Abstract

The inherent low-temperature brittleness has restricted the application of tungsten materials. One option for enhancing the tungsten fracture toughness is to use tungsten-based layered composites. In this study, W/(Ti/Ta/Ti) multilayer composites with the application of spark plasma sintering under varying bonding temperatures from 1,000 to 1,400°C were fabricated. The ambient- and high-temperature tensile mechanical performance of W/(Ti/Ta/Ti) samples is investigated to obtain the correspondence of microstructure to tensile performance. The as-fabricated composites exhibit significantly superior comprehensive tensile performance to the original foil. When bonded at 1,200°C, the comprehensive tensile performance of W/(Ti/Ta/Ti) samples is the best, showing an elongation of 5.0% and a tensile strength of 671 MPa. The bonding temperature leads to microstructural changes in the as-fabricated composites, thereby affecting their high-temperature tensile mechanical properties. When bonded at 1,000°C, the ductile–brittle transition temperature (DBTT) is approximately 100°C. When bonded at 1,200°C, the DBTT is approximately between 100 and 200°C. When bonded at 1,400°C, the DBTT is between 100 and 200°C. For W/(Ti/Ta/Ti) multilayer composites having low interfacial bonding strength, the primary energy dissipation modes include intermediate-layer plastic deformation, multi-tunnel crack propagation in the W layer, as well as W/Ti interfacial delamination. As for W/(Ti/Ta/Ti) multilayer composites having high interfacial bonding strength, energy can only be consumed through the principal crack propagation. Meanwhile, a tensile strength model is constructed based on the stress concentration coefficient after the nucleation of microcracks at the W/Ti interface.

1 Introduction

The advantages of tungsten (W), as a metal whose melting point is the highest (3,695 K), include high-temperature strength, as well as low thermal conductivity (173 W/(m·K)), and thermal expansion coefficient [1,2,3]. Besides, its nuclear radiation resistance is high and tritium retention rate low. Thus, tungsten represents a major optional plasma-facing material (PFM) for nuclear fusion reactors [4,5,6]. Nonetheless, low-temperature failure of tungsten is likely to occur due to brittle fracture [7]. Therefore, the focus of PFM development is on overcoming the brittleness of tungsten material. To achieve this, the crack propagation resistance, toughness, and ductile–brittle transition temperature (DBTT) should be improved for tungsten [8]. Two principles exist for improving the W toughness: one is to enhance the W plasticity (internal toughening) and the other is to exploit the pseudo-ductile behavior of composites (external toughening) [9]. The specific methods are as follows: alloying [10,11], grain refinement [12,13], fiber toughening [14,15], ductile phase toughening [16], roughening with W-particles [15], as well as layered toughening W composites [17,18,19,20]. The last one can be formed by bonding the W and toughened layers together. The principle is to optimize the composite properties such as ductility and strength through the adjustment of layered structure. There are two measures for adjusting the layered structure of composites: the tungsten is cold-rolled to modify its microstructure, thus enabling enhanced mechanical performance for tungsten matrix, and another material is used as a suitable toughening layer between the tungsten matrixes. Our prior work [19] has explored the W/Ta, W/Ti binary, and W/(Ti/Ta/Ti) ternary multilayer composites bonded at 1,200°C, finding excellent elongation and strength of the W/(Ti/Ta/Ti) composites in the axial tensile experiment, which resemble the metal–ceramic structural materials. The Ti and Ta layers are regarded as a low-strength, high-toughness soft (metal) layer, whereas the W layer is regarded as a high-strength, low-toughness hard (ceramic) layer.

To explore the composite toughening behavior and fracture toughness, spark plasma sintering (SPS) was employed to fabricate a range of W/(Ti/Ta/Ti) multilayer composites. Although the influence of bonding temperature over the composite microstructure and bending behavior had been illustrated in our previous work [20], multilayer composites as structural materials are often under diverse stress states. Therefore, this article investigates the tensile mechanical performance of W/(Ti/Ta/Ti) multilayer composites that vary in bonding temperatures, in order to obtain the correspondence of microstructure to tensile performance. For the investigated composites, tensile strength model is constructed based on the classical strength mixing theory according to the material fracture mechanism. Additionally, samples with different bonding temperatures are subjected to high-temperature tensile tests to analyze the DBTT of the composites by studying the variation pattern of the tensile properties of the samples with temperature.

2 Materials and experimental procedures

Raw materials used were 100 μm-thick cold-rolled pure W foils, recrystallized pure Ti foils, as well as recrystallized pure Ta foils. Electrical discharge machining was applied to cut these materials into Φ 30 × 0.1 mm disks. The microstructures and chemical compositions of the foils, along with the procedure for preparing W/(Ti/Ta/Ti) multilayer composites prior to FAST-diffusion bonding, have all been described in our prior work [20].

The diffusion bonding was performed with the SPS technique using SINTER LAND (LABOX-350) device, where the heating rate was 50°C·min−1 and the bonding temperatures were 1,000, 1,100, 1,200, 1,300, and 1,400°C. A 33 MPa load was imposed under vacuum and at each bonding temperature was held for 10 min. The samples were subjected to furnace cooling to ambient temperature at 30°C·min−1. Finally, five types of 4 mm-thick W/(Ti/Ta/Ti) multilayer composites of 30 mm in diameter were fabricated.

The composites were subjected to tensile tests with an AGS-X universal tester (Shimadzu) at different temperatures by setting the rate of displacement loading to 0.1 mm·min−1. After processing through electrical discharge machining and polishing by diamond polisher liquid, the tensile samples were subjected to ultrasonic cleaning in absolute ethanol, followed by drying. In our previous work, the dimension of the tensile specimen was shown [19]. Five specimens were tested per composite. The fracture surfaces and microstructure of as-fabricated W/(Ti/Ta/Ti) composites were microscopically investigated (GeminiSEM 300, Zeiss).

3 Results

3.1 Room-temperature mechanical properties

Tensile engineering stress–strain graphs for the W/(Ti/Ta/Ti) multilayer composites are depicted in Figure 1. The tensile strength of W foil is 1,384 MPa, with a strain of 0.45%, which is a typical brittle fracture. W/(Ti/Ta/Ti) samples exhibit lower tensile strength, despite considerably higher strain compared to W foil, so their ambient-temperature fracture toughness is better. As displayed in Figure 1b, with the rise in bonding temperature, the elongation and tensile strength of as-fabricated composites increase and then decrease. At a bonding temperature of 1,200°C, the as-fabricated composites have the best comprehensive performance, with elongation being 5.0% and ultimate tensile strength being 671 MPa. At a bonding temperature of 1,400°C, the mechanical properties of the samples become poor.

