Abstract

The forming-induced residual stress of metallic parts could cause undesired deformation in the final machining process, especially for the thin-walled parts. Therefore, heat treatment is essential to release the residual stress prior to machining. This study investigates the residual stress change of a forged pure iron part in annealing heat treatment and material removal processes. A modified creep constitutive model with the consideration of microstructure evolution was established to describe the residual stress relaxation in the annealing. Stress relaxation tests were conducted to calibrate the material constants. This constitutive model was then implemented into the finite element model of annealing for the cold-forged semi-spherical shell. The residual stress and the grain size of the shell were predicted at different heating temperatures. The semi-spherical shells were machined to the final thin-walled parts, and the deformation owing to the residual stress release was measured and compared to the simulation results. The heating temperature was determined aiming to minimize the machining-induced deformation as well as to ensure the microstructure. This study could provide guidance to the elimination of the residual stress and the improvement of the geometrical accuracy for thin-walled parts in the machining process.

1 Introduction

Thin-walled parts have great significance in reducing weight and improving the performance of the components. The forming processes of these thin-walled parts mainly include casting, forging, welding, and additive manufacturing, in which large residual stress could be generated. In the subsequent machining process, the release and redistribution of this residual stress, as one of the main reasons for the part deformation owing to the weak rigidity, deteriorates the geometrical accuracy of the parts [1]. Therefore, the measures to eliminate the forming-induced residual stress are essential prior to machining.

Many methods have been developed to reduce the forming-induced residual stress, such as heat treatment, vibration aging, and cryogenic treatment, among which annealing heat treatment is widely used for its advantages of high efficiency and convenience. Since various forming processes cause different residual stress distributions, the heat treatment parameters are normally determined by trial-and-error tests. Some researchers developed empirical models to predict the stress change in the annealing for the parts fabricated by shot peening [2,3], additive manufacturing [4], and cutting [5]. However, it was a lack of mechanism interpretation in these empirical models. Classical creep models take into account the effects of initial strain hardening of the parts and have been applied to explain the residual stress relaxation in the annealing for the parts fabricated by shot peening [6], welding [7,8,9], coating [10], and cold-rolling [11]. In the process of heat treatment, due to the initial strain hardening and high-temperature conditions of the parts, recovery and recrystallization may occur. However, the microstructure is supposed to maintain the optimal state, accompanied by the residual stress relaxation after the annealing heat treatment. Therefore, in order to determine the annealing parameters to achieve the required microstructure and residual stress, it is necessary to develop a residual stress prediction modeling considering microstructure evolution in heat treatment.

Stress measurement is needed to verify the prediction of the residual stress of a part. Normally, residual stress can be measured by hole drilling method, ring core method, and diffraction method. Among these methods, the measurement accuracy of hole drilling is around ±50 MPa under ideal conditions [12]. The basic principle of the ring core method is similar to that of the hole drilling method, but the accuracy is usually higher than the hole drilling method, which may reach the value of ±15 MPa [13]. The X-ray diffraction (XRD) method is the most commonly used method with a measurement accuracy of ±20 MPa [14]. After heat treatment, the absolute value of residual stress is small [15]. As a result, it is difficult to measure the residual stress accurately by using the aforementioned methods. The deformation of thin-walled components after machining is usually caused by the initial residual stress [16,17]. Therefore, the residual stress with a small absolute value can be evaluated by using the deformation of low-stiffness parts after machining.

In this article, a stress relaxation model considering microstructure evolution was established to predict microstructure evolution and residual stress relaxation during heat treatment. The residual stress after heat treatment was evaluated by measuring the deformation of the parts after material removal. The accuracy of the proposed stress relaxation model was verified by comparing the microstructure prediction with the measured results.

2 Experimental procedures

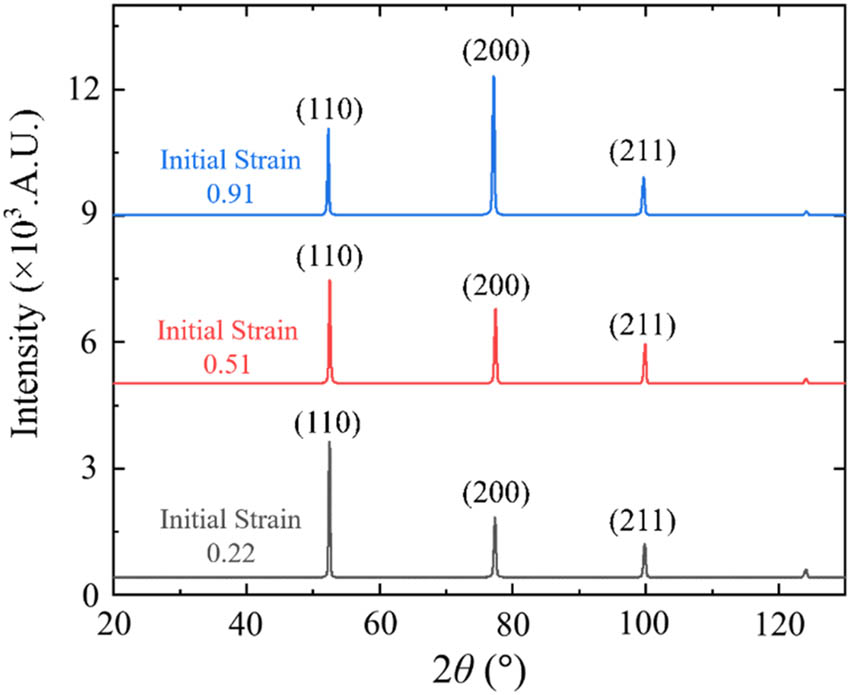

The stress relaxation tests were conducted to study the stress change at annealing temperatures. The initial strain hardening affects the residual stress relaxation during the heat treatment. As a result, the rolling process was carried out to introduce different initial strain levels in the stress relaxation test samples, as shown in Figure 1. Three pure iron plates with a diameter of 180 mm and a height of 50 mm were cold-rolled to heights of 40, 30, and 20 mm, respectively. These three cold-rolled plates had different initial strains of 0.22, 0.51, and 0.91, respectively. Cylindrical samples (Figure 1(b)) were then obtained by wire cutting and turning for the stress relaxation tests. The initial grain size was 45 μm.

(a) Cold-rolled pure iron plates; (b) dimension of the stress relaxation test samples.

In the proposed stress relaxation model in this article, dislocation density was involved to describe the stress change during annealing. The initial dislocation densities of the rolled iron plates were measured using an Empyrean XRD instrument with Co-target. Bragg diffraction angle was 20–130°, and the angle step was 0.013°. The tube current was 40 mA with a tube voltage of 40 kV. The experimental data were analyzed using Jade. 5 software. Initial dislocation density was calculated from the diffraction pattern (Figure 2) with the Williamson equation:

where D is the crystallite size, and

where

The heat treatment experiments were carried out in a furnace (SG-XQL1200, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, China). In order to study the microstructure evolution during the annealing, the grain size was observed after different heating times and temperatures. Cubic samples were cut from rolled plates with different initial strains. Subsequently, heat treatment was performed as shown in Table 1. After the heat treatment, the samples were polished and etched in a solution of nitric acid (4 mL) and C2H5OH (100 mL) at ambient temperature for 30 s. Optical microscopy observations and Vickers hardness measurements were carried out.

Process parameters of heat treatment

| Initial strain | Heat treatment temperature T (°C) | Holding time t (min) |

|---|---|---|

| 0.22 | 650 | 0–360 |

| 700 | ||

| 800 | ||

| 0.51 | 650 | 0–240 |

| 700 | ||

| 800 | ||

| 0.91 | 650 | 0–120 |

| 700 | ||

| 800 |

XRD patterns of the samples with different initial strains.

The stress relaxation experimental procedure included three stages: heating stage, loading stage, and constant strain stage. The temperature and load profiles in the stress relaxation test are shown in Figure 3(a). In stage I, the samples were heated to test temperatures (i.e., 500, 600, and 650°C) at a heating rate of 0.5°C·s−1. In stage II, the samples were held at the test temperatures for 5 min; in the meantime, the load was increased at a loading speed of 0.583 MPa·s−1. In stage III, a constant strain was held. With the increased time, the stress was released. The stress relaxation tests were conducted in a stress relaxation testing machine of RDL-50, according to the GB/T 2039–2012 standard (Figure 3(b)).

(a) Schematic of stress relaxation test procedures; (b) stress relaxation testing machine.

Thin-walled pure iron spherical shell parts were fabricated as shown in Figure 4. First, pure iron plates with a diameter of 385 mm and a thickness of 23 mm were cold-forged to obtain the semi-spherical shells, and the maximum load during the forging process was 170 tons (Figure 4(a)). The thickness of the shell was 22 mm, and the inner diameter was 236 mm (Figure 4(b)). Then, the heat treatment annealing was conducted for the shells with a temperature of 650°C and a holding time of 4 h. Finally, the shells were machined by turning to fabricate the final parts (Figure 4(c)). The final thickness of the part was 2.4 mm, indicating the low stiffness feature of the part.

(a) Cold-forging process; dimensions of (b) cold-forged semi-spherical shell; and (c) final part machined by turning.

3 Residual stress relaxation model

The residual stress in cold-forged parts is mainly produced by uneven plastic deformation in the forging process. As shown in equation (4), the total strain (ε tot) consisting of elastic strain (ε e), plastic strain (ε pl), and creep strain (ε c) remains constant [18]. During the heat treatment process, the residual elastic strain of the metal material changes to creep strain, and thus, the residual stress gradually decreases.

The creep strain rate ε c can be calculated with the classic power law creep model [19]:

where σ is the residual stress,

where A is the material constant,

In equation (6), n is the material constant which is dependent on the extent of plastic deformation [18]:

where n 0 and B are the material constants and ε ini is the initial strain.

The slip resistance of dislocation

where M is the average Taylor factor, b is the Burgers vector, and the shear modulus G is dependent on the temperature and can be written as [20]:

where G 0 is a temperature-dependent constant, T is the heat treatment temperature, and T m is the melting temperature.

During the process of stress relaxation, the evolution of dislocation density is related to the initial hardening, the recovery, and the static recrystallization. The variation of ρ in the process of creep at high temperatures is described as equation (11) [21,22].

where X srex represents the volume fraction of recrystallization, and it can be calculated using Avrami model [23,24]; k 1, k 2, m, k 3, l, and k 4 are the material constants.

Generally, the kinetics of recrystallization is expressed by the Avrami equation as follows:

where t 0.5 is a characteristic time for recrystallization corresponding to X srex = 0.5, d 0 is the initial grain size, ε is the initial strain, Q 3 is the activation energy of the recrystallization, and R is the gas constant.

The recrystallized volume fraction, X srex, is calculated based on Vickers hardness measurements [25]:

where

Different initial strains and heat treatment conditions have great effects on the microstructure evolution. Figure 5 shows the microstructure of pure iron samples with different initial strains after heat treatments. With the increase in the heat treatment temperature and the initial strain, the volume fraction of the crystallization was increased. It is attributed to the fact that the stored strain energy generated from cold-forging was the driving force for the recrystallization, and the high temperature enhanced the velocity of grain boundary migration to accelerate the recrystallization process. Micro-hardnesses of these samples were measured to calibrate the parameters in the Avrami model in equation (12). The fitted parameters are shown in Table 2. The fitted curves of the volume fraction of recrystallization are in good agreement with the experimental data, which indicates that the calibrated Avrami model was validated to predict the microstructure evolution in the annealing heat treatment.

Experimental data and fitted curves of volume fraction of recrystallization (

Fitted parameters in the Avrami model

| β (–) | k s (–) | a 3 (–) | h 3 (–) | n 3 (–) | Q 3 (J) |

|---|---|---|---|---|---|

| 1,250 | 1.78 | 5.8 × 10−4 | 0.4 | −2.15 | 125,000 |

Based on the stress relaxation experimental results, the fitted parameters of the stress relaxation model are calibrated as shown in Table 3. The stress relaxation experimental and fitted results are plotted in Figure 6. The stress of the samples with different initial strains decreases rapidly at a temperature between 873 and 963 K. Since the dislocation density in the material was decreased during the annealing, the decreasing rate of residual stress gradually slowed down until it finally reached a relatively stable value.

Fitted parameters in the stress relaxation model

|

|

Q (J) | n 0 (–) |

|

|

|

m (–) |

|

l (–) |

|

|---|---|---|---|---|---|---|---|---|---|

| 1.2

|

444,500 | 9.3 | 0.39 | 1.2

|

0.04 | −3.5 | 1

|

2.26 | 0.8 |

Experimental and fitted curves of the stress relaxation with (a) different initial strains; (b) different heat treatment temperatures.

Figure 6(a) shows the stress dropped to 49, 36, and 25 MPa at 923 K for the samples with the initial strain of 0.22, 0.51, and 0.91, respectively. With a higher initial strain, the residual stress is reduced faster due to more mobile dislocations generated by the initial hardening. In addition, the recrystallization occurred in the samples with the initial strain of 0.91 at 923 K in Figure 5, which eliminated the dislocations and accelerated the stress drop.

Figure 6(b) shows the normalized stress change for the samples with the initial strain of 0.22 at different temperatures of 873, 923, 943, and 963 K, respectively. It indicates that the relaxation behavior of the cold-rolled samples had temperature sensitivity. For samples with the initial strain of 0.22, the thermal activation at a lower temperature was insufficient to start the stress relaxation completely. By contrast, with the increase in the heating temperature, the thermal activation was increased, which led to a significant decrease in stress.

4 Finite element (FE) model of forging, annealing, and material removal processes

A three-dimensional FE model was developed using the commercial software ABAQUS to predict the residual stress and deformation of the thin-walled part in the cold-forging, heat treatment, and material removal processes. The FE model of the cold-forging process (Figure 7(a)) consisted of rigid molds and a deformable blank. The element type of the part was C3D8R with a size of 2 mm × 2 mm × 2 mm. The movement velocity of the upper mold was 12 mm·s−1. In this model, the material of the workpiece was assumed isotropic, Poisson’s ratio was 0.34, and Young’s modulus was calculated in equation (10). The residual stress and plastic strain distribution in the semi-spherical shell were obtained from the cold-forging FE analysis. Then, the annealing heat treatment was simulated to predict the stress relaxation of the cold-forged semi-spherical shell (Figure 7(b)). The proposed stress relaxation model was implemented in the user-defined subroutine CREEP. The heat treatment temperature in the FE analysis was set at 500, 600, and 650°C, respectively. The evolution of residual stress and grain size in the shell during heat treatment was obtained. Finally, the material removal process was simulated to obtain the final part by using the element birth and death method (Figure 7(c)). The final residual stress distribution and the part deformation caused by the release of the residual stress were predicted and compared with the experimental results.

FE model of (a) cold-forging, (b) annealing heat treatment, and (c) material removal processes.

5 Results and discussion

5.1 Residual stress distribution

The simulated residual stress distributions of the semi-spherical shells after cold-forging and after annealing are shown in Figure 8. After forging, the maximum principal stress was compressive in the inner surface. From the inner surface to the outer surface, the compressive residual stress was increased to the maximum value of −335.8 MPa and then transformed into tensile stress of 196.4 MPa.

Residual stress distributions (a) after cold-forging, and after annealing at (b) 500°C, (c) 600°C, and (d) 650°C.

In general, the residual stress remaining in the workpiece was due to the uneven elastoplastic deformation. During the process of the cold-forging, the deformation was mainly concentrated on the surfaces of the part, i.e., the inner surface was squeezed and the outside surface was stretched. After forging, the elastic deformation remaining on the surface had the trend of recovering to the original state. However, the material inside the part hindered the recovery of the material on the surface. As a result, the stress at the inner surface was compressive, and the stress at the outside surface was tensile. On the one hand, the state of residual stress after heat treatment was the same as that after cold-forging. With the increase in the annealing temperature, the residual stress in the semi-spherical shell decreased obviously (Figure 8(b–d)) and reached a value between −20 and 20 MPa at 650°C. Therefore, the influence of residual stress on the final part deformation could be reduced.

5.2 Grain size distribution

Figure 9 shows the grain size distributions of the semi-spherical shell at different annealing temperatures. The initial grain size was 45 μm. As shown in Figure 9(a), with an annealing temperature of 650°C, the recrystallization occurred at the top of the semi-spherical shell, and thus, the grain size was decreased to 33.7 μm. Little recrystallization occurred in most other areas. As shown in Figure 9(b), with an annealing temperature of 700°C, recrystallization and grain growth occurred in a larger area. The largest grain size reached 139 μm due to a higher temperature, which resulted in an uneven distribution of the grain size in the semi-spherical shell.

Grain size distributions of the semi-spherical shell at annealing temperatures of (a) 650°C and (b) 700°C.

To verify the microstructure prediction results of the cold-forging and heat treatment simulation, the experimental and predicted results of grain size were analyzed. The simulated grain size distribution of the semi-spherical shell after 650°C heat treatment is shown in Figure 10(a). Four areas in the section were selected for microstructure observation. The microstructure metallographic images of these areas after heat treatment were obtained using Olympus metallographic microscope, as shown in Figure 10(b). By comparing the results in Figure 10(a) and (b), the predicted grain size distribution of the stress relaxation model based on dislocation density was validated.

(a) Simulated results of grain size; (b) microstructure images and average grain size at 650°C.

5.3 Deformation of the final part

In this study, the thin-walled spherical shell was machined to achieve the final part. The machining setup is shown in Figure 11. The semi-spherical shell was mounted onto the jaw chuck of a lathe machine. The machining process of thin-walled parts was divided into three steps, i.e., roughing, semi-finishing, and finishing steps, respectively. The machining parameters for these three steps are shown in Table 4.

Machining setup of thin-walled parts.

Machining parameters of thin-walled parts

| Cutting speed (m·min−1) | Feed rate (mm·r−1) | Cutting depth (mm) | |

|---|---|---|---|

| Roughing | 120 | 0.15 | 0.5 |

| Semi-finishing | 120 | 0.1 | 0.2 |

| Finishing | 100 | 0.06 | 0.1 |

Since the very small residual stress was difficult to measure using conventional method, the deformation after material removal was measured to verify the prediction results. The outer surface profile of the final part was measured using a coordinate measuring machine. The measuring paths shown in Figure 12(a) were parallel to the horizontal plane. The measured profile of the outer surface in the Cartesian absolute coordinate system is shown in Figure 12(c) and (d). It is found that the deformation value of the final part without heat treatment was larger than that with 650°C heat treatment. This phenomenon indicates that annealed part was not prone to deform, which was caused by the residual stress relaxation during heat treatment.

(a) Three-dimensional measurement path, (b) measurement setup, and the experimental measurement results (c) without and (d) with 650°C heat treatment.

In the FE simulation of the material removal process, different residual stress distributions were obtained after heat treatments for semi-spherical shells. Subsequently, the material allowance was removed using the birth–death element method, and the deformation of the final part caused by the residual stress release was calculated. The deformation along the radial direction is shown in Figure 13. The deformation of the final part presents a centrosymmetric distribution. The flange area shrunk inward, while the other areas extended outward along the radial direction.

Simulated results of the deformation for the final part with different heat treatments: (a) without heat treatment, (b) with 500°C, (c) 600°C, and (d) 650°C heat treatment.

Based on the developed FE model of forging, heat treatment, and material removal processes, the effect of annealing temperature on the residual stress-induced deformation after machining was studied. The prediction results of the deformation for the final parts were compared with the measured results after different heat treatment temperatures, as shown in Figure 14. The prediction results have a good agreement with the measured deformation from the experiments. With the increase in the heat treatment temperature, the deformation of the final parts after machining was decreased, which is attributed to the residual stress relaxation during the annealing. The predictive error might be attributed to the residual stress induced by machining, which led to a larger deformation in the experiments.

Experimental and simulated results of deformation and grain size for final parts with different annealing temperatures.

With regard to the grain size distribution, the maximum grain size of the semi-spherical shell was around 63 μm when the heat treatment temperature was lower than 650°C, but the grain size was increased rapidly to 140 μm at a heat treatment temperature of 700°C due to grain growth, as shown in Figure 14. Therefore, the annealing temperature of 650°C was determined to eliminate residual stress as well as to obtain a uniform grain size distribution.

6 Conclusion

In this article, the residual stress change of a forged pure iron part in annealing heat treatment and material removal was investigated. A modified creep constitutive model with the consideration of microstructure evolution was established to describe the residual stress relaxation in the annealing. The grain size after the heat treatment was predicted and validated by the microstructure observation. The simulated deformation after machining had a good agreement with the experimental results. The key findings were summarized as follows:

The proposed stress relaxation model considered the effect of initial strain hardening and microstructure evolution, which could accurately predict the residual stress change during heat treatment.

The residual stress was indirectly evaluated by measuring the machining deformation of the thin-walled parts, which can be used as an effective method for the evaluation of the very low-level residual stress.

For pure iron thin-walled parts, the determined annealing temperature is 650°C, at which the deformation of the component was minimum and the grain size distribution was uniform.

The proposed method for the determination of heat treatment parameters could be applied to the thin-walled parts with other materials such as aluminum and titanium alloys.

Acknowledgment

The financial supports from the Science Challenge Project (JCKY2016212A506-0101) and the National Natural Science Foundation of China (52175381) are gratefully acknowledged.

-

Funding information: The Science Challenge Project (JCKY2016212A506-0101) and the National Natural Science Foundation of China (52175381).

-

Author contributions: Qian Bai: conceptualization, methodology and draft preparation. Ziliang Chen: methodology and draft preparation. Yingming Gao: conceptualization and methodology. Hang Li: methodology. Jingang Tang: investigation. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: Not applicable.

References

[1] Wang, Z., W. Y. Chen, Y. D. Zhang, Z. T. Chen, and Q. Liu. Study on the machining distortion of thin-walled part caused by redistribution of residual stress. Chinese Journal of Aeronautics, Vol. 18, No. 2, 2005, pp. 175–179.10.1016/S1000-9361(11)60325-7Search in Google Scholar

[2] Foss, B. J., S. Gray, M. C. Hardy, S. Stekovic, D. S. McPhail, and B. A. Shollock. Analysis of shot-peening and residual stress relaxation in the nickel-based superalloy RR1000. Acta Materialia, Vol. 61, No. 7, 2013, pp. 2548–2559.10.1016/j.actamat.2013.01.031Search in Google Scholar

[3] Wang, C., C. Jiang, and V. Ji. Thermal stability of residual stresses and work hardening of shot peened tungsten cemented carbide. Journal of Materials Processing Technology, Vol. 240, 2017, pp. 98–103.10.1016/j.jmatprotec.2016.09.013Search in Google Scholar

[4] Wang, Z., A. D. Stoica, D. Ma, and A. M. Beese. Stress relaxation in a nickel-base superalloy at elevated temperatures with in situ neutron diffraction characterization: Application to additive manufacturing. Materials Science and Engineering: A, Vol. 714, 2018, pp. 75–83.10.1016/j.msea.2017.12.058Search in Google Scholar

[5] Epp, J., H. Surm, T. Hirsch, and F. Hoffmann. Residual stress relaxation during heating of bearing rings produced in two different manufacturing chains. Journal of Materials Processing Technology, Vol. 211, No. 4, 2011, pp. 637–643.10.1016/j.jmatprotec.2010.11.022Search in Google Scholar

[6] Radchenko, V. P., M. N. Saushkin, and V. V. Tsvetkov. Effect of thermal exposure on the residual stress relaxation in a hardened cylindrical sample under creep conditions. Journal of Applied Mechanics and Technical Physics, Vol. 57, No. 3, 2016, pp. 559–568.10.1134/S0021894416030202Search in Google Scholar

[7] Dong, P., S. Song, and J. Zhang. Analysis of residual stress relief mechanisms in post-weld heat treatment. International Journal of Pressure Vessels and Piping, Vol. 122, 2014, pp. 6–14.10.1016/j.ijpvp.2014.06.002Search in Google Scholar

[8] Zhang, W., X. Wang, Y. Wang, X. H. Yu, Y. F. Gao, and Z. L. Feng. Type IV failure in weldment of creep resistant ferritic alloys: I. Micromechanical origin of creep strain localization in the heat affected zone. Journal of the Mechanics and Physics of Solids, Vol. 134, 2020, id. 103774.10.1016/j.jmps.2019.103774Search in Google Scholar

[9] Zhang, W., X. Wang, Y. Wang, X. H. Yu, Y. F. Gao, Z. L. Feng. Type IV failure in weldment of creep resistant ferritic alloys: II. Creep fracture and lifetime prediction. Journal of the Mechanics and Physics of Solids, Vol. 134, 2020, id. 103775.10.1016/j.jmps.2019.103775Search in Google Scholar

[10] Zhang, X. C., B. S. Xu, H. D. Wang, and Y. X. Wu. Residual stress relaxation in the film/substrate system due to creep deformation. Journal of Applied Physics, Vol. 101, No. 8, 2007, id. 83530.10.1063/1.2717551Search in Google Scholar

[11] Hadadian, A. and R. Sedaghati. Investigation on thermal relaxation of residual stresses induced in deep cold rolling of Ti–6Al–4V alloy. The International Journal of Advanced Manufacturing Technology, Vol. 100, No. 1–4, 2019, pp. 877–893.10.1007/s00170-018-2668-4Search in Google Scholar

[12] Zhang, Z. Research on residual stress and machining distortion of aeronautic weak rigidity in aluminum structure, Nanjing University of Aeronautics and Astronautics, Nan Jing, 2015.Search in Google Scholar

[13] Ajovalasit, A., G. Petrucci, and B. Zuccarello. Determination of nonuniform residual stresses using the ring-core method. Journal of Engineering Materials and Technology, Vol. 118, No. 2, 1996, pp. 224–228.10.1115/1.2804891Search in Google Scholar

[14] Withers, P. J. and H. K. D. H. Bhadeshia. Residual stress. I – Measurement techniques. Materials Science and Technology, Vol. 17, No. 4, 2001, pp. 355–365.10.1179/026708301101509980Search in Google Scholar

[15] Bai, Q., H. Feng, L.K. Si, R. Pan, and Y. Q. Wang. A novel stress relaxation modeling for predicting the change of residual stress during annealing heat treatment. Metallurgical and Materials Transactions A, Vol. 50, No. 12, 2019, pp. 5750–5759.10.1007/s11661-019-05454-zSearch in Google Scholar

[16] Gao, H., Y. Zhang, Q. Wu, and B. H. Li. Investigation on influences of initial residual stress on thin-walled part machining deformation based on a semi-analytical model. Journal of Materials Processing Technology, Vol. 262, 2018, pp. 437–448.10.1016/j.jmatprotec.2018.04.009Search in Google Scholar

[17] Huang, X., J. Sun, and J. Li. Finite element simulation and experimental investigation on the residual stress-related monolithic component deformation. The International Journal of Advanced Manufacturing Technology, Vol. 77, No. 5–8, 2015, pp. 1035–1041.10.1007/s00170-014-6533-9Search in Google Scholar

[18] Zheng, J., J. Lin, J. Lee, R. Pan, C. Li, and C. M. Davies. A novel constitutive model for multi-step stress relaxation ageing of a pre-strained 7xxx series alloy. International Journal of Plasticity, Vol. 106, 2018, pp. 31–47.10.1016/j.ijplas.2018.02.008Search in Google Scholar

[19] Estrin, Y. Dislocation theory based constitutive modelling: foundations and applications. Journal of Materials Processing Technology, Vol. 80, 1998, pp. 33–39.10.1016/S0924-0136(98)00208-8Search in Google Scholar

[20] Frost, H. J. and M. F. Ashby. Deformation mechanism maps: the plasticity and creep of metals and ceramics, Pergamon Press, 1982.Search in Google Scholar

[21] Sun, Z. C., H. Yang, G. J. Han, and X. G. Fan. A numerical model based on internal-state-variable method for the microstructure evolution during hot-working process of TA15 titanium alloy. Materials Science and Engineering: A, Vol. 527, No. 15, 2010, pp. 3464–3471.10.1016/j.msea.2010.02.009Search in Google Scholar

[22] Kocks, U. F. Laws for work-hardening and low-temperature creep. Journal of Engineering Materials and Technology, Vol. 98, No. 1, 1976, pp. 76–85.10.1115/1.3443340Search in Google Scholar

[23] Avrami, M. Granulation, phase change, and microstructure kinetics of phase change. III. The Journal of Chemical Physics, Vol. 9, No. 2, 1941, pp. 177–184.10.1063/1.1750872Search in Google Scholar

[24] Siwecki, T. Modelling of microstructure evolution during recrystallization controlled rolling. ISIJ International, Vol. 32, No. 3, 1992, pp. 368–376.10.2355/isijinternational.32.368Search in Google Scholar

[25] Lü, Y., D. A. Molodov, and G. Gottstein. Recrystallization kinetics and microstructure evolution during annealing of a cold-rolled Fe–Mn–C alloy. Acta Materialia, Vol. 59, No. 8, 2011, pp. 3229–3243.10.1016/j.actamat.2011.01.063Search in Google Scholar

© 2022 Qian Bai et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Numerical and experimental research on solidification of T2 copper alloy during the twin-roll casting

- Discrete probability model-based method for recognition of multicomponent combustible gas explosion hazard sources

- Dephosphorization kinetics of high-P-containing reduced iron produced from oolitic hematite ore

- In-phase thermomechanical fatigue studies on P92 steel with different hold time

- Effect of the weld parameter strategy on mechanical properties of double-sided laser-welded 2195 Al–Li alloy joints with filler wire

- The precipitation behavior of second phase in high titanium microalloyed steels and its effect on microstructure and properties of steel

- Development of a huge hybrid 3D-printer based on fused deposition modeling (FDM) incorporated with computer numerical control (CNC) machining for industrial applications

- Effect of different welding procedures on microstructure and mechanical property of TA15 titanium alloy joint

- Single-source-precursor synthesis and characterization of SiAlC(O) ceramics from a hyperbranched polyaluminocarbosilane

- Carbothermal reduction of red mud for iron extraction and sodium removal

- Reduction swelling mechanism of hematite fluxed briquettes

- Effect of in situ observation of cooling rates on acicular ferrite nucleation

- Corrosion behavior of WC–Co coating by plasma transferred arc on EH40 steel in low-temperature

- Study on the thermodynamic stability and evolution of inclusions in Al–Ti deoxidized steel

- Application on oxidation behavior of metallic copper in fire investigation

- Microstructural study of concrete performance after exposure to elevated temperatures via considering C–S–H nanostructure changes

- Prediction model of interfacial heat transfer coefficient changing with time and ingot diameter

- Design, fabrication, and testing of CVI-SiC/SiC turbine blisk under different load spectrums at elevated temperature

- Promoting of metallurgical bonding by ultrasonic insert process in steel–aluminum bimetallic castings

- Pre-reduction of carbon-containing pellets of high chromium vanadium–titanium magnetite at different temperatures

- Optimization of alkali metals discharge performance of blast furnace slag and its extreme value model

- Smelting high purity 55SiCr automobile suspension spring steel with different refractories

- Investigation into the thermal stability of a novel hot-work die steel 5CrNiMoVNb

- Residual stress relaxation considering microstructure evolution in heat treatment of metallic thin-walled part

- Experiments of Ti6Al4V manufactured by low-speed wire cut electrical discharge machining and electrical parameters optimization

- Effect of chloride ion concentration on stress corrosion cracking and electrochemical corrosion of high manganese steel

- Prediction of oxygen-blowing volume in BOF steelmaking process based on BP neural network and incremental learning

- Effect of annealing temperature on the structure and properties of FeCoCrNiMo high-entropy alloy

- Study on physical properties of Al2O3-based slags used for the self-propagating high-temperature synthesis (SHS) – metallurgy method

- Low-temperature corrosion behavior of laser cladding metal-based alloy coatings on EH40 high-strength steel for icebreaker

- Study on thermodynamics and dynamics of top slag modification in O5 automobile sheets

- Structure optimization of continuous casting tundish with channel-type induction heating using mathematical modeling

- Microstructure and mechanical properties of NbC–Ni cermets prepared by microwave sintering

- Spider-based FOPID controller design for temperature control in aluminium extrusion process

- Prediction model of BOF end-point P and O contents based on PCA–GA–BP neural network

- Study on hydrogen-induced stress corrosion of 7N01-T4 aluminum alloy for railway vehicles

- Study on the effect of micro-shrinkage porosity on the ultra-low temperature toughness of ferritic ductile iron

- Characterization of surface decarburization and oxidation behavior of Cr–Mo cold heading steel

- Effect of post-weld heat treatment on the microstructure and mechanical properties of laser-welded joints of SLM-316 L/rolled-316 L

- An investigation on as-cast microstructure and homogenization of nickel base superalloy René 65

- Effect of multiple laser re-melting on microstructure and properties of Fe-based coating

- Experimental study on the preparation of ferrophosphorus alloy using dephosphorization furnace slag by carbothermic reduction

- Research on aging behavior and safe storage life prediction of modified double base propellant

- Evaluation of the calorific value of exothermic sleeve material by the adiabatic calorimeter

- Thermodynamic calculation of phase equilibria in the Al–Fe–Zn–O system

- Effect of rare earth Y on microstructure and texture of oriented silicon steel during hot rolling and cold rolling processes

- Effect of ambient temperature on the jet characteristics of a swirl oxygen lance with mixed injection of CO2 + O2

- Research on the optimisation of the temperature field distribution of a multi microwave source agent system based on group consistency

- The dynamic softening identification and constitutive equation establishment of Ti–6.5Al–2Sn–4Zr–4Mo–1W–0.2Si alloy with initial lamellar microstructure

- Experimental investigation on microstructural characterization and mechanical properties of plasma arc welded Inconel 617 plates

- Numerical simulation and experimental research on cracking mechanism of twin-roll strip casting

- A novel method to control stress distribution and machining-induced deformation for thin-walled metallic parts

- Review Article

- A study on deep reinforcement learning-based crane scheduling model for uncertainty tasks

- Topical Issue on Science and Technology of Solar Energy

- Synthesis of alkaline-earth Zintl phosphides MZn2P2 (M = Ca, Sr, Ba) from Sn solutions

- Dynamics at crystal/melt interface during solidification of multicrystalline silicon

- Boron removal from silicon melt by gas blowing technique

- Removal of SiC and Si3N4 inclusions in solar cell Si scraps through slag refining

- Electrochemical production of silicon

- Electrical properties of zinc nitride and zinc tin nitride semiconductor thin films toward photovoltaic applications

- Special Issue on The 4th International Conference on Graphene and Novel Nanomaterials (GNN 2022)

- Effect of microstructure on tribocorrosion of FH36 low-temperature steels

Articles in the same Issue

- Research Articles

- Numerical and experimental research on solidification of T2 copper alloy during the twin-roll casting

- Discrete probability model-based method for recognition of multicomponent combustible gas explosion hazard sources

- Dephosphorization kinetics of high-P-containing reduced iron produced from oolitic hematite ore

- In-phase thermomechanical fatigue studies on P92 steel with different hold time

- Effect of the weld parameter strategy on mechanical properties of double-sided laser-welded 2195 Al–Li alloy joints with filler wire

- The precipitation behavior of second phase in high titanium microalloyed steels and its effect on microstructure and properties of steel

- Development of a huge hybrid 3D-printer based on fused deposition modeling (FDM) incorporated with computer numerical control (CNC) machining for industrial applications

- Effect of different welding procedures on microstructure and mechanical property of TA15 titanium alloy joint

- Single-source-precursor synthesis and characterization of SiAlC(O) ceramics from a hyperbranched polyaluminocarbosilane

- Carbothermal reduction of red mud for iron extraction and sodium removal

- Reduction swelling mechanism of hematite fluxed briquettes

- Effect of in situ observation of cooling rates on acicular ferrite nucleation

- Corrosion behavior of WC–Co coating by plasma transferred arc on EH40 steel in low-temperature

- Study on the thermodynamic stability and evolution of inclusions in Al–Ti deoxidized steel

- Application on oxidation behavior of metallic copper in fire investigation

- Microstructural study of concrete performance after exposure to elevated temperatures via considering C–S–H nanostructure changes

- Prediction model of interfacial heat transfer coefficient changing with time and ingot diameter

- Design, fabrication, and testing of CVI-SiC/SiC turbine blisk under different load spectrums at elevated temperature

- Promoting of metallurgical bonding by ultrasonic insert process in steel–aluminum bimetallic castings

- Pre-reduction of carbon-containing pellets of high chromium vanadium–titanium magnetite at different temperatures

- Optimization of alkali metals discharge performance of blast furnace slag and its extreme value model

- Smelting high purity 55SiCr automobile suspension spring steel with different refractories

- Investigation into the thermal stability of a novel hot-work die steel 5CrNiMoVNb

- Residual stress relaxation considering microstructure evolution in heat treatment of metallic thin-walled part

- Experiments of Ti6Al4V manufactured by low-speed wire cut electrical discharge machining and electrical parameters optimization

- Effect of chloride ion concentration on stress corrosion cracking and electrochemical corrosion of high manganese steel

- Prediction of oxygen-blowing volume in BOF steelmaking process based on BP neural network and incremental learning

- Effect of annealing temperature on the structure and properties of FeCoCrNiMo high-entropy alloy

- Study on physical properties of Al2O3-based slags used for the self-propagating high-temperature synthesis (SHS) – metallurgy method

- Low-temperature corrosion behavior of laser cladding metal-based alloy coatings on EH40 high-strength steel for icebreaker

- Study on thermodynamics and dynamics of top slag modification in O5 automobile sheets

- Structure optimization of continuous casting tundish with channel-type induction heating using mathematical modeling

- Microstructure and mechanical properties of NbC–Ni cermets prepared by microwave sintering

- Spider-based FOPID controller design for temperature control in aluminium extrusion process

- Prediction model of BOF end-point P and O contents based on PCA–GA–BP neural network

- Study on hydrogen-induced stress corrosion of 7N01-T4 aluminum alloy for railway vehicles

- Study on the effect of micro-shrinkage porosity on the ultra-low temperature toughness of ferritic ductile iron

- Characterization of surface decarburization and oxidation behavior of Cr–Mo cold heading steel

- Effect of post-weld heat treatment on the microstructure and mechanical properties of laser-welded joints of SLM-316 L/rolled-316 L

- An investigation on as-cast microstructure and homogenization of nickel base superalloy René 65

- Effect of multiple laser re-melting on microstructure and properties of Fe-based coating

- Experimental study on the preparation of ferrophosphorus alloy using dephosphorization furnace slag by carbothermic reduction

- Research on aging behavior and safe storage life prediction of modified double base propellant

- Evaluation of the calorific value of exothermic sleeve material by the adiabatic calorimeter

- Thermodynamic calculation of phase equilibria in the Al–Fe–Zn–O system

- Effect of rare earth Y on microstructure and texture of oriented silicon steel during hot rolling and cold rolling processes

- Effect of ambient temperature on the jet characteristics of a swirl oxygen lance with mixed injection of CO2 + O2

- Research on the optimisation of the temperature field distribution of a multi microwave source agent system based on group consistency

- The dynamic softening identification and constitutive equation establishment of Ti–6.5Al–2Sn–4Zr–4Mo–1W–0.2Si alloy with initial lamellar microstructure

- Experimental investigation on microstructural characterization and mechanical properties of plasma arc welded Inconel 617 plates

- Numerical simulation and experimental research on cracking mechanism of twin-roll strip casting

- A novel method to control stress distribution and machining-induced deformation for thin-walled metallic parts

- Review Article

- A study on deep reinforcement learning-based crane scheduling model for uncertainty tasks

- Topical Issue on Science and Technology of Solar Energy

- Synthesis of alkaline-earth Zintl phosphides MZn2P2 (M = Ca, Sr, Ba) from Sn solutions

- Dynamics at crystal/melt interface during solidification of multicrystalline silicon

- Boron removal from silicon melt by gas blowing technique

- Removal of SiC and Si3N4 inclusions in solar cell Si scraps through slag refining

- Electrochemical production of silicon

- Electrical properties of zinc nitride and zinc tin nitride semiconductor thin films toward photovoltaic applications

- Special Issue on The 4th International Conference on Graphene and Novel Nanomaterials (GNN 2022)

- Effect of microstructure on tribocorrosion of FH36 low-temperature steels