Abstract

Dicyclopentadiene (DCPD) resin has gained popularity owing to its fast curing time and ease of processing with a low viscosity in the monomer state. In the present study, the impact and shear properties of a carbon fiber (CF)/p-DCPD composite were investigated. The CF/p-DCPD composite was manufactured by vacuum-assisted resin transfer molding with CF as the reinforcement and p-DCPD as the resin with a maximum fiber volume fraction of 55 weight percent. Impact and shear properties of the CF/p-DCPD composite were evaluated and compared with those of a CF/Epoxy composite. The maximum shear stress and modulus of the CF/p-DCPD composite were lower than that of the CF/Epoxy composite. However, the CF/p-DCPD composite had higher toughness than that of the CF/Epoxy composite; this indicates that it is tougher and exhibits a more ductile load-displacement response with a lower modulus and larger failure deformation. The impact strength of the CF/p-DCPD composite was about three time that of the CF/Epoxy composite. The higher impact strength of the CF/p-DCPD composite is attributed to the resin characteristics: epoxy resin has a more brittle behavior, and hence, higher energy is required for crack propagation due to fracture.

1 Introduction

With the rapid development of high-performance fibers and their increasing use in critical structural applications, there is a great need for high strength and lightweight. These trends have led to an increase in the use of fiber-reinforced composite (FRC) materials in many areas such as structure applications, including rehabilitation and retrofitting, mainly because of their superior high-strength properties, corrosion resistance, and low weight (1,2). New types of resin and fiber that can adopt the liquid composite molding (LCM) process are made of a wide range of thermosetting resins and reinforcements, respectively. Among them, poly-dicyclopentadiene (p-DCPD) has gained popularity because of its fast curing time, excellent impact resistance, high chemical corrosion resistance, and dimensional stability (3). Due to productivity advantage with short curing time, the DCPD resin is usually used for applications such as automobile bumpers and heavy equipment bodies. Carbon fiber (CF) reinforcement has also attracted much attention and has long been a subject of investigation for its use as reinforcements in polymer matrices because of its high stiffness, high strength, low weight, and good thermal properties (4). Therefore, the evaluation of mechanical properties such as impact and shear strengths is required for carbon fiber-reinforced plastics (CFRPs) and new types of resin composites.

Extensive research has made it possible to evaluate resins and fibers suitable for the LCM process. Among the various researches, several recent investigations deal with the impact property of CFRPs (5, 6, 7, 8, 9, 10). Harris and Bunsell investigated the Charpy impact properties of mixed glass fiber/CF composites measured as a function of composition on notched and un-notched rod samples (5). Premalal et al. (6) studied the effect of unmodified and ground talc and rice husk fillers compounded with polypropylene (PP) separately in a Brabender Plasticorder internal mixer. Ruksakulpiwat et al. (7) examined the rheological, morphological, and mechanical properties of PP and PP composites prepared by injection molding with and without natural rubber (NR) or ethylene propylene diene monomer (EPDM) rubber. They reported that the impact strength and elongation at break of the PP composite significantly increased with the addition of more than 20 weight percent of NR or EPDM rubber to PP. Harish et al. (8) developed coir composites and evaluated their mechanical properties such as flexural and impact strengths and revealed that coir can be used as a potential reinforcing material for making low-load bearing thermoplastic composites. Liu et al. (9) conducted Charpy impact tests on notched PP specimens and unnotched polystyrene specimens at room temperature and showed that the impact property improved by the addition of graft-modified rubbers. Park et al. (10) fabricated CFRPs incorporated with core-shell rubbers (CSRs) by the vacuum-assisted resin transfer molding (VARTM) process and investigated the impact strength of the CFRPs. They reported that the impact strength of the CFRPs improved by up to 87.5% depending on an increase in the CSR content. However, investigations on correlating the impact behavior of CF/p-DCPD composites are limited. It is with this view that the present study on the impact properties of CF/p-DCPD composites manufactured with liquid composite molding process has been undertaken, especially for the improvement of mechanical properties of CF/p-DCPD composites (3,11).

The shear strength is a critical aspect in the evaluation of mechanical property of CF/p-DCPD composites because it is mainly related with the interfacial property for the composite matrix and reinforcement. Several studies have been conducted on the shear property of CFRPs in search of suitable materials. The curing kinetics can be conveniently measured by isothermal DSC measurements; however, some inevitable problems exist such as dynamic preheat time and limited temperature (11, 12, 13, 14). Dominguez et al. (11) studied the room‐temperature mechanical properties of unidirectional CF‐reinforced phthalonitrile composite panels by short beam shear, tension, and flexural tests. Kretsis (12) investigated the basic mechanical properties including shear strength of continuous-fiber hybrids, that is, carbon and glass hybrid fiber-reinforced epoxy and predicted a model to compare the strengths. Valluzzi et al. (13) performed an experimental study on brick masonry panels strengthened by FRP laminates to evaluate the compressive and shear strengths to simulate the in-plane shear phenomenon. Gabor et al. (14) examined the behavior of unreinforced and FRP-strengthened masonry walls when subjected to a predominant shear load using different finite element modelling approaches.

