Abstract

In this article, a new technology of surface wrapping and strengthening of expandable polystyrene (EPS) beads is proposed. Three wrapping materials including magnesium phosphate cement (MPC), ultra-high performance concrete (UHPC), and water-borne polyurethane (WPU) were evaluated. Four groups of uniaxial compression tests of EPS concrete specimens were conducted: the failure process and the characteristics of the specimens were analyzed; and the complete stress–strain equation is proposed based on these analyses. The research shows that the EPS beads were strengthened by wrapping, and the axial compressive strength of concrete is increased by 50–75%; the concrete with EPS beads wrapped by MPC and WPU has obvious brittleness; the concrete with EPS beads wrapped by UHPC has axial compressive strength close to that of EPS concrete wrapped with MPC and WPU but has a larger ductility coefficient (150%), a larger toughness coefficient (50–90% larger), a higher energy dissipation coefficient (40% larger), and larger residual stress. The proposed stress–strain model is in good agreement with the experimental results, which can accurately describe the stress and deformation characteristics of EPS concrete under uniaxial compression and has good applicability. The discovery of this study provides background knowledge for the structural analysis and design of this kind of concrete; it provides a basis for selecting EPS concrete as structural materials.

1 Introduction

At present, most buildings waste a lot of energy because of the poor thermal insulation of the exterior wall [1]. In order to reduce building energy consumption, the thermal performance of exterior wall must be improved. The exterior wall should not only have the character of thermal insulation, but also be able to bear the load. Therefore, it is very necessary to choose a kind of thermal insulation material with load-bearing capacity to be used in the exterior walls. Expandable polystyrene (EPS) concrete has the advantages of light weight, thermal insulation, vibration absorption, and energy absorption [2]. It is an ideal wall insulation material. Compared with ordinary concrete, the strength of EPS concrete is relatively low. It is mainly used for functional materials [3]. In order to reduce building energy consumption, it is particularly necessary to extend EPS concrete into structural materials; therefore, the strength of EPS concrete needs to be improved.

Many scholars have done a lot of research on the strength improvement of EPS concrete. Some scholars adapt mineral admixtures such as silica fume [4] and fly ash [5] to improve the strength of EPS concrete; some other scholars improved the strength of EPS concrete by adding polyvinyl alcohol fiber [6] and polypropylene fiber [7,8]; some scholars also used dispersible latex powder [9], triethanolamine [10], polyvinyl alcohol [10], surface active agent [11], and composite modifier to change the surface properties of EPS beads to improve the strength of the EPS concrete. However, the improvement effect of current methods is limited. This article proposed an EPS beads strengthening technology, that is, to wrap the surface of EPS beads with materials, and the strength of EPS concrete was improved by the wrapped EPS beads. When selecting the wrapping material, it should be considered that the wrapping material can form a high-strength shell on the surface of EPS beads. Silica fume, cement, coal fly ash, nano-admixture [12,13,14,15], microbeads [16,17], and the combination of these materials can be appropriate packaging materials. In this study, magnesium phosphate cement (MPC), ultra-high performance concrete (UHPC), and water-borne polyurethane (WPU) were used to wrap EPS beads. Then, EPS beads and wrapped EPS beads were used to prepare concrete. The mechanical properties of concrete with wrapped EPS beads were greatly improved. In order to provide a basis for structural material design, it is necessary to explore its mechanical constitutive relationship. However, scholars mainly focus on the compressive strength [18,19,20,21] and splitting strength [7,8,22] of the EPS concrete. There are few studies on axial compressive properties, only a few scholars have done relevant research. These scholars have studied the performance of concrete from axial compression failure mode [23], axial compression curve equation [24,25], curing time [26], peak stress, peak strain [27], and the EPS content [28,29]. However, there are few studies on the axial compressive properties of high strength EPS concrete. EPS concrete after strengthening its axial compressive properties need to be further studied. In this article, the axial compressive properties of EPS concrete after strengthening were studied. The failure mode, ductility, energy dissipation capacity, stiffness attenuation, and stress–strain curve equations of EPS concrete were analyzed. It provides a theoretical basis for EPS concrete used as structural material, and promotes the development of low-carbon buildings, with great significance to reduce building energy consumption.

2 Experiment overview

2.1 Raw materials

The cement adopted is P.C (composite Portland cement) 42.5. The sand adopted is ordinary river sand and the apparent density is 2,650 kg/m3. Silica fume is produced by Beijing Muhu Admixture Co., Ltd, with SiO2 content >92% and apparent density is 2,200 kg/m3. Microbeads are produced by Tianjin Zhucheng New Material Technology Co., Ltd, the apparent density is 2,520 kg/m3 and bulk density is 760 kg/m3. Silane coupling agent adopted is KH550. Water reducing agent adopted is polycarboxylic acid water reducing agent. The size of EPS beads is 3–6 mm and the bulk density is 5.6 kg/m3. MPC is produced by Guizhou Magnesium Phosphate Material Co., Ltd. WPU and polyurethane mortar are produced by BASF Building Materials Systems (China) Co., Ltd. The mix proportion of UHPC is shown in Table 1.

UHPC mix proportion

| Materials | Cement | Microbeads | Silica fume | Quartz sand (40 mesh) | Quartz sand (80 mesh) | Quartz sand (120 mesh) | Water reducing agent | Water |

