Abstract

In this research, we were interested in studying whether vetiver fibers (VFs) treated with different concentrations of sodium hydroxide (NaOH) affect the mechanical properties of VF and epoxy resin (ER) composite material in a better way. As part of the experiment, VFs were treated with NaOH in various concentrations ranging from 0.5, 1, 1.5, 2, 2.5, and 3 mol/L. All of them were molded into composite material in the ratio of 10 wt% with ER. After that, they were tested for mechanical properties such as the tensile strength, impact strength, bending strength, and compressive strength to find the best mechanical properties. In addition, the surface was investigated with scanning electron microscopy (SEM) for adhesion of the VFs with ER. The results of the experiment were not as expected. We found that, increasing the concentration of vetiver treated with sodium hydroxide resulted in a decrease in the mechanical properties of the composite. The best values for impact, tensile, bending, and compressive strengths were 256.42 kJ/m2, 38.45 MPa, 43.70 MPa, and 110.27 MPa, respectively, and 0.5 mol/L is the best concentration of NaOH for mechanical strengths of the composites. Moreover, from SEM technique, it was found that the mechanical properties decreased at higher concentrations. This may be caused by damage to the VFs due to excessive NaOH corrosion and this point should be taken for further study.

1 Introduction

Nowadays, polymer matrix composites, or materials consisting of a polymer (resin) matrix combined with a fibrous reinforcing dispersed phase, are widely used in military ordnance, construction, and automotive parts industries due to its low cost, low density, ease in processing, and comparable mechanical properties with metal and ceramic [1,2]. However, the polymers in applications generally contain petropolymers which come from unrenewable sources and non-biodegradable polymers [3] as well as the reinforcing materials commonly used are the non-biodegradable glass fibers [4,5]. Therefore, the development of environmental-friendly material has become an interesting research area with the advantages of high strength and modulus, low levels of volatiles, excellent adhesion, low shrinkage, good chemical resistance, and ease of processing [6]; epoxy resins (ERs) are widely used as prepregs and structural adhesives.

Natural fibers have been increasingly used as alternative fillers in many areas of polymer composites [7,8]. Their advantages over synthetic fiber are low cost, less tool wear during processing, low density, environmentally friendly, and biodegradability [9]. Nevertheless, natural fibers also have some limitations such as high moisture absorption and subsequent swelling and degradation, poor chemical and fire resistance, and poor mechanical properties [10,11,12]. Therefore, surface modifications of natural fibers are required to improve the bonding properties of fibers before they are used as reinforcement in composite materials with good mechanical properties and high strength [13,14]. The process used to modify the fiber surface can be divided into two main methods: mechanical method and chemical method [15,16]. As for natural fibers, the alkaline treatment technique is one of the chemical methods often used as the composite material obtained becomes more rigid with less porosity and increased density. The chemical modification of natural fibers is a frequent use of alkaline treatment. The surface roughness is raised as a result of the alkaline treatment’s modification or disruption of the hydrogen bonding that holds the system structure together. This is a significant improvement. In addition, the surface modifications also increase the surface tension and roughness [13,14,15,16,17]. Natural fibers which have already been used in polymer composite industry are jute, flax, sisal fibers with vetiver fiber (VF) as one of the interesting candidates because special characteristics of vetiver grass: vetiver grass has many joints on the stem. It can be propagated using shoots all year long. It has long leaves that are easy to cut and grow again. Strong and resistant to degradation. The ER/VF composite looks most promising.

In addition, each type of natural fibers responds differently to the methods and chemicals utilized. And in the case of VF, there is not much information about the treatment to prepare the surface of fibers for use in composites. For this reason, in this work, the authors focused on the effect of alkaline treatment on mechanical properties of VFs and ER composites. The composite samples were prepared using hand lay-up technique. Mechanical properties were investigated and microstructure of samples was determined by scanning electron microscopy (SEM) technique.

2 Materials and method

2.1 Materials

Sri Lanka Ecotype vetiver grass grown in Thailand, analytical reagent grade of sodium hydroxide, and the epoxy and hardener at a ratio of 100:27 by volume were used in our work. The density of the matrix is 1.176 g/cm3.

2.2 Preparation of VFs

The vetiver leaves were cleaned in running water and sundried to remove the moisture. The prepared leaves were chopped and treated with sodium hydroxide (NaOH) solution of various concentration (0.5, 1, 1.5, 2, 2.5, 3 mol/L) for 4 h. The VF was washed by deionized water until the pH level became 7. The leaves were then spun in a blender and sieved into length of 1 mm before mixing with ER.

2.3 Fabrication of the ER/VF composite

The ER and VF were mixed together by hand for 5 min. The ER and VF were mixed together in the ratio of 1:10 by weight with hand for 5 min. The mixture was then sonicated by ultrasonic device for another 5 min, after which the mixture was molded by hand layup technique and left in room temperature for 8 h to settle (Figure 1).

2.4 Characterization method

Tensile strength as per ASTM standard D638-10 [18], bending strength as per ASTM standard D790-03 [19], and compressive strength were measured by a universal testing machine (CAT NO. 2603-080). Impact strength was measured by impact tester with Charpy impact test. And microstructure of composite was studied by SEM (JEOL JSM-5910LV).

The VF and ER composite samples.

3 Results and discussion

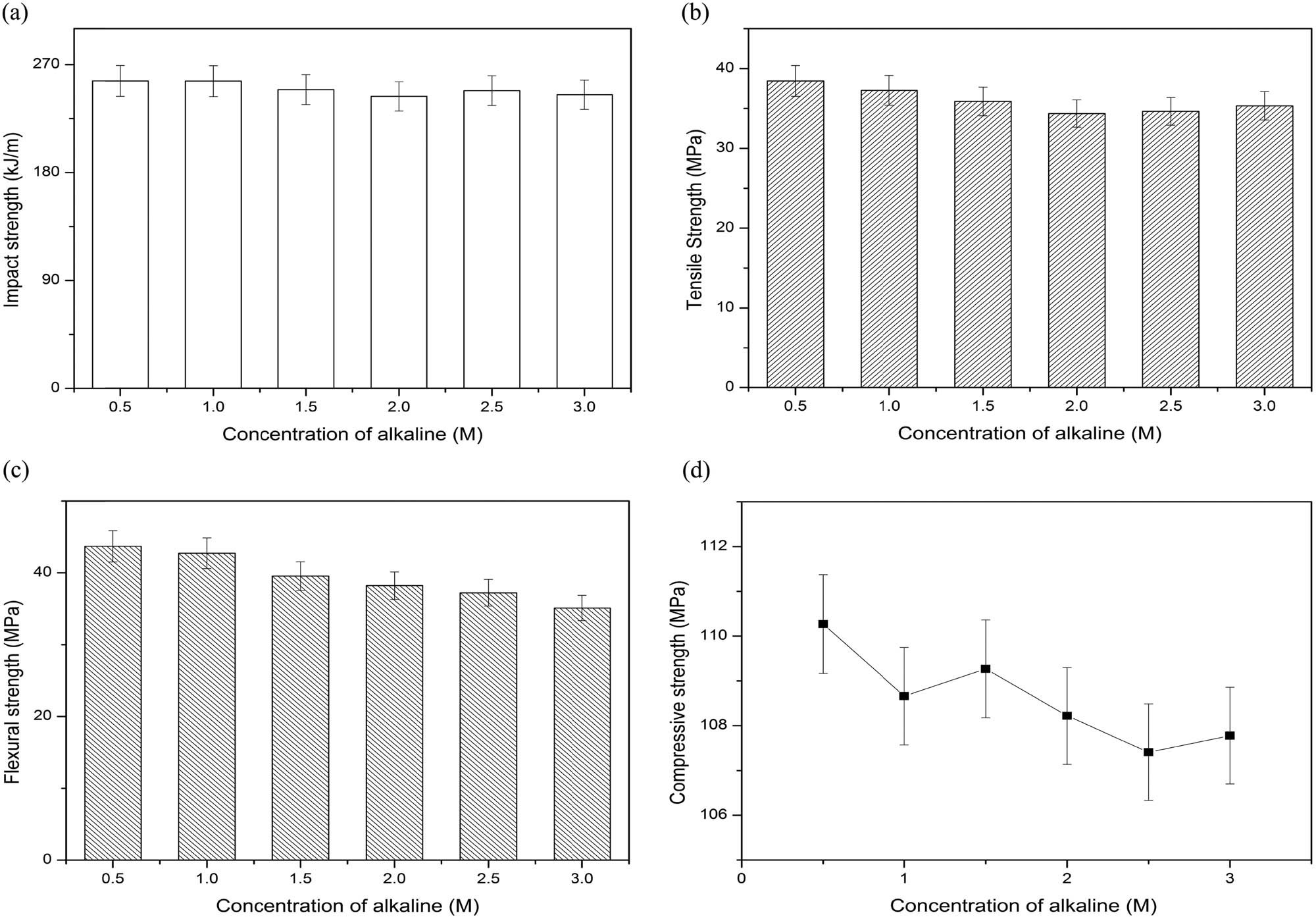

The mechanical properties of composite samples are shown in Table 1. It could be seen that the mechanical properties of the composites decreased with the increase in the concentration of NaOH. It could be due to that when fibers are treated in too high concentration of treatment substances, inevitable damage is caused to the fibers. Then, the mechanical properties are lower when fibers was mixed with ER which corresponds to Karthikeyan and Balamurugan [20] and Mouhoubi et al. [21]. Besides, according to Hamidon et al. [22], excessive delignification of natural fiber can result from a higher percentage of alkaline content, which weakens or destroys the fiber. Increase in the concentration of NaOH has also been observed to significantly reduce the tensile strength of the resulting composite.

Mechanical properties of ER and VF composite treated with NaOH of various concentrations (VFT)

| Sample | Impact strength (kJ/m2) | Tensile strength (MPa) | Bending strength (MPa) | Compressive strength (MPa) |

|---|---|---|---|---|

| VF + ER | 236.64 | 35.67 | 35.61 | 109.44 |

| 0.5 mol/L VFT+ER | 256.42 | 38.45 | 43.70 | 110.27 |

| 1 mol/L VFT+ER | 256.28 | 37.27 | 42.73 | 108.66 |

| 1.5 mol/L VFT+ER | 249.17 | 35.88 | 39.55 | 109.27 |

| 2 mol/L VFT+ER | 243.64 | 34.36 | 38.22 | 108.22 |

| 2.5 mol/L VFT+ER | 248.32 | 34.64 | 37.22 | 107.41 |

| 3 mol/L VFT+ER | 244.87 | 35.33 | 35.11 | 107.78 |

The results obtained exhibited that the maximum values of 256.42 kJ/m2, 38.45 MPa, 43.70 MPa, and 110.27 MPa for the impact, tensile, bending, and compressive strengths, respectively, were obtained at the concentration of 0.5 mol/L NaOH. Moreover, the mechanical properties of 3 mol/L+ER decreased significantly, even less than those of VF+ER, which caused the fiber surface to be destroyed by the surface treatment process.

However, increasing the concentration of NaOH had a greater effect on raising the overall mechanical properties than that of not adding NaOH, except in the 3 mol/L alkali-treated vetiver fibers (VFT) + ER condition. Increasing the surface area or roughness will improve the mechanical interaction of the fiber with the matrix. Then, the alkaline treatment’s exposure of the cellulose on the fiber surface increases the potential number of reaction sites. Therefore, the alkaline treatment directly affects the cellulosic fibrils, the extraction of lignin, and hemi cellulosic compounds, as well as the level of polymerization which is in agreement with that reported by Prince et al. [23].

Impact strengths of the composite samples, measured by Charpy impact test with cross head speed of 10 mm/min, are shown in Figure 2(a). We found that the impact strength of the samples ranged from 243.64 to 256.42 kJ/m2. From Figure 2(b), it could be seen that the tensile strength of the samples ranged between the values of 26.78 and 38.33 MPa. The maximum tensile strength occurred at the concentration of 0.5 mol/L of NaOH which agreed with that reported by Wong et al. [24] that an increase in alkaline concentration reduces the strain at failure and ductility of fiber. Figure 2(c) shows the results of the bending test by universal testing machine with cross head speed of 5 mm/min. The values of flexural strength ran between 35.11 and 43.70 MPa. Therefore, the compressive strength of the sample is 107.41–110.27 MPa.

Mechanical properties tested result of composite samples (a) impact strength, (b) tensile strength, (c) flexural strength, and (d) compressive strength.

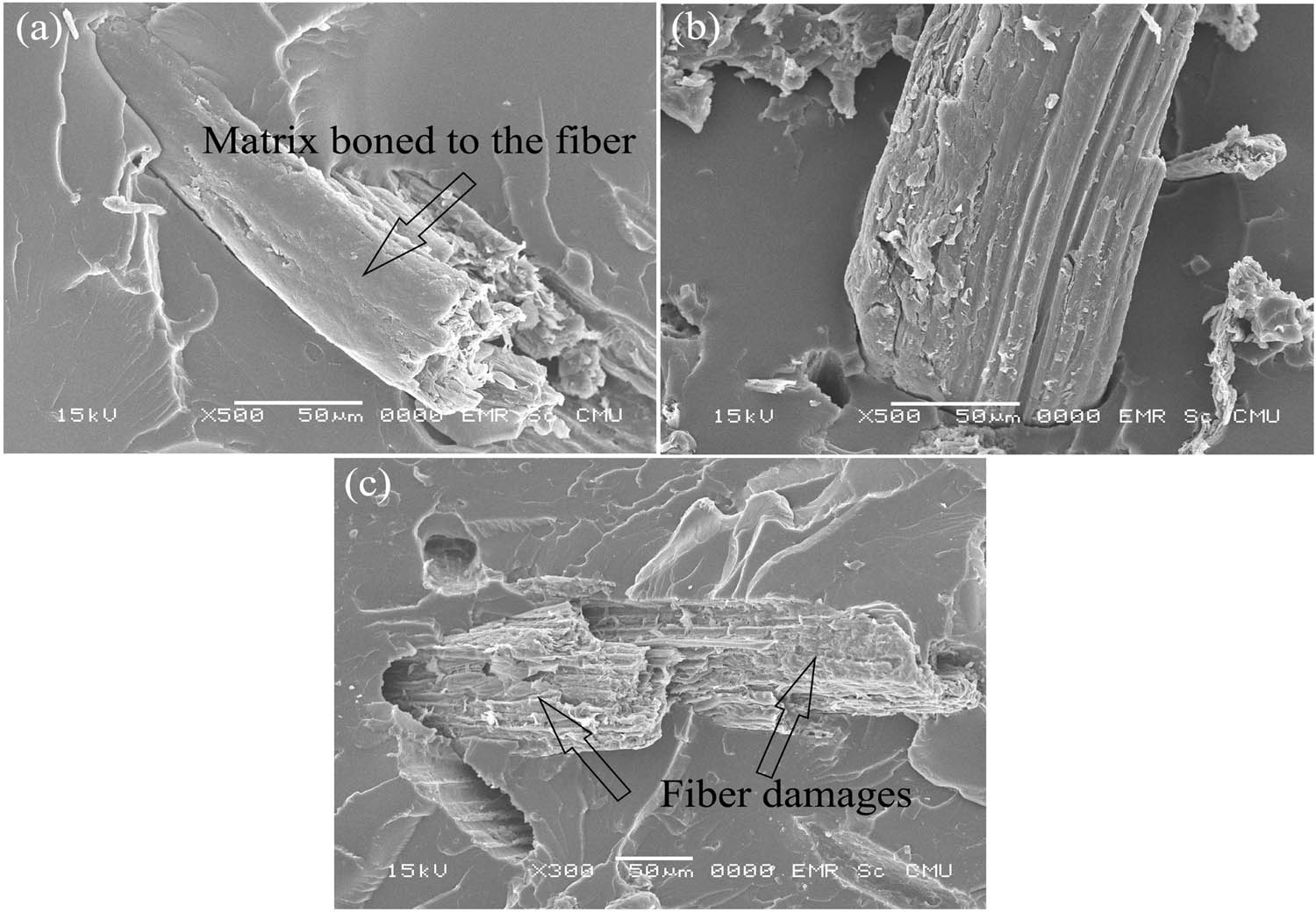

Finally, the morphology of the composite samples was studied employing the SEM method. The morphology of the best mechanical properties is presented in Figure 3(a). The surface of the fibers and the epoxy matrix are well matched. This makes the gap between the fiber and the matrix smaller. As a result, the mechanical properties are improved. Whereas Figure 3(b) shows the morphology of 1.5 mol/L VF/ER. The SEM image of the composites in Figure 3(c) shows the damage of VF of 3 mol/L VFT+ER. Due to the excessive concentration of NaOH, the inhomogeneous VFs damages result in weak fiber matrix adhesion between VFs and ER, which corresponds to the mechanical property results reported by Oushabi et al. [25].

SEM images of composite samples: (a) 0.5 mol/L VFT+ER, (b) 1.5 mol/L VFT+ER, and (c) 3 mol/L VFT+ER.

4 Conclusion

The alkaline-treated VFs and ER composites were fabricated using hand layup technique. The obtained composites showed a homogeneous distribution and adhesion between VF and ER. The maximum mechanical properties, i.e., the impact, tensile, compressive, and flexural strengths of the VF/ER composites were obtained when the VFs were alkali-treated in a 0.5 mol/L of NaOH solution for 4 h. At higher concentration of NaOH, the VFs were damaged and the mechanical strengths of the VF/ER composites decreased. However, the VFs have been treated. It still improves the mechanical properties of composite materials more than that of the untreated VFs. But it must be at the right level, which can be applied in other reinforcement materials.

Acknowledgements

The authors express their warm thanks to The Composites and Reinforced Nanocomposites Research Laboratory, Department of Physics and Materials Science, Faculty of Science, Chiang Mai University. The authors also wish to thank Center of Excellence in Materials Science and Technology, Chiang Mai University for financial support under the administration of Materials Science Research Center, Faculty of Science, Chiang Mai University. The authors also extend their thanks are to The Graduate School of Chiang Mai University.

-

Funding information: This research was supported by Chiang Mai University.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. IGH and JB designed the experiments and CC carried them out. HD developed the model code and performed the simulations. AA prepared the manuscript with contributions from all co-authors.

-

Conflict of interest: The authors declared no competing interests.

-

Data availability statement: Data sharing is not applicable to this article as no datasets were generated or analysed during the current study.

References

[1] Herrera-Franco PJ, Valadez-González A. Mechanical properties of continuous natural fibre-reinforced polymer composites. Compos - A: Appl Sci Manuf. 2004;35(3):339–45.10.1016/j.compositesa.2003.09.012Search in Google Scholar

[2] Gupta MK, Srivastava RK. Mechanical properties of hybrid fibers-reinforced polymer composite: A review. Polym Plast Technol Eng. 2016;55(6):626–42.10.1080/03602559.2015.1098694Search in Google Scholar

[3] Mohanty AK, Misra M, Drzal LT. Natural fibers, biopolymers, and biocomposites. 1st edn. Florida, Boca Raton: Taylor & Franics; 2005.10.1201/9780203508206Search in Google Scholar

[4] John MJ, Thomas S. Biofibres and biocomposites. Carbohydr Polym. 2008;71(3):343–64.10.1016/j.carbpol.2007.05.040Search in Google Scholar

[5] Landesmann A, Seruti CA, Batista EdM. Mechanical properties of glass fiber reinforced polymers members for structural applications. Mater Res. 2015;18(6):1372–83.10.1590/1516-1439.044615Search in Google Scholar

[6] Singla M, Chawla V. Mechanical properties of epoxy resin–fly ash composite. J Min Mater Char Eng. 2010;9(3):199–210.10.4236/jmmce.2010.93017Search in Google Scholar

[7] Sanjay MR, Arpitha GR, Yogesha B. Study on mechanical properties of natural-glass fibre reinforced polymer hybrid composites: A review. Mater Today: Proc. 2015;2(4–5):2959–67.10.1016/j.matpr.2015.07.264Search in Google Scholar

[8] Wambua P, Ivens J, Verpoest I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos Sci Technol. 2003;63(9):1259–64.10.1016/S0266-3538(03)00096-4Search in Google Scholar

[9] Belgacem MN, Gandini A. Monomers, polymers and composites from renewable resources. 1st edn. Netherlands, Amsterdam: Elsevier; 2008.10.1016/B978-0-08-045316-3.00001-6Search in Google Scholar

[10] Cruz J, Fangueiro R. Surface modification of natural fibers: A review. Procedia Eng. 2016;155:285–8.10.1016/j.proeng.2016.08.030Search in Google Scholar

[11] Pommet M, Juntaro J, Heng JYY, Mantalaris A, Lee AF, Wilson K, et al. Surface modification of natural fibers using bacteria: Depositing bacterial cellulose onto natural fibers to create hierarchical fiber reinforced nanocomposites. Biomacromolecules. 2008;9(6):1643–51.10.1021/bm800169gSearch in Google Scholar PubMed

[12] Li X, Tabil LG, Panigrahi S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J Polym Env. 2007;15:25–33.10.1007/s10924-006-0042-3Search in Google Scholar

[13] Lu N, Oza S, Tajabadi MG. Surface modification of natural fibers for reinforcement in polymeric composites. In: Thakur VK, Singha AS, editors. Surface modification of biopolymers. New Jersey: John Wiley & Sons, Inc; 2015. p. 224–37.10.1002/9781119044901.ch9Search in Google Scholar

[14] Lu N, Swan RH Jr, Ferguson I. Composition, structure, and mechanical properties of hemp fiber reinforced composite with recycled high-density polyethylene matrix. J Compos Mater. 2011;46(16):1915–24.10.1177/0021998311427778Search in Google Scholar

[15] Shahidi S, Wiener J, Ghoranneviss M. Surface modification methods for improving the dyeability of textile fabrics. In: Günay M, editors. Eco-friendly textile dyeing and finishing. London: IntechOpen Limited; 2013. p. 34–50.10.5772/53911Search in Google Scholar

[16] Arsyad M, Wardana ING, Pratikto, Irawan YS. The morphology of coconut fiber surface under chemical treatment. Rev Mater. 2015;20(1):169–77.10.1590/S1517-707620150001.0017Search in Google Scholar

[17] Gandini A, Belgacem MN. Modifying cellulose fiber surfaces in the manufacture of natural fiber composites. In: Zafeiropoulos N, editor. Interface engineering of natural fibre composites for maximum performance. Sawston: Woodhead Publishing; 2011. p. 3–42.10.1533/9780857092281.1.3Search in Google Scholar

[18] ASTM D638-10. Standard test method for tensile properties of plastics. ASTM International, West Conshohocken, PA; 2010.Search in Google Scholar

[19] ASTM D790-03. Standard test method for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. ASTM International, West Conshohocken, PA; 2003.Search in Google Scholar

[20] Karthikeyan A, Balamurugan K. Effect of alkali treatment and fiber length on impact behavior of coir fiber reinforced epoxy composites. J Sci Ind Res. 2012;71(9):627–31.Search in Google Scholar

[21] Mouhoubi S, Bourahli MEH, Osmani H, Abdeslam S. Effect of alkali treatment on alfa fibers behavior. J Nat Fibers. 2017;14(2):239–349.10.1080/15440478.2016.1193088Search in Google Scholar

[22] Hamidon MH, Sultan MTH, Ariffin AH, Shah AUM. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: a review. J Mater Res Technol. 2019;8(3):3327–37.10.1016/j.jmrt.2019.04.012Search in Google Scholar

[23] Prince M, Kumar AP, Mahesh E, Ragj GSU, Vinayagamoorthi MA, Sivaraman P, et al. Mechanical characterization of alkaline treated Ananus Comosus and Musa Sepientum fibers reinforced epoxy hybrid composites. Mater Today-Proc. 2022;64(4):2320–5.10.1016/j.matpr.2022.04.108Search in Google Scholar

[24] Wong KJ, Yousif BF, Low KO. The effects of alkali treatment on the interfacial adhesion of bamboo fibres. Proc Inst Mech Eng L: J Mater: Des Appl. 2010;224(3):139–48.10.1243/14644207JMDA304Search in Google Scholar

[25] Oushabi A, Sair S, Hassani Fo, Abboud Y, Tanane O, Bouari AE. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF-Polyurethane composite. S Afr J Chem Eng. 2017;23:116–23.10.1016/j.sajce.2017.04.005Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Evaluation of the mechanical and dynamic properties of scrimber wood produced from date palm fronds

- Performance of doubly reinforced concrete beams with GFRP bars

- Mechanical properties and microstructure of roller compacted concrete incorporating brick powder, glass powder, and steel slag

- Evaluating deformation in FRP boat: Effects of manufacturing parameters and working conditions

- Mechanical characteristics of structural concrete using building rubbles as recycled coarse aggregate

- Structural behavior of one-way slabs reinforced by a combination of GFRP and steel bars: An experimental and numerical investigation

- Effect of alkaline treatment on mechanical properties of composites between vetiver fibers and epoxy resin

- Development of a small-punch-fatigue test method to evaluate fatigue strength and fatigue crack propagation

- Parameter optimization of anisotropic polarization in magnetorheological elastomers for enhanced impact absorption capability using the Taguchi method

- Determination of soil–water characteristic curves by using a polymer tensiometer

- Optimization of mechanical characteristics of cement mortar incorporating hybrid nano-sustainable powders

- Energy performance of metallic tubular systems under reverse complex loading paths

- Enhancing the machining productivity in PMEDM for titanium alloy with low-frequency vibrations associated with the workpiece

- Long-term viscoelastic behavior and evolution of the Schapery model for mirror epoxy

- Laboratory experimental of ballast–bituminous–latex–roving (Ballbilar) layer for conventional rail track structure

- Eco-friendly mechanical performance of date palm Khestawi-type fiber-reinforced polypropylene composites

- Isothermal aging effect on SAC interconnects of various Ag contents: Nonlinear simulations

- Sustainable and environmentally friendly composites: Development of walnut shell powder-reinforced polypropylene composites for potential automotive applications

- Mechanical behavior of designed AH32 steel specimens under tensile loading at low temperatures: Strength and failure assessments based on experimentally verified FE modeling and analysis

- Review Article

- Review of modeling schemes and machine learning algorithms for fluid rheological behavior analysis

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part I

- Creep–fatigue damage assessment in high-temperature piping system under bending and torsional moments using wireless MEMS-type gyro sensor

- Multiaxial creep deformation investigation of miniature cruciform specimen for type 304 stainless steel at 923 K using non-contact displacement-measuring method

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part I

- Sustainable concrete production: Partial aggregate replacement with electric arc furnace slag

- Exploring the mechanical and thermal properties of rubber-based nanocomposite: A comprehensive review

- Experimental investigation of flexural strength and plane strain fracture toughness of carbon/silk fabric epoxy hybrid composites

- Functionally graded materials of SS316L and IN625 manufactured by direct metal deposition

- Experimental and numerical investigations on tensile properties of carbon fibre-reinforced plastic and self-reinforced polypropylene composites

- Influence of plasma nitriding on surface layer of M50NiL steel for bearing applications

Articles in the same Issue

- Research Articles

- Evaluation of the mechanical and dynamic properties of scrimber wood produced from date palm fronds

- Performance of doubly reinforced concrete beams with GFRP bars

- Mechanical properties and microstructure of roller compacted concrete incorporating brick powder, glass powder, and steel slag

- Evaluating deformation in FRP boat: Effects of manufacturing parameters and working conditions

- Mechanical characteristics of structural concrete using building rubbles as recycled coarse aggregate

- Structural behavior of one-way slabs reinforced by a combination of GFRP and steel bars: An experimental and numerical investigation

- Effect of alkaline treatment on mechanical properties of composites between vetiver fibers and epoxy resin

- Development of a small-punch-fatigue test method to evaluate fatigue strength and fatigue crack propagation

- Parameter optimization of anisotropic polarization in magnetorheological elastomers for enhanced impact absorption capability using the Taguchi method

- Determination of soil–water characteristic curves by using a polymer tensiometer

- Optimization of mechanical characteristics of cement mortar incorporating hybrid nano-sustainable powders

- Energy performance of metallic tubular systems under reverse complex loading paths

- Enhancing the machining productivity in PMEDM for titanium alloy with low-frequency vibrations associated with the workpiece

- Long-term viscoelastic behavior and evolution of the Schapery model for mirror epoxy

- Laboratory experimental of ballast–bituminous–latex–roving (Ballbilar) layer for conventional rail track structure

- Eco-friendly mechanical performance of date palm Khestawi-type fiber-reinforced polypropylene composites

- Isothermal aging effect on SAC interconnects of various Ag contents: Nonlinear simulations

- Sustainable and environmentally friendly composites: Development of walnut shell powder-reinforced polypropylene composites for potential automotive applications

- Mechanical behavior of designed AH32 steel specimens under tensile loading at low temperatures: Strength and failure assessments based on experimentally verified FE modeling and analysis

- Review Article

- Review of modeling schemes and machine learning algorithms for fluid rheological behavior analysis

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part I

- Creep–fatigue damage assessment in high-temperature piping system under bending and torsional moments using wireless MEMS-type gyro sensor

- Multiaxial creep deformation investigation of miniature cruciform specimen for type 304 stainless steel at 923 K using non-contact displacement-measuring method

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part I

- Sustainable concrete production: Partial aggregate replacement with electric arc furnace slag

- Exploring the mechanical and thermal properties of rubber-based nanocomposite: A comprehensive review

- Experimental investigation of flexural strength and plane strain fracture toughness of carbon/silk fabric epoxy hybrid composites

- Functionally graded materials of SS316L and IN625 manufactured by direct metal deposition

- Experimental and numerical investigations on tensile properties of carbon fibre-reinforced plastic and self-reinforced polypropylene composites

- Influence of plasma nitriding on surface layer of M50NiL steel for bearing applications