The cost using DCPD composite was mostly dependent on the cost of catalyst that improves reactivity. Molybdenum (Mo), ruthenium (Ru), titanium (Ti) and chromium (Cr) are commonly used catalysts for manufacturing DCPD composites (15). Among these catalysts, lots of applications using Mo-Based Catalysts were increased due to cost effectiveness. Much research has also been conducted to reduce the cost using Ru-Based catalysts. Regarding manufacturing cost, DCPD composite will be advantageous with productivity advantage with short curing time along with reduced cost of catalyst (3,15).

Although there is a compelling need for the evaluation of mechanical properties of CFRPs and new types of DCPD resin composites, fewer studies were conducted on the mechanical properties of composites. Limited number of studies was investigated mainly on CF/epoxy and glass fibers/unsaturated polyester resin composites as show in Table 1. The evaluation of mechanical properties for the CF/p-DCPD composites was mainly conducted for the shear and impact properties because measuring these properties were to investigate matrix effect rather than reinforcement effects. The present paper reports the manufacturing of CF/p-DCPD composites by the VARTM process as well as the evaluation of their impact and shear properties and comparison with CF/Epoxy composites to examine the effect of different resins.

Comparison between characteristics of the present system and other known systems using VARTM technique.

| Composite | CF/p-DCPD | CF/Epoxy (16) | GF/UPR (17) |

|---|---|---|---|

| Reinforcement | Carbon fabric | Carbon/Glass fabric | Woven glass fiber |

| Matrix | Dicyclopentadiene | Epoxy | Unsaturated polyester |

| Volume fraction | 55 wt% | 50 vol% | 50 wt% |

2 Experimental

2.1 Materials

A CF/p-DCPD composite was used in this study. Carbon fabric (3K plain carbon fabric, C-120, Muhan Composite Corp.,) and DCPD resin (454338, contains BHT; Sigma-Aldrich Korea) were used as the reinforcement and resin, respectively. Ru-based Grubbs second-generation catalyst (Sigma-Aldrich Corp., U.S.A) was used to initiate polymerization of the DCPD resin. For the impact strength tests, a CF/Epoxy composite was also manufactured to prepare the test specimen using an epoxy resin (KFR-130, Kukdo Chemical Corp., Korea) and hardener (KFH-140, Kukdo Chemical Corp., Korea).

2.2 Recrystallization of catalyst

The catalyst was recrystallized to ensure its uniform dispersion in the resin to obtain uniform particles (18). The catalyst used in the present study is in a solid powder state; therefore, a solvent is necessary to dissolve the catalyst. The solvent used in the study was dichloromethane (CH2Cl2). The solvent was evaporated in a vacuum chamber for 24 h after the catalyst was completely dissolved in the solvent in a glove box. After the catalyst was treated with dichloromethane, the catalyst was changed into relatively regular spherical particles with the recrystallization process. The recrystallized catalyst can be advantageous for achieving a rapid reaction with the resin.

2.3 Manufacturing of CF/p-DCPD composites by VARTM process

In the VARTM process, carbon fabric sample was prepared to cut into a size of 150 × 150 mm, as shown in Figure 1. To prevent the vacuum bag from sticking to the fabric, a peel ply was used. To allow the resin to enter into the fabric end, a flow media along with a vacuum pump and resin trap was used in the process, as shown in Figure 2. To achieve a more stable curing process, curing was carried out on a heater. The composite materials were manufactured by the VARTM process with a heating system wherein the mold was maintained at 100°C for more than 10 min (3,15).

Plain carbon fabric (left) and peel ply (right).

Vacuum-assisted resin transfer molding (VARTM) process with DCPD resin.

2.4 In-plane shear stress test

To measure the in-plane shear property of the new CF/p-DCPD composite material, ± 45° tensile specimens were prepared according to ASTM D3518. Rectangular specimens of the fabricated composite materials with dimensions of 25 mm (W) × 2.5 mm (T) × 150 mm (L), where W, T, and L are the width, thickness, and length, respectively, were prepared for the shear test. The shear strength was measured using a universal testing machine (UTM) with a strain gage attached in the middle of the specimen, as shown in Figure 3. The test speed was maintained at 2 mm/min. The data of the shear stress/strain curves were obtained from the load cell and strain gauge readings and specimen dimensions. The results were measured at least five times under each condition and are shown with an error bar including the average values.