|---|---|---|---|---|---|---|---|---|

| Unit | kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 |

| UHPC mix proportion | 763 | 218 | 109 | 397 | 397 | 397 | 10.9 | 174.4 |

2.2 Experiment mix proportion and specimen preparation

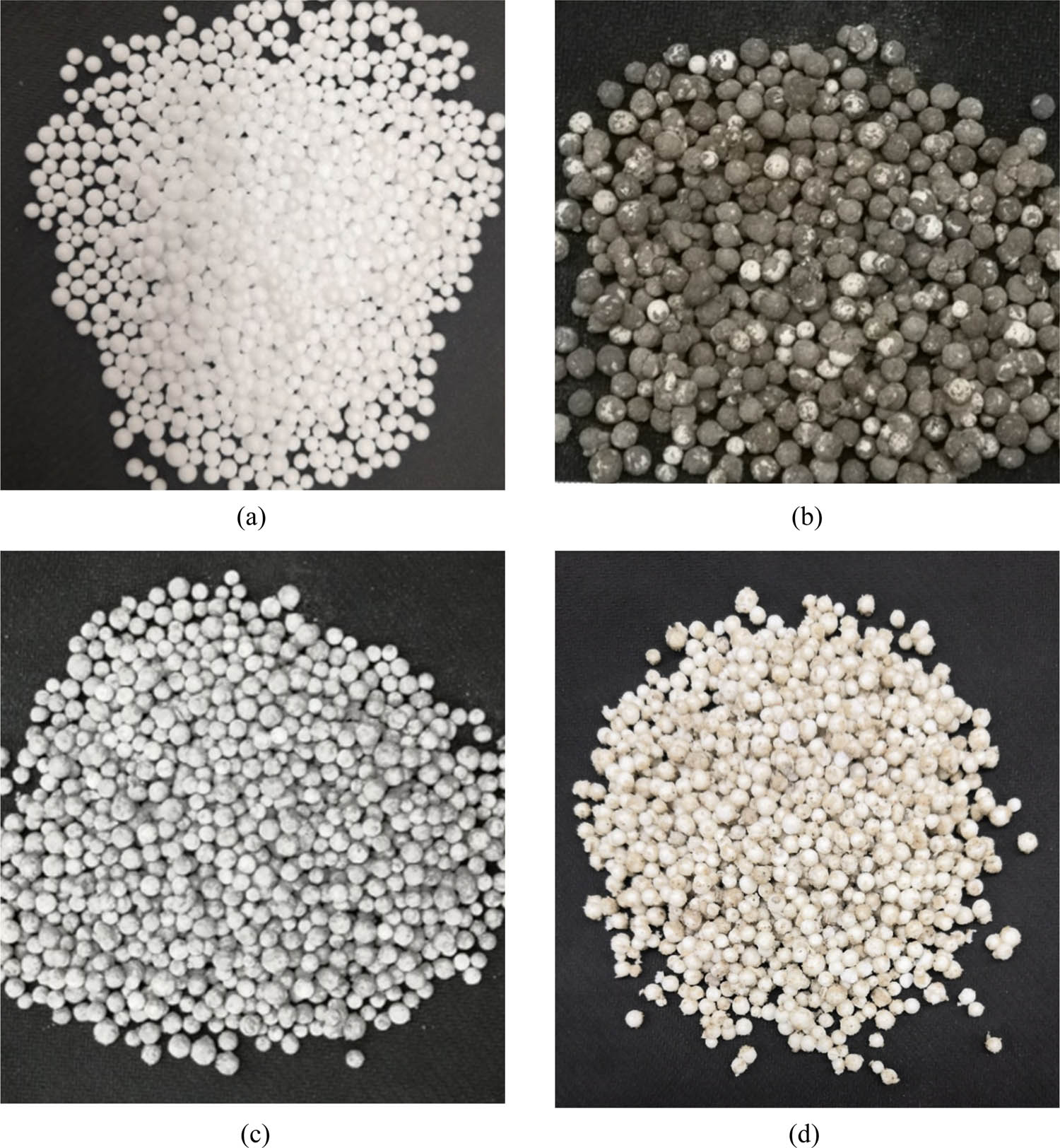

Four groups of EPS concrete specimens were designed in this article. In group Y which is the blank control group, the EPS beads did not make any changes; the EPS beads of group M were wrapped with MPC, group U were wrapped with UHPC, and group W were wrapped with WPU and polyurethane mortar. The wrapping process was carried out in the mixer. First, the wrapping materials were evenly mixed, as shown in Figure 1(a). Second, EPS beads were placed in the mixer, for group M and group U, and the surface of EPS beads was wetted by adding water with silane coupling agent; in group W, the surface of EPS beads was wetted by WPU, as shown in Figure 1(b). Third, the EPS beads of group M were sprinkled into MPC and group U were sprinkled into mixed UHPC powder until the EPS beads surface was wrapped; group W were sprinkled into polyurethane mortar until the EPS beads surface was wrapped, as shown in Figure 1(c). The wrapped EPS beads were placed in the natural curing room for aging, as shown in Figure 1(d). After aging for 2 days, the wrapped EPS beads were strengthened, as shown in Figure 2.

Manufacturing process of wrapped EPS beads: (a) powder mixing, (b) drop in solvent or WPU, (c) EPS beads wrapping, and (d) aging of wrapped EPS beads.

Unwrapped EPS beads and wrapped EPS beads: (a) unwrapped EPS beads, (b) EPS beads wrapped with MPC, (c) EPS beads wrapped with UHPC, and (d) EPS beads wrapped with WPU.

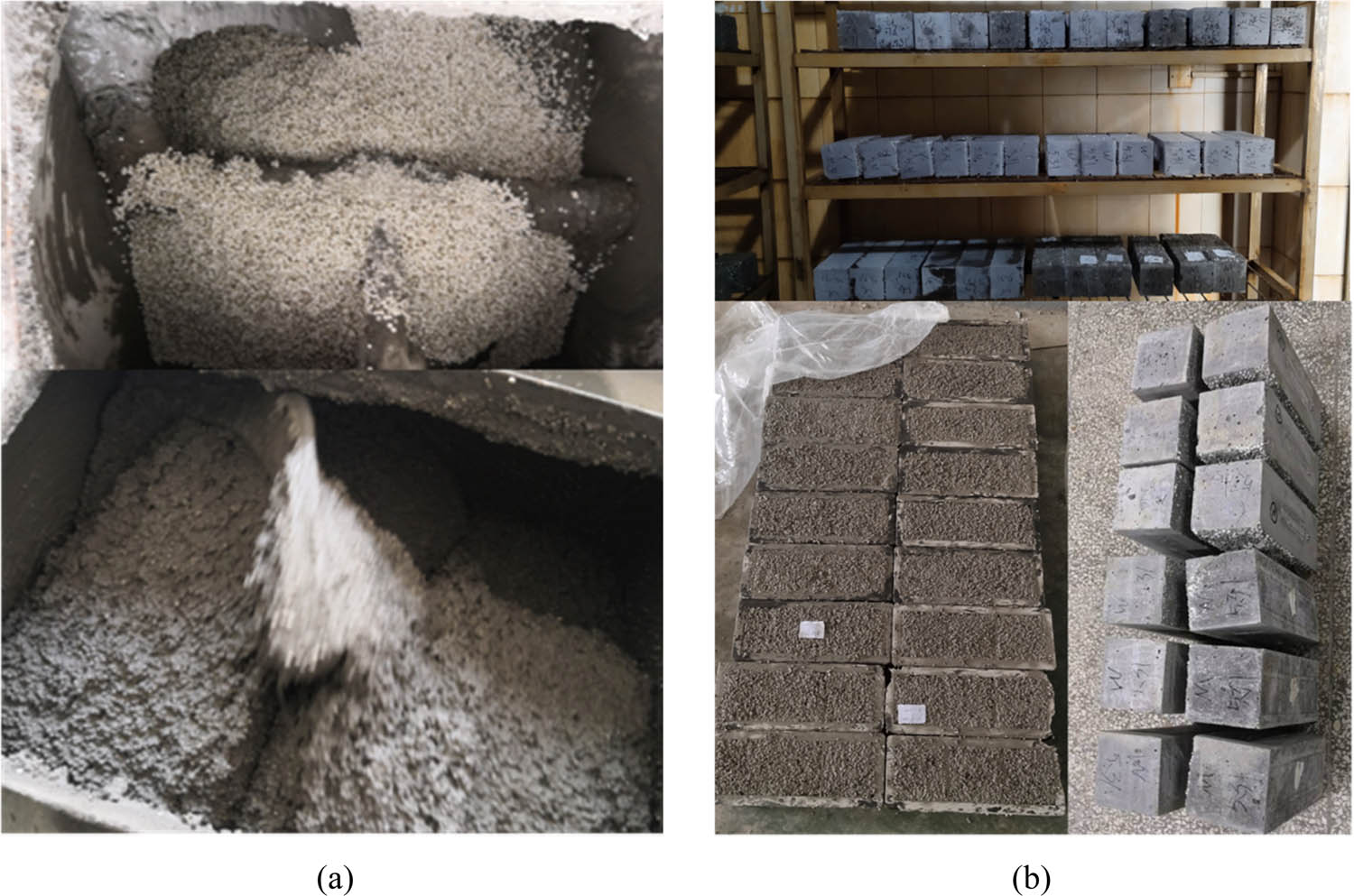

The next step is to prepare EPS concrete with wrapped EPS beads and unwrapped EPS beads, the concrete mixing process is shown in Figure 3(a). The mix proportion of EPS concrete is shown in Table 2. During the preparation of fresh concrete, subtract the amount of cementing materials and sand used in EPS beads wrapping from the mix proportion. Four groups of EPS concrete prismatic specimens (100 mm × 100 mm × 300 mm) and cube specimens (100 mm × 100 mm × 100 mm) were prepared and placed in the natural curing room. After the specimens were cured in the natural curing room for 1 day, the mold was taken off and the specimens were placed in the standard curing room and cured for 28 days, the manufacturing process of EPS concrete specimen is shown in Figure 3(b).

Manufacturing process of EPS concrete specimens: (a) concrete mixing and (b) specimens forming.

EPS concrete mix proportion

| Specimen number | Type of EPS beads | Cement | Silica fume | Micro beads | Sand | Water reducing agent | Water | EPS beads |

|---|---|---|---|---|---|---|---|---|

| (kg) | (kg) | (kg) | (kg) | (kg) | (kg) | (L) | ||

| Y | Unwrapped EPS beads | 517 | 52 | 108 | 357 | 7.5 | 166 | 710 |

| M | EPS beads wrapped with MPC | 370 | 52 | 108 | 357 | 7.5 | 162 | 710 |

| U | EPS beads wrapped with UHPC | 476 | 47 | 96 | 316 | 7.5 | 151 | 710 |

| W | EPS beads wrapped with WPU | 517 | 52 | 108 | 282 | 7.5 | 166 | 710 |

2.3 Test set and test method

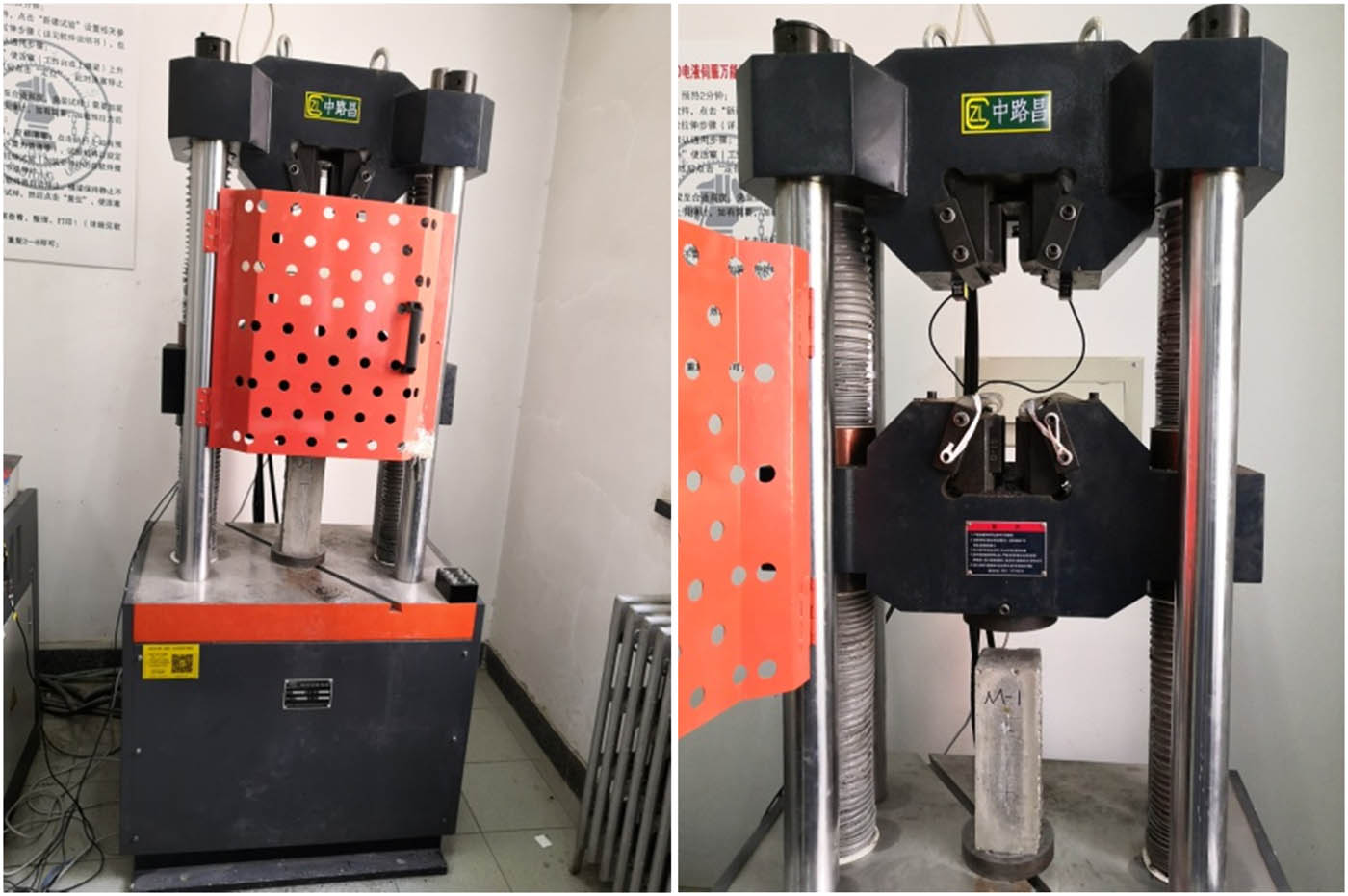

The EPS concrete axial compression test and cube compression test adopted WAW-600D universal testing machine, which has the functions of automatic control, automatic measurement, data acquisition, and screen display. The test process is fully controlled and measured automatically. The machine is shown in Figure 4. In the test, loading is carried out in three steps. The first step is contact determination, when the pressure of the test piece is 1 kN, it is judged that the tester is in good contact with the test piece; the second step is uniform force loading, the loading rate is 0.2 kN/s, loading is done until the load reaches about 0.6 f c, the elastic modulus of the concrete is obtained in this step; the third step is displacement loading, the loading rate is 0.05 mm/min, loading is done until the test piece is completely crushed. Three specimens were tested for each group of EPS concrete and the complete stress–strain curves data were obtained.

WAW-600D universal testing machine.

3 Experiment results and analysis

3.1 Failure mode of specimen

The failure process of EPS concrete can be divided into three stages: elastic stage, working stage with cracks, and failure stage [30,31]. The failure process of four groups of specimens is shown in Figures 5–8. The failure process and failure mechanism of four groups of specimens are described in Table 3.

Failure mode of group Y specimens.

Failure mode of group M specimens.

Failure mode of group U specimens.

Failure mode of group W specimens.

Failure mode and failure mechanism of specimens

| Specimen number | Failure process | Phenomenon of destruction | ||

|---|---|---|---|---|

| Elastic stage | Working stage with cracks | Failure stage | ||

| Y | The strength increases rapidly and there are no obvious cracks | A faint sound is heard, cracks appear on the left and right of the upper end, the cracks width are small and expand slowly, the bearing capacity increases first and then decreases slowly, and small pieces of concrete are peeling off | The concrete on the upper part of the specimens continues to peel off. The width of the upper fracture zone is increasing. At last, the upper part is crushed and the lower part is basically intact | Obvious ductility |

| M | The strength increases rapidly and small cracks appear on the upper part | The initial cracks begin to expand, the wide vertical crack in the middle expands downward and become the main crack, the skin of the test pieces begin to peel off, and the bearing capacity of the specimens rise rapidly to the peak point and then decrease rapidly | After a short period of stress yield, a bursting sound is heard, the middle crack penetrates up and down, and the bearing capacity of the specimens drop sharply | Obvious brittleness |

| U | The strength increases rapidly and there are no obvious cracks | There are some small vertical and oblique cracks at the upper end, the wide vertical crack in the middle expands downward and gradually becomes the main crack, the crack is small and long, and parallel to the force direction. The bearing capacity increases, and there is a fracture zone at the upper end | The width of the fracture zone is increasing, the middle crack continues to widen, but not reached the bottom, there is a small amount of peeling on the upper skin of the test piece, the test pieces were slowly crushed, and the bearing capacity shows a downward trend | Obvious ductility |

| W | The strength increases rapidly and there are no obvious cracks | Oblique and vertical cracks appear in the upper part, the cracks gradually expand and begin to cross, the oblique cracks develop to the edge, vertical cracks rapidly expand downward and widen, the skin of the test piece begins to peel off, and the bearing capacity of the specimens rise rapidly to the peak point and then decrease rapidly | These cracks widen and develop into three main cracks. The vertical cracks continue to expand downward and widen rapidly and extended to the bottom, and the bearing capacity of the specimens drop sharply | Obvious brittleness |

Group Y and group U showed better ductility. Group M and group W showed obvious brittleness. The failure mode of EPS concrete is related to the strength of EPS concrete and the volume content of EPS concrete [32]. The different failure modes of the four groups of EPS concrete are due to different strengths and properties of the wrapping materials.

In group M, the EPS beads were wrapped with MPC cement. MPC has some defects, such as high brittleness, poor crack resistance, and deformation ability [33]. The shell layer on the surface of the EPS beads is relatively easy to damage. When cracks appear, it breaks quickly. Therefore, when the specimen is damaged, it shows brittleness. The EPS beads of Group U were wrapped with UHPC. It is mainly composed of cement, silica fume, and quartz sand. Its composition is similar to mortar and has good compatibility. Therefore, it showed better ductility. Group W showed brittleness, but brittleness was not as obvious as group M. For one thing, group W has the highest strength, which results in obvious brittleness; for another thing, WPU as wrapping material of EPS beads has good tensile strength and good ductility [34], therefore its brittleness is not as obvious as group M.

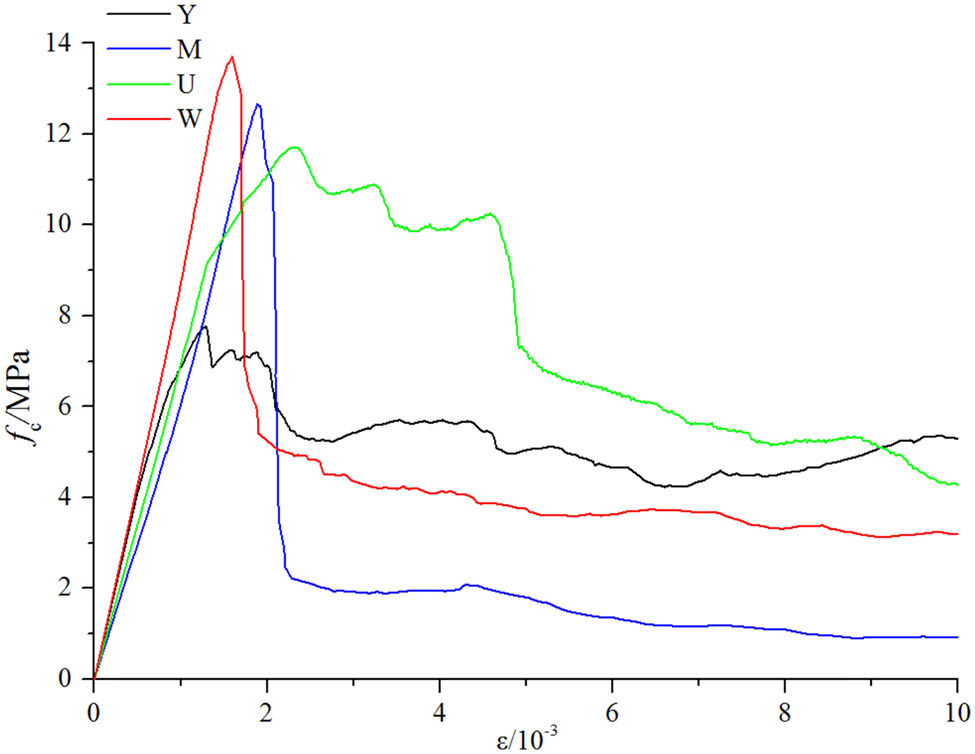

3.2 Complete stress–strain curves

The complete stress–strain curves of four types of EPS concrete are shown in Figure 9. The strength of the EPS concrete in group Y is low, but the ductility is good. After the curve reaches the peak, the descending section is gentle; the residual strength is high, it is about 5 MPa. The area of the whole curve envelope is large. There is a process of strength decline and then recovery. The strength of EPS concrete in group M is next highest. After the strength reaches the peak, the curve drops sharply, there is no obvious ductility, it shows brittleness. The residual stress is about 1.5 MPa. The strength of EPS concrete in group U is also high. The ductility of the specimens is good, there is a process of stress drop and then rise in the curve. The descending section of the curve is relatively gentle. The envelope area of the whole curve is large, the residual strength is high, it is about 4.5 MPa. The strength of EPS concrete in group W is the highest. When the stress reaches the peak, the curve drops suddenly, but the residual stress of the specimens is high, it is about 4 MPa.

Complete stress–strain curves.

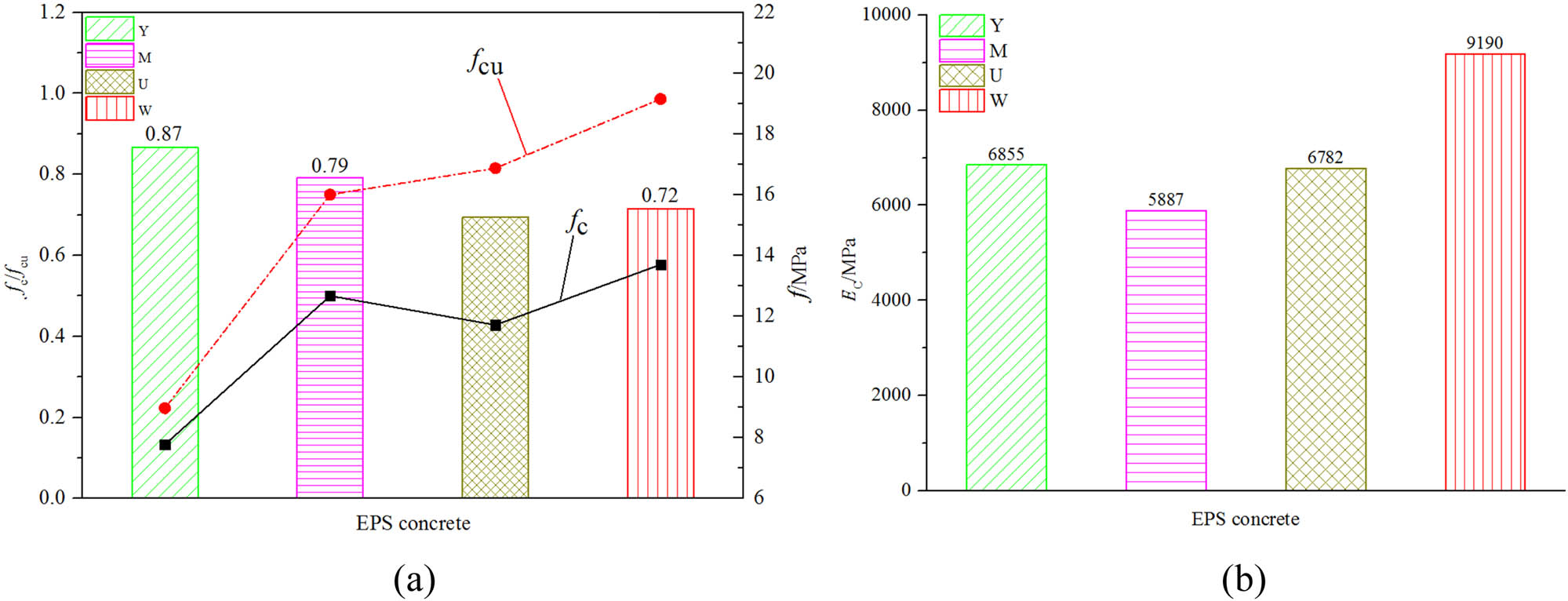

3.3 Strength and modulus of elasticity

Cube compressive strength (f cu), axial compressive strength (f c), and ratio of axial compressive strength to cube compressive strength (f c/f cu) are shown in Figure 10(a). The axial compressive strength and cube compressive strength of concrete with EPS beads wrapped are significantly increased. The ratio of axial compressive strength to cube compressive strength is between 0.7 and 0.9, it is similar to ordinary concrete [35]. The elastic modulus of EPS concrete is calculated according to formula (1).

where E is the elastic modulus; σ 1 is the stress corresponding to the longitudinal strain of 50 × 10−6; σ 2 is the stress corresponding to 40% of ultimate strain; and ε 2 is the longitudinal strain produced by σ 2. The elastic modulus of the four groups of specimens is shown in Figure 10(b). The elastic modulus of group W is the largest and the group M is the smallest.

Strength and elastic modulus of test pieces: (a) specimen strength and (b) elastic modulus of the test piece.

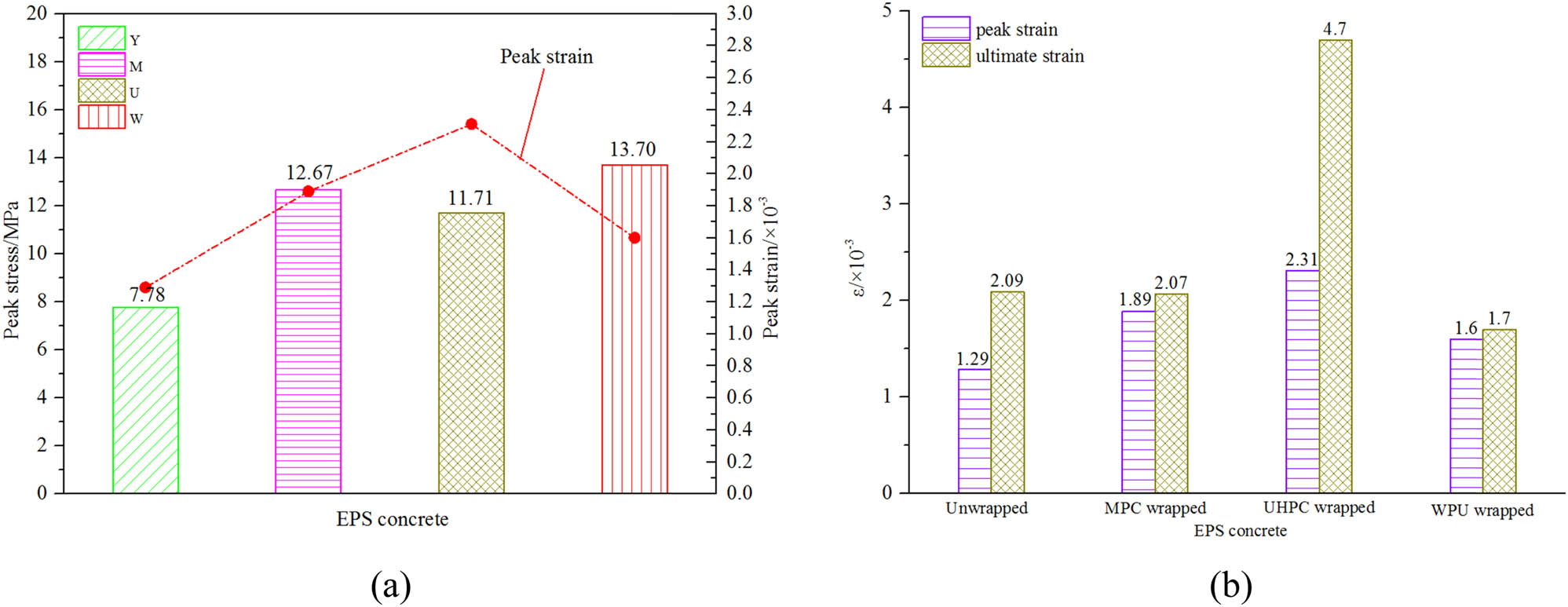

3.4 Peak strain and ultimate strain

The strain at 0.85 times the peak stress in the descending section of complete stress–strain curve is taken as the ultimate strain. The peak strain and ultimate strain test results of four groups of EPS concrete are shown in Figure 11. Compared to the concrete in which EPS beads are not wrapped, the peak stress of concrete with EPS wrapped with MPC, UHPC, and WPU increased by 62.85, 70.69, and 76.09%, respectively; the peak stress strain increased by 46.51, 146.51 and 24.03% respectively; the ultimate strain of group U increased by 124.88%, but the group M and the group W decreased. It shows that the concrete with EPS beads wrapped with MPC and WPU is brittle, the stress decreases rapidly after the peak stress. Compared to MPC and WPU, UHPC, as the wrapping material of EPS beads, has the advantages of improving the ductility of the EPS concrete.

