Abstract

In this paper, an attempt is made to describe the method that combines the results obtained from nanoindentation experiment with finite element simulation to determine or establish the elastic-plastic properties of a super-hydrophobic anti-icing coating. The nanoindentation test was conducted and elastic properties of the coating, to include elastic modulus and hardness were obtained. The plastic properties, to include yield stress, monotonic strength coefficient and monotonic strain hardening exponent, were obtained using an inverse, iterative method of experimental measurement in synergism with finite element simulation. This approach, which is a combination of experimental data obtained from the nanoindentation test and results obtained from numerical finite element simulation, was found to be effective for determining mechanical properties of the chosen coating.

1 Introduction

The presence of a hydrophobic coating on the surface of an aluminum alloy skin used in aircraft structures does aid in preventing the formation of ice while concurrently minimizing drag and contributing in an observable way to decreasing cost while concurrently enhancing performance [1, 2]. Therefore, there does exist a need to carry out research that is aimed at conducting a performance test on a hydrophobic coating that is often chosen for use on an aircraft structure [3]. Up until now a survey of the mechanical testing methods, published in the open literature, reveals a few of the methods to be both suitable and appropriate for coatings that offer a combination of properties. The test methods are the following: (i) stretching method, (ii) scratch test method, (iii) nanoindentation method, (iv) laser scratch method, and (v) wedge loading method [1,2,3]. Each of these test methods are fairly well known for both the advantages and disadvantages they have to offer, which makes them an appropriate choice for selection and use in a spectrum of relevant applications [4,5,6]. The technique of nanoindentation is by far the most popular and preferentially chosen method for the purpose of not only determining but also understanding the mechanical properties of a coating. Since the technique of nanoindentation is both easy to implement and does not cause any observable damage to the material, it has been increasingly preferred and chosen for the study of both micro-mechanical properties and nano-mechanical properties of a coating [7, 8]. Information specific to both the elastic modulus and hardness of a coating can be obtained from use of the nanoindentation test technique. However, the technique of nanoindentation is not easily applicable under a few conditions. These conditions include the presence of ‘local’ stress distribution and stress concentration. Also, the stress versus strain response and resultant properties of the coating cannot be easily obtained by use of the nanoindentation test technique [9].

With continuing developments in the domain of numerical simulation technology, sustained advances have made it possible to enable numerical simulation of the microstructure with the primary and only intent of obtaining the mechanical properties of a coating. One such numerical method, the finite element method (FEM), has in recent years, i.e., since the early 1980s, been preferentially chosen and used for studying the mechanical properties of materials, structures and coatings [10,11,12,13]. Among the FEM techniques, the ABAQUS software is widely used in material performance analysis [14]. Use of the numerical finite element technique is a good supplement to the nanoindentation method and the two can be combined to obtain mechanical properties of a coating. For example, the plastic properties of a coating can be obtained through a synergism of the nanoindentation test and finite element simulation while concurrently obtaining the stress versus strain response of the coating [8, 15].

In their novel research study, Hyun and co-workers [16] simulated the double indentation test using a conical indenter with the finite element method by simplifying and deducing a relationship to exist between the following:

contact radius of the indenter and indenter angle,

arc radius at the tip of the chosen indenter,

material properties.

A prediction of both the yield strength (σYS) and hardening exponent (n) of the chosen material was made possible by use of this approach. In their study, Hyun and coworkers [16] also documented noticeable differences to exist between the results obtained from simulation using a three-dimensional Berkovich indenter and simulation using a two-dimensional conical indenter. Other related and relevant research studies have attempted to study and record the findings from: (i) finite element analysis of a layered elastic solid in normal contact with a rigid substrate [17], (ii) the stress distribution that occurs during sliding contact of a double coating system [18], and (iii) use of the numerical simulation technique to establish the maximum contact pressure that can occur at the coating-matrix interface under the influence of Hertzian pressure [19]. Even the interlayer stress for a titanium / titanium nitride [Ti / TIN] coating that was prepared by magnetron physical deposition was precision determined and the findings compared with the experimental results [20]. Several of these studies aimed at determining the mechanical properties of the coating-substrate interface were focused predominantly on theoretical analysis, with the interface between two coatings and/or the coating and the substrate being simplified to be a thin layer for the purpose of ease in analysis [21, 22].

In this research paper, the results of a recent study on super hydrophobic coatings that show much promise for selection and use in emerging civilian aircraft is presented and briefly discussed. The substrate material chosen was sheet of aluminum alloy 2024-T3, which is the preferred material, [i.e., aluminum alloy] for use as aircraft skin. The microstructure, surface morphology and interfacial structure of the super-hydrophobic ice-proof coating was observed and characterized using a scanning electron microscope. This enabled in establishing an understanding of the basic structure of the chosen coating and the ‘key’ performance parameters that exist at the coating-substrate interface. Also, based on experimental data obtained from the nanoindentation test, the elastic-plastic properties of the chosen coating were determined by use of a combination of finite element simulation and results obtained from the nanoindentation test.

2 Experimental procedure

2.1 Specimen preparation

It is both important and essential to prepare the surface of the test sample prior to initiating the indentation measurement at the nanoscale level. Test samples (10-mm × 10-mm × 2-mm) were precision cut from the super-hydrophobic anti-icing coated plate. This was followed by grounding using 500, 1000, 1500, and 2000 grit abrasive papers, then ultrasonically cleaned for 15 min. The test samples were then thoroughly cleaned by immersion in alcohol to remove any and all impurities present on the surface and placed in an environment box to ensure drying. The cleaned samples were then observed in a scanning electron microscope (SEM) [Model: TEXCAN (Czechoslovakia) MIRA3 XMU] for the following: (i) morphology of intrinsic microstructural features, and (ii) the presence and distribution of impurities on the coating surface, which could contribute to erroneous results for the hardness at the nano-level. It can be clearly seen that there are easily identifiable layers (red dotted lines) in the coating as shown in Figure 1. The thickness of the chosen coating was around 100 μm.

Scanning electron micrograph depicting the microstructures at the interface of the aluminum alloy (2024-T3) substrate and the coating

2.2 Nanoindentation experiment

The surface microstructure of the chosen coating was observed, step by step, from low magnification to high magnification. An observation of the surface of the coating revealed it to be essentially compact with the absence of voids, scratches and other fine microstructural-related defects. A smooth surface does help in obtaining accurate results from the nanoindentation test.

The values of elastic modulus [E] and hardness [H] of the chosen anti-icing coating was measured using the technique of nanoindentation. A nano-mechanical tester [Model: Hysteron TI950] was used for the experiments. The maximum pressure during the indentation experiment was 2700 μN based on the material chosen and used for the coating, and the maximum displacement value for the experiment was set to 3000 nm. Since overall thickness of the coating is less than 100 μm the displacement that occurs during loading was noticeably less than 10 percent of the coating thickness.

3 Elastic properties

The experimental results are shown in Figure 2. Six points on the flat surface of the test sample were randomly selected for the purpose of indentation. Load control was used during the experiment and when the load reached 2700 μN, a load holding phase starts as is evident from the straight portion of the force versus displacement curve. This was followed by the unloading phase. From the figure is seen the existence and occurrence of indentation creep at the fine microscopic level. The loading curve is microscopically nonlinear. The relationship between P and h can be expressed as a function as follows [9]

In this expression, P is the load, C is curvature of the loading curve and h is measure of depth of indent into the surface of the chosen coating. The curvature value of C was obtained by data fitting and is equal to 0.00394. Subsequent to the nanoindentation test, the morphology of the indent was observed using in-situ scanning probe imaging (SPM). A 3-D morphology of the coating was obtained. Overall morphology of the surface of the indent was observed to be “concave”. The surface morphology of the coating immediately following nanoindentation is shown in Figure 3. The height value at the bottom of the concave is −712.73nm (in purple).