Mechanical properties of the W/(Ti/Ta/Ti) multilayer composites bonded at different temperatures: (a) tensile stress–strain curves and (b) the ultimate strength and elongation.

Figure 2 illustrates the fracture surface morphology for the investigated composites. With the rise in bonding temperature, the W, Ti, and Ta layers show changes in fracture mode. The W layer undergoes transgranular fracture for samples bonded at 1,000 and 1,300°C; undergoes cleavage fracture for samples bonded at 1,200°C; and exhibits a mixed fracture (cleavage along with transgranular) for samples bonded at 1,100°C. The Ti layer differs completely from the W layer regarding fracture mode, which exhibits micro-void accumulation fracture for samples bonded at 1,300°C, with many dimples visible. For samples bonded at 1,400°C, the Ti layer undergoes intergranular fracture; besides, W/Ti interfacial debonding is also observable. As for samples bonded at 1,200°C, tearing sheets are visible at the W/Ti interface. At all bonding temperatures, the Ta layers show plastic fracture and exhibit a similar “bidirectional” fracture morphology. It is known that the shape of the cracks depends only on the direction of crack propagation [21]. Hence, we can hardly distinguish the fracture morphological differences among the Ta layers in the investigated composites that are bonded at varying temperatures.

Tensile fracture surfaces of the W/(Ti/Ta/Ti) multilayer composites: (a), (c), (e), and (g) is the fracture surface of W/Ti interface at 1,000, 1,100, 1,200, and 1,400°C, respectively. (b), (d), (f), and (h) is the fracture surface of Ti/Ta interface at 1,000–1,400°C, respectively.

Figure 3 shows the macroscopic fracture morphology for the investigated composites with different bonding temperatures. The preferable bonding at Ti/Ta interfaces indicates high interfacial bond strength. The fracture behaviors of samples bonded at 1,000 and 1,200°C resemble each other, with the main cracks showing zigzag propagation paths. The energy dissipation is mainly reflected in the crack deflection at the W/Ti interfaces, the shear fracture in the Ti/Ta/Ti layers, along with the multi-tunnel cracks in the W layers. With the elevation of bonding temperature, the samples exhibit fracture morphological alterations. For samples bonded at 1,400°C, the path of principal crack propagation becomes smoother. The W layers change from multi-tunnel crack propagation to single crack propagation. The debonding behavior at the W/Ti interface becomes less obvious. Additionally, the Ti/Ta/Ti layer undergoes a transition from ductile fracture to brittle fracture as well.

Fracture characteristics of W/(Ti/Ta/Ti) multilayer composites at different bonding temperatures: (a) and (b) 1,000°C, (c) and (d) 1,200°C, (e) and (f) 1,400°C.

As a candidate PFM material, the high-temperature mechanical properties are critical for tungsten. Hence, evaluating the high-temperature tensile tests for the as-fabricated composites is required, where the test temperatures range between 100 and 600°C. All tests are conducted under atmosphere.

Figure 4 displays the stress–strain graphs for W/(Ti/Ta/Ti) multilayer composites during the high-temperature tensile tests. The corresponding ultimate strengths and elongations are shown in Table 1. As is clear from Figure 4a, for the as-fabricated composites bonded at 1,000°C, the sample strength decreases gradually with the rise in test temperature. When the test temperature is 100°C, the samples begin to experience plastic deformation, albeit relatively small. When the test temperature is 200°C, the samples show great plasticity, with elongations of up to 20% and strength of 470 MPa. As the test temperature further increases, both strength and plasticity decrease, but the plasticity remains good. As shown in Figure 4b, for the as-fabricated composites bonded at 1,200°C, the sample strength is the highest and starts to show plasticity characteristics when tested at 100°C. The plasticity of samples reaches the highest when tested at 400°C. As displayed in Figure 4c, for the as-fabricated composites bonded at 1,400°C, the sample strength is the highest, and the samples begin to undergo plastic deformation when tested at 100°C. Therefore, the DBTTs are also around 100°C for W/(Ti/Ta/Ti) composites.

Tensile stress–strain curves of the W/(Ti/Ta/Ti) multilayer composites tested at different temperature: (a) 1,000°C, (b) 1,200°C, and (c) 1,400°C.

Ultimate strength and elongation of the W/(Ti/Ta/Ti) multilayer composites at various testing temperatures

