Abstract

Based on the three-dimensional field of molten pool and twin-roll strip casting experiments, this work verified the cracking mechanism of the strip by establishing mathematical model and rolling experiments. The results showed that due to the instability of the thermophysical field of the molten pool and the inconsistency of kiss curve height, the newly solidified strip will undergo incompatible deformation through the rolling. The stress concentration will appear around the large reduction area and then form slip bands. When plastic strain exceeds the limit of the metal, the oblique cracks will appear in the slip bands periodically or completely penetrate the strip. In addition, tensile cracks could also be produced by incompatible deformation. Therefore, keeping the uniformity and stability of the thermal physical field in molten pool is the key factor to restrain cracks.

1 Introduction

The twin-roll strip casting (TRC) uses a pair of relatively rotating rollers as crystallizers to solidify and roll the liquid metal to a strip in a short time [1,2] (Figure 1). However, this technology is not mature enough [3,4]. The crack problem has a very harmful effect on the mechanical properties of the strip [5]. However, the causes of cracks are complex and variable, such as chemical composition, thermal stress, grain dislocation and other factors [6,7].

The TRC processing.

Harada et al. [8] found that higher casting speed and higher cooling rate can reduce the occurrence rate of cracks on the strip surface effectively. El-Bealy [9] also proved that the interdendritic crack is related to cooling conditions and strain distribution. Xu et al. [10] believed that the crack sources mainly appear at the grain boundary of the strips’ surface and propagate along the grain boundary, and the rapid solidification of small-size grains would be helpful for the crack propagation. However, Hu et al. [11] researched high silicon steel and found that the number of oblique and longitudinal cracks are far more than the transverse cracks on the strip surfaces, and the transverse and longitudinal cracks have caused transgranular fracture, he also pointed out that the uneven heat transfer is the main factor leading to surface cracks. Kim et al. [12] reported that the thermal conductivity of semi-solid area in molten pool is so weak, which leads to the interlayer cracks. He also pointed out that the rolling force should be increased to move the semi-solid area up, which could restrain the cracks. However, Zang et al. [13] believed that if the rolling force is increased, the deformation of strip will be enlarged, and the as-cast strip will be prone to cracking more easily. Therefore, the rolling force cannot be excessive during the TRC process.

In fact, most of the strip cracks are oblique cracks (Figure 3). So the crack problems are difficult to be solved in the two-dimensional field [13]. In the three-dimensional field, this work studies the cracking mechanism through experiments and mathematical models, based on the molten pool temperature field, material deformation and cracking theory.

2 Analysis of TRC cracks

Based on the Φ265 × 120 strip casting mill (Figure 2) with copper alloy crystallization rollers, the thin casting strip has been carried out. As shown in Figure 3, cracks often occur on casting strip forming crack bands (such as edge crack bands). In order to study the causes of the cracks, the fracture morphology of the cracks was analyzed by stereomicroscope (Figure 4). The results show that there is a certain thickness of oxide layer on the fracture surface, which indicates that the crack was generated in the high temperature period, which is similar to the experimental results of Hu et al. [14].

The TRC mill.

The crack of cast-rolling strip: (a) Surface oblique cracks and (b) edge cracks.

Fracture morphology of the oblique crack.

However, there are obvious directional plastic deformation marks on the oblique crack fracture, and the flow traces are basically parallel to the crack direction. It means that the crack in this region grew by the action of shear force mainly. So these oblique cracks are sliding mode cracks, and the crack band is shear slip band. In general, slip band is hard to be formed during the solidification, so it should be produced during rolling deformation.

Although the kiss point (KP) and solidification interface can be obtained clearly in the two-dimensional field, due to the uneven distribution of flow and temperature in the molten pool, it is difficult to get a parallel and smooth kiss curve in the three-dimensional field. As shown in Figure 5a, the KP may be moving up the area which has low flow rate or efficient heat transfer (such as point A). On the contrary, the KP will decline where there is large flow rate or weak heat exchange (such as point B) [15].

The mechanism of casting strip crack: (a) uneven kiss curve of molten pool; (b) material deformation tendency by rolling; (c) traces of material deformation cause cracks.

So different positions correspond to different rolling reductions (Figure 5b). The rolling reduction (

where

3 Rolling experiment of cracks

In order to verify the cracking mechanism in this study, rolling experiments of cracks were designed by using as-cast A3003 aluminum alloy slab with uneven thickness (Figure 6). To ensure that the experimental conditions are close to the twin-roll casting process, the alloy slab had been heated to 600°C (close to solidus temperature) for rolling, the specific experimental parameters are shown in Table 1.

As-cast 3003 aluminum alloy slab.

Crack experimental parameters of strip rolling

| Project | Parameter | Project | Parameter |

|---|---|---|---|

| Initial rolling temperature | 600°C | Experiment material | A3003 (as-cast) |

| Roller diameter | 265 mm | Thickness of slab thick area | 4.5 mm |

| Roll gap | 2.0 mm | Width of slab thick area | 30 mm |

| Rolling speed | 30 mm·s−1 | Thickness of slab thin area | 2.1 mm |

As shown in Figure 7, the experimental results show that the metal strip changes from the rectangular shape into a long polygon, the deformation is incongruous. The central thick area mainly endures bearing stress, which is much larger than the thin areas. The thick area material flows transversely and extrudes the surrounding region, resulting in forming complex shear slip bands near the juncture between thick and thin areas. Figure 7 also shows that there are obvious oblique macro cracks near the junctures, which are distributed periodically or completely penetrable. In addition, many tiny micro-cracks also appear in the slip area.

Crack experimental results by rolling.

The TRC technology belongs to sub-rapid solidification, the liquid metal solidifies so fast that the solidification defects cannot be filled in time. So there are many defects in casting structure frequently, the intermolecular dislocation defects are numerous, and the crack sources may occur randomly. But the cracks are mainly concentrated in the transition area between thick and thin areas. The main reason is that the material in the transition area not only has lots of longitudinal deformations, but also has a large number of transverse deformations, so that the accumulation strain is larger than other areas. According to crack theory, the slip bands easily generate stress concentration at the intermolecular dislocation defects, forming many tiny micro-cracks first. Then, the micro-cracks continue to expand and interconnect to form macro-cracks under external pressure. The incompatible deformation and deformation potential energy will promote the slip cracks’ growth [16], but the crack growth can release a part of potential energy. When the two effects reach equilibrium, the cracks will stop growing. However, the incompatible deformation and deformation potential energy may accumulate on the slab surface again with the rolling, until a new crack appeared. Therefore, the oblique cracks of the experimental strips will be periodically distributed, and the cracks may penetrate strips completely when deformation potential energy is excessive [17].

In addition, the material structure is mainly high temperature solid solution when the metal is just solidifying during the casting process. The plastic and slip property of the high temperature metal is unstable relatively, and easy to be changed by the temperature, which makes the processing more complex. Therefore, the incongruous deformation of the material is the main factor to produce cracks.

4 Mathematical model of strip casting and cracking

4.1 Constitutive equation of the materials

Based on the assumption of this work, the mathematical model of TRC cracks is established. The strength of the metal is weak when the temperature is little lower than the solidus temperature, so the metal is elastic viscoplastic material [18]. The constitutive equation is as follows:

where

4.2 Heat transfer model

The influence of contact stress on interface heat transfer is very obvious. Liu et al. [19] presented a high precision heat transfer theory for aluminum alloy.

where

where

4.3 Crack propagation theory

As shown in Figure 8, it is assumed that point O is the original position of the shear crack and the crack surface is subjected to a pair of tangential stresses

Force analysis of crack propagation.

The propagation conditions of sliding crack are calculated as follows:

where

4.4 Numerical simulation model

An equal scale mathematical model corresponding to the experimental conditions is established (Figure 9), and mesh encryption is carried out at key locations such as the junction area of the model. For the quasi-static problem of rolling, the explicit algorithm is used to analyze the deformation distribution and deduce the cracking trend and change. The process conditions of numerical simulation model are identical with the crack experiment of strip rolling (as shown in Table 1).

The mesh of mathematical model.

5 Result analysis of mathematical model

5.1 Result analysis of simulation model

The temperature field distribution shows differences between thin and thick areas (Figure 10). Because heat transfer is associated with contact stress, the thick area has larger contact area, contact stress and heat transfer. The temperature of the thick area is about 36.3°C lower than others, which means that the thick area metal has high stress intensity to extrude the surrounding areas. In addition, the temperature difference may lead to uneven shrinkage through subsequent processing, which will promote the crack propagation.

Temperature distribution of simulation model (°C).

After rolling, the metal with thin areas is subjected to tension, but thick area is under compressive force (Figure 11), slip bands emerge near the junction. So, the Tresca stress is the key parameter for cracks. Figure 11 also shows that periodical Tresca stress emerges at the slip bands. According to crack theory, if

Tresca stress distribution of simulation model (MPa).

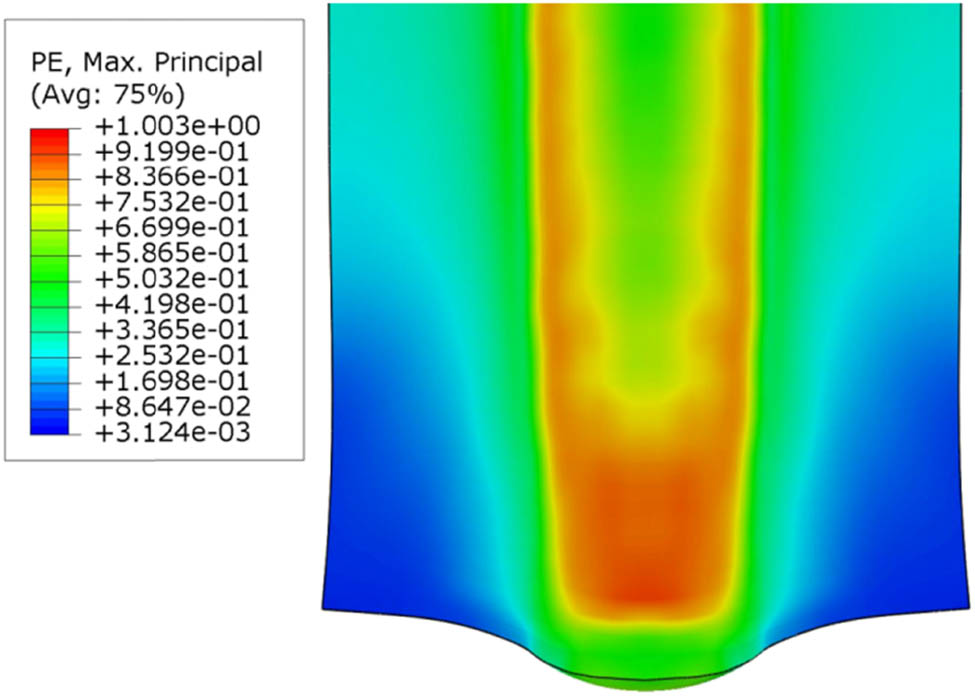

The plastic strain of slip bands is much larger than others (Figure 12), because the uneven deformation can extrude the material to flow transversely. Slip bands are subjected to not only longitudinal deformation but also transverse deformation; therefore, the plastic strain is concentrated at the slip bands, which tends to crack, or even break. In addition, the cracks will further grow to small reduction area because of its tension, which is similar to the experimental results.

Plastic strain distribution of simulation model.

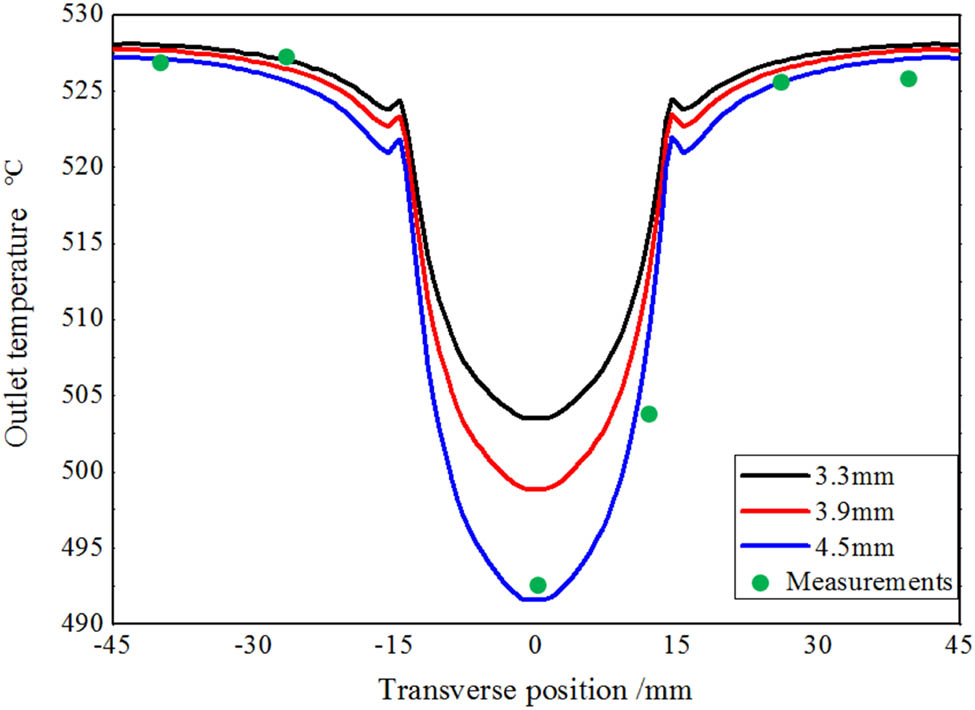

5.2 Analysis of non-uniform rolling reduction

This work further studies the effect of different rolling reductions on temperature and strain. This work set the thickness of center area as 3.3, 3.9 and 4.5 mm (altitude differences of kiss curve are 9.5, 12.2 and 14.5 mm), and the same boundary conditions of Table 1. The results of temperature and strain are shown in Figures 13 and 14.

Temperature distribution of strip in transverse direction.

Plastic strain distribution of strip in transverse direction.

After rolling, thick area temperature is lower than the rest of the areas. With the decrease in the rolling reduction, the temperature at the central area increases gradually, while the temperature of thin areas is not changed much, because the rolling reduction has no significant change. However, the strain results show a different trend. The plastic strain of slip area is the maximum, and its distribution is in the shape of “M.” The maximum plastic strain increases linearly with the increase in strip thickness, and when the strain exceeds the allowable limit [20] of the metal at high temperature, the slip area will crack first and extend to the thin areas, because the thin areas bear the tensile stress. The amount of uncoordinated deformation is directly determined by the altitude difference of KP curve. Therefore, controlling the stability of KP curve is the key factor to suppress crack generation.

In addition, the higher rolling speed and larger strain rate could reduce the plastic properties of metal, which may increase cracking tendency for some materials with poor plasticity.

6 Conclusion

The main influencing factor of the TRC crack is the thermal physical field. The altitude difference of kiss curve will lead to different rolling reductions and different heat transfer conditions in each area, which will result in uneven structure of the strip. While the small reduction area is subjected to tension, and the large deformation area is under compressive stress after rolling, then slip bands will emerge between the two areas, and the slip bands are easier to crack.

If the stress or plastic strain in the slip bands exceeds the limit of the material, many tiny micro-cracks will appear in the slip bands first. With the increase in the deformation potential energy, these micro-cracks continue to grow and connect with each other, which result in macro-cracks. The macro-cracks will be distributed periodically or penetrated completely and may continue growing to small reduction area because of its tension.

Reducing the altitude difference of kiss curve can suppress the difference in stress, temperature and strain effectively, which reduces the cracking tendency.

Acknowledgements

The authors gratefully acknowledge the fundamental support from the National Natural Science Foundation of China (Grant nos 51804095 and 51904085) and Key Research Project of Higher Education in Hebei Province (ZD2021020).

-

Funding information: This research was funded by National Natural Science Foundation of China (Grant nos 51804095 and 51904085) and Key Research Project of Higher Education in Hebei Province (ZD2021020).

-

Author contributions: Zheng Lv: performed the data analyses and wrote the manuscript; Zhou-Yi Yang, Jian-Yu Zhang and Xue-Tong Li: performed the experiment; Peng Ji: modified and polished the manuscript; Qian Zhou: contributed to the conception of the study; Xi-Liang Zhang and Yin-Dong Shi: contributed significantly to analysis and manuscript preparation.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data that support the findings of this study are available from the first author and corresponding author upon reasonable request.

References

[1] Zhi, C., L. Ma, W. Jia, X. Huo, Q. Fan, Z. Huang, et al. Dependence of deformation behaviors on temperature for twin-roll casted AZ31 alloy by processing maps. Journal of Materials Research and Technology, Vol. 8, No. 6, 2019, pp. 5217–5232.10.1016/j.jmrt.2019.08.044Search in Google Scholar

[2] Lv, Z., Z. Sun, Z. Hou, Z. Yang, X. Zhang, and Y. Shi. Numerical simulation and experimental study on Twin-roll Strip Casting T2 copper alloy. High Temperature Materials and Processes, Vol. 41, No. 1, 2022, pp. 1–7.10.1515/htmp-2022-0251Search in Google Scholar

[3] Ji, C., H. Huang, X. Zhang, and R. Zhao. Numerical and experimental research on fluid flow, solidification, and bonding strength during the Twin-Roll Casting of Cu/Invar/Cu Clad strips. Metallurgical and Materials Transactions B, Vol. 51, No. 2, 2020, pp. 1617–1631.10.1007/s11663-020-01854-4Search in Google Scholar

[4] Qian, X., X. Li, Y. Li, G. Xu, and Z. Wang. Microstructure evolution during homogenization and hot workability of 7055 aluminum alloy produced by twin-roll casting. Journal of Materials Research and Technology, Vol. 5, 2021, pp. 2536–2550.10.1016/j.jmrt.2021.05.114Search in Google Scholar

[5] Pesin, A. and D. Pustovoytov. Research of edge defect formation in plate rolling by finite element method. Journal of Materials Processing Technology, Vol. 220, 2015, pp. 96–106.10.1016/j.jmatprotec.2015.01.001Search in Google Scholar

[6] Lv, Z., F. S. Du, Z. An, H. Huang, Z. Xu, and J. Sun. Centerline segregation mechanism of twin-roll cast A3003 strip. Journal of Alloys and Compounds, Vol. 643, 2015, pp. 643–650.10.1016/j.jallcom.2015.04.132Search in Google Scholar

[7] Xu, M., Z. Li, Z. Wang, and M. Zhu. Computational and experimental study of the transient transport phenomena in a full-scale twin-roll continuous casting machine. Metallurgical and Materials Transactions, B Process Metallurgy and Materials Processing Science, Vol. 48B, No. 1, 2017, pp. 471–487.10.1007/s11663-016-0845-0Search in Google Scholar

[8] Harada, H., S. Nishida, E. Masaki, and H. Watari. Casting of high-aluminum-content Mg alloys strip by a horizontal twin-roll caster. Metallurgical & Materials Transactions B, Vol. 45, No. 2, 2014, pp. 427–437.10.1007/s11663-013-9913-xSearch in Google Scholar

[9] El-Bealy, M. O. Modelling of heat flow and interdendritic crack formation in twin-roll strip casting of aluminium alloys. Canadian Metallurgical Quarterly, Vol. 55, No. 1, 2016, pp. 23–44.10.1080/00084433.2015.1118841Search in Google Scholar

[10] Xu, M., G. H. Liu, T. R. Li, B. X. Wang, and Z. D. Wang. Microstructure characteristics of Ti–43Al alloy during twin-roll strip casting and heat treatment. Transactions of Nonferrous Metals Society of China, Vol. 29, No. 5, 2019, pp. 1017–1025.10.1016/S1003-6326(19)65010-7Search in Google Scholar

[11] Hu, W. L., Y. X. Zhang, G. Yuan, and G. D. Wang. Crack formation mechanism of high silicon steel during twin-roll strip casting. Materials Science Forum, Vol. 898, No. Pt.2, 2017, pp. 1276–1282.10.4028/www.scientific.net/MSF.898.1276Search in Google Scholar

[12] Kim, M. S., Y. Arai, Y. Hori, and S. Kumai. Formation of internal crack in high-speed twin-roll cast 6022 aluminum alloy strip. Materials Transactions Jim, Vol. 51, No. 10, 2010, pp. 1854–1860.10.2320/matertrans.L-M2010818Search in Google Scholar

[13] Zang, X., L. Liu, and Q. Yang. Cracking possibility evaluation of 304 stainless steel during twin roll casting by 3D simulation. Journal of Materials Engineering and Performance, Vol. 30, No. 3, 2021, pp. 2014–2020.10.1007/s11665-021-05530-9Search in Google Scholar

[14] Hu, W. L., Y. X. Zhang, G. Yuan, and G. D. Wang. Crack formation mechanism of high silicon steel during twin-roll strip casting. Materials Science Forum, Vol. 4502, 2017, pp. 1276–1282.10.4028/www.scientific.net/MSF.898.1276Search in Google Scholar

[15] Baek, M. S., K. Euh, and K. A. Lee. Microstructure, tensile and fatigue properties of high strength Al 7075 alloy manufactured via twin-roll strip casting. Journal of Materials Research and Technology, Vol. 9, No. 5, 2020, pp. 9941–9950.10.1016/j.jmrt.2020.06.097Search in Google Scholar

[16] Huang, Y., B. Xiao, J. Song, H. Zhao, Q. Liu, B. Jiang, et al. Effect of tension on edge crack of on-line heating rolled AZ31B magnesium alloy sheet – ScienceDirect. Journal of Materials Research and Technology, Vol. 9, No. 2, 2020, pp. 1988–1997.10.1016/j.jmrt.2019.12.031Search in Google Scholar

[17] Zhang, S. Q., S. H. Jiao, J. H. Ding, Q. F. Zhang, and H. S. Jiang. Simulation study on shear crack of steel plate. Materials Science Forum, Vol. 941, 2018, pp. 480–485.10.4028/www.scientific.net/MSF.941.480Search in Google Scholar

[18] Kroon, M., P. Lindstrm, and M. B. Rubin. An Eulerian thermomechanical elastic-viscoplastic model with isotropic and directional hardening applied to computational welding mechanics. Acta Mechanica, Vol. 232, No. 1, 2021, pp. 189–218.10.1007/s00707-020-02835-zSearch in Google Scholar

[19] Liu, X., K. Ji, O. El Fakir, H. Fang, M. M. Gharbi, and L. Wang. Determination of the interfacial heat transfer coefficient for a hot aluminium stamping process. Journal of Materials Processing Technology, Vol. 247, 2017, pp. 158–170.10.1016/j.jmatprotec.2017.04.005Search in Google Scholar

[20] Chen G., G. Fu, T. Wei, C. Cheng, H. Wang, and J. Wang. Effect of initial grain size on the dynamic recrystallization of hot deformation for 3003 aluminum alloy. Metals and Materials International, Vol. 24, No. 4, 2018, pp. 711–719.10.1007/s12540-018-0093-8Search in Google Scholar

© 2022 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Numerical and experimental research on solidification of T2 copper alloy during the twin-roll casting

- Discrete probability model-based method for recognition of multicomponent combustible gas explosion hazard sources

- Dephosphorization kinetics of high-P-containing reduced iron produced from oolitic hematite ore

- In-phase thermomechanical fatigue studies on P92 steel with different hold time

- Effect of the weld parameter strategy on mechanical properties of double-sided laser-welded 2195 Al–Li alloy joints with filler wire

- The precipitation behavior of second phase in high titanium microalloyed steels and its effect on microstructure and properties of steel

- Development of a huge hybrid 3D-printer based on fused deposition modeling (FDM) incorporated with computer numerical control (CNC) machining for industrial applications

- Effect of different welding procedures on microstructure and mechanical property of TA15 titanium alloy joint

- Single-source-precursor synthesis and characterization of SiAlC(O) ceramics from a hyperbranched polyaluminocarbosilane

- Carbothermal reduction of red mud for iron extraction and sodium removal

- Reduction swelling mechanism of hematite fluxed briquettes

- Effect of in situ observation of cooling rates on acicular ferrite nucleation

- Corrosion behavior of WC–Co coating by plasma transferred arc on EH40 steel in low-temperature

- Study on the thermodynamic stability and evolution of inclusions in Al–Ti deoxidized steel

- Application on oxidation behavior of metallic copper in fire investigation

- Microstructural study of concrete performance after exposure to elevated temperatures via considering C–S–H nanostructure changes

- Prediction model of interfacial heat transfer coefficient changing with time and ingot diameter

- Design, fabrication, and testing of CVI-SiC/SiC turbine blisk under different load spectrums at elevated temperature

- Promoting of metallurgical bonding by ultrasonic insert process in steel–aluminum bimetallic castings

- Pre-reduction of carbon-containing pellets of high chromium vanadium–titanium magnetite at different temperatures

- Optimization of alkali metals discharge performance of blast furnace slag and its extreme value model

- Smelting high purity 55SiCr automobile suspension spring steel with different refractories

- Investigation into the thermal stability of a novel hot-work die steel 5CrNiMoVNb

- Residual stress relaxation considering microstructure evolution in heat treatment of metallic thin-walled part

- Experiments of Ti6Al4V manufactured by low-speed wire cut electrical discharge machining and electrical parameters optimization

- Effect of chloride ion concentration on stress corrosion cracking and electrochemical corrosion of high manganese steel

- Prediction of oxygen-blowing volume in BOF steelmaking process based on BP neural network and incremental learning

- Effect of annealing temperature on the structure and properties of FeCoCrNiMo high-entropy alloy

- Study on physical properties of Al2O3-based slags used for the self-propagating high-temperature synthesis (SHS) – metallurgy method

- Low-temperature corrosion behavior of laser cladding metal-based alloy coatings on EH40 high-strength steel for icebreaker

- Study on thermodynamics and dynamics of top slag modification in O5 automobile sheets

- Structure optimization of continuous casting tundish with channel-type induction heating using mathematical modeling

- Microstructure and mechanical properties of NbC–Ni cermets prepared by microwave sintering

- Spider-based FOPID controller design for temperature control in aluminium extrusion process

- Prediction model of BOF end-point P and O contents based on PCA–GA–BP neural network

- Study on hydrogen-induced stress corrosion of 7N01-T4 aluminum alloy for railway vehicles

- Study on the effect of micro-shrinkage porosity on the ultra-low temperature toughness of ferritic ductile iron

- Characterization of surface decarburization and oxidation behavior of Cr–Mo cold heading steel

- Effect of post-weld heat treatment on the microstructure and mechanical properties of laser-welded joints of SLM-316 L/rolled-316 L

- An investigation on as-cast microstructure and homogenization of nickel base superalloy René 65

- Effect of multiple laser re-melting on microstructure and properties of Fe-based coating

- Experimental study on the preparation of ferrophosphorus alloy using dephosphorization furnace slag by carbothermic reduction

- Research on aging behavior and safe storage life prediction of modified double base propellant

- Evaluation of the calorific value of exothermic sleeve material by the adiabatic calorimeter

- Thermodynamic calculation of phase equilibria in the Al–Fe–Zn–O system

- Effect of rare earth Y on microstructure and texture of oriented silicon steel during hot rolling and cold rolling processes

- Effect of ambient temperature on the jet characteristics of a swirl oxygen lance with mixed injection of CO2 + O2

- Research on the optimisation of the temperature field distribution of a multi microwave source agent system based on group consistency

- The dynamic softening identification and constitutive equation establishment of Ti–6.5Al–2Sn–4Zr–4Mo–1W–0.2Si alloy with initial lamellar microstructure

- Experimental investigation on microstructural characterization and mechanical properties of plasma arc welded Inconel 617 plates

- Numerical simulation and experimental research on cracking mechanism of twin-roll strip casting

- A novel method to control stress distribution and machining-induced deformation for thin-walled metallic parts

- Review Article

- A study on deep reinforcement learning-based crane scheduling model for uncertainty tasks

- Topical Issue on Science and Technology of Solar Energy

- Synthesis of alkaline-earth Zintl phosphides MZn2P2 (M = Ca, Sr, Ba) from Sn solutions

- Dynamics at crystal/melt interface during solidification of multicrystalline silicon

- Boron removal from silicon melt by gas blowing technique

- Removal of SiC and Si3N4 inclusions in solar cell Si scraps through slag refining

- Electrochemical production of silicon

- Electrical properties of zinc nitride and zinc tin nitride semiconductor thin films toward photovoltaic applications

- Special Issue on The 4th International Conference on Graphene and Novel Nanomaterials (GNN 2022)

- Effect of microstructure on tribocorrosion of FH36 low-temperature steels

Articles in the same Issue

- Research Articles

- Numerical and experimental research on solidification of T2 copper alloy during the twin-roll casting

- Discrete probability model-based method for recognition of multicomponent combustible gas explosion hazard sources

- Dephosphorization kinetics of high-P-containing reduced iron produced from oolitic hematite ore

- In-phase thermomechanical fatigue studies on P92 steel with different hold time

- Effect of the weld parameter strategy on mechanical properties of double-sided laser-welded 2195 Al–Li alloy joints with filler wire

- The precipitation behavior of second phase in high titanium microalloyed steels and its effect on microstructure and properties of steel

- Development of a huge hybrid 3D-printer based on fused deposition modeling (FDM) incorporated with computer numerical control (CNC) machining for industrial applications

- Effect of different welding procedures on microstructure and mechanical property of TA15 titanium alloy joint

- Single-source-precursor synthesis and characterization of SiAlC(O) ceramics from a hyperbranched polyaluminocarbosilane

- Carbothermal reduction of red mud for iron extraction and sodium removal

- Reduction swelling mechanism of hematite fluxed briquettes

- Effect of in situ observation of cooling rates on acicular ferrite nucleation

- Corrosion behavior of WC–Co coating by plasma transferred arc on EH40 steel in low-temperature

- Study on the thermodynamic stability and evolution of inclusions in Al–Ti deoxidized steel

- Application on oxidation behavior of metallic copper in fire investigation

- Microstructural study of concrete performance after exposure to elevated temperatures via considering C–S–H nanostructure changes

- Prediction model of interfacial heat transfer coefficient changing with time and ingot diameter

- Design, fabrication, and testing of CVI-SiC/SiC turbine blisk under different load spectrums at elevated temperature

- Promoting of metallurgical bonding by ultrasonic insert process in steel–aluminum bimetallic castings

- Pre-reduction of carbon-containing pellets of high chromium vanadium–titanium magnetite at different temperatures

- Optimization of alkali metals discharge performance of blast furnace slag and its extreme value model

- Smelting high purity 55SiCr automobile suspension spring steel with different refractories

- Investigation into the thermal stability of a novel hot-work die steel 5CrNiMoVNb

- Residual stress relaxation considering microstructure evolution in heat treatment of metallic thin-walled part

- Experiments of Ti6Al4V manufactured by low-speed wire cut electrical discharge machining and electrical parameters optimization

- Effect of chloride ion concentration on stress corrosion cracking and electrochemical corrosion of high manganese steel

- Prediction of oxygen-blowing volume in BOF steelmaking process based on BP neural network and incremental learning

- Effect of annealing temperature on the structure and properties of FeCoCrNiMo high-entropy alloy

- Study on physical properties of Al2O3-based slags used for the self-propagating high-temperature synthesis (SHS) – metallurgy method

- Low-temperature corrosion behavior of laser cladding metal-based alloy coatings on EH40 high-strength steel for icebreaker

- Study on thermodynamics and dynamics of top slag modification in O5 automobile sheets

- Structure optimization of continuous casting tundish with channel-type induction heating using mathematical modeling

- Microstructure and mechanical properties of NbC–Ni cermets prepared by microwave sintering

- Spider-based FOPID controller design for temperature control in aluminium extrusion process

- Prediction model of BOF end-point P and O contents based on PCA–GA–BP neural network

- Study on hydrogen-induced stress corrosion of 7N01-T4 aluminum alloy for railway vehicles

- Study on the effect of micro-shrinkage porosity on the ultra-low temperature toughness of ferritic ductile iron

- Characterization of surface decarburization and oxidation behavior of Cr–Mo cold heading steel

- Effect of post-weld heat treatment on the microstructure and mechanical properties of laser-welded joints of SLM-316 L/rolled-316 L

- An investigation on as-cast microstructure and homogenization of nickel base superalloy René 65

- Effect of multiple laser re-melting on microstructure and properties of Fe-based coating

- Experimental study on the preparation of ferrophosphorus alloy using dephosphorization furnace slag by carbothermic reduction

- Research on aging behavior and safe storage life prediction of modified double base propellant

- Evaluation of the calorific value of exothermic sleeve material by the adiabatic calorimeter

- Thermodynamic calculation of phase equilibria in the Al–Fe–Zn–O system

- Effect of rare earth Y on microstructure and texture of oriented silicon steel during hot rolling and cold rolling processes

- Effect of ambient temperature on the jet characteristics of a swirl oxygen lance with mixed injection of CO2 + O2

- Research on the optimisation of the temperature field distribution of a multi microwave source agent system based on group consistency

- The dynamic softening identification and constitutive equation establishment of Ti–6.5Al–2Sn–4Zr–4Mo–1W–0.2Si alloy with initial lamellar microstructure

- Experimental investigation on microstructural characterization and mechanical properties of plasma arc welded Inconel 617 plates

- Numerical simulation and experimental research on cracking mechanism of twin-roll strip casting

- A novel method to control stress distribution and machining-induced deformation for thin-walled metallic parts

- Review Article

- A study on deep reinforcement learning-based crane scheduling model for uncertainty tasks

- Topical Issue on Science and Technology of Solar Energy

- Synthesis of alkaline-earth Zintl phosphides MZn2P2 (M = Ca, Sr, Ba) from Sn solutions

- Dynamics at crystal/melt interface during solidification of multicrystalline silicon

- Boron removal from silicon melt by gas blowing technique

- Removal of SiC and Si3N4 inclusions in solar cell Si scraps through slag refining

- Electrochemical production of silicon

- Electrical properties of zinc nitride and zinc tin nitride semiconductor thin films toward photovoltaic applications

- Special Issue on The 4th International Conference on Graphene and Novel Nanomaterials (GNN 2022)

- Effect of microstructure on tribocorrosion of FH36 low-temperature steels