Abstract

The pursuit of sustainability in the construction industry has stimulated interest in seeking environmentally friendly alternatives to natural aggregates in concrete production. This study evaluates the behavior of concrete when electric arc furnace (EAF) slag is used as aggregates in its production. The primary research gap filled by this study is to deduce the blend of the fine and coarse EAF slag aggregates that would produce concrete of comparative strengths to concrete made with natural aggregates. Concrete mixtures were formulated using varied EAF slag content in the proportions of 0, 10, 15, 25, and 50%, respectively. The compressive strength values increased as the EAF slag content increased. However, this trend was not evident for the density and tensile strength values. The concrete mixture containing 25% EAF slag with 15% fine and 20% coarse EAF slag aggregates had the greatest density value of 2550.00 kg/m3 and the tensile strength value of 4.8 Pa respectively. This could be due to the distribution of the fine and coarse aggregate grains in the mixture. Since the percentage of fine and coarse aggregate grains were 10 and 15%, respectively, it was a close enough range for the fines to fill in the void spaces. This made the mixture more compact which resulted in a higher density and tensile strength values.

1 Introduction

Due to the long-standing reputation of harming the environment in the construction sector, in recent times, sustainable building practices have recently begun to be integrated into the operations. The sector has posed a major global challenge regarding sustainability in terms of its inability to meet the demand for natural resources in the concrete manufacturing industry. Concrete is a fundamental building material, such that it is the most consumed material of all types of infrastructure. Its main constituent is natural aggregates which are extracted from the environment contributing significantly to environmental degradation. The high demand for concrete suggests that sustainable solutions should be investigated to lessen its adverse impacts on the environment. Literature explained that one such approach would be to incorporate industrial waste materials into concrete mixtures [1]. Thus, the use of industrial by-products as replacement aggregates for natural aggregates in concrete has become an appealing sustainable approach.

Electric arc furnace (EAF) steel slag is a by-product of the steel manufacturing process. It is non-metallic and mainly consists of oxides and silicates formed during the refining process of molten steel. Despite the aforementioned minerals, it possesses other components that can be harmful to the environment when carelessly disposed [2]. The annual global production of steel for 2022 was 1.96 billion metric tons, and the projected amount for 2023 is expected to be higher [3,4]. This suggests that large volumes of steel slag are also produced, which are either inefficiently stored in steel plants or disposed of into the environment.

Researchers in [5,6] have conducted wide research on the methods of incorporating industrial by-products into concrete production. However, the search for the most suitable incorporation methods of EAF steel slag as aggregates in concrete remains ongoing. The problem, however, is the lack of studies that added varied percentages of a blend of both fine and coarse EAF steel slag aggregate and studies that properly evaluated the effects of EAF steel slag aggregate size on the mechanical properties of concrete. Furthermore, generalized findings of EAF steel slag impacts on concrete properties cannot be made since the characteristics of steel slag are dependent on numerous external factors.

This study assesses the effect of the partial replacement of natural aggregates with EAF steel slag aggregates on the mechanical properties of concrete. The mechanical properties examined were compressive strength and tensile strength. Properties of fresh concrete such as workability and fresh density were also evaluated. The findings are expected to inform researchers and practitioners of the impacts of a blend of fine and coarse aggregate on the mechanical properties of concrete. These findings are expected to provide insights to effectively decrease the consumption of natural resources, the emissions generated from mining activities, and the amount of EAF steel slag being improperly discarded. If these societal impacts are improved, the repurposing of the contemporary usage of steel slag will promote circularity in the nation’s economy and promote the achievement of environmental, economic, and social pillars of sustainability.

The primary purpose of this study is to provide insights into the strengths of concrete that are obtained when using varied proportions of fine and coarse EAF slag aggregates.

The objectives of this study are to:

Compare the physical properties of concrete (water absorption, specific gravity) made of the EAF slag to that made of natural aggregates.

Deduce the ratio of the fine and coarse EAF aggregate that would give the highest values of the tensile and compressive strengths of the concrete.

2 Literature review

As the building industry seeks to become more environmentally friendly, the use of sustainable alternatives for construction materials has become a popular green practice, specifically natural aggregate replacement in concrete with EAF steel slag aggregates. Concrete is a composite material consisting of cement, water, fine aggregates, and coarse aggregate mixture that is well-combined and appropriately cured. The studies [7,8] claim that over 60% of the volume of concrete is occupied by fine and coarse natural aggregates that are typically extracted from riverbeds and quarries, respectively. An overabundance in the extraction of sand can lead to riverbank erosion and flooding due to uncontrolled mining.

Gencel et al. [1] investigated the demand for concrete and reported that stopping concrete production is impossible. This was supported by Habert et al. [9]. The authors explained that the anticipated global population growth, from the present day to the year 2050, will cause a surge in the demand for infrastructure and hence, the demand for concrete as the main building material. The accelerating use of concrete directly implies an increase in the demand for natural aggregates, that countries are expected to fall short of meeting. This unattainable demand creates an issue that highlights the significance of investigating the suitability of recycling industrial waste materials as the aggregate component in concrete.

2.1 Effects of EAF steel slag on the properties of fresh concrete

Certain aggregate properties of the EAF steel slag should also be comparable to those of natural aggregates used in concrete. Additional research examined the water absorption of EAF steel slag aggregate where it was found to have less than a 5% greater water absorption [10]. In Santamaría et al. [11], the authors evaluated the hardened densities of each mixture as another parameter to consider and explained the importance of ensuring correlation to their fresh densities.

In a study conducted by Maharaj et al. [12]; the fresh densities of concrete with 30–100% replacement of coarse aggregate with EAF steel slag were 2,434–2,651 kg/m3, both surpassing the control sample’s fresh density of 2,355 kg/m3. Additionally, it was found that slump height decreased with the increasing content of slag. Similarly, studies [13,14] found that increasing EAF steel slag content when replacing fine aggregate decreased the workability, especially after 50% replacement. The writers of both [13,14] recommended the use of admixtures to decrease the negative effect. These fresh concrete properties are the first steps to any test involving the formation of a concrete mixture.

2.2 Methods of incorporating EAF steel slag into concrete

There are different techniques for incorporating EAF steel slag into concrete as shown by previous research which include the following: partial or total replacement of fine natural aggregates, coarse natural aggregates, specified sizes of coarse aggregates, or both fine and coarse aggregates. Qasrawi et al. [13] investigated replacing fine aggregate with EAF steel slag in concrete with design strengths of 25–45 MPa, where they found that the mechanical properties had the best performance at a 50% replacement. Olonade et al. [15] examined the partial and total replacement of fine aggregate with EAF steel slag for 20 MPa strength concrete. It was found that 50% replacement was optimum and had similar findings on the workability. However, the studies [12,14] conducted investigations where they found 20 and 30 MPa strength concrete, respectively. They both found that the optimum replacement ratio was 30% after replacing fines with EAF steel slag in 10% increments from 0 to 50%. Furthermore, Borole et al. [16] also replaced fines for 30 MPa strength concrete and closed by stating their optimum replacement ratio was 25%. Despite producing the same concrete grade, the optimum replacement ratios of slag varied. This was due to the inconsistent characteristics of EAF steel slag, justifying the need to perform these tests locally.

To continue the discussion of implementation strategies, there is literature that explored coarse aggregate replacement with EAF steel slag. Similar to the studies that explored fine aggregate substitution, a study by Maharaj et al. [12] aimed to identify an optimum replacement ratio for the fresh and hardened properties of concrete. The authors found that there was not a specific ratio that allowed all properties to produce optimal results. Diotti et al. [17] realized this and used a 30% replacement ratio to obtain satisfactory physical and mechanical performances of their concrete. Moreover, the engineering properties of concrete were found to benefit from total replacement by EAF steel slag. Literature [18] reported this, as did Maharaj et al. [12] later on. The former authors though, claimed that establishing a controlled concrete grade for analysis would permit more precise conclusions. Despite the accurate results obtained from designing a specific concrete grade, the researcher focused more on the change in strength than on aiming for a desired value. Instead, a standard mix design was chosen based on the available resources.

