Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

-

Anjan Kumar B. Hanumantharayappa

Abstract

The present research reports improvement in mechanical performance of Copper-Tin(Cu-Sn) composites due to the addition of hard Si3N4 particles as reinforcement. Two-step stir casting technique was adopted to prepare Si3N4-reinforced Cu-Sn based composites. The uniform distribution of the reinforcement in the matrix was ensured by SEM morphology and energy-dispersive X-ray (EDAX) spectrum of the developed composites. Brinell hardness test and tension test were used to estimate the hardness and tensile strength of the composite. Si3N4 reinforcing materials added to the extent of 7.5% by wt. to Cu-Sn matrix enhanced hardness by 41% and UTS by 33%, YS by 29% and showed 23% decrement in ductility. Thus a comparison of Si3N4-reinforced Cu-Sn based composites with base metal has shown that considerable improvement in tensile properties such as UTS and YS and hardness if reinforcing material is added to the extent of 7.5%.

1 Introduction

Copper has exceptionally useful properties such as good electrical and thermal conductivity, corrosion resistance and can be readily alloyed. These properties make it an attractive candidate for matrix material in thermal and electronic applications [1]. Conversely, its poor mechanical performance inhibits its usage in strength requirement applications. However, this drawback can be compensated by reinforcing it with the hard and fine ceramic materials such as carbides/borides/oxides/nitrides. These inclusions enhance hardness and strength at the expense of a relatively little loss in electrical conductivity [2]. Numerous evidences are found in literature which showed the improvement of the mechanical strength of copper matrix by the addition of reinforcements of TiC, Cr2O3, Al2O3, TiO2, B4C, carbon nano tube, SiC, graphite, carbon fibre, rice husk ash etc. [3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13]. Recently addition of another ceramic silicon nitride (Si3N4) has gained interest in research due to its excellent wear, corrosion resistance, high-temperature mechanical properties, exceptional thermal shock resistance owing to its low coefficient of thermal expansion and high thermal conductivity. The mechanical and chemical stability at elevated temperatures made Si3N4 to be attractive and promising candidate for high temperature engineering applications. Very few studies are found in literature on investigations connected to influence of Si3N4 on copper matrix. These countable investigations majorly deal with the effect of Si3N4 on the electrical and thermal conductivity [14] of composites and mechanical characterization and wear behavior of composites. Robin et al. [15] have developed soft copper coatings with well-distributed Si3N4 particles on carbon steel by novel coelectro-deposition method and reported improved microhardness and strength compared to pure copper coating and no difference in corrosion resistance. Solderability properties of Si3N4 reinforced in Sn-0.7Cu solder was systematically investigated by MAA et al. [16]. They showed that an improvement in solderability was achieved with optimum wettability when 1.0 wt.% Si3N4 was reinforced in Sn-0.7Cu solder. Further, MAA et al. [17] studied the influences of the Si3N4 particulates on the mechanical properties of the same composite solder and reported improved microhardness value and lap-shear strength when higher reinforcements of Si3N4 particulates were present in the monolithic matrix solder. Using Modulus of elasticity-porosity relationships, empirical equations were proposed for indicating the porosity dependence of the strength of Si3N4 ceramics [18]. Effect of reinforcement content on the hardness, strength [19] and adhesive wear behaviour of Cu10Sn5Ni/Si3N4 composites were studied and results reported the improved strength and toughness when compared to pure Cu [20, 21].

Copper alloys are majorly employed in machine parts subjected to high-friction such as bearings. Copper–tin (Cu-Sn) alloys used in bearings need solid lubricants such as grease which have minor effects on the environment compared to Copper-lead alloys which release harmful gases at high temperatures when continuously used [22]. The desirable properties of bearings are high thermal conductivity to dissipate heat generated due to friction, high corrosion resistance, high fatigue, tensile, shear, compressive strength and wear resistance and be able to bear shocks and vibrations. Higher tensile and compressive strengths increase the ability of the bearing material, to resist formation and propagation of cracks under high contact pressures and to avoid extrusion or other permanent deformation of the bearing [23]. Hence in this study, an attempt is made to evaluate the influence of addition of Si3N4 as reinforcement to Cu-Sn matrix Composites on mechanical properties of the composite.

2 Experimental procedures

2.1 Materials used

The Cu-Sn alloys possess superior properties and hence are employed for various mechanical and electronics industrial applications. Cu-rich Cu–Sn alloys are employed as structural materials and Sn-rich alloys as lead-free solder materials. The latter application avoids toxicity of lead and hence has attracted researchers due to health and environmental concerns. [24, 25].

Commercially available Cu-Sn alloy was considered as the matrix for composite preparation. Table 1 presents its chemical composition. It is stronger and more ductile than red brasses and has high wear resistance. Despite having low solubility in Cu at room temperature the tin is a solid solution strengthening in Cu [26].

Chemical composition of Cu-Sn alloy in weight percentage.

| Element | Al | Si | Sn | O | Cu |

|---|---|---|---|---|---|

| Wt.% | 0.47 | 0.06 | 7.85 | 0.2 | Remaining |

In present investigation, to enhance the mechanical performance of Cu-Sn alloy, Si3N4 particles of size 40 μm were used as reinforcement material. Liquid stir casting technique was adopted to develop Cu-Sn/Si3N4 composites. Figures 1(a) and 2(a) show the SEM and EDAX pattern of Cu-Sn base metal (A sample) and Figures 1(b) and 2(b) depict the SEM and EDAX pattern of Si3N4 particulates used to fabricate the composites. The intensity peaks of Cu and Sn are mainly observed in the EDAX spectrum of the A sample as they are the major elements present along with negligible amounts of Al, Si and O.

SEM of (a) Base metal ‘A’ and (b) Si3N4 particulates.

EDAX of (a) Base metal ‘A’ and (b) Si3N4 particulates.

2.2 Fabrication procedure

The morphology and mechanical properties are established at the production stage of composite and hence the materials used and the preparation method have to be carefully planned and executed. The cost of production is also dependent on it. Though a number of difficulties are faced due to the formation of porosity and poor wettability between reinforcement phase and matrix, when compared to other MMC preparation routes, liquid state processing method is eye-catching one because of low cost and its simplicity. Under liquid state processing method, stir casting technique is more established and promising one, as it ensures the proper dispersion of reinforcements with in matrix due to mechanical stirring action [27].

In this work, one of the variants of liquid stir casting called two step stir casting method is adopted for sample preparation. The set up used for casting is shown in Figure 3(a) and 3(b). Initially required amount of charge or matrix material was placed in a graphite crucible, and was placed in electric mu e furnace. It was then heated to a temperature of around 1150°C above the liquidus temperature of the matrix to melt completely. After complete melting of a Cu-Sn matrix, degassing was carried out by using solid hexachloro-ethane (C2Cl6) degassing tablet. It removed unwanted adsorbed gases from the melt. Once degassing got over, the preheated (to 500°C) ceramic reinforcement Si3N4 particles were introduced into the matrix and mixed manually. Two-stage addition of reinforcement during stirring was adopted. This novel two stage additions of reinforcement into Cu-Sn matrix helped in increasing the wettability of the matrix and ceramic reinforcement, and ensured uniform distribution of the particles in matrix. Mechanical stirring was carried out for about 15 min at an average mixing speed of 250 rpm. The melted material was poured finally to a cast iron die with the dimensions of 120 mm length and 15mm diameter preheated to a temperature of 200°C and there it was allowed to cool to get the required casting. Table 2 gives the composition of the composite prepared.

(a) Schematic diagram of Stir casting set up and (b) Photo of stir casting set up.

Composition of prepared samples.

| Sample | Cu-Sn alloy | Si3N4 particles |

|---|---|---|

| Base alloy (A) | 100% | 0% |

| Composite (ASiN) | 92.5% | 7.5% |

2.3 Characterization procedure

2.3.1 Microstructural characterization

Microstructural characterization of the prepared composites was done using Scanning Electron Microscopy and EDAX analysis. The microstructure of the cast A and ASiN samples were obtained by scanning electron microscope (TESCAN VEGA, Czech Republic). The samples of cast A and ASiN composite for microstructural study were cut from cast rods. The surface of the specimen was first made flat by rough grinding using Abrasive paper of grit size 200–320 and subsequently with grit sizes of (600–1200) to replace course lines with finer ones. The final layer is removed chemically by etching with Keller's reagent. It was then examined under scanning electron microscope.

2.3.2 Mechanical characterisation

To investigate the mechanical performance of the composites the tensile and hardness tests were carried out. Tensile testing was conducted on round test specimens of diameter 9mm and gauge length of 36mm prepared from cast A and ASiN composite using a computerized universal testing machine of 400 kN capacity at ambient temperature. Yield strength, ultimate tensile strength and elongation percentage were calculated based on three samples and result was obtained based on average value. Figure 4(a) and 4(b) depict the test coupons used for the tensile test according to the ASTM E8-18 standard [28]. To evaluate the influence of Si3N4 particulates in the matrix material hardness test was performed on cast A and ASiN composite. The polished specimens were tested for hardness, using Brinell hardness testing machine having ball indenter of 5mm diameter applied for 250kgf load and dwell time of 30sec as per the standard of ASTM 10–18 [29]. Nine sets of readings were taken at different places of the specimen and an average value was used for calculation.

(a) Dimensions of tensile test specimen in mm as per ASTM 10–18 and (b). Tensile test specimens as per ASTM 10–18.

3 Results and discussion

3.1 Microstructural characterization

EDAX characterization is one of the known methods to confirm the elemental presence in the developed composite. Figures 5a, 5b show the SEM and EDAX spectrum of the ASiN composite respectively. The EDAX spectrum of the developed composite ASiN has the intensity peaks of Cu, Sn of matrix and Si, N of reinforcing materials.

ASiN composite samples (a) SEM and (b) EDAX pattern.

As seen in Figure 5a, the surface of the composites obtained after polishing and chemical etching has SiN reinforcements homogeneously dispersed in the Cu-Sn matrix without any noticeable large agglomerations. Also the sample matrix is continuous and no clear pores or cracks are visible at the interface of matrix and reinforcement particles on the surfaces of the composite. This is attributed to the two stage addition of SiN reinforcement into Cu-Sn matrix. This novel method helped in increasing the wettability of the matrix and ceramic reinforcement, and ensured uniform distribution of the particles in matrix [30].

3.2 Mechanical characterization

3.2.1 Tensile behaviour

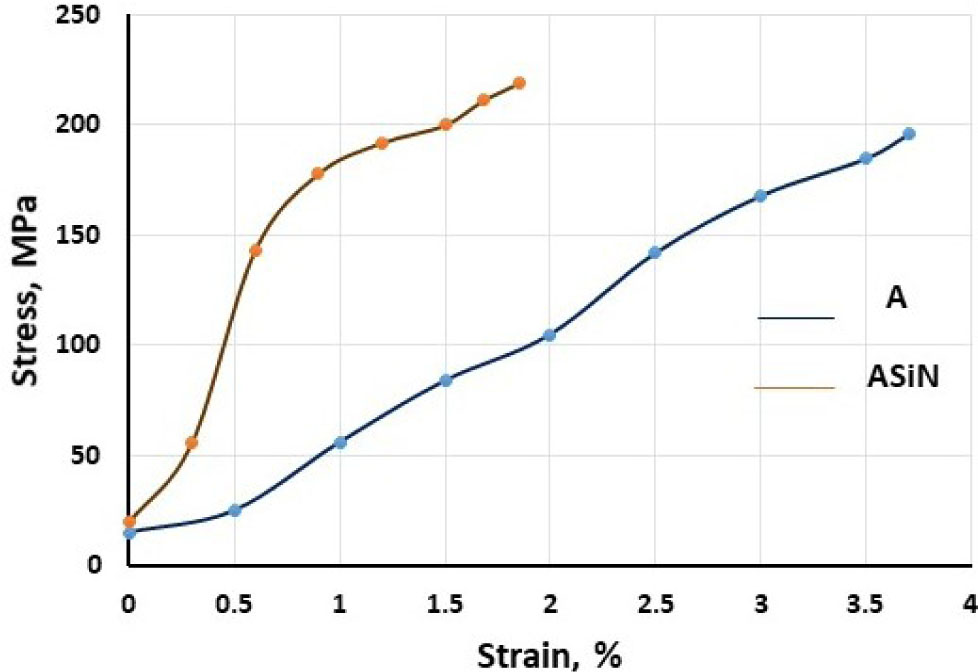

The tensile properties such as yield strength (YS), ultimate tensile strength (UTS) and percentage elongation (PE) of base metal and developed copper based composite ASiN are evaluated and presented in Table 3. Compared to base metal, ASiN composite showed 33% increase in UTS, 29% increase in YS and 23% decrement in PE. From the tabulated values, it is evident that Si3N4 particles are very effective in improving the tensile strength of Cu-Sn matrix. This rise in UTS and YS can be attributed to the presence of hard Si3N4 reinforcing particles in the matrix. The application of uniaxial tensile load results in the movement of dislocations through the matrix. They pile up near the boundaries of reinforcement particles, giving rise to plastic zones. The size of this plastic zone depends on difference in coefficient of thermal expansion of the matrix and the reinforcement phase [31]. It is known that thermal expansion co-efficient of Si3N4 particulate is 1.4–3.7 × 10-6/K and that of Copper is 17 × 10-6/K [32, 33]. As this mismatch in thermal expansion coefficients of the composite constituent's increases, the size of the plastic zone also increases [34]. The piled up dislocations eventually propagate through the interface when a critical shear stress is induced at higher loads [35]. Thus the interface between reinforcement and copper matrix provides efficient barrier to the propagation of dislocations across the interface. That is how Si3N4 hard particles impart strength to the matrix and due to this strengthening mechanism, composite offers more resistance to tensile force applied.

Tensile test results of A and ASiN composite.

| Mechanical properties | As cast (0% Si3N4) | (7.5% Si3N4) | % change |

|---|---|---|---|

| Tensile strength (MPa) | 170 | 226 | 33 |

| % Elongation | 3.704 | 2.852 | −23 |

| Yield stress (MPa) | 145.5 | 187.5 | 29 |

Nevertheless, percentage elongation has reduced by 23 %, only to infer that higher tensile strength is achieved at the cost of ductility of copper Matrix. Reinforcing Si3N4 particles when added to Cu-Sn matrix, the matrix content gets reduced and the reinforcing particles being less ductile inhibit the flow-ability of Cu-Sn matrix. Similar results of improvement in tensile strength due to the addition of reinforcement to the matrix and reduction in strain at failure are documented in research regardless of the preparation method of Copper MMCs [15, 19, 21]. Figure 6 shows the fractured tensile specimens of both A and ASiN and Figure 7 presents stress-strain graphs for both Cu-Sn base material and ASiN composite.

Fractured tensile specimens of (a) base metal ‘A’ and (b) ASiN composite.

Stress-Strain curve for (a) base metal ‘A’ and (b) ASiN reinforced composites.

3.2.2 Fractography

This deals with the study of fractured surface of the material. The SEM micrograph of the fractured surfaces after the tensile testing of the pure copper and ASiN composites are shown in Figure 8. The base metal exhibits ductile fracture as depicted in Figure 8(a). Characteristic feature of ductile fracture is the presence of dimples and can be observed all over the surface of the SEM micrograph. Voids nucleate at inclusions, due to plasticity they grow and then finally coalesce, to form cracks resulting in ductile fracture of the material [36]. The smaller dimples are observed in Figure 8(b) in the micrograph of the fractured surface of ASiN composite compared to its matrix. This confirms that the fracture behaviour of the ASiN composite is brittle in nature. Large voids and propagated cracks also can be seen in the micrograph. The reinforcing hard particles entrapped in the matrix material play a vital role in inhibiting the faster propagation of cracks in the materials. Hence these materials have better tensile strength compared to matrix material.

Fractured surfaces of (a) base metal ‘A’ and (b) ASiN composite.

3.3 Hardness

Hardness is a mechanical property which signifies the resistance to permanent deformation. The hardness behaviour of both base metal ‘A’ sample and ASiN composite were evaluated using Brinell hardness test and values are presented in the Figure 9. The BHM of ASiN is higher than the base metal ‘A’ sample. The higher hardness of the ASiN is because of the presence of hard reinforcement of SiN particles. When an external load is applied, as per the composite loading rule, the hard SiN reinforcement share more load, when compared to soft matrix. Addition of 7.5 wt% of SiN to Cu-Sn matrix has resulted in increased hardness of matrix by 41%. This increment in the hardness signifies proper distribution of the reinforcing particles in the matrix and the good interfacial contact between the reinforcing particles and copper matrix. They strengthen the composite materials by restricting the grain growth [37].

Hardness values of Base metal ‘A’ and ASiN reinforced composites.

This is in consistence with already presented results which can be summarised as; hardness of MMC is dependent on the:

4 Conclusions

In the present investigation, SiN-reinforced Cu-Sn based composites were successfully prepared two-step stir casting technique. The focus of study was to evaluate the influence of addition of hard SiN reinforcing particles to soft Cu-Sn matrix on its mechanical performance. The SEM morphology and EDAX spectrum of the developed ASiN composites conclude the uniform distribution of the reinforcement in the matrix. Hardness and tensile behaviour of the composites were studied using Brinell hardness test and tension test. The addition of hard SiN particles is found to increase hardness and ultimate tensile strength of the composite. SiN reinforcing materials added to the extent of 7.5% wt to Cu-Sn matrix enhanced hardness by 41% and UTS by 33%, YS by 29% and showed 23% decrement in ductility. Thus a comparison of SiN-reinforced Cu-Sn based composites with base metal has shown improved hardness and tensile properties such as UTS and YS.

Funding information:

The authors state no funding involved.

Author contributions:

All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

Conflict of interest:

The authors state no conflict of interest.

References

[1] Copper and Copper Alloys. ASM Specialty Handbook. USA: ASM International; 2001:446–8. ISBN: 978-0-87170-726-0.Suche in Google Scholar

[2] Manvandra KS, Rakesh KG. Synthesis of copper metal matrix hybrid composites using stir casting technique and its mechanical, optical and electrical behaviours. Trans Indian Inst Met. 2017;70(9):2415–8.10.1007/s12666-017-1103-0Suche in Google Scholar

[3] Rathod S, Modi OP, Prasad BK, Chrysanthou A, Vallauri D, Deshmukh VP, et al. Cast in situ Cu-TiC composites: synthesis by SHS route and characterization. Mater Sci Eng A. 2009;502(1–2):91–8.10.1016/j.msea.2008.10.002Suche in Google Scholar

[4] Dash K, Chaira D, Ray BC. Microstructural evolution and sliding wear studies of copper-alumina micro and nano-composites fabricated by spark plasma sintering. J Mech Behav Mater. 2015;24(1–2):25–4.10.1515/jmbm-2015-0003Suche in Google Scholar

[5] Shojaeepour F, Abachi P, Purazrang K, Moghanian AH. Production and properties of Cu/Cr2O3 nanocomposites. Powder Technol. 2012;222:80–4.10.1016/j.powtec.2012.02.001Suche in Google Scholar

[6] Saravanakumar S, Gopalakrishnan S, Kalaiselvan K. Development of empirical relationships for prediction of mechanical and wear behaviour of copper matrix surface composite by friction stir processing technique. Arch Metall Mater. 2021;66(2):617–6Suche in Google Scholar

[7] Ying DY, Zhang DL. Processing of Cu-Al2O3 metal matrix nanocomposite materials by using high energy ball milling. Mater Sci Eng A. 2000;286(1):152–6.10.1016/S0921-5093(00)00627-4Suche in Google Scholar

[8] Zhao Y, Fan H. Effect of pulse parameters on the microstructural evolution and properties of jet electrodeposited Cu–Al2O3 nanocomposite coating. Mater Trans. 2021;62(6):726–0.10.2320/matertrans.MT-M2020398Suche in Google Scholar

[9] Wang F, Li Y, Wang X, Koizumi Y, Kenta Y, Chiba A. In-situ fabrication and characterization of ultrafine structured Cu-TiC composites with high strength and high conductivity by mechanical milling. J Alloys Compd. 2016;657:122–2.10.1016/j.jallcom.2015.10.061Suche in Google Scholar

[10] Sathiskumar R, Murugan N, Dinaharan I, Vijay SJ. Characterization of boron carbide particulate reinforced in situ copper surface composites synthesized using friction stir processing. Mater Charact. 2013;84:16–7.10.1016/j.matchar.2013.07.001Suche in Google Scholar

[11] Zhao N, Li J, Yang X. Influence of the P/M process on the microstructure and properties of WC reinforced copper matrix composite. J Mater Sci. 2004;39(15):4829–4.10.1023/B:JMSC.0000035321.65140.14Suche in Google Scholar

[12] Naik R, Bheekya K, Venkateswara Reddy G. Madhusudhan Reddy, Arockia Kumar R. Development of high strength and high electrical conductivity Cu/Gr composites through friction stir processing. Mater Lett. 2020;265:12743–7.10.1016/j.matlet.2020.127437Suche in Google Scholar

[13] Guiderdoni C, Pavlenko E, Turq V, Weibel A, Puech P, Estourne's C, et al. The preparation of carbon nanotube (CNT)/copper composites and the effect of the number of CNT walls on their hardness, friction and wear properties. Carbon. 2013;58:185–7.10.1016/j.carbon.2013.02.049Suche in Google Scholar

[14] Ahmed Mahmoud A, Walid M. Daoush, Ahmed E, El-Nikhaily. Fabrication and characterization of Copper/Silicon Nitride composites. Adv Mat Res. 2016;5(3):131–7.10.12989/amr.2016.5.3.131Suche in Google Scholar

[15] Robin A, Pinheiro de Santana JC, Sartori AF. Co-electrodeposition and characterization of Cu–Si3N4 composite coatings. Surf Coat Tech. 2011;205(19):4596–1.10.1016/j.surfcoat.2011.03.142Suche in Google Scholar

[16] Mohd Salleh MAA, Mustafa Al Bakri AM, Kamarudin H, Bnhussain M, Somidin F. Solderability of Sn-0.7 Cu/Si3N4 lead-free composite solder on Cu-substrate. Phys Procedia. 2011;22:299–4.10.1016/j.phpro.2011.11.047Suche in Google Scholar

[17] Mohd Salleh MAA, Mustafa Al Bakri AM, Zan@Hazizi MH, Somidin F, Noor Farhani Mohd Alui, Zainal Arifin Ahmad. Mechanical properties of Sn–0.7 Cu/Si3N4 lead-free composite solder. Mater Sci Eng A. 2012;556:633–7.10.1016/j.msea.2012.07.039Suche in Google Scholar

[18] Datta SK, Mukhopadhyay AK, Chakraborty D. Porosity Dependence of Strength of Si3N4 Ceramics. J Mech Behav Mater. 1990;3(1):35–2.10.1515/JMBM.1990.3.1.35Suche in Google Scholar

[19] Nithesh R, Radhika N, Shiam Sunder S. Mechanical properties and adhesive scuffing wear behavior of stir cast Cu–Sn–Ni/Si3N4 composites. J Tribol. 2017;139(6):17–2.10.1115/1.4036185Suche in Google Scholar

[20] Sanesh KS, Shiam S, Radhika N. Effect of reinforcement content on the adhesive wear behaviour of Cu10Sn5Ni/Si3N4 composites produced by stir casting. Int J Miner Metall Mater. 2017;24(9):1052–0.10.1007/s12613-017-1495-1Suche in Google Scholar

[21] Radhika N, Thirumalini S, Jojith R. Development and properties of centrifugally cast silicon nitride reinforced functionally graded copper matrix composite. Silicon. 2019;11(4):2103–16.10.1007/s12633-018-0030-ySuche in Google Scholar

[22] Kestursatya M, Kim JK, Rohatgi PK. Wear performance of copper–graphite composite and a leaded copper alloy. Mater Sci Eng A. 2003;339(1–2):150–158.10.1016/S0921-5093(02)00114-4Suche in Google Scholar

[23] Balakrishnan S, Baker CE, Rahnejat H. Tribology and Dynamics of Engine and Powertrain. Woodhead Publishing. 2010:591–4.10.1533/9781845699932.2.591Suche in Google Scholar

[24] Zhai W, Wang WL, Geng DL, Wei B. A DSC analysis of thermodynamic properties and solidification characteristics for binary Cu-Sn alloys. Acta Mater. 2012;60(19):6518–7.10.1016/j.actamat.2012.08.013Suche in Google Scholar

[25] El-Daly AA, Hammad AE, Fawzy A, Nasrallh DA. Microstructure, mechanical properties, and deformation behaviour of Sn–1.0Ag–0.5Cu solder after Ni and Sb additions. Mater Des. 2013;43:40–9.10.1016/j.matdes.2012.06.058Suche in Google Scholar

