a significant phenomenon that marks a departure from traditional knowledge. As the industrial sector adjusts to the ever-changing digital era, it will go through a profound transition. The industrial sector is a lynchpin of economic growth that is always there. This research aims to undertake a scholarly endeavour to understand the intricacies of the resilience of supply chains in the manufacturing industry. This research is inspired by the digital revolution that is now taking place.

Following a thorough analysis of scholarly discourse, the narrative of resiliency in manufacturing develops, descending into a captivating web intertwined with the digital economy’s revolutionary threads. The principles of resilience, which have been around for a very long time, are included in this intricate system, along with the new dynamics that have emerged as a result of the development of the digital era. When academics and experts in the area try to construct resilience indicators, they encounter increasing opposition; hence, it is necessary to transition away from traditional methodologies and toward more innovative ways (Zhang et al., 2023). Because of the complexity of the industrial sector, we need to completely rethink our idea of resilience and how we evaluate it. Researchers and practitioners in the sector are pushing for a novel strategy that rejects conventional methodologies in favour of more inventive alternatives. They face comparable challenges when constructing resilience measures (Zhang et al., 2023).

In a broader sense, we intend to contribute to the existing body of knowledge concerning the resilience of companies. In response to the ever-evolving opportunities and dangers presented by the digital economy, we provide the ICM, which represents a revolutionary paradigm shift. Through the provision of a theoretical foundation, the overriding objective of this model is to incorporate the numerous and intricate facets of resilience. We are hopeful that by putting it into action, we will be able to set the framework for a complete evaluation system that goes beyond the standard criteria to provide a more nuanced perspective on the adaptability of industrial supply chains.

As we embark on this research endeavour, we recognize the need to venture into new digital land; incorporating technology is causing a fundamental shift in the structure of industrial processes. This research aims to shed light on the resilience dynamics that define the present industrial environment by bridging the gap between innovation and tradition.

It will become abundantly evident that defining resilience metrics is a challenging endeavour as we proceed through the future chapters and examine the existing body of knowledge. As a result of the complex link that exists between the digital economy and industrial resilience, the amount of information that is rising in this area is a reflection of that relationship. We will describe in full the arduous procedures utilized to construct the ICM in the methodology portion of our article (Liu et al., 2023). This will guarantee that the framework is robust and backed by empirical evidence.

1.2 Significance of the Study

The proposed ICM represents a tangible approach to comprehensively evaluating the resilience of manufacturing industry chains.This type of research aims to amuse oneself; rather, it is a direct response to the shifting requirements of the manufacturing sector. Through the framework we have built and the outcomes analysis that will follow, our objective is to make a difference in the procedures utilized by industry players and the conversations in academic circles. By scrutinizing the resilience of manufacturing industry chains in the digital era, we aim to equip policymakers, practitioners, and academics with valuable insights that can inform decision-making processes and foster sustainable growth within this vital sector of the global economy.

Many factors controlling the supply chain have changed due to the high complexity of the business environment (Aliahmadi et al., 2022), environmental change and dynamism, unpredictability, and ideas like globalization and increased rivalry of businesses nationally and worldwide. In such a scenario, businesses in the supply chain need to be ready for anything that might come their way, as the environment is always changing. Building a robust supply chain is one way to deal with these problems. A resilient supply chain can weather economic storms and other forms of uncertainty. The manufacturing industry faces many difficulties in today’s digital economy, highlighting the fundamental need for strong resilience methods. To begin, fast technical improvements often result in diminished product life cycles and increased complexity in manufacturing procedures. This phenomenon makes it necessary to continuously adapt and upgrade digital infrastructure, increasing the likelihood that these technologies may become obsolete shortly. Second, the operations of manufacturing facilities are exposed to major risks posed by cybersecurity threats. These risks include the theft of intellectual property, interruptions in operations, and the possibility of breaches in supply chain networks. Thirdly, the globalization of supply chains has resulted in the introduction of additional complications in managing linked networks that span a variety of geographical locations. This makes the supply chains more vulnerable to global disruptions such as natural disasters or geopolitical conflicts.

The article has been organized as follows: Section 2 discusses the related work of this proposed work. Section 3 discusses the methodology of the proposed work. Section 4 discusses the results, and Section 5 concludes the research.

2 Literature Review

According to Liu et al. (2023), the resilience of the industry may be inferred from the many perspectives that have been expressed on the consequences of digitization. According to Jain et al. (2017), the author first sketched the interaction between many enablers to construct a hierarchical supply chain resilience model (SCRES). The concept of a digital SC twin was initially put up by Ivanov and Dolgui (2021), who put forward the proposal.

Research conducted by Zhang et al. (2023) suggests that it provides a unified perspective to explore the intricate relationship between digitalization and resilience. By presenting the ICM (Liu et al., 2023), we want to usher in a new age of measurement and comprehension. According to Zhang et al. (2023), the industry’s dynamic nature is exemplified by the significant number of academic viewpoints that contribute to the digital transformation of the industrial sector.

To accomplish this objective, one must go into supply chain optimization, a topic brought up in a great deal of academic discourse. It is a contested question in academic circles how the responsiveness and flexibility of industrial supply networks have been transformed due to the introduction of digital technologies.

Innovative approaches to optimizing the intricate web of distribution and production networks are abundant in the published literature. Some examples of these approaches include incorporating advanced data analytics for demand forecasting and implementing smart manufacturing processes. According to Tao et al. (2023), this exemplifies the industry’s need to enhance its operating efficiency to adapt to the ever-evolving technology settings.

The author proposed research to advocate for the most suitable functional production process for the most common industrial sectors. Achieving maximum output employing the Cobb-Douglas production function has been the primary goal, with two-input and three-input situations being studied independently. A simple advantage between the two models has been identified (Hanan & Ali, 2023).

Simultaneously, the literature examines adaptive strategies within manufacturing resilience. The spectrum of adaptive measures spans a continuum from agile production methodologies to dynamic risk management frameworks. Scholars contribute richly to this narrative, exploring how digital tools and technologies empower manufacturers to adapt swiftly to unforeseen disruptions. The findings of this study shed light on the dynamic nature of adaptive strategies and the myriad of ways in which manufacturers are utilizing digital capabilities to become more flexible and responsive (Zhao et al., 2023a). Amid this diverse array of scholarly viewpoints, a harmonious link emerges between the time-tested principles of industrial resilience and the cutting-edge technical breakthroughs that are changing the bounds of this concept. This is a concise summary of the challenges that arise when integrating old practices with contemporary technologies. According to Tao et al. (2023), the tale of resilience is determined by a delicate balancing act between the strategies of robust supply chain management that have stood the test of time and the possibilities of digitalization that have the potential to change the game completely. As we work through this mound of research, we can figure out the intricate ballet of existing resilience variables and novel dynamics of the digital economy. In this context, resilience covers more than a variety of perspectives; it also encompasses the dynamic character of the manufacturing sector (which is always evolving). Throughout the narrative, new understandings of how the digital economy influences the resilience dynamics of supply chains in manufacturing are contributed to the current body of knowledge (Duan, 2023).

The purpose of our literature study is not simply to compile a list of viewpoints; rather, it is an attempt to elucidate the fundamental aspects of digital manufacturing resilience. The circumstance allows us to engage in synthesis, which in turn inspires us to conceive of a model of index contribution that has the potential to depict the intricate interdependencies that exist between the many components. We wish to provide some structure to the inherent resilience discovered in the body of literature as we work toward achieving this aim. According to the findings of Liu et al. (2023), our objective is to develop a structured framework that will assist us in comprehending the intricate connections within the industrial resilience landscape.

In addition to doing a literature analysis, our objective is to identify essential aspects that will assist us in comprehending the concept of industrial resilience in its totality. The technique involves dealing with inherent resilience, necessitating an organized approach owing to the varying sentence lengths and complexity observed in academic discourse. When dealing with inherent resilience, the method is presented. In our efforts to comprehend these complexities, we have realized the significance of adopting a nuanced perspective beyond the conventional categorization practice. In manufacturing resilience, the suggested ICM may serve as a guide for professionals and academics since it provides a methodical approach to examining the numerous linkages within the sector. It is the intention of the Tao et al. (2023) that by dissecting the subject matter into its component elements, readers would be able to acquire a more comprehensive understanding of the opportunities and risks that are posed by the digital era.

The Artificial Intelligence of Things (AIoT) was proposed to evaluate key impressions of the resilient supply chain (Aliahmadi et al., 2022). Through an analysis of the AIoT-based supply chain’s dimensions and components, this research sought to understand how these technologies affect equality. At last, the most crucial aspects of the effect on the resilient smart supply chain are identified by employing the nonlinear fuzzy decision-making approach. The smart supply chain may be strengthened by comprehending this evaluation.

A fuzzy analytic hierarchy process was suggested to prioritize Green Project Management (GPM) (Alavi et al., 2022). This research used A pairwise comparison questionnaire to gather data from specialists in the building sector. One way to determine how trustworthy the survey is is to look at the consistency rate index. According to the findings, one of the five GPM tasks is to form a team capable of coordinating the project’s execution with pertinent environmental regulations. In that order, development, project charter documentation, objective formulation in the project charter, quality control, cost, planning, environmental activity safety, and GPM program preparation should all get increased focus.

Antifragility Analysis Algorithm was recommended for Assessing Digitalization Strategies of the Agricultural Economy in the Small Farming Section (Li et al., 2023). The heuristic used in this study is adjusting model inputs for future scenarios while considering the most important environmental elements influencing future uncertainty. Adjustments to the present situation do not improve the average outcomes as much as an antifragile approach. At last, the antifragility scores are used to rank the antifragility strategies. For this method’s explanation, the author looked at seven approaches to digitizing Iran’s small-scale agricultural industry. The author then constructed the future scenarios using six critical indicators and displayed the choices’ relative importance.

A meta-analysis study was discussed to identify effective factors of organizational resilience (Hamidavi Nasab et al., 2023). Using a systematic coding approach, 14 themes were discovered as determinants impacting OR after data analysis, summarization, and synthesis. Some identified factors were organizational culture, personnel, financial and economic viability, cooperation, customers and markets, learning, redundancy and resources, control, flexibility, and readiness. So were resilience policymaking, social capital, and planning and preparation. This research is groundbreaking since it is one of the first to use a meta-synthesis of qualitative data to present a new way of looking at the elements that impact OR and how to improve the field.

A conceptual framework was deliberated for green smart IoT-based supply chain management (Nozari et al., 2021). The four-stage architecture of the Internet of Things served as the basis for this framework, which was developed via a combination of literature study, expert interaction, and expert opinion. Sustainable and environmentally friendly decision-making in the supply chain may be mapped out with the help of this framework, which shows how data creation is directly related to the sectors impacted by environmental sustainability. Industry leaders in supply chain management have approved this framework, which they believe may help manufacturing companies adopt a green supply chain strategy that prioritizes technological advancements.

Resilient supplier selection under disruption risks was presented for the robust supply chain network design (Rezaei & Qiong, 2024).The first objective function maximizes overall profit, and the total supplier resilience score is maximized in the second. The resilience scores for the objective functions and the five resiliency criterion weights were obtained using Fuzzy SECA. Using the fuzzy SECA technique, the author can determine the resilient suppliers’ rankings. The team has developed a method to integrate better production scheduling, vendor evaluation, and order distribution. To maximize profit for a real-life case study, the ε-constraint approach was used to determine the optimal number of choice variables. The author has completed the Pareto solution analysis for the tradeoff between resilience and robustness.

Economic uncertainty was introduced to address the supply chain risks of industrial plants (Rahmani Fazli & Teymori, 2024). Analysis in this study was performed using structural equation modelling and Amos software. 385 observations were collected through questionnaires from managers of manufacturing joint-stock companies, ranging from production workshop supervisors to higher positions, using random sampling based on Morgan’s table. Evidence suggests that supply-side risks may impact downstream supply chains when implemented as preventative measures since they can set off supply and manufacturing risks, which can cause delivery risks. As a result, manufacturing and delivery risks may be better managed by lowering supply risks. Coefficients of 1.1, 2.8, and 1.95 for economic uncertainty show that it substantially affects supply chain risks (production), delivery risks (supply), and profitability (economic stability).

Step Wise Weight Assessment Ratio Analysis (SWARA) and Technique for Order Preference by Similarity for evaluating green and resilient suppliers by path analysis (Mansory et al., 2021). According to the route analysis, each defined criterion affects the supplier’s performance. Afterwards, the criteria and sub-criteria were assessed, and their relative relevance was determined using the novel SWARA decision-making process in conjunction with the expertise of thirty experts. Among the primary factors that were ultimately considered, “resilience” ranked highest, followed by “green” in second place, and “traditional” at the very bottom. Accordingly, business leaders may benefit greatly from this study’s conceptual framework to better the suppliers’ environmental challenges and resilience situations. Additionally, this study aimed to build and refine existing criteria and improve the company’s supplier selection process by including green standards and resilience.

Cobb–Douglas Production Function was implemented for Production Optimization in Manufacturing Industries (Hanan & Ali, 2023). This research aims to recommend the best functional form of the production process for the most common industrial industries to meet this goal. Achieving maximum output employing the Cobb–Douglas production function has been the primary goal, with two-input and three-input situations being studied independently. A clear winner between the two models has been identified. Finally, state-of-the-art optimization subroutines are used to estimate the production function parameters.

The Resilience of Steel Moment Frame Structures has been analyzed (Faghihmaleki et al., 2023). The results show that on the three-story frame, the axial force of the beams next to the removal location increases by around 2.15 times compared to the values associated with corner beam extraction. On the flip side, under beam removal circumstances, the axial force of the beams close to the removed column ranged from 5 to 49% of their respective values in the five-story frame. More so, it was discovered that the maximum displacement decreased as the number of storeys increased. Results showed that maximum displacements in five-story frames ranged from around 7 to 22% of the comparable values in three-story frames, with variation according to the position of the removed column. According to these findings, bracing-based reinforcement becomes more successful in preventing a progressive collapse in steel moment frame structures as the number of storeys increases. When it comes to constructions with more stories, this improvement in performance against progressive collapse becomes even more important.

Ranking Technological Capabilities to Enhance Resilience of the Supply Chain was implemented (Hosseini Dehshiri & Aghaei, 2021). To begin, experts in the area were given a set of criteria based on the review’s investigation of supply chain resilience indicators about technical capabilities and their impact on the field. After these criteria were reviewed in the case study and by experts using the Fuzzy Delphi approach, they were refined and finalized. The next stage was to use the SWARA method to weigh important indications. It was determined that the most important metrics were technical cooperation, supply chain agility, and supply flexibility.

A Big Data-based Supply Chain (Case Study: FMCG Companies) was established (Nozari, Ghahremani-Nahr, 2021). The study conducted here is qualitative and falls under developmental and applied analyses. Utilizing big data derived from the Internet of Things, this research presents the conceptual framework of an agile supply chain and identifies the components that impact its agility. The findings provide a blueprint for anticipating and meeting the organization’s agility requirements, boosting customer happiness, increasing market share, and giving the business a competitive edge.

A network analysis technique was proposed to Investigate the influence of blockchain technologies on the performance of road freight transportation management (Negravi & Titidezh, 2023). The network analysis method is among the most reliable options based on several factors. Considering blockchain technology in four domains: digital infrastructure, transparency, trust, and safety and fourteen sub-domains with four levels, the author constructed this model with four primary performance waste criteria (time, cost, trust, and security and safety). The research shows that this technology has made road freight management systems more efficient. Time wastage was cut by 46.44%, and money wastage was cut by 53.56% thanks to digital infrastructure technologies. Cost wastage decreased by 23.19%, time wastage by 22.30%, and safety wastage by 53.71% due to increased visibility. Smart contracts impacted the two waste mentioned above categories by 88.81 and 11.19%, respectively, while transparency technologies impacted time by 22.63% and trust and security by 77.37%. Transportation expenses, control costs, information transparency, product condition management, and driver monitoring were determined to be the most effective wastes.

2.1 Research Gap

There is a noticeable deficiency in the number of studies conducted on the applicability of these theoretical models in the real world. Through providing real examples that bring theoretical concepts to life, our study endeavours to help bridge this gap in knowledge. We intend to add a practical dimension to the current body of knowledge by employing this method to provide practical insights that follow what practitioners in the area have encountered.

To put it succinctly, the literature review is the first chapter of our research project and acts as the foundation for the project. By combining traditional resilience characteristics with the digital economy’s revolutionary implications, one may understand the complexities involved in the situation. With an eye toward the future, we demonstrate our dedication to understanding the complexity of manufacturing resilience through the model we have developed for index contribution. The inherent resilience in the emerging discourse guides this model.

The literature study, which comprises a rigorous analysis of prior academic publications, provides a comprehensive look at what is now known regarding the intersection of the digital economy and manufacturing industry chains. This is accomplished by providing a comprehensive assessment of what is currently known. We based our assessment on pertinent scholarly articles, research studies, and books. Our review uses data from many sources to identify regions with inadequate information and provide useful conclusions. Scholarly publications frequently address how the emergence of the digital economy has altered conventional industrial techniques. Many scholarly works have concentrated on incorporating digital technologies such as Artificial intelligence (AI) and the Internet of Things into manufacturing procedures. This digital connection can make industrial chains more agile, efficient, and responsive from what we can tell from the literature review, many still express concern that the emerging digital economy will leave the industrial sector behind. Many people are worried about interruptions to the supply chain, cybersecurity, and the need to retrain employees to handle new technology. The current body of research delves deeply into the intricate relationship between the online economy and the reliability of supply chains in manufacturing.