In-plane shear stress test (ASTM D3518).

2.5 Izod impact strength test

Impact testing of the CF/p-DCPD and CF/Epoxy composites was performed according to ASTM D256. Specimens of the fabricated composite materials with dimensions of 12.7 mm (W) × 12.7 mm (T) × 63.5 mm (L), where W, T, and L are the width, thickness, and length, respectively, were prepared for the impact test. A notch was created in the specimens with a central 45° V-notch to a depth of 2.54 mm and a radius of 0.25 mm. These specimens were tested using an Izod pendulum-type impact tester, which uses a standard method for testing the Izod impact resistance of the specimens measuring the absorbed energy. The impact results were also measured at least five times under each condition and are shown with an error bar including the average values.

3 Results and discussion

3.1 In-plane shear stress of CF/p-DCPD composites

The shear stress and shear strain values were determined with ± 45° tensile specimens expressed as follows (19,20):

Here, τ12 is the shear stress, σx is the tensile stress in the specimen, and γ12 is the shear strain. The strains εx and εy expressed in Eq. 1 and 2 represent the strain in the loading direction and the strain perpendicular to the loading direction, respectively.

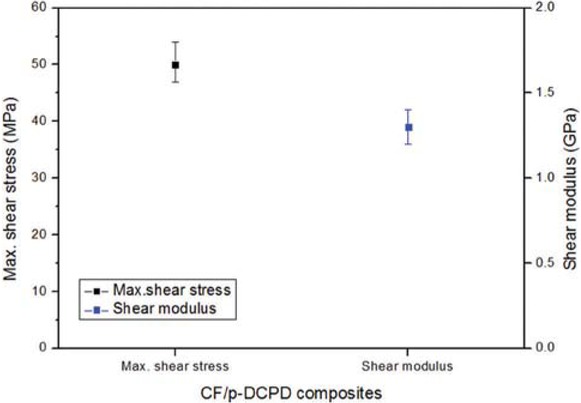

Generally, the maximum fiber volume fraction of a composite manufactured by the VARTM process is about 50-60 weight percent (wt%) (21). In the present CF/p-DCPD composites, a fiber volume fraction of 55 wt% was achieved, and the shear property was evaluated for this volume fraction. The entire process of shear response of the CF/p-DCPD composites manufactured by VARTM was obtained from the axial load-displacement curves, as shown in Figure 4. Small differences were observed in the shear modulus, shear strength, and ultimate stress of the specimens having the same configurations. As can be seen, for the CF/p-DCPD composites with 55 wt% fiber volume fraction, a maximum shear stress of 50.3 MPa was obtained. The experimental data for the entire process of shear response of the CF/Epoxy composites manufactured by VARTM provided by Liang et al. (22) are shown to compare the effect of different resins (Figure 4). The CF/Epoxy composites achieved a shear stress of 61.9 MPa and modulus of 4.14 GPa, while the CF/p-DCPD composites achieved a shear stress of 50.3 MPa and modulus of 1.26 GPA, as shown in Figure 5 and Table 2. However, the CF/p-DCPD composites exhibit about 30% larger strain until fracture compared with the CF/Epoxy composites. The overall comparison of the shear properties of the CF/p-DCPD and CF/Epoxy composites revealed that the maximum shear stress and modulus of CF/Epoxy are higher than those of the CF/p-DCPD composites tested according to ASTM D3518. However, the CF/p-DCPD composites have higher toughness than that of the CF/Epoxy composites: similar results were reported by Toplosky and Walsh (23) and Rohde (24). This indicates that the CF/p-DCPD material is tougher and exhibits a more ductile load-displacement response with a lower modulus and larger failure deformation.

Load-displacement curves of CF/Epoxy (22) and CF/p-DCPD composites.

Maximum shear stress and shear modulus of CF/p-DCPD composites.

Maximum shear stress and shear modulus of CF/p-DCPD composites.

| CF/p-DCPD composites | CF/epoxy composites | |

|---|---|---|

| Max. shear stress (MPa) | 50.3 | 61.9 |

| Shear modulus (GPa) | 1.26 | 4.14 |

| Max. extension (mm) | 31 | 18 |

3.2 Impact strength of CF/p-DCPD composites

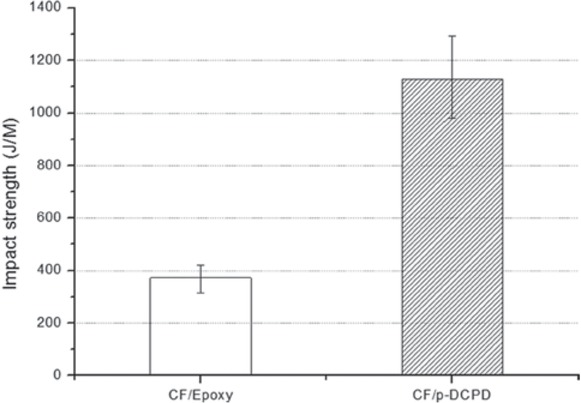

The Izod impact tests for the CF/p-DCPD composites were performed to evaluate the impact properties for 55 wt% fiber volume fraction. Furthermore, the impact strength of the CF/p-DCPD composite was compared with that of CF/Epoxy with the same fiber volume fraction of 55 wt%. The impact test results are shown in Figure 6 and Table 3. The impact energy of the CF/p-DCPD composite was estimated to be approximately 1120 J/m, while that of the CF/Epoxy composite was 390 J/m. This result showed that the impact strength of CF/p-DCPD is about three times that of CF/Epoxy.

Impact strengths of CF/p-DCPD and CF/Epoxy composites.

Impact strengths of CF/p-DCPD and CF/Epoxy composites.

| CF/p-DCPD | CF/Epoxy | |

|---|---|---|

| Impact strength (J/m) | 390 | 1120 |

3.3 Fractography analysis

The SEM micrographs of the fracture surfaces of CF/p-DCPD composite after the Izod impact tests and that of the CF/Epoxy composite are shown in Figure 7 to compare the fracture behavior. The two specimens show the typical characteristics of brittle fracture. In detail, rougher surfaces are observed with tortuous ridges and river marks the fracture surface in the fractographs of the CF/p-DCPD composite. It is suggested that the shear specimens broke more yieldingly than the CF/Epoxy composite did. Meanwhile, in the CF/Epoxy composite, a smooth glassy fracture surface with cracks can be observed, as shown in Figure 7b. The fracture surface is very smooth and shows brittle fracture behavior, suggesting that brittle fracture of the epoxy network occurred. The fracture surface of the epoxy resin is smoother than that of the DCPD resin. This indicates the more brittle behavior of the epoxy resin; therefore, higher energy is required for crack propagation due to fracture, and the impact strength of the CF/p-DCPD composite is much higher than that of the CF/Epoxy composite.

Fracture surfaces of CF/p-DCPD composite (a) and CF/Epoxy composite (b).

4 Conclusion

CF/p-DCPD composites were manufactured by the VARTM process with a maximum fiber volume fraction of 55 wt% and its impact and shear properties were evaluated and compared with those of a CF/Epoxy composite. The main conclusions of the study are as follows:

The experiment for the entire process of shear response for the CF/p-DCPD composites was conducted and the shear properties value was compared with CF/Epoxy composite. The maximum shear stress and modulus of the CF/Epoxy composite are higher than those of the CF/p-DCPD composite. However, the CF/p-DCPD composite has higher toughness than that of the CF/Epoxy composite.

The Izod impact tests were conducted for the CF/p-DCPD and CF/Epoxy composite to evaluate the impact strength with the same fiber volume fraction condition of 55 wt%. The results showed that the impact strength of CF/p-DCPD is about three times larger than that of CF/Epoxy.

The fracture surfaces of CF/p-DCPD and CF/Epoxy composites showed the typical characteristics of brittle fracture. Rougher surfaces are observed in the fractographs of the CF/p-DCPD composite, while the CF/Epoxy composite showed a smoother surface.

From the impact test with fractography analysis, it is found higher energy is required for crack propagation due to fracture. This results in higher impact strength for the CF/p-DCPD composite.

In our future research, we will perform the investigations for the impact properties evaluations for the temperature dependency especially for the effect of cryogenic temperature.

Acknowledgments

This work was supported in part by the National Research Foundation (NRF) of Korea funded by the Korea government (MSIP; Ministry of Science, ICT & Future Planning) (Grant No.: NRF-2018R1C1B5086170), and in part by Basic Science Research Program through the National Research Foundation of Korea(NRF) funded by the Ministry of Education (grant no 2018R1D1A1B07044505).

References

1 Hardeo P., Karunasena W., Buckling of fibre-reinforced plywood plates, World Scientific Publishing, 2003.10.1142/9789812776228_0062Search in Google Scholar

2 Choi S.W., Li M., Lee W.I., Kim H. S., Analysis of buckling load of glass fiber/epoxy-reinforced plywood and its temperature dependence. J. Compos. Mater., 2014, 48(18), 2191-2206.10.1177/0021998313495071Search in Google Scholar

3 Yoo H.M., Jeon J.H., Li M., Lee W.I., Choi S.W., Analysis of curing behavior of endo-dicyclopentadiene using different amounts of decelerator solution. Compos. Part B-Eng., 2019, 161, 439-454.10.1016/j.compositesb.2018.12.068Search in Google Scholar

4 Hussain M., Nakahira A., Nishijima S., Niihara K., Evaluation of mechanical behavior of CFRC transverse to the fiber direction at room and cryogenic temperature. Compos. Part A-Appl. S., 2000, 31(2), 173-179.10.1016/S1359-835X(99)00060-3Search in Google Scholar

5 Harris B., Bunsell A.R., Impact properties of glass fibre/carbon fibre hybrid composites. Composites, 1975, 6(5), 197-201.10.1016/0010-4361(75)90413-9Search in Google Scholar

6 Premalal H.G.B., Ismail H., Baharin A., Comparison of the mechanical properties of rice husk powder filled polypropylene composites with talc filled polypropylene composites. Polym. Test., 2002, 21(7), 833-839.10.1016/S0142-9418(02)00018-1Search in Google Scholar

7 Ruksakulpiwat Y., Sridee J., Suppakarn N., Sutapun W., Improvement of impact property of natural fiber–polypropylene composite by using natural rubber and EPDM rubber. Compos. Part B-Eng., 2009, 40(7), 619-622.10.1016/j.compositesb.2009.04.006Search in Google Scholar

8 Harish S., Michael D.P., Bensely A., Mechanical property evaluation of natural fiber coir composite. Mater. Charact., 2009, 60(1), 44-49.10.1016/j.matchar.2008.07.001Search in Google Scholar

9 Liu H., Zuo D., Liu H., Li L., Li J., Wu W., Enhanced impact strength and deviated thermal decomposition of PP and PS toughened with graft-modified rubbers. e-Polymers, 2010, 10(1), 134.10.1515/epoly.2010.10.1.1499Search in Google Scholar

10 Park H., Jung H., Yu J., Park M., Kim S.Y., Carbon fiber-reinforced plastics based on epoxy resin toughened with core shell rubber impact modifiers. e-Polymers, 2015, 15(6), 369-375.10.1515/epoly-2015-0068Search in Google Scholar

11 Dominguez D.D., Jones H.N., Keller T.M., The effect of curing additive on the mechanical properties of phthalonitrile-carbon fiber composites. Polym. Composite., 2004, 25(5), 554-561.10.1002/pc.20049Search in Google Scholar

12 Kretsis G., A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites, 1987, 18(1), 13-23.10.1016/0010-4361(87)90003-6Search in Google Scholar

13 Valluzzi M.R., Tinazzi D., Modena C., Shear behavior of masonry panels strengthened by FRP laminates. Constr. Build. Mater., 2002, 16(7), 409-416.10.1016/S0950-0618(02)00043-0Search in Google Scholar

14 Gabor A., Bennani A., Jacquelin E., Modelling approaches of the in-plane shear behaviour of unreinforced and FRP strengthened masonry panels. Compos. Struct., 2006, 74(3), 277-288.10.1016/j.compstruct.2005.04.012Search in Google Scholar

15 Yoo H.M., Kwon D.J., Park J.M., Yum S.H., Lee W.I., Mechanical properties of norbornene-based silane treated glass fiber reinforced polydicyclopentadiene composites manufactured by the S-RIM process. e-Polymers, 2017, 17(2), 159-166.10.1515/epoly-2016-0257Search in Google Scholar

16 Song J.H., Manufacturing method of carbon and glass fabric composites with dispersed nanofibers using vacuum-assisted resin transfer molding. e-Polymers, 2014, 14(5), 345-352.10.1515/epoly-2014-0091Search in Google Scholar

17 Hoang V.T., Yum Y.J., Optimization of the fabrication conditions and effects of multi-walled carbon nanotubes on the tensile properties of various glass fibers/unsaturated polyester resin composites. e-Polymers, 2018, 18(5), 441-451.10.1515/epoly-2018-0033Search in Google Scholar

18 Jones A.S., Rule J.D., Moore J.S., White S.R., Sottos N.R., Catalyst Morphology and Dissolution Kinetics of Self-Healing Polymers. Chem. Mater., 2006, 18(5), 1312-1317.10.1021/cm051864sSearch in Google Scholar

19 Lee S., Munro M., Scott R.F., Evaluation of three in-plane shear test methods for advanced composite materials. Composites, 1990, 21(6), 495-502.10.1016/0010-4361(90)90422-SSearch in Google Scholar

20 Rosen B.W., A simple procedure for experimental determination of the longitudinal shear modulus of unidirectional composites. J. Compos. Mater., 1972, 6(3), 552-554.10.1177/002199837200600411Search in Google Scholar

21 Chuang K.C., Criss J.M., Mintz E.A., Shonkwiler B., McCorkle L.S., Composite Properties of RTM370 Polyimide Fabricated by Vacuum Assisted Resin Transfer Molding (VARTM). NASA Glenn Research Center, Ohio, USA, 2011.Search in Google Scholar

22 Liang Y., Wang H., Gu X., In-plane shear response of unidirectional fiber reinforced and fabric reinforced carbon/epoxy composites. Polym. Test., 2013, 32(3), 594-601.10.1016/j.polymertesting.2013.01.015Search in Google Scholar

23 Toplosky V.J., Walsh R.P., Thermal and Mechanical Properties of Poly-Dicyclopentadiene (DCPD) at Cryogenic Temperatures. AIP Conference Proceedings, 2006, 824(219).10.1063/1.2192354Search in Google Scholar

24 Rohde B.J., Robertson M.L., Krishnamoorti R., Concurrent curing kinetics of an anhydride-cured epoxy resin and polydicyclopentadiene. Polymer, 2015, 69, 204-214.10.1016/j.polymer.2015.04.066Search in Google Scholar

© 2019 Yoo et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Articles in the same Issue

- Special Issue: Polymers and Composite Materials / Guest Editor: Esteban Broitman

- A novel chemical-consolidation sand control composition: Foam amino resin system

- Bottom fire behaviour of thermally thick natural rubber latex foam

- Preparation of polymer–rare earth complexes based on Schiff-base-containing salicylic aldehyde groups attached to the polymer and their fluorescence emission properties

- Study on the unsaturated hydrogen bond behavior of bio-based polyamide 56

- Effect of different nucleating agent on crystallization kinetics and morphology of polypropylene

- Effect of surface modifications on the properties of UHMWPE fibres and their composites

- Thermal degradation kinetics investigation on Nano-ZnO/IFR synergetic flame retarded polypropylene/ethylene-propylene-diene monomer composites processed via different fields

- Properties of carbon black-PEDOT composite prepared via in-situ chemical oxidative polymerization

- Regular articles

- Polyarylene ether nitrile and boron nitride composites: coating with sulfonated polyarylene ether nitrile

- Influence of boric acid on radial structure of oxidized polyacrylonitrile fibers

- Preparing an injectable hydrogel with sodium alginate and Type I collagen to create better MSCs growth microenvironment

- Application of calcium montmorillonite on flame resistance, thermal stability and interfacial adhesion in polystyrene nanocomposites

- Modifications of microcrystalline cellulose (MCC), nanofibrillated cellulose (NFC), and nanocrystalline cellulose (NCC) for antimicrobial and wound healing applications

- Polycation-globular protein complex: Ionic strength and chain length effects on the structure and properties

- Improving the flame retardancy of ethylene vinyl acetate composites by incorporating layered double hydroxides based on Bayer red mud

- N, N’-sebacic bis(hydrocinnamic acid) dihydrazide: A crystallization accelerator for poly(L-lactic acid)

- The fabrication and characterization of casein/PEO nanofibrous yarn via electrospinning

- Waterborne poly(urethane-urea)s films as a sustained release system for ketoconazole

- Polyimide/mica hybrid films with low coefficient of thermal expansion and low dielectric constant

- Effects of cylindrical-electrode-assisted solution blowing spinning process parameters on polymer nanofiber morphology and microstructure

- Stimuli-responsive DOX release behavior of cross-linked poly(acrylic acid) nanoparticles

- Continuous fabrication of near-infrared light responsive bilayer hydrogel fibers based on microfluidic spinning

- A novel polyamidine-grafted carboxymethylcellulose: Synthesis, characterization and flocculation performance test

- Synthesis of a DOPO-triazine additive and its flame-retardant effect in rigid polyurethane foam

- Novel chitosan and Laponite based nanocomposite for fast removal of Cd(II), methylene blue and Congo red from aqueous solution

- Enhanced thermal oxidative stability of silicone rubber by using cerium-ferric complex oxide as thermal oxidative stabilizer

- Long-term durability antibacterial microcapsules with plant-derived Chinese nutgall and their applications in wound dressing

- Fully water-blown polyisocyanurate-polyurethane foams with improved mechanical properties prepared from aqueous solution of gelling/ blowing and trimerization catalysts

- Preparation of rosin-based polymer microspheres as a stationary phase in high-performance liquid chromatography to separate polycyclic aromatic hydrocarbons and alkaloids

- Effects of chemical modifications on the rheological and the expansion behavior of polylactide (PLA) in foam extrusion

- Enhanced thermal conductivity of flexible h-BN/polyimide composites films with ethyl cellulose

- Maize-like ionic liquid@polyaniline nanocomposites for high performance supercapacitor

- γ-valerolactone (GVL) as a bio-based green solvent and ligand for iron-mediated AGET ATRP

- Revealing key parameters to minimize the diameter of polypropylene fibers produced in the melt electrospinning process

- Preliminary market analysis of PEEK in South America: opportunities and challenges