| Sample | Testing temperature/°C | 25 | 100 | 200 | 400 | 600 |

|---|---|---|---|---|---|---|

| 1,000°C | Ultimate strength/MPa | 582 | 562 | 470 | 358 | 280 |

| Elongation/% | 4.5 | 11.1 | 20.0 | 14.2 | 8.5 | |

| 1,200°C | Ultimate strength/MPa | 671 | 698 | 608 | 512 | 202 |

| Elongation/% | 5.0 | 9.0 | 13.8 | 16.0 | 10.2 | |

| 1,400°C | Ultimate strength/MPa | 514 | 621 | 568 | 436 | 228 |

| Elongation/% | 3.1 | 9.2 | 11.1 | 8.5 | 7.8 |

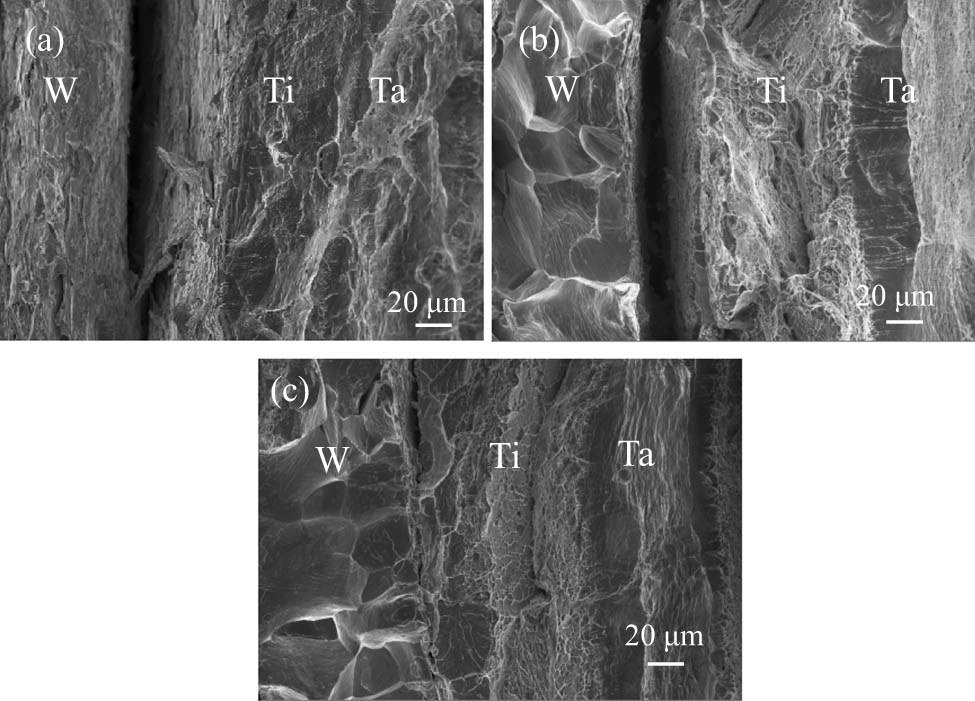

Figure 5 depicts the fracture morphology of the investigated composites at a test temperature of 400°C. As is clear, many slip lines appear on the W-layer grains, indicating plastic deformation in W layers. At room temperature, the Ti and Ta layers show identical fracture mode.

Fracture morphology of the W/(Ti/Ta/Ti) multilayer composites bonded at different temperatures tested at 400°C: (a) 1,000°C, (b) 1,200°C, and (c) 1,400°C.

Figure 6 illustrates the fracture morphology for the investigated composites at a test temperature of 600°C. The fracture structure is as the same as the samples tested at 400°C, and many slip lines also appear on the grains of the W layers. At 600°C, the sample tensile strength along with elongation is the lowest. Besides, overall oxidation phenomenon of the samples is observed, which also agrees with the tensile curve results.

Fracture morphology of the W/(Ti/Ta/Ti) multilayer composites bonded at different temperatures tested at 600°C: (a) and (b) 1,000°C, (c) and (d) 1,200°C, (e) and (f) 1,400°C.

Figure 7 displays the ultimate tensile strengths along with elongations for the investigated composites at varying test temperatures. According to Figure 7a, when the temperature range is between 100 and 400°C, the samples bonded at 1,200°C have the largest tensile strength, followed by the samples bonded at 1,400°C, and the samples bonded at 1,000°C have the smallest. When the test temperature is 600°C, the ultimate tensile strength of the samples bonded at three temperatures decreases significantly. As is clear from Figure 7b, the samples bonded at 1,000°C have the greatest elongation when the test temperature is below 200°C. When the test temperature is above 200°C, the samples bonded at 1,200°C have the maximum elongation.

Mechanical properties of the W/(Ti/Ta/Ti) multilayer composites tested at different temperature: (a) ultimate strength and (b) elongation.

Generally speaking, the strength of the bulk material decreases and the plasticity increases as the test temperature increases. However, for samples bonded at 1,200 and 1,400°C, the strength and plasticity of the samples increase when tested at 100°C. The increase in strength may be attributable to enhanced strength of interfacial bonding. During the heating process and holding stage, some defects at the interface are healed. The stronger interfacial bonding increases the strength of the material as well. After the test temperature surpasses 100°C, the sample strength begins to decrease, while the sample plasticity increases. After the test temperature surpasses 400°C, the sample strength and plasticity decrease. It may be attributable to the high-temperature oxidation of the samples, causing the plasticity to decrease. It can be inferred that if high-temperature tensile test is performed in vacuum, the strength and toughness of the samples will be better as the test temperature rises. The plasticity of W/(Ti/Ta/Ti) samples should always increase.

4 Discussion

4.1 Tensile strength model

For W/(Ti/Ta/Ti) multilayer composites, bonding temperature significantly influences their fracture behavior, especially their interfacial bonding strength. When bonded at low temperature, the W/Ti interface exhibits low bonding strength, leading to interfacial debonding behavior. When bonded at high temperature, the bonding strength at W/Ti interface becomes high and interfacial debonding disappears, which also affects the energy dissipation mechanism of as-fabricated composites. Therefore, to clarify how the interfacial bonding strength influences the crack propagation behavior of as-fabricated composites, the fracture processes of samples with weak interfacial bonding at bonding temperatures below 1,200°C and samples with strong interfacial bonding at bonding temperatures above 1,200°C are investigated.

Due to the significant differences in tensile strength and plasticity between the original W, Ti, and Ta foils, there is a stage of coexisting elastic–plastic deformation in the as-fabricated composites during tensile tests. The hard W layer and the soft Ti/Ta/Ti layer both experience elastic deformation and exhibit identical strains. The strain states of both layers are plane because they are constrained by neighboring layers along the thickness direction.

With further loading, internal stress is generated at the W/Ti interface. The Ti/Ta/Ti layer begins to experience plastic deformation when the internal stress exceeds its yield strength. At this point, the W layer remains in the elastic deformation phase, resulting in inconsistent deformation between the W and Ti/Ta/Ti layers. Therefore, cracks initiate at the W/Ti interface, forming small pores. At this point, the as-fabricated composites with strong and weak interface bonding will exhibit different crack propagation modes.

Figure 8 diagrammatizes the fracture process for W/(Ti/Ta/Ti) multilayer composites having weak interfacial bonding. Given the low bonding strength at W/Ti interface, small pores are formed at the interface. With further loading, the pores gradually grow, so that the stress concentration is stronger at the crack tip. With further deformation of the Ti/Ta/Ti layer, there are increases in interfacial shear stress and propagation of cracks along the interface, leading to interfacial debonding behavior. In case the crack tip stress concentration surpasses the W-layer fracture strength, the crack propagates into the W layer, forming a tunnel crack. Due to extensive crack deflection occurring at the W/Ti interface, the propagation path of sample cracks is extended and their surface area is enlarged. As the cracks begin to propagate along the interface, the stress state of the Ti/Ta/Ti layer transitions to plane, facilitating the improvement of its plasticity. Therefore, the Ti/Ta/Ti layer undergoes necking, causing extensive plastic deformation and consuming a lot of energy through plastic deformation. The crack deflection and plastic deformation in the Ti/Ta/Ti layers lead to weakened stress concentration at the principal crack tip and delayed crack development, thus enhancing the fracture toughness. Additionally, the multi-tunnel crack propagation in the W layer enables the absorption of more energy.

Schematic diagram of the fracture modes for the W/(Ti/Ta/Ti) multilayer composites bonded at temperature lower than 1,200°C during uniaxial tensile tests. (a) initial stage, (b, c) intermediate stage, and (d) final stage.

Figure 9 diagrammatizes the fracture process for the investigated composites having strong interfacial bonding when bonded higher than 1,200°C. Given the high bonding strength at W/Ti interface, cracks cannot propagate along the interface after the interfacial formation of small pores, and no interfacial debonding occurs, as shown in Figure 9b. With further loading, there appears a tunnel crack in the brittle W layer, and a small shear band develops from its tip to the Ti layer. With the intensification of stress concentration, the shear band extends deeper to the Ti layer. Finally, the Ti/Ta/Ti layer fractures along the shear band, since the shear stress surpasses its shear strength.

Schematic diagram of the fracture modes for the W/(Ti/Ta/Ti) multilayer composites bonded at temperature higher than 1,200°C during uniaxial tensile tests. (a) initial stage, (b, c) intermediate stage, and (d) final stage.

Because of the sufficiently high interfacial bonding strength, which avoids interfacial debonding, the strain state of the Ti/Ta/Ti layer remains plane. Thus, its necking is suppressed and its plasticity is reduced. It can be inferred that under this condition, the energy dissipated decreases because of plastic deformation in the Ti/Ta/Ti layer. Meanwhile, with a decrease in the plastic deformation, it becomes impossible to release the crack tip stress concentration. Moreover, when the stress state of the W layer remains plane, its plastic deformation is inhibited, and brittle fracture is inevitable.

Thus, the main mechanisms of energy consumption for the as-fabricated composites having low interfacial bonding strength include the Ti/Ta/Ti-layer plastic deformation, the multi-tunnel crack propagation in W layers, and the debonding at the W/Ti interface. With the rise of temperature, the plastic deformation in the Ti/Ta/Ti layer decreases, the W-layer transitions from multi-tunnel crack propagation to single-crack propagation, and the strength of interfacial bonding increases. Therefore, for the as-fabricated composites having high interfacial bonding strength, energy can only be consumed through main crack propagation. In summary, selecting a bonding temperature below 1,200°C is beneficial for improving the comprehensive tensile performance of W/(Ti/Ta/Ti) composites.

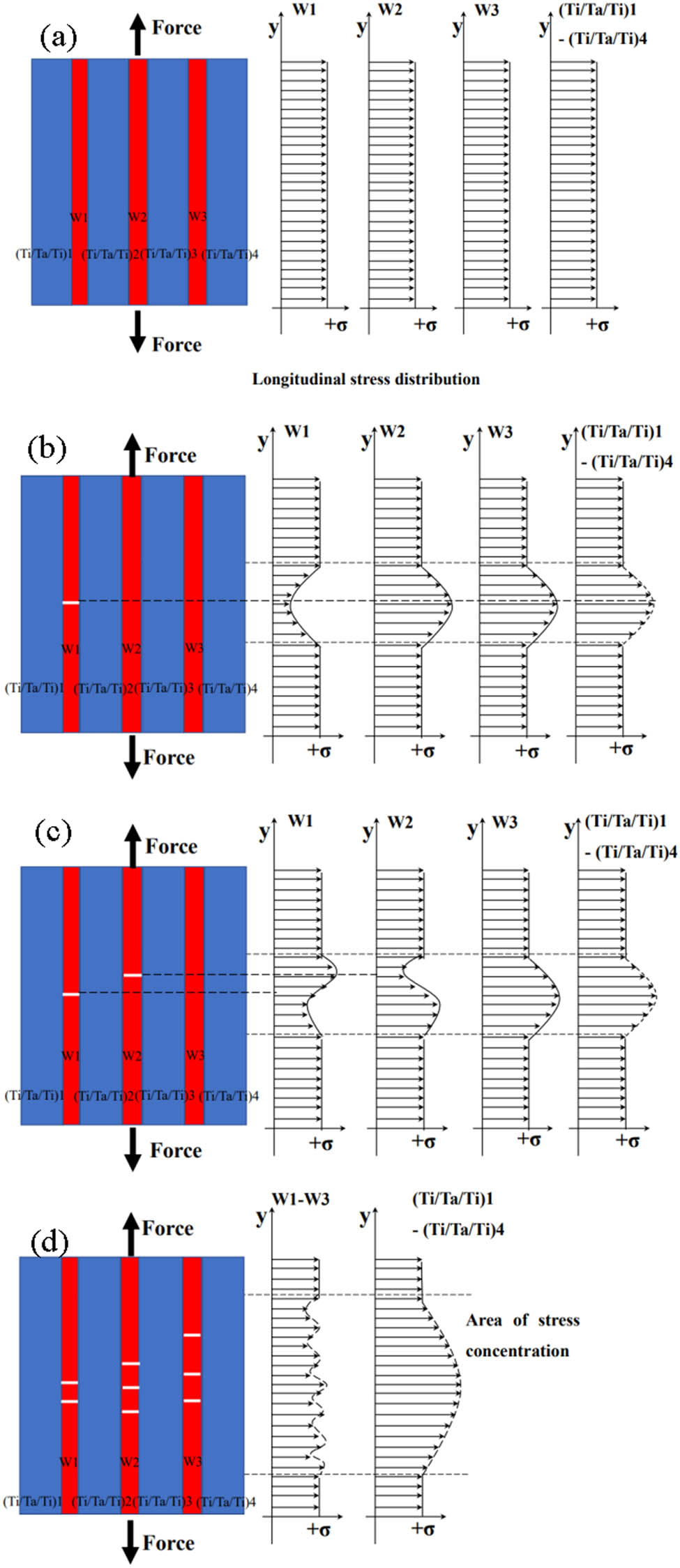

Figure 10 diagrammatizes the stress distribution generated by the W-layer cracks in the as-fabricated composites under tensile load. During longitudinal tensile testing, the deformation in W and Ti/Ta/Ti layers obeys the lamination theory-based equal-strain model [22]. During the deformation, these two layers in Poisson’s ratio and elastic modulus, which will lead to differences in stress distribution to result in higher tensile stress on the W layer, despite the homogeneous stress distribution in various layers along the longitudinal direction, are displayed in Figure 10a. As the strain increases, the W and Ti/Ta/Ti layers exhibit completely different deformation behaviors. The Ti/Ta/Ti layers undergo plastic deformation once the applied stress surpasses the yield strength. Contrastively, the W layer is so brittle that microcracks nucleate inside the W layer and then propagate in a brittle mode. However, the Ti/Ta/Ti layer has a certain degree of plasticity, which can suppress the further propagation of microcracks. Therefore, the as-fabricated composites will not undergo catastrophic fracture similar to brittle bulk materials.

Schematic diagram of crack generation in the W layers of the W/(Ti/Ta/Ti) multilayer composites during tensile test. (a) initial stage, (b, c) intermediate stage, and (d) final stage.

Once microcracks appear on the W1 layer, the stress distribution of as-fabricated composites will change. As is clear from Figure 10b, the strain relaxation resulting from crack generation can lead to reduced local stress on the W1 layer containing microcracks [23]. Nonetheless, stresses are concentrated in the layers near the initial crack, such as the W2 and W3 layers that have not yet developed microcracks, as well as all Ti/Ta/Ti layers, which is attributable to stress redistribution on the W layer, as illustrated in Figure 10b [24,25]. Therefore, as the strain increases, microcracks are more likely to occur in the stress concentration zone. Once another microcrack occurs in a local area of the W2 layer, it will further alter the stress distribution, as shown in Figure 10c.

In this case, due to the superposition effect of two microcracks on the W1 and W2 layers, the stress distribution will become more complex, but the composites are still impacted by stress concentration. Since these two microcracks cannot be distributed in a straight line, the stress concentration area will further extend. As displayed in Figure 10d, a growing number of microcracks appear in this area with further increase in the strain, increasingly complicating the stress distribution. As the stress concentration deepens and substantial microcracks appear, there will also be the formation of principal crack in this area. Most microcracks are mainly distributed around the principal crack, which is consistent with Fig. 3. The existence of substantial microcracks reflects better toughness of composite, as a large amount of energy can be absorbed by microcracks prior to failure. In addition, the impact of stress concentration can be weakened by the relatively dispersed pattern of microcrack distribution [26].

4.2 Calculation model for tensile strength

The composite tensile strength is lower than the W foil tensile strength, whereas is higher than the yield strengths of Ti and Ta foils [19]. This is explainable by the mixing rules of multilayer composite materials [27,28]. Given the good Ti/Ta interfacial bonding strength, interfacial debonding is absent, so the interface can be considered as a layer. Therefore, the as-fabricated composites are each dividable into a W layer and a Ti/Ta/Ti layer. Assuming that the composite tensile strength is as follows:

where

For the Ti/Ta/Ti layer, we assume that its tensile strength is as follows:

where

According to previous research, the Ti layer undergoes change in its microstructure with the rise of bonding temperature. At bonding temperatures below 1,300°C, the Ti layer comprises three layers of structure, namely, the β-Ti (W) solid solution, the α/β-Ti double-phase region, and the β-Ti (Ta) solid solution. At bonding temperatures exceeding 1,300°C, the Ti layer completely becomes β-Ti. Therefore, the tensile strength calculation for the Ti layer in the following two situations is necessary.

When bonded below 1,300°C, assuming that the tensile strength of the Ti layer is as follows:

where

When bonded above 1,300°C, the Ti-layer tensile strength is precisely the strength of β-Ti.

Hardness can be a rough indicator estimating the alloy tensile strength [29]. There is a correlation of tensile strength with hardness, namely:

Table 2 details the microhardness of each region in the as-fabricated composites with varying bonding temperatures.

Microhardness in different structure of the W/(Ti/Ta/Ti) multilayer composites

| Sample | Hardness in different structure (HV) | ||||

|---|---|---|---|---|---|

| W layer | β-Ti(W) | α/β-Ti | β-Ti(Ta) | Ta layer | |

| 1,000°C | 452 | 343 | 289 | 236 | 100 |

| 1,100°C | 421 | 346 | 301 | 249 | 107 |

| 1,200°C | 415 | 348 | 291 | 249 | 103 |

| 1,300°C | 405 | 373 | — | 257 | 106 |

| 1,400°C | 399 | 401 | — | 287 | 95 |

Therefore, when the bonding temperatures are 1,000, 1,100, and 1,200°C, the Ti layer shows the respective theoretical tensile strengths of 1,022, 1,188, and 1,077 MPa. At bonding temperatures of 1,300 and 1,400°C, the corresponding theoretical tensile strengths are 1,050 and 850 MPa, respectively, for the Ti layer.

When the annealing temperatures are 1,000, 1,100, 1,200, and 1,300°C, the Ta foil exhibits respective tensile strengths of 280, 251, 250, and 225 MPa. Obviously, the annealing temperature produces little influence over the tensile strength of Ta foil. Therefore, it is assumed that Ta foil has a tensile strength of 225 MPa when the annealing temperature is 1,400°C. Hence, at bonding temperatures of 1,000, 1,100, 1,200, 1,300, and 1,400°C, the Ti/Ta/Ti layer has respective theoretical tensile strengths of 678, 836, 699, 889, and 671 MPa.

According to the fracture model of the as-fabricated composites, the W and Ti/Ta/Ti layers separately exhibit brittle and plastic fractures. Due to stress concentration, cracks are prone to nucleation at the W/Ti interface, causing small pore formation. Therefore, the impact of stress concentration must be considered in the actual tensile strength of the W layer. We can derive the stress concentration coefficient

where d denotes the crack diameter; B stands for representative volume element (RVE), which is the width of a W layer plus a Ti/Ta/Ti layer. Given the brittleness of the W layer, the d value is extremely small, so d/B approaches zero, resulting in a

Therefore, the tensile strength of the as-fabricated composites are calculated as follows:

Based on the tensile strength model, the as-fabricated composites have respective theoretical tensile strengths of 617, 735, 765, 619, and 604 MPa, when the bonding temperatures are 1,000, 1,100, 1,200, 1,300, and 1,400°C.

Figure 11 shows the comparison of estimated versus experimental tensile strengths for the as-fabricated composites. It can be found that the strength has errors, and the reasons may be as follows. First, the strengths of the W and Ti layers are approximated by exploiting the approximate empirical correlation of tensile strength with microhardness. Second, for Ti/Ta/Ti layers with good deformation coordination ability, it is difficult to quantitatively analyze the impact of stress concentration coefficient.

Comparison of the calculated and experimental results of the tensile strength of the W/(Ti/Ta/Ti) multilayer composites.

4.3 Toughening mechanism

With the rise in bonding temperature, the elongation of W/(Ti/Ta/Ti) composites first increases and then decreases, reaching its maximum at a bonding temperature of 1,200°C. At other bonding temperatures, the elongation is similar. Noticeably, the interfacial debonding at the W/Ti interface becomes less obvious with the elevation of connection temperature. In addition, at 1,200°C, there will be tearing flakes at the interface. Interfacial debonding can improve the toughness of composite materials [14,31]. In this case, the W/Ti interface exhibits a lower strength compared to the matrix.

