Abstract

Biocomposites have been implemented in various industrial applications. However, it is necessary to demonstrate their desired mechanical performance aspects for the near future green products. The aim of this work is to study the efficiency of utilizing both coconut and pomegranate lignocellulosic fiber as green reinforcement types for the low-density polyethylene, LDPE. Desired mechanical performance trends are investigated for the green composites including the tensile strength, tensile modulus, and elongation to break properties as a function of various reinforcement configurations. This was performed to properly optimize the reinforcement conditions to obtain desirable mechanical characteristics of such types of bio-composites for more sustainable functional attributes. Results have demonstrated that the best tensile strength for the coconut/PE was achieved at 20wt.% case with 8.2 MPa, and the best regarding this property for the pomegranate/PE was at 30wt.% with a value close to 8.3 MPa. Moreover, obvious inverse relationship between strength and strain for the coconut composite type was revealed at both low and high fiber contents. It was also noticed that the 20wt.% coconut-based composite has demonstrated the best optimal values of tensile strength and tensile modulus simultaneously. But no reinforcement condition was found for pomegranate/LDPE as an optimal for these mechanical properties concurrently.

1 Introduction

Petroleum based plastics are being used in all aspects of our life, they are cheap, easy to produce, and readily available. However, they are hardly degradable materials that increase waste accumulation worldwide [1,2,3]. It is estimated according to the global economic growth that by 2050 the plastic waste produced will exceed 25 billion metric tons [4, 5]. Most recent research are focusing on different alternatives, one of the most promising is the bio-composites. They use natural ingredients to produce non-petroleum-based plastics [6, 7]. Most countries are forcing manufacturers to switch for more eco-friendly solutions by giving financial incentives or by introducing new regulations [8]. In the last decade there has been a huge production growth in several bio based plastics, such as, bio-based polyethylene (Bio-PE), bio-based polyethylene terephthalate (Bio-PET), polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) as well as others [9,10,11,12]. These plastic replacements are more sustainable for their lower associated carbon emissions and improved performance. Manufacturing of bio-composites is one of the most ecofriendly methods for producing alternative materials for the synthetic ones and makes proper waste utilization. Materials that link cellulosic fibers with granulated plastic is important for the industry. Systems for manufacturing bio-composites, which consist of a variety of compositions and properties, were already presented several times. Natural fiber, owing to its easy availability, positive mechanical properties, easy and direct processing, and most of all their renewability predispose them for fabricating composites, especially the features of flax fibers, which are the strongest amongst all-natural fibers and has a lower density in comparison to glass fiber, ability to muffling vibration as well as its positive environmental impact [13].

Biocomposites are material that is composed of at least one natural resource. The addition of natural fibers to polymeric matrices results in a wide range of physical, mechanical, and other properties that made them suitable for various applications including medical and environmental ones [6, 14,15,16,17,18]. Nevertheless, natural fiber characteristics are complex and unpredictable, which make the properties of bio-composites very sensitive to the manufacturing processes. Where the fibers can be aligned, or woven, within the material in the desired direction to achieve the desired mechanical properties [19,20,21,22,23,24,25,26]. Other aspects that must be considered in the production process includes the type of the fiber, its chemical compatibility, the corresponding surface energies and the quality of the interface with polymers that is affected by the fiber's hydrophilicity and matrix hydrophobicity [27,28,29,30]. In most cases it is required to treat the surface of the fiber to optimize the interaction [31,32,33,34].

Plant based fibers contain four main components: cellulose, hemicellulose, wax, and lignin. The stiffest component is cellulose, which makes it suitable to reinforce polymer matrices for various applications. Several types of natural fiber have been proposed to be used as reinforcement in polymer matrices, such as jute, flax, hemp, sisal, hardwood, softwood, silk, wool, and various other fibers [35,36,37,38]. The resulting composite strength depends on different aspects, such as the type of the fiber and its orientation in the matrix. It was suggested by many research papers that the performance of the composite is mainly influenced by several factors such as the type of matrix, filler, reinforcements, and plasticizers [38,39,40,41,42]. Natural fibers have relative strong polar bonds that usually make them incompatible with most of the polymer matrices. Thus, various chemical treatment processes to the surface of the fibers can enhance the interfacial adhesion between the fiber and the polymer.

The mechanical properties of bio-composite are very complex and not easy to be predicted, they widely depend on many factors, for example heating and cooling rate, applied forces, deformation and its rate [43,44,45], the type of polymer used, crystallization, molecular weight, morphology, chemical composition, orientation, concentration and the type of reinforcement also affect the final product [8, 46]. Thus, the mechanical properties of bio-composites are very important to enhance their reliability for different industrial applications particularly when different reinforcement conditions and polymer /fiber compatibility make generation of bio-composites with various mechanical properties.

Consequently, this work aims to investigate the effectiveness of utilizing coconut and pomegranate lignocellulosic fibers with low density polyethylene through assessing their mechanical performance regarding various desired properties. This was targeted to produce eco-friendly composite materials with optimized reinforcement to attain appropriate mechanical characteristics capable of developing more functional bio-products. This would enhance the reliability of producing low-cost bio-composites with more consistent performance for the green products.

In section 2 we will discuss the preparation method for the material and the fibers used to create the biocomposite, then we will describe the mechanical test performed and the specimen used to find the desired properties. In section 3 we will show the results obtained from the test and our discussion regarding the behavior of the biocomposites. The results are shown for PE with coconut and pomegranate fibers at 10%, 20%, and 30% weight ratios. Finally, in section 4 the conclusion of the test findings is shown.

2 Materials and methods

2.1 Preparation of composites

One of the common manufacturing processes for plastics is the extrusion process. It is considered as the most common technique for manufacturing bio-composites especially when the shape for the handled materials is simple with acceptable dimensional tolerance. This is due to shorter cycles along with few post-processing operations. Low density polyethylene (LDPE) (SABIC LDPE 1965N0) was provided by the SABIC Company, Saudi Arabia. Its density is 919 Kg/m3, its tensile strength at break is 7 MPa, and its modulus of elasticity is 165 MPa. The LDPE pellets were mixed with the natural fibers. The considered lignocellulosic coconut and pomegranate fibers were collected, cut with lengths of (5–8) mm and prepared for the composites in Jordan, then were mixed with low density polyethylene using a double screw mixing machine. The short natural fibers were then fed into the hopper of the extrusion machine, then the matrix polymer was melted and poured into the spaces between the reinforcement material; this was thru subsequent melting process using dual-directional screw extruder machine to ensure the proper dispersion of the fiber within the matrix. Mixing time was 7 minutes with a speed of 40 rpm and 185°C. The mixture output was then placed into a mold to make 1mm thickness composite sheets. Later samples were prepared and cut for the tensile test. Composites were designed and produced with various fiber contents of 10wt.%, 20wt.% and 30wt.% for each fiber type.

2.2 Tensile testing

The mechanical properties of green composites including tensile strength, tensile modulus and mechanical strain are crucial properties for green materials as they determine their mechanical load resistance as well as geometrical stability. Furthermore, tensile modulus is desirable to evaluate the response of the material under loading conditions. Thus, it is important to assess such a parameter of the produced green composites. The elongation to break property of the produced material is also necessary to demine its ductility. Reinforcing natural fibers with polymeric matrices will produce a lower ductility composite; hence, mechanical strain should be investigated to determine the fracture behavior of the composites, which is usually changed from a high ductile matrix into a relatively brittle behavior composite. As a result, all these mechanical responses were investigated via proper tensile testing experiments. The tensile testing was carried out using Instron 3365 machine. The testing was performed according to the ASTM D 638. The crosshead speed was 2mm/min. Tensile strength, modulus and strain were recorded and the average of five trials for each considered property was considered.

3 Results and discussion

The compatibility between fibers and matrix in bio-based materials is generally weak due to their nature. This in order makes the interfacial bonding developed inside the composite not sufficiently strong if not compensated by proper fiber loading. Thus, evaluating bio-composites regarding desired mechanical properties is necessary. Figure 1 shows the stress-strain result for one sample of the tensile test for both the coconut and pomegranate LDPE at 20wt.% fiber content. The ultimate tensile strength with the coconut was around 8.4 MPa with a strain of around 0.031%, whereas pomegranate has an ultimate tensile strength of 7.8 MPa at a strain of 0.035%. The fracture stress for the coconut was around 3.9 MPa and for the pomegranate it was 4.8 MPa. To be able to compare with the LDPE, the tensile strength of the polymer was carried out. It was found that the tensile strength of the LDPE was 7.58 MPa, while its modulus of elasticity was 166.8 MPa and its elongation to break was found to be 0.041%.

Stress-strain diagram and the specimens’ fracture surface of bio-composites.

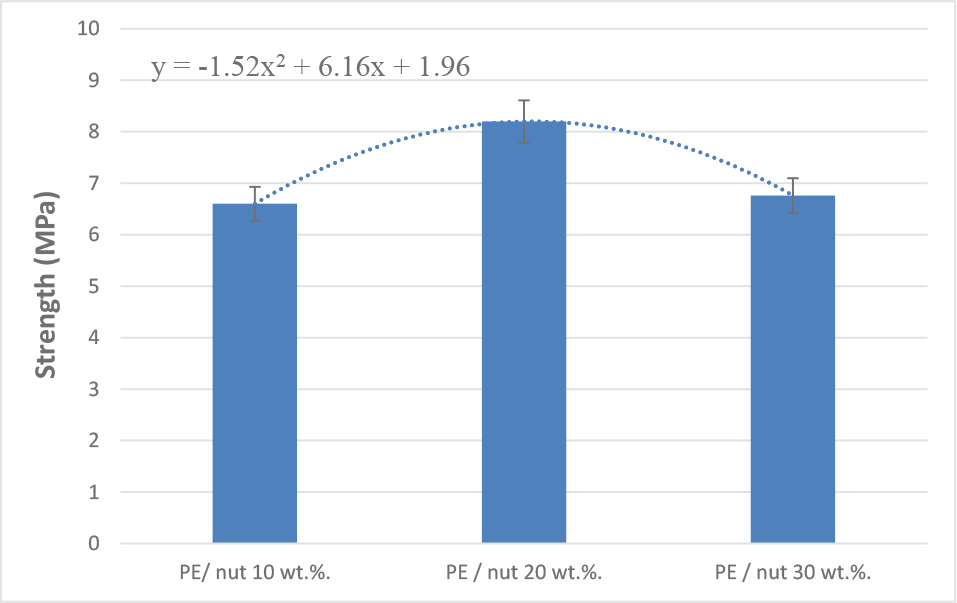

The average result of five samples of the ultimate tensile strength property for the coconut/LDPE with fiber content is demonstrated in Figure 2. It can be noticed that the best result was achieved with the 20wt.% case at 8.2 MPa. The trend of the tensile strength was enhanced form 10wt.% to the 20wt.% then decreased in the case of 30wt.%.

Strengths of coconut /PE bio-composites with various fiber loading.

This demonstrates that the proper stress transfer efficiency between the matrix and the fibers occurred inside the 20wt.% composite. However, increasing the fiber content to 30wt.% have reduced the strength of the composite because excess fibers found less wetting matrix to properly bond and interlock within. This in fact resulted in less stress transfer efficiency inside the composite that reduced the strength of the composite comparable to the 20wt.% fiber loading case [19, 25, 27, 41, 47].

Similarly, Figure 3 shows the average result of five samples of the ultimate tensile strength for pomegranate/LDPE fiber content. It can be noticed here that an increase of the ultimate strength with increasing fiber content has occurred. This was due to the proper compatibility of the pomegranate with polymer matrix and the proper stress transfer inside the matrix at 30wt.% as more fibers were capable of enhancing the strength of the matrix itself. It can be also noticed that the pomegranate fibers had enhanced the ultimate strength of the LDPE matrix. It was 6.4 MPa at 10wt.% fiber content then enhanced to 7.7 MPa at 20wt.%, then reached the best of about 8.3 MPa in the 30wt.% case.

Strengths of pomegranate/PE bio-composites with various fiber loading.

In addition, trends of tensile strength of the bio-composites with fiber loadings are illustrated in Figure 4. It can be noticed that the performance of coconut was better for low weight ratios. However, higher weight ratio of the pomegranate performance was better. This was due to the fact that additional fibers more than 20wt.% in case of coconut were found less beneficial for the composite. This in fact was due to the insufficient wetting between the fibers and the polymer as an excess of fibers couldn’t contribute well to the strength of the composites because excess fibers would not properly interlock with the matrix [19, 25, 27, 41, 47, 48].

Trends of tensile strength of the bio-composites with fiber loadings.

In a similar manner, trends of the modulus of elasticity property for the composites with fiber content are presented in Figure 5. It is clear that the highest modulus of elasticity was achieved with 20wt.% fiber content for both types of composites. It was around 271.6 MPa for the pomegranate fibers and 286.0 MPa for the coconut. It started at 228 MPa for the pomegranate and 197.2 MPa for the coconut at 10wt.% ratio and ended at 253.01 MPa and 221.65 MPa for the 30wt.% pomegranate and the coconut fiber content, respectively. Here, 20 wt.% fiber content case was capable of enhancing the modulus of the composite as the fiber modulus can support the matrix in resisting deformations while applying the load [21, 48, 49]. However, additional fibers more than 20wt.% had made the excess fibers with lower interfacial bonding with matrix as excess fibers would not properly interlock with the matrix due to the lower amount of wetting matrix for such excess fibers. Figure 6 on the other hand, demonstrates the comparison between tensile strength and tensile strain properties for the coconut composites with different fiber content. It can be noticed that at 10wt.% fiber content, coconut-based composite had 6.6 MPa strength with about 0.03% strain.

Trends of moduli of elasticity for the bio-composites with fiber loadings.

Stress and strain behavior of the coconut-based bio-composites with fiber content.

However, the 20wt.% fiber content, the strength was enhanced, and its ductility was reduced due to the better adhesion inside the composite. That is; the brittleness was enhanced due to the effect of low ductile behavior of fibers that restricted the ductility of the matrix. However, once the fiber content was increased, the adhesion inside the composite was reduced and the brittleness was also reduced. It can be noticed that the maximum strain was at 30 wt.% while the max stress was for 20 wt.%, this demonstrates that the optimal reinforcement condition can be determined upon the application of such materials, if low ductility is required or high strength. It can be seen that the 30wt.% case has achieved both reasonable strength and ductility, thus, it can be considered as the optimal case for a certain application where both reasonable values for both properties are required.

In addition, Figure 7 illustrates the comparison between tensile strength and tensile strain properties for the pomegranate composites with fiber content. The inverse relationship between strength and strain for such composite type is obvious at both low and high fiber contents. It can be noticed that at 10wt.% fiber content, 0.033% strain was associated with 6.4 MPa strength but, 0.034% strain was achieved with 8.3 MPa strength at 30wt.% fiber content case. However, 0.036% strain with 7.7 MPa strength was found in case of 20wt.% fiber content as an optimal desired reinforcing condition for these mechanical properties.

Stress and strain behavior of the pomegranate-based bio-composites with fiber loading.

Moreover, the modulus of elasticity and strength trends of the composites are illustrated in Figure 8. It can be seen that the 20wt.% coconut-based composite demonstrated the best optimal values of tensile strength and tensile modulus simultaneously. The maximum modulus was 286 MPa for 20% with strength of 8.2 MPa. However, in case of pomegranate-based composite the maximum modulus was for 20wt.% fiber content with a value of 271.6 MPa, but it was not the best regarding the tensile strength as the 30wt.% was demonstrating a strength of 8.3 MPa. Therefore, there was one optimal reinforcing condition for the pomegranate/LDPE composites regarding the tensile strength and modulus properties.

Stress and moduli of elasticity behavior of various bio-composites.

The maximum elongation before fracture for all the composites is shown in Figure 9. Coconut based composite with 30wt.% demonstrated the highest elongation of 0.032%, while for pomegranate the highest elongation was with 20wt.% fiber content with a value of 0.036%. Also, it can be noticed that the pomegranate/LDPE composites are more ductile than that of coconut/LDPE composites at all fiber contents indicating their suitability for wide industrial applications where ductility is required including automotive applications. The results gained for the mechanical properties of the considered composites are summarized in Table 1.

Elongation at break property for all prepared bio-composites.

Mechanical properties for PE/coconut and PE/pomegranate composites.

| Material | Strength MPa | Modulus of elasticity MPa | Elongation to break (%) |

|---|---|---|---|

| PE/nut 10% | 6.6 | 197 | 0.03 |

| PE/nut 20% | 8.3 | 286 | 0.027 |

| PE/nut 30% | 6.8 | 222 | 0.032 |

| PE/ pomegranate 10% | 6.4 | 228 | 0.033 |

| PE/ pomegranate 20% | 7.7 | 272 | 0.036 |

| PE/ pomegranate 30% | 8.3 | 253 | 0.034 |

4 Conclusions

Investigating the potential mechanical performance trends of both coconut and pomegranate lignocellulosic fiber in reinforcing LDPE matrix was performed. Various mechanical properties were enhanced with fiber content for both types of composites. It was revealed that the 20wt.% fiber content coconut composite had improved the tensile strength but reduced the ductility of the matrix due to the better adhesion inside the composite. However, once the fiber content was increased, the adhesion inside the composite was also reduced. It was also concluded that proper stress transfer efficiency between the matrix and the fibers was achieved inside several composites for both coconut and pomegranate lignocellulosic fibers. Moreover, the maximum modulus of elasticity for the coconut fiber-based composites was 286 MPa for the 20% with strength of 8.2 MPa resulting in optimal reinforcement condition for both mechanical properties. As mechanical properties of bio-composites are very important to enhance their reliability for different industrial applications particularly when different reinforcement conditions and polymer /fiber compatibility, further work on the reinforcement of such green fibers under chemical treatments are still required and encouraged to properly address their performance trends and determining their optimal reinforcement conditions to enhance the reliability of producing low-cost materials for green bio-products.

Funding information:

The authors state no funding involved.

Author contributions:

All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

Conflict of interest:

The authors state no conflict of interest.

References

[1] El-Shekeil Y, AL-Oqla F, Sapuan S. Performance tendency and morphological investigations of lignocellulosic tea/polyurethane bio-composite materials. Polym Bull. 2020;77(8):3907–20.10.1007/s00289-019-02947-0Search in Google Scholar

[2] Yousef S, Mumladze T, Tatariants M, Kriūkienė R, Makarevicius V, Bendikiene R, et al. Cleaner and profitable industrial technology for full recovery of metallic and non-metallic fraction of waste pharmaceutical blisters using switchable hydrophilicity solvents. J Cleaner Prod. 2018.10.1016/j.jclepro.2018.06.154Search in Google Scholar

[3] Di Mauro C, Genua A, Rymarczyk M, Dobbels C, Malburet S, Graillot A, et al. Chemical and mechanical reprocessed resins and bio-composites based on five epoxidized vegetable oils thermosets reinforced with flax fibers or PLA woven. Compos Sci Technol. 2021:108678.10.1016/j.compscitech.2021.108678Search in Google Scholar

[4] AL-Oqla FM. Introduction to Biobased Composites. In: Khan A, Rangappa SM, Siengchin S, Asiri AM, editors. Biobased Composites: Processing, Characterization, Properties, and Applications. 2021:1–14.10.1002/9781119641803.ch1Search in Google Scholar

[5] AL-Oqla FM. Biocomposites in Advanced Biomedical and Electronic Systems Applications. Composites in Biomedical Applications. 1st ed. CRC Press; 2020. p. 49–70.10.1201/9780429327766-3Search in Google Scholar

[6] AL-Oqla FM. Performance trends and deteriorations of lignocellulosic grape fiber/polyethylene biocomposites under harsh environment for enhanced sustainable bio-materials. Cellulose. 2021;28(4):2203–13.10.1007/s10570-020-03649-xSearch in Google Scholar

[7] Zuccarello B, Militello C, Bongiorno F. Influence of the anisotropy of sisal fibers on the mechanical properties of high performance unidirectional biocomposite lamina and micromechanical models. Compo Part A: Appl SciManuf. 2021:106320.10.1016/j.compositesa.2021.106320Search in Google Scholar

[8] AL-Oqla FM, Salit MS. Materials Selection for Natural Fiber Composites. Cambridge, USA: Woodhead Publishing, Elsevier; 2017. p. 286.10.1016/B978-0-08-100958-1.00002-5Search in Google Scholar

[9] AL-Oqla FM, Rababah M. Challenges in design of nanocellulose and its composites for different applications. Cellulose-Reinforced Nanofibre Composites: Elsevier; 2017. p. 113–27.10.1016/B978-0-08-100957-4.00005-XSearch in Google Scholar

[10] AL-Oqla FM, Sapuan S. Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers. Cambridge, USA: Elsevier; 2020.Search in Google Scholar

[11] Zhao L, Hu X, Zi F, Liu Y, Hu D, Li P, et al. Preparation and adsorption properties of Ni (ii) ion-imprinted polymers based on synthesized novel functional monomer. e-Polymers. 2021;21(1):590–605.10.1515/epoly-2021-0055Search in Google Scholar

[12] Nikravan G, Haddadi-Asl V, Salami-Kalajahi M. Stimuli-responsive DOX release behavior of cross-linked poly (acrylic acid) nanoparticles. e-Polymers. 2019;19(1):203–14.10.1515/epoly-2019-0021Search in Google Scholar

[13] Thanushan K, Yogananth Y, Sangeeth P, Coonghe JG, Sathiparan N. Strength and durability characteristics of coconut fibre reinforced earth cement blocks. J Nat Fibers. 2021;18(6):773–88.10.1080/15440478.2019.1652220Search in Google Scholar

[14] Aridi N, Sapuan S, Zainudin E, AL-Oqla FM. Investigating morphological and performance deterioration of injection-molded rice husk–polypropylene composites due to various liquid uptakes. Int J Polym Anal Charact. 2016;21(8):675–85.10.1080/1023666X.2016.1207006Search in Google Scholar

[15] Keya KN, Kona NA, Koly FA, Maraz KM, Islam MN, Khan RA. Natural fiber reinforced polymer composites: history, types, advantages and applications. Mat Eng Res. 2019;1(2):69–85.10.25082/MER.2019.02.006Search in Google Scholar

[16] Yang Y, He R, Cheng Y, Wang N. Multilayer-structured fibrous membrane with directional moisture transportability and thermal radiation for high-performance air filtration. e-Polymers. 2020;20(1):282–91.10.1515/epoly-2020-0034Search in Google Scholar

[17] AL-Oqla FM. Flexural characteristics and impact rupture stress investigations of sustainable green olive leaves bio-composite materials. J Polym Envir 2021;29(3):892–9.10.1007/s10924-020-01889-3Search in Google Scholar

[18] AL-Oqla FM. Effects of Intrinsic Mechanical Characteristics of Lignocellulosic Fibres on the Energy Absorption and Impact Rupture Stress of Low Density Polyethylene Biocomposites. Int J Sust Eng. 2021:1–9.10.1080/19397038.2021.1966127Search in Google Scholar

[19] Alaaeddin M, Sapuan S, Zuhri M, Zainudin E, AL-Oqla FM. Physical and mechanical properties of polyvinylidene fluoride-Short sugar palm fiber nanocomposites. J Cleaner Prod. 2019;235:473–82.10.1016/j.jclepro.2019.06.341Search in Google Scholar

[20] Alaaeddin M, Sapuan S, Zuhri M, Zainudin E, AL-Oqla FM. Polymer matrix materials selection for short sugar palm composites using integrated multi criteria evaluation method. Compo Part B: Eng. 2019:107342.10.1016/j.compositesb.2019.107342Search in Google Scholar

[21] AL-Oqla FM. Investigating the mechanical performance deterioration of Mediterranean cellulosic cypress and pine/polyethylene composites. Cellulose. 2017;24(6):2523–30.10.1007/s10570-017-1280-3Search in Google Scholar

[22] AL-Oqla FM. Evaluation and Comparison of Date Palm Fibers with Other Common Natural Fibers. Date Palm Fiber Composites: Springer; 2020. p. 267–86.10.1007/978-981-15-9339-0_10Search in Google Scholar

[23] AL-Oqla FM, Almagableh A, Omari MA. Design and Fabrication of Green Biocomposites. Green Biocomposites. Cham, Switzerland: Springer; 2017. p. 45–67.10.1007/978-3-319-49382-4_3Search in Google Scholar

[24] AL-Oqla FM, Hayajneh MT. A hierarchy weighting preferences model to optimise green composite characteristics for better sustainable bio-products. Int J Sust Eng. 2020:1–6.10.1080/19397038.2020.1822951Search in Google Scholar

[25] AL-Oqla FM, Hayajneh MT, Fares O. Investigating the mechanical thermal and polymer interfacial characteristics of Jordanian lignocellulosic fibers to demonstrate their capabilities for sustainable green materials. J Cleaner Prod. 2019;241:118256.10.1016/j.jclepro.2019.118256Search in Google Scholar

[26] Aridi N, Sapuan S, Zainudin E, AL-Oqla FM. Mechanical and morphological properties of injection-molded rice husk polypropylene composites. Int J Polym Anal Charact. 2016;21(4):305–13.10.1080/1023666X.2016.1148316Search in Google Scholar

[27] Ilyas RA, Sapuan SM, Ibrahim R, Abral H, Ishak M, Zainudin E, et al. Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: a comprehensive approach from macro to nano scale. J Mat Res Tech. 2019.10.1016/j.jmrt.2019.04.011Search in Google Scholar

[28] AL-Oqla FM, Omar AA, Fares O. Evaluating sustainable energy harvesting systems for human implantable sensors. I J Electr. 2018;105(3):504–17.10.1080/00207217.2017.1378377Search in Google Scholar

[29] AL-Oqla FM, Omari MA, Al-Ghraibah A. Predicting the potential of biomass-based composites for sustainable automotive industry using a decision-making model. Lignocellulosic Fibre and Biomass-Based Composite Materials: Elsevier; 2017. p. 27–43.10.1016/B978-0-08-100959-8.00003-2Search in Google Scholar

[30] Al-Ghraibah AM, Al-Qudah M, AL-Oqla FM. Medical Implementations of Biopolymers. Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers: Elsevier; 2020. p. 157–71.10.1016/B978-0-12-819661-8.00010-XSearch in Google Scholar

[31] Abdal-hay A, Suardana NPG, Jung DY, Choi K-S, Lim JK. Effect of diameters and alkali treatment on the tensile properties of date palm fiber reinforced epoxy composites. Int J Preci Eng and Manuf. 2012;13(7):1199–206.10.1007/s12541-012-0159-3Search in Google Scholar

[32] Yang M, Zhang X, Cheng G. A two-stage pretreatment using dilute sodium hydroxide solution followed by an ionic liquid at low temperatures: Toward construction of lignin-first biomass pretreatment. Biores Techn Rep. 2019;7:100286.10.1016/j.biteb.2019.100286Search in Google Scholar

[33] AL-Oqla FM. Predictions of the Mechanical Performance of Leaf Fiber Thermoplastic Composites by FEA. I J Appli Mech. 2021.10.1142/S1758825121500666Search in Google Scholar

[34] AL-Oqla FM, Hayajneh MT, Aldhirat A. Tribological and mechanical fracture performance of Mediterranean lignocellulosic fiber reinforced polypropylene composites. Polym Compo. 2021.10.1002/pc.26241Search in Google Scholar

[35] Alaaeddin M, Sapuan S, Zuhri M, Zainudin E, M AL-Oqla F. Lightweight and Durable PVDF–SSPF Composites for Photovoltaics Backsheet Applications: Thermal, Optical and Technical Properties. Materials. 2019;12(13):2104.10.3390/ma12132104Search in Google Scholar PubMed PubMed Central

[36] AL-Oqla FM, Sapuan S, Jawaid M. Integrated Mechanical-Economic–Environmental Quality of Performance for Natural Fibers for Polymeric-Based Composite Materials. J Nat Fibers. 2016;13(6):651–9.Search in Google Scholar

[37] AL-Oqla FM, Al-Jarrah R. A novel adaptive neuro-fuzzy inference system model to predict the intrinsic mechanical properties of various cellulosic fibers for better green composites. Cellulose. 2021.10.1007/s10570-021-04077-1Search in Google Scholar

[38] Hayajneh M, AL-Oqla FM, Aldhirat A. Physical and Mechanical Inherent Characteristic Investigations of Various Jordanian Natural Fiber Species to Reveal Their Potential for Green Biomaterials. J Nat Fibers. 2021:1–14.10.1080/15440478.2021.1944432Search in Google Scholar

[39] Madhu P, Sanjay M, Jawaid M, Siengchin S, Khan A, Pruncu CI. A new study on effect of various chemical treatments on Agave Americana fiber for composite reinforcement: physico-chemical, thermal, mechanical and morphological properties. Polym Test. 2020;85:106437.10.1016/j.polymertesting.2020.106437Search in Google Scholar

[40] AL-Oqla FM, Sapuan S. Investigating the inherent characteristic/performance deterioration interactions of natural fibers in bio-composites for better utilization of resources. J Polym Env. 2018;26(3):1290–6.10.1007/s10924-017-1028-zSearch in Google Scholar

[41] AL-Oqla FM, El-Shekeil Y. Investigating and predicting the performance deteriorations and trends of polyurethane bio-composites for more realistic sustainable design possibilities. J Cleaner Prod. 2019;222:865–70.10.1016/j.jclepro.2019.03.042Search in Google Scholar

[42] Hayajneh MT, AL-Oqla FM, Mu’ayyad M. Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations. e-Polymers. 2021;21(1):710–21.10.1515/epoly-2021-0074Search in Google Scholar

[43] Fares O, AL-Oqla FM, Hayajneh MT. Dielectric relaxation of Mediterranean Lignocellulosic Fibers for Sustainable Functional Biomaterials. Mat Chem Phys. 2019.10.1016/j.matchemphys.2019.02.095Search in Google Scholar

[44] Almagableh A, Al-Oqla FM, Omari MA. Predicting the Effect of Nano-Structural Parameters on the Elastic Properties of Carbon Nanotube-Polymeric based Composites. Int J Perform Eng. 2017;13(1):73.10.23940/ijpe.17.01.p6.7386Search in Google Scholar

[45] Friedrich K, Almajid AA. Manufacturing aspects of advanced polymer composites for automotive applications. Appl Comp Mat. 2013;20(2):107–28.10.1007/s10443-012-9258-7Search in Google Scholar

[46] AL-Oqla FM, Sapuan S. Polymer Selection Approach for Commonly and Uncommonly Used Natural Fibers Under Uncertainty Environments. JOM. 2015;67(10):2450–63.10.1007/s11837-015-1548-8Search in Google Scholar

[47] Alaaeddin M, Sapuan S, Zuhri M, Zainudin E, Al-Oqla FM. Photo-voltaic applications: Status and manufacturing prospects. Ren Sust Ene Rev. 2019;102:318–32.10.1016/j.rser.2018.12.026Search in Google Scholar

[48] Haque M, Islam S, Islam S, Islam N, Huque M, Hasan M. Physicomechanical properties of chemically treated palm fiber reinforced polypropylene composites. J Rein Plast Compo. 2010;29(11):1734–42.10.1177/0731684409341678Search in Google Scholar

[49] El-Shekeil YA, Sapuan S, Algrafi MW. Effect of fiber loading on mechanical and morphological properties of cocoa pod husk fibers reinforced thermoplastic polyurethane composites. Mat Des. 2014;64:330–3.10.1016/j.matdes.2014.07.034Search in Google Scholar

© 2021 Suleiman BaniHani et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**

Articles in the same Issue

- Research Articles

- The elastic-plastic properties of an anti-icing coating on an aluminum alloy: Experimental and numerical approach

- Optimization of recycled slag-fresh flux mixture based upon weld bead quality for submerged arc welding of stainless steel

- Design and optimization of differential capacitive micro accelerometer for vibration measurement

- Mechanical performance of abrasive sandpaper made with palm kernel shells and coconut shells

- Experimental investigation of WEDM process through integrated desirability and machine learning technique on implant material

- Mechanical properties and microstructural characteristics of rotating arc-gas metal arc welded carbon steel joints

- Assessment of cement replacement with fine recycled rubber particles in sustainable cementitious composites

- Structural response and sensitivity analysis of granular and asphaltic overlayment track considering linear viscoelastic behavior of asphalt

- Unmanned aerial vehicle evasion manoeuvres from enemy aircraft attack

- Effect of corrosion on surface degradation of galvanized steel in poultry dung, pig dung and urea solutions using rice straw as an inhibitor

- Mathematical modeling of AZ30 magnesium alloys at high temperature using the ring compression test and genetic algorithm method

- Study on hot deformation behavior and workability of stir-cast Al6063-6wt.% steelp based composites

- The effects of processing parameters on the formation of oxide layers in aluminium alloys using plasma electrolytic oxidation technique

- Behavior of green reactive powder mortar reinforced with steel fibers

- On the hygrothermal properties of sandcrete blocks produced with sawdust as partial replacement of sand

- Mechanical behavior of thin-walled steel under hard contact with rigid seabed rock: Theoretical contact approach and nonlinear FE calculation

- Mechanical properties and microstructural characteristics of rotary friction welded dissimilar joints of rolled homogeneous armor steel and medium carbon steel

- Studies of carboxylated nitrile butadiene rubber/butyl reclaimed rubber (XNBR/BRR) blends for shoe soles application

- Mechanical properties of wire arc additive manufactured carbon steel cylindrical component made by gas metal arc welding process

- Synthesis and mechanical characterization of Si3N4 reinforced copper-tin matrix composites

- Analysis of plated-hull structure strength against hydrostatic and hydrodynamic loads: A case study of 600 TEU container ships

- Mechanical performance investigation of lignocellulosic coconut and pomegranate / LDPE biocomposite green materials

- Special Issue MICAP-2021

- Double hydrothermal synthesis of iron oxide/silver oxide nanocomposites with antibacterial activity**

- Enhanced photocatalytic activity of TiO2-CdS composite nanofibers under sunlight irradiation**

- Structural properties of CoxCu1−xFe2O4 solid solution**

- Green-synthesis of Ag2O nanoparticles for antimicrobial assays**

- Effect of current density on the porous silicon preparation as gas sensors**

- A mechanochemical preparation, properties and kinetic study of kaolin–N, P fertilizers for agricultural applications**

- Impact strength of surface treated SS316L wires reinforced PMMA**

- Computational studies on electronic and optical properties of dopamine derivatives structure: A DFT study**

- Multilayer coating effects on the thermal conductivity of tools using an electric furnace technique**

- The positron and mechanical parameters of a cold-worked aluminum alloy (3004) Using PALT, PADBT and HV**

- Effect of thermal annealing on the structural and optical properties of TiO2 nanostructures**

- Improvement of forging die life by failure mechanism analysis**