The final incorporation method examined by existing literature involved replacing portions of both fine and coarse natural aggregate with slag. In [19], it was deduced that the mechanical performance of concrete was commendable for the partial substitution of both types of natural aggregates with EAF slag. Other literature followed with a similar study, examining the properties of concrete when its fine aggregate, coarse aggregate, and total aggregate, are replaced by EAF slag. They determined that it would be worthwhile to replace either fine or coarse aggregate with slag, but replacing both causes detrimental effects on concrete strength [20]. Desirable conclusions may result from a study that incorporates partial replacement of both fine and coarse natural aggregate.

2.3 Effects of EAF steel slag on the mechanical properties of hardened concrete

As a building material, the mechanical properties of concrete must meet specified requirements since these properties are what influence the durability and structural integrity of any structure made from it. This study investigates the plausibility of altering the composition of concrete mixtures with a new material as aggregate. Thus, a thorough evaluation of the effects of this substitute material on the engineering characteristics of concrete is critical. The mechanical properties emphasized are compressive strength and tensile strength. A comprehensive analysis of literature discussing the results of EAF steel slag concrete properties follows.

Compressive and tensile strength tests are not optional when assessing the mechanical properties of concrete, therefore they were evaluated in all pertinent sources. In Qasrawi et al. [13], it was observed that depending on the replacement ratio and concrete grade, incorporating EAF slag as fine aggregates can cause a 1.1–1.3 times improvement in 28-day compressive strength, and a 1.4–2.4 times improvement in 28-day tensile strength in comparison with traditional concrete. Research papers [7,14–16] conducted subsequent fine aggregate replacement studies which yielded comparable findings to the increase in strengths with similar reasoning. In addition, marginal improvements in compressive strength were found more so than in tensile strength in studies by the authors of [12,17] with incremental coarse aggregate replacement. These outcomes imply that replacement ratios containing a blend of both fine and coarse aggregate can be an effective replacement method, and that there is an optimum coarse aggregate size rather than a relationship between aggregate size and mechanical properties.

2.4 Concrete mix design optimization to include EAF steel slag

The emphasis of this study is to produce an advanced form of concrete, so it is critical to establish the necessary parameters to obtain its desired characteristics. One such parameter is the gradation of aggregate sizes. The writers of Qasrawi et al. [13] outlined the necessity of grading aggregates for concrete production to obtain desirable characteristics of the concrete, such as workability and mechanical strength.

Authors from [21,22] found that larger aggregate sizes resulted in stiffer and more unworkable concrete mixtures. Further, studies have shown that an irregular distribution of coarse aggregates in concrete mixtures can significantly impact its compressive strength. The researchers in [23] tested and compared the compressive strengths of concrete mixtures made with 10 and 20 mm coarse aggregates. They found that the larger aggregate size had a 45.7% greater compressive strength. A similar comparative experiment was conducted in [24] where it was concluded that compressive strength increases with increasing coarse aggregate size from 6 to 20 mm but drops with 25 mm particles. This showed that while an excess of coarse aggregate can increase strength, a lack of the same can produce concrete that displays weaker strengths. The aim of this paper is to examine the effects of concrete strength with the incorporation of slag aggregates into the mixture. Thus, aggregate grading must be done to eliminate other factors affecting concrete mixture properties and hardened concrete strength.

In addition, the water to cement (w/c) ratio is another important parameter for mix design. Researchers investigated the compressive and tensile strengths of EAF steel slag aggregate concrete produced in Trinidad [12]. The water to cement ratios used were 0.4, 0.45, and 0.5 and discovered that the concrete with a w/c ratio of 0.4 had the best performance in the compressive strength test, with a value of 80.5 MPa. This research project did not involve assessing the effect of the w/c ratio on the mechanical properties of EAF steel slag concrete but used steel slag from similar sources. Thus, a w/c ratio of 0.4 was considered.

2.5 Identification of gaps and future research

The aforementioned discussion of EAF steel slag explained that its physical and chemical properties depended on the raw material used to produce the steel. The diverse locations of the studies, as well as the vast mix design options for concrete production, meant an exact optimum ratio could not be decided. It also meant that the specific steel-making material and concrete grade influences the relationship between replacement ratios and their effect on the mechanical properties. Furthermore, EAF steel slag is known to be susceptible to physical and chemical changes when exposed to different environmental conditions. Due to the storing conditions being unknown, it was also impossible to know the exact influence that the EAF slag would have had on the properties of the concrete. Proper evaluation of these effects can be done if the EAF slag produced from the same plant is used. Generalized conclusions for each grade can only be drawn if the EAF steel slag used complies with some international standards for manufacturing and storing. The insufficiency of the local steel plant, Arcelor Mittal Company, to provide such information posed limitations in this dissertation. It is also noted that this company has not been in operation for some years and any existing EAF steel slag stored was expected to be in unattended and unmaintained conditions.

Consequently, to incorporate EAF steel slag into concrete, the articles reviewed focused on the partial replacement of fine aggregates, or coarse aggregates. The few studies that replaced both aggregate types did it in individual mixtures, despite there being countless existing literature supporting that method. This research perceives the benefits of replacing both aggregate types to indicate that replacing a blend of both would also produce concrete with satisfactory mechanical performance. For example, EAF steel slag can be added in volumes of 15, 30, 50, and 100%, with each percentage consisting of a specified amount of fine and coarse aggregate.

3 Materials and methods

3.1 Materials

The materials used in the concrete mixtures were blended cement, water, natural aggregates, and EAF steel slag used as both fine and coarse aggregates, which were all locally sourced. The blended cement used was from Trinidad Cement Limited. The natural coarse and fine aggregates used were quartzite obtained from the quarry in Valencia, Trinidad, and the EAF slag was acquired from stockpiles at Arcelor Mittal, in Point Lisas, Trinidad. The EAF steel slag was used as both fine and coarse aggregates.

3.2 Specimen preparation procedure

3.2.1 Sieve analysis of natural aggregate and EAF steel slag aggregate

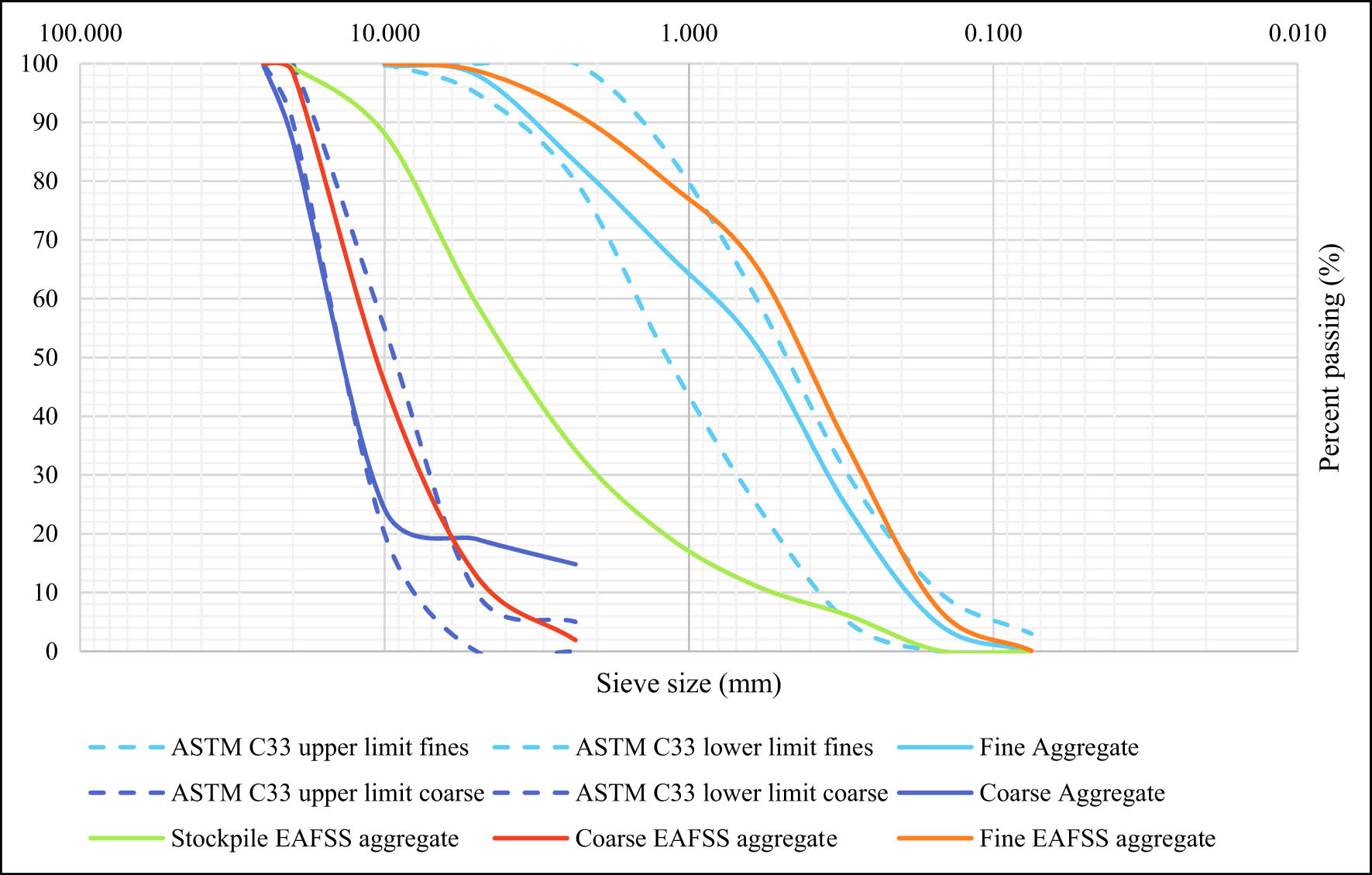

The natural coarse and fine aggregates were graded according to the ASTM C33 standard to ensure a suitable size for concrete production. The findings from the sieve analysis conducted on the fine and coarse slag aggregates are illustrated in Tables 1 and 2 respectively. Figure 1 illustrates the gradation curves of the aggregates.

Particle size distribution for fine EAF slag aggregate

| Sieve size (mm) | Individual fine NA weight retained (g) | Percentage of fine NA weight retained (%) | Required mass of EAF slag from 13 kg (kg) |

|---|---|---|---|

| 10 | 6 | 0.30 | 0.04 |

| 5 | 31 | 1.55 | 0.20 |

| 2.36 | 296 | 14.80 | 1.92 |

| 1.18 | 310 | 15.50 | 2.02 |

| 0.6 | 317 | 15.85 | 2.06 |

| 0.3 | 553 | 27.65 | 3.59 |

| 0.15 | 397 | 19.85 | 2.58 |

| 0.075 | 89 | 4.45 | 0.58 |

| TOTAL | 1,999 | 99.95 | 12.99 |

Particle size distribution for coarse EAF slag aggregate

| Sieve size (mm) | Individual coarse NA weight retained (g) | Percentage of coarse NA weight retained (%) | Required mass of EAF from 20 kg (kg) |

|---|---|---|---|

| 25 | 0 | 0.00 | 0.00 |

| 20 | 266 | 13.30 | 2.66 |

| 10 | 1,190 | 59.50 | 11.90 |

| 5 | 163 | 8.15 | 1.63 |

| 2.36 | 85 | 4.25 | 0.85 |

| PAN | 296 | 14.80 | 2.96 |

| TOTAL | 2,000 | 100 | 20.00 |

Grading of natural and EAF slag aggregates.

Figure 1 represents the grading of the fine and coarse natural aggregates and fine, coarse, and stockpile steel slag aggregates with reference to the upper and lower limits as defined by the ASTM C33 standards. The fine natural aggregates met the grading requirements since it fell within the range of the upper and lower limits. However, the coarse natural aggregates fell slightly out of the boundary for the 10 and 5 mm sieves, but the grading curve was still deemed acceptable.

The grading curve of the slag aggregates directly from the stockpile fell between the upper coarse limit and the lower fine limit. It showed that 59.2% of the stockpile aggregate was 5 mm, so the stockpile slag had more fine than coarse aggregates. It was therefore separated into the relevant particle sizes and graded as coarse and fine aggregates accordingly.

Grading the steel slag aggregate was recommended by Pellegrino and Gaddo [19], where the writers explained the importance of aggregate grading to produce desirable workability and mechanical properties. The grading curves of the fine and coarse slag aggregates can also be seen in Figure 1 both falling very closely within their respective upper and lower limits.

3.3 Specific gravity, particle water absorption, and aggregate density of natural aggregate and EAF slag aggregate

Specific gravity, particle water absorption, and aggregate density tests were performed on the fine and coarse natural and slag aggregates. These tests were conducted in accordance with the ASTM C127-15 standards. The aggregate impact value (AIV) test was performed in accordance with ASTM D5874 testing procedure.

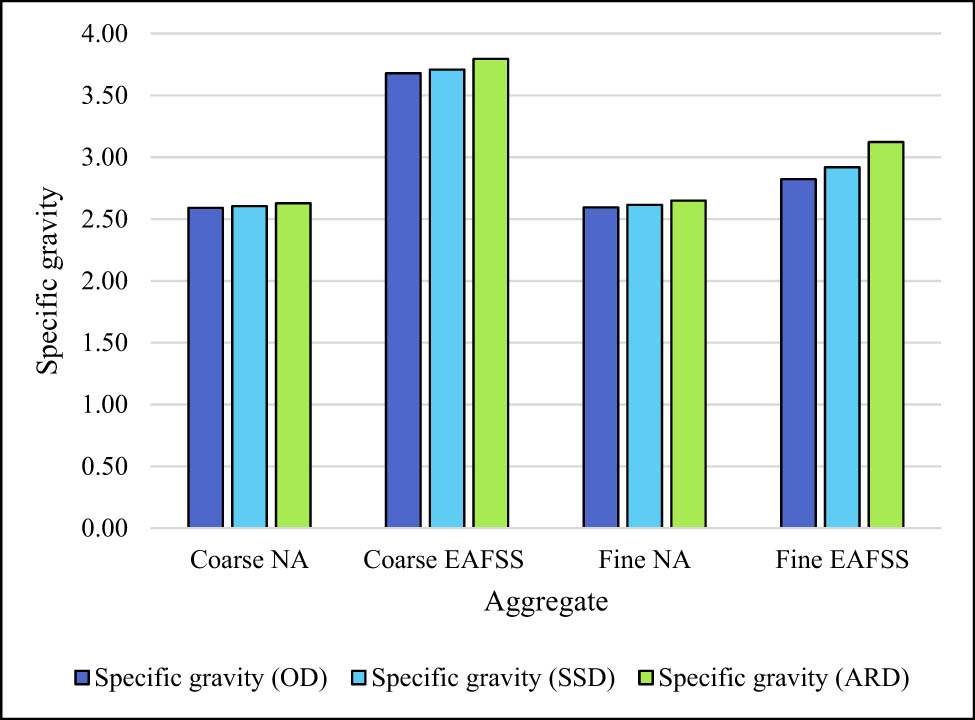

3.3.1 Specific gravity

Table 3 and Figure 2 illustrate the specific gravity values of the natural aggregates and the EAF slag aggregates. According to Table 3 and Figure 2, the specific gravity values of the slag aggregates are greater than that of the natural aggregates for both coarse and fine. The oven dried (OD), saturated surface dried (SSD), and apparent specific gravity (ARD) of the slag aggregates were overall greater than that of the natural aggregates. These results match the trends of the values obtained by testing from Maharaj et al. [12]. It can be inferred from these findings that the slag aggregates are stronger than the natural aggregates and should produce a higher-strength concrete.

Specific gravity of natural and EAF slag aggregates

| Aggregate property | Coarse natural aggregate | Coarse EAF slag | Fine natural aggregates | Fine EAF slag aggregates |

|---|---|---|---|---|

| Specific gravity (OD) | 2.59 | 3.68 | 2.59 | 2.82 |

| Specific gravity (SSD) | 2.60 | 3.71 | 2.62 | 2.92 |

| Specific gravity (ARD) | 2.63 | 3.80 | 2.65 | 3.12 |

Specific gravity of natural and EAFSS aggregates.

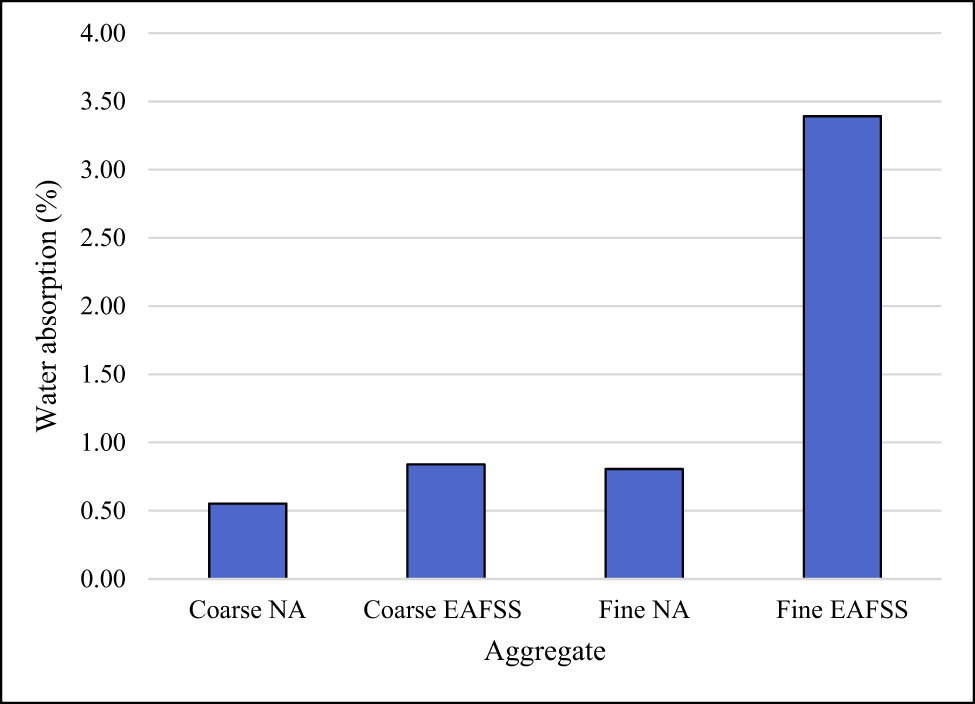

3.3.2 Water absorption

Table 4 and Figure 3 display the water absorption of each aggregate type and material, where the fine slag aggregates are shown to have the highest water absorption of 3.39%, which is 4.2 times greater than the fine natural aggregates. The coarse slag aggregates had a 1.15 times higher water absorption than coarse natural aggregates. Research in San-José et al. [10] found that the water absorption of slag aggregates was greater than that of natural aggregates but by less than 5%.

Water absorption of natural and EAF slag aggregates

| Aggregate property | Coarse NA | Coarse EAFSS | Fine NA | Fine EAFSS |

|---|---|---|---|---|

| Water absorption (%) | 0.55 | 0.84 | 0.81 | 3.39 |

Water absorption of natural and EAFSS aggregates.

The water absorption of aggregate depends on its chemical makeup. Yildirim and Prezzi proposed that the chemical composition of steel slag aggregates depends on the raw materials used to make the steel that it is made from, which can differ for every country and every steel plant [21]. Thus, the difference in results is likely due to the different chemical properties of the slag aggregate used by the authors and that which was sourced locally. This idea was supported by the findings of Maharaj et al. [12] since the steel slag utilized in the research was sourced locally and had a 4.5 times greater water absorption than the natural aggregates.

The steel slag aggregates have an overall higher water absorption than the natural aggregates; however, this implies that these aggregates are able to remove the water in the concrete mixture needed for proper hydration of the cement. The water-to-cement ratio of concrete does not account for any water that is absorbed by aggregates; it is only enough for proper hydration of the cement matrix. Therefore, it can be deduced that increasing steel slag aggregate content may eventually cause the strength of the concrete to decrease.

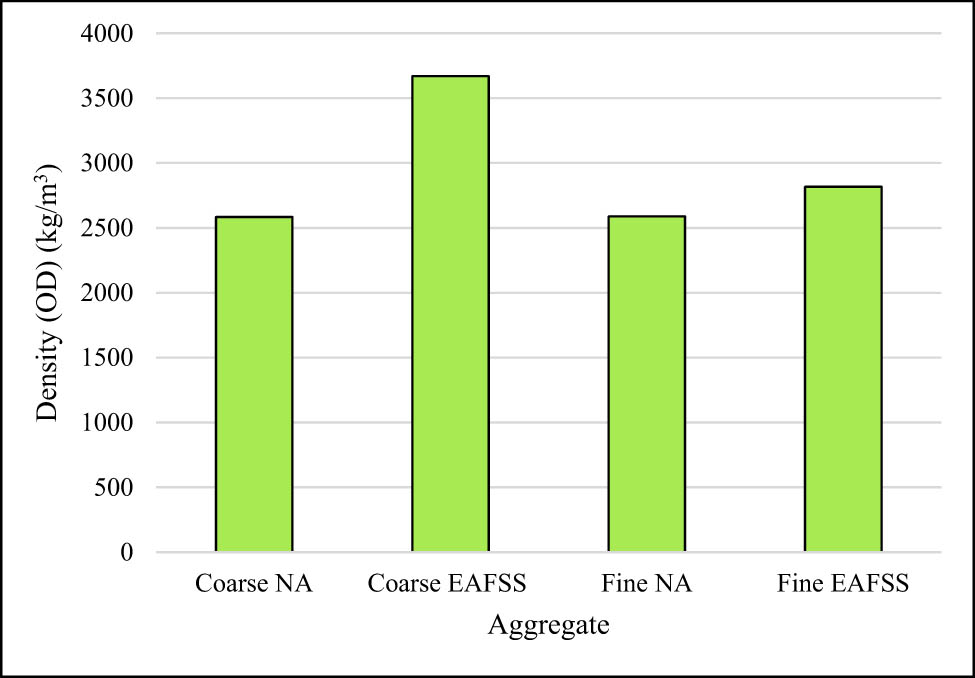

3.3.3 Aggregate density

Table 5 and Figure 4 show the aggregate densities of each type and classification of aggregate used in the experiment. The slag aggregates are shown to have an overall higher density than the natural aggregates. This suggests that it would require a smaller amount of the steel slag aggregate to fill a given volume than it would for natural aggregates.

Aggregate density of natural and EAFSS aggregates

| Aggregate property | Coarse NA | Coarse EAFSS | Fine NA | Fine EAFSS |

|---|---|---|---|---|

| Density (OD) (kg/m3) | 2,583 | 3,670 | 2,588 | 2,816 |

Aggregate density of natural and EAFSS aggregates.

The higher density of the steel slag aggregates infers that it is stronger than the natural aggregates and could create stronger concrete. From this, it can be deduced that increasing the amount of steel slag aggregate could increase the strength of the concrete specimens.

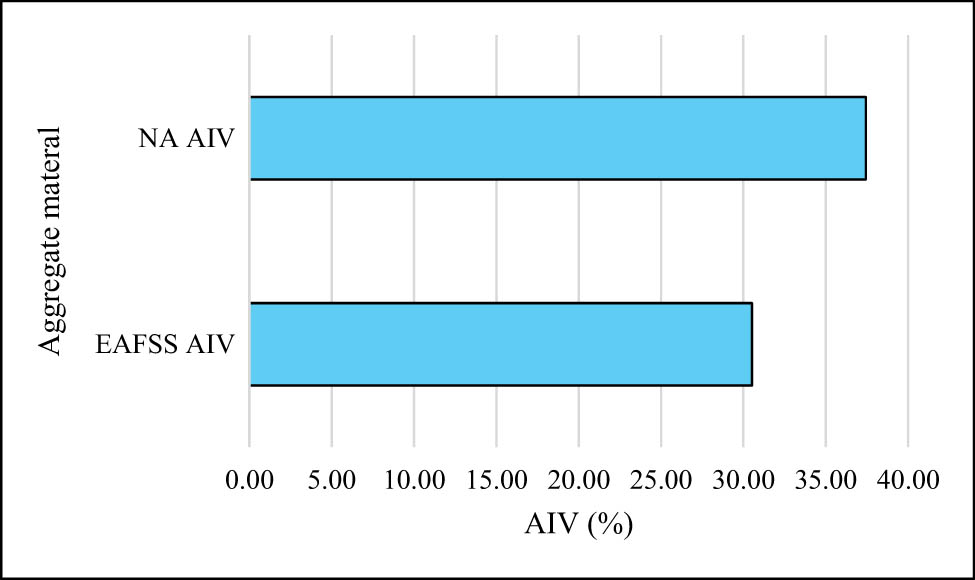

3.3.4 AIV

Table 6 and Figure 5 illustrate that steel slag aggregates have a lower AIV value than natural aggregates, with values of 30.52 and 37.44%, respectively. A lower value means that a smaller proportion of the steel slag aggregates was fractured during the test, so it is stronger than the natural aggregate. From this, it can be deduced that the slag aggregates could produce stronger concrete specimens than natural aggregate.

Aggregate impact test

| 3/8″ EAFSS aggregates | 3/8″ NA | ||||

|---|---|---|---|---|---|

| Mass | Test 1 | Test 2 | Mass | Test 1 | Test 2 |

| Initial mass (g) | 332.0 | 383.0 | Initial mass (g) | 348.0 | 332.0 |

| Retained mass (g) | 230.5 | 262.0 | Retained mass (g) | 217.5 | 204.0 |

| Mass passed (g) | 99.5 | 119.0 | Mass passed (g) | 128.5 | 126.0 |

| AIV (%) | 29.97 | 31.07 | AIV (%) | 36.93 | 37.95 |

| Average AIV (%) | 30.52 | Average AIV (%) | 37.44 | ||

AIVs for each aggregate material.

3.4 Mix design of concrete

Table 7 shows the proportions of the fine and coarse natural and slag aggregates incorporated into each concrete mixture.

Proportions of the fine to coarse aggregate ratio

| Fine natural aggregates (%) | Coarse natural aggregates (%) | Total natural aggregate content (%) | Fine EAF slag content (%) | Coarse EAF slag content (%) | Total EAF slag aggregate (%) |

|---|---|---|---|---|---|

| 40 | 60 | 100 | 0 | 0 | 0 |

| 45 | 45 | 90 | 10 | 0 | 10 |

| 50 | 35 | 85 | 15 | 0 | 15 |

| 30 | 45 | 75 | 10 | 15 | 25 |

| 20 | 30 | 50 | 20 | 30 | 50 |

For Table 7, the following ratios were used:

Fine to coarse aggregate: 0.4/0.6,

Aggregate-to-cement ratio: 3.5, and

Water-to-cement ratio: 0.4.

Each mixture was to produce six concrete specimens, three cubes (100 mm × 100 mm × 100 mm), and three cylinders (100 mm diameter × 203.2 mm height). This mix design procedure was used, rather than designing a specific grade of concrete since the aim of this project was to examine the variation of concrete strength with increasing the slag aggregate content.

3.4.1 Casting of concrete samples

Prior to mixing and casting the test specimens, the cubical and cylindrical concrete molds were cleaned, and lubricated with oil. The coarse aggregates, cement, and fine aggregates were weighed and added to the mixing drum to ensure the proper incorporation of the constituents into the mixture.

The drum was allowed to mix the concrete mixture for 1 min before stopping. Prior to placing the mixture into the molds, a slump test following ASTM C143 was conducted to test the workability.

A density bucket was also filled in a similar manner to molds. The bucket was used to determine the fresh densities of the mixtures according to ASTM C138. The filled molds were placed in a curing room and left to set and harden for 24 h.

3.5 Testing of fresh properties of concrete

3.5.1 Workability

The results of the slump test illustrated in Table 8 showed that the 100% natural aggregate mixture had a 0.00 mm slump height, which was further depicted in Figure 6. The slump height remained similar to the 25 and 50% slag aggregate mixtures.

Slump height of each concrete mixture

| Concrete mix (percentage of EAF slag) (%) | Slump height (cm) |

|---|---|

| 0 | 4.2 |

| 10 | 0.5 |

| 15 | 0.5 |

| 25 | 0.0 |

| 50 | 0.0 |

Slump height of mixture containing 0% EAF slag.

The recorded data challenge the expected decrease in the workability with increasing slag content [14,20]. However, while working with the mixtures during the experiment, the mixtures were observed to become stiffer and more unworkable with increasing amounts of slag aggregate.

A slump measuring 0.00 mm in height indicates maximum stiffness, so any increase in the stiffness of the mixture caused by adding slag to the mixtures would not have been reflected by the slump height. Thus, based on this theory and the visual observations, it can be deduced that the slag aggregate did, in fact, decrease the workability of the mixtures. This deduction is further supported by the water absorption result since the higher water absorption of the steel slag aggregates than the natural aggregates also suggests that the workability should have decreased, once the water-to-cement ratio remained the same.

4 Results and discussion

Using the varied proportions of the fine and coarse aggregates, density, compressive, and tensile strength tests were conducted on the cubical and cylindrical specimens, respectively, after 28 days of curing. The compressive test followed the ASTM C39 standard, and the tensile test followed the ASTM C496 standard (split tensile strength test). The appearance of each of the specimens after curing can be seen in Figure 7.

Hardened cubical and cylindrical specimens after 28 days of curing.

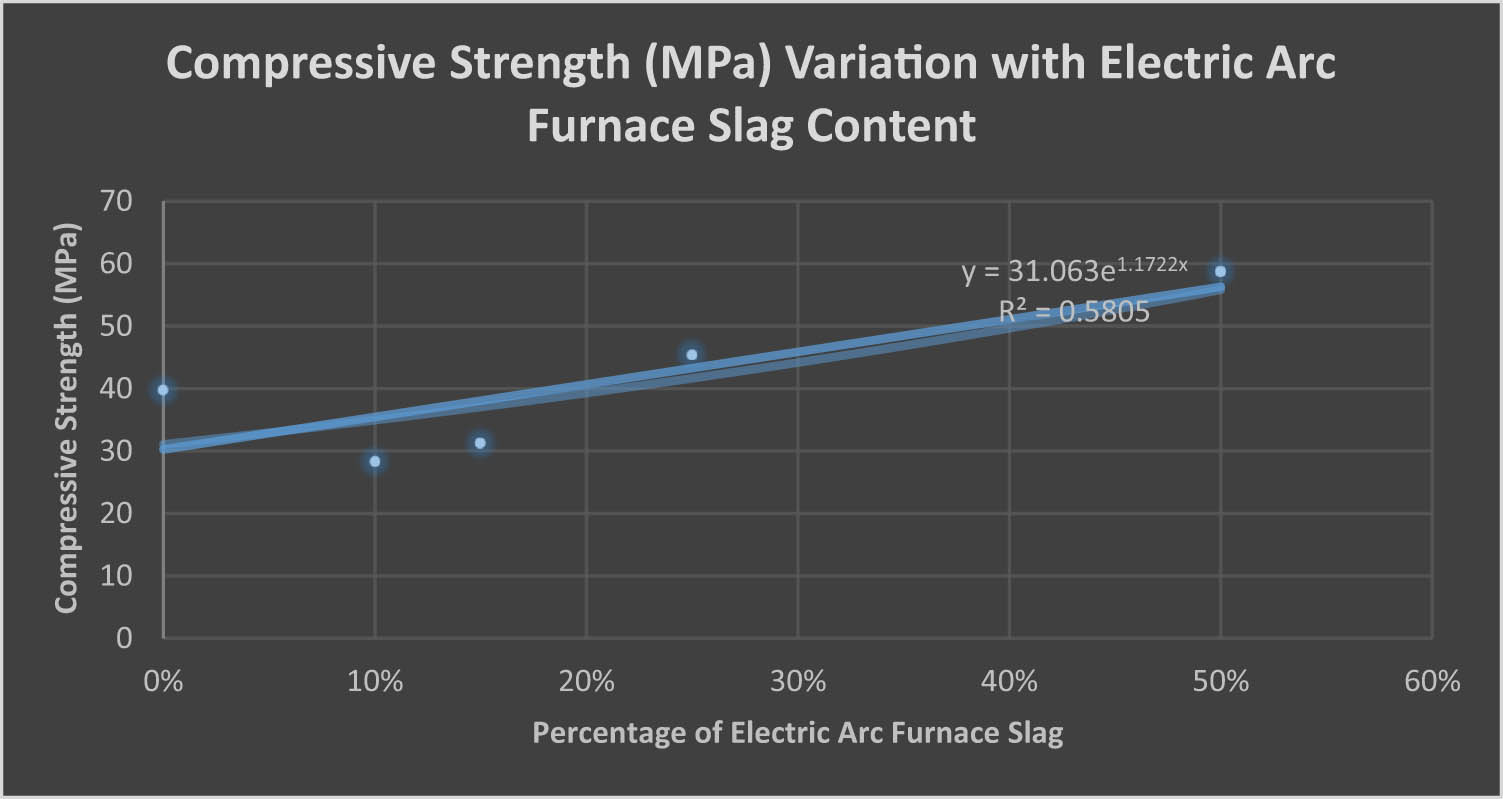

4.1 Compressive strength

Table 9 and Figure 8 display the effects of increasing slag aggregate content on the compressive strength of concrete. The graph shows an increase in strength from 0 to 25% slag content and then a drastic decrease from 25 to 50% slag content. The 25% slag aggregate mixture had a 1.15 times improvement in the 28-day compressive strength than the 100% natural aggregate mixture.

Hardened concrete density, compressive strength (MPa), and tensile strength values using varied EAF slag content

| Concrete mix (percentage of EAF slag) (%) | Hardened concrete density (kg/m3) | Compressive strength (MPa) | Tensile strength (MPa) |

|---|---|---|---|

| 0 | 2466.33 | 39.70 | 3.4 |

| 10 | 2499.26 | 28.29 | 2.9 |

| 15 | 2466.80 | 31.20 | 2.3 |

| 25 | 2550.00 | 45.40 | 4.8 |

| 50 | 2400.00 | 58.70 | 1.1 |

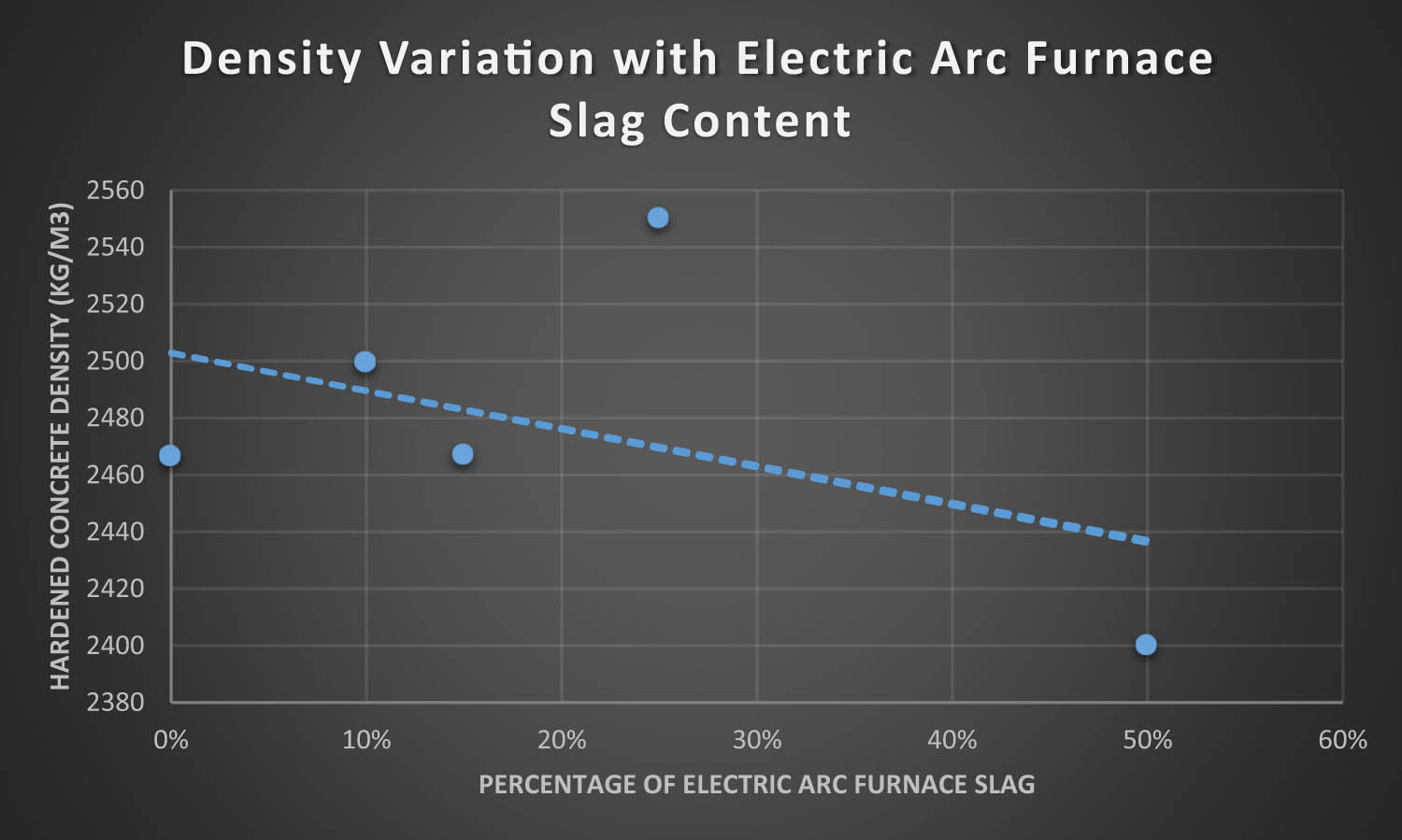

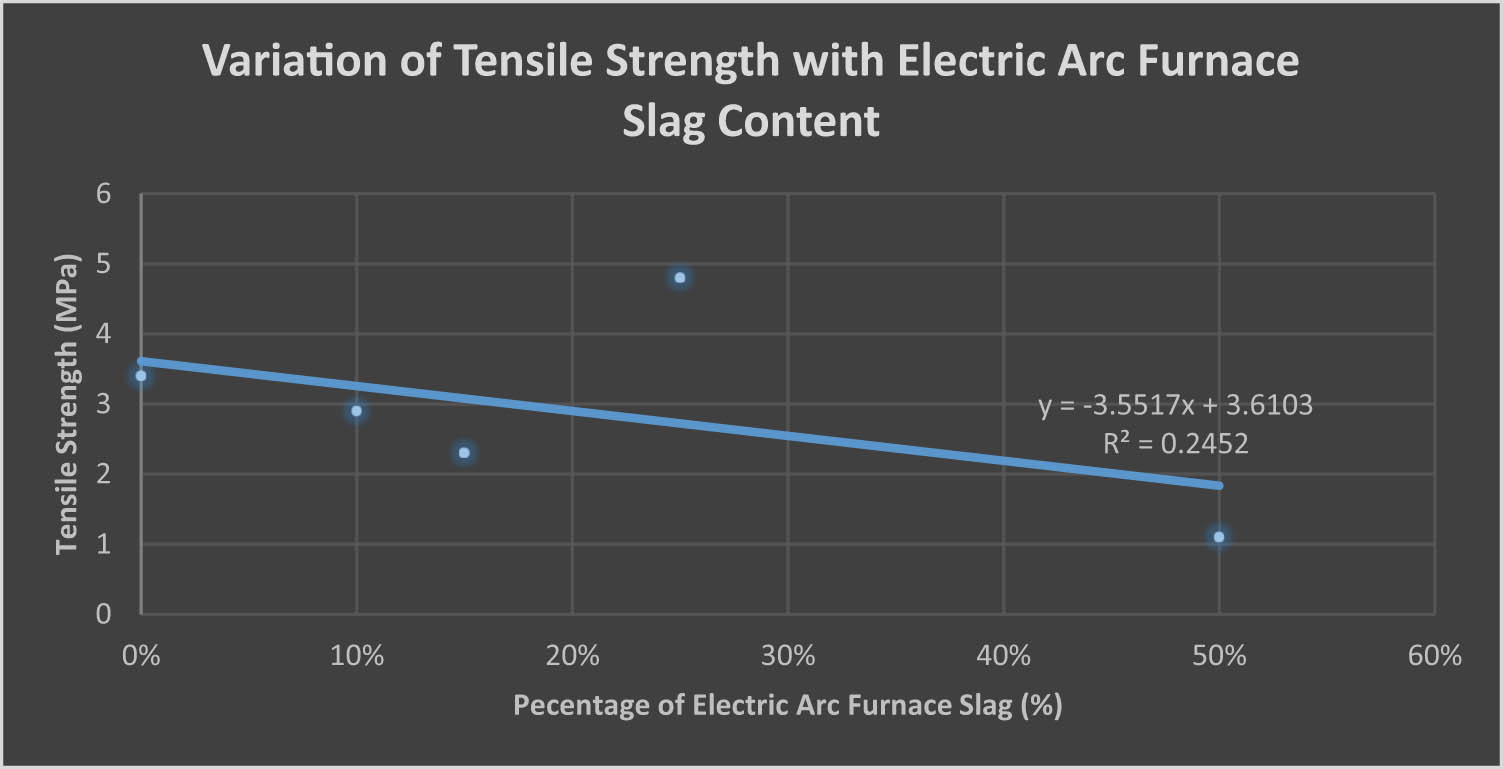

Figures 8–10 illustrate the variation of the density, compressive strength, and tensile strength respectively with increased content of the EAF slag aggregates.

Density variation with EAF slag content.

Compressive strength (MPa) variation with EAF slag content.

Tensile strength (MPa) variation with EAF slag content.

The compressive strength values increased as the percentage of the EAF slag aggregates increased, the highest value of the compressive strength was calculated to be 58.70 MPa using 50% EAF slag. This finding is in good agreement with the work done in Pellegrino et al. [25].

However, the density of the hardened concrete was highest using 25% EAF slag aggregates and lowest using 50% EAF slag aggregates. This finding is in contradiction with the work done by researchers in Qasrawi et al. [13] found that replacing fine aggregates in 25 MPa concrete produced concrete with compressive strengths 1.1–1.3 times greater than 100% EAF slag aggregates. Furthermore, papers [12,17] replaced coarse aggregate with slag and also found improved compressive strength results. Those three papers support the improved compressive strength of the 25% slag aggregate mixture in this study since it replaced both fine and coarse aggregates.

The anomaly in this finding can be justified by Table 6 in which the increases in the coarse EAF slag aggregate content would have initiated increases in the air spaces between the fine and the coarse particles. With 50% EAF slag aggregates, 30% of the EAF slag was coarse aggregates, and 20% fine aggregate, there would not have been adequate fine slag content to fill in the void spaces between the slag particles. This could have been attributed to a reduction in the overall density value of the concrete produced. This could also be justified from Table 10.

Mathematical relations between tested parameters and the EAF slag content

| Tested parameters | Exponential | Linear |

|---|---|---|

| Density | y = 2502.9e−0.054x | y = −131.26x + 2502.7 |

| R 2 = 0.2171 | R 2 = 0.2087 | |

| Compressive strength | y = 31.063e1.1722x | y = 52.076x + 30.243 |

| R² = 0.5805 | R 2 = 0.665 | |

| Tensile strength | y = 3.8626e−1.971x | y = −3.5517x + 3.6103 |

| R² = 0.4639 | R² = 0.2452 |

Table 10 displays the mathematical relations formulated between the tested parameters (density, compressive strength, and tensile strength) values and the percentage of the EAF slag aggregates.

It is evident that the R 2 values are highest having a value of 0.663 for the linear prediction of compressive strength variation with the percentage of EAF slag. It can be deduced that the linear approximation is a good prediction for the compressive strength variation. This linear prediction can be attributed to an increase in the compressive strength values as the percentage of EAF slag content increases.

5 Conclusions and recommendations

The significance of this study was to deduce the ratio of the fine to coarse EAF slag aggregates that would produce concrete of comparative strengths to concrete made with natural aggregates. Concrete mixtures were formulated using varied EAF slag content in the proportions of 0, 10, 15, 25, and 50%, respectively. The compressive strength values increased as the EAF slag content increased. However, this trend was not evident for the density and tensile strength values. The concrete mixture containing 25% EAF slag with 15% fine and 20% coarse EAF slag aggregates had the greatest density value of 2550.00 kg/m3 and tensile strength value of 4.8 Pa, respectively. This could be due to the distribution of the fine and coarse aggregate grains in the mixture. Since the percentage of fine and coarse aggregate grains was 10 and 15%, respectively, it was a close enough range for the fines to fill in the void spaces. This could have caused the density to increase due to the mixture being more compact and the tensile strength having a higher value.

5.1 Recommendations

While this study followed standard testing procedures and methods that are directly applied in the field, there are some additions to this experiment that can improve its quality and the accuracy of its outcomes. They are as follows:

Aggregate properties such as porosity, fineness modulus, and resistance to abrasion should be studied to better understand the differences between EAF steel slag aggregates and natural aggregates.

Chemical testing of the EAF steel slag aggregate can be done to better understand its content. This would foster a prediction to be made with the cement and water mixture in concrete. The findings of such a test can potentially explain ways of increasing the tensile strength of concrete.

Investigations on the long-term performance of slag aggregates in concrete, and their performance when exposed to different environments can also be done. This would reveal areas for practical application.

-

Funding information: This research received no external funding.

-

Author contributions: Kristyn Lakshmi Narine: conceptualization, methodology, original draft preparation; Aaron Anil Chadee: formal analysis, writing – review; Davatee Maharaj: resources, data curation; Festus Olutoge: review and editing; Hazi Mohammad Azamathulla: supervision, project administration; all authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: The authors declare no conflict of interest.

-

Data availability statement: All supporting data used during this study can be made available from the corresponding author upon reasonable request.

References

[1] Gencel O, Karadag O, Oren OH, Bilir T. Steel slag and its applications in cement and concrete technology: A review. Constr Build Mater. 2021;283:122783.10.1016/j.conbuildmat.2021.122783Search in Google Scholar

[2] Singh S, Vashistha P, Chandra R, Rai AK. Study on leaching of electric arc furnace (EAF) slag for its sustainable applications as construction material. Process Saf Environ Prot. 2021;148:1315–26.10.1016/j.psep.2021.01.039Search in Google Scholar

[3] Statista. World crude steel production from 2012 to 2022: Statista Research Department; 2023 [Available from: https://www.statista.com/statistics/267264/world-crude-steel-production/.Search in Google Scholar

[4] Chadee AA, Allis C, Rathnayake U, Martin H, Azamathulla HM. Data exploration on the factors associated with cost overrun on social housing projects in Trinidad and Tobago. Data Brief. 2024;52:109966.10.1016/j.dib.2023.109966Search in Google Scholar PubMed PubMed Central

[5] Sugrañez R, Cruz‐Yusta M, Mármol I, Martín F, Morales J, Sánchez L. Use of industrial waste for the manufacturing of sustainable building materials. ChemSusChem. 2012;5(4):694–9.10.1002/cssc.201100552Search in Google Scholar PubMed

[6] Cherian C, Siddiqua S, Arnepalli DN. Utilization of recycled industrial solid wastes as building materials in sustainable construction. Advances in sustainable materials and resilient infrastructure. Singapore: Springer; 2022. p. 61–75.10.1007/978-981-16-9744-9_4Search in Google Scholar

[7] Malathy PKDR, Kothai R. Utilization of steel slag in concrete as a partial replacement material for fine aggregates. Int J Innovative Res Sci Eng Technol. 2014;3(4):11585–92.Search in Google Scholar

[8] Naderi M, Kaboudan A. Experimental study of the effect of aggregate type on concrete strength and permeability. J Build Eng. 2021;37:101928.10.1016/j.jobe.2020.101928Search in Google Scholar

[9] Habert G, Miller SA, John VM, Provis JL, Favier A, Horvath A, et al. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat Rev Earth Environ. 2020;1(11):559–73.10.1038/s43017-020-0093-3Search in Google Scholar

[10] San-José JT, Vegas I, Arribas I, Marcos I. The performance of steel-making slag concretes in the hardened state. Mater Des. 2014;60:612–9.10.1016/j.matdes.2014.04.030Search in Google Scholar

[11] Santamaría A, Orbe A, San José J, González J. A study on the durability of structural concrete incorporating electric steelmaking slags. Constr Build Mater. 2018;161:94–111.10.1016/j.conbuildmat.2017.11.121Search in Google Scholar

[12] Maharaj D, Parris J, Mwasha A. Physical and mechanical properties of concrete manufactured using electric arc furnace slag as coarse aggregates. Int J Environ Waste Manag. 2017;20(1):21–34.10.1504/IJEWM.2017.086025Search in Google Scholar

[13] Qasrawi H, Shalabi F, Asi I. Use of low CaO unprocessed steel slag in concrete as fine aggregate. Constr Build Mater. 2009;23(2):1118–25.10.1016/j.conbuildmat.2008.06.003Search in Google Scholar