Given the differences of the W layer from the Ti layer in strength and microstructure, layered toughness is noted at the W/Ti interface fracture at bonding temperatures lower than 1,200°C, which is more pronounced when bonded at 1,200°C. The debonding behavior of the W/Ti interface disappears at 1,400°C. The intergranular fractures and transgranular fractures are particularly evident in the W layer. The fracture mode of the Ti layer has also transitioned from ductile to intergranular, as its structure has altered from α/β-mixed phase to become complete β-phase.

The grain size increase in the Ti layer leads to toughness reduction in composite material. The fracture mode of the Ta layer is ductile with substantial dimples, and dislocation slip appears on its fracture surface. During the propagation of crack, the Ta layer experiences local plastic deformation because of stress concentration in the crack tip vicinity, which passivates the crack tip. Under continuous loading, the crack propagates forward again, and this process is repeated until rupture of the Ta layer.

Unlike the W/Ti interfacial debonding, the Ti/Ta interface is in an uncracked bonding state. The bonding effect is so strong that the crack propagation or plastic deformation in Ta layers tends to release stress concentration at the interface rather than interfacial debonding. The interfacial crack propagation and the plastic deformation in the Ta layer will lead to energy dissipation, thereby resulting in increased toughness of as-fabricated composites.

5 Summary

In this study, ambient- and high-temperature tensile tests were conducted on W/(Ti/Ta/Ti) multilayer composites with bonding temperatures of 1,000–1,400°C to investigate their tensile behavior and DBTT. The following conclusions are reached:

W/(Ti/Ta/Ti) multilayer composites exhibit significantly superior comprehensive tensile performance to the original foil. The comprehensive tensile performance of W/(Ti/Ta/Ti) samples bonded at 1,200°C is optimal, showing elongation and tensile strength of 5.0% and 671 MPa, respectively. At a bonding temperature of 1,400°C, the overall performance of the sample deteriorates.

When bonded at 1,000°C, the DBTT is approximately 100°C. When bonded at 1,200°C, the DBTT is approximately between 100 and 200°C. When bonded at 1,400°C, the DBTT is between 100 and 200°C. It means that the bonding temperature causes microstructural alteration in W/(Ti/Ta/Ti) multilayer composites, thereby affecting their high-temperature tensile mechanical properties.

In the case of W/(Ti/Ta/Ti) composites having low interfacial bonding strength, the primary energy dissipation modes are intermediate-layer plastic deformation, multi-tunnel crack propagation in the W layer, as well as W/Ti interfacial delamination. With the rise of temperature, the W/Ti interfacial bonding strengthens, the intermediate-layer plasticity decreases, and the W layer changes from multi-tunnel crack propagation to single crack propagation. Therefore, when the interfacial bonding strength of W/(Ti/Ta/Ti) composites is high, energy can only be consumed through the principal crack propagation.

The fracture mode of the W layer is brittle. Due to the stress concentration, cracks are prone to nucleate at the W/Ti interface, forming tiny pores. For W/(Ti/Ta/Ti) multilayer composites, a tensile strength model is constructed based on the stress concentration coefficient after the nucleation of microcracks at the W/Ti interface.

Acknowledgements

This work was supported by Natural Science Foundation of Shaanxi Province (2023-JC-QN-0429), Qinchuangyuan Project of Shaanxi Province (QCYRCXM-2022-96, QCYRCXM-2022-181), and the National Natural Science Foundation of China (Grant No. 12205242).

-

Funding information: This work is funded by Natural Science Foundation of Shaanxi Province (2023-JC-QN-0429), Qinchuangyuan Project of Shaanxi Province (QCYRCXM-2022-96, QCYRCXM-2022-181), and the National Natural Science Foundation of China (Grant No. 12205242).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. Houlong Liu and Rui Liu conceived and designed the experiments; Jie Zhu and Rui Liu performed the experiments. All authors participated in discussing the results, drafting the manuscript, and providing feedback during the review process.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The raw data related to this manuscript would be made available on request.

References

[1] Sahin, Y. Recent progress in processing of tungsten heavy alloys. Journal of Powder Technology, Vol. 2014, 2014, id. 764306.10.1155/2014/764306Search in Google Scholar

[2] Kiran, U. R., A. Panchal, M. Sankaranarayana, G. V. S. N. Rao, and T. K. Nandy. Effect of alloying addition and microstructural parameters on mechanical properties of 93% tungsten heavy alloys. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 640, 2015, pp. 82–90.10.1016/j.msea.2015.05.046Search in Google Scholar

[3] Cai, W. D., Y. Li, R. Dowding, F. Mohamed, and E. Lavernia. A review of tungsten-based alloys as kinetic energy penetrator materials. Reviews in Particulate Materials, Vol. 3, 1995, pp. 71–132.Search in Google Scholar

[4] Neu, R., C. Hopf, A. Kallenbach, T. Pütterich, R. Dux, H. Greuner, et al. Operational conditions in a W-clad tokamak. Journal of Nuclear Materials, Vol. 367-370, 2007, pp. 1497–1502.10.1016/j.jnucmat.2007.04.018Search in Google Scholar

[5] Coenen, J. W., S. Antusch, M. Aumann, W. Biel, J. Du, J. Engels, et al. Materials for DEMO and reactor applications – Boundary conditions and new concepts. Physica Scripta, Vol. 167, 2016, id. 014002.10.1088/0031-8949/2016/T167/014002Search in Google Scholar

[6] Travere, J. M., M. H. Aumeunier, M. Joanny, T. Loarer, M. Firdaouss, E. Gauthier, et al. Imaging challenges for ITER plasma-facing component protection. Fusion Science and Technology, Vol. 64, 2017, pp. 735–740.10.13182/FST13-A24093Search in Google Scholar

[7] Lassner, E. and W. D. Schubert. Tungsten: Properties, chemistry, technology of the element, alloys, and chemical compounds, Springer, Berlin, 1999.10.1007/978-1-4615-4907-9Search in Google Scholar

[8] Reiser, J., L. Garrison, H. Greuner, J. Hoffmann, T. Weingärtner, U. Jäntsch, et al. Ductilisation of tungsten (W): Tungsten laminated composites. International Journal of Refractory Metals and Hard Materials, Vol. 69, 2017, pp. 66–109.10.1016/j.ijrmhm.2017.07.013Search in Google Scholar

[9] Ritchie, R. O. Mechanisms of fatigue – crack propagation in ductile and brittle solids. International Journal of Fracture, Vol. 100, 1999, pp. 55–83.Search in Google Scholar

[10] Gumbsch, P. Brittle fracture and the brittle-to-ductile transition of tungsten. Journal of Nuclear Materials, Vol. 323, 2003, pp. 304–312.10.1016/j.jnucmat.2003.08.009Search in Google Scholar

[11] Romaner, L., C. Ambrosch-Draxl, and R. Pippan. Effect of rhenium on the dislocation core structure in tungsten. Physical Review Letters, Vol. 104, 2010, id. 195503.10.1103/PhysRevLett.104.195503Search in Google Scholar PubMed

[12] Rupp, D., R. Mönig, P. Gruber, and S. M. Weygan. Fracture toughness and microstructural characterization of polycrystalline rolled tungsten. International Journal of Refractory Metals and Hard Materials, Vol. 28, 2010, pp. 669–673.10.1016/j.ijrmhm.2010.05.006Search in Google Scholar

[13] Zhang, Y., A. V. Ganeev, J. T. Wang, J. Q. Liu, and I. V. Alexandrov. Observations on the ductile-to-brittle transition in ultrafine-grained tungsten of commercial purity. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 503, 2009, pp. 37–40.10.1016/j.msea.2008.07.074Search in Google Scholar

[14] Mao, Y., J. W. Coenen, J. Riesch, S. Sistla, J. Almanstötter, B. Jasper, et al. Influence of the interface strength on the mechanical properties of discontinuous tungsten fiber-reinforced tungsten composites produced by field assisted sintering technology. Composites Part A: Applied Science and Manufacturing, Vol. 107, 2018, pp. 342–353.10.1016/j.compositesa.2018.01.022Search in Google Scholar

[15] Waseem, O. A. and H. J. Ryu. Toughening of a low-activation tungsten alloy using tungsten short fibers and particles reinforcement for fusion plasma-facing applications. Nuclear Fusion, Vol. 59, 2018, id. 026007.10.1088/1741-4326/aaf43fSearch in Google Scholar

[16] Henager, C. H., W. Setyawan, T. J. Roosendaal, N. R. Overman, and K. H. Cunningham. Ductile-phase toughened tungsten for plasma-facing materials in fusion reactors. International Journal of Powder Metallurgy, Vol. 53, 2017, pp. 53–69.Search in Google Scholar

[17] Chen, C., J. Xu, R. Liu, X. Xie, S. Wang, Z. Zhang, et al. The effect of sintering temperature on the tensile properties and fracture behaviors of W/Ta multilayer composites. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 768, 2019, id. 138450.10.1016/j.msea.2019.138450Search in Google Scholar

[18] Chen, C., S. F. Qian, R. Liu, S. Wang, B. Liao, Z. H. Zhong, et al. The microstructure and tensile properties of W/Ti multilayer composites prepared by spark plasma sintering. Journal of Alloys and Compounds, Vol. 780, 2019, pp. 116–130.10.1016/j.jallcom.2018.11.346Search in Google Scholar

[19] Liu, R., X. Xia, M. Y. Xie, C. Chen, S. Wang, Z. H. Zhong, et al. Effect of interlayers on the tensile behaviors of tungsten multilayered composites. Journal of Alloys and Compounds, Vol. 827, No. 827, id. 154286.10.1016/j.jallcom.2020.154286Search in Google Scholar

[20] Liu, R., X. S. Hou, S. Y. Yang, C. Chen, Y. R. Mao, S. Wang, et al. The effect of bonding temperature on the bending behaviors and toughening mechanism of W/(Ti/Ta/Ti) multilayer composites prepared by field activated sintering technique. Materials Characterization, Vol. 172, 2021, id. 110875.10.1016/j.matchar.2021.110875Search in Google Scholar

[21] Wurster, S., B. Gludovatz, A. Hoffmann, and R. Pippan. Fracture behaviour of tungsten–vanadium and tungsten-tantalum alloys and composites. Journal of Nuclear Materials, Vol. 413, 2011, pp. 166–176.10.1016/j.jnucmat.2011.04.025Search in Google Scholar

[22] Jeong, C., T. Oya, and J. Yanagimoto. Analysis of fracture behavior and stress–strain distribution of martensite/austenite multilayered metallic sheet. Journal of Materials Processing Technology, Vol. 213, 2013, pp. 614–620.10.1016/j.jmatprotec.2012.10.017Search in Google Scholar

[23] Li, T., F. Grignon, D. J. Benson, K. S. Vecchio, E. A. Olevsky, F. Jiang, et al. Modeling the elastic properties and damage evolution in Ti–Al 3Ti metal–intermetallic laminate (MIL) composites. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 374, 2004, pp. 10–26.10.1016/j.msea.2003.09.074Search in Google Scholar

[24] Ashbaugh, N. E. Stresses in laminated composites containing a broken layer. Journal of Applied Mechanics, Vol. 40, 1973, pp. 533–540.10.1115/1.3423019Search in Google Scholar

[25] Wang, B. L., J. C. Han, and S. Y. Du. Cracks problem for non-homogeneous composite material subjected to dynamic loading. International Journal of Solids and Structures, Vol. 37, 2000, pp. 1251–1274.10.1016/S0020-7683(98)00292-3Search in Google Scholar

[26] Yuan, H. M., A. G. Evans, and J. M. Hutchinson. Crack deflection at an interface between dissimilar elastic materials: Role of residual stresses. International Journal of Solids and Structures, Vol. 31, 1994, pp. 3443–3455.10.1016/0020-7683(94)90025-6Search in Google Scholar

[27] Mao, S. X. and M. Z. Li. Effects of dislocation shielding on interface crack initiation and growth in metal/ceramic layered materials. Journal of the Mechanics and Physics of Solids, Vol. 47, 1999, pp. 2351–2379.10.1016/S0022-5096(99)00015-0Search in Google Scholar

[28] Lee, S., J. Wadsworth, and O. D. Sherby. Tensile properties of laminated composites based on ultrahigh carbon steel. Journal of Composite Materials, Vol. 25, 2016, pp. 842–853.10.1177/002199839102500704Search in Google Scholar

[29] Wang, S., S. K. Feng, C. Chen, B. Liao, L. F. Cao, and Z. H. Zhong. Size effects on tensile properties and deformation mechanism of commercial pure tantalum foils. International Journal of Refractory Metals and Hard Materials, Vol. 80, 2019, pp. 161–173.10.1016/j.ijrmhm.2019.01.015Search in Google Scholar

[30] Heywood, R. B. Definitions-photo elasticity for designers, 111th edn., Pergamon Press, London, 1969, pp. 238–238.10.1111/j.1475-1305.1969.tb01629.xSearch in Google Scholar

[31] Zhang, Y., T. Ouyang, D. Liu, Y. Wang, J. Du, C. Zhang, et al. Effect of thickness ratio on toughening mechanisms of Ta/W multilayers. Journal of Alloys and Compounds, Vol. 666, 2016, pp. 30–37.10.1016/j.jallcom.2016.01.084Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Endpoint carbon content and temperature prediction model in BOF steelmaking based on posterior probability and intra-cluster feature weight online dynamic feature selection

- Thermal conductivity of lunar regolith simulant using a thermal microscope

- Multiobjective optimization of EDM machining parameters of TIB2 ceramic materials using regression and gray relational analysis

- Research on the magnesium reduction process by integrated calcination in vacuum

- Microstructure stability and softening resistance of a novel Cr-Mo-V hot work die steel

- Effect of bonding temperature on tensile behaviors and toughening mechanism of W/(Ti/Ta/Ti) multilayer composites

- Exploring the selective enrichment of vanadium–titanium magnetite concentrate through metallization reduction roasting under the action of additives

- Effect of solid solution rare earth (La, Ce, Y) on the mechanical properties of α-Fe

- Impact of variable thermal conductivity on couple-stress Casson fluid flow through a microchannel with catalytic cubic reactions

- Effects of hydrothermal carbonization process parameters on phase composition and the microstructure of corn stalk hydrochars

- Wide temperature range protection performance of Zr–Ta–B–Si–C ceramic coating under cyclic oxidation and ablation environments

- Influence of laser power on mechanical and microstructural behavior of Nd: YAG laser welding of Incoloy alloy 800

- Aspects of thermal radiation for the second law analysis of magnetized Darcy–Forchheimer movement of Maxwell nanomaterials with Arrhenius energy effects

- Use of artificial neural network for optimization of irreversibility analysis in radiative Cross nanofluid flow past an inclined surface with convective boundary conditions

- The interface structure and mechanical properties of Ti/Al dissimilar metals friction stir lap welding

- Significance of micropores for the removal of hydrogen sulfide from oxygen-free gas streams by activated carbon

- Experimental and mechanistic studies of gradient pore polymer electrolyte fuel cells

- Microstructure and high-temperature oxidation behaviour of AISI 304L stainless steel welds produced by gas tungsten arc welding using the Ar–N2–H2 shielding gas

- Mathematical investigation of Fe3O4–Cu/blood hybrid nanofluid flow in stenotic arteries with magnetic and thermal interactions: Duality and stability analysis

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part II

- Effects of heat treatment on microstructure and properties of CrVNiAlCu high-entropy alloy

- Enhanced bioactivity and degradation behavior of zinc via micro-arc anodization for biomedical applications

- Study on the parameters optimization and the microstructure of spot welding joints of 304 stainless steel

- Research on rotating magnetic field–assisted HRFSW 6061-T6 thin plate

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part II

- Microwave hybrid process-based fabrication of super duplex stainless steel joints using nickel and stainless steel filler materials

- Special Issue on Polymer and Composite Materials and Graphene and Novel Nanomaterials - Part II

- Low-temperature corrosion performance of laser cladded WB-Co coatings in acidic environment

- Special Issue for the conference AMEM2025

- Effect of thermal effect on lattice transformation and physical properties of white marble

Articles in the same Issue

- Research Articles

- Endpoint carbon content and temperature prediction model in BOF steelmaking based on posterior probability and intra-cluster feature weight online dynamic feature selection

- Thermal conductivity of lunar regolith simulant using a thermal microscope

- Multiobjective optimization of EDM machining parameters of TIB2 ceramic materials using regression and gray relational analysis

- Research on the magnesium reduction process by integrated calcination in vacuum

- Microstructure stability and softening resistance of a novel Cr-Mo-V hot work die steel

- Effect of bonding temperature on tensile behaviors and toughening mechanism of W/(Ti/Ta/Ti) multilayer composites

- Exploring the selective enrichment of vanadium–titanium magnetite concentrate through metallization reduction roasting under the action of additives

- Effect of solid solution rare earth (La, Ce, Y) on the mechanical properties of α-Fe

- Impact of variable thermal conductivity on couple-stress Casson fluid flow through a microchannel with catalytic cubic reactions

- Effects of hydrothermal carbonization process parameters on phase composition and the microstructure of corn stalk hydrochars

- Wide temperature range protection performance of Zr–Ta–B–Si–C ceramic coating under cyclic oxidation and ablation environments

- Influence of laser power on mechanical and microstructural behavior of Nd: YAG laser welding of Incoloy alloy 800

- Aspects of thermal radiation for the second law analysis of magnetized Darcy–Forchheimer movement of Maxwell nanomaterials with Arrhenius energy effects

- Use of artificial neural network for optimization of irreversibility analysis in radiative Cross nanofluid flow past an inclined surface with convective boundary conditions

- The interface structure and mechanical properties of Ti/Al dissimilar metals friction stir lap welding

- Significance of micropores for the removal of hydrogen sulfide from oxygen-free gas streams by activated carbon

- Experimental and mechanistic studies of gradient pore polymer electrolyte fuel cells

- Microstructure and high-temperature oxidation behaviour of AISI 304L stainless steel welds produced by gas tungsten arc welding using the Ar–N2–H2 shielding gas

- Mathematical investigation of Fe3O4–Cu/blood hybrid nanofluid flow in stenotic arteries with magnetic and thermal interactions: Duality and stability analysis

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part II

- Effects of heat treatment on microstructure and properties of CrVNiAlCu high-entropy alloy

- Enhanced bioactivity and degradation behavior of zinc via micro-arc anodization for biomedical applications

- Study on the parameters optimization and the microstructure of spot welding joints of 304 stainless steel

- Research on rotating magnetic field–assisted HRFSW 6061-T6 thin plate

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part II

- Microwave hybrid process-based fabrication of super duplex stainless steel joints using nickel and stainless steel filler materials

- Special Issue on Polymer and Composite Materials and Graphene and Novel Nanomaterials - Part II

- Low-temperature corrosion performance of laser cladded WB-Co coatings in acidic environment

- Special Issue for the conference AMEM2025

- Effect of thermal effect on lattice transformation and physical properties of white marble