Abstract

Graphite flakes/Al composites are promising thermal management materials due to high thermal conductivity (TC) in basal plane orientation, matched coefficient of thermal expansion, and good machinability. In this article, the acoustic mismatch model and the effective medium approach are applied to predict the influence of different interfacial coatings on the interfacial thermal conductance (ITC) and the TC of graphite flakes/Al composites, respectively. With the increase in the thickness of interfacial coatings, the ITC and the TC of graphite flakes/Al composites decrease. For the composites with Ni, Cr/Cr7C3/Cr3C2, Si/SiC, Ti/TiC, WC, and Mo/Mo2C coatings, the ITC is sensitive to coating thickness. In order to obtain ideal TC of graphite flakes/Al composites, the thickness of the coatings should be controlled below 1 μm. It is reasonable that the TC of the graphite flakes/Al composites increases as the volume fraction of graphite flakes increases. The TC of the graphite flakes/Al composites increases with the ITC and changes slowly when the ITC increases to a certain extent. Si/SiC and WC coatings are proposed to be the most promising candidates to improve the thermal performance of graphite flakes/Al composites.

1 Introduction

The rapid development of smaller, more powerful, and more efficient electronic systems has created a very challenging set of heat dissipation, a critical factor in guaranteeing performance and reliability in electronic devices [1,2]. Hence, there is a great desire to develop very efficient thermal management materials with ideally lightweight, extremely high thermal conductivity (TC), and low coefficient of thermal expansion (CTE). In recent years, aluminum matrix composites with excellent comprehensive properties are therefore becoming promising materials for heat sinks and spreaders in multi-functional electronic packaging systems. Among these, SiC/Al composites, due to their low price, matched CTE, and near-net-shape fabrication versatility, are frequently used in the thermal management market [3,4]. However, their relatively low TC (below 250 W/m K) [5] cannot meet well with the increasing requirement in packaging application. Diamond/Al composites with higher TC (∼750 W/m K) [6] have high potential in this regard; however, their high price and poor processability limit their application [7]. Due to their low price, high TC in basal plane orientation, and good machinability, graphite flakes/Al composites have received ever-growing attention [8,9,10,11,12,13,14,15,16].

Similar to other carbon/Al composites, the optimization of the interface plays a crucial role in determining the thermophysical properties of the graphite flakes/Al composites. It is well known that during the fabrication of graphite flakes/Al composites at elevated temperatures, it is extremely easy to form interfacial aluminum carbide (Al4C3), which is easy to hydrolyze under water vapor condition and can cause the interfacial de-bonding and deteriorate the properties of the composites [17]. Meanwhile, excessive Al4C3 may also greatly deteriorate the interfacial thermal conductance (ITC) to some extent due to its rather low intrinsic TC [18]. It is widely known that the ITC is important in various applications and metrologies of various forms of composites [19,20,21,22,23]. Recent studies have shown that graphite flake surface coating can be applied to prevent the formation of Al4C3 and enable good bonding with the Al matrix, thus significantly improve the thermal and mechanical properties of graphite flakes/Al composites [24,25,26,27,28,29]. Although good interfacial bonding is helpful for desirable TC, the additional interface layers will probably also act as thermal boundary barriers, which will influence the thermal properties of composites [18]. Moreover, systematic experimental research studies on quantitative evaluation and comparison of interface layers on the thermal properties are still insufficient yet. Based on the performance parameters of the surface coatings [22,30,31,32,33], the prediction of the ITC and the TC of the composites will help to improve the process of the surface coating of reinforcements and the design of the composites.

The present work aims to theoretically evaluate the effects of various coating types and their thicknesses on the ITC and the TC of graphite flakes/Al composites. Typical interfacial coatings are divided into metals and their carbides, and a calculating method based on the acoustic mismatch model (AMM) and effective medium approach (EMA) are applied. The results may guide for choosing the appropriate interface types and their thicknesses for graphite flakes/Al composites.