Peak stress, peak strain, and ultimate strain: (a) peak stress and peak strain and (b) peak strain and ultimate strain.

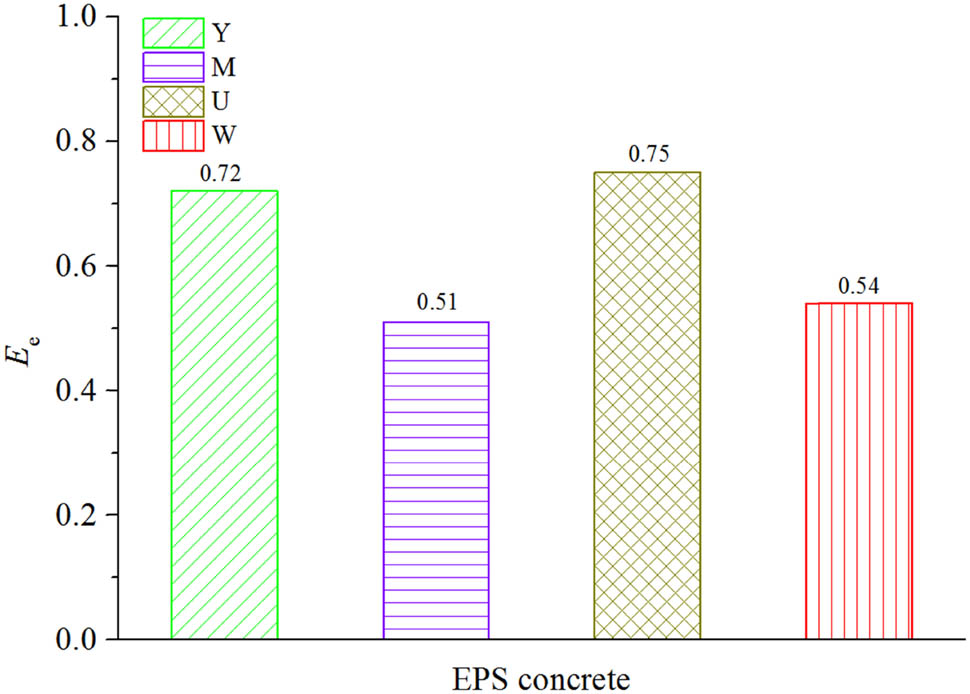

3.5 Energy dissipation capacity

Referring to relevant theories of building earthquake resistance [36], the energy dissipation capacity of EPS concrete specimen can be expressed by energy dissipation coefficient (E e). The calculation diagram of energy dissipation coefficient is shown in Figure 12, the calculation formula is calculated according to formula (2) [37].

where S OABC is the area enclosed by the load-displacement curve, vertical line of ultimate load (F u), and the abscissa axis; S OEDC is the area enclosed by horizontal line of maximum load (F max), vertical line of ultimate load (F u), and the coordinate axis. The ultimate load is equal to 0.85 times the maximum load (F u = 0.85F max).

![Figure 12

Schematic diagram of energy dissipation calculation [37].](/document/doi/10.1515/secm-2022-0005/asset/graphic/j_secm-2022-0005_fig_012.jpg)

Schematic diagram of energy dissipation calculation [37].

The energy dissipation coefficients of four groups of specimens are shown in Figure 13. The group U is the largest and the value is 0.75, second is group Y, and the groups M and W are small. The energy dissipation coefficient of group U was 37 and 45% higher than that of group M and group W, respectively. The concrete with EPS beads wrapped with UHPC has the best energy dissipation capacity.

Energy dissipation coefficient.

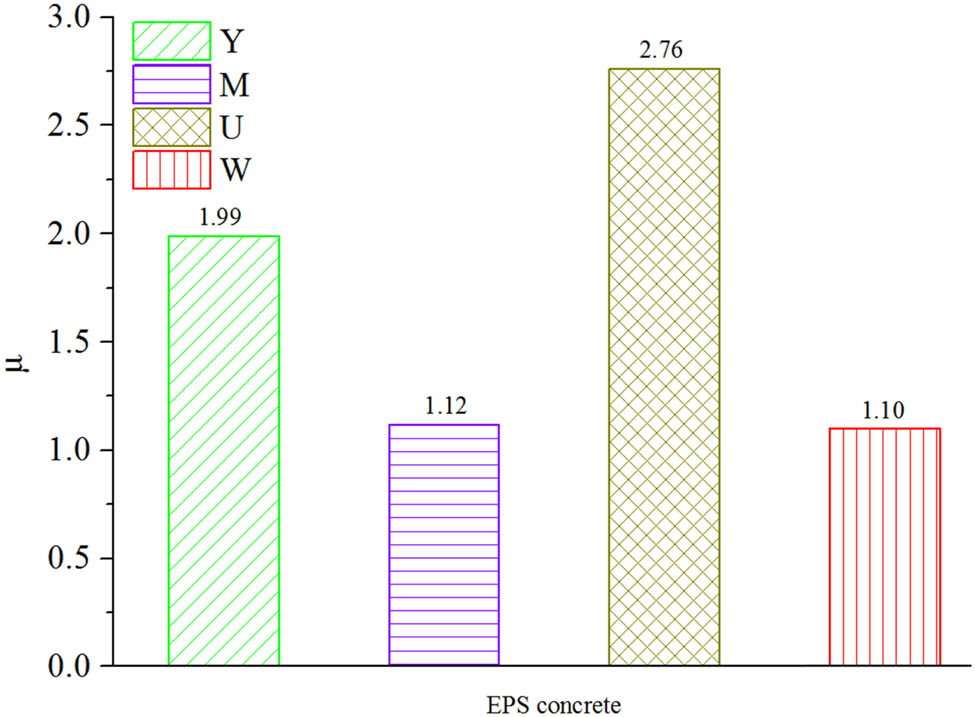

3.6 Ductility performance

The ductility of concrete is expressed by ductility coefficient (μ), the ductility coefficient is calculated according to formula (3).

3where Δu represents the displacement corresponding to the ultimate load and Δy represents the yield displacement of the yield point. The yield point is found by PAPK method, as shown in Figure 14. Draw a horizontal line perpendicular to the longitudinal axis at the maximum load point, find the point in the longitudinal axis where the value is 0.75 times the maximum load value, then make a horizontal straight line through this point and intersect the load displacement curve at point A, connect OA so that its extension line meets point B, make a vertical line from point B to the horizontal axis, the intersection is Δy [38,39].

![Figure 14

Schematic diagram of yield point of PAPK method [37].](/document/doi/10.1515/secm-2022-0005/asset/graphic/j_secm-2022-0005_fig_014.jpg)

Schematic diagram of yield point of PAPK method [37].

The ductility coefficients of four groups of specimens are shown in Figure 15. The group U is the largest and the value is 2.76, the second is group Y, and the groups M and W are small. The ductility coefficient of group U is 39, 146, and 151% higher than that of group Y, group M, and group W, respectively. The ductility of concrete with EPS beads wrapped by UHPC is the best.

Ductility coefficient of EPS concrete.