3 Methodology

To provide evidence in support of our argument, we provide instances of real-world scenarios in which the Internet economy has either strengthened or damaged industrial supply networks. The reader should be able to better understand the practical consequences of our index contribution process by looking at the examples included below. This study provides a comprehensive understanding of the effects that occur in the actual world through qualitative research approaches. This is accomplished by delving into specific examples. Due to its representative size and willingness to participate in the research, the case study company was chosen from the manufacturing sector. Several sources provided the analysed data, including operational performance records, supply chain interruptions, and resilience measures. Each resilience indicator’s contribution to overall resilience was assessed using a hierarchical model created by the ICM. This study built simulation models to assess the ICM and test robustness under different circumstances.

Through case studies, the research presents a comprehensive picture of how the growth of the digital economy has either reinforced or jeopardized supply chains in the industrial sector. (Garrido & Nunes, 2023) Our research provides a more comprehensive picture when the quantitative and qualitative aspects are considered together.

3.1 Illustrative Example 1: Enhancing Resilience in the Supply Chain through Strategic Digital Integration

A business’s level of digitization is proportional to the usage of smart goods and interconnected technology in everyday tasks. Various business operations nowadays are centred upon digitalization. The whole supply chain is undergoing digital transformation, impacting not just corporate goods and business procedures. Information and network technologies have advanced in recent years due to cloud computing, big data, the Internet of Things, and blockchain. The capacity of a business to rapidly adjust to a complicated external environment; thus, the capacity to quickly recover from supply chain risks and learn from them. The capacity to enhance supply chain performance is directly proportional to the degree of strength. Businesses and consumers may better coordinate their interactions by creating standard information-sharing channels.

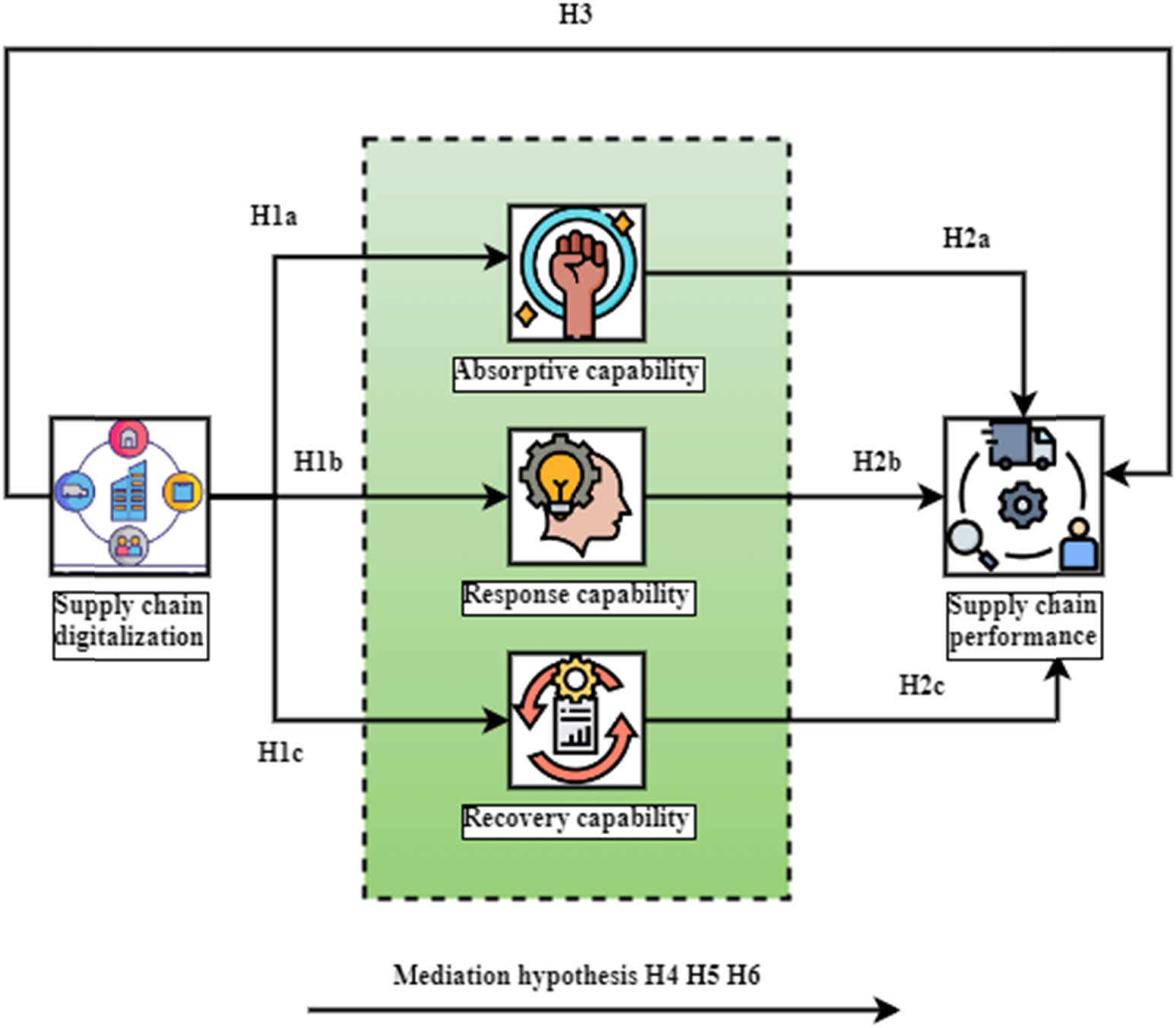

Introduction: In this investigation, according to Figure 1, we delve into the transformative journey of a prominent manufacturing conglomerate, Quantum Manufacturing Solutions, which strategically employed digital technologies to reinforce its supply chain resilience. The objective was to navigate the intricate challenges presented by an ever-evolving business landscape and optimize operational efficiency through cutting-edge digital solutions (Zhao et al., 2023a).

Supply chain resilience based on digitalization. Source: Figure was created by the author.

Digital Integration Approach: Quantum Manufacturing Solutions embraced a comprehensive strategy for digital integration, leveraging advanced analytics and real-time data monitoring as pivotal components of their approach. The company gained unparalleled insights into its supply chain dynamics by deploying sophisticated algorithms, facilitating proactive decision-making and adaptive responses to emerging challenges (Liu et al., 2023).

Optimization, also known as augmentation, of industrial processes was the key pillar of the strategy for digital integration. By doing data analysis in real-time, Quantum Manufacturing Solutions was able to identify the operational inefficiencies and bottlenecks that were occurring inside their organization. Following the implementation of more automation and improvements that were directed by data-driven insights, the outcomes included the optimization of resources, the decrease in lead times, and the simplification of procedures. In addition, these improvements were successfully implemented. Strategies for avoiding problems: Keeping a close check on the data in real time enabled the company to implement a preventative strategy, which was an extremely important step. For Quantum Manufacturing Solutions, the ability to apply preventative measures was made possible by rapidly detecting problems in the supply chain. Because of this, they could take action before the problems became more severe. This strategy not only decreased the amount of time that the production environment was exposed to downtime, but it also safeguarded the production environment as a whole, as Zhao et al. (2023a) discovered.

This was accomplished through the collaborative efforts of digital monitoring and intelligent analytics, which resulted in a considerable increase in overall efficiency. Quantum obtained enhanced operational productivity and efficiency due to production processes that were more adaptable and sensitive to changes in the market. Quantum accomplished this. Having this link is both powerful and advantageous. According to Kumar et al. (2023), the organization successfully improved its capacity to endure the effects of unknowns and influences from the outside world. Utilizing data-driven insights derived from digital technology was made feasible by adopting a proactive approach to the difficulties faced. Last but not least, Case Study 1 illustrates how implementing intelligent digital technologies might enhance the supply chains of the industrial sector. Quantum Manufacturing Solutions overcame ever-changing external difficulties using advanced analytics and real-time data monitoring. This was accomplished by continuously simplifying production processes. We accomplished this by monitoring the data in real-time during the process. The evidence shown here (Atif, 2023) lends validity to this assertion and emphasizes the need for industrial companies to use digitalization as a long-term survival and development strategy.