[14] Tangadagi R, Maddikeari M, Ashwath B, Shailaja P. Utilization of steel slag as an eco-friendly material in concrete for construction. J Green Eng. 2020;10:2408–19.Search in Google Scholar

[15] Olonade K, Kadiri M, Aderemi P. Performance of steel slag as fine aggregate in structural concrete. Nigerian J Technol. 2015;34(3):452–8.10.4314/njt.v34i3.4Search in Google Scholar

[16] Borole S, Shinde R, Mhaske R, Pagare S, Tribhuvan K, Pawar N, et al. Replacement of fine aggregate by steel slag. Int J Innovative Res Sci Eng. 2016;2(3):628–35.Search in Google Scholar

[17] Diotti A, Cominoli L, Galvin AP, Sorlini S, Plizzari G. Sustainable recycling of electric arc furnace steel slag as aggregate in concrete: effects on the environmental and technical performance. Sustainability. 2021;13(2):521.10.3390/su13020521Search in Google Scholar

[18] Abu-Eishah SI, El-Dieb AS, Bedir MS. Performance of concrete mixtures made with electric arc furnace (EAF) steel slag aggregate produced in the Arabian Gulf region. Constr Build Mater. 2012;34:249–56.10.1016/j.conbuildmat.2012.02.012Search in Google Scholar

[19] Pellegrino C, Gaddo V. Mechanical and durability characteristics of concrete containing EAF slag as aggregate. Cem Concr Compos. 2009;31(9):663–71.10.1016/j.cemconcomp.2009.05.006Search in Google Scholar

[20] Sezer Gİ, Gülderen M. Usage of steel slag in concrete as fine and/or coarse aggregate. Indian J Eng Mater Sci. 2015;22:339–44.Search in Google Scholar

[21] Arum C, Olotuah A. Making of strong and durable concrete. Emir J Eng Res. 2006;11(1):25–31.Search in Google Scholar

[22] Ukala D. Effects of combined aggregate gradation on the compression strength and workability of concrete using fineness modulus. J Appl Sci Environ Manag. 2019;23(5):851–6.10.4314/jasem.v23i5.13Search in Google Scholar

[23] Musa MF, bin Saim AA, eds. The effect of aggregate size on the strength of concrete. The Colloquium. 2017;10:9–11.Search in Google Scholar

[24] Ogundipe OM, Olanike AO, Nnochiri ES, Ale PO. Effects of coarse aggregate size on the compressive strength of concrete. Civ Eng J. 2018;4(4):836–42.10.28991/cej-0309137Search in Google Scholar

[25] Pellegrino C, Faleschini F, Pellegrino C, Faleschini F. Electric arc furnace slag concrete. Sustainability Improvements Concr Industry: Use Recycled Mater Struct Concr Prod. 2016;77–106.10.1007/978-3-319-28540-5_4Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Evaluation of the mechanical and dynamic properties of scrimber wood produced from date palm fronds

- Performance of doubly reinforced concrete beams with GFRP bars

- Mechanical properties and microstructure of roller compacted concrete incorporating brick powder, glass powder, and steel slag

- Evaluating deformation in FRP boat: Effects of manufacturing parameters and working conditions

- Mechanical characteristics of structural concrete using building rubbles as recycled coarse aggregate

- Structural behavior of one-way slabs reinforced by a combination of GFRP and steel bars: An experimental and numerical investigation

- Effect of alkaline treatment on mechanical properties of composites between vetiver fibers and epoxy resin

- Development of a small-punch-fatigue test method to evaluate fatigue strength and fatigue crack propagation

- Parameter optimization of anisotropic polarization in magnetorheological elastomers for enhanced impact absorption capability using the Taguchi method

- Determination of soil–water characteristic curves by using a polymer tensiometer

- Optimization of mechanical characteristics of cement mortar incorporating hybrid nano-sustainable powders

- Energy performance of metallic tubular systems under reverse complex loading paths

- Enhancing the machining productivity in PMEDM for titanium alloy with low-frequency vibrations associated with the workpiece

- Long-term viscoelastic behavior and evolution of the Schapery model for mirror epoxy

- Laboratory experimental of ballast–bituminous–latex–roving (Ballbilar) layer for conventional rail track structure

- Eco-friendly mechanical performance of date palm Khestawi-type fiber-reinforced polypropylene composites

- Isothermal aging effect on SAC interconnects of various Ag contents: Nonlinear simulations

- Sustainable and environmentally friendly composites: Development of walnut shell powder-reinforced polypropylene composites for potential automotive applications

- Mechanical behavior of designed AH32 steel specimens under tensile loading at low temperatures: Strength and failure assessments based on experimentally verified FE modeling and analysis

- Review Article

- Review of modeling schemes and machine learning algorithms for fluid rheological behavior analysis

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part I

- Creep–fatigue damage assessment in high-temperature piping system under bending and torsional moments using wireless MEMS-type gyro sensor

- Multiaxial creep deformation investigation of miniature cruciform specimen for type 304 stainless steel at 923 K using non-contact displacement-measuring method

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part I

- Sustainable concrete production: Partial aggregate replacement with electric arc furnace slag

- Exploring the mechanical and thermal properties of rubber-based nanocomposite: A comprehensive review

- Experimental investigation of flexural strength and plane strain fracture toughness of carbon/silk fabric epoxy hybrid composites

- Functionally graded materials of SS316L and IN625 manufactured by direct metal deposition

- Experimental and numerical investigations on tensile properties of carbon fibre-reinforced plastic and self-reinforced polypropylene composites

- Influence of plasma nitriding on surface layer of M50NiL steel for bearing applications

Articles in the same Issue

- Research Articles

- Evaluation of the mechanical and dynamic properties of scrimber wood produced from date palm fronds

- Performance of doubly reinforced concrete beams with GFRP bars

- Mechanical properties and microstructure of roller compacted concrete incorporating brick powder, glass powder, and steel slag

- Evaluating deformation in FRP boat: Effects of manufacturing parameters and working conditions

- Mechanical characteristics of structural concrete using building rubbles as recycled coarse aggregate

- Structural behavior of one-way slabs reinforced by a combination of GFRP and steel bars: An experimental and numerical investigation

- Effect of alkaline treatment on mechanical properties of composites between vetiver fibers and epoxy resin

- Development of a small-punch-fatigue test method to evaluate fatigue strength and fatigue crack propagation

- Parameter optimization of anisotropic polarization in magnetorheological elastomers for enhanced impact absorption capability using the Taguchi method

- Determination of soil–water characteristic curves by using a polymer tensiometer

- Optimization of mechanical characteristics of cement mortar incorporating hybrid nano-sustainable powders

- Energy performance of metallic tubular systems under reverse complex loading paths

- Enhancing the machining productivity in PMEDM for titanium alloy with low-frequency vibrations associated with the workpiece

- Long-term viscoelastic behavior and evolution of the Schapery model for mirror epoxy

- Laboratory experimental of ballast–bituminous–latex–roving (Ballbilar) layer for conventional rail track structure

- Eco-friendly mechanical performance of date palm Khestawi-type fiber-reinforced polypropylene composites

- Isothermal aging effect on SAC interconnects of various Ag contents: Nonlinear simulations

- Sustainable and environmentally friendly composites: Development of walnut shell powder-reinforced polypropylene composites for potential automotive applications

- Mechanical behavior of designed AH32 steel specimens under tensile loading at low temperatures: Strength and failure assessments based on experimentally verified FE modeling and analysis

- Review Article

- Review of modeling schemes and machine learning algorithms for fluid rheological behavior analysis

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part I

- Creep–fatigue damage assessment in high-temperature piping system under bending and torsional moments using wireless MEMS-type gyro sensor

- Multiaxial creep deformation investigation of miniature cruciform specimen for type 304 stainless steel at 923 K using non-contact displacement-measuring method

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part I

- Sustainable concrete production: Partial aggregate replacement with electric arc furnace slag

- Exploring the mechanical and thermal properties of rubber-based nanocomposite: A comprehensive review

- Experimental investigation of flexural strength and plane strain fracture toughness of carbon/silk fabric epoxy hybrid composites

- Functionally graded materials of SS316L and IN625 manufactured by direct metal deposition

- Experimental and numerical investigations on tensile properties of carbon fibre-reinforced plastic and self-reinforced polypropylene composites

- Influence of plasma nitriding on surface layer of M50NiL steel for bearing applications