Force versus displacement curves obtained from the nanoindentation tests

Profile showing morphology of the indent on the coating surface subsequent to unloading

The experimental results are summarized in Table 1, where E represents the elastic modulus and H represents the hardness. The elastic modulus (E) and hardness [H] values were calculated from slope of the loading curve and the unloading curve very much in conformance with the method provided and recommended by Oliver and Pharr [9]. The duplicate measurement results at each point of the nanoindentation test revealed minimum scatter. To minimize and/or eliminate scatter in the test data, all of the outliers were excluded by use of the criterion put forth by Grubb [23].

Summary of results obtained from the nanoindentation tests

| Number | Pmax (μN) | E (GPa) | H (GPa) |

|---|---|---|---|

| 1 | 2700 | 4.046 | 0.187 |

| 2 | 2700 | 3.580 | 0.168 |

| 3 | 2700 | 5.027 | 0.217 |

| 4 | 2700 | 3.587 | 0.175 |

| 5 | 2700 | 3.824 | 0.169 |

| 6 | 2700 | 3.505 | 0.165 |

Let Gn represent the Grubbs value for the measurement made at point n. This can then be defined as

In this expression X(n) represents the measured value, Xaverage is the mean value, and S is the standard deviation. From the six measured values provided in Table 1, the mean value of the elastic modulus [E] is 3.94 GPa with a standard deviation (S) of 0.5290.

Let G (α, m) be the critical value of Grubb with α being the significance level and ‘m’ being the number of measurements made. For the six measurements made, the critical value of Grubb is G (0.01, 6) = 1.944. The average value for elastic modulus (E) of the coating was found to be 3.92 GPa. The average value for hardness [H] for the coating was calculated to be 169 MPa. The results obtained reveal elastic modulus (E) of the chosen coating to be equivalent to that of a polymer-based material.

4 An evaluation of elastic-plastic properties and discussion

In the previous section, the material parameters, namely elastic modulus [E], and hardness [H] of the chosen coating, were obtained using the nanoindentation test. However, its plastic properties remain unknown. Therefore, using a combination of finite element (FE) simulation and the nanoindentation experiment the plastic portion of the stress versus strain curve is obtained by using the inverse, iterative method. For this study, the anti-icing coating is assumed to be essentially isotropic. Following an initial linear elastic stage, it obeys a power-law hardening stress versus strain relationship, which is expressed as follows [8, 9].

In this expression: (i) E represents the elastic modulus, (ii) σy is the yield stress, (iii) K is the monotonic strength coefficient, and (iv) n is the strain hardening exponent. By varying the values of the strength coefficient (K) and strain hardening exponent (n) in the finite element simulation and by comparing the resultant load versus displacement curve with experimental measurements, the plastic properties of the chosen anti-icing coating is obtained when results provided by the finite element (FE) simulation agree well with the experimental results obtained from the nanoindentation test. Thus, is made possible a fairly accurate determination of the elastic-plastic properties of the chosen anti-icing coating.

The finite element model [FEM] used to simulate nanoindentation test considers the following aspects:

The geometric model and boundary conditions should represent the experimental nanoindentation test while correctly establishing the two key geometric parameters, namely: (i) coating thickness, and (ii) radius of head of the chosen indenter.

The mechanical properties of the substrate, coating and indenter to include elastic modulus [E], Poisson's ratio [ν], and stress versus strain relationship that governs plastic response. For this the materials chosen for both the substrate (aluminum alloy) and the coating are considered to be essentially isotropic.

An interaction between the contact surfaces.

For the finite element simulation, a “local” model was built around the chosen indenter, which includes the indenter, coating, and substrate. The Berkovich indenter used in the nanoindentation experiment was simulated to be a cone having a half-apex angle of 70.32° [12, 24]. Due to symmetry, an axisymmetric model was established by combining the load and boundary conditions of the coating during the experiment. The thickness of the substrate was 20μm and thickness of the chosen coating was 100μm.