- Influence of mid-stress on the dynamic fatigue of a light weight EPS bead foam

- Manipulating the thermal and dynamic mechanical properties of polydicyclopentadiene via tuning the stiffness of the incorporated monomers

- Voigt-based swelling water model for super water absorbency of expanded perlite and sodium polyacrylate resin composite materials

- Simplified optimal modeling of resin injection molding process

- Synthesis and characterization of a polyisocyanide with thioether pendant caused an oxidation-triggered helix-to-helix transition

- A glimpse of biodegradable polymers and their biomedical applications

- Development of vegetable oil-based conducting rigid PU foam

- Conetworks on the base of polystyrene with poly(methyl methacrylate) paired polymers

- Effect of coupling agent on the morphological characteristics of natural rubber/silica composites foams

- Impact and shear properties of carbon fabric/ poly-dicyclopentadiene composites manufactured by vacuum‐assisted resin transfer molding

- Effect of resins on the salt spray resistance and wet adhesion of two component waterborne polyurethane coating

- Modifying potato starch by glutaraldehyde and MgCl2 for developing an economical and environment-friendly electrolyte system

- Effect of curing degree on mechanical and thermal properties of 2.5D quartz fiber reinforced boron phenolic composites

- Preparation and performance of polypropylene separator modified by SiO2/PVA layer for lithium batteries

- A simple method for the production of low molecular weight hyaluronan by in situ degradation in fermentation broth

- Curing behaviors, mechanical properties, dynamic mechanical analysis and morphologies of natural rubber vulcanizates containing reclaimed rubber

- Developing an epoxy resin with high toughness for grouting material via co-polymerization method

- Application of antioxidant and ultraviolet absorber into HDPE: Enhanced resistance to UV irradiation

- Study on the synthesis of hexene-1 catalyzed by Ziegler-Natta catalyst and polyhexene-1 applications

- Fabrication and characterization of conductive microcapsule containing phase change material

- Desorption of hydrolyzed poly(AM/DMDAAC) from bentonite and its decomposition in saltwater under high temperatures

- Synthesis, characterization and properties of biomass and carbon dioxide derived polyurethane reactive hot-melt adhesives

- The application of a phosphorus nitrogen flame retardant curing agent in epoxy resin

- High performance polyimide films containing benzimidazole moieties for thin film solar cells

- Rigid polyurethane/expanded vermiculite/ melamine phenylphosphate composite foams with good flame retardant and mechanical properties

- A novel film-forming silicone polymer as shale inhibitor for water-based drilling fluids

- Facile droplet microfluidics preparation of larger PAM-based particles and investigation of their swelling gelation behavior

- Effect of salt and temperature on molecular aggregation behavior of acrylamide polymer

- Dynamics of asymmetric star polymers under coarse grain simulations

- Experimental and numerical analysis of an improved melt-blowing slot-die

Articles in the same Issue

- Special Issue: Polymers and Composite Materials / Guest Editor: Esteban Broitman

- A novel chemical-consolidation sand control composition: Foam amino resin system

- Bottom fire behaviour of thermally thick natural rubber latex foam

- Preparation of polymer–rare earth complexes based on Schiff-base-containing salicylic aldehyde groups attached to the polymer and their fluorescence emission properties

- Study on the unsaturated hydrogen bond behavior of bio-based polyamide 56

- Effect of different nucleating agent on crystallization kinetics and morphology of polypropylene

- Effect of surface modifications on the properties of UHMWPE fibres and their composites

- Thermal degradation kinetics investigation on Nano-ZnO/IFR synergetic flame retarded polypropylene/ethylene-propylene-diene monomer composites processed via different fields

- Properties of carbon black-PEDOT composite prepared via in-situ chemical oxidative polymerization

- Regular articles

- Polyarylene ether nitrile and boron nitride composites: coating with sulfonated polyarylene ether nitrile

- Influence of boric acid on radial structure of oxidized polyacrylonitrile fibers

- Preparing an injectable hydrogel with sodium alginate and Type I collagen to create better MSCs growth microenvironment

- Application of calcium montmorillonite on flame resistance, thermal stability and interfacial adhesion in polystyrene nanocomposites

- Modifications of microcrystalline cellulose (MCC), nanofibrillated cellulose (NFC), and nanocrystalline cellulose (NCC) for antimicrobial and wound healing applications

- Polycation-globular protein complex: Ionic strength and chain length effects on the structure and properties

- Improving the flame retardancy of ethylene vinyl acetate composites by incorporating layered double hydroxides based on Bayer red mud

- N, N’-sebacic bis(hydrocinnamic acid) dihydrazide: A crystallization accelerator for poly(L-lactic acid)

- The fabrication and characterization of casein/PEO nanofibrous yarn via electrospinning

- Waterborne poly(urethane-urea)s films as a sustained release system for ketoconazole

- Polyimide/mica hybrid films with low coefficient of thermal expansion and low dielectric constant

- Effects of cylindrical-electrode-assisted solution blowing spinning process parameters on polymer nanofiber morphology and microstructure

- Stimuli-responsive DOX release behavior of cross-linked poly(acrylic acid) nanoparticles

- Continuous fabrication of near-infrared light responsive bilayer hydrogel fibers based on microfluidic spinning

- A novel polyamidine-grafted carboxymethylcellulose: Synthesis, characterization and flocculation performance test

- Synthesis of a DOPO-triazine additive and its flame-retardant effect in rigid polyurethane foam

- Novel chitosan and Laponite based nanocomposite for fast removal of Cd(II), methylene blue and Congo red from aqueous solution

- Enhanced thermal oxidative stability of silicone rubber by using cerium-ferric complex oxide as thermal oxidative stabilizer

- Long-term durability antibacterial microcapsules with plant-derived Chinese nutgall and their applications in wound dressing

- Fully water-blown polyisocyanurate-polyurethane foams with improved mechanical properties prepared from aqueous solution of gelling/ blowing and trimerization catalysts

- Preparation of rosin-based polymer microspheres as a stationary phase in high-performance liquid chromatography to separate polycyclic aromatic hydrocarbons and alkaloids

- Effects of chemical modifications on the rheological and the expansion behavior of polylactide (PLA) in foam extrusion

- Enhanced thermal conductivity of flexible h-BN/polyimide composites films with ethyl cellulose

- Maize-like ionic liquid@polyaniline nanocomposites for high performance supercapacitor

- γ-valerolactone (GVL) as a bio-based green solvent and ligand for iron-mediated AGET ATRP

- Revealing key parameters to minimize the diameter of polypropylene fibers produced in the melt electrospinning process

- Preliminary market analysis of PEEK in South America: opportunities and challenges

- Influence of mid-stress on the dynamic fatigue of a light weight EPS bead foam

- Manipulating the thermal and dynamic mechanical properties of polydicyclopentadiene via tuning the stiffness of the incorporated monomers

- Voigt-based swelling water model for super water absorbency of expanded perlite and sodium polyacrylate resin composite materials

- Simplified optimal modeling of resin injection molding process

- Synthesis and characterization of a polyisocyanide with thioether pendant caused an oxidation-triggered helix-to-helix transition

- A glimpse of biodegradable polymers and their biomedical applications

- Development of vegetable oil-based conducting rigid PU foam

- Conetworks on the base of polystyrene with poly(methyl methacrylate) paired polymers

- Effect of coupling agent on the morphological characteristics of natural rubber/silica composites foams

- Impact and shear properties of carbon fabric/ poly-dicyclopentadiene composites manufactured by vacuum‐assisted resin transfer molding

- Effect of resins on the salt spray resistance and wet adhesion of two component waterborne polyurethane coating

- Modifying potato starch by glutaraldehyde and MgCl2 for developing an economical and environment-friendly electrolyte system

- Effect of curing degree on mechanical and thermal properties of 2.5D quartz fiber reinforced boron phenolic composites

- Preparation and performance of polypropylene separator modified by SiO2/PVA layer for lithium batteries

- A simple method for the production of low molecular weight hyaluronan by in situ degradation in fermentation broth

- Curing behaviors, mechanical properties, dynamic mechanical analysis and morphologies of natural rubber vulcanizates containing reclaimed rubber

- Developing an epoxy resin with high toughness for grouting material via co-polymerization method

- Application of antioxidant and ultraviolet absorber into HDPE: Enhanced resistance to UV irradiation

- Study on the synthesis of hexene-1 catalyzed by Ziegler-Natta catalyst and polyhexene-1 applications

- Fabrication and characterization of conductive microcapsule containing phase change material

- Desorption of hydrolyzed poly(AM/DMDAAC) from bentonite and its decomposition in saltwater under high temperatures

- Synthesis, characterization and properties of biomass and carbon dioxide derived polyurethane reactive hot-melt adhesives

- The application of a phosphorus nitrogen flame retardant curing agent in epoxy resin

- High performance polyimide films containing benzimidazole moieties for thin film solar cells

- Rigid polyurethane/expanded vermiculite/ melamine phenylphosphate composite foams with good flame retardant and mechanical properties

- A novel film-forming silicone polymer as shale inhibitor for water-based drilling fluids

- Facile droplet microfluidics preparation of larger PAM-based particles and investigation of their swelling gelation behavior

- Effect of salt and temperature on molecular aggregation behavior of acrylamide polymer

- Dynamics of asymmetric star polymers under coarse grain simulations

- Experimental and numerical analysis of an improved melt-blowing slot-die