3.7 Toughness and brittleness analysis

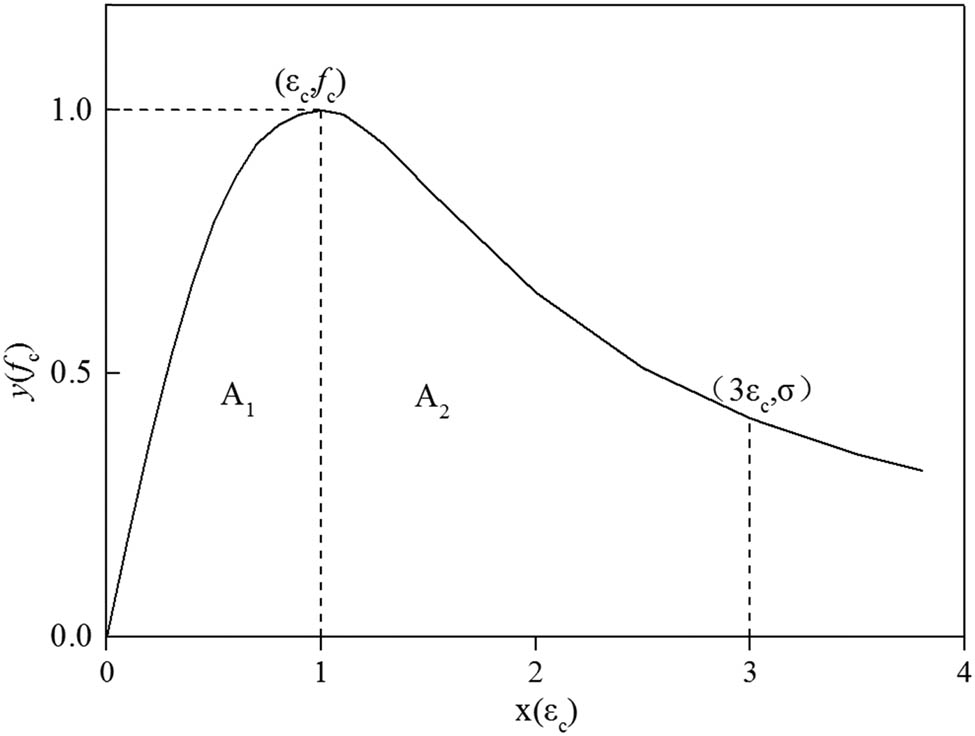

The toughness of material is mainly reflected in two aspects: the ultimate strength of the material and the size of deformation when the material is damaged. The ultimate strength is small, but the deformation is large at failure, it shows toughness. Some materials have high ultimate strength, but the deformation is very small during failure, it shows brittleness [40]. The calculation diagram of toughness and brittleness coefficients is shown in Figure 16. The toughness index is calculated according to formula (4), and the brittleness index is calculated according to formula (5).

where A 1 is the area enclosed by the stress–strain curve before the peak point, its physical meaning is that the energy density is to be absorbed by light concrete failure; A 2 is the area enclosed by the stress–strain curve between the peak point and the corresponding point of three times the peak strain, its physical meaning is that the energy density is to be released by the destruction of light concrete.

Characteristic points of toughness and brittleness index.

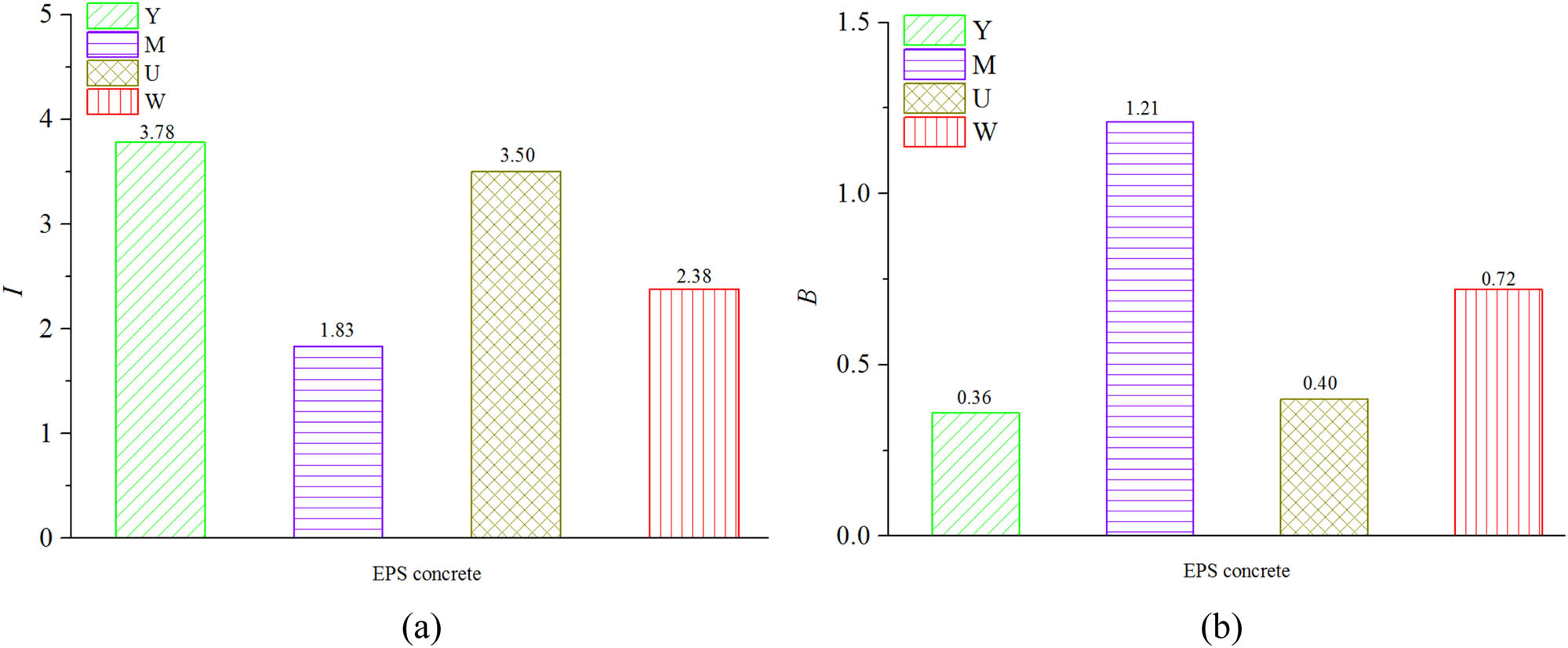

The calculation of toughness and brittleness indices of four groups of specimens are shown in Figure 17. The toughness indices of group Y and group U were relatively high and the values are 3.78 and 3.50, respectively. The toughness index of group U is 91 and 47% larger than that of group M and group W, respectively. The EPS concrete of group M and group W have larger brittleness index and the values are 1.21 and 0.72, respectively. The brittleness index of group M was the highest. The concrete with EPS beads wrapped by UHPC has better toughness.

Toughness and brittleness index: (a) toughness indices and (b) brittleness indices.

3.8 Stiffness degradation

Secant stiffness is used to calculate the stiffness of the specimen, secant stiffness (K) is calculated according to formula (6) [37].

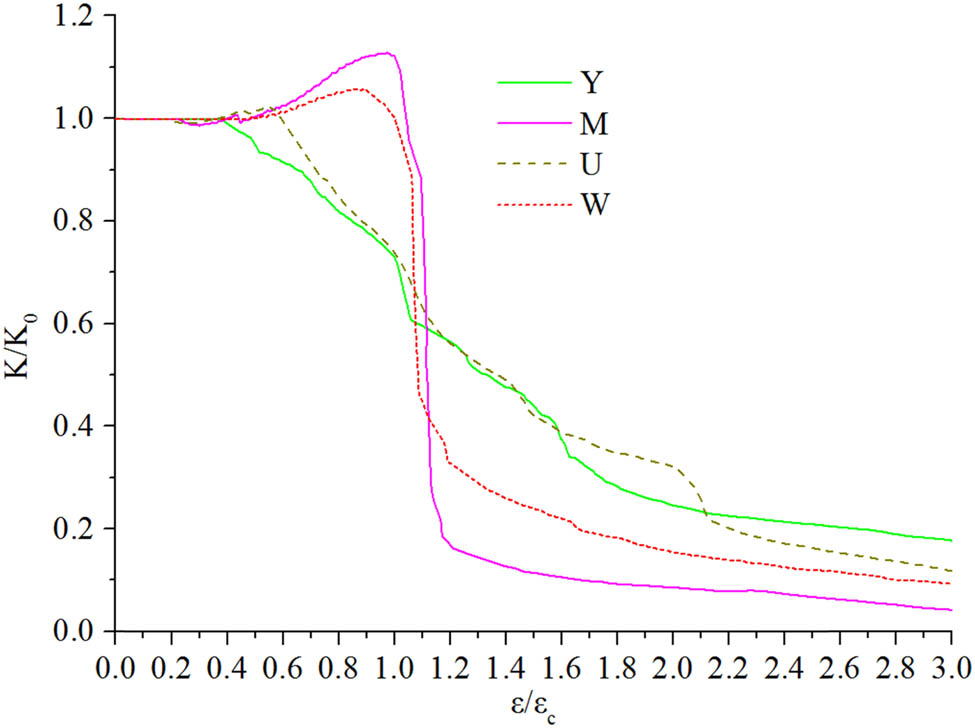

where F represents the load, and Δ represents the displacement corresponding to the load. Based on the initial stiffness (K 0), and calculating the stiffness (K) corresponding to the displacement of EPS concrete specimen, the stiffness ratio (K/K 0) under the corresponding displacement is obtained. The stiffness degradation curves are shown in Figure 18.

Stiffness degradation curves of EPS concrete.

When ε/ε c is less than 0.5, the stiffness degradation remains basically at the same level, the concrete is in the elastic stage; When ε/ε c is 0.5–1.0, there is a strengthening growth process in the stiffness of concrete in which EPS beads is wrapped. The stiffness strengthening of EPS concrete with group M and group W is more significant. However, after the stiffness reaches the peak, the stiffness degenerates rapidly. The stiffness degradation curves of group U and group Y are relatively flat, showing that the ductility of the concrete with EPS beads wrapped with UHPC is good.

4 Complete stress–strain curve equation under uniaxial compression

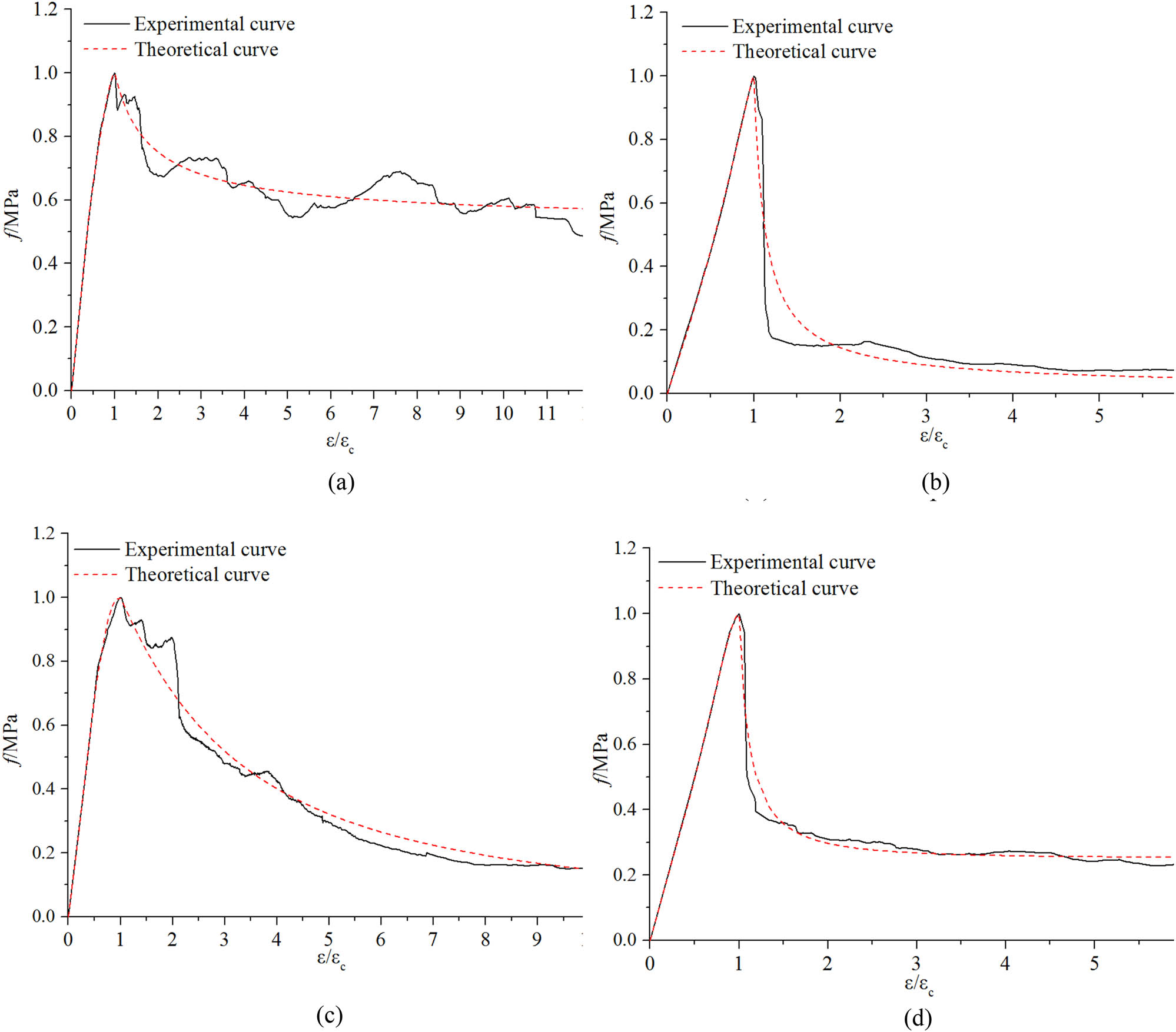

It can be seen from Figure 18, in the stiffness degradation curves, that EPS concrete with EPS beads wrapped with materials has a stiffness strengthening stage before reaching the peak strain. In this stage, the secant modulus increases gradually, there is an inflection point in the rising section of the stress–strain curve. Besides, it can be seen from Figure 9 that EPS concrete specimens have residual stress. From these two points, it is shown that EPS concrete is obviously different from ordinary concrete [24]. In order to obtain accurate stress–strain curve equation, in this article, Sargin’s [41] ordinary concrete equation is used in the rising section and rational fraction in descending section, as shown in formula (7).

where x = ε/ε c, y = f/f c, f c is the peak stress, and ε c is the peak strain. The fitting parameters and fitting correlation coefficients of EPS concrete were obtained by origin software, as shown in Table 4. The comparison between the fitting curves and the experimental curves are shown in Figure 19, the experimental curves are in good agreement with the theoretical curves.

The parameters of stress–strain curves equation

| Specimen No. | Rising section of curvesFalling section of curves | |||||

|---|---|---|---|---|---|---|

| a | b |

|

c | d |

|

|

| Y | 1.691 | −0.508 | 0.9988 | −2.045 | −0.613 | 0.8302 |

| M | 0.803 | 0.214 | 0.9996 | −0.949 | 0.381 | 0.8273 |

| U | 1.200 | 0.738 | 0.9964 | 2.608 | 1.337 | 0.9670 |

| W | 0.880 | 0.223 | 0.9997 | −1.336 | −2.282 | 0.9113 |

Comparison between theoretical curves and experimental curves: (a) group Y test piece, (b) group M test piece, (c) group U test piece, and (d) group W test piece.

5 Conclusion

In this study, a new type of EPS beads wrapping strengthening technology was proposed. MPC, UHPC, and WPU were used as wrapping materials and were successfully wrapped with EPS beads. Compared with concrete of unwrapped EPS beads, it was found that the axial compressive strength of concrete of EPS beads wrapped with MPC, UHPC, and WPU increased by 62.85, 50.51, and 76.09%, respectively. Compared with concrete of EPS beads wrapped with MPC and WPU, the concrete with EPS beads wrapped with UHPC has better ductility and higher residual stress; the descending section of stress–strain curve is more flat; the energy dissipation coefficient is increased by 47.06 and 38.89%, the ductility coefficient is increased by 146.42 and 150.91%, and the toughness coefficient is increased by 91.25 and 47.06%, respectively, than MPC and WPU. Hence, UHPC as EPS beads wrapping material is better than MPC and WPU. At last, based on Sargin’s ordinary concrete equation and rational fraction, the complete stress–strain equations of four kinds of EPS concrete were fitted and the recommended parameters were obtained; they were in good agreement with the experiment curves, it provided a reference for the design of EPS concrete structure and will promote the development of low-carbon buildings.

-

Funding information: This research was financially supported by the Beijing major science and technology projects (No. Z191100008019002), Science and technology project plan of the Ministry of Housing and Urban-Rural Development of the people’s Republic of China “Study on fabricated light steel light concrete structure system” (2016-K5-001).

