Editorial

-

Holger Pfaff

Dear Reader,

Going into its seventh year, Nanomech has become a well established meeting for the nanoindentation and nanomechanics community in Germany, Europe and beyond.

2005 was a year of change for the symposium as Prof. Peter Grau (left) and Dr. Ude. D. Hangen (right), both founding members of the Nanomech conference and strong contributors to its success, stepped down from their responsibilities within the conference committee.

We would like to thank them for their persistent efforts to make the Nanomech a platform for vivid scientific exchange.

Prof. R. Spolenak (ETH Zurich) has joined the committee as a new member. He studied Physics at the University of Vienna and received his PhD in 1999 at the Max Planck Institute for Metals Research in Stuttgart and was awarded the Otto Hahn medal for his achievements during his thesis on Alloying effects in electromigration. After his postdoctoral engagement at Bell Laboratories and his employment as a group leader in the department of Prof. E. Arzt at the MPI for Metals Research in Stuttgart, he became assistant professor at the ETH Zurich and chair of the Laboratory for Nanometallurgy in 2004.

As a further new member of the committee, I would like to draw your attention to the following collection of publications providing a summary of the research presented during the Nanomech 6 – the 6th European symposium on nanomechanical testing, that took place from Aug 30th to Sept 1st 2005 in Hückelhoven.

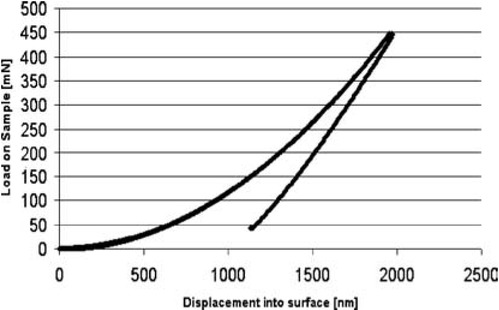

Nanoindentation has become an established and standardized (ISO 14577) technique for testing the nanohardness and related mechanical properties of surfaces. In the standard experiments a pyramidal diamond tip is pressed into the specimen surface (Fig. 1) while measuring the applied force and displacement (Fig. 2).

Indents in a polymer surface

Load-Displacement curve

The hardness and modulus of the material are obtained by analyzing the respective data according to the Oliver and Pharr model. The will to understand fully the underlying mechanisms with increasing sample complexity (e. g. multiphase materials, multilayer thin films) has generated a growing need to supplement the mechanical experiments with refined analytical and numerical modeling (Fig. 3).

Simulated stress distribution in an indentation experiment

Therefore, Nanomech 6 focused on modeling the nanoindentation process but also, once again, covered a wide range of research topics in the field of micro- and nanomechanical testing of various materials, thin films and microstructures. The following articles report on recent research work related to such questions in the field of nanomechnical testing. We wish you interesting reading and hope to welcome you at one of the future Nanomech meetings.

© 2006 Carl Hanser Verlag, München

Articles in the same Issue

- Contents

- Editorial

- Nanoindentation creep and stress relaxation tests of polycarbonate: Analysis of viscoelastic properties by different rheological models

- Investigation of SiO2 thin films on Si substrates for use as standards for laser-acoustic measuring devices

- Determination of the critical tensile stress of sapphire by spherical indentation with additional lateral forces

- The deformation behaviour of electrodeposited nanocrystalline Ni in an atomic force microscope with a newly developed in situ bending machine

- In situ electrochemical nanoindentation of a nickel (111) single crystal: hydrogen effect on pop-in behaviour

- Indentation behaviour of (011) thin films of III–V semiconductors: polarity effect differences between GaAs and InP

- Multiwall carbon nanotubes-based composites – mechanical characterization using the nanoindentation technique

- Nanoindentation studies of stamp materials for nanoimprint lithography

- Experimental and thermodynamic evaluation of the Co–Cr–C system

- Thermodynamics of high-temperature cuprous sulfide

- Sintering of Si3N4 with Li-exchanged zeolite additive

- Effect of LiYO2 addition on sintering behavior and indentation properties of silicon nitride ceramics

- Mechanism of quasi-viscous flow of zinc single crystals

- The absolute thermoelectric power of chromium, molybdenum, and tungsten

- Modelling of metal – mould interface resistance in the Al-11.5 wt.% Si alloy casting process

- Award/Preisverleihung

- Personal

- Conferences

- Contents

- Editorial

- Editorial

- Basic

- Nanoindentation creep and stress relaxation tests of polycarbonate: Analysis of viscoelastic properties by different rheological models

- Investigation of SiO2 thin films on Si substrates for use as standards for laser-acoustic measuring devices

- Determination of the critical tensile stress of sapphire by spherical indentation with additional lateral forces

- The deformation behaviour of electrodeposited nanocrystalline Ni in an atomic force microscope with a newly developed in situ bending machine

- In situ electrochemical nanoindentation of a nickel (111) single crystal: hydrogen effect on pop-in behaviour

- Indentation behaviour of (011) thin films of III–V semiconductors: polarity effect differences between GaAs and InP

- Multiwall carbon nanotubes-based composites – mechanical characterization using the nanoindentation technique

- Nanoindentation studies of stamp materials for nanoimprint lithography

- Experimental and thermodynamic evaluation of the Co–Cr–C system

- Applied

- Thermodynamics of high-temperature cuprous sulfide

- Sintering of Si3N4 with Li-exchanged zeolite additive

- Effect of LiYO2 addition on sintering behavior and indentation properties of silicon nitride ceramics

- Mechanism of quasi-viscous flow of zinc single crystals

- The absolute thermoelectric power of chromium, molybdenum, and tungsten

- Modelling of metal – mould interface resistance in the Al-11.5 wt.% Si alloy casting process

- Kösterpreis

- Award/Preisverleihung

- Notifications

- Personal

- Conferences

Articles in the same Issue

- Contents

- Editorial

- Nanoindentation creep and stress relaxation tests of polycarbonate: Analysis of viscoelastic properties by different rheological models

- Investigation of SiO2 thin films on Si substrates for use as standards for laser-acoustic measuring devices

- Determination of the critical tensile stress of sapphire by spherical indentation with additional lateral forces

- The deformation behaviour of electrodeposited nanocrystalline Ni in an atomic force microscope with a newly developed in situ bending machine

- In situ electrochemical nanoindentation of a nickel (111) single crystal: hydrogen effect on pop-in behaviour

- Indentation behaviour of (011) thin films of III–V semiconductors: polarity effect differences between GaAs and InP

- Multiwall carbon nanotubes-based composites – mechanical characterization using the nanoindentation technique

- Nanoindentation studies of stamp materials for nanoimprint lithography

- Experimental and thermodynamic evaluation of the Co–Cr–C system

- Thermodynamics of high-temperature cuprous sulfide

- Sintering of Si3N4 with Li-exchanged zeolite additive

- Effect of LiYO2 addition on sintering behavior and indentation properties of silicon nitride ceramics

- Mechanism of quasi-viscous flow of zinc single crystals

- The absolute thermoelectric power of chromium, molybdenum, and tungsten

- Modelling of metal – mould interface resistance in the Al-11.5 wt.% Si alloy casting process

- Award/Preisverleihung

- Personal

- Conferences

- Contents

- Editorial

- Editorial

- Basic

- Nanoindentation creep and stress relaxation tests of polycarbonate: Analysis of viscoelastic properties by different rheological models

- Investigation of SiO2 thin films on Si substrates for use as standards for laser-acoustic measuring devices

- Determination of the critical tensile stress of sapphire by spherical indentation with additional lateral forces

- The deformation behaviour of electrodeposited nanocrystalline Ni in an atomic force microscope with a newly developed in situ bending machine

- In situ electrochemical nanoindentation of a nickel (111) single crystal: hydrogen effect on pop-in behaviour

- Indentation behaviour of (011) thin films of III–V semiconductors: polarity effect differences between GaAs and InP

- Multiwall carbon nanotubes-based composites – mechanical characterization using the nanoindentation technique

- Nanoindentation studies of stamp materials for nanoimprint lithography

- Experimental and thermodynamic evaluation of the Co–Cr–C system

- Applied

- Thermodynamics of high-temperature cuprous sulfide

- Sintering of Si3N4 with Li-exchanged zeolite additive

- Effect of LiYO2 addition on sintering behavior and indentation properties of silicon nitride ceramics

- Mechanism of quasi-viscous flow of zinc single crystals

- The absolute thermoelectric power of chromium, molybdenum, and tungsten

- Modelling of metal – mould interface resistance in the Al-11.5 wt.% Si alloy casting process

- Kösterpreis

- Award/Preisverleihung

- Notifications

- Personal

- Conferences