2 Model employed for calculating the ITC and the TC

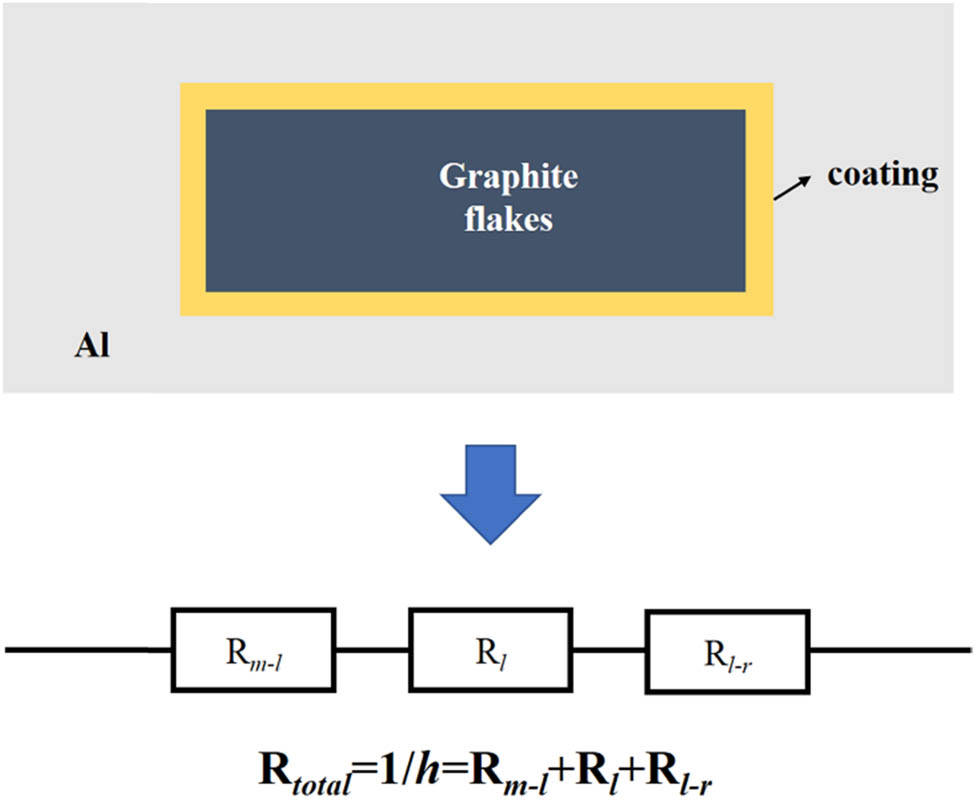

Considering the differences in the electronic and vibrational properties, there is an interface thermal barrier for heat transfer between Al matrix and graphite flakes, known as Kapitza resistance, which will limit the improvement of the TC of composites. The ITC h is the reciprocal of Kapitza resistance. For graphite flakes/Al composites with various coatings, the schematic of the multi-layered interfacial structure and physical model of the interfacial thermal resistance are shown in Figure 1. The total interfacial thermal resistance (R total) includes the Kapitza resistance between Al matrix and the coating layer (R m-l), the thermal resistance of the coating layer (R l), and the Kapitza resistance between the coating and graphite flakes (R l-r).

Schematic diagram of the interfacial thermal resistance of graphite flakes/Al composites with an interfacial coating.

The AMM can be used to theoretically estimate the R m-l and R l-r :

where

As a typical anisotropic material, however, graphite flake still has three modes: one longitudinal, one transverse, and one out-of-plane mode (

The R l can be expressed by the equation:

where

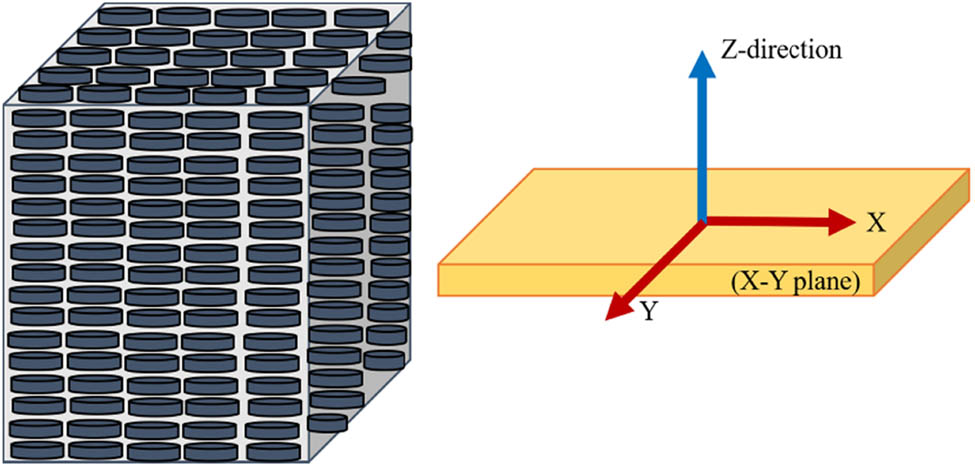

The TC of graphite flakes/Al composites in the basal plane of graphite flakes (defined as the X–Y plane) is much higher (∼880 W/m K) than that perpendicular to the basal plane (defined as the Z-direction). The schematic diagram of the X–Y plane and the Z-direction of graphite flakes/Al composites are shown in Figure 2.

Schematic diagram of the X–Y plane and the Z-direction of graphite flakes/Al composites.

The EMA can theoretically estimate the TC of graphite flakes/Al composites (K c), which can be expressed as follows [16,20]:

with

where

where D and t are the diameter and thickness of graphite flakes, respectively. Hence, the EMA can be reduced to:

The effect of multilayer interface (Figure 1) on the TC of graphite flakes may be equivalent to that of graphite flakes covered with a thermal barrier. Hence, the relationship between the effective TC of graphite flakes (K r) and their intrinsic TC (K Gf ) and ITC (h = 1/Rtotal) is as follows [7,21]:

In our calculations and numerical analyses, the constants of materials involved are listed in Table 1. The representative values of 50 vol%, 500, and 20 μm are assigned to f, D, and t, respectively.

| Materials | Density/(kg m−3) | Sound velocity/(m s−1) | Specific heat/(J K−1 kg−1) | TC/(W m−1 K−1) | ||

|---|---|---|---|---|---|---|

| Longitudinal | Transverse | Average | ||||

| Al | 2,700 | 6,240 | 3,040 | 880 | 237 | |

| Graphite flakes | 2,250 | 23,600 | 15,900 | 710 | 880 (a-axis) | |

| 1,960 | 700 | 27 (c-axis) | ||||

| Si | 2,330 | 8,970 | 5,332 | 703 | 126 | |

| SiC | 3,100 | 12,810 | 7,530 | 678 | 179 | |

| W | 19,320 | 4,029 | 133 | 178 | ||

| WC | 14,900 | 4,697 | 203 | 120 | ||

| Mo | 10,200 | 3,916 | 248 | 138 | ||

| Mo2C | 9,000 | 6,257 | 3,605 | 4,003 | 347 | 21 |

| Cr | 7,190 | 6,980 | 4,100 | 4,545 | 446 | 90 |

| Ti | 4,540 | 6,070 | 3,120 | 522 | 22 | |

| TiC | 4,930 | 9,330 | 6,092 | 569 | 36 | |

| Cu | 8,900 | 4,910 | 2,500 | 2,801 | 386 | 398 |

| Ni | 8,800 | 5,630 | 2,960 | 3,310 | 447 | 88 |

| Ag | 10,500 | 3,780 | 1,740 | 1,960 | 237 | 427 |

3 Predictions and numerical analyses

Based on the aforementioned models, the effects of various coating types and their thicknesses on the ITC and the TC of graphite flakes/Al composites can be theoretically evaluated. Furthermore, the variation of the ITC and the TC of graphite flakes/Al composites with a different volume fraction of graphite flakes has been systematically analyzed.

3.1 ITC of graphite flakes/Al composites

As a bridge between the matrix and the reinforcements, the interface can transfer the external force borne by the matrix to the reinforcements; meanwhile, the appropriate interface bonding can prevent crack propagation and slow down stress concentration. Light wave, acoustic wave, thermoelastic wave, and shock wave will scatter and absorb at the interface, resulting in discontinuity of physical properties. From this point of view, the carrier transport at the interface is blocked, which is not conducive to the heat conduction of the material, especially the condition of a weak bonding at the interface. Due to the poor wettability of graphite and Al, it is more feasible and necessary to improve interfacial bonding by introducing additional interface layers by surface metallization of graphite flakes. Generally, the commonly used coating materials include metals and their carbides.

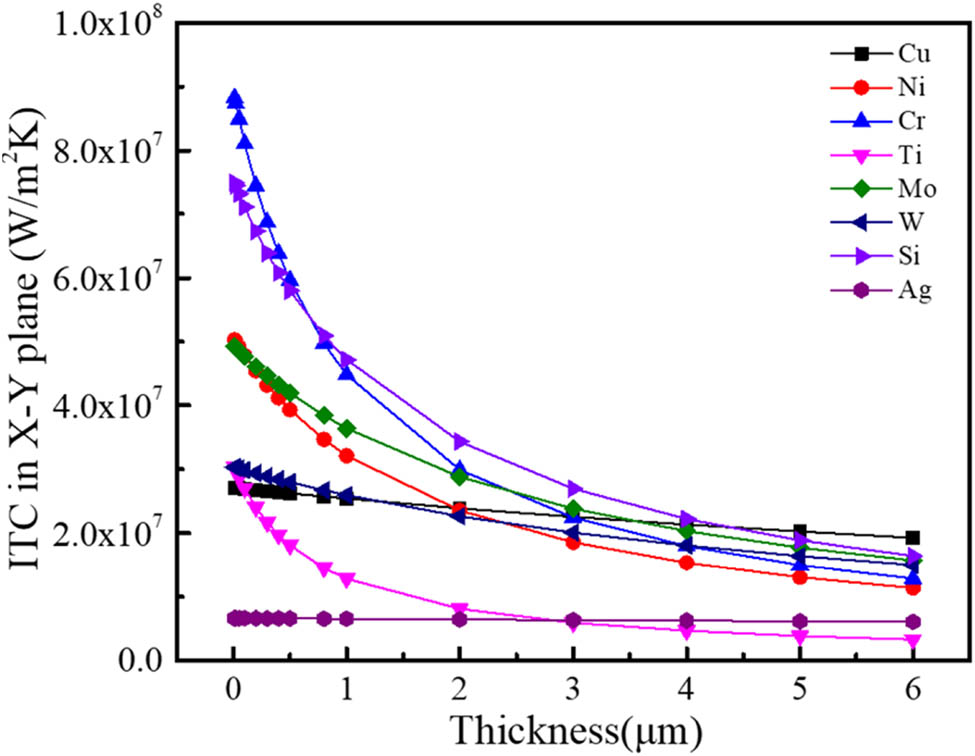

As shown in Figure 3, the ITC of graphite flakes/Al composites with metal coatings decreases with the increase in coating thickness, but the trend of variation is obviously different. For the composites with W, Cu, and Ag coatings, the ITC decreases slowly with the increase in coating thickness. Particularly, the ITC of composites with Ag coating is relatively lower than others, which is not suitable for coating material of graphite flakes/Al composites. That is because of the lower sound velocities of Ag. For the composites with Cr, Si, Mo, Ni, and Ti coatings, the ITC is sensitive to coating thickness. When the coating thickness is 1 μm, the ITC of composites with Cr, Si, Mo, Ni, and Ti coating decreases 49.3, 37.1, 26.2, 36.2, and 57.3%, respectively. Hence, in order to obtain satisfied interface heat transfer behavior, the thickness of the coating of the composites should be strictly controlled. Among these coatings, the ITC of composites with Ti coating is relatively low, and the coating thickness should be controlled at tens of nanometers. Cr and Si are better coating materials due to their higher ITC. However, the solubility of Cr in the Al matrix is so large that it is not advisable to be used as a coating material of diamond/Al composites [18]. Mo, as a diamond coating material, has been found to form intermetallic compounds with Al at the interface, so the TC of the diamond/Al composites has not been improved [23]. Therefore, Si is a suitable coating material of the graphite flakes/Al composites from the point of view of improving the ITC of the composites; however, the thickness of the coating still needs to be controlled.

ITC of graphite flakes/Al composites with typical metal coatings as a function of coating thickness.

For graphite flakes/Al composites with carbide coatings, as shown in Figure 4, the ITC similarly decreases with the increase in coating thickness and changes gradually after falling to a certain extent. The ITC of graphite flakes/Al composites with ZrC coating is at a lower level; hence, ZrC is not a suitable coating material. The graphite flakes/Al composites with other coating are all sensitive to the thickness of the coating, and the ITC has been significantly reduced when the coating thickness is more than 500 nm. Particularly, for Cr7C3, Cr3C2, TiC, and Mo2C coatings, the ITC of composites with 100 nm thickness coatings decreases 30.1, 32.9, 22.4, and 21.6%, respectively. Considering the coating process of flake graphite, it is relatively difficult to realize the coating thickness under 100 nm. Compared with other carbide coatings, SiC is more suitable as a coating material for graphite flakes/Al composites. The ITC of graphite flakes/Al composites with SiC coating is higher as a whole; meanwhile, when the coating thickness is 500 nm, the ITC only decreases 22.35%.

ITC of graphite flakes/Al composites with typical carbide coatings as a function of coating thickness.

3.2 TC of graphite flakes/Al composites

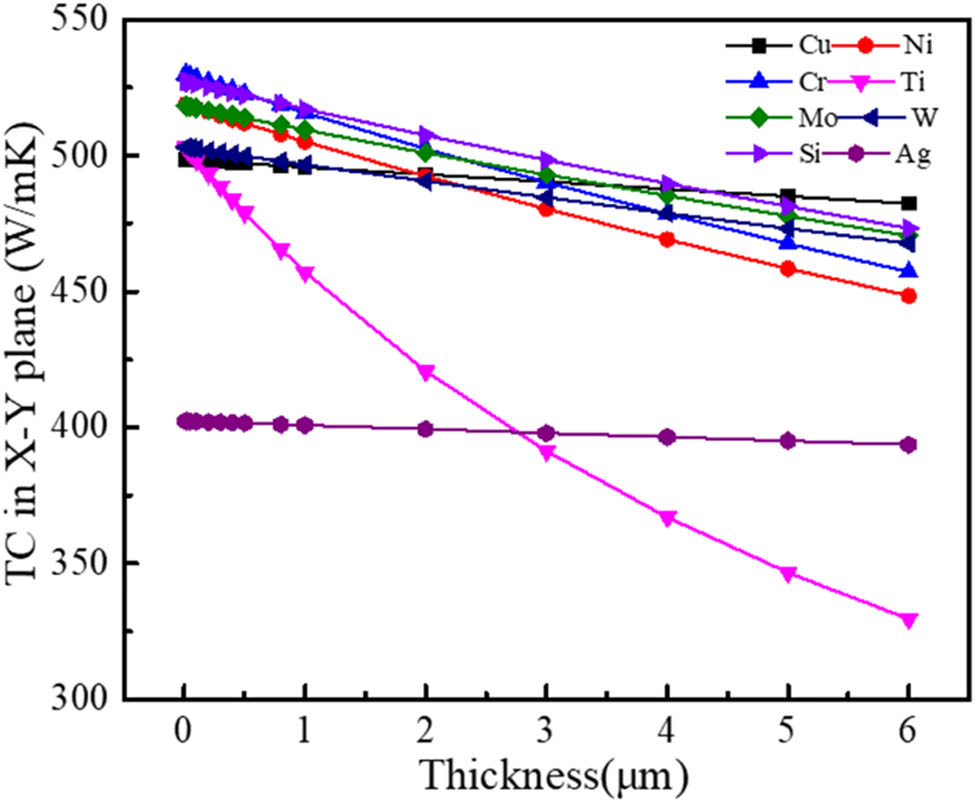

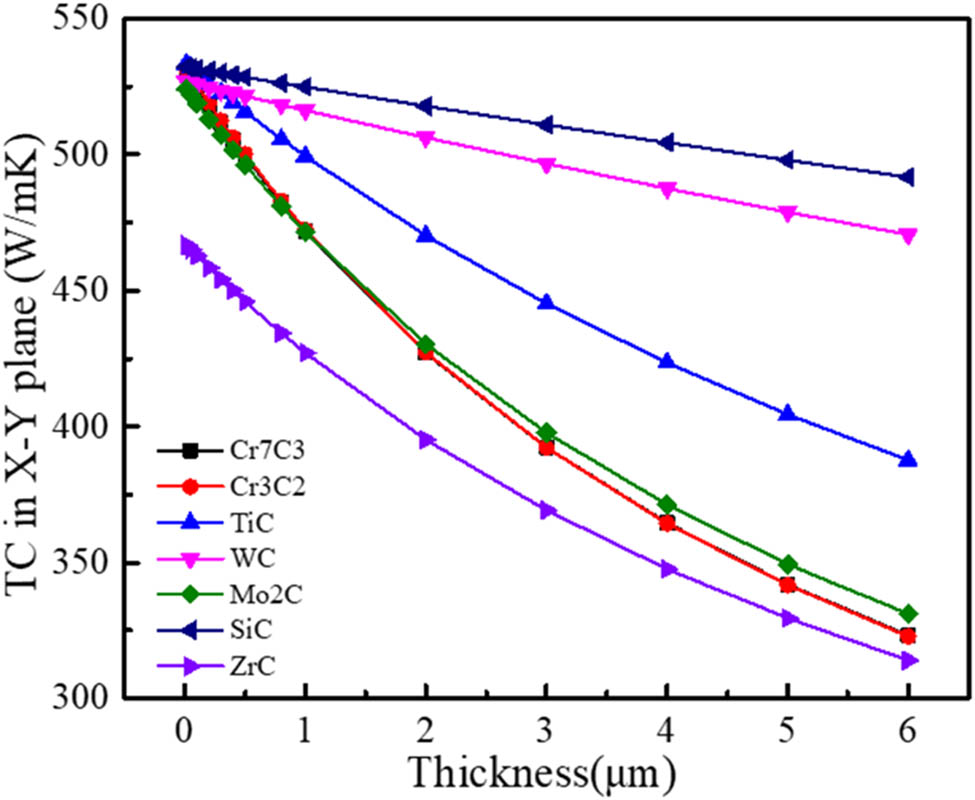

Figures 5 and 6 show the variation of the TC of graphite flakes/Al composites with different coatings along the X–Y plane, which is consistent with the ITC. With the increase in the thickness of interfacial coatings, the TC of graphite flakes/Al composites decreases. The overall level of the TC of Ag coating composite is low, and the TC of Ti coating composites decreases rapidly with the increase in coating thickness. When the coating thickness is 1 μm, the TC of composites with Ti coating decreases 9.1%. The graphite flakes/Al composites with Cr and Si coatings exhibit higher TCs when coating thickness is less than 1 μm.

TC of graphite flakes/Al composites with typical metal coatings as a function of coating thickness.

TC of graphite flakes/Al composites with typical carbide coatings as a function of coating thickness.

In comparison, the thickness of the carbide coating has a more significant effect on the TC of the composites. The TC of composites with ZrC coating is relatively lower, which is consistent with the variation trend of the ITC. The TC of Cr7C3, Cr3C2, TiC, and Mo2C coating composites changes significantly with the coating thickness. The overall TC of SiC and WC coating composites is relatively high, and SiC or WC coating can be used for graphite flakes/Al composites.

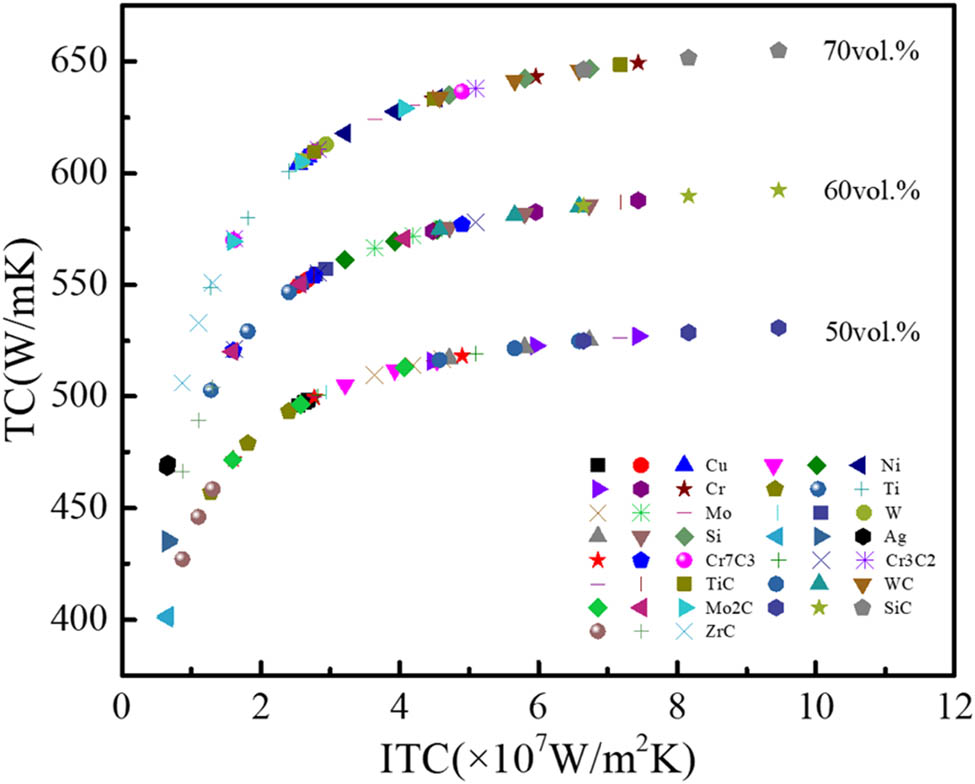

Figure 7 shows the calculated ITC and the TC of 50–70 vol% graphite flakes/Al composites with various coatings with a thickness of 0.2–1.0 μm. It is well reasonable that the TC of the graphite flakes/Al composites increases as the volume fraction of graphite flakes increases. Since the graphite flakes as high thermal reinforcements construct the heat conduction path of the composites, the increase in their contents is bound to improve the TC of the composites. Furthermore, as for the case of the introduced interface coatings, it can be seen that the TC of the graphite flakes/Al composites increases with the ITC and changes gradually when the ITC increases to a certain extent. The ITC plays an important role in improving the TC of graphite flakes/Al composites. Because of the differences between the physical properties of graphite and Al, thermal flux through the interfaces changes and this so-called thermal resistance limits the heat transfer of composites. Once the interface coating layers introduced in the composites can improve the ITC, such as Si and SiC, and the TC of the composites can reach higher level. The TC of the graphite-SiC/Al composite in the X–Y plane fabricated by vacuum hot pressing technology can reach (528–735) W/(m K) [24]. In order to obtain better ITC, the coating layers should be with a nanoscale thickness. However, the interface is one of the factors affecting the TC of composites. Once the perfect interface bonding is obtained, the TC of composites often depends on other factors, such as the size and volume fraction of graphite, the distribution of graphite in the matrix, the composition of matrix alloy, and so on. Apparently, the size and volume fraction of graphite flake are also the factors affecting the ITC.

Predicted ITC and TC of 50–70 vol% graphite flakes/Al composites with a coating thickness of 0.2–1.0 μm.

It can be seen that there are still some errors in the prediction model of the ITC and the TC of the composites. AMM assumes that phonons are reflected and refracted at the interface. The smaller the ratio of interface roughness to phonon mean free path, the closer the interface thermal resistance is to the calculated value of the AMM model. Hence, the actual situation of the ITC of composites is higher than that predicted by the AMM model. Meanwhile, other factors, such as relative density and interfacial reaction of the graphite/Al composite, are not considered in these models. When there are pores in the composites, it is easy to form microcrack under stress and further reduce the mechanical properties of the composites. Meanwhile, these pores can also affect the heat conduction of phonons and electrons and reduce the thermophysical properties of the composites. It is well known that graphite and Al will react during preparation in high temperature and the TC of the reaction products Al4C3 is very low, which is not benefit for the improvement of the TC of the composites. It should be noted that these predictive models are still very effective to evaluate the effects of various coatings on the ITC and select a desired interface layer for graphite flakes/Al composites.

4 Conclusion

Graphite flakes/Al composites are promising thermal management materials due to high TC and low CTE. In this work, the prediction models based on the AMM and EMA are developed to evaluate the effect of various interfacial coatings on the ITC and the TC of graphite flakes/Al composites. The ITC decreases with the increase in coating thickness. For the composites with Ni, Cr/Cr7C3/Cr3C2, Si/SiC, Ti/TiC, WC, and Mo/Mo2C coatings, the ITC is relatively sensitive to coating thickness. With the increase in the thickness of interfacial coatings, the TC of graphite flakes/Al composites decreases. The coatings with a nanoscale thickness are positive to improve the thermal properties of graphite flakes/Al composites. Si/SiC and WC coating can be used as suitable coating materials of the graphite flakes/Al composites from the point of view of improving the TC of the composites; however, the thickness of the coatings still needs to be controlled. The TC of the graphite flakes/Al composites increases as the volume fraction of graphite flakes increases. The TC of the graphite flakes/Al composites increases with the ITC and changes slowly when the ITC increases to a certain extent.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant no. 51801002), the R&D Program of Beijing Municipal Education Commission (Grant no. KM202010009004), and the Scientific Research Foundation of North China University of Technology (Grant no. 110051360002).

-

Conflict of interest: The authors declare that they have no conflict of interest.

-

Data availability statement: All data included in this study are available upon request by contact with the corresponding author.

References

[1] Moore AL, Shi L. Emerging challenges and materials for thermal management of electronics. Mater Today. 2014;17(4):163–74. 10.1016/j.mattod.2014.04.003 Search in Google Scholar

[2] Tong XC. Advanced materials for thermal management of electronic packaging. New York: Springer; 2011. p. 1–2.10.1007/978-1-4419-7759-5Search in Google Scholar

[3] Chu K, Jia C, Liang X, Chen H, Guo H, Yin F, et al. Experimental and modeling study of the thermal conductivity of SiCp/Al composites with bimodal size distribution. J Mater Sci. 2009;44(16):4370–8. 10.1007/s10853-009-3655-9.Search in Google Scholar

[4] Zhang Z, Ge B, Xie W, Wei Z, Yang W, Li Y, et al. Effect of Si alloying content on the microstructure and thermophysical properties of SiC honeycomb/Al-Mg-Si composites prepared by spontaneous infiltration. Ceram Int. 2020;46(8):10934–41. 10.1016/j.ceramint.2020.01.108.Search in Google Scholar

[5] Arpon R, Molina JM, Saravanan RA, Garcia-Cordovilla C, Louis E, Narciso J. Thermal expansion behaviour of aluminum/SiC composites with bimodal particle distributions. Acta Mater. 2003;51:3145–56. 10.1016/S1359-6454(03)00126-5.Search in Google Scholar

[6] MMCC Metal Matrix Cast Composites, AlGrp™ thermal management composites, summer July 2015 [accessed July 2015], http://www.mmccinc.com.Search in Google Scholar

[7] Molina JM, Rheme M, Carron J, Weber L. Thermal conductivity of aluminum matrix composites reinforced with mixtures of diamond and SiC particles. Scr Mater. 2008;58(5):393–6. 10.1016/j.scriptamat.2007.10.020.Search in Google Scholar

[8] Prieto R, Molina JM, Narciso J, Louis E. Thermal conductivity of graphite flakes-SiC particles/metal composites. Compos Part A Appl Sci Manuf. 2011;42(12):1970–7. 10.1016/j.compositesa.2011.08.022.Search in Google Scholar

[9] Chen JK, Huang IS. Thermal properties of aluminum-graphite composites by powder metallurgy. Compos Part B Eng. 2013;44(1):698–703. 10.1016/j.compositesb.2012.01.083.Search in Google Scholar

[10] Li WJ, Liu Y, Wu GH. Preparation of graphite flakes/Al with preferred orientation and high thermal conductivity by squeeze casting. Carbon. 2015;95:545–51. 10.1016/j.carbon.2015.08.063.Search in Google Scholar

[11] Zhou C, Ji G, Chen Z, Wang M, Addad A, Schryvers D, et al. Fabrication, interface characterization and modeling of oriented graphite flakes/Si/Al composites for thermal management applications. Mater Des. 2014;63(2):719–28. 10.1016/j.matdes.2014.07.009.Search in Google Scholar

[12] Oddone V, Segl J, Prakasam M, Hartmann MT, Silvain JF, Edtmaier C, et al. Isotropic thermal expansion in anisotropic thermal management composites filled with carbon fibres and graphite. J Mater Sci. 2018;53(15):10910–9. 10.1007/s10853-018-2373-6.Search in Google Scholar

[13] Chamroune N, Delange F, Caillault N, Morvan F, Lu Y, Kawasaki A, et al. Synergetic effect of discontinuous carbon fibers and graphite flakes on thermo-mechanical properties of aluminum matrix composites fabricated by solid-liquid phase sintering. Met Mater Int. 2020;26(2):155–67. 10.1007/s12540-019-00324-0.Search in Google Scholar

[14] Shen Z, Ji G, Silvain JF. From 1D to 2D arrangements of graphite flakes in an aluminium matrix composite: Impact on thermal properties. Scr Mater. 2020;183:86–90. 10.1016/j.scriptamat.2020.03.022.Search in Google Scholar

[15] Li D, Wang C, Su Y, Zhang D, Ouyang Q. Governing the inclination angle of graphite flakes in the graphite flake/Al composites by controlling the Al particle size via flake powder metallurgy. Acta Metall Sin. 2020;33:1–10. 10.1007/s40195-019-00994-0.Search in Google Scholar

[16] Zhou C, Chen D, Zhang XB, Chen Z, Zhong SY, Wu Y, et al. The roles of geometry and topology structures of graphite fillers on thermal conductivity of the graphite/aluminum composites. Phys Lett A. 2015;379(5):452–7. 10.1016/j.physleta.2014.10.048.Search in Google Scholar

[17] Lin RY. Interface evolution in aluminum matrix composites during fabrication. Key Eng Mater. 1995;104–107:507–22. 10.4028/www.scientific.net/KEM.104-107.507.Search in Google Scholar

[18] Tan Z, Li Z, Xiong DB, Fan G, Ji G, Zhang D. A predictive model for interfacial thermal conductance in surface metallized diamond aluminum matrix composites. Mater Des. 2014;55(mar):257–62. 10.1016/j.matdes.2013.09.060.Search in Google Scholar

[19] Prasher R. Thermal boundary resistance and thermal conductivity of multiwalled carbon nanotubes. Phys Rev B. 2008;77(7):439–46. 10.1103/PhysRevB.77.075424.Search in Google Scholar

[20] Lin W, Zhang R, Wong CP. Modeling of thermal conductivity of graphite nanosheet composites. J Electron Mater. 2010;39(3):268–72. 10.1007/s11664-009-1062-2.Search in Google Scholar

[21] Tavangar R, Molina JM, Weber L. Assessing predictive schemes for thermal conductivity against diamond-reinforced silver matrix composites at intermediate phase contrast. Scr Mater. 2007;56:357–60. 10.1016/j.scriptamat.2006.11.008.Search in Google Scholar

[22] Wu Y, Luo J, Wang Y, Wang G, Wang H, Yang Z, et al. Critical effect and enhanced thermal conductivity of Cu-diamond composites reinforced with various diamond prepared by composite electroplating. Ceram Int. 2019;45(10):13225–34. 10.1016/j.ceramint.2019.04.008.Search in Google Scholar

[23] Ma S, Zhao N, Shi C, Liu E, He C, He F, et al. Mo2C coating on diamond: Different effects on thermal conductivity of diamond/Al and diamond/Cu composites. Appl Surf Sci. 2017;402:372–83. 10.1016/j.apsusc.2017.01.078.Search in Google Scholar

[24] Xue C, Bai H, Tao PF, Wang JW, Jiang N, Wang SL. Thermal conductivity and mechanical properties of flake graphite/Al composite with a SiC nano-layer on graphite surface. Mater Des. 2016;108(100):250–8. 10.1016/j.matdes.2016.06.122.Search in Google Scholar

[25] Wang C, Bai H, Xue C, Tong X, Zhu Y, Jiang N. On the influence of carbide coating on the thermal conductivity and flexural strength of X (X=SiC, TiC) coated graphite/Al composites. Rsc Adv. 2016;6(109):107483–90. 10.1039/c6ra21754k.Search in Google Scholar

[26] Peng X, Huang Y, Sun X, Han X, Fan R. Effect of chromium coated carbon fiber on the thermal and mechanical properties of Cr@Gf/Cr@CF/Al composites. J Mater Sci Mater Electron. 2019;30(1):1–8. 10.1007/s10854-019-01014-8.Search in Google Scholar

[27] Jiang DP, Zhu XM, Yu JK. Enhanced thermal conductivity and bending strength of graphite flakes/aluminum composites via graphite surface modification. J Wuhan Univ Technol Mat Sci Ed. 2020;35(1):9–15. 10.1007/s11595-020-2220-x.Search in Google Scholar

[28] Hui X, Jiakang Y, Dapeng J, Jipeng L. Microstructure and thermal properties of Cr7C3 coated graphite flakes/Al composites. Mater Res Express. 2019;6(6):066308. 10.1088/2053-1591/ab0d9f.Search in Google Scholar

[29] Liu Q, He Z, Cheng J, Chen Y, Wang F, Lv Z, Qi J. Theoretical and predictive modeling of interfacial thermal conductance and thermal conductivity in graphite flake/Al composites. Compos Interface. 2021;28(1):101–14. 10.1080/09276440.2020.1726135.Search in Google Scholar

[30] Lubbers R, Grunsteudel HF, Chumakov AI, Wortmann G. Density of phonon states in iron at high pressure. Science. 2000;287(5456):1250–3. 10.1126/science.287.5456.1250.Search in Google Scholar PubMed

[31] He LF, Wang JY, Bao YW, Zhou YC. Elastic and thermal properties of Zr2Al3C4: Experimental investigations and ab initio calculations. J Appl Phys. 2007;102(4):043531. 10.1063/1.2773679.Search in Google Scholar

[32] Nakamura M, Matsumoto S, Hirano T. Elastic constants of MoSi2 and WSi2 single crystals. J Mater Sci. 1990;25(7):3309–13. 10.1007/BF00587691.Search in Google Scholar

[33] Nakamura M, Kimura K. Elastic constants of TiAl3 and ZrAl3 single crystals. J Mater Sci. 1991;26:2208–14. 10.1007/BF00549190.Search in Google Scholar

© 2022 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete

Articles in the same Issue

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete