Abstract

The aim of this study is to investigate an approach to the electricity conductivity of nano-graphite in concrete by experiments, and different doses of nano-graphite have a different influence on the electrical conductivity of the whole structure. In this research project, the compression test was carried out on a 50 mm × 100 mm cylinder using a Baldwin machine and a digital multimeter to measure the conductivity. To find out the patterns of how different nano-graphites influence the properties of concrete structures, multifarious percentages of nano-graphite’s content are employed for testing both the electrical resistivity and compressive strength. These results are important to predict and prevent structural failure and fill the gap in nano-graphene concrete research, thereby saving human lives and significantly reducing the structures’ cost of maintenance and repair.

1 Introduction

Concrete is the most widely used construction material in the world. About four tons of concrete are produced per person per year worldwide [1]. Concrete is made up of three basic components: water, aggregate (rock, sand, or gravel), and Portland cement. Although concrete has a high compressive strength, it is relatively weak and brittle under tension. Therefore, concrete structures are usually reinforced with steel bars to overcome the defects of concrete. Under the reinforced concrete structure, the crack is formed as tensile stress. And under the condition of constant loading on concrete, the width of the crack will be widely distributed, and when a larger crack is formed, it allows water or other chemicals to easily pass through the crack and come into contact with the steel bar, which causes corrosion problems [2].

Health monitoring is really important, which can detect cracks or any other kind of damage in the concrete. Damages may induce collapses. Structural health monitoring (SHM) refers to strategies and processes for damage identification and characterization of engineering structures [3]. Structural damage is defined as changes in structural material parameters and their geometric characteristics, such as fracture, corrosion, fatigue, and so on. The SHM process involved uses a periodically sampled sensor array to acquire structural responses, extract damage-sensitive indicators, and statistically analyze damage-sensitive indicators to determine current structural health conditions. In the past few decades, cement materials with conductive particles can be used to provide a method for health monitoring and have attracted much interest in the self-sensing of SHM, which aims to continuously monitor the state of a structure to prevent failure by detecting the development of flaws [4]. The most important advantage is the assessment of a detected flaw can be discovered early, and the damage can be remedied, if it is necessary. SHM is known from the prior literature that various materials and sensors have been developed for SHM, but are still not commonly used in practice because the materials used for the conductive phase can be extremely expensive and difficult to disperse in the cement matrix. However, nano-graphite is different; it can increase the electrical conductivity and hence increase the ability of sensing to help SHM [5].

In this research project, nano-graphite which is two-dimensional carbon nano-materials having a nanometer thickness and a few micrometers diameter [6], which will be added to the concrete to measure the effect of nano-graphite on concrete, and it may indicate different physical and chemical properties and compare the results with iron-ion nano-graphite. In addition, using the multifarious percentage of nano-graphite’s content to find the optimized content, which has the most efficient conductivity and strength. Pure concrete with nano-graphite is a new concept introduced in this article. This study has explored experimentally the mechanical and conductive behaviors of nano-graphite-based concrete.

2 Raw materials and test methods

2.1 Conductivity of materials

Adding some materials to the concrete improves its strength and electricity conductivity. From the review of the existing literature, it is clear that the use of nanomaterials in concrete is beneficial to improve certain technical properties of cement-based materials. The application of nanomaterials has received a lot of attention to improve the performance of conventional concrete at present. Eventually, nanomaterials are introduced into concrete to increase its strength and durability [7]. Huang et al. observed that the addition of nano-graphite increased the flexural strength of the cement composite by 82% compared to plain ones. The electrical properties of the composite material are significantly improved, and the composite material becomes highly conductive [8]. In addition, the cost of nano-graphite is lower than that of other materials.

2.2 Design philosophy

The aim of this experiment is to investigate the mechanical and electrical properties of the concrete with different content of pure and iron-ion-contained nano-graphite. More important is to figure out an ideal mixture for more stable resistivity measurement with less deviation as well as less influence on mechanical properties. The compressive, strength, and electrical conductivity of cylindrical nano-graphite concrete will be measured during the test, respectively. In this experiment, the shape of concrete is a fixed cylinder (50 mm × 100 mm). The different content of nano-graphite and iron-included nano-graphite are 1, 3, and 5%. Each content will consist of three specimens to find the best-performed specimen and ensure the accuracy of the experiment in order to alleviate experimental errors by calculating the mean of each test. All the experiments were conducted in the Concrete Laboratory at the University of Western Australia. The specimens and scale of experiments were designed to be appropriate for the timeframe and available testing machines in the laboratory.

2.3 Specimens design

The concrete considered here is prepared with the following ingredients: cement, water, and aggregate (coarse aggregate – normally sand – and fine aggregate). In this experimental program, Type I ordinary Portland cement conforming to CNS 61 R2001 was used in all mixes [9]. C35 concrete is commonly used for structural piling and creating external slabs and walls [10]. As the subject of this experiment is investigating the most common building concrete, the choice of concrete is the most commonly used type of the moment; then, C35 concrete has been selected [11]. The mixture ratio of C35 concrete typically is about 1 cement, 2.485 aggregate, and 0.46% water. In order to establish and retain the workability and flowability of the mixtures after the addition of nano-graphite, a super-plasticizer is needed, and the amount of super-plasticizer added is proportional to the amount of nano-graphite added into the mix [12,13]. The amount of super-plasticizer added is proportional to the amount of fiber added into the mix. The water–binder ratio used in this experiment is 0.46, and the sand–binder ratio was 0.364. The total binder (cement and fly ash) was 1,548 g. The amount of super-plasticizer was between 0.1 and 1% by the weight of cement. In addition, the proportion of nano-graphite is presented in Table 1.

Proportion of materials in the experiment

| Index | W/C | Cement | Water | Fine agg | Corse agg | Nano-additive | SuperP (mL) |

|---|---|---|---|---|---|---|---|

| PC | 0.46 | 420 | 150 | 548 | 1,000 | 0 | 3 |

| PNGC1 | 0.46 | 420 | 150 | 548 | 1,000 | 4 | 3 |

| PNGC3 | 0.46 | 420 | 200 | 548 | 1,000 | 12 | 3 |

| PNGC5 | 0.46 | 420 | 300 | 548 | 1,000 | 20 | 3 |

| IPNGC1 | 0.46 | 420 | 150 | 548 | 1,000 | 4 | 3 |

| IPNGC3 | 0.46 | 420 | 150 | 548 | 1,000 | 12 | 3 |

| IPNGC5 | 0.46 | 420 | 150 | 548 | 1,000 | 20 | 3 |

The order of mix procedures should be rearranged, especially when it comes to how to make a sufficiently dispersed nano-graphite solution by ultrasonic vibrating before adding it to the mixed homogeneous dry materials. First, all dry materials are weighed and poured into a blender. And they are mixed at low speed for approximately five minutes. Then, the water and super-plasticizer were mixed and slowly added to the dry matter matrix and mixed for an additional five minutes. During the mixing process, it was shown that the addition of excess super-plasticizer caused the nano-graphite to sink into the bottom of the mortar. Therefore, the amount of super-plasticizer added is precisely adjusted to ensure uniformity of the mixture design and used ultra-sonicator to make water, super-plasticizer, and nano-graphite mixed evenly. During the mixing period, the mixture is checked if it is thoroughly mixed and any remaining dry material is removed from the bottom of the mixer using a trowel or manual spatula. After the mixing is complete, it is necessary to check the mortar for no lumps or nano-graphite bundles are found. It was found that a sufficient plasticizer was needed to prevent nano-graphite from bundling (balling effect).

2.4 Experiment setup

If we want to conduct compressive on all specimens, three specimens for each mixture should be prepared while there is no need to prepare extra specimens for electrical conductivity test as that can be done before mechanical tests. For these three tests, cylinders with a dimension of 50 mm × 100 mm were recommended and used for testing. The sizes of the cylinders were determined. After the mixing process, the mixture was poured from the blender into the molds for each specimen using a scoop. The cylinder mold is shown in Figure 1. The mixture was then vibrated on a vibrating table to ensure the mixture was sufficiently compacted, and there were no trapped air bubbles remained in the mortar. Each specimen was then covered with a lid to maintain moisture content and stored at room temperature (23°C) for 24 h before being demolded. After 24 h, all the specimens were demolded and transferred to the curing room (parameters like temperature and humidity) and stored for 28 days of curing before testing. Before this, there is another 7-day-water-curing process that should be conducted, which means all demolded specimens should be immersed in the lime-water tank to get full hydration. The completed cylindrical concrete is shown in Figure 2.

Specimens before demolding.

Specimens after curing process.

3 Experimental results and discussions

3.1 Electrical resistivity test

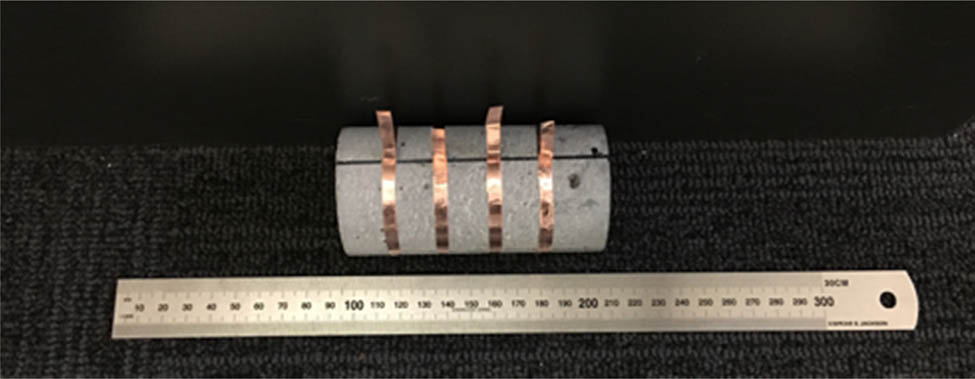

For the electric conductivity test, a digital multimeter, a test tool, is used to measure two or more electrical values – principally voltage, current, and resistance. And it is wrapped with copper tape every 2 cm on the sample, and copper tape is used as a conductive material to connect the samples with a digital multimeter. Current is passed through two outer probes that are connected with these two copper tapes and measured the voltage through the inner probes which is connected with these two copper tapes that allow the measurement of the resistivity. Specific test samples are shown in Figure 3. The following equation is used to calculate the electrical resistivity:

where

Samples with copper tapes every 2 cm.

3.2 Compression test

The compression test was carried out on a 50 mm × 100 mm cylinder using a Baldwin machine. A total of 21 specimens were tested. The maximum load of the Baldwin machine used is 60 tonnes under quasi-static conditions and a displacement rate of 0.5 mm min−1. The purpose of this test was to find the compressive strength of the nano-graphite concrete and obtained a strain–stress curve. A strain gauge was placed vertically on the surface of the specimen to measure the strain and Young’s modulus of the Nano-graphite concrete mixture. The type of strain gauge used was PL-60-11-1L with a gauge length of 60 mm. A 50 mm × 100 mm specimen was placed vertically in the machine, and square plywood was placed thereon to ensure that the load was evenly distributed over the surface of the specimen. Test specimens shall be kept moist by any convenient method during the period between removals from moist storage and testing. Specimens should be levelly attached to the top and bottom of the plate and to ensure the indicator starts with zero. Specific test samples are shown in Figure 4. The compressive strength was calculated as follows:

Baldwin machine.

3.3 Experimental result

3.3.1 Electrical resistivity

The results of electrical resistivity of PC, PNGC1, PNGC3, PNGC5, IPNGC1, IPNGC3 and IPNGC5 are shown in Figure 5.

Results of electrical resistivity.

The average electrical resistivity is calculated using equation (1). From Figure 5, it is observed that the addition of nano-graphite has resulted in an increase in electrical conductivity compare to PC. IPNGC1 shows a lower electrical resistivity of 1.16 × 106 MΩ m than PNGC1. In addition, iron-included nano-graphite has shown higher electrical conductivity than PNGC. The five volume fractions of PNGC and IPNGC have the lowest electrical resistivity of 6.19 × 105 and 2.87 × 105 MΩ m, respectively, in comparison with the same material’s content range. Meanwhile, for PNGCE and IPNGC, it demonstrates a decreasing trend of electrical resistivity as volume fractions increase.

3.3.2 Compressive strength

Twenty-eight-day compressive strength test results of the cylinders are presented in Figure 6.

Compressive test results.

Three specimens were tested for each test to obtain the compressive strength of the composites, and the compressive strength is obtained by computing equation (2). Pure concrete has the highest value of compressive strength, and among different volume fractions of nano-graphite, it is noted that PNGC1 exhibits the highest average compressive strength when compared to PNGC3 and PNGC5. Hence, nano-graphite with a volume fraction of 1% has the best compressive strength except pure concrete, and a further increase in volume fraction resulted in a decrease in compressive strength. The average compressive strength of IPNGC1 is slightly lower than PNGC1. But IPNGC5 has higher compressive strength than PNGC3. It is observed that the average compressive strength of PNGC3 has the lowest compressive strength compared to other composites, and PNGC has better compressive strength than IPNGC. The reason is the amount of water of PNGC is more that of than IPNGC; water can improve the compressive strength. Therefore, 1% of nano-graphite is the ideal volume content to be the conductive material in pure concrete to reach the optimum compressive strength.

3.3.3 Stress–strain curve

Comparing stress–strain curve with different mixtures of samples is shown in Figures 7–9. PC, PNGC, and IPNGC have different maximum loading, the reason is that the amount of water is different in these three samples. PNGC needs more water, as the pure nano-graphite has the ability to absorb water, and the surface area of pure nano-graphite is bigger than iron-included nano-graphite. Meanwhile, the displacement of PNGC and IPNGC is greater than that of PC; because graphite has a lubricating effect, it fills the voids in the concrete.

PC stress–strain curve.

PNG stress–strain curve.

IPNG stress–strain curve.

4 Conclusion

In this experimental study, the following conclusions and recommendations were drawn: (1) Pure concrete in this study has proven to exhibit the best mechanical behavior accompanied by the others materials. But it is lack of electrical resistivity. (2) The 5% content of nano-graphite in concrete shows the best electrical resistivity comparing with the same material’s content range, which is 6.19 × 105 MΩ m. Meanwhile, the iron included nano-graphite has a better result of electrical resistivity than pure nano-graphite. Among the three IPNGC, the five volume fractions of IPNGC have the highest average electrical resistivity of 2.87 × 105 MΩ m. And both PNGC and IPNGC showed better electrical resistivity than pure concrete. (3) Comparing with the pure concrete, the compressive strength of PNGC and IPNGC has been decreased. The 1% content of pure nano-graphite has the highest average compressive strength of 39.86 kPa when compared to PNGC3 and PNGC5. In addition, the IPNGC1 has the best average compressive strength of 35.65 kPa among the IPNGC specimens. The average compressive strength of IPNGC1 is slightly lower than PNGC1. But IPNGC5 has higher compressive strength than PNGC3. (4) It is observed that the average compressive strength of PNGC3 has the lowest compressive strength compared to those of other composites. Therefore, 1% of nano-graphite is the ideal volume content to be the conductive material in pure concrete to reach the optimum compressive strength. Nano-graphite in concrete indicated a decrease in compressive strength. And with the increased content of nano-graphite, the compressive strength is decreased.

Acknowledgment

Thanks to the help provided by Fan Li of the college of Water Resources and Hydropower from Hohai University.

-

Funding information: This work was supported by a grant from the National Natural Science Foundation of China (No. 519040311).

-

Author contributions: Jie Zhou: Conceptualization, Methodology; Fan Li: Software, Formal analysis; Yanan Zhang: Resources, Data Curation; Xin Du: Visualization, Supervision.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: Data openly available in a public repository.

References

[1] Ackermann CK. Self-sensing concrete for structural health monitoring of smart infrastructures. USA: University of Rhode Island; 2018. 10.23860/thesis-ackermann-kay-2018.Search in Google Scholar

[2] Azhari F, Banthia N. Carbon fiber/nanotube cement-based sensors for structural health monitoring; 2009. https://www.researchgate.net/publication/290543673_Carbon_fibernanotube_cement-based_sensors_for_structural_health_monitoring.Search in Google Scholar

[3] Alessandro AD, Ubertini F, Materazzi AL, Porfiri M. Electrical modelling of carbon nanotube cement-based sensors for structural dynamic monitoring. AIP Conference Proceedings. American Institute of Physics; 2014. 10.1063/1.4883038.Search in Google Scholar

[4] Du H, Quek ST, Pang SD. Smart multifunctional cement mortar containing graphite nanoplatelet. Sensors & smart structures technologies for civil, mechanical, & aerospace systems. 2013. p. 869238. 10.1117/12.2009005.Search in Google Scholar

[5] Granju JL, Balouch SU. Corrosion of steel fibre reinforced concrete from the cracks. Cem Concr Res. 2005;35(3):572–7. 10.1016/j.cemconres.2004.06.032.Search in Google Scholar

[6] Berrocal CG. Chloride induced corrosion of steel bars in fibre reinforced concrete. Sverige: Chalmers University of Technology; 2015. https://research.chalmers.se/publication/210374.Search in Google Scholar

[7] Su Y, Wu C, Li J, Li ZX, Li W. Development of novel ultra-high performance concrete: From material to structure. Constr Build Mater. 2017;135:517–28. 10.1016/j.conbuildmat.2016.12.175.Search in Google Scholar

[8] Adessina A, Ben Fraj A, Barthélémy JF, Chateau C, Garnier DA. Experimental and micromechanical investigation on the mechanical and durability properties of recycled aggregates concrete. Cem Concr Res. 2019;126(C):105900. 10.1016/j.cemconres.2019.105900.Search in Google Scholar

[9] Tang J, Yu C, Wang R, Liu J. Sulfonation of graphene and its effects on tricalcium silicate hydration. Constr Build Mater. 2019;206:600–8. 10.1016/j.conbuildmat.2019.01.155.Search in Google Scholar

[10] Chu H, Ge X, Jiang J, Tang J, Zhang Z. Mechanical properties and ablation behaviour of nuclear sacrificial materials containing graphene sulfonate nanosheets. Constr Build Mater. 2018;191:69–79. 10.1016/j.conbuildmat.2018.10.016.Search in Google Scholar

[11] Chu H, Jiang J, Sun W, Zhang M. Effects of graphene sulfonate nanosheets on mechanical and thermal properties of sacrificial concrete during high temperature exposure. Cem Concr Compos. 2017;82:252–64. 10.1016/j.cemconcomp.2017.06.007.Search in Google Scholar

[12] Hong-yan C, Jin-yang J, Sun W, Zhang M. Mechanical and thermal properties of graphene sulfonate nanosheet reinforced sacrificial concrete at elevated temperatures. Constr Build Mater. 2017;153:682–94. 10.1080/01694243.2021.1877017.Search in Google Scholar

[13] Silva RV, de Brito J, Dhir RK. Establishing a relationship between modulus of elasticity and compressive strength of recycled aggregate concrete. J Clean Prod. 2016;112:2171–86. 10.1016/j.jclepro.2015.10.064.Search in Google Scholar

© 2022 Jie Zhou et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete

Articles in the same Issue

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete