Abstract

In order to improve the quality of the bonding interface between dissimilar metals, friction stir lap welding was used to weld TA1/6061Al. The effects of multi-pass welding parameters on the mechanical properties, elements distribution, and intermetallic compounds of the lap interface were investigated. The results showed that the fracture locations of the specimens under multi-pass welding and single-pass welding were different. The latter was sheared from the bonding interface, while the former failed near the thermo-mechanically affected zone on the advancing side of the Al side. Moreover, multi-pass welding significantly improved the tensile-shear resistance of the joints. The maximum fracturing load of multi-pass welding reached 7,150 N when adjacent welds interval (L) was 12 mm, which was much higher than single-pass welding 3,861 N. The thermal–mechanical coupling effect of the tool during the welding process resulted in the formation of Ti/Al atomic diffusion layers of different thicknesses and the formation of Ti/Al intermetallic compound (mainly TiAl3) at the bonding interface. Diffusion bonding was the main way for multi-pass welded lap joints to form a reliable connection. The thicknesses of the interfacial diffusion layers at the first weld of multi-pass welding under different L values were approximately the same as that of single-pass welding, in the range of 4–4.4 μm.

1 Introduction

Titanium alloy possesses the advantages of high strength and corrosion resistance; however, its processability is poor. In contrast, aluminum alloy is characterized by low density and good processability. The composite of titanium and aluminum heterogeneous alloys can achieve complementary advantages, reduce costs, and realize lightweight components. Currently, it is widely applied in the aerospace field, such as the utilization of titanium/aluminum composite structures in the seat rails of Airbus aircraft [1,2]. Many scholars have tried laser welding [3,4], gas tungsten arc welding [5,6], and cold metal transfer [7] to weld Ti/Al dissimilar metals. However, the thermophysical properties and chemical properties of Ti/Al dissimilar metals are greatly different. There are several challenges when using fusion welding to connect titanium alloy and aluminum alloy, such as aluminum element evaporation, metallurgical incompatibility, and large welding residual stress. One of the key problems is the formation of brittle intermetallic compounds in Ti/Al joints [8]. Friction stir welding, a new type of solid-state welding technique with no metal melt and solidification process during the welding process, has significant advantages in overcoming the welding difficulties caused by the difference in the performance of dissimilar materials [9].

Friction stir welding has attracted increasing attention due to its high efficiency, high quality, and low welding stress. It has become a promising technique for connecting dissimilar metal materials in composites [10]. The most significant feature of friction stir welding is that the welding process is conducted in the solid state. Consequently, defects related to metallurgical solidification, such as cracks, porosity, and burning loss of alloy elements, are avoided in the welded joint. Furthermore, the performance of the welded joint approximates that of the base metal. Huseyin et al. [11] has proved that friction stir welding can be used for the connection of Al6063 alloy and X5CrNi18-10 stainless steel through experiments, and it has been observed that the hardness distribution correlates well with the welding zones. The friction stir lap welding of 6061 aluminum alloy and commercial pure copper was studied by Firouzdor and Kou [12], and the quality of Al-to-Cu joint under certain process parameters was significantly improved through modified lap friction stir welding. As for the friction stir welding of Ti/Al dissimilar metals, Chen and Nakata [13] used single-pass friction stir welding technology to connect the Al–Si alloy to pure titanium and tested the tensile properties of joint. The joint fractured at the interface and the maximum failure load reached 62% of the Al–Si alloy base metal. X-ray diffraction results showed that new phase of TiAl3 formed at the interface. Therefore, it attracts a considerable interest to investigate the effect of intermetallic compounds on fracture load. Wu et al. [14] explored the factors affecting the mechanical properties of the joint through the friction stir butt welding experiment of titanium and aluminum dissimilar metals, and proposed that the tensile strength of the joint mainly depended on the rotation rate, while the interface and the intermetallic compound layers were the governing factors. Similar conclusion, the tensile strength of the joint affected intermetallic compounds, was drawn by Aonuma and Nakata [15] through the butt welding of 2024 aluminum alloy and 6061 aluminum alloy. In the friction stir lap welding of Ti/Al dissimilar metals, in order to further explore the qualitative relationship between shear strength and intermetallic compounds, Yu et al. [16] carried out single-pass friction stir lap welding experiments and pointed out that the intermetallic compound layer was found to be mainly composed of TiAl3 and the shear strength of single-pass friction stir welding lap AA6061–Ti6Al4V welds was determined by the interface structure. The formation of a small amount of intermetallic compounds had an initial promotion effect on the shear performance, while an excessive amount of intermetallic compounds caused the residual stresses to be exorbitant, resulting in decreasing the maximum shear load. The microstructure and hardness distribution of Ti/Al dissimilar metals friction stir lap welding joints were also concerned by researchers. For instance, it was found by Wei et al. [17] that there was an obvious eddy current mixing zone at the Ti/Al interface, where aluminum metal, titanium metal, and their mixed layers all appeared. Chen et al. [18] fabricated the lap joints of TC1 titanium alloy and LF6 aluminum alloy by friction stir welding, and the characteristics of related materials were studied. It was found that the microhardness distribution of the lap joints was uneven and the maximum hardness appears in the middle of the stirred zone. Moreover, Dressler et al. [19] investigated the connection mechanism of the single-pass friction stir weld-bonding interface of Ti/Al dissimilar metals. The experimental results showed that under reasonable welding parameters, a small amount of TiAl3 new phase was formed at the interface by diffusion reaction. The connection mechanism of the bonding interface was mainly atomic diffusion bonding. These studies had confirmed that the shear strength at the bonding interface of single-pass friction stir welding Ti/Al dissimilar metals was significantly lower than that of the aluminum alloy base material (BM), which depended on the interfacial diffusion layer thickness and Ti/Al intermetallic compound layer thickness. Excessive intermetallic compounds often lead to a significant decrease in the mechanical properties of the joint. Muribwathoho et al. [20] investigated the multi-pass friction stir welding of AA1050 and AA6062 aluminum alloys, and it was found that with the increase of passes, grain refinement was increased, and the tensile strength at the joint was enhanced. Mirjavadi et al. [21] studied the mechanical properties and wear behavior of AA5083/ZrO2 composites processed by friction stir welding. The research revealed that with the increase of passes, the grain refinement, dislocation density, and hardness of the joint were increased. According to the above research, multi-pass friction stir welding can be used to refine the grain at the joint, thereby enhancing the tensile strength at the joint.

In order to improve the defects of traditional Ti/Al dissimilar metal single-pass friction stir welding and improve the quality of lap interface, the mechanical properties of Ti/Al dissimilar metal multi-pass welding were studied. Meanwhile, the mechanical properties, elements distribution, and Ti/Al intermetallic compounds of the interface with different adjacent welds interval were studied and compared with single-pass welding under the same welding parameters. A foundation for further improving the process, obtaining high-quality lap interface, and promoting the application of multi-pass friction stir welding of Ti/Al dissimilar metals was built.

2 Materials and methods

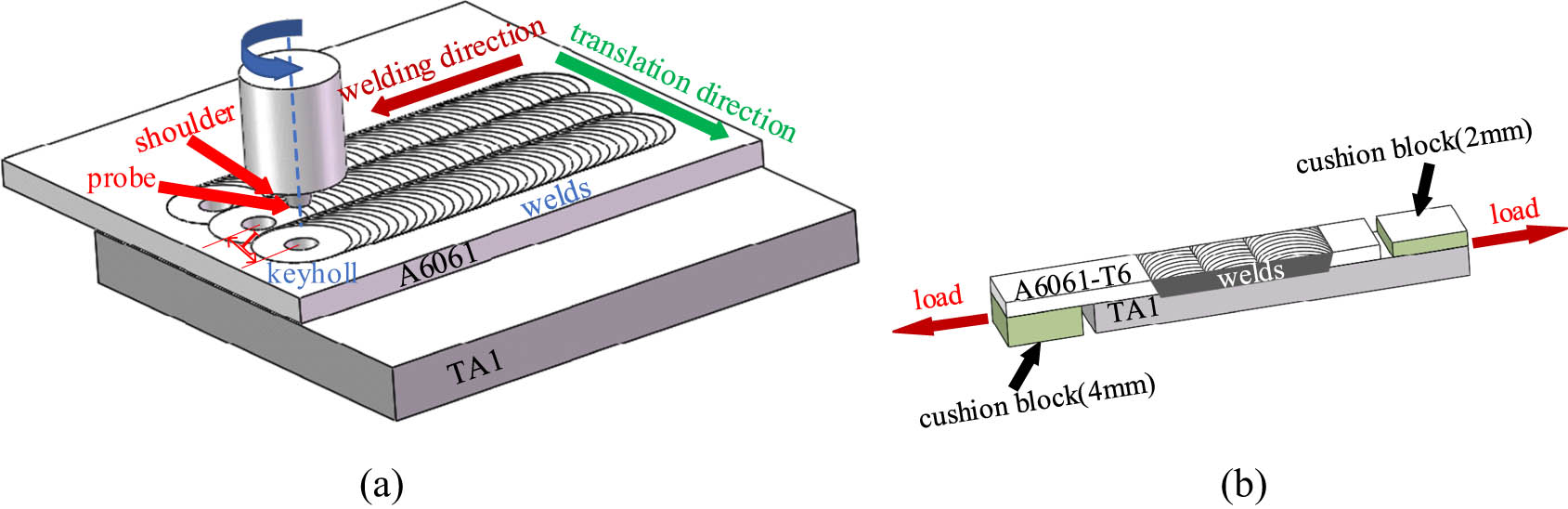

Industrial pure titanium TA1 plates and 6061-T6 aluminum alloy plates with dimensions of 150 mm × 75 mm × 4 mm and 150 mm × 75 mm × 2 mm, respectively, were used in the present study. The chemical compositions are shown in Tables 1 and 2, respectively. The surfaces of the pure titanium and aluminum alloy were ground by sandpaper and degreased with acetone before welding, then fixed on the self-improved friction stir machine with clamps. Continuous welding was adopted, which meant the tool was immediately translated a specific distance from the starting point for the next welding without any treatment after the previous welding was completed as shown in Figure 1a.

Chemical composition of 6061-T6 aluminum alloy (wt%)

| Cu | Si | Fe | Mn | Mg | Zn | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|

| 0.5 | 1.3 | 0.5 | 0.2 | 0.26 | 0.2 | 0.15 | 0.1 | Bal |

Chemical composition table of industrial pure titanium TA1 (wt%)

| Fe | Si | C | N | H | O | Ti |

|---|---|---|---|---|---|---|

| 0.15 | 0.1 | 0.05 | 0.03 | 0.015 | 0.15 | Bal |

Schematic diagram: (a) multi-pass FSW and (b) tensile-shear specimen.

The welding tool was made of tungsten steel alloy and consisted of a columnar shaped shoulder (10 mm) and a circular truncated cone-shaped probe (root: ϕ3.5 mm, tip: ϕ2.5 mm, length: 2.1 mm). During welding, the probe was mainly inserted into aluminum alloy while the shoulder plunge depth was 0.2 mm and the tool-tilting angle was 0°. The same welding parameters such as a constant rotating rate of 900 rpm and a fixed welding speed of 100 mm·min−1 were used during multi-pass friction stir lap welding (the welding parameters were optimized after lots of trial and error). The adjacent welds interval (L) of the same group welding experiment was equal, and the L value of the five sets of welding experiments were set to 0 (single-pass welding), 3, 6, 9, and 12 mm.

The tensile-shear test was carried out using a Zwick 100 kN instrument. The stretching speed was 0.5 mm·min−1. Three specimens were cut along the translation direction for each L value and were tested to obtain an average shear strength. On the upper side of the titanium plate and the lower side of the aluminum plate, compensation cushion blocks of 2 mm thickness and 4 mm thickness were placed, respectively, as shown in Figure 1b.

Specimens for microstructure examination were extracted along the translation direction. The surfaces of the specimens were sanded with 4,000-grit sandpaper and polished with an SiO2 suspension with a particle size of 0.04 μm, and then, the samples were etched with Keller’s reagent (1 mL HCl, 1.5 mL HNO3, 2.5 mL HF, and 95 mL H2O). Microstructural characteristics of the joints were observed by optical microscope (OM; DSX 510). The morphology of the bonding interface was investigated using scanning electron microscopy (SEM; JSM-7900F). The distribution of elements across the interface was examined by SEM equipped with an energy dispersive spectrometer (EDS). The interfacial intermetallic compounds were analyzed using an X-ray diffractometer (XRD; D-Max 2500). The microhardness near the interface was obtained using a microhardness tester (Q10A+).

3 Results and discussion

3.1 Macro- and micro-structure

The macroscopic structure of the cross-section of the lap joint under various welding parameters is shown in Figure 2. The numbers in the figure indicate the positions of the welds. Each set of process parameters used in this experiment has achieved the connection of Ti/Al dissimilar metals. The total weld width at the lap interface was defined as the effective bonding width (D). Obviously, compared with single-pass welding, multi-pass welding significantly increased the D value of the lap interface. Under each set of process parameters, the hooks on both sides of the weld were clearly visible. The special feature was that when L = 3 mm, the adjacent hooks were clearly crossed, accompanied by the generation of void defect around them.

Macrostructures of cross-sections of lap joints at (a) L = 0 mm, (b) L = 3 mm, (c) L = 6 mm, and (d) L = 9 mm.

Microstructural characteristics of the third weld of typical Ti/Al lap joint (L = 6) are shown in Figure 3. According to the report by Nandan et al. [22], the joint was divided into five zones: stir zone (SZ), thermo-mechanically affected zone (TMAZ), heat affected zone (HAZ), BM, and Ti/Al interface zone, as shown in Figure 3a. The grains of the BM (6061 aluminum alloy and TA1) had average diameters of 30.76 and 33.69 μm, respectively. Aluminum alloy is a high stacking fault energy material. The materials of the SZ on Al side underwent continuous dynamic recrystallization under the intense thermal–mechanical coupling during the friction stir welding process. That is, the sub-crystals constantly absorbed dislocation and increased misorientation, and the small angle grain boundary transformed into large angle grain boundary. Finally, the grains of SZ on the Al side (Figure 3b) reduced to 12.93 μm with no obvious directionality. This was in good agreement with that by Song et al. [23] on friction stir butt joint of Ti6Al4V and A6061 dissimilar metals. For the Ti side (Figure 3c), the length of the probe inserted into it was only 0.3 mm. Therefore, the thermal–mechanical coupling effect on the SZ was much weaker than that on the Al side, which made it difficult for dynamic recrystallization behavior to occur. Some of the grains of SZ on Ti side were deformed into long strips or broken into particles due to the “stir-extrusion” compound mechanical action of the tool. The grains of SZ on the Ti side had an average diameter of 20.64 μm. The grain size and morphology of the zone below the SZ on Ti side were close to the BM (Ti). TMAZ (Figure 3d) was composed of elongated grains and a few fine recrystallized grains, resulting from heat input and comparatively weak stirring effect. The average diameter of grains in TMAZ was 23.74 μm. The average diameter of grains in the HAZ (Figure 3e), obviously bigger than that in SZ and TMAZ, was 47.08 μm, which was attributed to the influence of heat. There was a thin interfacial layer formed between Ti/Al dissimilar metals, as shown in Figure 3f, indicating a successful combination. The explicit microstructure and phase composition on the interface were further studied using SEM-EDS and XRD. The average grain diameters are listed in Table 3.

OM macrostructure of L = 6: (a) overview, (b) SZ on the Al side, (c) SZ and zone below the SZ on the Ti side, (d) TMAZ, (e) HAZ, and (f) interface.

SEM images and EDS liner analysis results for interface from first weld to third weld of L = 3 mm and L = 12 mm: (a) first weld of L = 3 mm, (b) second weld of L = 3 mm, (c) third weld of L = 3 mm, (d) first weld of L = 12 mm, (e) second weld of L = 12 mm, and (f) third weld of L = 12 mm.

Average grain diameters of different zones of Al/Ti third lap welds (μm)

| Zones | L = 0 mm | L = 3 mm | L = 6 mm | L = 9 mm | L = 12 mm |

|---|---|---|---|---|---|

| SZ on the Al side | 11.86 | 12.79 | 12.53 | 12.21 | 12.05 |

| SZ on the Ti side | 18.46 | 21.35 | 20.64 | 19.15 | 18.94 |

| TMAZ | 22.03 | 24.35 | 23.74 | 23.26 | 22.87 |

| HAZ | 42.17 | 50.28 | 47.08 | 45.39 | 43.86 |

3.2 Interfacial characterization

SEM images and EDS liner analysis results for interface from first weld to third weld of L = 3 mm and L = 6 mm are shown in Figure 4. When L = 3 mm, after the initial welding, the material is subjected to welding temperature and stirring, which enhances the softening and plastic deformation ability of the material. When the interval is close, the second welding is pressed into the first welding zone, resulting in increased plastic flow of the material at the inter-shaft extrusion zone. The extruded material cannot be completely backfilled, resulting in extrusion accumulation occurring at the forward side and the formation of a small flash. Therefore, the lap interfaces at the three welds of L = 3 mm were all bent as shown in Figure 4(a)–(c). According to the elements distribution profiles, the content of Ti element and Al element had a gradual change process at the interface, which meant that a very thin diffusion layer was formed at the interface. The thicknesses of the diffusion layers at the interfaces of the three welds were 4.3, 7.2, and 8.4 μm, respectively. For L = 12 mm, the lap interface at the three welds was flat with the diffusion thickness of 4.3, 4.4, and 4.7 μm, respectively, as shown in Figure 4(d)–(f). The formation of the diffusion layer was attributed to the mixing, diffusion, and dissolution of Ti and Al, which formed a metallurgical bonding at the lap interface due to the influence of high welding temperature and severe deformation. The thicknesses of the diffusion layers at each weld interface under different welding conditions are shown in Table 4. The study on single-pass friction stir lap welding joints of AA6061 and Ti6Al4V conducted by Yu et al. [16] showed that temperature was the main factor affecting the thickness of the diffusion layer. In this experiment, under the same L value, as the number of weld passes increased, the diffusion layer gradually thickened. This was because the heat generated by the completed welding passes facilitated the diffusion of atoms at the weld interface during subsequent passes. The thickness of the diffusion layer at the first weld interface remained consistent across various L values, ranging from 4 to 4.4 μm. As the L value increased, the previously mentioned promotion effect was relatively weakened. Therefore, the thickness of the diffusion layer at the subsequent weld interface is reduced (Table 4).

Thicknesses of the diffusion layers at each weld under different L values

| Welding parameters | The first pass (μm) | The second pass (μm) | The third pass (μm) |

|---|---|---|---|

| L = 0 mm | 4.2 | — | — |

| L = 3 mm | 4.3 | 7.2 | 8.4 |

| L = 6 mm | 4 | 5.8 | 7.3 |

| L = 9 mm | 4.2 | 4.8 | 5.6 |

| L = 12 mm | 4.3 | 4.4 | 4.7 |

The SEM profiles and EDS mapping results of the various regions marked in Figure 2 are shown in Figure 5. The pure titanium, softened by the heat generated through high-speed friction with the tool, was stirred into the aluminum alloy under the combined action of the downward extrusion force and friction force of the tool. The pure titanium entering the Al side mainly existed in the connection interface in the following three forms: (1) hook on the Al side. Since the shoulder had a certain plunge depth, the height of the pure titanium plastic material flow entering the aluminum alloy side was reduced by the downward pressure in the thickness direction of the weld, resulting in the formation of a hook on the aluminum alloy side near the interface. Therefore, the hook was surrounded by Al elements and its interior was mainly Ti element, as shown in Figure 5a. When L = 3 mm, adjacent hooks crossed, and the hook formed in the previous pass affected the material flow in the corresponding zone during the subsequent welding. This especially impacted the part surrounded by it, leading to the formation of an obvious void defect. Meanwhile, the plastic material flow in the subsequent welding process exerted a scouring effect on the former hook, leading to its noticeable lateral extension, as shown in Figure 5b. The distribution of elements in region B was similar to that in region A. (2) Ti/Al composite laminated structure. The tool’s simultaneous axial rotation and linear movement along the welding direction resulted in uneven stirring of the material due to its combined normal and tangential actions. Meanwhile, due to the difference in physical properties between aluminum alloy and pure titanium, the material flow in this area also exhibited a certain degree of unevenness. In the end, the microstructure of the region reveals an aluminum/titanium composite laminated structure, as shown in Figure 5a. (3) Titanium particles reinforced the aluminum matrix composite structure, which appeared on the Al side close to the interface. Under the action of the tool, pure titanium, which differs from aluminum alloy in performance, fractured and mixed into the aluminum alloy side. This resulted in a weak flow in certain areas. Some of the pure titanium mixed into the Al side did not form a continuous composite laminated structure. Instead, it formed titanium particles of various shapes dispersed in the aluminum alloy matrix, as shown in Figure 5c. Moreover, a thin diffusion layer whose brightness was between Ti element and Al element in EDS mapping result was observed on the region C (interface) as shown in Figure 5c, which was consistent with EDS liner analysis results. The chemical compositions listed in Table 5 indicate the presence of Ti/Al intermetallic compounds in all three regions, except for Ti and Al. When L = 3 mm, the Ti/Al intermetallic compound may have been composed of TiAl3 and TiAl, while only TiAl3 existed when L = 12 mm.

SEM profiles and EDS mapping results of different regions marked in Figure 2: (a) region A, (b) region B, and (c) region C.

EDS results of the points marked in Figure 5 (at%)

| Points | Al | Ti | Possible phases |

|---|---|---|---|

| A | 67.25 | 30.65 | Ti + TiAl3 |

| B | 62.94 | 30.54 | Ti + TiAl3 |

| C | 80.24 | 18.13 | Al + TiAl3 |

| D | 3.12 | 94.74 | Al + Ti |

| E | 78.87 | 13.42 | Al + TiAl |

| F | 92.16 | 5.38 | Al + Ti |

| G | 62.49 | 35.54 | Ti + TiAl3 |

| H | 73.43 | 24.91 | TiAl3 |

| I | 32.57 | 65.31 | TiAl + Ti |

In order to identify the phase structure, XRD analysis was performed on both sides of the bonding interface at various L values. The XRD spectra obtained are shown in Figure 6, revealing that the phase structure in the interfaces primarily consists of Al, Ti, and a few new phases of TiAl3. In addition, a trace amount of the TiAl new phase was detected when L = 3 mm. XRD analysis results coincided with the EDS results. In multi-pass welding, the interface microstructure and phase become more complicated as the L value decreases. When L = 3 mm, the type and quantity of intermetallic compounds at the interface were the highest. The analysis results suggest that the degree of material mixing, concentration of elements, and welding thermal cycle process varied at different locations along the bonding interface. This variability led to the formation of various types of Ti/Al intermetallic compounds at the joint interface. The types of Ti/Al intermetallic compounds are related to the free energy of formation in the Ti/Al binary system as a function of temperature, as calculated by Kattner et al. [24].

XRD spectrums of the bonding interface under different welding parameters: (a) Al side and (b) Ti side.

3.3 Fracture locations and tensile-shear properties of joints

The failed tensile-shear specimens are shown in Figure 7a. The fracture morphology is shown in Figure 8. Three important observations can be drawn. First, the fracture modes of multi-pass welding and single-pass welding showed obvious differences. The former with increased D value improved the tensile-shear resistance of lap interface. In this case, according to the study of Liu et al. [25], the advancing side of the Al side was the weakest zone in the joint. Hook and brittle intermetallic compounds around it near the AS-TMAZ were likely to lead to stress concentration, causing cracks to initiate here and extend along the AS-TMAZ, eventually failed there; the latter was sheared from the interface, which was consistent with the study of Zhao et al. [26]. Second, in multi-pass welding, the fracture occurred at a position almost perpendicular to the tensile axis. Research by Ren et al. [27] inferred that the fracture path was closely related to the hardness distribution of the AS-TMAZ. Under tensile stress, the joint stretched and deformed along the optimal path according to the principle of minimum potential energy until it failed, and finally formed a traction fracture. Third, as the L value increased, failure occurred with more obvious plastic deformation and necking. This was due to the fact that the thermal influence between adjacent welds weakened as the L value increased, resulting in weakening of the grain growth trend near the third weld AS-TMAZ of the aluminum alloy, as listed in Table 3. Meanwhile, there were relatively few brittle intermetallic compounds generated around the hook, as shown in Figure 6. Therefore, the joint withstood more plastic deformation. Based on the fracture morphology, the region below the fracture surface is observed to be relatively flat, exhibiting few dimples and a small amount of in-plane tearing. Brittle characteristics are evident in this area, indicative of low bonding strength at the connection interface. This lower fracture region corresponds to the interface between the hook and the aluminum. As the hook is primarily composed of titanium, the lower section of the aluminum plate becomes characterized as the joint surface between dissimilar materials results in reduced connection strength. In contrast, numerous dimples are densely arranged in other fracture areas. Large dimples are frequently accompanied by smaller ones, which is typical of ductile fracture. Concurrently, it was found that an increase in welding spacing tends to result in smaller and deeper dimples, signifying an enhancement in mechanical properties. When the welding distance is close, the concentrated heat input from multiple welds leads to increased heat accumulation within the HAZ. Consequently, grain growth and the growth of its second phase become more pronounced. The fracturing loads of the tensile-shear specimens under different L values are shown in Figure 7b. The fracturing loads of multi-pass welding were significantly greater than those of the single-pass welding. When the value of L increased from 0 to 3 mm, the fracture load increases from 3,861 to 4,730 N. The effective bonding width is a crucial factor that influences the tensile-shear performance of lap joints. Combined with the analysis results of Figure 2, although there were obvious void defects at the bonding interface when L = 3 mm, the much larger D value compared with single-pass welding significantly improved the tensile-shear strength. Therefore, the lap joint exhibited a significantly higher fracturing load than that of single-pass welding and was not separated from the lap interface. Meanwhile, the superfluous intermetallic compounds at the interface led to remarkable volume variation and higher residual stress [28]. The void defect disappeared (Figure 2) and the intermetallic compounds content obviously reduced (Figure 6) with the L value varying from 3 to 6 mm, resulting in the load increasing from 4,730 to 6,160 N at a much faster rate. The D value of the lap interface no longer changed and there was no void defect with the L value increasing from 6 to 12 mm. Therefore, the decrease of intermetallic compounds content around the hook and the increase of grain size near TMAZ (Table 3) became dominant factors, whose changes gradually decrease. The fracturing load increased from 6,160 to 7,150 N at a gradually decreasing rate.

Tensile-shear test results under different welding parameters: (a) appearance of failed specimens and (b) the fracturing load and rate of change.

Fracture morphology at L = 3 mm, L = 6 mm, L = 9 mm, and L = 12 mm: (a) L = 3 mm, (b) enlarged morphology of L = 3 mm region, (c) L = 6 mm, (d) enlarged morphology of L = 6 mm region, (e) L = 9 mm, (f) enlarged morphology of L = 9 mm region, (g) L = 12 mm, and (h) enlarged morphology of L = 12 mm region.

3.4 Microhardness distribution

The microhardness near the lap interface of each weld under different L values are shown in Figure 9. Comparing the hardness near the lap interface under different welding parameters, the following rules can be found the hardness profiles of multi-pass and single-pass welds show identical trends. The hardness value of the Al side was the lowest, and the hardness of the pure titanium side near the interface was significantly increased. Subsequently, the hardness value of the pure titanium side reduced and fluctuated around BM (Ti). This was because the SZ on Al sides under different welding parameters were all composed of dynamically recrystallized fine grains with little difference in size, while work hardening caused by the strong stirring effect of the tool occurred on the Ti side near the interface. The overall hardness values of multi-pass welding were slightly lower than those of single-pass welding. The hardness values of the Al side, the lap interface, and the SZ on the Ti side under different L values of multi-pass welding fluctuate around 75, 162, and 230 HV, respectively. In contrast, for the corresponding parts of the single-pass welding, the hardness values were 80, 165, and 238 HV, respectively. The slight decrease in overall hardness values of multi-pass welding compared with single-pass welding was attributed to its higher heat input, which resulted in a larger grain size of the entire SZ larger than that of single-pass welding.

Hardness change curve near the lap interface of each weld: (a) L = 0 mm, (b) L = 3 mm, (c) L = 6 mm, and (d) L = 9 mm.

4 Conclusions

Ti/Al joints with high-quality lap interface were fabricated by multi-pass friction stir lap weld. The microstructure and mechanical properties of the Ti/Al lap interface were studied. The conclusions are as follows:

The interface bonding mechanism was still mainly atomic diffusion connection. The thicknesses of the interfacial diffusion layers at the first weld of multi-pass welding under different L values were approximately the same as that of single-pass welding, in the range of 4–4.4 μm. The diffusion layers of subsequent welds gradually became thicker, varying from 4.4 to 8.4 μm.

Ti and Al atoms diffuse into each other and form intermetallic compounds due to the action of welding thermal cycle. TiAl3 was the major product of the Ti/Al reaction in multi-pass friction stir lap weld as a small fraction of Ti/Al also formed at the interface when L = 3 mm. Meanwhile, the excessive intermetallic compounds formed at the interface reduced the tensile-shear strength.

Compared with single-pass welding, multi-pass welding resulted in a significantly wider effective interface bonding width, with the maximum fracturing load reaching 7,150 N. The tensile-shear specimens failed near the AS-TMAZ on Al side and exhibited greater plastic deformation resistance. The overall hardness distribution law of multi-pass welding was similar to that of single-pass welding, while the hardness value slightly reduced.

Acknowledgments

This work was supported by the Major Science and Technology Projects in Sichuan Province (Grant No. 2023ZDZX0026).

-

Funding information: This work was supported by the Major Science and Technology Projects in Sichuan Province (Grant No. 2023ZDZX0026).

-

Author contributions: Guyangyao Tang: methodology, investigation, experiment, formal analysis, visualization, writing – original draft; Zhanrui Wang: methodology, experiment, resources, analysis; Zhuoran Ping: resources, analysis; Xuchong Yuan: analysis; Hui Yu: writing – review & editing, guidance, supervision.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Ni, R. Y., L. Liu, Y. F. Shen, F. J. Gao, Y. F. Yan and M. W. Liu. Friction forge riveting of AA6061-T6 and TA2 plates with large diameter TA2 titanium rivets. Journal of Materials Processing Technology, Vol. 294, 2021, pp. 117–119.10.1016/j.jmatprotec.2021.117119Search in Google Scholar

[2] Bang, H. S., H. S. Bang, H. J. Song and S. M. Joo. Joint properties of dissimilar Al6061-T6 aluminum alloy/Ti–6%Al–4%V titanium alloy by gas tungsten arc welding assisted hybrid friction stir welding. Materials & Design, Vol. 51, No. 5, 2013, pp. 545–551.10.1016/j.matdes.2013.04.057Search in Google Scholar

[3] Tomashchuk, I., P. Sallamand, E. Cicala, P. Peyre and D. Grevey. Direct keyhole laser welding of aluminum alloy AA5754 to titanium alloy Ti6Al4V. Journal of Materials Processing Technology, Vol. 217, 2015, pp. 96–104.10.1016/j.jmatprotec.2014.10.025Search in Google Scholar

[4] Casalino, G., M. Mortello and P. Peyre. Yb-YAG laser offset welding of AA5754 and T40 butt joint. Journal of Materials Processing Technology, Vol. 223, 2015, pp. 139–149.10.1016/j.jmatprotec.2015.04.003Search in Google Scholar

[5] Liu, K., Y. J. Li, S. Z. Wei and J. Wang. Interfacial microstructural characterization of Ti/Al joints by gas tungsten arc welding. Materials and Manufacturing Processes, Vol. 29, No. 8, 2014, pp. 969–974.10.1080/10426914.2013.864414Search in Google Scholar

[6] Ma, Z. P., C. W. Wang, H. C. Yu, J. C. Yan and H. R. Shen. The microstructure and mechanical properties of fluxless gas tungsten arc welding-brazing joints made between titanium and aluminum alloys. Materials & Design, Vol. 45, No. 6, 2013, pp. 72–79.10.1016/j.matdes.2012.09.007Search in Google Scholar

[7] Sun, Q. J., J. Z. Li, Y. B. Liu, P. B. Li, P. W. Xu and J. C. Feng. Microstructural characterization and mechanical properties of Al/Ti joint welded by CMT method – assisted hybrid magnetic field. Materials & Design, Vol. 116, 2017, pp. 316–324.10.1016/j.matdes.2016.12.025Search in Google Scholar

[8] Chularis, A. A., A. B. Kolpachev, O. V. Kolpacheva and V. M. Tomashevskii. Electron structure and properties of intermetallic compounds in titanium-metal dissimilar joints. Welding International, Vol. 9, 1995, pp. 812–814.10.1080/09507119509548899Search in Google Scholar

[9] Karlsson, L., E. L. Berqvist and H. Larsson. Application of friction stir welding to dissimilar welding. Welding in the World, Vol. 46, No. 1, 2002, pp. 10–14.10.1007/BF03266360Search in Google Scholar

[10] Elrefaey, A., M. Gouda, M. TaKahashi and K. Ikeuchi. Characterization of aluminum/steel lap joint by friction stir welding. Journal of Materials Engineering and Performance, Vol. 14, No. 1, 2005, pp. 10–17.10.1361/10599490522310Search in Google Scholar

[11] Huseyin, U., D. D. Claudio, A. Alberto, G. Tommaso and C. Gambaro. Friction stir welding of dissimilar Al 6013-T4 To X5CrNi18-10 stainless steel. Materials & Design, Vol. 26, 2005, pp. 41–46.10.1016/j.matdes.2004.04.002Search in Google Scholar

[12] Firouzdor, V. and S. Kou. Al-to-Cu friction stir lap welding. Metallurgical and Materials Transactions A, Vol. 43, 2012, pp. 303–315.10.1007/s11661-011-0822-9Search in Google Scholar

[13] Chen, Y. C. and K. Nakata. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Materials & Design, Vol. 30, 2009, pp. 469–474.10.1016/j.matdes.2008.06.008Search in Google Scholar

[14] Wu, A. P., Z. H. Song, K. Nakata, J. S. Liao and L. Zhou. Interface and properties of the friction stir welded joints of titanium alloy Ti6Al4V with aluminum alloy 6061. Materials & Design, Vol. 71, No. 6, 2015, pp. 85–92.10.1016/j.matdes.2014.12.015Search in Google Scholar

[15] Aonuma, M. and K. Nakata. Dissimilar metal joining of 2024 and 7075 aluminium alloys to titanium alloys by friction stir welding. Materials Transactions, Vol. 52, No. 5, 2011, pp. 948–952.10.2320/matertrans.L-MZ201102Search in Google Scholar

[16] Yu, M. R., H. Y. Zhao, Z. H. Jiang, F. Guo, L. Zhou and X. G. Song. Microstructure and mechanical properties of friction stir lap AA6061-Ti6Al4V welds. Journal of Material Processing Technology, Vol. 270, 2019, pp. 274–284.10.1016/j.jmatprotec.2019.03.007Search in Google Scholar

[17] Wei, Y. N., J. L. Li, J. T. Xiong, F. Huang, F. S. Zhang and S. H. Raza. Joining aluminum to titanium alloy by friction stir lap welding with cutting pin. Materials Charaterization, Vol. 71, No. 5, 2012, pp. 1–5.10.1016/j.matchar.2012.05.013Search in Google Scholar

[18] Chen, Y. H., N. Quan and L. M. Ke. Interface characteristic of friction stir welding lap joints of Ti/Al dissimilar alloys. Transactions of Nonferrous Metals Society of China, Vol. 22, No. 2, 2012, pp. 299–304.10.1016/S1003-6326(11)61174-6Search in Google Scholar

[19] Dressler, U., G. Biallas and U. A. Mercado. Friction stir welding of titanium alloy TiAl6V4 to aluminum alloy AA2024-T3. Materials Science and Engineering A, Vol. 526, No. 1–2, 2009, pp. 113–117.10.1016/j.msea.2009.07.006Search in Google Scholar

[20] Muribwathoho, O., V. Msomi, S. Mabuwa, and S. S. Motshwanedi. Impact of multi-pass friction stir processing on microhardness of AA1050/AA6082 dissimilar joints. Materials & Design, Vol. 57, 2014, pp. 269–278.Search in Google Scholar

[21] Mirjavadi, S. S., M. Alipour, A. M. S. Hamouda, A. Matin, S. kord, B. M. Afshari, et al. Effect of multi-pass friction stir processing on the microstructure, mechanical and wear properties of AA5083/ZrO2 nanocomposites. Journal of Alloys and Compounds, Vol. 726, No. 5, 2017, pp. 1262–1273.10.1016/j.jallcom.2017.08.084Search in Google Scholar

[22] Nandan, R., T. Debroy and H. K. D. H. Bhadeshia. Recent advances in friction-stir welding – process, weldment structure and properties. Progress in Materials Science, Vol. 53, No. 6, 2008, pp. 98–1023.10.1016/j.pmatsci.2008.05.001Search in Google Scholar

[23] Song, Z. H., K. Nakata, A. P. Wu, J. S. Liao and L. Zhou. Influence of probe offset distance on interfacial microstructure and mechanical properties of friction stir butt welded joint of Ti6Al4V and A6061 dissimilar alloys. Material & Design, Vol. 57, 2014, pp. 269–278.10.1016/j.matdes.2013.12.040Search in Google Scholar

[24] Kattner, U. R., J. C. Lin and Y. A. Chang. Thermodynamic assessment and calculated of the Ti/Al system. Metallurgical and Materials Transactions A, Vol. 23, 1992, pp. 2081–2090.10.1007/BF02646001Search in Google Scholar

[25] Liu, H. J., H. Fujii, M. Maeda and K. Nogi. Tensile properties and fracture locations of friction-stir-welded joints of 2017-T351 aluminum alloy. Journal of Material Processing Technology, Vol. 142, No. 3, 2003, pp. 692–696.10.1016/S0924-0136(03)00806-9Search in Google Scholar

[26] Zhao, H. Y., M. R. Yu, Z. H. Jiang, L. Zhou and X. G. Song. Interfacial microstructure and mechanical properties of Al/Ti dissimilar joints fabricated via friction stir welding. Journal of Alloys and Compounds, Vol. 789, 2019, pp. 139–149.10.1016/j.jallcom.2019.03.043Search in Google Scholar

[27] Ren, S. R., Z. Y. Ma and L. Q. Chen. Effect of welding parameters on tensile properties and fracture behavior of friction stir welded Al–Mg–Si alloy. Scripta Materialia, Vol. 56, No. 1, 2007, pp. 69–72.10.1016/j.scriptamat.2006.08.054Search in Google Scholar

[28] Tseng, W. T. Calculations of lattice parameters and reaction-induced volume and stress changes for Al(Ti) alloys. Applied Physics, Vol. 79, No. 7, 1996, pp. 3521–3527.10.1063/1.361403Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Endpoint carbon content and temperature prediction model in BOF steelmaking based on posterior probability and intra-cluster feature weight online dynamic feature selection

- Thermal conductivity of lunar regolith simulant using a thermal microscope

- Multiobjective optimization of EDM machining parameters of TIB2 ceramic materials using regression and gray relational analysis

- Research on the magnesium reduction process by integrated calcination in vacuum

- Microstructure stability and softening resistance of a novel Cr-Mo-V hot work die steel

- Effect of bonding temperature on tensile behaviors and toughening mechanism of W/(Ti/Ta/Ti) multilayer composites

- Exploring the selective enrichment of vanadium–titanium magnetite concentrate through metallization reduction roasting under the action of additives

- Effect of solid solution rare earth (La, Ce, Y) on the mechanical properties of α-Fe

- Impact of variable thermal conductivity on couple-stress Casson fluid flow through a microchannel with catalytic cubic reactions

- Effects of hydrothermal carbonization process parameters on phase composition and the microstructure of corn stalk hydrochars

- Wide temperature range protection performance of Zr–Ta–B–Si–C ceramic coating under cyclic oxidation and ablation environments

- Influence of laser power on mechanical and microstructural behavior of Nd: YAG laser welding of Incoloy alloy 800

- Aspects of thermal radiation for the second law analysis of magnetized Darcy–Forchheimer movement of Maxwell nanomaterials with Arrhenius energy effects

- Use of artificial neural network for optimization of irreversibility analysis in radiative Cross nanofluid flow past an inclined surface with convective boundary conditions

- The interface structure and mechanical properties of Ti/Al dissimilar metals friction stir lap welding

- Significance of micropores for the removal of hydrogen sulfide from oxygen-free gas streams by activated carbon

- Experimental and mechanistic studies of gradient pore polymer electrolyte fuel cells

- Microstructure and high-temperature oxidation behaviour of AISI 304L stainless steel welds produced by gas tungsten arc welding using the Ar–N2–H2 shielding gas

- Mathematical investigation of Fe3O4–Cu/blood hybrid nanofluid flow in stenotic arteries with magnetic and thermal interactions: Duality and stability analysis

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part II

- Effects of heat treatment on microstructure and properties of CrVNiAlCu high-entropy alloy

- Enhanced bioactivity and degradation behavior of zinc via micro-arc anodization for biomedical applications

- Study on the parameters optimization and the microstructure of spot welding joints of 304 stainless steel

- Research on rotating magnetic field–assisted HRFSW 6061-T6 thin plate

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part II

- Microwave hybrid process-based fabrication of super duplex stainless steel joints using nickel and stainless steel filler materials

- Special Issue on Polymer and Composite Materials and Graphene and Novel Nanomaterials - Part II

- Low-temperature corrosion performance of laser cladded WB-Co coatings in acidic environment

- Special Issue for the conference AMEM2025

- Effect of thermal effect on lattice transformation and physical properties of white marble

Articles in the same Issue

- Research Articles

- Endpoint carbon content and temperature prediction model in BOF steelmaking based on posterior probability and intra-cluster feature weight online dynamic feature selection

- Thermal conductivity of lunar regolith simulant using a thermal microscope

- Multiobjective optimization of EDM machining parameters of TIB2 ceramic materials using regression and gray relational analysis

- Research on the magnesium reduction process by integrated calcination in vacuum

- Microstructure stability and softening resistance of a novel Cr-Mo-V hot work die steel

- Effect of bonding temperature on tensile behaviors and toughening mechanism of W/(Ti/Ta/Ti) multilayer composites

- Exploring the selective enrichment of vanadium–titanium magnetite concentrate through metallization reduction roasting under the action of additives

- Effect of solid solution rare earth (La, Ce, Y) on the mechanical properties of α-Fe

- Impact of variable thermal conductivity on couple-stress Casson fluid flow through a microchannel with catalytic cubic reactions

- Effects of hydrothermal carbonization process parameters on phase composition and the microstructure of corn stalk hydrochars

- Wide temperature range protection performance of Zr–Ta–B–Si–C ceramic coating under cyclic oxidation and ablation environments

- Influence of laser power on mechanical and microstructural behavior of Nd: YAG laser welding of Incoloy alloy 800

- Aspects of thermal radiation for the second law analysis of magnetized Darcy–Forchheimer movement of Maxwell nanomaterials with Arrhenius energy effects

- Use of artificial neural network for optimization of irreversibility analysis in radiative Cross nanofluid flow past an inclined surface with convective boundary conditions

- The interface structure and mechanical properties of Ti/Al dissimilar metals friction stir lap welding

- Significance of micropores for the removal of hydrogen sulfide from oxygen-free gas streams by activated carbon

- Experimental and mechanistic studies of gradient pore polymer electrolyte fuel cells

- Microstructure and high-temperature oxidation behaviour of AISI 304L stainless steel welds produced by gas tungsten arc welding using the Ar–N2–H2 shielding gas

- Mathematical investigation of Fe3O4–Cu/blood hybrid nanofluid flow in stenotic arteries with magnetic and thermal interactions: Duality and stability analysis

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part II

- Effects of heat treatment on microstructure and properties of CrVNiAlCu high-entropy alloy

- Enhanced bioactivity and degradation behavior of zinc via micro-arc anodization for biomedical applications

- Study on the parameters optimization and the microstructure of spot welding joints of 304 stainless steel

- Research on rotating magnetic field–assisted HRFSW 6061-T6 thin plate

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part II

- Microwave hybrid process-based fabrication of super duplex stainless steel joints using nickel and stainless steel filler materials

- Special Issue on Polymer and Composite Materials and Graphene and Novel Nanomaterials - Part II

- Low-temperature corrosion performance of laser cladded WB-Co coatings in acidic environment

- Special Issue for the conference AMEM2025

- Effect of thermal effect on lattice transformation and physical properties of white marble