3.2 Case Study 2: Digital Challenges at Techno-Forge Industries: Navigating Disruptions

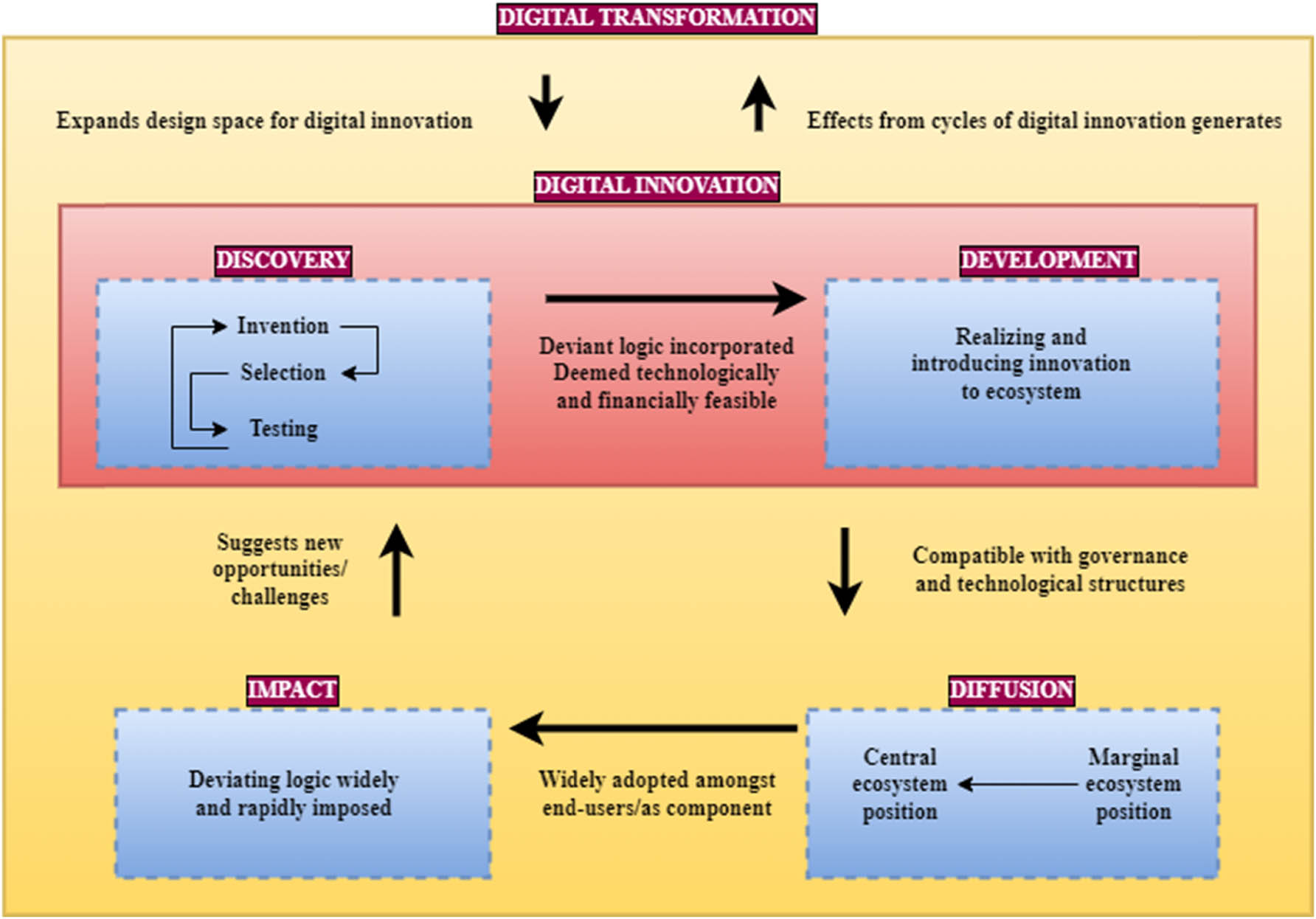

As seen in Figure 2, the arrival of the digital era has presented manufacturing with new opportunities and new challenges that need smart responses. Our second case study sheds light on a poignant example of an industrial giant, Techno-Forge Industries, grappling with the consequences of inadequate cybersecurity measures (Luo et al., 2023).

Model of digital disruptions.

The Scenario: Within the confines of Techno-Forge Industries, the lack of robust cybersecurity protocols proved to be a critical vulnerability. As the organization increasingly depended on interconnected digital systems, the latent vulnerabilities within its cyber infrastructure became glaringly apparent. The convergence of inadequately protected networks and sophisticated cyber threats led to a cascade of disruptions in the production line (Oosthuizen & Manzini, 2022).

Although innovations in both processes and products may cut costs or alter demand and, by extension, income potential, they are still expensive endeavours. Management strategy, demand-side variables, sector regulation, chances to appropriate innovation rents (which are likely to be affected by the intensity of competition), technology possibilities, and competition are the variables that businesses use to guide their innovation activities. These other aspects must be included as control variables to isolate the impacts of regulation. There is a disparity between regulated and uncontrolled enterprises at the level of the network platform because regulation is often unequal. Companies operating at the content/application layer are not expected to be subject to regulations particular to their industry, but competition laws still govern them. The following equations outline the fundamental framework of the conceptual model.

Equation (1) represents the potential return on investment for regulated network operators investing in process enhancements. Including the expense of pursuing process improvements, a profit-seeking corporation will want to maximize the gap between revenues and costs. The service’s production cost is subsequently decreased due to process advancements. The technical possibilities (

Equation (2) describes the optimal circumstances under which an uncontrolled rival may maximize profits.

Horizontal regulatory measures that facilitate entrance to the market (such as local loop unbundling) often have different effects on new entrants than on regulated incumbents. Reducing the cost of delivering a service is one benefit of such methods. However, these regulations will encourage innovation to focus on services-based entrance to the market, which may take advantage of horizontal regulation’s cost-cutting measures.

Comparing the quantities offered by

in which

Optimization criteria that are known to work are obtained by solving these circumstances. For instance, established service providers will pour resources into R&D until the marginal cost of new features is equivalent to the marginal gain.

Industry-specific breakthroughs:

By summing up the choices made at the company level, we may find the linkages at the sector level (refer to equations (4)–(6)). Revolutionizing the network layer throughout the industry. The total industry-wide innovation is the sum of innovations at both the network layer and the application layer:

Revolutionizing the application layer throughout the industry

Progress in a certain industry

Heterogeneity in invention processes complicates aggregation, as discussed in the following section. By delving further, comparable measurements that can overcome this obstacle may be defined. Given that regulations impact various types of businesses in different ways, sometimes in ways that foster innovation and sometimes influence innovation, statistics at the sector level only show the overall impact of these competing factors. The study project will capture evolving patterns of innovation, revealing how rules impact various forms of innovation differently. Vertical kinds of regulation are usually not applied to unregulated market entrants. New entrants and incumbents are affected differentially by horizontal regulations, such as local loop unbundling. Regulators may minimize innovation incentives for incumbents and promote service-based innovation for new entrants by lowering service delivery costs. Vertical regulations often affect application providers because they restrict network operators’ capacity to distinguish services. Reduced resources spent and more innovative service delivery might result from this.

Disruptions Unveiled: The disruptions manifested in multifaceted dimensions, encompassing operational inefficiencies, compromised data integrity, and, most notably, significant downtimes. The production line, once a symbol of seamless efficiency, now bore the brunt of cyber intrusions, resulting in prolonged periods of inactivity. Financial losses accrued rapidly, with each moment of downtime translating into tangible economic repercussions (Zhao et al., 2023a).

Financial Consequences The shocking facts that were uncovered by measuring the financial toll these disruptions took to bring to light the urgent need to rethink cybersecurity regulations. Indirect costs were associated with missed productivity and damaged consumer relationships, which added to the total financial losses. These costs were in addition to the direct charges incurred to rectify the cyber breach. However, Tao et al. (2023) discovered that the economic repercussions had a significant impact on the manufacturing ecosystem, which in turn had a ripple effect that affected distributors, suppliers, and the economy as a whole.

This case study demonstrates that digital security measures must be completed now, particularly those implemented in industrial settings. This is an essential component of comprehensive cybersecurity. Because the discovered vulnerabilities demonstrate how linked the digital world is, it is necessary to take safeguards to protect against cyberattacks. According to Pang et al. (2023), industrial organizations need robust cybersecurity procedures to guarantee their continued profitability and efficiency in the current digital age.

The lessons that can be learned from the case study underline the interconnectivity of digital security and operational resilience, which benefits academic institutions and enterprises (Yazdi et al., 2023).

4 Results and Discussion

By analysing the data from the case study company using the ICM, Empirical Analysis confirmed that the model effectively measured and improved resilience. This study tested the model’s reliability and stability by comparing its output to standards and best practices in the business world. This study used sensitivity analysis to see how well the model held up when subjected to different values for the input parameters and starting assumptions. This study included stakeholder input from the case study company to confirm the applicable and workable resilience measures found by the model. As described in the methodology section, the manufacturing industry chain’s resilience was evaluated using three critical metrics: technical adaptation, supply chain flexibility, and digital infrastructure robustness. Machine learning techniques were used for quantitative analysis, and the results showed strong connections between digital infrastructure robustness and the industrial chain’s capacity to tolerate disturbances. This parameter is crucial for improving resilience.

4.1 Case Study 1: Enhancing Supply Chain Resilience through Strategic Digital Integration

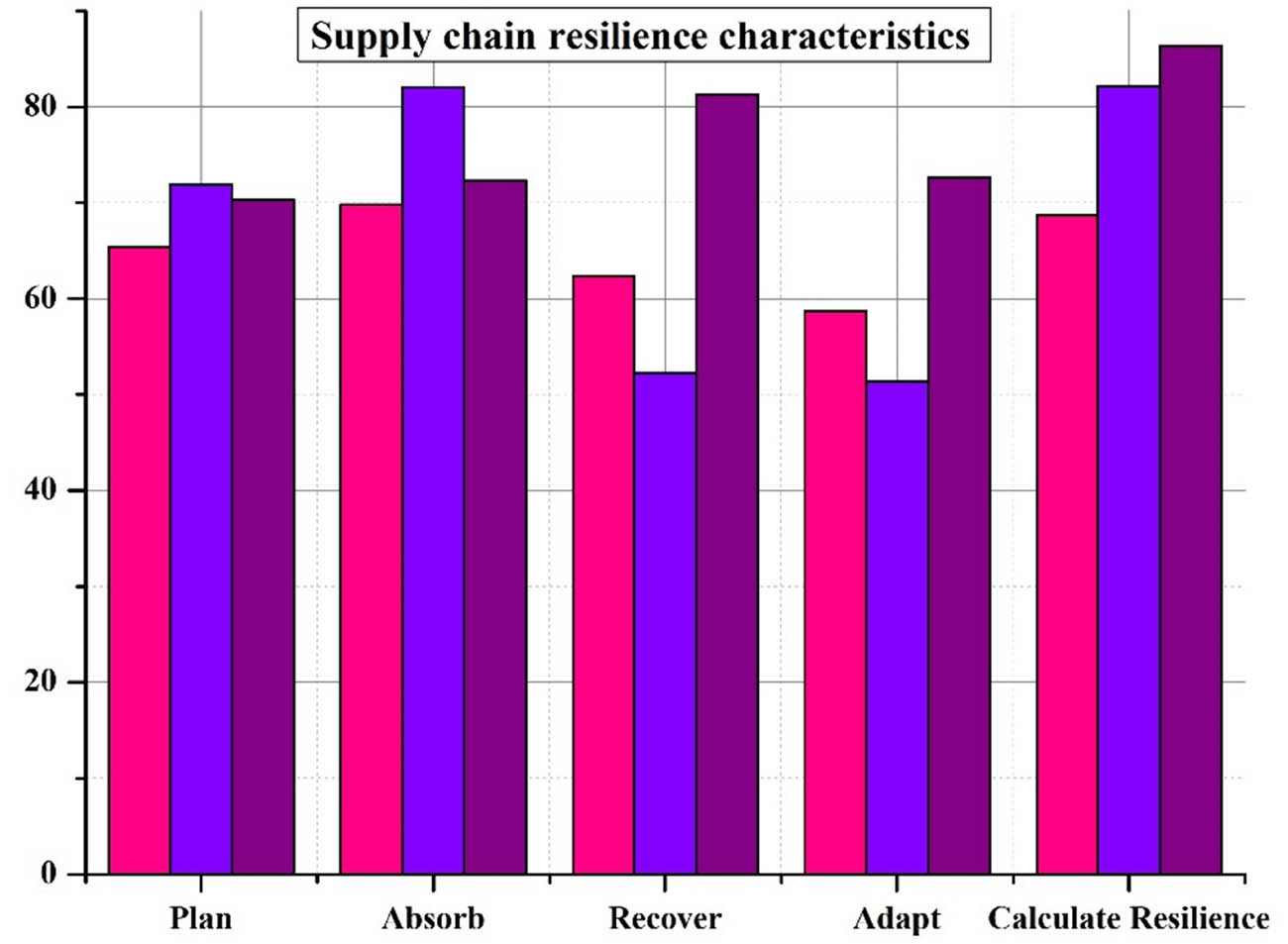

The industrial giant demonstrated its foresight in preventing disruptions by demonstrating how digital technology may effectively address issues at an earlier stage. When minimizing downtime and preserving the integrity of the production environment, it is necessary to implement a proactive data-driven strategy, as demonstrated by the findings in Figure 3. Research conducted by Liu et al. (2023) suggests that for manufacturing businesses to traverse the complex modern business environment successfully, they must implement this strategy.

Supply chain resilience characteristics.

4.2 Case Study 2: Digital Challenges in Manufacturing: Navigating Disruptions

On the other hand, the second case study illustrates how industrial ecosystems are put in jeopardy due to poor cybersecurity protections. The disruptions in the scenario bring to light the intricacy of cyber assaults, which can result in operational inefficiencies, breaches of data integrity, and significant downtime. According to Le et al. (2023), there is an immediate need for reform in cybersecurity policy because of the potentially catastrophic financial implications that might result from it.

In addition to the immediate costs, the lack of financial resources impacts the timeliness of production, the connections with customers, and the economy as a whole. This illustration demonstrates how intertwined the digital world is and how important it is to have a comprehensive collection of digital security measures. According to Zhang et al. (2023), manufacturing companies must establish robust cybersecurity policies as a top priority to guarantee operational integrity and economic survival in the digital age. To accomplish this objective, a mechanism for resolving regional disputes, enhancing communication and collaboration among national cybersecurity agencies, designing protocols for managing hacking events, and sharing data pertinent to the situation must be established.

4.3 Synthesis and Practical Implications

Case Study 2, on the other hand, serves as a cautionary tale about how susceptible systems are to attacks in the absence of robust cybersecurity controls. The disruptions at the manufacturing company brought to light the far-reaching repercussions resulting from inadequate cyber threat protection in this particular instance. Inefficiencies in operations, monetary losses, and larger economic effects were some of the disturbances that occurred when these things happened. This episode indicates very clearly that in this digital era, industrial chains have the potential to be badly and substantially disrupted owing to poor cybersecurity (Le et al., 2023). It is time for all of us to consider this as a warning.

These results are practically relevant for academics and businesspeople involved in decision-making and dialogue about the continuous digitization of production processes. As a result of their accessibility, members of the academic community may use these case studies to inform the development of research priorities and courses. Shen et al. (2022) provide an example of how digital technologies have affected industrial sector resilience and call on scholars to find ways to handle digital transitions well.

Experts in the field may also use the information for risk management and strategic planning. Investments in digital technology may provide industrial organizations with a strategic edge, according to Case Study 1, which found a favourable association between digital integration and operational resilience. Case Study 2 is a cautionary story highlighting the need to prioritize cybersecurity as an essential part of any digitalization project. Corporate executives may utilize these data to inform decision-making, set priorities for resource allocation, and develop strong digital strategies to reduce risks and increase overall resilience (Tao et al., 2023).

Simply put, these case studies add significantly to the continuing discussion about digitizing production processes. The pros and cons of the digital economy must be carefully considered to craft a balanced strategy. To stay successful, resilient, and economically stable in the long run, manufacturing organizations need to carefully integrate digital technology and cybersecurity measures as they traverse this changing terrain (Le et al., 2023). Success, resilience, and sustained economic stability require this. Organizations in the industrial sector would do well to take note of the examples given here and implement a holistic strategy that combines smart digital absorption with strong cybersecurity safeguards. When combined, these data points provide a blueprint for navigating the digital landscape; this blueprint will be invaluable to supply chains in the industrial sector in the years to come. These insights will help us create a more secure and all-encompassing production environment as we navigate the shifting digital economy. Based on an in-depth understanding of the complex relationship between cybersecurity and strategic digital integration in contemporary industrial settings, the results of the previous case studies support the recommendation that manufacturing businesses adopt a comprehensive approach (Zhang et al., 2023).

In the first place, a holistic approach would see cybersecurity and digital integration not as separate things but as interdependent parts of a larger whole. This is where the strategy would begin. On the contrary, it promotes a mutually beneficial partnership between digital technology breakthroughs and strong cybersecurity measures. This integration is essential to build an all-encompassing defence against the dangers and difficulties presented by the digital world (Duan, 2023).

Due to the rapid digitalization occurring worldwide shows a strong relationship between the digital and social economies. The use of digital technology to power industrial and commercial operations is widespread across many sectors. The digital economy has become a constant motivator when promoting structural upgrades in the industry. The industrial structure is additionally quite susceptible to shifts in demand. A consumer’s spending behaviours have a significant impact on output. One way that consumption has altered dramatically due to the fast growth of the digital economy is the widespread adoption of online shopping. Thanks to big data technologies, platforms can more precisely assess customer wants and trends, allowing them to recommend products that are more likely to meet those demands.

In this regard, the synthesis provides direction to enhance the infrastructure for cybersecurity and make it easier to integrate digital technologies into industrial processes smoothly (Govindan et al., 2020). Much like a road map, this guide identifies the most appropriate action.

I would want to take this synthesis one step further and say that it is about resolving issues and constructing supply networks capable of withstanding the test of time in the industrial sector. In this case, we refer to resilience’s capacity to endure and adapt to changes, regardless of whether technical advancements, economic factors, or other factors produce such changes. By enhancing the operational efficiency and responsiveness of the organization, digital technology, which is influenced by the results of the case studies (Liu et al., 2023), contributes to the organization’s resilience.

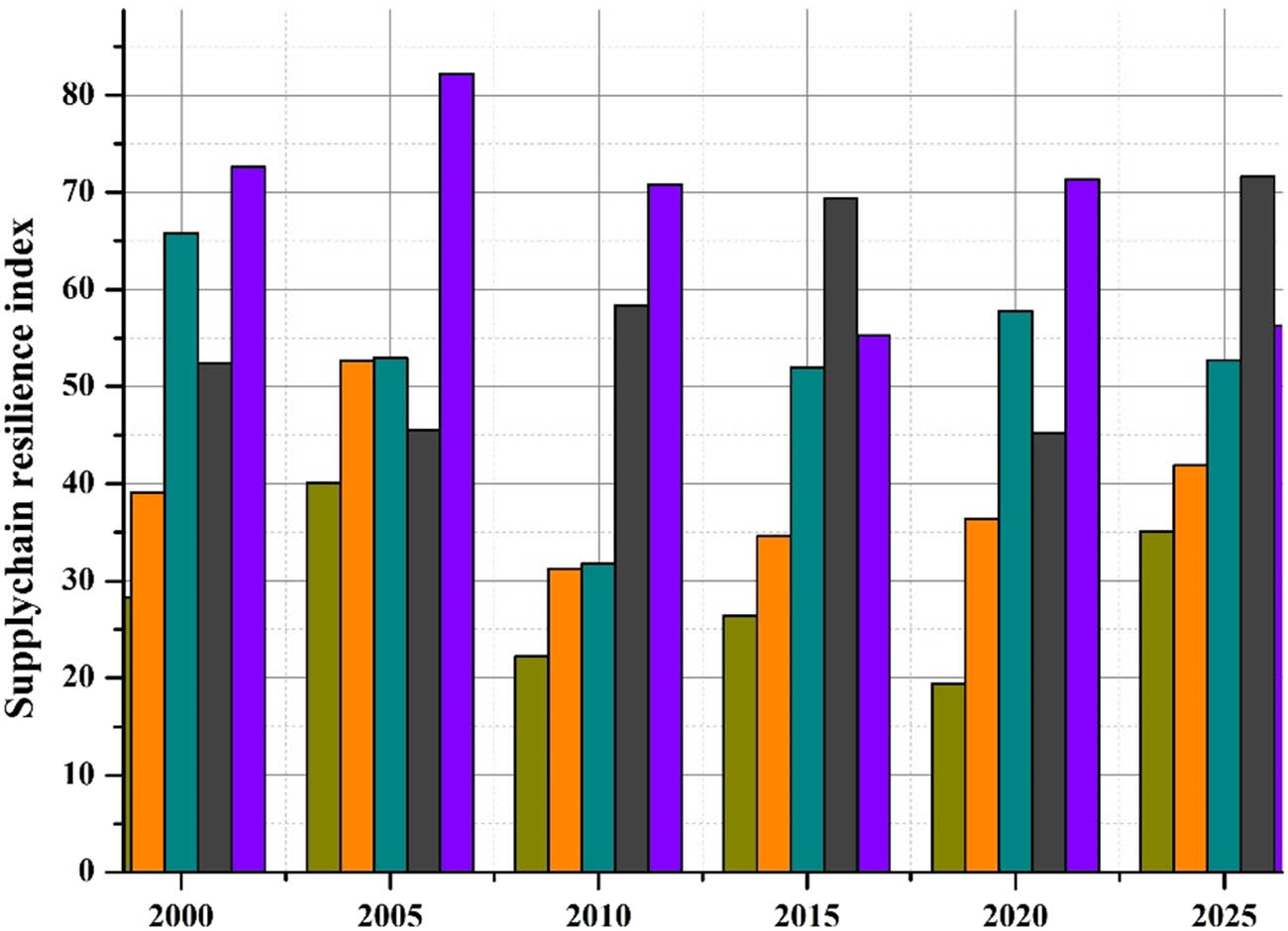

The findings from these case studies act as guiding lights in the ever-changing digital economy, as seen in Figure 4, where both opportunities and risks are shaped by technological progress. In doing so, they shed light on the future and help industrial firms navigate the possibilities and threats posed by the digital landscape. Not only do the symbolic beacons represent light, but they also represent guidance and safety. As businesses continue to traverse the evolving landscape of the digital economy, these insights act as guiding principles, ensuring a more secure, adaptive, and resilient manufacturing ecosystem (Chang et al., 2022).

Supply chain resilience in the digital economy.

This empirical study suggests that employees should improve their digital proficiency and provide a stronger basis for positive relationships with suppliers and customers. To develop corporate digital management, managers should be aware that digital management needs to influence the direction of SCI. This includes accurately acquiring data on consumer consumption and supplier supply. The results of our study provide insight into the effect of SCI and demonstrate that DT has some influence on SC resilience. When digitization and SCI are combined, companies can obtain more accurate information on them, digitize their relationships with suppliers, and digitize their interactions with consumers. Supply chain flexibility factors influence upstream and downstream SCI integration, including business environment adaptability, firm risk information acquisition speed, and risk team formation efficiency.

Consistent with other research, our results highlight the fundamental importance of digital technology in strengthening supply chains in the industrial sector. Their automotive supply chain resilience study found comparable outcomes, demonstrating the significance of predictive analytics and real-time data integration. In addition, our research adds to the literature by presenting a new ICM that encompasses resilience features in the digital economy using measurements from that sector. This method proves that digitization improves industrial resilience and paves the way for better resilience measuring techniques in the future. Further studies might examine other elements impacting resilience in this digital transition age and see whether our model can be scaled across other manufacturing environments.

5 Conclusion

This scholarly exposition enriches the expanding dialogue on fortifying manufacturing resilience within the digital era. The establishment of resilience metrics encounters attention through our model’s index contribution, while resilience manifests in the myriad factors shaping resilience. As the manufacturing milieu transforms, our study provides a groundwork for policymakers, industry professionals, and academics to navigate the intricacies and uncertainties inherent in the digital economy-driven epoch.

This academic thesis substantially augments the escalating discourse encircling manufacturing resilience amid the digital age. A pivotal facet addressed is the definition and quantification of resilience metrics, achieved through our pioneering ICM. The phenomenon of resilience prominently characterizes our work, reflecting the diverse and dynamic factors impacting resilience within the manufacturing domain.

In the perpetually evolving manufacturing landscape, our research is an invaluable asset for policymakers, industry experts, and scholars alike. By furnishing a foundational comprehension of resilience metrics, our work equips stakeholders with the tools to negotiate the intricacies and uncertainties intrinsic to an era propelled by the digital economy. The practical insights presented in this dissertation contribute to the academic knowledge of manufacturing resilience and have implications in the real world. A manufacturing ecosystem that is more resilient and flexible may be established as a result of these insights.

Our research reveals essential resilience metrics and establishes the framework for a full knowledge of the contributing components of resilience. This discovery comes when the industrial sector is undergoing digital change. People dealing with the intricacies and threats of an economy powered by digital technology, such as policymakers, industry practitioners, and academics, will find this information extremely meaningful.Insights like those offered in this dissertation are a valuable resource for anybody attempting to make sense of this age driven by the digital economy. Policymakers can profit from resilience measures when formulating policies to strengthen and adapt the industrial sector. Acquiring an understanding of the factors that influence operational resilience enables practitioners in the industry to take preventative measures against risks. At the same time, scholars investigating industrial resilience lay the framework for subsequent inquiries in the field. Future work will leverage big data analytics and AI to gather real-time data from various sources for more accurate and dynamic resilience measurement.

6 Recommendations

After conducting an exhaustive study on the resilience of manufacturing in the digital era, we have come up with the following collection of recommendations:

6.1 Integration of Resilience Metrics into Policy Frameworks

Integrating resilience metrics into existing policy frameworks becomes an extremely important factor regarding industrial sector policies. This strategic approach is necessary to preserve regulatory measures following the ever-evolving digital economy challenges.

6.2 Continuous Monitoring and Adaptation

The importance of conducting frequent reviews cannot be overstated regarding this advice. Practitioners inside the company must conduct assessments regularly to provide a comprehensive perspective of the robustness of their manufacturing processes. In their capacity as diagnostic tools, these evaluations shed light on the ever-evolving nature of the digital domain, highlight areas of weakness, and highlight areas of strength.

For the response plan to be successful, the adaption phases must be included without any problems. It is the responsibility of practitioners to implement modifications in a timely and efficient manner whenever there is a change in the problems that are occurring in the industrial environment. Adopting a proactive strategy and carefully modifying policies, procedures, and technological infrastructure are necessary to maintain a competitive advantage, adapt to the ever-changing threat landscape, and meet the needs of operational activities. For it to be done, something is necessary. This advice encourages a proactive strategy emphasizing the significance of predicting and eliminating disruptions during the process. Businesses in the industrial sector may increase their ability to anticipate and prepare for potential hazards if they undertake assessments regularly and constantly monitor resilience indicators. Because of their extraordinary talent for prediction and planning, they can make adjustments to reduce disruptions’ impact before they even begin.

6.3 Investment in Cybersecurity and Digital Infrastructure

When one considers the grave threat that cyberattacks pose to the dependability of industrial operations, it is difficult to stress the significance of prioritizing investments in cybersecurity measures and digital infrastructure. To accomplish this objective, it is required to consistently develop and implement new security rules, train workers on cyber hygiene, and use cutting-edge technology to enhance the digital basis of production systems. The various industry participants must prioritize their expenditures in cybersecurity measures to handle this danger appropriately. Since this is the case, it is necessary to maintain a persistent focus on staying current on developing cyber threats and vulnerabilities. Because cyber dangers are always evolving, improving security measures consistently is necessary. Regularly updating their security systems is the most effective method for manufacturing companies to ensure their digital assets are protected from potentially dangerous new threats. This is by far the most effective path to take. Because people are the most crucial component of cybersecurity, there is an immediate need for comprehensive cyber hygiene training programs for personnel working within the firm. After completing this course, employees will be better equipped to identify and respond to cyber threats. The firm’s employees are the first line of defence against cyberattacks; thus, they must be aware of how to protect the organization’s digital infrastructure from being compromised. This includes the ability to recognize phishing attempts, adhere to the security standards that have been created, and handle credentials appropriately. Within the context of strengthening the digital basis of industrial systems, incorporating human-centric measures with cutting-edge technology is of the utmost importance. It is necessary to have cutting-edge technical solutions and technologies to have a state-of-the-art system capable of instantly recognizing, stopping, and responding to cyberattacks. Secure communication protocols, intrusion detection systems, and security analytics supported by artificial intelligence are all essential components of a good cybersecurity strategy.

6.4 Collaborative Research Initiatives

Establishing research collaborations that bring together academics, corporate executives, and government officials ought to be a top priority for educational institutions. These joint efforts can potentially expedite the development of creative solutions, selecting the most effective techniques, and a deeper knowledge of the always-evolving challenges. The execution of a more comprehensive strategy to build resilience in the industrial sector would be significantly aided by participation in research initiatives that involve several disciplines.

6.5 Training Programs for Workforce Resilience

Since the staff is the most important factor in determining the operational resilience of a manufacturing company, the training programs should be prioritized at the highest budget level. The primary purpose of these programs should be to educate and empower personnel to deal with cyber risks, adapt to digital disruptions, and strengthen the organization’s resilience toward disruptions. Because the staff plays such an important part in guaranteeing the robustness of operational processes, industrial firms must implement comprehensive training programs as a top priority. With the help of these programs, employees will be equipped with the information and skills essential to deal with cyber dangers, adapt to digital disruptions, and ultimately provide benefits for the firm.

6.6 Scenario-based Preparedness Exercises

Practitioners of industrial preparation are required to take part in scenario-based exercises to evaluate various resilience evaluation techniques and to forecast the possibility of interruptions during events. In addition to assisting the organization in becoming more adept at dealing with unforeseen circumstances, these exercises also highlight areas where the organization has room for improvement.

In essence, the purpose of these scenario-driven exercises is to serve as an opportunity for organizational rehearsals. In the controlled environment that these provide, employees have the opportunity to polish their responses to various situations that might be disruptive. Using this feature’s dual function, it is much simpler to identify areas in which preparedness is weak and establish a culture of readiness and adaptation throughout the business.

As an illustration, in cybersecurity, a fictitious attack on the organization’s computer networks can be regarded as a believable scenario. Following the implementation of predefined cybersecurity protocols, the reaction team would next proceed to restrict and diminish the impact of the fake assault. A thorough analysis is performed on the outcomes of these tests, and the information gleaned from this analysis is utilized to enhance and perfect the entire strategy for resilience. By doing these drills regularly, experts in the industry ensure that their organizations are prepared to deal with any disaster. When leaders take the initiative to do so, the culture of a company has the potential to be reinforced and equipped to tackle the challenges of the digital era with more agility and resilience.

6.7 International Collaboration on Standardization

Standardization, which makes it easier to maintain consistency, is the most important factor in effectively navigating these hurdles. The goal of the international standard-setting endeavour that has been suggested is to develop norms and standards that are applicable everywhere, free from the constraints of state legislation. Every manufacturing facility that uses standards must adhere to a uniform and established methodology to conduct resilience assessments and take cybersecurity precautions. Through this partnership, it is possible to easily achieve the goals of interoperability, decreased complexity, and enhanced overall production efficiency globally. With the help of this cooperation, it will be possible to accomplish these goals easily.

When it comes to facilitating communication between governments in different parts of the world, one solution that has been advocated is to strengthen collaboration through the global harmonization of existing standards. To our great fortune, this framework will assist us in formulating a set of principles that can exist independently of national laws and be applied wherever in the world. When applied in commercial contexts, the standardized methodology guarantees the execution of resilience measurements and cybersecurity criteria in a manner that is both uniform and straightforward. The only way to generate synergies, streamlined manufacturing, and better overall efficiency in the global industrial sector is through collaboration of this kind. Because of this, the likelihood of disruptions brought on by disparities in cybersecurity standards or regulatory demands is reduced. As a result of manufacturers being able to do business and command things worldwide, there is an encouragement for items to be shipped more quickly and with greater reliability. To take the first step toward resolving the digital issues businesses face worldwide, it is essential to establish a common ground in global standards. Collaborating, sharing information, and communicating are much simpler when all parties involved are on the same page. It is essential to establish a foundation of common knowledge about existing practices, emerging dangers, and successful solutions, regardless of the environment or the organization. Constructing long-lasting networks worldwide and overcoming the challenges presented by the constantly developing digital environment is necessary. It is necessary to establish this foundation before confronting the challenges in today’s digital environment.

6.8 Public-Private Partnerships for Resilience R&D

The government, industry, and educational institutions need to investigate the possibility of forming public-private partnerships focusing on research and development initiatives related to manufacturing resilience. As a result of connecting individuals and resources, these networks facilitate the acceleration of development and the implementation of new ways that enhance production resilience. By putting these recommendations into action, stakeholders have the potential to contribute to the process of making products more adaptive and helpful in the digital era. They will decrease the impact of crises and put manufacturing in a better position to survive and compete in the more computerized global economy of the nineteenth century. This is because these actions will put manufacturing in a better position to prosper.

-

Funding information: The author states no funding involved.

-

Author contribution: The sole author actively participated in every phase of this research, encompassing conception, design, data collection, analysis, interpretation, and manuscript preparation.

-

Conflict of interest: The author states no conflict of interest.

-

Data availability statement: Data sharing is not applicable to this article as no new data were created or analyzed in this study.

-

Article note: As part of the open assessment, reviews and the original submission are available as supplementary files on our website.

References

Alavi, S., Zeinalnezhad, M., & Mousavi, E. (2022). Prioritization of GPM activities from lean-agile-resilience perspective using fuzzy analytic hierarchy process. Journal of Fuzzy Extension and Applications, 3(3), 263–278.Suche in Google Scholar

Aliahmadi, A., Nozari, H., Ghahremani-Nahr, J., & Szmelter-Jarosz, A. (2022). Evaluation of key impression of resilient supply chain based on artificial intelligence of things (AIoT). arXiv preprint arXiv:2207.13174.Suche in Google Scholar

Atif, S. (2023). Analyzing the alignment between circular economy and industry 4.0 nexus with industry 5.0 era: An integrative systematic literature review. Sustainable Development, 31(4), 2155–2175.10.1002/sd.2542Suche in Google Scholar

Chang, X., Su, J., & Yang, Z. (2022). The effect of digital economy on urban green transformation – An empirical study based on the Yangtze River Delta City Cluster in China. Sustainability, 14(21), 13770.10.3390/su142113770Suche in Google Scholar

Duan, C. (2023). A state-of-the-art review of sharing economy business models and a forecast of future research directions for sustainable development: A bibliometric analysis approach. Sustainability, 15(5), 4568.10.3390/su15054568Suche in Google Scholar

Faghihmaleki, H., Habibpour, F., & Rahanjam, A. (2023). Analyzing and enhancing the resilience of steel moment frame structures against progressive collapse. Journal of Operational and Strategic Analytics, 1(2), 90–105.10.56578/josa010206Suche in Google Scholar

Garrido, S., & Nunes, C. S. (2023). Implementation of an ethical circular hub: Framework proposal. European Journal of Sustainable Development, 12(4), 109.10.14207/ejsd.2023.v12n4p109Suche in Google Scholar

Govindan, K., Shankar, K. M., & Kannan, D. (2020). Achieving sustainable development goals through identifying and analyzing barriers to industrial sharing economy: A framework development. International Journal of Production Economics, 227, 107575.10.1016/j.ijpe.2019.107575Suche in Google Scholar

HamidaviNasab, Y., Amiri, M., Keyghobadi, A., FathiHafshejani, K., & Zandhessami, H. (2023). Identifying effective factors of organizational resilience: A meta-synthesis study. International Journal of Research in Industrial Engineering, 12(2), 177–196.Suche in Google Scholar

Hanan, F., & Ali, R. (2023). Production optimization in manufacturing industries using Cobb-Douglas production function. Journal of Operational and Strategic Analytics, 1(3), 131–139.10.56578/josa010304Suche in Google Scholar

Hosseini Dehshiri, S. J., & Aghaei, M. (2021). Identifying and ranking technological capabilities to enhance resilience of the supply chain. Innovation Management and Operational Strategies, 2(3), 229–243.Suche in Google Scholar