For the finite element simulation, the following assumptions were made [8, 15]:

The coating-substrate interface is completely bonded with an absence of slip, and

Friction between the contacting surfaces of the indenter and the coating is neglected.

The elastic properties of the indenter, coating and aluminum alloy substrate are summarized in Table 2. From the results, it was found that both the indenter and the aluminum alloy substrate remain in the elastic region during the entire process. The coating was considered to be an isotropic, elastic-plastic material that obeys the stress versus strain relationship given by Equation (3). The values of plastic parameters of the chosen coating were determined using the inverse, iterative method by comparing the finite element computed curve with the measured load-displacement curve obtained from the nanoindentation test.

Elastic properties of the materials

| Material | Elastic modulus E (GPa) | Poisson's ratio (ν) |

|---|---|---|

| Indenter [15] | 1141 | 0.07 |

| Coating | 3.62 | 0.25 |

| Substrate [Aluminum alloy] | 73.1 | 0.3 |

The boundary conditions are prescribed such that bottom of the substrate is fixed, and an axisymmetric condition is imposed along the axis of symmetry. This is shown in Figure 4. A load is then applied to the indenter, in incremental stages, such that the model can simulate both the loading process and the unloading process specific to the nanoindentation experiment.

A schematic showing the boundary conditions used for purpose of computation

The finite element software ABAQUS was used for the purpose of simulation, and the CAX4I element was chosen and used to generate the mesh. The finite element mesh is refined in the immediate vicinity of the indent due to the occurrence of high stress and resultant deformation gradients in this region. A coarser mesh was used in the region away from the indent. The overall partition of the mesh is shown in Figure 5.

A schematic showing the mesh division used in the finite element simulation

At first, a convergence study was conducted to ensure that a refinement in the mesh chosen is both adequate and sufficient for the purpose of this research study. To meet this objective three meshes, each consisting of: (i) 7250 elements, (ii) 8400 elements, and (iii) 9020 elements, were generated. Following computation, it was found that the load versus displacement curve for each of the three chosen meshes differ by less than one percent. This provides a convincing indication for the occurrence of a converged solution for the mesh configuration chosen.

Next, a series of finite element simulations were conducted using different values of monotonic strength coefficient (K) and strain hardening exponent (n) for the chosen coating. The computed load versus displacement curve was compared with the experimental curve, as shown in Figure 6. The value of strength coefficient (K) and strain hardening exponent (n) that results in the best fit between the finite element computed curve and the experimental curve obtained from the nanoindentation test was taken to be the strength coefficient (K) and strain hardening exponent (n) of the coating. Based on the stress versus strain curve the yield strength (σy) was obtained. The plastic parameters for the chosen anti-ice coating were found to be the following: (i) Yield strength (σy) = 15 MPa, (ii) strain hardening exponent (n) = 0.75, and (iii) Strength coefficient (K) = 918.45 MPa.

A comparison of the simulation curve with the experimental curve

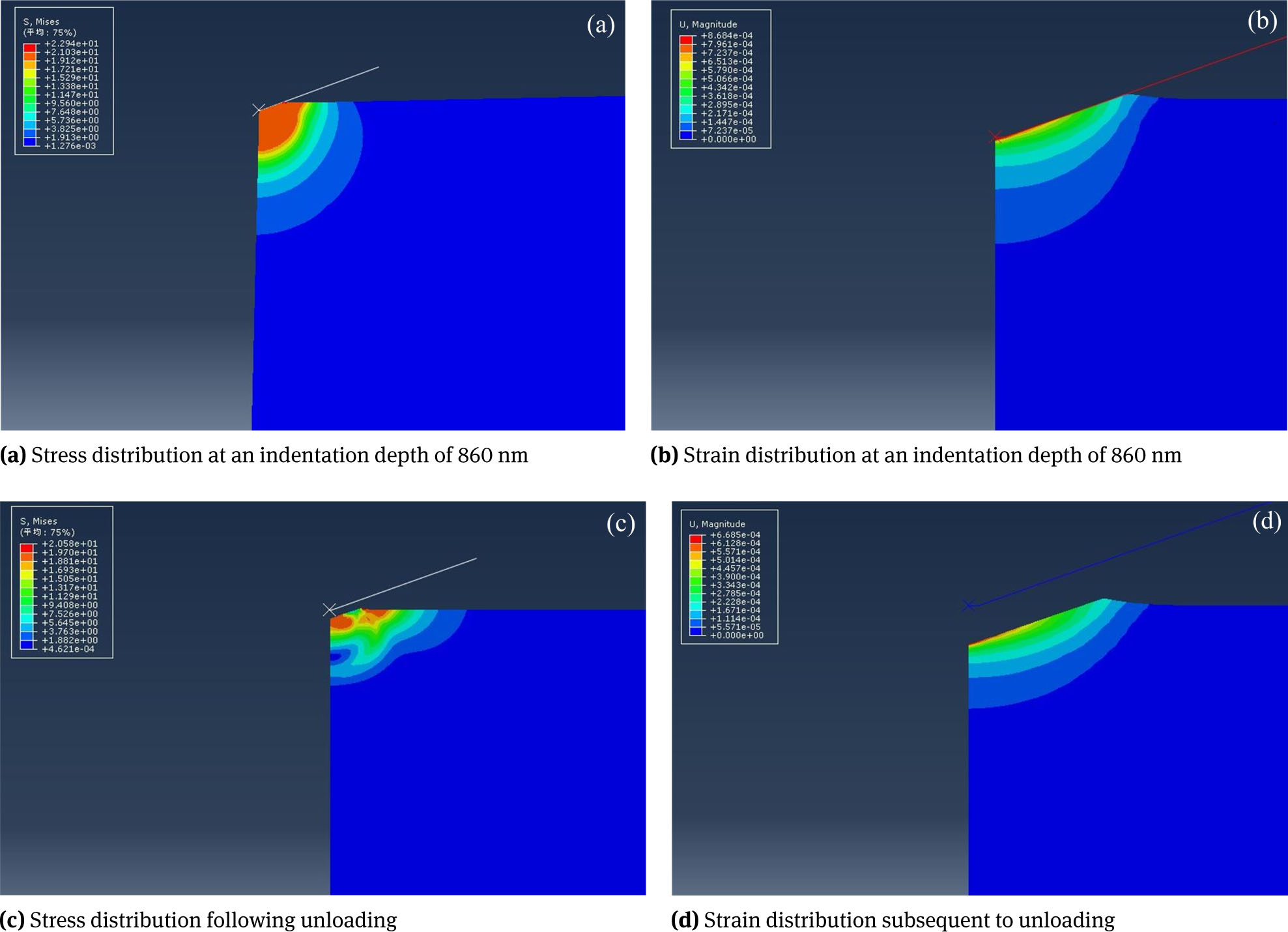

In Figure 7 is shown the contours for the von Mises stress and equivalent strain induced in the chosen coating. The von Mises stress contour for an indentation depth of 860 nm is shown in Figure 7a. The stress is high near the center of the indent and gradually decreases as distance from the indent increases. The maximum von Mises stress was found to be 22.94 MPa. This value is greater than yield strength (σYS) of the chosen coating. Hence, the occurrence of plastic deformation both at and near the indenter is evident. The strain contour for gradual loading up to the maximum displacement is shown in Figure 7(b). Maximum deformation was found to occur immediately below the indenter.

Contours of von Mises stress and equivalent strain during loading and unloading processes

During unloading, due to elastic-plastic properties of the chosen coating, the severity of deformation that occurs at location of the indent decreases but does not completely disappear. As shown in Figure 7(c) and Figure 7(d), the residual stress was 20.58 MPa and the depth following unloading was 668 nm. The value of residual stress exceeds the yield strength of the chosen coating providing a convincing indication of the occurrence of highly “localized” plastic deformation. Comparing one-to-one, the results obtained from the nanoindentation experiment, it was found that results of the finite element simulation are consistent with the experimental results.

5 Conclusions

In accordance with characteristics of a super-hydrophobic anti-icing coating, the nanoindentation test was determined to be an ideal experimental approach. The inverse, iterative method was used to obtain plastic properties of the chosen coating. The key findings of this research study are the following:

Based on results of the nanoindentation experiments, the elastic modulus [E] of the hydrophobic coating was 3.62 GPa with an average hardness [H] of 169 MPa. The plastic behavior of the coating cannot be obtained using the nanoindentation experiment. The finite element method was used to simulate the nanoindentation process. In combination with experimental results, the power law hardening model was used to represent the stress versus strain relationship of the chosen coating. The plastic parameters were obtained using the inverse iterative method. The plastic parameters for the chosen coating were found to be the following: (i) yield strength (σy) is 15 MPa, (ii) strain hardening exponent (n) is 0.75, and (iii) monotonic strength coefficient (K) is 918.45 MPa.

Finite element simulation revealed the occurrence of plastic deformation both at and near the region of the indent. Even subsequent to unloading the localized plastic deformation persists in the region of the indent with the residual stress exceeding the yield strength (σYS) of the chosen coating.

This study clearly shows that by combining the nanoindentation test with finite element simulation, it is possible to obtain the elastic-plastic properties of the chosen coating.

Acknowledgement

The authors would extend abundance of thanks and appreciation to Mr. Yong Liu for providing valuable assistance with the finite element simulation.

Funding information: This research was financially supported by Program 41402020401.

Authors contribution: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

Conflict of interest: The authors state no conflict of interest.

References

[1] Morita K, Gonzales J, Sakaue H. Effect of PTFE Particle Size on Superhydrophobic Coating for Supercooled Water Prevention. Coatings. 2018;8(12):1–9.10.3390/coatings8120426Search in Google Scholar

[2] Karapanagiotis I, Manoudis P. Superhydrophobic surfaces. J Mech Behav Mater. 2012;21(1–2):21–32.10.1515/jmbm-2012-0022Search in Google Scholar

[3] Paul D. D Dolatabadi., Effect of Super Hydrophobic Coating on the Anti-Icing and Deicing of an Airfoil. J Aircr. 2017;54(2):490–9.10.2514/1.C033828Search in Google Scholar

[4] Kash L. Mittal., Adhesion measurements of films and coatings. 2nd ed. CRC Press; 2001.Search in Google Scholar

[5] Malzbendera J. Measuring the mechanical properties of coatings: a methodology applied to nano-particle-filled sol–gel coatings on glass. Mater Sci Eng Rep. 2002;36(2–3):47–103.10.1016/S0927-796X(01)00040-7Search in Google Scholar

[6] Tabatabaei M, Shodja HM. A combined first principles and Mohr-Coulomb criterion for the determination of the nanohardness of amorphous silicon. J Mech Behav Mater. 2015;24(5–6):145–51.10.1515/jmbm-2015-0023Search in Google Scholar

[7] Mallikarjunachari G, Ghosh P. Analysis of strength and response of polymer nano thin film interfaces applying Nanoindentation and nano scratch techniques. Polymer (Guildf). 2016;90:53–66.10.1016/j.polymer.2016.02.042Search in Google Scholar

[8] Yang Y, Liao N, Zhang M, Li F. Evaluation of the elastic-plastic properties of SiC coating system by finite element simulations’. J Eur Ceram Soc. 2017;37(13):3891–7.10.1016/j.jeurceramsoc.2017.05.017Search in Google Scholar

[9] Oliver WC, Pharr GM. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res. 1992;7(6):1564–83.10.1557/JMR.1992.1564Search in Google Scholar

[10] Shi R, Nie Z, Fan Q, Li G. Elastic plastic deformation of TC6 titanium alloy analyzed by in-situ synchrotron-based X-ray diffraction and microstructure based finite element modeling. J Alloys Compd. 2016;688:788–92.10.1016/j.jallcom.2016.07.105Search in Google Scholar

[11] Kang JJ, Becker AA, Sun W. Determining elastic–plastic properties from indentation data obtained from finite element simulations and experimental results. Int J Mech Sci. 2012;62(1):34–46.10.1016/j.ijmecsci.2012.05.011Search in Google Scholar

[12] Yang Y. Study on mechanical behavior of coating-substrate based on finite element modeling. PhD thesis. Wenzhou university of China, Wenzhou, China; 2017. (in Chinese)Search in Google Scholar

[13] Gupta AK, Porwal D, Dey A, Sridhara N, Mukhopadhyay AK, Sharma AK, et al. Evaluation of elastic-plastic properties of ITO film using combined Nanoindentation and finite element approach. Ceram Int. 2016;42(1):7225–33.10.1016/j.ceramint.2015.09.054Search in Google Scholar

[14] Allali A, Belbachir S, Alami A, Boucham B, Lousdad A. Sadia Belbachir., Ahmed Alami., Belhadj Boucham., Abdelkader Lousdad., The effect of the outlet angle β2 on the thermomechanical behavior of a centrifugal compressor blade. J Mech Behav Mater. 2020;29(1):1–8.10.1515/jmbm-2020-0001Search in Google Scholar

[15] Yang Y, Liao N, Zhang M, Li F. Numerical investigation on the bond strength of a SiC-based multi-layer coating system. J Alloys Compd. 2017;710:468–71.10.1016/j.jallcom.2017.03.286Search in Google Scholar

[16] Hyun HC, Kim MS, Lee JH, Lee H. A Conical Indentation Technique Based on FEA Solutions for Property Evaluation. Mech Mater. 2011;43(6):313–31.10.1016/j.mechmat.2011.03.003Search in Google Scholar

[17] Komovopoulus K. Finite element analysis of a layered elastic solid in normal contact with a rigid substrate. J Tribol-T Asme. 1988;110(3):477–85.10.1115/1.3261653Search in Google Scholar

[18] Tian H, Saka N. Finite element analysis of an elastic-plastic two-layered half-space: sliding contact. Wear. 1991;148:262–85.10.1016/0043-1648(91)90206-ASearch in Google Scholar

[19] Diaod K. Interface yield map of a hard coating under sliding contact. Thin Solid Films. 1994;245(1–2):115–21.10.1016/0040-6090(94)90886-9Search in Google Scholar

[20] Dobrzanski LA, Sliwa A, Kwasny W. Employment of the finite element method for determining stresses in coatings obtained on high-speed steel with the PVD process. J Mater Process Technol. 2005;164:1192–6.10.1016/j.jmatprotec.2005.02.134Search in Google Scholar

[21] Zhang Y. Kong de-Jun., Study on the determination of interfacial binding strength of coatings(I): theoretical analysis of stress in thin film binding interface. Acta Phys Sin-Ch Ed. 2006;6:2897–900.10.7498/aps.55.2897Search in Google Scholar

[22] Song YS. Yao Shu-ren., Adhesive Between Organic Coating and Metal Substrate [in Chinese] Mater Prot. 1999;32:21–2.Search in Google Scholar

[23] Standardization Administration of the People's Republic of China. GB/T 4883-2008 Statistical Interpretation of Data – Detection and Treatment of Outliers in the Normal Sample. Beijing: Standards Press of China; 2008. (in Chinese)Search in Google Scholar

[24] Ma ZS. Characterization of the mechanical properties of metallic films by Nanoindentation method. PhD thesis. Xiangtan University of China, Xiangtan; 2011. (in Chinese)Search in Google Scholar

© 2021 Wei Zhanget al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**

Articles in the same Issue

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**