[26] Atsumi H, Imai H, Li S, Kondoh K, Kousaka Y, Kojima A. High-strength, lead-free machinable α–β duplex phase brass Cu–40Zn–Cr–Fe–Sn–Bi alloys. Mater Sci Eng A. 2011;529:275–1.10.1002/9781118511435.ch6Suche in Google Scholar

[27] Arunachalam R, Krishnan PK, Muraliraja R. A review on the production of metal matrix composites through stir casting - Furnace design, properties, challenges, and research opportunities. J Manuf Process. 2019;42:213–5.10.1016/j.jmapro.2019.04.017Suche in Google Scholar

[28] Designation: (E8/E8-09) Standard Test for Tension Testing of Metallic Materials. ASTM International; 2010.Suche in Google Scholar

[29] ASTM E10-18 Standard Test Method for Brinell hardness of metallic materials ASTM International; 2018.Suche in Google Scholar

[30] Chawla N, Shen YL. Mechanical behaviour of particle reinforced metal matrix composites. Adv Eng Mater. 2001;3(6):357–0.10.1002/1527-2648(200106)3:6<357::AID-ADEM357>3.0.CO;2-ISuche in Google Scholar

[31] Dunand DC, Mortensen A. On plastic relaxation of thermal stresses in reinforced metals. Acta Metall Mater. 1991;39(2):127–9.10.1016/0956-7151(91)90261-XSuche in Google Scholar

[32] Sharma P, Sharma S, Khanduja D. Production and some properties of Si3N4 reinforced aluminium alloy composites. Journal of Asian Ceramic Societies. 2015;3(3):352–9.10.1016/j.jascer.2015.07.002Suche in Google Scholar

[33] White GK. Thermal expansion of reference materials: copper, silica and silicon. J Phys D Appl Phys. 1973;6(17):2070–8.10.1088/0022-3727/6/17/313Suche in Google Scholar

[34] Srivastava VC, Ojha SN. Microstructure and electrical conductivity of Al-SiCp composites produced by spray forming process. Bull Mater Sci. 2005;28(2):125–0.10.1007/BF02704231Suche in Google Scholar

[35] Kim Y, Lee J, Yeom MS, Shin JW, Kim H, Cui Y, et al. Strengthening effect of single-atomic-layer graphene in metal-graphene nanolayered composites. Nat Commun. 2013;4(1):2114.10.1038/ncomms3114Suche in Google Scholar

[36] Pineau A, Benzerga AA, Pardoen T, Rajkumar K, Arvindan S. Failure of metals I: brittle and ductile fracture. Acta Mater. 2016;107:424–3.10.1016/j.actamat.2015.12.034Suche in Google Scholar

[37] Rajkumar K, Arvindan S. Tribological performance of microwave sintered copper–TiC–graphite hybrid composites. Tribol Int. 2011;44(4):20–8.10.1016/j.triboint.2010.11.008Suche in Google Scholar

[38] Thiemig D, Lange R, Bund A. Influence of pulse plating parameters on the electrodeposition of matrix metal nanocomposites. Electrochim Acta. 2007;52(25):7362–1.10.1016/j.electacta.2007.06.009Suche in Google Scholar

[39] Medeliene V, Kosenko A. Structural and functional properties of electrodeposited copper metal matrix composite coating with inclusions of WC. Mater Sci. 2008;14(1):29–3.Suche in Google Scholar

[40] Wang YL, Wan YZ, Sh M. Zhao, Tao HM, Dong XH. Electrode-position and characterization of Al2O3–Cu (Sn), CaF2–Cu (Sn) and talc–Cu (Sn) electro composite coatings. Surf Coat Tech. 1998;106(2–3):162–6.10.1016/S0257-8972(98)00522-2Suche in Google Scholar

[41] Stankovic VD, Gojo M. Miroslav Gojo. Electrodeposited composite coatings of copper with inert, semi conductive and conductive particles. Surf Coat Tech. 1996;81(2–3):225–2.10.1016/0257-8972(95)02486-7Suche in Google Scholar

[42] Mangam V, Das K, Das S. Structure and properties of electrode-posited Cu–CeO2 nanocomposite thin films. Mater Chem Phys. 2010;120(2–3):631–5.10.1016/j.matchemphys.2009.12.017Suche in Google Scholar

© 2021 Anjan Kumar B. Hanumantharayappa et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**

Artikel in diesem Heft

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**