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Zhang W, Lv Y, Liu P. Review on the research progress of EPS concrete. Mater Rep. 2019;33(7):2214–28.Suche in Google Scholar

[2] Guo L. Study on Energy Absorption Characteristics and Frost Resistance of Foam Concrete and EPS Concrete. [Chinese dissertation]. Harbin: Northeast Forestry University; 2019 (in chinese).Suche in Google Scholar

[3] Dissanayake DMKW, Jayasinghe C, Jayasinghe MTR. A comparative embodied energy analysis of a house with recycled expanded polystyrene (EPS) based foam concrete wall panels. Energy Build. 2016;135:1–23.10.1016/j.enbuild.2016.11.044Suche in Google Scholar

[4] Ran XM. Experimental study on the influence of silica fume to static and dynamic mechanical properties of EPS concrete [Chinese dissertation]. Huainan: AnHui University of Science and Technology; 2016 (in Chinese).Suche in Google Scholar

[5] Chen B, Liu N, Deng C. Experimental studies on the properties of EPS thermal insulating mortar. J Harbin Eng Univ. 2012;33(6):671–6.Suche in Google Scholar

[6] Liu F, Wei K, Yang F. Experimental investigation on performance of polyvinyl alcohol fiber modified EPS concrecte. J Funct Mater. 2021;52(12):12055–60.Suche in Google Scholar

[7] Chen B, Zhou K. Experimental study on Influencing Factors of mechanical properties of EPS lightweight high performance concrete. China Concr Cem Products. 2009;3:47–50 (in Chinese).Suche in Google Scholar

[8] Liu N, Chen B. Experimental study of the influence of EPS particle size on the mechanical properties of EPS lightweight concrete. Constr Build Mater. 2014;68:227–32.10.1016/j.conbuildmat.2014.06.062Suche in Google Scholar

[9] Sun G. Mix proportion and performance of modified EPS thermal insulating mortar. J Zhengzhou Univ (Eng Sci). 2011;32(5):7–10 (in Chinese).Suche in Google Scholar

[10] Chen X, Dong J, Wu H. Relationship between EPS modification method and mechanical properties of cement-based materials. Concrete. 2013;284(6):13–4 (in Chinese).Suche in Google Scholar

[11] Hu X, Huang S, Zhang S. EPS surface modification and its effect on mechanical properties of thermal insulation mortar. N Build Mater. 2008;11:4244 (in Chinese).Suche in Google Scholar

[12] Szostak B, Golewski GL. Rheology of cement pastes with siliceous fly ash and the CSH nano-admixture. Materials. 2021;14:3640.10.3390/ma14133640Suche in Google Scholar PubMed PubMed Central

[13] Golewski GL, Szostak B. Application of the C-S-H phase nucleating agents to improve the performance of sustainable concrete composites containing fly ash for use in the precast concrete industry. Materials. 2021;14:6514.10.3390/ma14216514Suche in Google Scholar PubMed PubMed Central

[14] Szostak B, Golewski GL. Effect of nano admixture of CSH on selected strength parameters of concrete including fly ash. IOP Conf Ser Mater Sci Eng. 2018;416:012105.10.1088/1757-899X/416/1/012105Suche in Google Scholar

[15] Golewski GL, Szostak B. Strengthening the very early-age structure of cementitious composites with coal fly ash via incorporating a novel nanoadmixture based on C-S-H phase activators. Constr Build Mater. 2021;312:125426.10.1016/j.conbuildmat.2021.125426Suche in Google Scholar

[16] Feng N, Li H. Characteristics and application of nano microbead. China Concr Cem Products. 2010;5:1–3 (in Chinese).Suche in Google Scholar

[17] Yuan J, Li W, Wang L. Study on carbonation resistance of EPS concrete based on mix proportion design. 2021 7th International Conference on Hydraulic and Civil Engineering & Smart Water Conservancy and Intelligent Disaster Reduction Forum (ICHCE & SWIDR). Nanjin, China: IEEE; 2021.10.1109/ICHCESWIDR54323.2021.9656423Suche in Google Scholar

[18] Wu X, Xie S, Hu J. Dynamic compressive strength and energy absortion property of EPS concrete. J Vib Shock. 2013;32(17):133–7.Suche in Google Scholar

[19] Chen B, Liu J. Mechanical properties of polymer-modified concretes containing expanded polystyrene beads. Constr Build Mater. 2007;21(1):7–11.10.1016/j.conbuildmat.2005.08.001Suche in Google Scholar

[20] Miled K, Sab K, Le Roy R. Particle size effect on EPS lightweight concrete compressive strength: Experimental investigation and modelling. Mech Mater. 2007;39(3):222–40.10.1016/j.mechmat.2006.05.008Suche in Google Scholar

[21] Babu DS, Ganesh Babu K, Tiong-Huan W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem Concr Comp. 2006;28(6):520–7.10.1016/j.cemconcomp.2006.02.018Suche in Google Scholar

[22] Wu X, Hu J, Xie S. Dynamic splitting-tensile strength and energy dissipation property of EPS concrete. Explos Shock Waves. 2013;33(4):369–74.Suche in Google Scholar

[23] Zhang ZR. Mechanical properties of lightweight aggregate concrete study and finite element analysis of multi-ribbed composite wall. [Chinese dissertation]. Beijing: Beijing Jiaotong University; 2010 (in Chinese).Suche in Google Scholar

[24] Cui CC. Seismic Behavior of Light Gauge Steel Reinforced EPS Concrete Shear Walls. [Chinese dissertation]. Beijing: Tsinghua University; 2016 (in Chinese).Suche in Google Scholar

[25] Cui C, Huang Q, Li D. Stress–strain relationship in axial compression for EPS concrete. Constr Build Mater. 2016;105:377–83.10.1016/j.conbuildmat.2015.12.159Suche in Google Scholar

[26] Ding G, Xu J, Bai E. Experiment research on static mechanic behavior of early-strengthed expanded polystyrene concrete. Sichuan Build Sci. 2011;3713:184–7 (in Chinese).Suche in Google Scholar

[27] Cheng C, Su D, Jiao C. Experimental Investigation into Compression Property of Organic Lightweight Aggregate Concrete Under Uniaxial Loading. J South China Univ Technol (Nat Sci Ed). 2011;39(11):114–8.Suche in Google Scholar

[28] Zhou KK. Experimental and numerical studies on EPS lightweight concrete. [Chinese dissertation]. Shanghai: Shanghai Jiao Tong University; 2010 (in Chinese).Suche in Google Scholar

[29] Wu Z. Experimental research and 3D modeling of EPS cellular Concrete. [Chinese dissertation]. Shanghai: Shanghai Jiao Tong University; 2012 (in Chinese).Suche in Google Scholar

[30] Xu Y, Jiang L, Xu J, Li Y. Mechanical properties of expanded polystyrene lightweight aggregate concrete and brick. Constr Build Mater. 2012;27(1):32–8.10.1016/j.conbuildmat.2011.08.030Suche in Google Scholar

[31] Wu H, Wang T, Wu C. Experimental research on compressive deformation performance of EPS lightweight energy saving concrete block and masonry. Constr Technol. 2016;45(12):90–4 (in Chinese).Suche in Google Scholar

[32] Saradhi Babu D, Ganesh Babu K, Wee TH. Properties of lightweight expanded polystyrene aggregate concretes containing fly ash. Cem Concr Res. 2005;35(6):1218–23.10.1016/j.cemconres.2004.11.015Suche in Google Scholar

[33] Qin JH. Study on Preparation and Mechanical Behavior of Ultra-high Strength Magnesium Phosphate Cement Composites. [Chinese dissertation]. Chongqing: Chongqing University; 2019 (in Chinese).Suche in Google Scholar

[34] Wu RB. Preparation and properties of modified polyurethane cement composites. [Chinese dissertation]. Xi an: Xi’an University of Architecture and Technology; 2020 (in Chinese).Suche in Google Scholar

[35] GB (2015) 50010-2010. Code for design of concrete structures. China: Ministry of Construction of the People’s Republic of China (in Chinese).Suche in Google Scholar

[36] JGJ (2015) JGJ/T101-2015. Specification for seismic test of buildings. Beijing, China: Ministry of Construction of the People’s Republic of China (in Chinese).Suche in Google Scholar

[37] Li Z, Wang G, Yang S. Experimental study on mechanical properties and stress–strain constitutive relations of desert sand concrete. Chin J Appl Mech. 2019;36(5):1131–7.Suche in Google Scholar

[38] Guo ZH. Principle of Reinforced Concrete. Beijing: Tsinghua University Press; 2013.Suche in Google Scholar

[39] Chen Z, Zhang Y, Yao R. Experimental study on complete stress–strain curve of sea sand concrete behavior under uniaxial loading. Bull Chin Ceram Soc. 2019;38(12):3934–40 (in Chinese).Suche in Google Scholar

[40] Zhao TJ. Study on Uniaxial Compressive Behavior of High Strength Lightweight Aggregate Concrete. [Chinese dissertation]. Xi an: Chang’an University; 2017 (in Chinese).Suche in Google Scholar

[41] Sargin M. Stress–strain relationships for concrete and the analysis of structural concrete sections. Waterloo: University of Waterloo; 1971.Suche in Google Scholar

© 2022 Yuan Ji et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete

Artikel in diesem Heft

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete