Abstract

In order to study the long-time safe storage performance of GaTo modified double base propellant, the accelerated aging tests at 65, 70, 75, and 85°C were conducted. The chemical stabilities, mechanical properties, and microstructure of the propellant samples were characterized by differential scanning calorimeter, bromize-titration, impact resistance testing, and field emission scanning electron microscopy in the aging duration. The results showed that the chemical stability of propellant became worse due to nitrate esters decomposition. The impact resistance degradation is the result of binder network collapse, phase separation between binder and plasticizer, and interfacial dewetting during aging. Hence, the storage life of the propellant at ambient temperature has been evaluated based on stabilizer depletion and impact resistance deterioration via Arrhenius approach

1 Introduction

Modified double base propellants, which are principally based on nitroglycerin (NG) and nitrocellulose (NC), are largely used in a wide range of applications because of their smokeless, low signature, simplicity, reliability, high thrust, and adaptable properties in burning rate. However, nitrate esters always decompose starting with the hemolytic breakdown of the O–NO2 bond. Even at normal storage conditions, these nitrate esters undergo an intrinsic chemical decomposition possibly leading to runaway autocatalytic reactions, which will cause mechanical, chemical, and ballistic properties degradation, even serious safety accidents [1,2]. Therefore, efficient stabilizers were added in order to absorb the decomposition products and to inhibit this catalytic reaction, so the early decomposition or even explosion during storage will be avoided. There are already several reports on the investigation of the stabilizer depletion and several milestones have been achieved in this field [3,4,5,6].

Till date several new techniques and methodologies have been used to accurately assess the chemical stability and life time prediction of solid propellants. For example, Chelouche et al. [7,8,9] reported a series of Fourier Transform Infrared Spectroscopy measurements carried out on double base rocket propellants with different natural aging times, and demonstrated that the homolytic scission of the O–NO2 bond and the hydrocarbon chains of the nitrate esters are the main processes that occurred when nitrate esters decompose. A new methodology has been established for the prediction of real and equivalent in-service-time by coupling vacuum stability test (VST) and principal component analysis, and kinetic modeling is carried out on VST data by model-free to estimate the activation energies for all samples.

The mechanical properties of solid propellants are also crucial for storage safety and usage safety of weapon systems. Post-curing, oxidative crosslinking and degradation of the adhesive system will cause the decrease in mechanical properties of the propellant, and generally result in a loss of the grain structural integrity. The increasing interest in structural integrity issues has paid more attention to the mechanical failure of solid propellants recently. Zhou et al. [10] investigated the effect of pre-strain aging on the micro damage properties of HTPB propellant during aging, and found that the bonding performance between HTPB propellant matrix and solid filler was mainly affected by aging temperature. Pan and Liu [11] investigated the correlation between chemical stability and binder network structure of NEPE propellant during aging storage, and provided a way of storage life modeling analysis based only on the parameter of tensile strength of NEPE propellant. Kumar et al. [12] predicted the shelf life of a heterogeneous solid propellant based on the classical Arrhenius equation using zero-order kinetics of degradation based on the percentage elongation of propellant reduced to 30%.

GaTo propellant is a new generation of modified double base propellant independently developed by China, with the formula based on NG and NC, ammonium percolates (AP) as oxidant and aluminum (Al) powder as combustion agent. The propellant has the advantages of wide adjustable range of phlogiston, good performance reproducibility and high instantaneous thrust in the process of service, and are widely used in multiple types of shoulder mounted individual rocket in recent years. Therefore, the following storage safety difficulties need to be solved urgently. The double base of NG and NC are easily decomposed in an autocatalytic way even under ambient conditions. With the accumulation of nitrogen oxides, the chemical stabilities and ballistic properties of GaTo propellants are seriously impaired. In addition, the mechanical behavior of GaTo propellants strongly depends on its microstructure, such as the binder matrix and interfacial bonding properties. GaTo propellants are usually manufactured into thin-walled hollow tubular structures, and equipped in the form of brush charge, which means that they are likely forced to strike the projectile base or wall and collide with each other during launch, transportation, and storage. These load and application conditions can result in interfacial dewetting between AP particles and the NC binder matrix which will cause the reduction in mechanical properties of GaTo propellant, and generally result in sudden surge of structure destruction. To study its aging problem, the correlation between chemical stability and mechanical aging must be considered.

In this study, in order to investigate the aging behavior of GaTo propellant during storage, the accelerated aging test was carried out, then stabilizer depletion and impact resistance have been measured in the aging duration. At the same time, the mechanism of chemical and mechanical performance degradation has been investigated via thermal decomposition behavior, degeneration of change in the cross-linked network, and the change in micro-phase structure. The safe storage life of GaTo propellants was predicted based on the degradation of stabilizer content and mechanical properties via Arrhenius equation. The research work is of great significance to the long-term storage safety evaluation, anti-aging measurement, and formulation optimization of GaTo propellant.

2 Materials and methods

2.1 Propellant manufacturing

The GaTo propellants were prepared by solvent extrusion process with the main components being NG, NC, AP, Al, compound stabilizer of Res (resorcinol), and C2 (1,3-dimethyl-1,3-diphenyl urea) and other functional additives. The propellant samples are hollow tubes with a length of 109 mm and average external longitude of 7 mm encapsulated in special capillary tubes.

2.2 Accelerated aging test

The aging experiments were carried out at air-circulating ovens (accurate to ±1°C). The round GaTo propellant samples were aged at elevated temperatures and then removed according to the scheduled times of the test matrix shown in Table 1. In order to avoid the explosion accidents, the aging test should be terminated when the residual stabilizer is less than 50%.

Accelerated aging schedule

| T (°C) | Aging time (days) |

|---|---|

| 85 | 1, 2, 3, 4, and 5 |

| 75 | 2, 5, 8, 15, 18, and 22 |

| 70 | 4, 8, 14, 21, 28, and 38 |

| 65 | 8, 20, 30, 40, 60, and 70 |

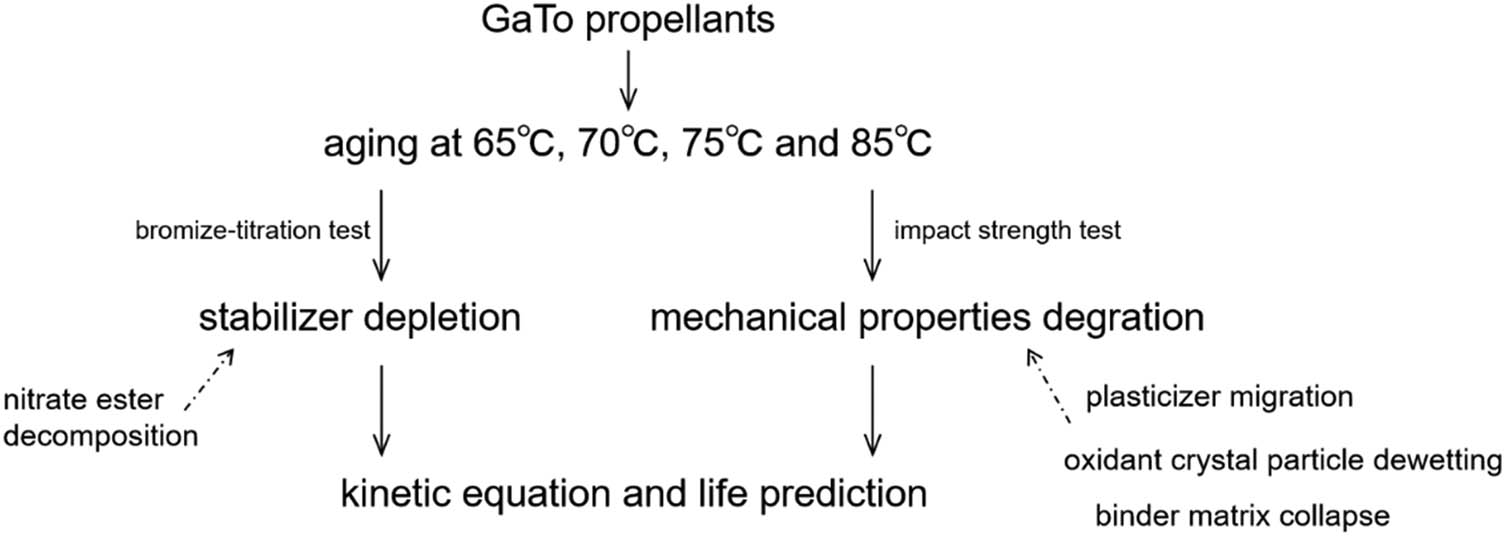

The samples before and after aging were selected to carry out the following tests, as shown in Figure 1.

The experimental scheme of GaTo accelerated aging test.

2.2.1 Determination of stabilizer

The content of effective stabilizer was tracked by bromize-titration in the aging duration according to GJB 770B-2005 [13]. The result of bromize-titration test is the effective stabilizer content converted according to C2. The result is the average of two measurements.

2.2.2 Impact test

The impact resistance was tested at 20 ± 2°C by Charpy impact tester according to GJB 770B-2005 [13]. The hollow tubular GaTo propellants with an outer diameter of 7 mm and an arc thickness of 1.2 mm were shaped into a 60 mm samples to be tested. The final absorbed energy of each specimen was the average of four samples.

In order to analyze the mechanism of aging behavior, GaTo propellant samples aging at 75°C were selected to carry out the following tests:

2.2.3 Thermal measurements

The differential scanning calorimeter (DSC) curves were obtained using a Mettler Toledo DSC model DSC1, at temperature range of 100–400°C. Samples were scanned at 10°C·min−1 under dry nitrogen atmosphere (20 mL·min−1). The weight of the samples was about 5 mg and sealed in alumina pan.

2.2.4 Cross-linking density

Cross-linking densities in aging process was characterized at 60°C by NIUMAG MicroMR-CL magnetic resonance cross-linking instrument.

2.2.5 Determination of NG Content

The retention time of NG is confirmed to detect their standard substances premixed according to a suitable ratio by high performance liquid chromatography (HPLC). GaTo propellant samples of different aging time weighing 0.4 g were put into 60 mL conical flasks, and soaked in chromatographic acetone/H2O mixture for 10 h. Afterwards the soaking liquid was detected by HPLC. The relative content of NG is obtained by calculating the ratio of peak area.

2.2.6 Micromorphology Characterization

Micromorphology of propellant samples before and after aging was characterized by QUANTA 600 FEG type field emission scanning electron microscopy (FESEM). Vacuum level was 10−3 Pa and working distance was 10 mm. Slices of propellant samples were cut after the impact tests to visually investigate the absence or presence of dewetting phenomena.

2.3 Safe storage life prediction

The values of safe storage performance deterioration thus obtained for different accelerated aging temperatures can be used to define the effect of temperature on the degradation rate or to predict the storage life. Arrhenius approach has been extensively used to analyze high-temperature accelerated aging propellants and then to extrapolate these results to make long-term predictions at lower temperature [14], typically at the storage temperature. The Arrhenius equation is given in equation (1):

which can be rearranged to:

where k is the reaction rate constant, E a is the activation energy (kJ·mol−1), R is the universal gas constant (J·mol−1·K−1), and T is the absolute temperature (K). Using activation energy (E a), storage, and aging temperatures, the shelf life of propellant is estimated as follows:

where t E and t T are shelf life at storage temperature and test time at accelerated aging temperature, T E and T T are storage and aging temperatures, respectively.

3 Results and discussion

3.1 Aging behavior of chemical stability (nitrate ester decomposition)

In the aging duration, nitrous oxides (NO x ) are produced continuously due to the decomposition of NG/NC in GaTo, which can affect the performance and long-term stability of such propellants. The stabilizer in GaTo propellants could absorb the NO x to prevent the autocatalytic accelerated decomposition, so the chemical stability of GaTo could be determined by the residual effective stabilizer content after aging [5]. The course of the stabilizer content during the aging of the GaTo propellants is presented in Figure 2.

Stabilizer depletion of GaTo propellants with error bars at 85, 75, 70, and 65°C.

The trend line of stabilizer depletion has been fitted via OriginLab, and the fitting equations are shown in Table 2. As can be seen from Figure 2 and Table 2, the curves of stabilizer consumption at 85, 75, 70, and 65°C trended to be linear, so the stabilizer depletion rate is constant and independent of reactant concentration, which means stabilizer consumption is conformity with the zero order reaction [15].

Fitting equation of stabilizer depletion

| T (°C) | Fitting equation | R 2 | ln k |

|---|---|---|---|

| 85 | ω = 5.6 – 0.543t | 0.9841 | −2.1628 |

| 75 | ω = 5.6 – 0.151t | 0.9818 | −3.6119 |

| 70 | ω = 5.6 – 0.092t | 0.9178 | −4.1352 |

| 65 | ω = 5.6 – 0.044t | 0.9943 | −4.8283 |

Based on the data in Table 2, the reaction rate constant and aging temperature are established (Figure 3). Where X axis is the 1/T (aging temperature) and Y axis is ln k. Figure 3 figures out that the 1/T and ln k have a linear relationship.

ln k as function of 1/T.

The kinetic equation of stabilizer depletion was calculated by 1/T and ln k via Arrhenius method:

In order to investigate the chemical stabilities of GaTo propellants during aging, GaTo propellants before and after aging at 75°C for 22 days were investigated by DSC experiments and the curves are shown in Figure 4, respectively. Generally, there were two characteristic endothermic peaks in the thermal decomposition process of GaTo. The exothermic peak in the temperature of 200–210°C reveals decomposition of NG/NC components (T p-NG-NC) [16], and the exothermic peak of about 315°C exhibits the solid-vapor reactions in the lower temperature thermal decomposition stage of AP (T p-AP). Meanwhile, there is a small exothermic peak at about 245°C representing the crystal transition of AP (T r-AP) [17]. After aging test, T p-NG-NC shifted to the high-temperature side and the exothermic enthalpy became larger, indicating that the rate of the thermal decomposition of NG/NC in aged GaTo propellants increased at higher heating rates.

DSC curves of GaTo before and after aging at 75°C for 22 days at the heating rate of 10°C·min−1.

Besides, there was no obvious difference in the shape of T

p-AP before and after aging tests. Theoretically, AP may decompose slightly to generate

The thermal decomposition of NG/NC in GaTo propellant can be divided into two stages. The first stage is the endothermic decomposition reaction of NC and NG, which is the rupture of the O–NO2 bond, with the formulas as follows [3,4,5,6]:

The second stage is the autocatalytic reaction between the decomposition product NO2 and other decomposition products, with the formulas as follows:

As a result, the decomposition goes faster and faster since the amount of NO x doubles and accumulates with the deep decomposition of nitrate esters. When NO x increases and accumulates too much, NG/NC will decompose in a rapid self-accelerating way until it explodes.

The decomposition reaction could be controlled when stabilizers are included in the propellant, which can quickly absorb the nitrogen oxide produced by the thermal decomposition of nitrate ester and effectively prevent the thermal acceleration reaction [19]. The values of activation barriers between the stabilizers and NO2 are lower or much lower than those of reactions between nitrate esters and NO2, which is depicted in Figure 5.

The aging decomposition of NG-NC in GaTo propellants.

The degradation criterion has been defined as a reduction in effective stabilizer concentration to less than 50 wt% according to GJB/770B-2005. In this work, stabilizer was not completely consumed during aging, which indicated that residual stabilizer still could delay the autocatalytic decomposition of NG/NC. NO x neutralized by stabilizer mainly occurs on the surface of GaTo propellant, and the reaction rate was decided by the concentration of stabilizer on the surface. At the same time, stabilizer diffused from the interior to the surface of GaTo propellant until the consumption and diffusion reached a state of equilibrium, which means the consumption rate is equal to the diffusion rate, hence the MNA content declined linearly and rapidly during aging.

3.2 Aging behavior of mechanical properties

GaTo propellants are usually equipped on individual rockets in the form of brush charge. Under the impact of burning gas, propellants are forced to strike the projectile base or wall and collide with each other. If the mechanical properties decrease to a critical point after long-term storage, sudden surge of combustion is inevitable. The impact tests have been carried out and the changes in impact resistance of GaTo at different aging temperatures are shown in Figure 6.

Changes in impact resistance of GaTo with error bars at 85, 75, 70, and 65°C.

As can be seen from Figure 6, impact resistance data decline linearly, and the rate of decline is temperature dependent. The trend line of impact resistance degradation has been fitted by OriginLab, and the results are shown in Table 3.

Fitting equation of impact resistance degradation

| T (°C) | Fitting equation | R 2 | ln k |

|---|---|---|---|

| 85 | Re = e −0.152t | 0.9215 | −1.8839 |

| 75 | Re = e −0.039t | 0.9358 | −3.2188 |

| 70 | Re = e −0.024t | 0.8991 | −3.7297 |

| 65 | Re = e −0.011t | 0.8515 | −4.5098 |

Based on the data in Table 3, the reaction rate constant and aging temperature are established (Figure 7), where X axis is the 1/T (aging temperature) and Y axis is ln k. Figure 7 figures out that the 1/T and ln k have a linear relationship.

ln k as function of 1/T.

The kinetic equation of impact resistance deterioration was calculated by 1/T and ln k via Arrhenius method:

The microstructure of a typical solid propellant material consists of polymeric binder (e.g., NC), plasticizer (e.g., NC), oxidizer (e.g., AP), and some other additives. From the mechanical behavior perspective, each of these phases exhibits a complex constitutive response that varies with temperature and load.

The binder network structure of propellants is closely related to its mechanical properties. Figure 8 shows the change behavior of cross-linking density with aging time at 75°C. The values of cross-linking density increased slightly in the early stage of aging, then declined wavelike, and decreased obviously at the later period of aging, which indicated that the post-curing reaction and the decomposition of NC binder network existed together in the aging duration. The post-curing reaction was the main reaction at the beginning of thermal aging due to the re-arrangement of the NC molecular chain. As the thermal aging continues, the NO x accumulation will accelerate the NC molecular chains degradation, not only thermal degradation but also oxidative degradation. Meanwhile, with residual solvent consumed, the post-curing reaction rate decreased and NC polymer molecular chains collapsed gradually.

Change behavior of cross-linking density of GaTo at 75°C.

The structure of NC is rigid liner molecules and connected with each other loosely. NG has a plasticization effect on NC so as to make NG molecular chains more flexible, thus enhancing the mechanical strength of GaTo propellants. Figure 9 shows the relationship between NG consumption and impact resistance degradation during 75°C aging.

NG contents vs impact resistance of GaTo under aging at 75°C.

As shown in Figure 9, impact resistance degradation has good liner relationship with NG depletion, with the equation as follows:

During the storage aging process, decomposition and migration of NG from the NC polymer bulk lead to the decrease in free volume of NC with the reduction in distance between NC macromolecules [20,21]. The shortening of NG plasticizer would also increase the interactions between segments of the NC polymer and decrease the plasticization between NC and NG, which has been found to result in the propellants being more brittle and easier to fracture [22].

In the aging duration, a few translucent white crystalline flakes were observed on the surface of the GaTo propellants, in the FESEM image as shown in Figure 10a. EDS pattern (Figure 10b) shows that the crystalline flake is AP, which indicated that the moisture in the atmosphere diffused into the interior of GaTo propellants, causing a few AP dissolution and recrystallization on the surface.

FESEM image (a) and EDS pattern (b) of crystalline flakes on the surface of GaTo aged at 75°C for 22 days.

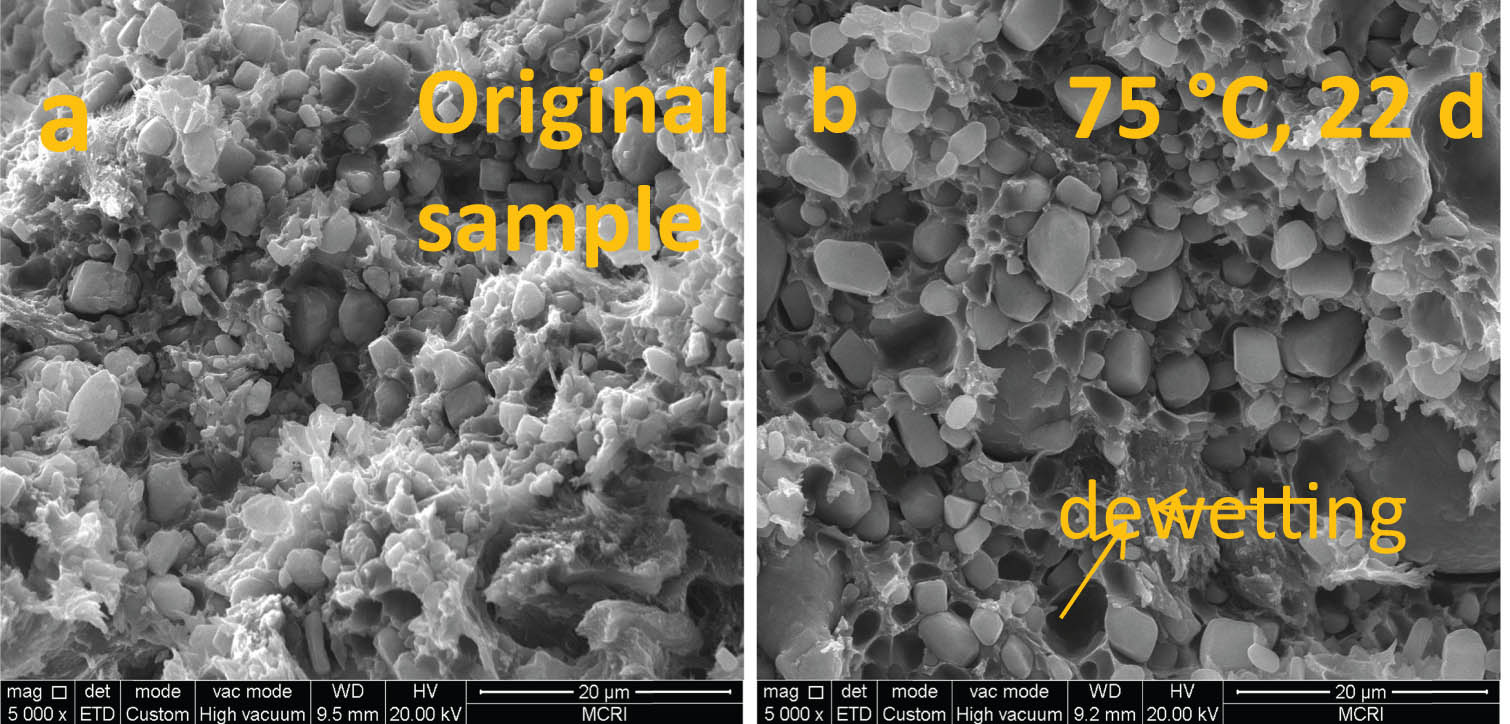

The mechanical failure properties of solid propellants are also determined by the bond of the particle/matrix interfaces. The fracture morphology of broken surface, obtained after the impact test of GaTo samples, has been characterized by FESEM, as shown in Figure 11.

FESEM images of GaTo impact fracture section before (a) and after (b) aging at 75°C for 22 days.

Figure 11(a) represents the morphology of unaged GaTo impact fracture. The AP particles are distributed in NC frameworks uniformly, and there is no obvious dewetting phenomenon (a process of large oxidizer particles debonding from the binder matrix). Figure 11(b) represents the morphology of GaTo impact fracture aged at 75°C for 22 days. There are voids and holes between the AP crystal particles and binder frames, which were probably caused by the AP crystal particles debonded from the binder matrix during the fracture process of impact test. It is obvious that the interfacial bonding performance of GaTo propellant degraded after aging. According to the theory of particle reinforced composites [23], in the aging process, AP particles became larger and more irregular, resulting in poor distribution uniformity in GaTo propellants, which reduce the adhesion of the AP particle surface to the NC binder matrix. Once AP particles debonded from NC polymer bulk, the binder could no longer withstand the impact force and GaTo propellants ruptured finally. In addition, the linear expansion coefficient of AP is far less than that of the binder matrix, and gas produced by NC/NG thermal decomposition may promote the interface dewetting between AP and NC matrix, further resulting in deterioration of mechanical performance.

Based on the analysis above, there are three key factors that affect the mechanical aging behavior of GaTo propellants: First, migration and decomposition of plasticizer lead to the decrease in mobility of polymer bulk, and then the GaTo propellants are easier to fracture. Second, NC polymer chains collapsed gradually in a thermal oxidative way during aging. Additionally, dewetting in AP particles/NC binder matrix resulted in the degradation of macro-mechanical properties. The factors above are closely connected with the decline of the mechanical properties.

3.3 Long-time safe storage life prediction

Based on the mechanism of aging behavior, the decline in both chemical stability and mechanical properties existed simultaneously during the thermal aging. NO x produced by nitrate esters decomposition not only lead to the stabilizer consumption but also to microstructure collapse and therefore, plasticization of NC/NG weakens.

Generally, a propellant is assumed to be safe when it meets the criteria, such as national military standard of China or the product finalization document. In this work, there are two types of indexes that are involved in the failure criterion of GaTo propellants: change in the properties and mechanical properties and loss of the stabilizer, which has been given in Table 4.

Safe storage life criteria of GaTo propellants

| Safe storage life criteria | Documents |

|---|---|

| 50% decreased in effective stabilizer content | GJB/770B-2005 |

| 20% decreased in impact resistance | The product finalization document from manufacturer |

Based on the kinetic equation of equations (5) and (6) and the failure criterions in Table 4, the safe storage life of the GaTo at 25°C can be estimated, and the results are listed in the Table 5.

Safe storage life predicted via Arrhenius approaches at 25°C

| Safe storage life criterion | Life assessment model | R 2 | τ 25/year |

|---|---|---|---|

| 50% decreased in effective stabilizer content | ln k = 44.59 – 16,139/T | 0.9961 | 39.7 |

| 20% decreased in impact resistance | ln k = 40.45 – 15,389/T | 0.9974 | 11.7 |

The results showed that τ 25 (the safe storage life at 25°C) based on stabilizer depletion and impact resistance remains 39.7 years and 11.7 years, respectively. Considering the safety and reliability aspect, the lower shelf life is recommended.

4 Conclusion

The storage behavior of GaTo propellant has been analyzed during the accelerated aging progress. The change in chemical stability and mechanical properties were tested in the aging duration. According to the experimental data analysis, a few conclusions can be drawn as follows:

The chemical stability of GaTo propellants decreased during accelerated aging due to the NG/NC thermal decomposition, which leads to stabilizer consumption in the 0th-order reaction way.

The mechanical properties of GaTo propellants decreased during aging due to decomposition and migration of NG, collapse of cross-linking density, and interfacial dewetting, which leads to the deterioration in plasticization of NC/NG and microstructure stabilities of GaTo. Degradation in chemical stability and mechanical properties happened simultaneously, and chemical stability plays a significant role in maintaining the firmness of network structure and microstructure during storage.

The safe storage life prediction at 25°C based on stabilizer consumption and impact resistance degradation has been calculated. The results showed that the safe storage life based on impact resistance decrease by 20% giving lower value (τ 25 = 11.7 years). Considering the safety and reliability aspect, the lower shelf life is recommended.

The life prediction and mechanism of aging behavior is of great significance in long-term storage safety evaluation, anti-aging measurement, and formulation optimization of GaTo propellants.

Symbols and abbreviations

- Al

-

aluminum powder

- AP

-

ammonium percolates

- C2

-

1,3-dimethyl-1,3-diphenyl urea

- DSC

-

differential scanning calorimeter

- FESEM

-

field emission scanning electron microscopy

- HPLC

-

high performance liquid chromatography

- NC

-

nitrocellulose

- NG

-

nitroglycerin

- R 2

-

coefficient of determination

- Res

-

resorcinol

- T

-

aging temperature/°C

- t

-

aging time/day

- τ 25

-

safe storage life at 25°C

Acknowledgment

This research was supported by Xi’an Modern Chemistry Research Institute. The authors would like to thank the anonymous referees for their valuable comments that greatly helped in improving this article.

-

Funding information: The authors state no funding involved.

-

Author contributions: Yan Gu: writing – original draft, writing – review & editing, and formal analysis. Silong Yu: writing – original draft, and visualization. Qiong Wang: formal analysis. Jiaojiao Du: formal analysis. Fangfang Wang: formal analysis.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Data are available on request from the authors.

References

[1] Tirak, Ea., M. Moniruzzaman, E. Degirmenci, and A. Hameed. Closed vessel burning behavior and ballistic properties of artificially degraded spherical double-base propellants stabilized with diphenylamine. Thermochimica Acta, Vol. 680, 2019, pp. 1–9.10.1016/j.tca.2019.178347Search in Google Scholar

[2] Boulkadid, M. K., M. H. Lefebyre, L. Jeunieau, and A. Dejeaifye. Burning rate of artificially aged solid double-base gun propellants. Journal of Energetic Materials, Vol. 38, No. 1, 2019, pp. 1–19.10.1080/07370652.2019.1657204Search in Google Scholar

[3] Tao, T., X. Sui, S. Li, and N. Wang. A Study on consumption and characterization of stabilizer content of NEPE propellant via FTIR. Propellants, Explosives, Pyrotechnics, Vol. 44, No. 7, 2019, pp. 889–895.10.1002/prep.201800340Search in Google Scholar

[4] Wu, W., C. Chen, X. Fu, C. Ding, and G. Wang. The correlation between chemical stability and binder network structure in NEPE propellant. Propellants, Explosives, Pyrotechnics, Vol. 42, No. 5, 2017, pp. 541–546.10.1002/prep.201600117Search in Google Scholar

[5] Sun, Z., X. Fu, H. Yu, X. Fan, and X. Ju. Theoretical study on stabilization mechanisms of nitrate esters using aromatic amines as stabilizers. Journal of Hazardous Materials, Vol. 339, 2017, pp. 401–408.10.1016/j.jhazmat.2017.06.025Search in Google Scholar PubMed

[6] Trache, D., K. Khimeche, and A. Dahmani. Study of (solid–liquid) phase equilibria for mixtures of energetic material stabilizers and prediction for their subsequent performance. International Journal of Thermophysics, Vol. 34, 2013, pp. 226–239.10.1007/s10765-013-1404-4Search in Google Scholar

[7] Chelouche, S., D. Trache, Z. Benayachi, A. Tarchoun, K. Khimeche, and A. Mezroua. A new procedure for stability control of homogeneous solid propellants by combination of vacuum stability test, FTIR and PCA. Propellants, Explosives, Pyrotechnics, Vol. 45, No. 7, 2020, pp. 1088–1102.10.1002/prep.201900424Search in Google Scholar

[8] Chelouche, S., D. Trache, I. Maamache, A. Tarchoun, K. Khimeche, and A. Mezroua. A new experimental way for the monitoring of the real/equivalent In-Service-Time of double base rocket propellant by coupling VST and PCA. Defence Technology, Vol. 17, No. 7, 2021, pp. 440–449.10.1016/j.dt.2020.04.008Search in Google Scholar

[9] Chelouche, S., D. Trache, R. Benlemir, and A. Soudani. Principal component analysis of FTIR data to accurately assess the real/equivalent In-Service-Times of homogenous solid propellant. Propellants, Explosives, Pyrotechnics, Vol. 47, No. 1, 2022, pp. 1–19.10.1002/prep.202100352Search in Google Scholar

[10] Zhou, D., X. Liu, X. Sui, Z. Wei, and N. Wang. Effect of pre-strain aging on the micro damage properties of composite solid propellant. Propellants, Explosives, Pyrotechnics, Vol. 42, No. 4, 2017, pp. 430–437.10.1002/prep.201600128Search in Google Scholar

[11] Pan, Z. and T. Liu. Storage lifetime prediction of composite solid propellant based on Šesták-Berggren model. Propellants, Explosives, Pyrotechnics, Vol. 46, No. 3, 2021, pp. 468–476.10.1002/prep.202000199Search in Google Scholar

[12] Kumar, A., V. Sadavarte, S. Mada, S. Pande, and P. Chavan. Studies on the effect of ageing on thermal, ballistic and mechanical properties of advanced. Propellants, Explosives, Pyrotechnics, Vol. 46, No. 4, 2021, pp. 626–635.10.1002/prep.202000241Search in Google Scholar

[13] National Military Standard of China, Test method of propellant GJB/770B-2005, 2005 (in Chinese).Search in Google Scholar

[14] Zhao, X., X. Rui, and R. Zhang. A novel method for prediction of propellant shelf-life based on Arrhenius equation. Propellants, Explosives, Pyrotechnics, Vol. 43, No. 8, 2018, pp. 348–354.10.1002/prep.201700271Search in Google Scholar

[15] Gorji, M. and K. Mohammadi. Comparison of Berthelot and Arrhenius approaches for prediction of liquid propellant shelf life. Propellants, Explosives, Pyrotechnics, Vol. 38, No. 5, 2013, pp. 715–720.10.1002/prep.201200214Search in Google Scholar

[16] Wu, X., G. Rao, L. Chen, J. Wang, and C. Zhang. Analysis for decomposition characteristics and piecewise thermo kinetics of nitramine modified double-base propellant with high solid content. Propellants, Explosives, Pyrotechnics, Vol. 42, No. 10, 2017, pp. 1149–1154.10.1002/prep.201700077Search in Google Scholar

[17] Zhu, Y., H. Huang, H. Ren, and Q. Jiao. Kinetics of thermal decomposition of ammonium perchlorate by TG/DSC-MS-FTIR. Journal of Energetic Materials, Vol. 32, No. 1, 2014, pp. 16–26.10.1080/07370652.2012.725453Search in Google Scholar

[18] Bai, S., X. Sun, N. Han, X. Shu, J. Pan, H. Guo, et al. rGO modified nanoplate-assembled ZnO/CdO junction for detection of NO2. Journal of Hazardous Materials, Vol. 394000, 2020, pp. 1–9.10.1016/j.jhazmat.2019.121832Search in Google Scholar PubMed

[19] Klerk, W. P. C. Assessment of stability of propellants and safe lifetimes. Propellants, Explosives, Pyrotechnics, Vol. 40, No. 3, 2015, pp. 388–393.10.1002/prep.201500040Search in Google Scholar

[20] Zhang, H. J. and S. Sellaiyan. Effect of free-volume holes on dynamic mechanical properties of epoxy resins for carbon-fiber reinforced polymers. Macromolecules, Vol. 50, No. 8, 2017, pp. 3934–3943.10.1021/acs.macromol.7b00472Search in Google Scholar

[21] Yang, Y., G. Xian, H. Li, and L. Sun. Thermal aging of an anhydride-cured epoxy resin. Polymer Degradation and Stability, Vol. 118, 2015, pp. 111–119.10.1016/j.polymdegradstab.2015.04.017Search in Google Scholar

[22] Rambaldi, D. C., C. Suryawanshi, C. Eng, and F. D. Preusser. Effect of thermal and photochemical degradation strategies on the deterioration of cellulose diacetate. Polymer Degradation and Stability, Vol. 107, 2014, pp. 237–245.10.1016/j.polymdegradstab.2013.12.004Search in Google Scholar

[23] Lebar, A., R. Aguiat, A. Odyy, and O. E. Petel. Particle surface effects on the spall strength of particle-reinforced polymer matrix composites. International Journal of Impact Engineering, Vol. 150, 2021, pp. 1–9.10.1016/j.ijimpeng.2020.103801Search in Google Scholar

© 2022 Yan Gu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Numerical and experimental research on solidification of T2 copper alloy during the twin-roll casting

- Discrete probability model-based method for recognition of multicomponent combustible gas explosion hazard sources

- Dephosphorization kinetics of high-P-containing reduced iron produced from oolitic hematite ore

- In-phase thermomechanical fatigue studies on P92 steel with different hold time

- Effect of the weld parameter strategy on mechanical properties of double-sided laser-welded 2195 Al–Li alloy joints with filler wire

- The precipitation behavior of second phase in high titanium microalloyed steels and its effect on microstructure and properties of steel

- Development of a huge hybrid 3D-printer based on fused deposition modeling (FDM) incorporated with computer numerical control (CNC) machining for industrial applications

- Effect of different welding procedures on microstructure and mechanical property of TA15 titanium alloy joint

- Single-source-precursor synthesis and characterization of SiAlC(O) ceramics from a hyperbranched polyaluminocarbosilane

- Carbothermal reduction of red mud for iron extraction and sodium removal

- Reduction swelling mechanism of hematite fluxed briquettes

- Effect of in situ observation of cooling rates on acicular ferrite nucleation

- Corrosion behavior of WC–Co coating by plasma transferred arc on EH40 steel in low-temperature

- Study on the thermodynamic stability and evolution of inclusions in Al–Ti deoxidized steel

- Application on oxidation behavior of metallic copper in fire investigation

- Microstructural study of concrete performance after exposure to elevated temperatures via considering C–S–H nanostructure changes

- Prediction model of interfacial heat transfer coefficient changing with time and ingot diameter

- Design, fabrication, and testing of CVI-SiC/SiC turbine blisk under different load spectrums at elevated temperature

- Promoting of metallurgical bonding by ultrasonic insert process in steel–aluminum bimetallic castings

- Pre-reduction of carbon-containing pellets of high chromium vanadium–titanium magnetite at different temperatures

- Optimization of alkali metals discharge performance of blast furnace slag and its extreme value model

- Smelting high purity 55SiCr automobile suspension spring steel with different refractories

- Investigation into the thermal stability of a novel hot-work die steel 5CrNiMoVNb

- Residual stress relaxation considering microstructure evolution in heat treatment of metallic thin-walled part

- Experiments of Ti6Al4V manufactured by low-speed wire cut electrical discharge machining and electrical parameters optimization

- Effect of chloride ion concentration on stress corrosion cracking and electrochemical corrosion of high manganese steel

- Prediction of oxygen-blowing volume in BOF steelmaking process based on BP neural network and incremental learning

- Effect of annealing temperature on the structure and properties of FeCoCrNiMo high-entropy alloy

- Study on physical properties of Al2O3-based slags used for the self-propagating high-temperature synthesis (SHS) – metallurgy method

- Low-temperature corrosion behavior of laser cladding metal-based alloy coatings on EH40 high-strength steel for icebreaker

- Study on thermodynamics and dynamics of top slag modification in O5 automobile sheets

- Structure optimization of continuous casting tundish with channel-type induction heating using mathematical modeling

- Microstructure and mechanical properties of NbC–Ni cermets prepared by microwave sintering

- Spider-based FOPID controller design for temperature control in aluminium extrusion process

- Prediction model of BOF end-point P and O contents based on PCA–GA–BP neural network

- Study on hydrogen-induced stress corrosion of 7N01-T4 aluminum alloy for railway vehicles

- Study on the effect of micro-shrinkage porosity on the ultra-low temperature toughness of ferritic ductile iron

- Characterization of surface decarburization and oxidation behavior of Cr–Mo cold heading steel

- Effect of post-weld heat treatment on the microstructure and mechanical properties of laser-welded joints of SLM-316 L/rolled-316 L

- An investigation on as-cast microstructure and homogenization of nickel base superalloy René 65

- Effect of multiple laser re-melting on microstructure and properties of Fe-based coating

- Experimental study on the preparation of ferrophosphorus alloy using dephosphorization furnace slag by carbothermic reduction

- Research on aging behavior and safe storage life prediction of modified double base propellant

- Evaluation of the calorific value of exothermic sleeve material by the adiabatic calorimeter

- Thermodynamic calculation of phase equilibria in the Al–Fe–Zn–O system

- Effect of rare earth Y on microstructure and texture of oriented silicon steel during hot rolling and cold rolling processes

- Effect of ambient temperature on the jet characteristics of a swirl oxygen lance with mixed injection of CO2 + O2

- Research on the optimisation of the temperature field distribution of a multi microwave source agent system based on group consistency

- The dynamic softening identification and constitutive equation establishment of Ti–6.5Al–2Sn–4Zr–4Mo–1W–0.2Si alloy with initial lamellar microstructure

- Experimental investigation on microstructural characterization and mechanical properties of plasma arc welded Inconel 617 plates

- Numerical simulation and experimental research on cracking mechanism of twin-roll strip casting

- A novel method to control stress distribution and machining-induced deformation for thin-walled metallic parts

- Review Article

- A study on deep reinforcement learning-based crane scheduling model for uncertainty tasks

- Topical Issue on Science and Technology of Solar Energy

- Synthesis of alkaline-earth Zintl phosphides MZn2P2 (M = Ca, Sr, Ba) from Sn solutions

- Dynamics at crystal/melt interface during solidification of multicrystalline silicon

- Boron removal from silicon melt by gas blowing technique

- Removal of SiC and Si3N4 inclusions in solar cell Si scraps through slag refining

- Electrochemical production of silicon

- Electrical properties of zinc nitride and zinc tin nitride semiconductor thin films toward photovoltaic applications

- Special Issue on The 4th International Conference on Graphene and Novel Nanomaterials (GNN 2022)

- Effect of microstructure on tribocorrosion of FH36 low-temperature steels

Articles in the same Issue

- Research Articles

- Numerical and experimental research on solidification of T2 copper alloy during the twin-roll casting

- Discrete probability model-based method for recognition of multicomponent combustible gas explosion hazard sources

- Dephosphorization kinetics of high-P-containing reduced iron produced from oolitic hematite ore

- In-phase thermomechanical fatigue studies on P92 steel with different hold time

- Effect of the weld parameter strategy on mechanical properties of double-sided laser-welded 2195 Al–Li alloy joints with filler wire

- The precipitation behavior of second phase in high titanium microalloyed steels and its effect on microstructure and properties of steel

- Development of a huge hybrid 3D-printer based on fused deposition modeling (FDM) incorporated with computer numerical control (CNC) machining for industrial applications

- Effect of different welding procedures on microstructure and mechanical property of TA15 titanium alloy joint

- Single-source-precursor synthesis and characterization of SiAlC(O) ceramics from a hyperbranched polyaluminocarbosilane

- Carbothermal reduction of red mud for iron extraction and sodium removal

- Reduction swelling mechanism of hematite fluxed briquettes

- Effect of in situ observation of cooling rates on acicular ferrite nucleation

- Corrosion behavior of WC–Co coating by plasma transferred arc on EH40 steel in low-temperature

- Study on the thermodynamic stability and evolution of inclusions in Al–Ti deoxidized steel

- Application on oxidation behavior of metallic copper in fire investigation

- Microstructural study of concrete performance after exposure to elevated temperatures via considering C–S–H nanostructure changes

- Prediction model of interfacial heat transfer coefficient changing with time and ingot diameter

- Design, fabrication, and testing of CVI-SiC/SiC turbine blisk under different load spectrums at elevated temperature

- Promoting of metallurgical bonding by ultrasonic insert process in steel–aluminum bimetallic castings

- Pre-reduction of carbon-containing pellets of high chromium vanadium–titanium magnetite at different temperatures

- Optimization of alkali metals discharge performance of blast furnace slag and its extreme value model

- Smelting high purity 55SiCr automobile suspension spring steel with different refractories

- Investigation into the thermal stability of a novel hot-work die steel 5CrNiMoVNb

- Residual stress relaxation considering microstructure evolution in heat treatment of metallic thin-walled part

- Experiments of Ti6Al4V manufactured by low-speed wire cut electrical discharge machining and electrical parameters optimization

- Effect of chloride ion concentration on stress corrosion cracking and electrochemical corrosion of high manganese steel

- Prediction of oxygen-blowing volume in BOF steelmaking process based on BP neural network and incremental learning

- Effect of annealing temperature on the structure and properties of FeCoCrNiMo high-entropy alloy

- Study on physical properties of Al2O3-based slags used for the self-propagating high-temperature synthesis (SHS) – metallurgy method

- Low-temperature corrosion behavior of laser cladding metal-based alloy coatings on EH40 high-strength steel for icebreaker

- Study on thermodynamics and dynamics of top slag modification in O5 automobile sheets

- Structure optimization of continuous casting tundish with channel-type induction heating using mathematical modeling

- Microstructure and mechanical properties of NbC–Ni cermets prepared by microwave sintering

- Spider-based FOPID controller design for temperature control in aluminium extrusion process

- Prediction model of BOF end-point P and O contents based on PCA–GA–BP neural network

- Study on hydrogen-induced stress corrosion of 7N01-T4 aluminum alloy for railway vehicles

- Study on the effect of micro-shrinkage porosity on the ultra-low temperature toughness of ferritic ductile iron

- Characterization of surface decarburization and oxidation behavior of Cr–Mo cold heading steel

- Effect of post-weld heat treatment on the microstructure and mechanical properties of laser-welded joints of SLM-316 L/rolled-316 L

- An investigation on as-cast microstructure and homogenization of nickel base superalloy René 65

- Effect of multiple laser re-melting on microstructure and properties of Fe-based coating

- Experimental study on the preparation of ferrophosphorus alloy using dephosphorization furnace slag by carbothermic reduction

- Research on aging behavior and safe storage life prediction of modified double base propellant

- Evaluation of the calorific value of exothermic sleeve material by the adiabatic calorimeter

- Thermodynamic calculation of phase equilibria in the Al–Fe–Zn–O system

- Effect of rare earth Y on microstructure and texture of oriented silicon steel during hot rolling and cold rolling processes

- Effect of ambient temperature on the jet characteristics of a swirl oxygen lance with mixed injection of CO2 + O2

- Research on the optimisation of the temperature field distribution of a multi microwave source agent system based on group consistency

- The dynamic softening identification and constitutive equation establishment of Ti–6.5Al–2Sn–4Zr–4Mo–1W–0.2Si alloy with initial lamellar microstructure

- Experimental investigation on microstructural characterization and mechanical properties of plasma arc welded Inconel 617 plates

- Numerical simulation and experimental research on cracking mechanism of twin-roll strip casting

- A novel method to control stress distribution and machining-induced deformation for thin-walled metallic parts

- Review Article

- A study on deep reinforcement learning-based crane scheduling model for uncertainty tasks

- Topical Issue on Science and Technology of Solar Energy

- Synthesis of alkaline-earth Zintl phosphides MZn2P2 (M = Ca, Sr, Ba) from Sn solutions

- Dynamics at crystal/melt interface during solidification of multicrystalline silicon

- Boron removal from silicon melt by gas blowing technique

- Removal of SiC and Si3N4 inclusions in solar cell Si scraps through slag refining

- Electrochemical production of silicon

- Electrical properties of zinc nitride and zinc tin nitride semiconductor thin films toward photovoltaic applications

- Special Issue on The 4th International Conference on Graphene and Novel Nanomaterials (GNN 2022)

- Effect of microstructure on tribocorrosion of FH36 low-temperature steels