Abstract

Distinct materials are used for the construction of battle tanks used in defense sectors. The hull and turret of the battle tanks are made up of rolled homogeneous armor steel (also known as armor steel). The inner portions like the driver cabin and control room are covered with medium carbon steel. Hence, the dissimilar joint between these materials is unavoidable in the battle tank construction. Conventional fusion welding processes like manual metal arc welding, gas metal arc welding, and gas tungsten arc welding are preferred to join the dissimilar metals. However, the high heat input nature of these processes will create hydrogen induced cracking, high residual tensile strain, and HAZ softening, etc. To minimize these issues, solid state welding processes were adopted. In the present study, mechanical properties and microstructural characteristics of rotary friction welded dissimilar joint of armor steel and medium carbon steel was analyzed. The ultimate tensile strength of the dissimilar joint is around 775 MPa and the failure occurred at the medium carbon steel side. The impact toughness value of dissimilar joints is higher than medium carbon steel and lower than armor steel. The microstructure across the dissimilar joint has distinct features and a complex pattern was observed at the weld interface.

1 Introduction

In defense sectors, the construction of hull and turret structures of combat vehicles were made up of rolled homogenous armor (RHA) steel because it offers a combination of strength, toughness, and ballistic resistance. This steel belongs to the low alloy steel category supplied in quenched and tempered (Q&T) conditions [1, 2]. The inner portions of combat vehicles that are not susceptible to ballistic attacks are made using medium carbon steel (MCS). Joining these materials is inevitable in combat vehicles and welding is considered to be the promising method among other joining techniques. Fusion welding processes, such as manual metal arc welding (MMAW), gas tungsten arc welding (GTAW), flux-cored arc welding (FCAW), and gas metal arc welding (GMAW) are generally preferred to join similar and dissimilar welding between RHA and MCS [3, 4, 5, 6, 7]. However, it involves some common problems like the selection of proper filler metal, joint preparation, higher heat flux per unit area, and evolution of tensile residual strain. On the other hand, metallurgical defects like hydrogen-induced cracking (HIC) after welding, and HAZ softening owing to higher thermal history will reduce the overall performance in service [8]. A solid-state welding process like friction welding will offer several advantages that include elimination of welding consumables, less distortion, reduced heat input, and less welding time. Friction welding is widely used in the automotive and aircraft sectors to join similar and dissimilar materials [9]. Mousavi et al. [10] developed a numerical model to predict the strain, temperature evolution, the final shape of the flash of friction welded dissimilar joint between mild steel and 4340 steel. The mechanical properties are also analyzed. The developed model is in good agreement with experimental results. Fine grains were observed at the weld zone and the location of rupture of all the samples is observed outside of the weld zone. Ozdemir [11] investigated the effect of rotational speed on mechanical properties of the dissimilar joint between 4340 low alloy steel and 304L stainless steel fabricated using rotary friction welding process. The rotational speed varied from 1500 rpm to 2500 rpm respectively. From the investigation, he concluded that an increase in rotational speed increases the tensile strength. Higher welding speed with shorter friction time minimizes the width of the fully plasticized deformed zone and improves the quality and mechanical properties of the joint. The fatigue behavior as a function of a rotational speed of friction welded dissimilar joint between 4340 low alloy steel and 304L stainless steel was investigated by Hascalik and Ozdemir [12]. Three different speeds ranging from 1500 rpm to 2100 rpm were used in the study. The hardness increases with an increase in rotational speed whereas, tensile and fatigue strength decreases. The formation of chromium carbide at the weld interface will act as a stress riser and decreases the tensile and fatigue strength. The effect of introducing a sliver interlayer between friction welded dissimilar joints of 4340 steel and AA6061 aluminum alloy was studied by Meshram and Madhusudhan [13]. A sliver interlayer was electroplated on 4340 steel to a width of 20 μm. Metallurgical and mechanical behavior of dissimilar joints with silver interlayer was analyzed and discussed. Uniform distribution of Mg across the weld interface promotes the formation of Fe-Al-based brittle intermetallics. The addition of a silver interlayer replaces the Mg with Si at the weld interface and forms Al-Ag-based softer intermetallics and promotes the tensile strength and ductility of the joint. The effect of rotational speed and friction time on mechanical properties of a dissimilar joint between 4340 steel 2205 duplex stainless steel was investigated by Caligulu et al. The width of the fully deformed zone decreases as the rotational speed and friction pressure increases. More axial shortening and lower interface temperature were observed for the joints with higher rotational speed [14]. Most of the investigations are discussed the mechanical properties, fatigue behavior, and effect of interlayers on friction welded dissimilar joints encompassing 4340 low alloy steel. The available literatures on dissimilar joints of armor steel (closely matching to AISI 4340) to medium carbon steel are very few in numbers. Hence, the present investigation focusses on evaluating the mechanical properties and metallurgical characteristics of friction welded dissimilar joint of armor steel (AISI 4340) and medium carbon steel (AISI 1029).

2 Experimental details

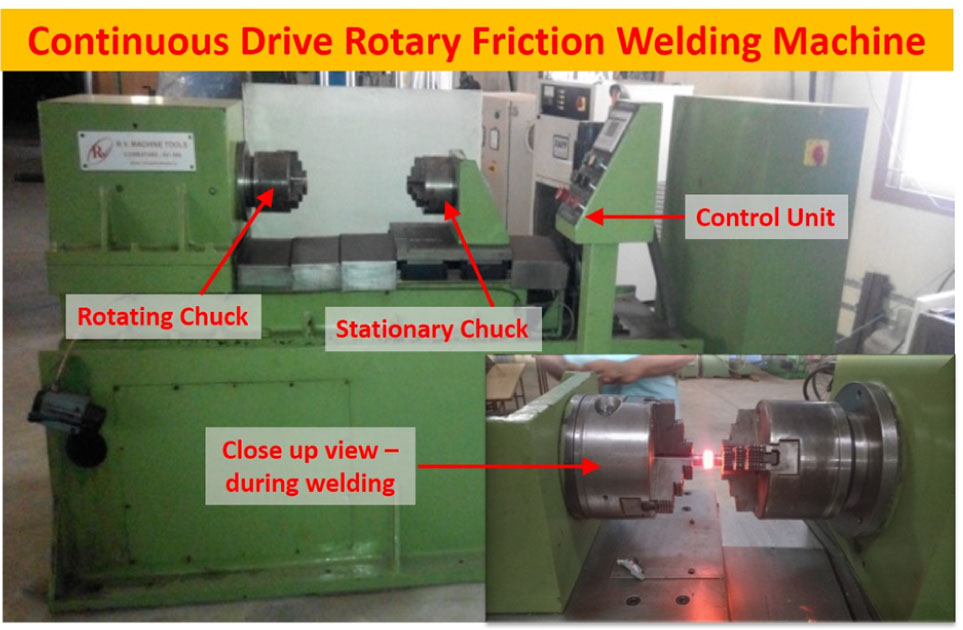

A 16 mm diameter and 90 mm length extruded rod of armor steel and medium carbon (MCS) steel was used in this investigation. The armor steel (AS) was supplied in quenched (austenitizing at 900 °C for 60 min. followed by oil quenching) and tempered (600 °C for 60 min. followed by furnace cooling) condition. This combined Q&T heat treatment enhances the strength and toughness of this steel [15]. The chemical composition of base materials is shown in Table 1. Before welding, the faying surfaces were cleaned with acetone to eliminate the foreign particles. A continuous drive rotary friction welding machine is used to fabricate the dissimilar joint. The photograph of the friction welding machine is shown in Figure 1. The welding parameters are selected from the previous literature [11, 12, 14] and defect free joints were obtained from the trial and error method. The welding parameters used to obtain the defect free dissimilar joint is shown in Table 2. The photograph of the fabricated dissimilar joint is shown in Figure 2. After welding, the flashes are removed to make the specimens for mechanical tests and microstructural characterization.

Chemical composition of base materials.

| (in wt. %) | C | Si | Mn | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| AS | 0.298 | 0.30 | 0.53 | 0.018 | 0.009 | 1.39 | 0.381 | 1.44 | Bal. |

| MCS | 0.31 | 0.6 | 0.78 | 0.03 | 0.05 | - | - | - | Bal. |

Photograph of RFW machine.

Welding parameters used to fabricate the dissimilar joint.

| Rotational speed (RPM) | Friction pressure (MPa) | Friction time (Seconds) | Forging pressure (MPa) | Forging time (Seconds) |

|---|---|---|---|---|

| 1900 | 17 | 5 | 24 | 7 |

Photograph of dissimilar joint.

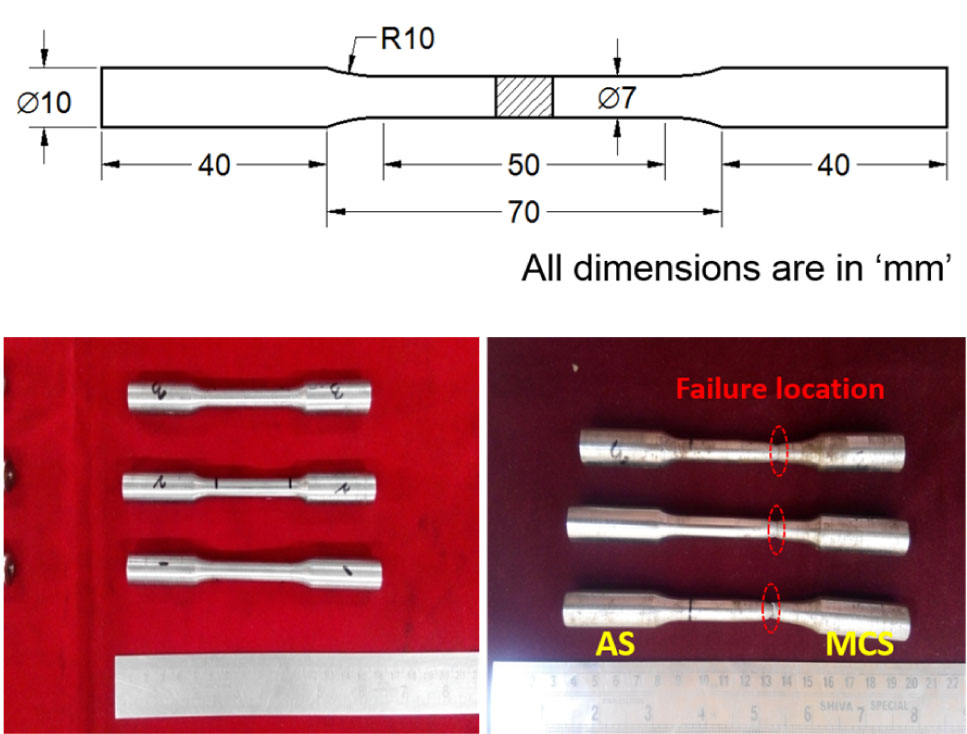

The properties like ultimate tensile strength, 0.2% offset yield strength, elongation, and reduction in cross sectional area are evaluated from smooth tensile specimens and the test was performed as per the ASTM E8 standard. The dimension details and photographs of smooth tensile specimens are shown in Figure 3. The notch tensile test is performed to understand notch sensitivity and notch brittleness of the joint [16]. For this test, a V-notch was machined at the joint interface. The dimension details and photographs of notch tensile specimens are shown in Figure 4. The room temperature impact toughness was evaluated using Charpy specimens with a velocity of 5.2 m/s as per the ASTM E23 standard. The microhardness was recorded across the dissimilar joint. A load of 500 g and a dwell time of 15 seconds was used. The microstructural characteristics of the dissimilar joint were analyzed using optical microscopy (OM). For this analysis, the dissimilar joint is sliced and grounded with different grades of SiC sheets. To reveal the structure under an optical microscope, 4% Nital solution was applied for AS side and 2% Nital solution was applied to the MCS side. Fracture surfaces of failed specimens are analyzed under scanning electron microscopy (SEM).

Dimension details and photograph of smooth tensile specimens.

Dimension details and photograph of notch tensile specimens.

3 Results and discussion

3.1 Macrostructure observation

The macrostructure of a dissimilar joint is shown in Figure 5. No visible cracks and porosity were observed and the flash formation is more for MCS than AS. This may be due to the presence of a soft ferrite phase which will deform during welding and expelled more material from the joint interface. Flow lines are visible on the AS side due to higher deformation at the weld interface [17]. The macrostructure reveals distinct regions across the dissimilar joint (fully deformed zone, partially deformed zone, heat affected zone, and base metal). During welding, the faying surfaces experience high temperatures and deform the material. The application of forging pressure at this stage will increase the strain rate up to 10−3 s−1 and resulted in a fully deformed zone (FDZ) [9].

Macrostructure of the dissimilar joint.

3.2 Microstructural variation across the dissimilar joint

The OM of FDZ is shown in Figure 6a. On, AS side un-tempered martensitic structure was observed. The interface temperature during friction welding exceeds the austenitizing temperature (above 950 °C), during cooling, is resulted in an un-tempered martensitic structure with pinned dislocations. The formation of this zone enhances the hardness and strength. Also, an alternate layer of un-tempered martensite and pearlite with minor traces of ferrite was observed at the weld interface. On the MCS side, ferrite patches along with pearlite and bainite were observed. The evolution of the alternate layer will make inter-locking effects and delays the necking formation and improves the tensile strength of the joint [18]. The OM of the partially deformed zone (PDZ) of AS is shown in Figure 6b. It consists of partially deformed grains of the martensite phase and larger grains compared to the FDZ region. The OM of PDZ of MCS is shown in Figure 6c. Deformed grains were observed in comparison with a base metal (Figure 6f). Insufficient temperature to plasticize the material and the high strain rate produced by forging pressure causes the formation of partially deformed grains. The heat affected zone (HAZ) for AS and MCS are shown in Figure 6d and 6e respectively. The microstructure of HAZ of AS (Figure 6d) has a similar feature to the base metal. The temperature of this region is almost similar to the tempering temperature of this steel and resulted in a tempered martensitic structure. The HAZ of MCS consists of pearlite and polygonal ferrite. The OM of AS base metal is shown in Figure 6f. It consists of a tempered martensitic structure along with chromium-rich carbides that are formed during the tempering process. The OM of MCS is shown in Figure 6g. It consists of equiaxed polygonal ferrite and pearlite.

Microstructural observations.

3.3 Tensile properties

The engineering stress strain behavior of smooth and notch tensile specimens is shown in Figure 7. To obtain smooth tensile properties, three specimens were tested for repeatability. For notch tensile properties, two specimens were tested. The average values with standard deviation for smooth and notch tensile specimens are furnished in Table 3. From the stress strain graph (Figure 7), it is understood that the notch tensile specimens exhibited a higher value than smooth specimens. The stress triaxiality created at the root of the notch will increase the tensile strength of notched specimens. The tensile behavior of smooth specimens exhibited higher ductility and toughness. From Table 3, it is evident that the ultimate tensile strength of the dissimilar joint is almost equal to the MCS base metal tensile strength, and failure location is in the MCS base metal. This behavior may be due to the presence of an alternate layer of un-tempered martensite and pearlite with minor traces of polygonal ferrite in the FDZ. During tensile deformation, this complex microstructure will delay the necking formation up to a certain limit then failure occurs. The formation of this kind of microstructures in the dissimilar joint is owing to optimum welding parameters like forging pressure, friction pressure, and friction time, etc. The joint efficiency of 100% in the dissimilar joint is possible when it is made with higher forging pressure, low friction pressure, and optimum friction time [19, 20]. In this investigation, we achieved 96 % of joint efficiency. Notch strength ratio is used to assess the plasticity of the material at the root of notch and notch brittleness [21]. In this investigation, both base metals and weld joint are having some degree of plasticity and behaves as notch ductile.

Tensile properties of base metals and dissimilar joint.

| 0.2 % yield strength (MPa) | Ultimate tensile strength (MPa) | Elongation in 50 mm GL (%) | Reduction in cross sectional area (%) | Notch tensile strength (MPa) | Notch strength ratio | Joint efficiency (%) | Failure location | |

|---|---|---|---|---|---|---|---|---|

| AS | 1090±5 | 1200±6 | 11.2 | 40 | 1650±7 | 1.38 | - | - |

| MCS | 450±6 | 804±11 | 22 | 59 | 927±14 | 1.15 | - | - |

| Weld | 670±12 | 775±15 | 11.9 | 52 | 1094±13 | 1.41 | 96 | MCS-BM |

Stress-strain behavior of dissimilar joint.

3.4 Impact toughness

Charpy V notch impact test conducted at room temperature (26 °C). Two specimens were tested and the average value with error bar is shown in Figure 8. The impact toughness value for a dissimilar joint is slightly higher than MCS base metal and lower than AS base metal. The presence of alternate layers of un-tempered martensite and pearlite with ferrite structure at the FDZ increases the impact toughness value. In general, friction welded components are having lower impact toughness than fusion-welded joints. But, the selection of proper welding parameters will minimize this issue [22].

Impact toughness of base metals and dissimilar joint.

3.5 Microhardness variation

The variation of microhardness across the dissimilar joint is shown in Figure 9. Peak hardness (about 550 HV) was observed at the weld interface (i.e. FDZ). The hardness value decreases in the AS side when it moves towards PDZ and HAZ etc. A similar trend was observed for MCS as well. The main reason for peak hardness is due to the presence of an un-tempered martensite structure that is formed during welding. The un-tempered martensite will have high dislocation density and residual stress. The strength may be high in this region but the ductility is very poor. The lowest hardness (around 230 to 240 HV) is observed for the MCS side. There is no softening or hardening was observed in the HAZ of both AS and MCS. The hardness results are consistent with tensile properties since the tensile specimens are failed in the MCS side.

Microhardness variation across the dissimilar joint.

3.6 SEM fracture surface analysis

The fracture surface of the smooth tensile specimen is shown in Figure 10a. It consists of fine and deep dimples with tear ridges. Also, a few fine secondary phase particles were visible inside of the dimples. The fracture surface of the notched tensile specimen (Figure 10b) has shallow dimples with stepped features. Due to stress triaxiality, the fracture propagates faster in a notched specimen compare to un-notched one. The fracture surface of the Charpy impact toughness specimen is shown in Figure 10c. It has a quasi-cleavage pattern and the crack propagates opposite to the loading direction. Also, flat facets with a small fraction of tear ridges are evident.

SEM fracture surface analysis.

4 Conclusions

The dissimilar joint between armor steel and medium carbon steel was successfully fabricated using a rotary friction welding machine. The mechanical properties and microstructural characterization of the dissimilar joint were analyzed and discussed. Based on this, the important conclusions are as follows:

From the macrostructure observation, it is evident that the dissimilar joint doesn’t have any macro-level defect and a narrow FDZ zone was observed. The flash formation is more for the MCS side.

A complex microstructure was observed at the FDZ. An alternate layer of un-tempered martensite and pearlite with minor traces of ferrite was observed. Deformed grains were evident at the PDZ for both AS and MCS. The grain size in the HAZ region is almost similar to that of base metals.

The tensile strength of the dissimilar joints is 3.6% lower than MCS base metal and 35.4 % lower than AS with a joint efficiency of 96%. This is due to the high forging pressure, low friction pressure, and optimum friction time. The notch tensile strength of the dissimilar joints is higher than un-notched one. Both base metal and dissimilar joint exhibits notch ductile behavior.

The impact toughness of dissimilar is marginally higher than MCS and lower than AS base metal values. The development of complex microstructure at the FDZ may be the reason for the high toughness value.

A peak hardness of 550 HV was recorded at the FDZ region and the lowest hardness of 240 HV is observed for the MCS region. The microhardness results are consistent with the tensile behavior.

The fracture surface of tensile and impact toughness exhibits ductile behavior. However, the fracture surface of smooth tensile specimens has deeper dimples with tear ridges.

Acknowledgement

The authors are thankful to combat vehicle research development and establishment (CVRDE), Avadi, Chennai for providing base metals to carry out this investigation. The experimental support rendered by Mr. Abeshek Dubey is acknowledged.

Funding information:

The authors state no funding involved.

Author contributions:

All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

Conflict of interest:

The authors state no conflict of interest.

References

[1] Atapek SH. Development of a new armor steel and its ballistic performance. Def Sci J. 2013;63(3):271–7.10.14429/dsj.63.1341Search in Google Scholar

[2] Yilmaz A. Development of an armor steel for ballistic protection. Mater Test. 2010;52(11–12):811–8.10.3139/120.110190Search in Google Scholar

[3] Balakrishnan M, Balasubramanian V, Madhusudhan Reddy G. Microstructural Analysis of Ballistic Tests on Welded Armor Steel Joints. Metallogr Microstruct Anal. 2013;2(3):125–39.10.1007/s13632-013-0069-5Search in Google Scholar

[4] Cabrilo A, Geric K, Jovanovic M, Vukic L. Weldability and Impact Energy Properties of High-Hardness Armor Steel. J Mater Eng Perform. 2018;27(3):1281–95. Available from: https://doi.org/10.1007/s11665-018-3211-310.1007/s11665-018-3211-3Search in Google Scholar

[5] Magudeeswaran G, Balasubramanian V, Sathyanarayanan S, Reddy GM, Moitra A, Venugopal S, et al. Dynamic fracture toughness (JId) behavior of armor-grade Q & T steel weldments: Effect of weld metal composition and microstructure. Met Mater Int. 2009;15(6):1017–26.10.1007/s12540-009-1017-4Search in Google Scholar

[6] Saxena A, Dwivedi SP, Sharma S, Srivastava VS, Singh G, Singh J, et al. A comparative numerical analysis on the effect of welding consumables on the ballistic resistance of SMAW joints of Armor steel. Appl Sci. 2021;11(8).10.3390/app11083629Search in Google Scholar

[7] Kostin VA, Grigorenko GM, Poznyakov VD, Zuber TO. Structural Transformations of the Metal of Heat-Affected Zone of Welded Joints of High-Strength Armor Steels. Mater Sci. 2020;55(6):863–9.10.1007/s11003-020-00380-7Search in Google Scholar

[8] Magudeeswaran G, Balasubramanian V, Madhusudan Reddy G. Metallurgical characteristics of armour steel welded joints used for combat vehicle construction. Def Technol. 2018;14(5):590–606. Available from: https://doi.org/10.1016/j.dt.2018.07.02110.1016/j.dt.2018.07.021Search in Google Scholar

[9] Uday MB, Fauzi MNA, Zuhailawati H, Ismail AB. Advances in friction welding process: A review. Sci Technol Weld Join. 2010;15(7):534–58.10.1179/136217110X12785889550064Search in Google Scholar

[10] Mousavi SAAA, Kelishami AR. Experimental and numerical analysis of the friction welding process for the 4340 steel and mild steel combinations. Weld J (Miami, Fla). 2008;87(7).Search in Google Scholar

[11] Özdemir N. Investigation of the mechanical properties of friction-welded joints between AISI 304L and AISI 4340 steel as a function rotational speed. Mater Lett. 2005;59(19–20):2504–9.10.1016/j.matlet.2005.03.034Search in Google Scholar

[12] Hasçalik A, Ünal E, Özdemir N. Fatigue behaviour of AISI 304 steel to AISI 4340 steel welded by friction welding. J Mater Sci. 2006;41(11):3233–9.10.1007/s10853-005-5478-7Search in Google Scholar

[13] Meshram SD, Madhusudhan Reddy G. Friction welding of AA6061 to AISI 4340 using silver interlayer. Def Technol. 2015;11(3):292–8. Available from: http://dx.doi.org/10.1016/j.dt.2015.05.00710.1016/j.dt.2015.05.007Search in Google Scholar

[14] Caligulu U, Yalcinoz M, Kati N, Balalan Z, Islak S. The effects of rotation speed and friction time for joining of AISI 4340-2205 steels by friction welding. Metallofiz i Noveishie Tekhnologii. 2015;37(5):665–81.10.15407/mfint.37.05.0665Search in Google Scholar

[15] Jiang B, Wu M, Zhang M, Zhao F, Zhao Z, Liu Y. Microstructural characterization, strengthening and toughening mechanisms of a quenched and tempered steel: Effect of heat treatment parameters. Mater Sci Eng A [Internet]. 2017;707:306–14. Available from: http://dx.doi.org/10.1016/j.msea.2017.09.06210.1016/j.msea.2017.09.062Search in Google Scholar

[16] Bacon, D., Dieter GE. Mechanical Metallurgy. McGraw-Hill Education; 1988. 768 p. Available from: https://www.google.co.in/books/edition/Mechanical_Metallurgy/aDfHQgAACAAJ?hl=enSearch in Google Scholar

[17] Madhusudhan Reddy G, Venkata Ramana P. Role of nickel as an interlayer in dissimilar metal friction welding of maraging steel to low alloy steel. J Mater Process Technol [Internet]. 2012;212(1):66–77. Available from: http://dx.doi.org/10.1016/j.jmatprotec.2011.08.00510.1016/j.jmatprotec.2011.08.005Search in Google Scholar

[18] Sahin M. Joining with friction welding of high-speed steel and medium-carbon steel. J Mater Process Technol. 2005;168(2):202–10.10.1016/j.jmatprotec.2004.11.015Search in Google Scholar

[19] Kimura M, Iijima T, Kusaka M, Kaizu K, Fuji A. Joining phenomena and tensile strength of friction welded joint between Ti–6Al–4V titanium alloy and low carbon steel. J Manuf Process. 2016;24:203–11.10.1016/j.jmapro.2016.09.004Search in Google Scholar

[20] KIMURA M, SAITOH Y, KUSAKA M, KAIZU K, FUJI A. Effect of Friction Welding Condition and Weld Faying Surface Properties on Tensile Strength of Friction Welded Joint between Pure Titanium and Pure Copper. J Solid Mech Mater Eng. 2011;5(12):849–65.10.1299/jmmp.5.849Search in Google Scholar

[21] Qu R, Zhang P, Zhang Z. Notch Effect of Materials: Strengthening or Weakening? J Mater Sci Technol. 2014;30(6):599–608. Available from: http://dx.doi.org/10.1016/j.jmst.2014.04.01410.1016/j.jmst.2014.04.014Search in Google Scholar

[22] Sathiya P, Aravindan S, Haq AN. Some experimental investigations on friction welded stainless steel joints. Mater Des. 2008;29(6):1099–109.10.1016/j.matdes.2007.06.006Search in Google Scholar

© 2021 K. Karthick et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**

Articles in the same Issue

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**