Ivanov, D., & Dolgui, A. (2021). A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Production Planning & Control, 32(9), 775–788.10.1080/09537287.2020.1768450Suche in Google Scholar

Jain, V., Kumar, S., Soni, U., & Chandra, C. (2017). Supply chain resilience: Model development and empirical analysis. International Journal of Production Research, 55(22), 6779–6800.10.1080/00207543.2017.1349947Suche in Google Scholar

Kumar, S., Darshna, A., & Ranjan, D. (2023). A review of literature on the integration of green energy and circular economy. Heliyon, 9(11), 1–18.10.1016/j.heliyon.2023.e21091Suche in Google Scholar

Le, T. T., Ferraris, A., & Dhar, B. K. (2023). The contribution of circular economy practices on the resilience of production systems: Eco-innovation and cleaner production’s mediation role for sustainable development. Journal of Cleaner Production, 424, 138806.10.1016/j.jclepro.2023.138806Suche in Google Scholar

Li, X., Zhang, Y., Sorourkhah, A., & Edalatpanah, S. A. (2023). Introducing antifragility analysis algorithm for assessing digitalization strategies of the agricultural economy in the small farming section. Journal of the Knowledge Economy, 226, 1–25.10.1007/s13132-023-01558-5Suche in Google Scholar

Liu, Y., Jiang, Y., Pei, Z., Xia, N., & Wang, A. (2023). Evolution of the coupling coordination between the marine economy and digital economy. Sustainability, 15(6), 5600.10.3390/su15065600Suche in Google Scholar

Luo, W., Tang, G., Yang, P., Jia, C., & Yang, R. (2023). Examining digital economy’s role in urban green development: A study of the Yangtze River Delta Region. Journal of the Knowledge Economy, 323, 1–36.10.1007/s13132-023-01532-1Suche in Google Scholar

Mansory, A., Nasiri, A., & Mohammadi, N. (2021). Proposing an integrated model for evaluation of green and resilient suppliers by path analysis, SWARA and TOPSIS. Journal of Applied Research on Industrial Engineering, 8(2), 129–149.Suche in Google Scholar

Negravi, A., & Titidezh, O. (2023). Investigating the blockchain technologies influences on the performance of road freight transportation management systems using network analysis technique. Journal of Decisions & Operations Research, 8(2), 492–506.Suche in Google Scholar

Nozari, H., Fallah, M., & Szmelter-Jarosz, A. (2021). A conceptual framework of green smart IoT-based supply chain management. International Journal of Research in Industrial Engineering, 10(1), 22–34.Suche in Google Scholar

Nozari, H., & Ghahremani-Nahr, J. (2021). Provide a framework for implementing agile big data-based supply chain (case study: FMCG companies). Innovation Management and Operational Strategies, 2(2), 128–136.Suche in Google Scholar

Oosthuizen, R., & Manzini, D. (2022). Systems thinking for the digital economy: A sociotechnical perspective. South African Journal of Industrial Engineering, 33(3), 262–273.10.7166/33-3-2801Suche in Google Scholar

Pang, J., Zhang, Y., & Jiao, F. (2023). The impact of the digital economy on transformation and upgrading of industrial structure: A perspective based on the “Poverty Trap”. Sustainability, 15(20), 15125.10.3390/su152015125Suche in Google Scholar

Rahmani Fazli, H., & Teymori, H. R. (2024). The effect of economic uncertainty on the supply chain risks of industrial plants. Journal of Applied Research on Industrial Engineering, 11(3), 487–496.Suche in Google Scholar

Rezaei, A., & Qiong, L. (2024). Robust supply chain network design with resilient supplier selection under disruption risks. Journal of Applied Research on Industrial Engineering, 11(3), 398–422.Suche in Google Scholar

Shen, X., Zhao, H., Yu, J., Wan, Z., He, T., & Liu, J. (2022). Digital economy and ecological performance: Evidence from a spatial panel data in China. Frontiers in Environmental Science, 10, 969878.10.3389/fenvs.2022.969878Suche in Google Scholar

Tao, J., Wang, Z., & Li, J. (2023). The spatial effect of digital economy on public psychological resilience during the diffusive crisis. Frontiers in Public Health, 11, 1156367.10.3389/fpubh.2023.1156367Suche in Google Scholar

Yazdi, M., Moradi, R., Pirbalouti, R. G., Zarei, E., & Li, H. (2023). Enabling safe and sustainable hydrogen mobility: Circular economy-driven management of hydrogen vehicle safety. Processes, 11(9), 2730.10.3390/pr11092730Suche in Google Scholar

Zhang, C., Yang, Q., Zhang, J., Gou, L., & Fan, H. (2023). Topic mining and future trend exploration in digital economy research. Information, 14(8), 432.10.3390/info14080432Suche in Google Scholar

Zhao, P., Guo, J., & Wang, Y. (2023a). How does the digital economy affect green development? – Evidence from 284 cities in China. Sustainability, 15(15), 11596.10.3390/su151511596Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Political Turnover and Public Health Provision in Brazilian Municipalities

- Examining the Effects of Trade Liberalisation Using a Gravity Model Approach

- Operating Efficiency in the Capital-Intensive Semiconductor Industry: A Nonparametric Frontier Approach

- Does Health Insurance Boost Subjective Well-being? Examining the Link in China through a National Survey

- An Intelligent Approach for Predicting Stock Market Movements in Emerging Markets Using Optimized Technical Indicators and Neural Networks

- Analysis of the Effect of Digital Financial Inclusion in Promoting Inclusive Growth: Mechanism and Statistical Verification

- Effective Tax Rates and Firm Size under Turnover Tax: Evidence from a Natural Experiment on SMEs

- Re-investigating the Impact of Economic Growth, Energy Consumption, Financial Development, Institutional Quality, and Globalization on Environmental Degradation in OECD Countries

- A Compliance Return Method to Evaluate Different Approaches to Implementing Regulations: The Example of Food Hygiene Standards

- Panel Technical Efficiency of Korean Companies in the Energy Sector based on Digital Capabilities

- Time-varying Investment Dynamics in the USA

- Preferences, Institutions, and Policy Makers: The Case of the New Institutionalization of Science, Technology, and Innovation Governance in Colombia

- The Impact of Geographic Factors on Credit Risk: A Study of Chinese Commercial Banks

- The Heterogeneous Effect and Transmission Paths of Air Pollution on Housing Prices: Evidence from 30 Large- and Medium-Sized Cities in China

- Analysis of Demographic Variables Affecting Digital Citizenship in Turkey

- Green Finance, Environmental Regulations, and Green Technologies in China: Implications for Achieving Green Economic Recovery

- Coupled and Coordinated Development of Economic Growth and Green Sustainability in a Manufacturing Enterprise under the Context of Dual Carbon Goals: Carbon Peaking and Carbon Neutrality

- Revealing the New Nexus in Urban Unemployment Dynamics: The Relationship between Institutional Variables and Long-Term Unemployment in Colombia

- The Roles of the Terms of Trade and the Real Exchange Rate in the Current Account Balance

- Cleaner Production: Analysis of the Role and Path of Green Finance in Controlling Agricultural Nonpoint Source Pollution

- The Research on the Impact of Regional Trade Network Relationships on Value Chain Resilience in China’s Service Industry

- Social Support and Suicidal Ideation among Children of Cross-Border Married Couples

- Asymmetrical Monetary Relations and Involuntary Unemployment in a General Equilibrium Model

- Job Crafting among Airport Security: The Role of Organizational Support, Work Engagement and Social Courage

- Does the Adjustment of Industrial Structure Restrain the Income Gap between Urban and Rural Areas

- Optimizing Emergency Logistics Centre Locations: A Multi-Objective Robust Model

- Geopolitical Risks and Stock Market Volatility in the SAARC Region

- Trade Globalization, Overseas Investment, and Tax Revenue Growth in Sub-Saharan Africa

- Can Government Expenditure Improve the Efficiency of Institutional Elderly-Care Service? – Take Wuhan as an Example

- Media Tone and Earnings Management before the Earnings Announcement: Evidence from China

- Review Articles

- Economic Growth in the Age of Ubiquitous Threats: How Global Risks are Reshaping Growth Theory

- Efficiency Measurement in Healthcare: The Foundations, Variables, and Models – A Narrative Literature Review

- Rethinking the Theoretical Foundation of Economics I: The Multilevel Paradigm

- Financial Literacy as Part of Empowerment Education for Later Life: A Spectrum of Perspectives, Challenges and Implications for Individuals, Educators and Policymakers in the Modern Digital Economy

- Special Issue: Economic Implications of Management and Entrepreneurship - Part II

- Ethnic Entrepreneurship: A Qualitative Study on Entrepreneurial Tendency of Meskhetian Turks Living in the USA in the Context of the Interactive Model

- Bridging Brand Parity with Insights Regarding Consumer Behavior

- The Effect of Green Human Resources Management Practices on Corporate Sustainability from the Perspective of Employees

- Special Issue: Shapes of Performance Evaluation in Economics and Management Decision - Part II