Abstract

The emergence and progression of synthetic rubber have paved the way in variegated prospects across various engineering and technological fields. Nonetheless, its inherent limitations such as poor mechanical and thermal properties including wear resistance, poor tensile strength, and lower thermal conductivity, as evident in styrene butadiene rubber and silicone rubber, have constrained its utility in numerous load-bearing scenarios. This limitation has been addressed by incorporating specific nanofillers into various rubber compositions, resulting in promising outcomes up to a certain threshold. Many nanofillers were trialed, such as graphite oxide, aluminum oxide, carbon nanotubes, and boron nitride. However, an attempt should be made to explore the disparity in dimensional attributes of nanofillers and their effect on different properties of rubber, thereby delineating the scope for future research. The exploration of dimensionally distinct nanofillers, such as 1D multiwalled carbon nanotubes and 2D graphene, can overcome these limitations and augment rubber’s mechanical properties and thermal properties. The study also delineates the scope of future research, which should be focused on optimizing the nanofillers’ dispersion and interfacial bonding within the rubber matrix by trying dimensionally different nanofillers.

1 Introduction

Synthetic rubber is a polymer type that originates from petroleum byproducts. The process of its creation involves the polymerization of different monomers, including styrene, butadiene, and isoprene, to name a few [1]. This method facilitates the alteration of molecular structures, enabling the customization of properties according to specific requirements. This is in contrast to natural rubber (NR), which is always derived from specific plants and has fixed properties. Synthetic rubber is a class of polymers that play a crucial role in different engineering applications [2]. Nanofillers were used for augmenting mechanical, tribological, and thermal properties of different polymeric materials, including rubber [3]. The first rubber-based nanocomposite using layered silicate clay was developed in 1993 by researchers Helmy, Sato, and others. This novel material combined rubber with nano clay and enhanced mechanical and thermal properties. It left an indelible mark in the automotive industry electronics and packaging industries. Gradually other nanofillers like carbon nanotubes (CNTs), graphite oxide, and graphene becomes popular nanofillers because of their remarkable properties, e.g., an extensive surface area and outstanding thermal properties and others such as mechanical, electrical, and optical characteristics [4]. Including these fillers in various synthetic rubbers has significantly improved the mechanical and thermal characteristics of the resulting composite materials [5]. This work presents a comprehensive review of the mechanical properties and thermo-mechanical properties of various rubber-based composites.

Synthetic rubber is crucial in engineering applications like, shock absorbers, oil, and, chemical-resistant components [6,7]. It is a versatile material but it does have some limitations such as poor abrasion resistance and stiffness (S). Figure 1 details the different synthetic rubbers and their limitations.

Synthetic rubbers and their limitations.

The integration of nanotechnology has facilitated the augmentation of diverse rubber properties [8] through the strategic utilization of various nanofillers, thereby enhancing their mechanical and ancillary characteristics [9]. Table 1 describes it in detail. All the abbreviations used in the study are described in Table A1.

Summary of literature survey

| Sl. no. | Matrix | Fillers | Advantages | Limitation | Objective | Result | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | NR | Purified attapulgite (PAT) | High adsorption capacity, good thermal stability and rheological properties | High cost of purification and limited swelling capacity | Tensile strength (TS), wear resistance (WR), and resistance to solvent action of the NR–PAT composite was investigated | TS is improved by 90% in comparison to NR | [10] |

| 2 | NR | CNT and graphene | CNT has high strength and conductivity and graphene has excellent thermal conductivity (TC) | CNT and graphene both have high production costs | TS and crystallization temperature of NR-CNT was analyzed | Nanofiller addition marked significant improvement in properties | [11] |

| 3 | NR | Titanium carbide (TiC) | High hardness (HD) and WR | Embrittlement risk | The mechanical properties of NR–TiC composite were investigated | The NR–TiC composite exhibits a TS of 31.13 MPa | [12] |

| 4 | NR | Acacia caesia | Biodegradable | Inconsistent fiber quality | TS, toughness (Ts), and HD of the composite were investigated | The composite’s Ts and HD were recorded to improve than NR | [13] |

| 5 | NR | Titanium dioxide | High durability | High cost | The TS and HD of the NR–TiO2 composite were examined | The composite exhibited higher TS and HD than NR | [14] |

| 6 | NR | Cellulose nanofibers | High strength and biodegradable | High production cost | TS and strain energy density of NR-CNF composite were explored | CNF enhanced the TS of composite | [15] |

| 7 | NR | Cellulose nanofibrils and sodium methacrylate | Sodium methacrylate is water soluble | Sodium methacrylate is reactive | The TS and storage modulus (SM) of the composite were analyzed | The composite material exhibited a high TS and SM. TS was increased by 78% compared to the NR | [16] |

| 8 | NR | Graphene oxide and silicon carbide | Silicon carbide has high HD and excellent TC | Silicon carbide is brittle in nature | TS and HD of the composite were investigated | A 4 wt% of nanofiller had increased the TS by 22.5% | [17] |

| 9 | NR | Ceria nanocrystals | High catalytic activity | Expensive to produce | The dynamic mechanical properties of the composite were analyzed | The addition of nanofillers has improved the SM and tan delta (damping) properties of the composite | [18] |

| 10 | NR | Activated carbon | High adsorption capacity | Limited reusability without regeneration | The TS and HD of the NR-AC composite were examined | The TS of the resulting material was found to be 20.3 MPa, which is 50% more than that of NR | [19] |

| 11 | NR | Oil palm boiler ash and carbon black (CB) | High adsorption capacity | Limited reusability without regeneration | The TS, % elongation at break, and HD of the composite were analyzed | Elongation at the breakdown is recorded to improve by 150% with increased HD and TS | [20] |

| 12 | NR | Carbon nanotube (CNT) | CNT has high strength and conductivity | High production costs | The TS, Young’s modulus (E), impact strength (IS), and HD of the composite were examined | The aforementioned properties were increased by 11, 21, 43, and 50%, respectively | [21] |

| 13 | Silicone rubber (SR) | Nanocarbon | High electrical conductivity | High production cost | The TS, HD, S, and % elongation at the break of SR-NC of the composite were analyzed | The addition of NC increased TS, S, and HD | [22] |

| 14 | SR | AT | High absorption capacity | Limited availability and high cost | The TS and impact properties of the SR-AT were observed | Recorded an increase of 21 and 80%, respectively | [23] |

| 15 | ER | CNT | CNT has high strength and conductivity | High production costs | The Ts, flexural strength (FS), and TS of the ER-CNT composite were investigate | The HD and TS were recorded to increase compared to the pure matrix | [24] |

| 16 | Butadiene-acrylonitrile | Nanosilica (NS) | High surface area | It is difficult to handle due to fine particle size | The S, TS, and HD of the composite were investigated | The addition of nanofiller (NS) has improved the mechanical properties | [25] |

| 17 | Styrene butadiene rubber (SBR) | NS | High surface area | It is difficult to handle due to fine particle size | TS and % elongation at break of SBR-nano silica composite were investigated | TS, EM, and elongation at break improved by 23, 40, and 110%, respectively | [26] |

| 18 | SBR | Nylon | High strength and durability | Absorbs moisture, which can affect mechanical properties | IS, FS, and compressive strength (CS) of SBR-nylon were analyzed | The aforesaid properties recorded an increase of 84, 58, and 67% higher than the pure SBR | [27] |

| 19 | SBR | SiO2 | High chemical stability | Brittle nature | The TS and HD of SBR-SiO2 composite were explored | The composite exhibited a higher HD than the SBR and recorded a 122% increase in TS | [28] |

| 20 | SBR | CNT and graphene | CNT has high strength and conductivity and graphene has excellent TC | CNT and graphene both have high production costs | The HD, SM, and TC of the composite was observed | HD of graphene-based composites has significantly increased, while the CNT-composite exhibited higher TC | [29] |

| 21 | Nitrile butyl rubber (NBR) | CNT | CNT has high strength and conductivity | High production costs | The HD and TS of NBR-CNT were investigated | The TS increased by 10%, YM by 16%, and HD by 12% | [30] |

2 Causes of increase in rubber properties on the addition of nanofillers

The incorporation of nanoparticles into rubber matrices enhances the mechanical properties through several mechanisms, including additional reinforcement, improved dispersion, strengthening the cross-linking density, and providing barrier effects.

Nanofillers are characterized by a high aspect ratio [31] and large surface area [32], thereby forming strong physical interactions with the matrix [31,32]. This reinforcement aids in distributing stress more effectively, improving properties such as TS, modulus, and tear resistance.

Similarly, nanofillers can be evenly diffused throughout the matrix compared to conventional fillers [33]. This uniform dispersion minimizes agglomeration and enhances the interplay between the fillers and the polymer chains, leading to better mechanical properties. Nanofillers also increase the cross-linking density by facilitating the formation of additional cross-links within the rubber matrix during curing [34]. This increased cross-linking density improves the network structure and enhances mechanical properties such as S and HD [35,36]. Barrier effects are also promoted through nanofillers, which act as a barrier for increasing the movement of polymer chains, hindering their mobility, and improving properties like dimensional stability, WR, and fatigue resistance. There are three central bonding mechanisms through which nanofillers bond to the rubber matrix. First, physical adsorption is used; in this process, Van der Waals forces cause nanofillers to be attracted to the rubber matrix. Second, in chemical bonding, covalent bonds are formed between functional groups on the nanofillers and rubber. Third, in hydrogen bonding, there is an interaction between hydroxyl groups on the nanofillers and rubber molecules [37]. One such interaction is shown in Figure 2.

Polymer–filler interaction scenarios for crosslinked elastomer: (a) No covalent bonds, (b) Covalent polymer -filler bonds, (c) Increased crosslink density near filler, (d) Covalent bonds with increased crosslink density, (e) Stronger interaction with higher crosslink density, and (f) Maximum crosslink density around filler.

3 Mechanical properties

Evaluation of the mechanical properties of rubber is essential for properly selecting material for a particular process, optimizing performance, quantifying the properties, and identifying the scopes of improvement. The addition of nanofillers like CNTs [38], graphene, nanodiamonds (NDs) [39], boron nitride (BN) [40], and others to threshold concentration has improved several mechanical properties [41,42,43] such as S [44,45,46], HD, IS, and other nanomechanical properties. The following section summarizes the mechanical properties of different rubber-based composites.

3.1 Stiffness

Stiffness is a material’s ability to resist deformation and a measure of how much material resists bending, stretching, or compression. It is quantified by modulus of elasticity or E [47]. A higher E indicates good S which signifies that larger force is required to induce a deformation [48]. The E is experimentally calculated using a Universal Tensile Tester and Badgayan et al. [49] have described the method for calculation of E of CNT based theoretically using a modified Halpin–Tsai equation [49] as follows:

where

The equation acronym is referred from the study by Badgayan et al. [49].

Kazemi et al. [50] analyzed the impact of the enhancement of NR’s mechanical properties by incorporating CNT. The study revealed a significant increase in the TS, modulus at 300% elongation, and E by 57, 137, and 120%, respectively. Bakošová and Bakošová [51] prepared a SBR/CNT composite and examined its mechanical characteristics [51]. The study showed that adding 2.00 phr of CNTs led to a 9.5% improvement in TS, a 15.44% improvement in E, and an 11.18% increase in HD, while the point of rupture decreased by 8.39% when tested against the reference compound [51]. Cui et al. studied the behavior of NR composites strengthened with CNT and boron nitride nanotubes (BNTs) [52]. The results showed a rise of 22.34 and 26.59% in E [52]. Teng et al. [53] utilized CNT as a reinforcing agent in NR and increased the mechanical properties of the composite [53]. The results showed that the increase in CNT content increased the bulk, shear, and E. The 15 wt% CNT/NR composite showed an increase of 19.13, 21.11, and 26.89% in bulk modulus, shear modulus, and E, respectively, compared to NR [53]. Shahamatifard et al. [54] investigated the impact of using a hybrid filler system which is comprised of CB and multiwalled carbon nanotubes (MWCNT) on the mechanical properties and TC of nanocomposites made from NR [54]. Dynamic mechanical analysis (DMA) determined the storage and loss modulus. The research findings depicted a significant increase of ∼72 and 54% in the storage and E [54]. Wang et al. [55] investigated the mechanical and thermal properties of a composite material made up of graphene, BN, CNT, and epoxy rubber (ER) [55]. Incorporating BN-CNT into the ER substantially improved fracture Ts, stress-energy release rate, and E [55]. Poikelispää et al. [56] examined the influence of replacing CB with NDs on the vulcanization of NR [56]. The findings showed a 28% increase in composite S [56]. Yang et al. [57] fabricated a graphene oxide (GO) and NDs composite of NR [57]. The TS, S, elongation at break, and stretching strength were improved by 59, 25, 18, and 9%, respectively, compared with those of pure NR [57]. Salaeh et al. [58] studied methylmethacrylate NR filled with MWCNTs [58]. The results showed improved mechanical reinforcement and a reduction in percolation threshold. The stress–strain curves of the NR/MWCNT composites with varying MWCNT contents are presented in Figure 3. The results indicate that a higher S was observed with 15 phr. of CNT [58]. Hashemi et al. [59] studied the mechanical behavior of the NR and glass fiber composite by incorporating 4–8 wt% of nanofillers [59]. At 8 wt% of the glass fiber, the composite’s TS, HD, and S were 57, 32, and 33%, respectively, notably exceeded that of the non-reinforced NR sample [59]. Krainoi et al. [60] prepared the nanocomposites of CNT filled NR by melt mixing method and studied its mechanical and electrical properties [60]. The higher S was observed at 7 phr of CNT loading. The E was 0.0275 MPa, which is a 72% increase compared to NR [60]. Valentini et al. [61] reported an 80% increase in S when combining graphene oxide and CNTs with nitrile–butadiene rubber, resulting in higher stress-strain improvement compared to the pure matrix [61].

![Figure 3

The tensile stress vs strain curves of NR/MWCNT. Reproduced with permission from [58], Copyright, Elsevier, 2020.](/document/doi/10.1515/jmbm-2024-0015/asset/graphic/j_jmbm-2024-0015_fig_003.jpg)

The tensile stress vs strain curves of NR/MWCNT. Reproduced with permission from [58], Copyright, Elsevier, 2020.

Evaluating the mechanical properties of rubber-based composites with nanofillers is requisite for advancing material applications. Integrating nanofillers such as CNT, graphene, NDs, and BN significantly enhances mechanical properties. The properties like E, HD, Ts, and IS were recorded to increase.

Research articles showed that adding CNTs to rubber composites had substantially improved TS and modulus, often exceeding the performance of conventional materials. For example, SBR composites with CNTs exhibit notable TS and HD increases. Similarly, NR composites with BNTs and hybrid fillers demonstrate significant mechanical enhancements, and incorporating GO and NDs also improves S and overall performance.

3.2 HD

HD is the capacity of a material to resist indentation which thereby has an effect on abrasion resistance or WR of material [62]. Harder material usually exhibits good resistance to wear [63]. Synthetic rubber-like SBR and nitrile rubber has appreciable resistance to wear; however, rubbers like neoprene rubber exhibit poor resistance to wear [64]. It has an excellent quality of anti-corrosion to environmental factors but poor resistance to wear makes them unusable for environment which calls for high abrasion resistance [65].

The following section summarizes different literature in the area.

Virág et al. [66] analyzed the HD of a rubber compound and CB [66]. The HD of the composite increased by 32% with CB loading compared to the pure matrix [66]. Zainal Abidin et al. [67] demonstrated the HD of NBR composites containing a hybrid of CB and Palm kernel shell (PKSBc) [67]. The composite without any filler showed the lowest HD value. However, with the addition of 35 phr of CB, the HD improved by 35.5%. The hybridization of CB with PKSBc further increased the composite’s HD by 18.8 and 31.6%, ascribed to a high density of crosslinks of the composite [67]. CNTs are gaining interest as fillers in rubber nanocomposites and the mechanical characteristics of a compound made up of NR/butadiene rubber (BR) and SBR that was reinforced with single-walled carbon nanotubes (SWCNT) were investigated [68]. The findings revealed that adding 2.00 phr of SWCNT resulted in a 9.5% increase in TS, 15.44% improvement in E, and 11.18% increase in HD [68]. Soundararaj et al. [69] prepared a composite of NR, CB, and CNT and studied the morphology and mechanical properties of the composite [69]. The incorporation of CNT in the NR matrix resulted in superior mechanical properties than NR composites containing only CB and also exhibits superior HD, as shown in Figure 4. NR hybrid nanocomposites with a loading of 2 parts per hundred of rubber loading and CNT exhibit the highest HD compared to others [69].

![Figure 4

HD of NR composite of CB/CNT [69].](/document/doi/10.1515/jmbm-2024-0015/asset/graphic/j_jmbm-2024-0015_fig_004.jpg)

HD of NR composite of CB/CNT [69].

Jawahar et al. [70] prepared rubber nanocomposites using MWCNT in different weight proportions ranging from 0.5 to 2.5% and analyzed their mechanical properties [70]. The study found that the inclusion of MWCNT had a notable positive impact on the mechanical properties of NR. Adding 2.5 wt% of CNTs to the matrix increased the HD of the NR–CNT composite by 44% [70]. Utrera-Barrios et al. [71] prepared NR composites with conventional and non-conventional fillers [71]. NR composites were prepared using conventional fillers (CB and precipitated-Si), non-conventional fillers (in situ-Si and in situ-Zi), and combinations of both (CB/p-Si and CB/i-Si). When CB was combined with in situ-Si, the composites exhibited higher mechanical strength, HD, tear resistance, and abrasion resistance. Figure 5 shows that F2, F3, and F4 have higher HD than F1 (unfilled), while F6, with the maximum capacity (conventional and unconventional) and highest crosslink density, reaches the highest HD value [71]. Kumar et al. [72] studied the impact of nanofillers, such as CNTs and Titanium dioxide (TiO2), on NR-based composites [72]. The TS of unfilled composites was 0.54 MPa, but this increased up to 1.37 MPa (CNT), 1.33 MPa (CNT-TiO2), and 0.61 MPa (TiO2) at a concentration of 5 phr. The result showed that the composite with 5 wt% CNT fillers has a greater HD compared to those with TiO2 and CNT-TiO2. It was discovered that the HD of CNT fillers was higher than that of CNT-TiO2 and TiO2 nanofillers, by 77 and 60%, respectively [72].

![Figure 5

HD and abrasion resistance of the rubber composites [71].](/document/doi/10.1515/jmbm-2024-0015/asset/graphic/j_jmbm-2024-0015_fig_005.jpg)

HD and abrasion resistance of the rubber composites [71].

Ismail et al. [73] reported an increase in the HD of NR composites with 2% CB [73]. Burgaz et al. [74] demonstrated the mechanical characteristics of CB strengthened NR/BR and SBR, with various viscosity [74]. The study examined the compression set behavior and HD measurements of rubber composites. The HD values of all composites made from NR, BR, and SBR were similar, indicating that changes in composition did not have a significant impact on HD values; however, the HD of the composite was found to be 58 ShA [74]. Kong et al. [75] the accelerated lifespan prediction of graphene-reinforced NR on the mechanical characteristics of NR composites and the accelerated lifetime prediction of graphene-reinforced NR composites [75]. Results indicate that increasing the graphene loading enhances the HD and compressive properties. The HD of the composite was found to be 73 ShA [75].

Chawla [76] developed graphene-reinforced NR composites to improve mechanical and tribological characteristics of NR. Results showed increased E, reduced friction coefficient, HD, and abrasion rate [76]. The addition of graphene to NR resulted in a 185% improvement in E, 32% improvement in shear modulus, and 48% improvement in HD [76].

Investigation showed significant improvements in HD with the addition of various fillers. For example, incorporating CB into rubber increased HD by 32%, and hybrid fillers in NBR further enhanced HD by up to 35.5%. Similarly, adding SWCNT to rubber compounds improved HD, TS, and E. NR composites with CNTs exhibited superior mechanical properties and HD compared to those with only CB. MWCNT increased HD by 44% with a 2.5 wt% addition. Combining conventional and non-conventional fillers with CB in NR composites resulted in higher HD and tear resistance.

3.3 Other mechanical and thermomechanical properties

Other properties of interest include IS and TC. Both the properties are critically important in selection of rubber-based material [77]. The properties are not directly related to each other but sometimes play a contrary roll [78]. For example, increased filler load would increase IS but hinder TC [79]. This section presents a review of both the properties in detail, Anidha et al. [80] studied the mechanical characteristics of a hybrid composite material made of epoxy and CNTs combined with varying amounts of NR [80]. High IS was observed for the incorporation of 10 wt% of CNT. IS was measured using the Izod test. The test was performed using an AIT-300N impact tester with a 600 mm pendulum swing and an 18.7 kg striking hammer weight [80]. Sementsov et al. [81] studied the modification of the rubber composition by incorporating CB [81]. The findings indicated that incorporating CB into NR significantly enhances its TS, IS, elongation at break, E, as well as its loss of stability modulus and SM [81]. Mateab and Albozahid [82] utilized MWCNTs to develop MWCNTs/epoxy nanocomposites with varied weight percentages [82]. The study demonstrated that varying the MWCNT content enhanced the epoxy nanocomposites’ mechanical properties, notably in impact resistance and HD. Specifically, the IS of the MWCNTs/epoxy nanocomposite saw significant increases of 33, 46, 75, and 108% with different loadings [82]. Nair et al. [83] reported that incorporating MWCNTs notably improves the tensile Ts and IS of polypropylene/NR (PP/NR) blends, especially when added at a concentration of 5 wt% [83]. Mat Desa et al. [84] studied the impact of core-shell rubber on the mechanical and thermal properties of poly lactic acid (PLA) and MWCNT [84]. It was observed that the impact resistance of PLA/CNT composites enhances as the content of core shell rubber increases, which leads to decrease in both TS and S [84]. Singh et al. [85] reinforced epoxy-glass fiber to ethylene propylene diene monomer (EPDM) rubber for increased IS [85]. The study revealed that nanocomposites based on epoxy and reinforced with untreated EPDM showed a boost in IS up to a concentration of 5.0 wt%. However, beyond this concentration, the strength decreased. The maximum improvement recorded was 27% at 5.0 wt% concentration [85]. A study was conducted by Ruksakulpiwat et al. [86] on polypropylene composites to identify the impact of using vetiver grass as a filler, in combination with NR and EPDM as impact modifiers [86]. The composites that incorporated EPDM rubber were found to have increased TS and IS as compared to the ones with NR. The IS of the composite with EPDM rubber was observed to have increased by 40% compared to NR [86].

Investigation showed that incorporating fillers like CNTs and CB significantly enhances IS. For example, adding 10 wt% CNT to composites significantly increases IS, while CB boosts IS and other mechanical properties in NR. MWCNTs also improve impact resistance in epoxy nanocomposites, increasing up to 108% at higher loadings. Additionally, MWCNTs enhance IS in polypropylene/NR blends.

4 TC

When rubber is exposed to temperature fluctuations, either high or low, its thermal property determines how the rubber’s molecules react. Therefore, it is essential to understand the thermal properties of rubber, such as TC, glass transition temperature, degree of crystallinity, and others, before applying rubber to low temperatures. A critical analysis of rubber composite’s heat conductivity, heat resistivity, and crystallinity was provided in Section 3. It was found that adding various nanofillers improved the rubber’s heat conductivity.

Kenganal and Sahoo [87] prepared a composite of ground tire rubber/activated carbon (AC)/polyethylene glycol for thermal energy storage application [87]. The composite showed a remarkable TC of 1.18 W m−1 K−1, 5.36 times higher than PEG’s 0.22 W m−1 K−1 [87]. Zhang et al. [88] developed a composite of SR and poly (p-phenylene benzobisoxazole) fiber (PBO) [88]. The composite’s thermogravimetric curve, which included 20% PBO by volume, revealed excellent thermal characteristics [88]. Chen et al. [89] studied the mechanical and thermal properties of NR composites of carbon fiber [89]. The TC of the composite was increased to 0.218W m−1 K−1 [89]. Ouyang et al. [90] reported that with 20 vol% B-Al2O3 and 0.5 wt% CNTs incorporation into SR, the composite shows good crystallinity and a greater thermal stability of 1.307 W m−1 K−1 [90]. Shi et al. [91] enhanced heat transmission of SR by adding GO and silicon carbide [91]. It exhibited a TC of 5.24 W m−1 K−1, approximately 31 times greater than SR [91]. Farahani et al. [92] prepared SR nanocomposites using BNs as nanofillers. The TC was improved by 20 times more compared to pure SR [92]. Duan et al. [17] studied the thermal properties of NR composites of silicon carbide and GO [17]. Heat conductivity increased by 21.2% compared to NR when 4 phr of SiC/GO-S (SG-S) filler was added to NR. [17]. Zhang et al. [6] studied the TC of SR composites incorporated with BN and polydopamine [6]. The thermogravimetric analysis (TGA) revealed a 0.95 W m−1 K−1 improvement in the material’s thermal stability. For 30 wt% of nanofillers, the temperature was 513.4°C at a 20% weight loss [6]. Razavi-Nouri et al. [93] studied the thermal and rheological properties of acrylonitrile-butadiene rubber nanocomposites filled by poly (ethylene-co-vinyl acetate) and dynamically cross-linked with 0–2 wt% dicumyl peroxide (DCP) [93]. Thermal analysis studies concluded that the heat resistance improved with an increase in the amount of DCP [93]. Lin et al. [94] improved the thermal properties of SR composites by incorporating CNTs and Al2O3 [94]. A higher mass percentage of Al2O3 powder in the composites results in higher TC [94]. Figure 6 illustrates the TC of the SR composite. It inferred that the TC of a SR composite of aluminum oxide and CNT. It is clear that when thermal conductive fillers were added to rubber composites, their TC increased compared to neat polymers. As the weight% increases, Al2O3 particles and CNTs can interact more readily, leading to improved composites’ thermal performance. The TC of the SR/Al2O3/CNTs composite is 0.28 W m−1 K−1, which is better than that of neat SR.

![Figure 6

TC of SR composite [94].](/document/doi/10.1515/jmbm-2024-0015/asset/graphic/j_jmbm-2024-0015_fig_006.jpg)

TC of SR composite [94].

Ouyang et al. [95] used Al2O3 as a nano reinforcement in SR to improve the thermal properties of the composite [95]. Excellent heat conductivity is demonstrated by SR composites, which is 665% improvement over SR [95]. Song et al. [96] synthesized SR composites by adding acrylate-grafted siloxane copolymers and investigated its TC [96]. The TC of the composite was increased from 1.42 to 1.73 W m−1 K−1 [96]. Lim et al. [97] prepared a NR graphene composite and examined its thermal and mechanical properties [97]. The material was found to exhibit a higher TC of 0.236 W m−1 K−1. Following the addition of GO, there was an increase of 36% of heat transfer capability [97]. Xue et al. [98] prepared SR/BN composites, and the TC was investigated [98]. It was observed that the composite possesses good heat transfer capacity. The processes followed here, caused an improvement in thermal conductivity TC, which is 33 times higher than pure SR [98]. Liu et al. [99] created carboxylate acrylonitrile-butadiene rubber (xNBR) and GO nanocomposites [99]. The TGA revealed that, at the precise filler amount, the T5, T50, and T max of xNBR-GO/SBR nanocomposites are higher than those of GO/SBR nanocomposites. For instance, T50 and T max of xGO5 are increased by 25.67 and 30.95°C, while those of GO5 are only increased by 8.08 and 14.07°C, respectively. Adding a 5 phr filler resulted in a 31.7% increase in xNBR-GO/SBR thermal stability [99].

Investigation has shown that incorporating nanofillers can significantly enhance TC. For instance, Kenganal et al. demonstrated that a composite of ground tire rubber with AC and polyethylene glycol achieved a TC of 1.18 W m−1 K−1, substantially higher than that of pure polyethylene glycol. Similarly, Shi et al. reported that adding graphene oxide and silicon carbide to SR improved its TC to 5.24 W m−1 K−1. Other studies, such as those by Ouyang et al. and Lin et al., also found notable increases in TC by adding materials like BN, CNTs, and aluminum oxide.

5 Future scope

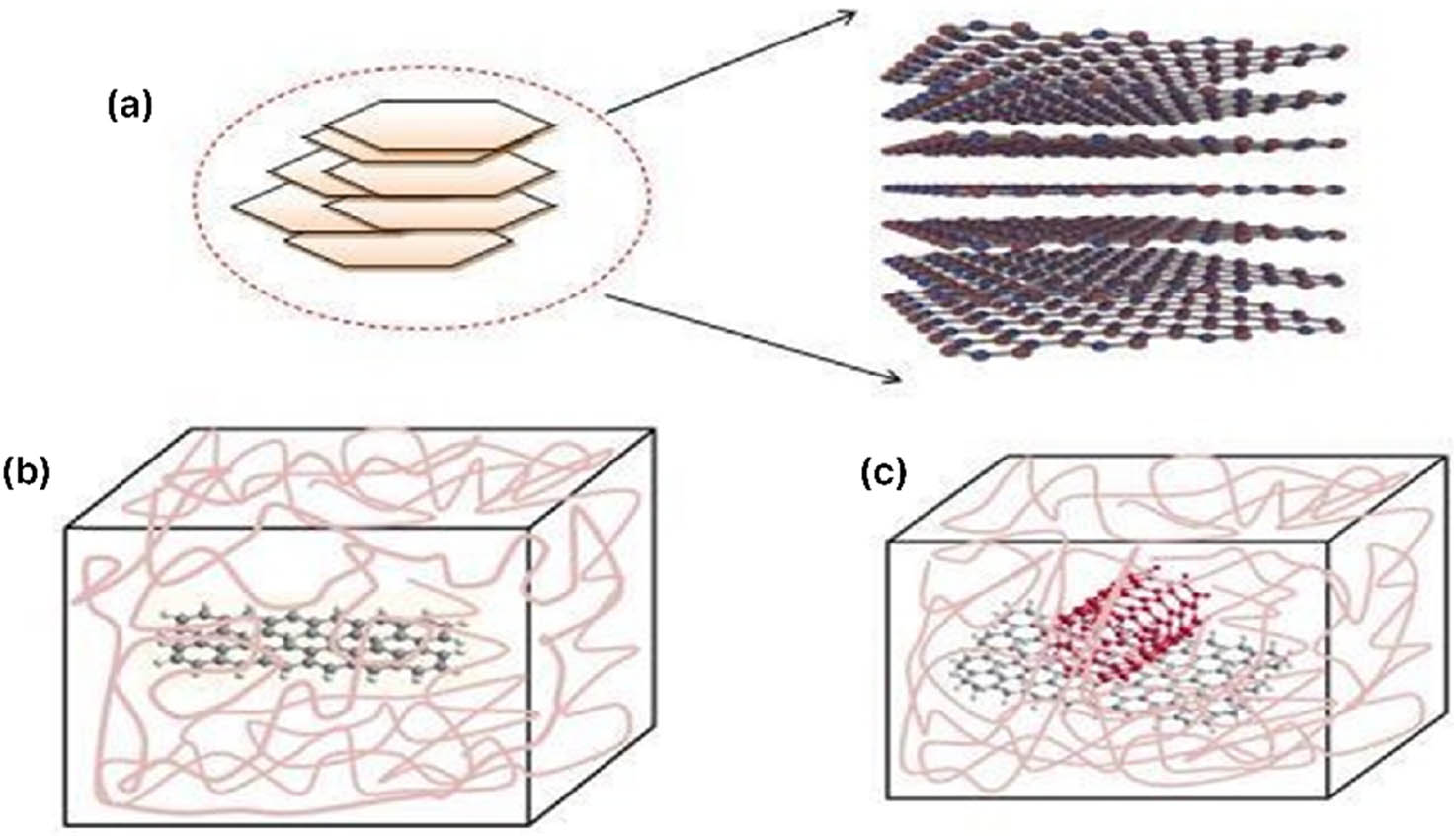

The current research is an effort to bridge the gap in the existing studies and outline a future research perspective. Researchers have attempted to reinforce nanofillers of different dimensions in matrix material [100–103]. Figure 7 shows the SEM images of the CNT/NR composite [104]. A significant property increase was also recorded, and threshold concentration was established [105–107]. However, combining two-dimensionally different nanofiller 2D graphene and 1D MWCNT needs a tryst [108–111]. The motivation for identifying the gap is the remarkable properties of graphene and MWCNT. With its 2D structure, graphene possesses high lubricity, making it suitable for enhancing tribological properties [112–114]. MWCNT offers a unique potential for improving mechanical properties. Incorporating nanofillers can ensure synergy between the dimensionally different nanofillers [115–118]. A constitutive model delineating interaction between 1D and 2D structures is presented in Figure 8.

SEM image of (a) CNT/NR; (b) CNT/WPRP/NR; (c) CNT/WPRP/NR; and (d) CNT/WPRP/NR composite.

(a) GNP nanofiller; (b) interaction of GNP in rubber matrix; and (c) interaction of MWCNT/GNP in rubber.

6 Conclusion

This review expounds on improving rubber-based composites’ mechanical and thermal properties by adding nanofillers. It also identifies a gap in incorporating dimensionally different nanofillers like 1D CNT and 2D graphene. The reinforcement of nanofillers in rubber matrix increases its properties and makes it suitable for applications in the automotive, aerospace, electronics, and medical industries, where superior performance and durability are critical. Future research should delve into optimizing the dimensional attributes of nanofillers, exploring the synergistic effects of hybrid nanofillers, and evaluating the environmental impact of these materials. Such efforts will pave the way for developing more efficient, sustainable, high-performance rubber nanocomposites.

Acknowledgement

The authors wish to acknowledge the funding provided by TJ Tires and appreciate the extension of research facilities. The authors acknowledge the contribution of Mr. Suraj Sahani for assisting in the experimental work being carried out.

-

Funding information: No funding was received for this study.

-

Author contributions: Conceptualization: S.P., S.M., S.P., and N.D.B; methodology: S.P., S.M., S.P., and N.D.B; formal analysis: S.P. and S.M.; resources: S.M., S.P., and N.D.B; data curation: S.P., S.M., S.P., and N.D.B; writing – original draft preparation: S.P.; writing – review and editing: S.M., S.P., and N.D.B.; visualization: S.M., S.P., and N.D.B.; supervision: S.M., S.P., and N.D.B.

-

Conflict of interest: The authors declare no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations used in the study

| Sl. no. | Abbreviation | Definition |

|---|---|---|

| 1 | NR | Natural rubber |

| 2 | SBR | Styrene-butadiene rubber |

| 3 | NBR | Nitrile butyl rubber |

| 4 | ER | Epoxy rubber |

| 5 | SR | Silicone rubber |

| 6 | PAT | Purified attapulgite |

| 7 | CNT | Carbon nanotube |

| 8 | AC | Activated carbon |

| 9 | NS | Nanosilica |

| 10 | TiC | Titanium carbide |

| 11 | ACC | Acacia caesia |

| 12 | CB | Carbon black |

| 13 | XNBR | Nitrile butadiene rubber |

| 14 | PKSB | Palm kernel shell |

| 15 | BR | Butadiene rubber |

| 16 | EPDM | Ethylene propylene diene monomer |

| 17 | AP | Attapulgite |

| 18 | HDPE | High Density Polyethylene |

| 19 | TS | Tensile strength |

| 20 | Ts | Toughness |

| 21 | HD | Hardness |

| 22 | WR | Wear resistance |

| 23 | SM | Storage modulus |

| 24 | E | Young’s modulus |

| 25 | IS | Impact strength |

| 26 | FS | Flexural strength |

| 27 | CS | Compressive strength |

| 28 | TC | Thermal conductivity |

| 29 | S | Stiffness |

References

[1] Yang S, Bieliatynskyi A, Trachevskyi V, Shao M, Ta M. Technology for improving modern polymer composite materials. Mater Sci-Pol. 2022;40:27–41. 10.2478/msp-2022-0027.Search in Google Scholar

[2] Dey M, Katabathuni RV, Badgayan ND, Sahu SK. Finite element analysis of high-density polyethylene (HDPE) nanocomposite for potential use as dental implant. Lecture notes in mechanical engineering. Singapore: Springer; 2022. 10.1007/978-981-19-0676-3_19.Search in Google Scholar

[3] Caselis JLV, Juárez JDS, Aguilar JAG, Alcalá MFD, Rosas ER, Hernández JCM, et al. Effect of addition of non-functionalized graphene oxide in a commercial epoxy resin used as coating. Mater Sci-Pol. 2021;39(4):467–77. 10.2478/msp-2021-0039.Search in Google Scholar

[4] Sakthi S, Mahendran S, Meignanamoorthy M, Mohanavel V. Investigation of the mechanical, corrosion, and tribological characteristics of AZ61 Mg with boron carbide nanoparticles via the stir casting route. Mater Sci-Pol. 2023;41:227–43. 10.2478/msp-2023-0019.Search in Google Scholar

[5] Sahu SK, Badgayan ND, Samanta S, Sahu D, Sreekanth PR. Influence of cell size on out of plane stiffness and in-plane compliance character of the sandwich beam made with tunable PCTPE nylon honeycomb core and hybrid polymer nanocomposite skin. Int J Mech Sci. 2018;148:284–92. 10.1016/j.ijmecsci.2018.08.011.Search in Google Scholar

[6] Zhang X, Yi J, Yin Y, Song Y, Xiong C. Thermal conductivity and electrical insulation properties of h-BN@PDA/silicone rubber composites. Diam Relat Mater. 2021;117:108485. 10.1016/j.diamond.2021.108485.Search in Google Scholar

[7] Kaliyathan AV, Mathew A, Rane AV, Kanny K, Thomas S. Natural rubber and silicone rubber-based biomaterials. In Fundamental biomaterials: polymers. United States: Woodhead Publishing; 2018. p. 71–84. 10.1016/B978-0-08-102194-1.00004-9.Search in Google Scholar

[8] Sahu SK, Sreekanth PR, Saxena KK, Ma Q. Effect of graphene reinforcement on the tensile and flexural properties of thermoplastic polyurethane nanocomposite using experimental and simulation approach. Adv Mater Process Technol. 2024;1–17. 10.1080/2374068X.2024.2341986.Search in Google Scholar

[9] Abdul Salim ZAS, Hassan A, Ismail H. A review on hybrid fillers in rubber composites. Polym-Plast Technol Eng. 2018;57(6):523–39. 10.1080/03602559.2017.1329432.Search in Google Scholar

[10] Wang J, Chen D. Mechanical properties of natural rubber nanocomposites filled with thermally treated attapulgite. J Nanomater. 2013;2013:496584. 10.1155/2013/496584.Search in Google Scholar

[11] Srivastava SK, Mishra YK. Nanocarbon reinforced rubber nanocomposites: detailed insights about mechanical, dynamical mechanical properties, payne, and mullin effects. Nanomaterials. 2018;8(11):945. 10.3390/nano8110945.Search in Google Scholar PubMed PubMed Central

[12] Jayasinghe JMARB, De Silva RT, de Silva KN, de Silva RM, Silva VA. Titanium carbide ceramic nanocrystals to enhance the physicochemical properties of natural rubber composites. RSC Adv. 2020;10(33):19290–9. 10.1039/D0RA01943G.Search in Google Scholar PubMed PubMed Central

[13] Santhosh N, Selvam S, Reghu R, Sundaran J, Mathew BC, Palanisamy S. Mechanical properties studies on rubber composites reinforced with Acacia Caesia fibre. Mater Today Proc. 2023;72:3172–6. 10.1016/j.matpr.2022.11.099.Search in Google Scholar

[14] Naphon P, Wiriyasart S, Naphon N. Thermal, mechanical, and electrical properties of rubber latex with TiO2 nanoparticles. Compos Commun. 2020;22:100449. 10.1016/j.coco.2020.100449.Search in Google Scholar

[15] Kulshrestha U, Gupta T, Kumawat P, Jaiswal H, Ghosh SB, Sharma NN. Cellulose nanofibre enabled natural rubber composites: Microstructure, curing behaviour and dynamic mechanical properties. Polym Test. 2020;90:106676. 10.1016/j.polymertesting.2020.106676.Search in Google Scholar

[16] Noguchi T, Bamba Y, Odaka I, Iwamoto R, Endo M, Isogai A. Natural rubber composites with high strength, modulus, water-resistance, and thermal stability, prepared with cellulose nanofibrils and sodium methacrylate. Compos Part A Appl Sci Manuf. 2023;173:107665. 10.1016/j.compositesa.2023.107665.Search in Google Scholar

[17] Duan X, Tao R, Chen Y, Zhang Z, Zhao G, Liu Y, et al. Improved mechanical, thermal conductivity and low heat build-up properties of natural rubber composites with nano-sulfur modified graphene oxide/silicon carbide. Ceram Int. 2022;48(15):22053–63. 10.1016/j.ceramint.2022.04.196.Search in Google Scholar

[18] Zhang C, Yu S, Tang Z, Guo B. Catalyzed silanization by supporting ceria on silica towards rubber composites with improved mechanical properties. Compos Commun. 2022;32:101168. 10.1016/j.coco.2022.101168.Search in Google Scholar

[19] Oyales MIK, Yorro MLH, Valdez-Liu MM, Razonado IAC, Diaz LJL. Cure characteristics and mechanical properties of rubber compound reinforced with activated carbon from coconut husks as alternative to carbon black. Mater Sci Forum. 2021;1041:17–22. 10.4028/www.scientific.net/MSF.1041.17.Search in Google Scholar

[20] Bukit N, Ginting EM, Sidebang E, Frida E, Bukit BF. Mechanical properties of natural rubber compounds with oil palm boiler ash and carbon black as a filler. J Phys Conf Ser. 2020;1428(1):012020. 10.1088/1742-6596/1428/1/012020.Search in Google Scholar

[21] Danafar F, Kalantari M. A review of natural rubber nanocomposites based on carbon nanotubes. J Rubber Res. 2018;21:293–310. 10.1007/BF03449176.Search in Google Scholar

[22] Gao X, Yang W, Wang C, Tian X. Study on properties of carbon-coated silica prepared by polymer pyrolysis reinforced rubber composites. Polym Test. 2022;110:107583. 10.1016/j.polymertesting.2022.10758.Search in Google Scholar

[23] Xia L, Zeng J, Xiao Y, Gong J, Chen Y. Surface-grafting modification of attapulgite nanorods with polysiloxane coupling agents for highly-efficient mechanical and triboelectric performance enhancement of silicone rubbers. Compos Part B Eng. 2024;271:111170. 10.1016/j.compositesb.2023.111170.Search in Google Scholar

[24] Barik SB, Patidar P, Bagade SS, Kumar A, Nayak RK, Patel PK. Recent progress in reinforcement of nanofillers in epoxy-based nanocomposites. Mater Today Proc. 2023. 10.1016/j.matpr.2023.03.116.Search in Google Scholar

[25] Mahmoud DS, Eldesouki EM, Abd El-Gawad WM. Nano-lithium ferrite/nanosilica-filled butadiene-acrylonitrile rubber for microwave absorption. Mater Chem Phys. 2024;313:128673. 10.1016/j.matchemphys.2023.128673.Search in Google Scholar

[26] Mohammadi A, Shojaei A, Khasraghi SS. Improvement of nanosilica effects on the performance of mechanically processed styrene-butadiene rubber by rational hybridization with nanodiamond. Diam Relat Mater. 2022;130:109487. 10.1016/j.diamond.2022.109487.Search in Google Scholar

[27] Tomar P, Gope PC. Effect of glass fiber and nylon fiber reinforcement on the mechanical and thermal properties of styrene butadiene rubber mixed PMMA denture base material. J Mech Behav Biomed Mater. 2024;150:106308. 10.1016/j.jmbbm.2023.106308.Search in Google Scholar PubMed

[28] Lin M, Yang X, Yang L, Fu L, Teng X, Lin B, et al. Effects of carboxymethyl chitosan-assisted dispersion of silica on interface and mechanical properties of rubber composites. Colloids Surf, A Physicochem Eng Asp. 2023;656:130525. 10.1016/j.colsurfa.2022.130525.Search in Google Scholar

[29] Song SH, Kwon O, Jeong HK, Kang YG. Properties of styrene-butadiene rubber nanocomposites reinforced with carbon black, carbon nanotube, graphene, graphite. Korean J Mater Res. 2010;20(2):104–10. 10.3740/MRSK.2010.20.2.104.Search in Google Scholar

[30] Radhamani AV, Lau HC, Ramakrishna S. CNT-reinforced metal and steel nanocomposites: A comprehensive assessment of progress and future directions. Composites, Part A: Appl Sci Manuf. 2018;114:170–87. 10.1016/j.compositesa.2018.08.010.Search in Google Scholar

[31] Nabeel M, Kuzsella L, Viskolcz B, Kollar M, Fiser B, Vanyorek L. Synergistic effect of carbon nanotubes and carbon black as nanofillers of silicone rubber pressure sensors. Arab J Chem. 2023;16(4):104594. 10.1016/j.arabjc.2023.104594.Search in Google Scholar

[32] Yang H, Li F, Chan TW, Liu L, Zhang L. Effect of nanofiller shape on viscoelasticity of rubber nanocomposite investigated by FEA. Compos Part B Eng. 2016;92:160–6. 10.1016/j.compositesb.2015.10.020.Search in Google Scholar

[33] Ben Ayed E, Ghorbel N, Kallel A, Putaux JL, Boufi S. Polyaniline-grafted chitin nanocrystals as conductive reinforcing nanofillers for waterborne polymer dispersions. Biomacromolecules. 2022;23(10):4167–78. 10.1021/acs.biomac.2c00635.Search in Google Scholar PubMed PubMed Central

[34] Li X, Li Y, Qian C, Wang S, Nie R. Design and preparation of sulfur vulcanized polyamide 66 cross-linked nitrile butadiene rubber networked and its application in blending with graphene oxide. Mater Today Commun. 2024;39:108704. 10.1016/j.mtcomm.2024.108704.Search in Google Scholar

[35] Wang M, Li Y, Qian C, Wang S, Liu D. Relationship between the aging thermal oxygen and mechanical properties of nitrile butadiene rubber reinforced by RD-loaded carboxylated carbon nanotubes. Appl Surf Sci. 2024;655:159569. 10.1016/j.apsusc.2024.159569.Search in Google Scholar

[36] Cui J, Zhao J, Wang S, Wang Y, Li Y. Effects of carbon nanotubes functionalization on mechanical and tribological properties of nitrile rubber nanocomposites: Molecular dynamics simulations. Comput Mater Sci. 2021;196:110556. 10.1016/j.commatsci.2021.110556.Search in Google Scholar

[37] Robertson CG, Hardman NJ. Nature of carbon black reinforcement of rubber: Perspective on the original polymer nanocomposite. Polymers. 2021;13(4):538. 10.3390/polym13040538.Search in Google Scholar PubMed PubMed Central

[38] Panda S, Mishra S, Pradhan S, Badgayan ND. Design and development of an affordable and suitable rubber compounding for high altitude application up to −40°C. Mater Today Proc. 2023;86:1097–101. 10.1016/j.matpr.2023.06.372.Search in Google Scholar

[39] Sahu SK, Badgayan ND, Samanta S, Sreekanth PR. Quasistatic and dynamic nanomechanical properties of HDPE reinforced with 0/1/2 dimensional carbon nanofillers based hybrid nanocomposite using nanoindentation. Mater Chem Phys. 2018;203:173–84. 10.1016/j.matchemphys.2017.09.063.Search in Google Scholar

[40] Badgayan ND, Sahu SK, Samanta S, Sreekanth PR. Assessment of nanoscopic dynamic mechanical properties and BCN triad effect on MWCNT/h-BNNP nanofillers reinforced HDPE hybrid composite using oscillatory nanoindentation: an insight into medical applications. J Mech Behav Biomed Mater. 2018;80:180–8. 10.1016/j.jmbbm.2018.01.027.Search in Google Scholar PubMed

[41] Gao X, Yang J, Shao J, Zhu H, Xu J, Haruna SI. Regulation of carbon nanotubes on internal humidity of concrete with recycled tire rubber: Mechanism analysis and modeling. J Build Eng. 2024;82:108253. 10.1016/j.jobe.2023.108253.Search in Google Scholar

[42] Qu J, Wang R, Huang F, Huang H, Ren R, Wang Y, et al. Wear particle matter emission of rubber reinforced by graphene and carbon nanotube hybrid fillers against a rolling-contact concrete surface. Wear. 2024;544:205318. 10.1016/j.wear.2024.205318.Search in Google Scholar

[43] Negri RBP, de Sousa AMF, da Silva ALN, da Rocha EBD. Improved mechanical and rheological behavior of nitrile rubber reinforced with multi-walled carbon nanotubes and carbon black dual-filler system. Mater Today Commun. 2021;26:101884. 10.1016/j.mtcomm.2020.101884.Search in Google Scholar

[44] Jinshuai Y, Han Z, Sui CE, Borito SM, Yang Z, Jianwen S. Research on the effect of carbon nanotubes on cracking and impact properties of rubber aggregate mortar. J Build Eng. 2021;43:103127. 10.1016/j.jobe.2021.103127.Search in Google Scholar

[45] Sahakaro K. Mechanism of reinforcement using nanofillers in rubber nanocomposites. In Progress in rubber nanocomposites. United States: Woodhead Publishing; 2017. p. 81–113. 10.1016/B978-0-08-100409-8.00003-6.Search in Google Scholar

[46] Kumar V, Lee DJ, Park SS. Multi-functionality prospects in functionalized and pristine graphene nanosheets reinforced silicone rubber composites: A focused review. FlatChem. 2023;41:100535. 10.1016/j.flatc.2023.100535.Search in Google Scholar

[47] Kumar V, Tang XW, Liu SC, Lee DJ. Studies on nanocomposites reinforced with CNTs in different types of dielectric rubber. Sens Actuators, A Phys. 2017;267:310–7. 10.1016/j.sna.2017.10.032.Search in Google Scholar

[48] Kumar V, Lee DJ. Effects of thinner on RTV silicone rubber nanocomposites reinforced with GR and CNTs. Polym Adv Technol. 2017;28(12):1842–50. 10.1002/pat.4071.Search in Google Scholar

[49] Badgayan ND, Sahu SK, Samanta S, Sreekanth PR. Evaluation of dynamic mechanical and thermal behavior of HDPE reinforced with MWCNT/h-BNNP: an attempt to find possible substitute for a metallic knee in transfemoral prosthesis. Int J Thermophys. 2019;40:1–20. 10.1007/s10765-019-2559-4.Search in Google Scholar

[50] Kazemi H, Mighri F, Park KW, Frikha S, Rodrigue D. Hybrid nanocellulose/carbon nanotube/natural rubber nanocomposites with a continuous three‐dimensional conductive network. Polym Compos. 2022;43(4):2362–74. 10.1002/pc.26546.Search in Google Scholar

[51] Bakošová D, Bakošová A. Testing of rubber composites reinforced with carbon nanotubes. Polymers. 2022;14(15):3039. 10.3390/polym14153039.Search in Google Scholar PubMed PubMed Central

[52] Cui J, Zeng F, Yuan B. A comparative study on the interfacial characteristics and tensile behaviors of natural rubber composites reinforced by carbon and boron nitride nanotubes. Polym Compos. 2022;43(9):6624–36. 10.1002/pc.26977.Search in Google Scholar

[53] Teng F, Wu J, Su B, Wang Y. Enhanced tribological properties of vulcanized natural rubber composites by applications of carbon nanotube: A molecular dynamics study. Nanomaterials. 2021;11(9):2464. 10.3390/nano11092464.Search in Google Scholar PubMed PubMed Central

[54] Shahamatifard F, Rodrigue D, Park KW, Frikha S, Mighri F. Natural rubber nanocomposites: Effect of carbon black/multi-walled carbon nanotubes hybrid fillers on the mechanical properties and thermal conductivity. Polym.-Plast. Technol Mater. 2021;60(15):1686–96. 10.1080/25740881.2021.1930044.Search in Google Scholar

[55] Wang S, Cao M, Cong F, Xue H, Li X, Zhao C, et al. Mechanical and thermal properties of graphene and carbon nanotube reinforced epoxy/boron nitride adhesives. J Adhes Sci Technol. 2021;35(19):2142–58. 10.1080/01694243.2021.1877017.Search in Google Scholar

[56] Poikelispää M, Shakun A, Sarlin E. Nanodiamond – carbon black hybrid filler system for demanding applications of natural rubber – butadiene rubber composite. Appl Sci. 2021;11(21):10085. 10.3390/app112110085.Search in Google Scholar

[57] Yang Z, Huang Y, Xiong Y. A functional modified graphene oxide/nanodiamond/nano zinc oxide composite for excellent vulcanization properties of natural rubber. RSC Adv. 2020;10(68):41857–70. 10.1039/D0RA07404G.Search in Google Scholar

[58] Salaeh S, Thitithammawong A, Salae A. Highly enhanced electrical and mechanical properties of methyl methacrylate modified natural rubber filled with multiwalled carbon nanotubes. Polym Test. 2020;85:106417. 10.1016/j.polymertesting.2020.106417.Search in Google Scholar

[59] Hashemi SJ, Sadooghi A, Rahmani K, Nokhbehroosta S. Experimental determining the mechanical and stiffness properties of natural rubber FRT triangle elastic joint composite reinforcement by glass fibers and micro/nano particles. Polym Test. 2020;85:106461. 10.1016/j.polymertesting.2020.106461.Search in Google Scholar

[60] Krainoi A, Kummerlöwe C, Nakaramontri Y, Vennemann N, Pichaiyut S, Wisunthorn S, et al. Influence of critical carbon nanotube loading on mechanical and electrical properties of epoxidized natural rubber nanocomposites. Polym Test. 2018;66:122–36. 10.1016/j.polymertesting.2018.01.003.Search in Google Scholar

[61] Valentini L, Bon SB, Hernández M, López-Manchado MA, Pugno NM. Nitrile butadiene rubber composites reinforced with reduced graphene oxide and carbon nanotubes show superior mechanical, electrical and icephobic properties. Compos Sci Technol. 2018;166:109–14. 10.1016/j.compscitech.2018.01.050.Search in Google Scholar

[62] Asl MS, Ahmadi Z, Parvizi S, Balak Z, Farahbakhsh I. Contribution of SiC particle size and spark plasma sintering conditions on grain growth and hardness of TiB2 composites. Ceram Int. 2017;43(16):13924–31. 10.1016/j.ceramint.2017.07.121.Search in Google Scholar

[63] Pangamol P, Malee W, Yujaroen R, Sae-Oui P, Siriwong C. Utilization of bagasse ash as a filler in natural rubber and styrene-butadiene rubber composites. Arab J Sci Eng. 2018;43:221–7. 10.1007/s13369-017-2859-6.Search in Google Scholar

[64] Cho YS, Cho D. Effect of Kenaf Fiber Content and Length on the Cure Characteristic, Hardness, Tensile Modulus, and Abrasion of Kenaf/Natural Rubber Composites in the Presence and Absence of Kenaf Fiber Treatment with Adhesive Solution. J Adhes Interface. 2018;19(2):60–7. 10.17702/jai.2018.19.2.60.Search in Google Scholar

[65] Yuniari A, Mayasari HE, Setyorini I. Curing characteristics, swelling, and mechanical properties of natural rubber/nitrile butadiene rubber blends with and without compatibilizer. Maj Kulit, Karet, Dan Plastik. 2017;33(2):65–72. 10.20543/mkkp.v33i2.3265.Search in Google Scholar

[66] Virág L, Egedy A, Varga C, Erdős G, Berezvai S, Kovács L, et al. Determination of the most significant rubber components influencing the hardness of natural rubber (NR) using various statistical methods. Heliyon. 2024;10(3):e25170. 10.1016/j.heliyon.2024.e25170.Search in Google Scholar PubMed PubMed Central

[67] Zainal Abidin Z, Mamauod SNL, Romli AZ, Sarkawi SS, Zainal NH. Synergistic effect of partial replacement of carbon black by palm kernel shell biochar in carboxylated nitrile butadiene rubber composites. Polymers. 2023;15(4):943. 10.3390/polym15040943.Search in Google Scholar PubMed PubMed Central

[68] Adu PCO, Aakyiir M, Su X, Alam J, Tran LC, Dai J, et al. Challenges and advancements in Elastomer/CNT nanocomposites with mechanochemical treatment, reinforcement mechanisms and applications. Smart Mater Manuf. 2024;2:100053.10.1016/j.smmf.2024.100053Search in Google Scholar

[69] Soundararaj R, Senthilvel K, Rathinam N, Prabu B. Experimental studies on mechanical properties of natural rubber carbon black-carbon nanotube composite. Mater Today: Proc. 2021;38:3077–84. 10.1016/j.matpr.2020.09.479.Search in Google Scholar

[70] Jawahar P, Payak V, Chandradass J, Prabhu P. Optimization of mechanical properties of CNT-rubber nanocomposites. Mater Today: Proc. 2021;45:7183–9. 10.1016/j.matpr.2021.02.413.Search in Google Scholar

[71] Utrera-Barrios S, Perera R, León N, Santana MH, Martínez N. Reinforcement of natural rubber using a novel combination of conventional and in situ generated fillers. Compos Part C: Open Access. 2021;5:100133. 10.1016/j.jcomc.2021.100133.Search in Google Scholar

[72] Kumar V, Kumar A, Han SS, Park SS. RTV silicone rubber composites reinforced with carbon nanotubes, titanium-di-oxide and their hybrid: Mechanical and piezoelectric actuation performance. Nano Mater Sci. 2021;3(3):233–40. 10.1016/j.nanoms.2020.12.002.Search in Google Scholar

[73] Ismail R, Rajhan NHB, Hamid HA, Ibrahim A. Experimental data for effect of carbon black loading on tensile, hardness and rebound of magnetic iron filled natural rubber composites. Data Brief. 2019;25:104166. 10.1016/j.dib.2019.104166.Search in Google Scholar PubMed PubMed Central

[74] Burgaz E, Gencoglu O, Goksuzoglu M. Carbon black reinforced natural rubber/butadiene rubber and natural rubber/butadiene rubber/styrene-butadiene rubber composites: Part I: Rheological, mechanical and thermomechanical properties. Res Eng Struct Mater. 2019;5(3):233. 10.17515/resm2019.74ma1123.Search in Google Scholar

[75] Kong E, Yoon B, Nam JD, Suhr J. Accelerated aging and lifetime prediction of graphene-reinforced natural rubber composites. Macromol Res. 2018;26(11):998–1003. 10.1007/s13233-018-6131-z.Search in Google Scholar

[76] Chawla R. Mechanical and tribological properties of graphene reinforced natural rubber composites: a molecular dynamics study. MRS Adv. 2018;3(10):525–30. 10.1557/adv.2018.178.Search in Google Scholar

[77] Song S, Zhang Y. Carbon nanotube/reduced graphene oxide hybrid for simultaneously enhancing the thermal conductivity and mechanical properties of styrene-butadiene rubber. Carbon. 2017;123:158–67. 10.1016/j.carbon.2017.07.057.Search in Google Scholar

[78] Gu J, Meng X, Tang Y, Li Y, Zhuang Q, Kong J. Hexagonal boron nitride/polymethyl-vinyl siloxane rubber dielectric thermally conductive composites with ideal thermal stabilities. Composites, Part A: Appl Sci Manuf. 2017;92:27–32. 10.1016/j.compositesa.2016.11.002.Search in Google Scholar

[79] Zhai S, Zhang P, Xian Y, Zeng J, Shi B. Effective thermal conductivity of polymer composites: Theoretical models and simulation models. Int J Heat Mass Transf. 2018;117:358–74. 10.1016/j.ijheatmasstransfer.2017.09.067.Search in Google Scholar

[80] Anidha S, Mozhuguan Sekar S, Natarajan E, Muthukkumar M, Markandan K, Ang CK, et al. Preliminary Investigations and Support for the Mechanical and Dynamic Characteristics of a Natural Rubber Reinforcement in E-Glass/CNT/Epoxy Composite. J Compos Sci. 2024;8(4):140. 10.3390/jcs8040140.Search in Google Scholar

[81] Sementsov Y, Yang W, Ivanenko K, Makhno S, Kartel M. Modification of rubber compositions by carbon nanotubes. Appl Nanosci. 2022;12(3):621–8. 10.1007/s13204-021-01730-w.Search in Google Scholar

[82] Mateab S, Albozahid M. Study the effect of adding MWCNTS on the hardness, impact strength, and structural properties of composite materials based on epoxy polymer. Egypt J Chem. 2022;65(3):147–52. 10.21608/EJCHEM.2021.88640.4262.Search in Google Scholar

[83] Nair ST, George SC, Kalarikkal N, Thomas S. Enhanced mechanical and thermal performance of multiwalled carbon nanotubes-filled polypropylene/natural rubber thermoplastic elastomers. New J Chem. 2021;45(11):4963–76. 10.1039/D0NJ05437B.Search in Google Scholar

[84] Mat Desa MSZ, Hassan A, Arsad A, Arjmandi R. Effect of core–shell rubber toughening on mechanical, thermal, and morphological properties of poly (lactic acid)/multiwalled carbon nanotubes nanocomposites. J Appl Polym Sci. 2019;136(28):47756. 10.1002/app.47756.Search in Google Scholar

[85] Singh K, Nanda T, Mehta R. Addition of nanoclay and compatibilized EPDM rubber for improved impact strength of epoxy glass fiber composites. Compos Part A: Appl Sci Manuf. 2017;103:263–71. 10.1016/j.compositesa.2017.10.009.Search in Google Scholar

[86] Ruksakulpiwat Y, Sridee J, Suppakarn N, Sutapun W. Improvement of impact property of natural fiber–polypropylene composite by using natural rubber and EPDM rubber. Compos Part B: Eng. 2009;40(7):619–22. 10.1016/j.compositesb.2009.04.006.Search in Google Scholar

[87] Kenganal SS, Sahoo A. Ground tire rubber/activated carbon/expanded graphite aerogels and foams as support material for the preparation of polyethylene glycol composite phase change materials for thermal energy storage applications. J Energy Storage. 2024;78:109805. 10.1016/j.est.2023.109805.Search in Google Scholar

[88] Zhang K, Qiu J, Sakai E, Zhang G, Wu H, Guo S, et al. Preparation of continuous PBO fiber-filled silicone rubber with high thermal conductivity through simple Wrapping. Compos Commun. 2024;45:101793. 10.1016/j.coco.2023.101793.Search in Google Scholar

[89] Chen Z, Tu Q, Shen X, Fang Z, Bi S, Yin Q, et al. Enhancing the thermal and mechanical properties of carbon fiber/natural rubber composites by co-modification of dopamine and silane coupling agents. Polym Test. 2023;126:108164. 10.1016/j.polymertesting.2023.108164.Search in Google Scholar

[90] Ouyang Y, Yang Z, Long T, Tian H, Bai L, Li X, et al. Preparation of branched Al2O3 and its synergistic effect with carbon nanotubes on the enhancement of thermal conductive and electrical insulation properties of silicone rubber composites. Mater Today Commun. 2023;34:105239. 10.1016/j.mtcomm.2022.105239.Search in Google Scholar

[91] Shi A, Zhang X, Meng J, Song J. Waffle-inspired thermal conductive silicone rubber composites with excellent electromagnetic shielding performance based on three-dimensional filler networks. Mater Lett. 2023;350:134940. 10.1016/j.matlet.2023.134940.Search in Google Scholar

[92] Farahani A, Jamshidi M, Foroutan M. Improving thermal/electrical properties of silicone rubber nanocomposite using exfoliated boron nitride nano sheets made by an effective/novel exfoliating agent. Mater Des. 2023;229:111935. 10.1016/j.matdes.2023.111935.Search in Google Scholar

[93] Razavi-Nouri M, Sabet A, Mohebbi M. Thermal, tensile and rheological properties of dynamically cross-linked organoclay filled poly (ethylene-co-vinyl acetate)/acrylonitrile-butadiene rubber nanocomposites: Effect of peroxide content. Polymer. 2020;190:122212. 10.1016/j.polymer.2020.122212.Search in Google Scholar

[94] Lin JL, Su SM, He YB, Kang FY. Improving thermal and mechanical properties of the alumina filled silicone rubber composite by incorporating carbon nanotubes. New Carbon Mater. 2020;35(1):66–72. 10.1016/S1872-5805(20)60476-0.Search in Google Scholar

[95] Ouyang Y, Li X, Ding F, Bai L, Yuan F. Simultaneously enhance thermal conductive property and mechanical properties of silicon rubber composites by introducing ultrafine Al2O3 nanospheres prepared via thermal plasma. Compos Sci Technol. 2020;190:108019. 10.1016/j.compscitech.2020.108019.Search in Google Scholar

[96] Song J, Peng Z, Zhang Y. Enhancement of thermal conductivity and mechanical properties of silicone rubber composites by using acrylate grafted siloxane copolymers. Chem Eng J. 2020;391:123476. 10.1016/j.cej.2019.123476.Search in Google Scholar

[97] Lim LP, Juan JC, Huang NM, Goh LK, Leng FP, Loh YY. Enhanced tensile strength and thermal conductivity of natural rubber graphene composite properties via rubber-graphene interaction. Mater Sci Eng, B. 2019;246:112–9. 10.1016/j.mseb.2019.06.004.Search in Google Scholar

[98] Xue Y, Li X, Wang H, Zhao F, Zhang D, Chen Y. Improvement in thermal conductivity of through-plane aligned boron nitride/silicone rubber composites. Mater Des. 2019;165:107580. 10.1016/j.matdes.2018.107580.Search in Google Scholar

[99] Liu P, Zhang X, Jia H, Yin Q, Wang J, Yin B, et al. High mechanical properties, thermal conductivity and solvent resistance in graphene oxide/styrene-butadiene rubber nanocomposites by engineering carboxylated acrylonitrile-butadiene rubber. Compos, Part B: Eng. 2017;130:257–66. 10.1016/j.compositesb.2017.07.048.Search in Google Scholar

[100] Nayak A, Rama Sreekanth PS, Sahu SK, Sahu D. Structural tuning of low band gap intermolecular push/pull side-chain polymers for organic photovoltaic applications. Chin J Polym Sci. 2017;35(9):1073–85. 10.1007/s10118-017-1967-9.Search in Google Scholar

[101] Sahu SK, Sreekanth PR. Experimental investigation of in-plane compressive and damping behavior anisotropic graded honeycomb structure. Arab J Sci Eng. 2022;47(12):15741–53. 10.1007/s13369-022-06771-z.Search in Google Scholar

[102] Yesaswi CS, Sahu SK, Sreekanth PR. Experimental investigation of electro-mechanical behavior of silver-coated teflon fabric-reinforced nafion ionic polymer metal composite with carbon nanotubes and graphene nanoparticles. Polymers. 2022;14(24):5497. 10.3390/polym14245497.Search in Google Scholar PubMed PubMed Central

[103] Sahu SK, Badgayan ND, Sreekanth PR. Numerical investigation on the effect of wall thickness on quasistatic crushing properties of nylon honeycomb structure. Mater Today: Proc. 2020;27:798–804. 10.1016/j.matpr.2019.12.351.Search in Google Scholar

[104] Guo X, Guo S, Liu G, Bai L, Liu H, Xu Y, et al. Improving dispersion of carbon nanotubes in natural rubber by using waterjet-produced rubber powder as a carrier. Polymers. 2023;15(3):477. 10.3390/polym15030477.Search in Google Scholar PubMed PubMed Central

[105] Sahu SK, Rama Sreekanth PS. Multiscale RVE modeling for assessing effective elastic modulus of HDPE based polymer matrix nanocomposite reinforced with nanodiamond. Int J Interact Des Manuf (IJIDeM). 2022;1–10. 10.1007/s12008-022-01080-z.Search in Google Scholar

[106] Pradhan S, Sahu SK, Pramanik J, Badgayan ND. An insight into mechanical & thermal properties of shape memory polymer reinforced with nanofillers; a critical review. Mater Today: Proc. 2022;50:1107–12. 10.1016/j.matpr.2021.07.504.Search in Google Scholar

[107] Sanaka R, Sahu SK. Experimental investigation into mechanical, thermal, and shape memory behavior of thermoresponsive PU/MXene shape memory polymer nanocomposite. Heliyon. 2024;10(2):e24014. 10.1016/j.heliyon.2024.e24014.Search in Google Scholar PubMed PubMed Central

[108] Sahu SK, Rama Sreekanth PS. Mechanical, thermal and rheological properties of thermoplastic polymer nanocomposite reinforced with nanodiamond, carbon nanotube and graphite nanoplatelets. Adv Mater Process Technol. 2022;8(sup4):2086–96. 10.1080/2374068X.2022.2034309.Search in Google Scholar

[109] Badgayan ND, Sahu SK, Samanta S, Sreekanth PSR. Assessment of bulk mechanical properties of HDPE hybrid composite filled with 1D/2D nanofiller system. Mater Sci Forum. 2018;917:12–6. 10.4028/www.scientific.net/MSF.917.12.Search in Google Scholar

[110] Sahu SK, Sreekanth PR, Deepthi YP, Ma Q, Erinle TJ. Tensile, flexural and free vibration characteristics of sustainable recycled polypropylene filled with spherical SiC through experimental and RVE analysis. Int J Struct Integr. 2024. 10.1108/IJSI-01-2024-0014.Search in Google Scholar

[111] Amirapu SL, Nelapati GS, Yalamanchili H, Badgayan ND, Sahu SK. HDPE based polymeric nanodiamond nanocomposite for total knee arthoplasty: A finite element based approach. Mater Today: Proc. 2022;56:1622–8. 10.1016/j.matpr.2022.03.290.Search in Google Scholar

[112] Sahu SK, Badgayan ND, Sreekanth PR. Rheological Properties of HDPE based thermoplastic polymeric nanocomposite reinforced with multidimensional carbon-based nanofillers. Biointerface Res Appl Chem. 2022;12(4):5709–15. 10.33263/BRIAC124.57095715.Search in Google Scholar

[113] Badgayan ND, Sahu SK, Sreekanth PR. Investigation of wetting behavior of HDPE reinforced with nanoscopic 1D/2D filler system using contact angle goniometry. Mater Today: Proc. 2020;26:331–4. 10.1016/j.matpr.2019.11.321.Search in Google Scholar

[114] Sahu SK, Badgayan ND, Samanta S, Sreekanth PSR. Dynamic mechanical thermal analysis of high density polyethylene reinforced with nanodiamond, carbon nanotube and graphite nanoplatelet. Mater Sci Forum. 2018;917:27–31. 10.4028/www.scientific.net/MSF.917.27.Search in Google Scholar

[115] Deepthi YP, Sahu SK, Anitha D, Gupta N, dude N, Setti SG, et al. Tribological investigation into nickel-coated graphite polytetrafluoroethylene composites. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering. 2024;09544089241255943. 10.1177/09544089241255943.Search in Google Scholar

[116] Sanaka R, Sahu SK. FEM based RVE modeling for estimating axial modulus of polyurethane composite reinforced with MXene. Int J Interact Des Manuf. 2023;18:3259–69. 10.1007/s12008-023-01485-4.Search in Google Scholar

[117] Sahu SK, Sreekanth PR. Artificial neural network for prediction of mechanical properties of HDPE based nanodiamond nanocomposite. Polym (Korea). 2022;46(5):614–20. 10.7317/pk.2022.46.5.614.Search in Google Scholar

[118] Kushwaha YS, Hemanth NS, Badgayan ND, Sahu SK. Free vibration analysis of PLA based auxetic metamaterial structural composite using finite element analysis. Mater Today: Proc. 2022;56:1063–7. 10.1016/j.matpr.2021.09.482.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Evaluation of the mechanical and dynamic properties of scrimber wood produced from date palm fronds

- Performance of doubly reinforced concrete beams with GFRP bars

- Mechanical properties and microstructure of roller compacted concrete incorporating brick powder, glass powder, and steel slag

- Evaluating deformation in FRP boat: Effects of manufacturing parameters and working conditions

- Mechanical characteristics of structural concrete using building rubbles as recycled coarse aggregate

- Structural behavior of one-way slabs reinforced by a combination of GFRP and steel bars: An experimental and numerical investigation

- Effect of alkaline treatment on mechanical properties of composites between vetiver fibers and epoxy resin

- Development of a small-punch-fatigue test method to evaluate fatigue strength and fatigue crack propagation

- Parameter optimization of anisotropic polarization in magnetorheological elastomers for enhanced impact absorption capability using the Taguchi method

- Determination of soil–water characteristic curves by using a polymer tensiometer

- Optimization of mechanical characteristics of cement mortar incorporating hybrid nano-sustainable powders

- Energy performance of metallic tubular systems under reverse complex loading paths

- Enhancing the machining productivity in PMEDM for titanium alloy with low-frequency vibrations associated with the workpiece

- Long-term viscoelastic behavior and evolution of the Schapery model for mirror epoxy

- Laboratory experimental of ballast–bituminous–latex–roving (Ballbilar) layer for conventional rail track structure

- Eco-friendly mechanical performance of date palm Khestawi-type fiber-reinforced polypropylene composites

- Isothermal aging effect on SAC interconnects of various Ag contents: Nonlinear simulations

- Sustainable and environmentally friendly composites: Development of walnut shell powder-reinforced polypropylene composites for potential automotive applications

- Mechanical behavior of designed AH32 steel specimens under tensile loading at low temperatures: Strength and failure assessments based on experimentally verified FE modeling and analysis

- Review Article

- Review of modeling schemes and machine learning algorithms for fluid rheological behavior analysis

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part I

- Creep–fatigue damage assessment in high-temperature piping system under bending and torsional moments using wireless MEMS-type gyro sensor

- Multiaxial creep deformation investigation of miniature cruciform specimen for type 304 stainless steel at 923 K using non-contact displacement-measuring method

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part I

- Sustainable concrete production: Partial aggregate replacement with electric arc furnace slag

- Exploring the mechanical and thermal properties of rubber-based nanocomposite: A comprehensive review

- Experimental investigation of flexural strength and plane strain fracture toughness of carbon/silk fabric epoxy hybrid composites

- Functionally graded materials of SS316L and IN625 manufactured by direct metal deposition

- Experimental and numerical investigations on tensile properties of carbon fibre-reinforced plastic and self-reinforced polypropylene composites

- Influence of plasma nitriding on surface layer of M50NiL steel for bearing applications

Articles in the same Issue

- Research Articles

- Evaluation of the mechanical and dynamic properties of scrimber wood produced from date palm fronds

- Performance of doubly reinforced concrete beams with GFRP bars

- Mechanical properties and microstructure of roller compacted concrete incorporating brick powder, glass powder, and steel slag

- Evaluating deformation in FRP boat: Effects of manufacturing parameters and working conditions

- Mechanical characteristics of structural concrete using building rubbles as recycled coarse aggregate

- Structural behavior of one-way slabs reinforced by a combination of GFRP and steel bars: An experimental and numerical investigation

- Effect of alkaline treatment on mechanical properties of composites between vetiver fibers and epoxy resin

- Development of a small-punch-fatigue test method to evaluate fatigue strength and fatigue crack propagation

- Parameter optimization of anisotropic polarization in magnetorheological elastomers for enhanced impact absorption capability using the Taguchi method

- Determination of soil–water characteristic curves by using a polymer tensiometer

- Optimization of mechanical characteristics of cement mortar incorporating hybrid nano-sustainable powders

- Energy performance of metallic tubular systems under reverse complex loading paths

- Enhancing the machining productivity in PMEDM for titanium alloy with low-frequency vibrations associated with the workpiece

- Long-term viscoelastic behavior and evolution of the Schapery model for mirror epoxy

- Laboratory experimental of ballast–bituminous–latex–roving (Ballbilar) layer for conventional rail track structure

- Eco-friendly mechanical performance of date palm Khestawi-type fiber-reinforced polypropylene composites

- Isothermal aging effect on SAC interconnects of various Ag contents: Nonlinear simulations

- Sustainable and environmentally friendly composites: Development of walnut shell powder-reinforced polypropylene composites for potential automotive applications

- Mechanical behavior of designed AH32 steel specimens under tensile loading at low temperatures: Strength and failure assessments based on experimentally verified FE modeling and analysis

- Review Article

- Review of modeling schemes and machine learning algorithms for fluid rheological behavior analysis

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part I

- Creep–fatigue damage assessment in high-temperature piping system under bending and torsional moments using wireless MEMS-type gyro sensor

- Multiaxial creep deformation investigation of miniature cruciform specimen for type 304 stainless steel at 923 K using non-contact displacement-measuring method

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part I

- Sustainable concrete production: Partial aggregate replacement with electric arc furnace slag

- Exploring the mechanical and thermal properties of rubber-based nanocomposite: A comprehensive review

- Experimental investigation of flexural strength and plane strain fracture toughness of carbon/silk fabric epoxy hybrid composites

- Functionally graded materials of SS316L and IN625 manufactured by direct metal deposition

- Experimental and numerical investigations on tensile properties of carbon fibre-reinforced plastic and self-reinforced polypropylene composites

- Influence of plasma nitriding on surface layer of M50NiL steel for bearing applications