Abstract

In this study, magnetic field–assisted high rotational-speed stir friction welding (MFA-HRFSW) and high rotational-speed friction stir welding (HRFSW) were carried out on a 1-mm-thick 6061-T6 aluminium alloy plate, and the macroscopic morphology, microstructure, corrosion for, mechanical properties and equipment tolerance of the two types of welded joints were studied and compared. By establishing a mathematical model of the MFA-HRFSW process, the temperature field characteristics of this process were analysed, revealing that the application of a rotating magnetic field during the friction stir welding (FSW) process influences the welding quality. The test results show that through the application of a magnetic field during the FSW process, the welding load of the equipment is reduced, and the peak axial force during the stabilization phase is reduced by 18.7%. Electrochemical tests show that the corrosion rate of 6061-T6 aluminium alloys is reduced when using MFA-HRFSW. This is mainly attributed to the presence of the rotating magnetic field in FSW, which endows the 6061-T6 aluminium alloys with finer grains, thereby improving the tensile strength and hardness of the alloys. This study provides new ideas for the development of FSW technology assisted by the application of an external energy source.

1 Introduction

Friction stir welding is a common method to connect non-ferrous metal materials (especially aluminium alloy) [1,2,3]. Adequate heat production and material flow ensure the production of good performance, defect-free friction stir welded joints [4,5]. However, the tiny tool used in the HRFSW process leads to inadequate stirring. Furthermore, the forward side of the plastic metal material often appears to flow unevenly, and the root of the weld exhibits clear holes, tunnels and other defects, which deteriorate the quality of the welded joint [6,7]. In order to improve the plastic flow of the metal and the grain refinement of the joint during FSW, extensive research has been carried out, such as ultrasonic vibration–assisted FSW [8,9,10], Laser-assisted FSW [11,12], and induction heating-assisted FSW [13] and so on.

Ahmad et al. [14] conducted research on laser-assisted FSW of steel using numerical simulation technology. The laser-assisted FSW increased the traverse speed to 1,500 mm·min−1, significantly higher than the results of conventional FSW of steel, and the axial force of the equipment was greatly reduced. Deng et al. [15] used high-frequency induction heating-assisted FSW to weld NiTi/Ti6Al4V, eliminating the cracks and tunnel defects caused by insufficient plastic fluidity and welding stress in the traditional friction stir welding process, and obtaining defect-free joints. Liu et al. [16] used ultrasonic-assisted FSW to weld 3-mm-thick 2024Al-T4 rolled plates. The results showed that the ultrasonic energy had a positive effect on the volume, flow rate, and strain/strain rate of the deformed material. However, for the welding of thin plates, the above methods face challenges in easily controlling welding temperature and minimizing welding defects. Additionally, there are limitations related to complex welding equipment, high welding costs, and significant energy loss.

With the rapid development of modern industry, utilizing magnetic field–assisted welding technology has been widely used in metal metallurgy, casting, and heat treatment, as well as laser welding, arc welding, and other fields, and it has a very promising development prospect. According to the magnetoplastic effect [17,18,19], the density and distribution characteristics of the electron cloud, the spin moment of the electrons will lead to the dispersion or bias of alloying elements inside the crystal. This will result in a change in the slip of the atomic layers, the shaping of the metal, and an increase in dislocation density [20]. Based on previous research, we proposed a new rotating-magnetic-field-assisted, ultra-high-rotation-speed friction stir welding (MFA-HRFSW) method for the butt joint testing of 1-mm-thick 6061-T6 aluminium alloy ultra-thin plates to enhance the fluidity of the metal inside the weld and study its mechanism, microstructure and mechanical properties [21]. Based on this previous work, in the present study, we establish a mathematical model of the MFA-HRFSW process, compare the variation in the axial force of the equipment during the MFA-HRFSW and HRFSW process of thin 6061-T6 aluminium alloy plates, and compare the electrochemical corrosion performance of the welded joints obtained via MFA-HRFSW and HRFSW.

2 Mathematical modelling and experimental investigations

2.1 Mathematical modelling

MFA-HRFSW is a method in which there exists a strong magnetic field in the region between the end of the tool and the surface of the workpiece to be welded, which assists the stirring needle in the mechanical.

The device used to generate the magnetic field during the MFA-HRFSW process could be adjusted to control the distance and inclination of the magnetic gap between the magnetically conductive lugs and the weld seam. The lug possessed S polarity, which matched and adjusted the magnetic field strength (Figure 1). The pad and table were made of stainless steel, which is not magnetic. A strong NdFeB magnet was placed directly below the tool, and the upper end was magnetic; the magnet surface facing the string needle possessed N polarity. The NdFeB magnet was fixed on an iron slider, which was connected to the movement via connecting rods, keeping the spatial position relative to the tool stationary.

Schematic diagram of magnetic-field-assisted high rotation speed friction stir welding.

Figure 1 shows the schematic of the MFA-HRFSW process. The NdFeB magnet created a strong magnetic field, which acted on the weld area and improved the weld seam. Due to the high rotation speed and the NdFeB magnet, the magnetic induction lines are concentrated in the centre of the weld seam, and during the movement of the aluminium metal plate, electromagnetic forces are generated inside the weld seam, inducing an electric field on the aluminium plate and creating eddy currents. These eddy currents both heat up the aluminium plate (thermal effect) and generate an electromagnetic force on the locally melted metal [21].

Figure 2 is a mathematical model of the magnetic field–assisted welding zone. A sector-shaped unit in the plate was located below the rotating tool, which had a thickness δ, a sector radius r, and an angle dφ. The resistance of this part was calculated as follows:

Mathematical model.

Only the uniform magnetic field distribution in the plate is considered to simplify the mathematical model.

Assuming magnetic field distribution is uniform to simplify the mathematical model.

According to the power maximization condition, the external resistance of the eddy current micro-element is assumed to be R′. By setting R = R′, according to Ohm’s law:

According to the equation of the Lorentz force, one obtains:

Then, the damping force ƒ of the eddy current damper generated by the eddy currents is expressed as follows:

Since the magnetic field generated by the permanent magnet is not uniformly distributed in the three-dimensional space, the magnetic field generated by the induced eddy currents will itself interact with the external magnetic field generated by the permanent magnet, thus offsetting part of the applied magnetic field.

where ω represents the angular velocity, and n represents the rotational speed. The torque M exerted onto the plate area is

By setting

According to the above mathematical model, with the increase in the rotation speed of the magnet, the force on the metal flow process becomes more significant.

2.2 Materials and methods

In this experiment, the high-speed friction stir welding machine developed by the research group was used, and the limit stable speed was 21,000 rpm. Figure 3(a) shows a physical picture of a magnetic field–assisted high-speed friction stir welding device. Figure 3(b) shows the magnetic field auxiliary device, where the clamping sleeve of the strong NdFeB magnet is fixed on the tool. Two identical strong magnets are installed in the clamping sleeve, and two pure iron rods are inserted in the extremity of the strong NdFeB magnets, which are bent at 40°. The magnet extremity is close to the extremity of the shaft shoulder, and the pure iron rods have a strong permeability and can be completely magnetized, thus generating a magnetic field at the extremity of the shaft shoulder and the stirring needle. To avoid the burnout of the equipment motor due to excessive torque during high-speed operation, the upper limit of the welding rotational speed parameter in this experiment is set at 12,000 rpm. Figure 3(c) shows the pressure sensor, which was used to detect the change in axial force during the welding process.

Physical picture of the device: (a) layout of the rotating magnetic field-assisted high-speed friction stir welding device; (b) coaxial rotating magnetic field generator; (c) pressure sensor beneath the workbench.

The base metal (BM) was a 1-mm-thick 6061-T6 rolled plate with a hardness and ultimate tensile strength of 95 HV and 290 MPa, respectively. Before welding, the welded parts were polished and cleaned to remove the oxide film, and after welding, the metallographic specimens (size: 10 × 20 mm2) were cut via wire cutting. During the welding process, the plunge depth is controlled at 0.1 mm. The tensile test was carried out using a WDW miniature universal electronic tensile machine, and the tensile speed was set to 2 mm·min−1; the results were averaged over three independent measurements. After grinding and polishing the metallographic specimens, etching with Keller’s reagent (95 mL H2O + 2.5 mL HNO3 + 1.5 mL HCl + 1 mL HF), and finally cleaning and blow drying with alcohol, the microstructure of the weld area and the tensile fracture were observed via optical microscopy (OM) and scanning electron microscopy (SEM). The microhardness was measured using a fully automatic KN30S microhardness tester at a loading pressure of 100 g (HV0.1) and a loading time of 20 s; the microhardness was measured in 50 points along the horizontal direction of the cross-section to obtain the spatial variation of the hardness. The electron backscatter diffraction (EBSD) test samples were prepared via electrolytic polishing, and the grain size distribution and tissue structure deformation of the base material and the weld core area were analysed using an EBSD system. The electrochemical test was performed at 25°C with Autolab using a three-electrode system. The counter electrode was a Pt sheet, the reference electrode was a saturated calomel electrode, and the specimen was connected to the working electrode. The open circuit potential (OCP) time was 1,800 s, and the result was the average of three independent measurements. The corrosive environment was a 3.5 wt% NaCl aqueous solution, the exposure area was 0.25 cm2, and the frequency range was 0.1–105 Hz.

3 Results and discussion

3.1 Macro forming analysis

Figure 4 shows the surface appearance of the HRFSW and MFA-HRFSW for different traverse speeds. The surface of the HRFSW weld shows large burrs and uneven fish-scale patterns; the surface of the MFA-HRFSW weld is flatter and smoother with a more detailed and uniform texture. A possible explanation for this phenomenon is that the application of the axial rotating magnetic field may assist the extrusion of the weld surface metal through the shoulder of the tool and the stirring effect of the stirring needle. The magnetic field generates an electromagnetic force in the plasticized metal of the weld, accelerates the stirring of the grains inside the weld, and softens the weld surface metal due to the eddy-current-induced heating of the weld surface. Furthermore, the electromagnetic force accelerates the flow of metal particles to avoid the accumulation of grains and the formation of burrs due to uneven stirring; it reduces the deformation resistance of the material, improves the plastic metal fluidity of the weld structure, forms a more dense structure, and makes the weld surface smooth and clear.

Weld surface forming effect.

Figure 5 shows the metallographic organization of HRFSW and MFA-HRFSW microscopic regions at 12,000 rpm and 700 mm·min−1. From Figure 5(a) and (b), it can be seen that the metal stacking streamlines on the advancing side (AS) of the HRFSW tissue become clearly shallow, the area of the streamline layer decreases, and the grain boundaries are not sharp. In the MFA-HRFSW process, the metal stacking streamlines all disappear. The themomechanically affected zone (TMAZ) is farther away from the stirring needle, and it is rarely affected by the stirring needle. From Figure 5(c) and (d), it can be seen that the MFA-HRFSW grain size is larger and the width of the TMAZ is narrower than those of HRFSW. By contrast, the HRFSW grain organization weld nucleation zone and the TMAZ demarcation line are blurred, the precipitated phase distribution is chaotic, and the grains are elongated. The action of the electromagnetic force makes the metallographic organization of the TMAZ to a certain degree of bending deformation, and the local area appears to revert to the grain organization, making the regional plastic metal mobility better. Figure 5(e) and (f) show that the weld nugget zone undergoes a significant plastic deformation due to intense stirring and the friction of the stirring needle, and the temperature is higher, reaching the recrystallization temperature. The grains of MFA-HRFSW are more refined than those of HRFSW, and the precipitated phase distribution is more uniform. This phenomenon can be explained by the fact that the electromagnetic force is more pronounced in the metal particles inside the weld under a high-speed rotating magnetic field, which disperses the metal impurity particles and makes the recrystallized tissue uniform. Furthermore, the refined grain tissue flows in several directions under the action of the electromagnetic force, and the plastic flow is enhanced, resulting in finer grains and a more uniform grain size distribution. This shows that the application of a coaxial rotating magnetic field can increase the fluidity of the metal in the NZ and increase the density of the metallographic organization, broadening the application range of the welding process.

The microstructure of different regions at parameters of 300 mm·min−1 and 12,000 rpm: (a) AS of HRFSW; (b) AS of MFA-HRFSW; (c) TMAZ of HRFSW; (d) TMAZ of MFA-HRFSW; (e) NZ of HRFSW; (f) NZ of MFA-HRFSW.

3.2 Axial pressure and temperature measurement

In order to explore the MFA-HRFSW process mechanism, we chose to test and analyse the force during the welding process. As can be seen from Figure 6, the MFA-HRFSW axial pressure is generally lower than that of the HRFSW process. When the traverse speed is 300 mm·min−1 and the rotation speed is 9,000 rpm, the maximum axial force of MFA-HRFSW is 18.7% lower than that of HRFSW. When the traverse speed is 300 mm·min−1 and the rotation speed is 12,000 rpm, the maximum axial force peak value of MFA-HRFSW is 19.4% lower than that of HRFSW. In addition, compared with HRFSW, the axial force of MFA-HRFSW in the stable stage fluctuates to a lower extent. With the increase in the spindle speed, the welding heat input required in the thin plate welding process will increase, and more heat will soften the plastic metal in the welding zone. The coaxial rotating magnetic field does no longer require a high axial force to increase the heat input, resulting in the formation of a good, dense welding seam.

Time-varying curve of axial pressure under different parameters: (a) 9,000 rpm, 300 mm·min−1; (b) 12,000 rpm, 300 mm·min−1; and (c) 12,000 rpm, 700 mm·min−1.

Figure 7 shows the measured temperature of different parameters of the welding stabilization stage. The plunge depth of HRFSW and MFA-HRFSW is 0.1 mm, the traverse speed is 300 mm·min−1, and rotation speeds are 8,000, 10,000, and 12,000 rpm·min−1, respectively. The experimental results show that under the action of a rotating magnetic field, the higher the traverse speed, the higher the peak temperature of the welding process. Given the same parameters, the peak temperature of the MFA-HRFSW welding process is 10–15°C higher than that of the HRFSW process. According to the law of electromagnetic induction, eddy currents are generated under the application of a rotating magnetic field, and heat is generated during the welding process. The increase in temperature can improve the fluidity of the metal [22].

Actual measured temperature results of different parameters at welding stability stage.

3.3 Mechanical properties and tensile fracture analysis

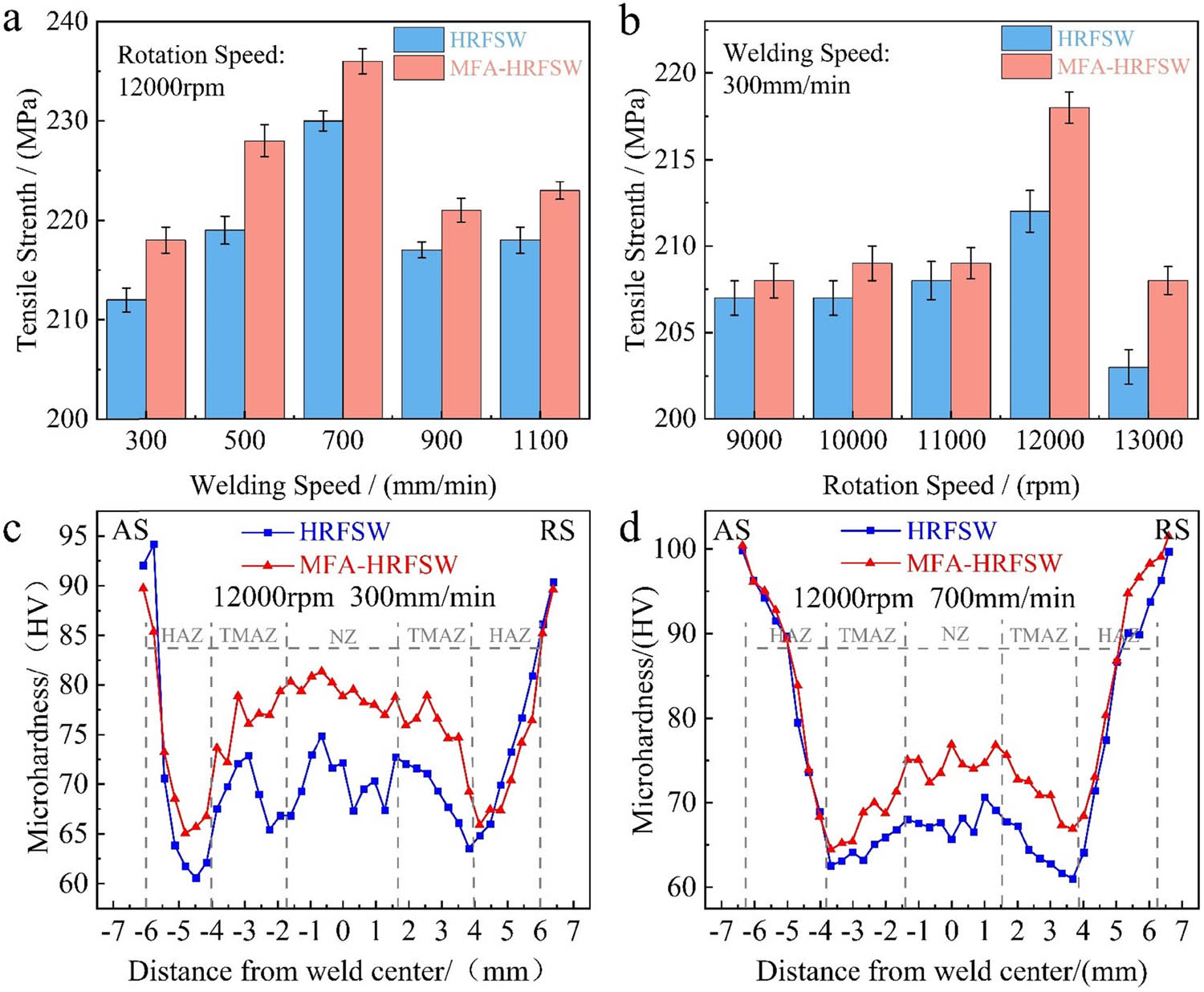

From Figure 8(a) and (b), it can be seen in the constant traverse speed of 300 mm·min−1 and a rotation speed of 9,000–13,000 (rpm), the ultimate tensile strength of the MFA-HRFSW weld first increases and then decreases with increasing rotation speed. On the other hand, for the HRFSW weld, the ultimate tensile strength changes more slowly. For the MFA-HRFSW method, the ultimate tensile strength reaches 81.4% of that of the base material. As seen from Figure 8(c) and (d), in the stirrer shoulder zone, the two microhardness value fluctuate to varying degrees. In the NZ, the microhardness of the MFA-HRFSW joint changes more slowly than that of the HRFSW joint, which is because the magnetic field is mainly concentrated near the NZ, and the mechanical stirring of the tool reduces the grain size of the welding zone and makes the structure more uniform.

The comparison of mechanical properties of HRFSW and MFAFSW weld joints under different welding parameters: (a) ultimate tensile strength of different welding speeds at 12000 rpm; (b) ultimate tensile strength of different revolution speeds at 300 mm·min−1; (c) weld cross-section center hardness distribution at 300 mm·min−1/12000 rpm; (d) weld cross-section center hardness distribution at 700 mm·min−1/12000 rpm.

As can be seen in Figure 9(a) and (b), both fractures show a typical ductile fracture morphology. The two fractures though have different sizes. The HRFSW fracture exhibits an uneven distribution of tough nests, with clear changes between small and large tough nests, the tearing ribs of the fracture are very evident and uneven in height, and the second-phase particles at the bottom of the tough nests are coarse. As can be seen in Figure 9(c) and (d), the number of large-size tough nests in the MFA-HRFSW fracture is significantly reduced, and the large tough nests also contained many fine tough nests with a predominant distribution of small-size tough nests; furthermore, the tough nests are shallow in depth, and the tearing ribs flat. The application of a rotating magnetic field promotes the fluidity of the plasticized metal in the weld, and the difference of each region of the weld is significantly improved. The bottom of the weld nucleus area energy increases significantly, and the metal material flow improves the power source, while the mobility of the material in the vertical direction is enhanced. Thus, the bottom material plastic flow forms more fully, the bond strength of the cross section of the joint is increased, the toughness is enhanced, and the overall performance of the welded joint is improved. The above results are in excellent agreement with the tensile test results.

Fracture morphology (12,000 rpm, 700 mm·min−1): (a) and (b): HRFSW; (c) and (d): MFA-HRFSW.

3.4 EBSD analysis

The EBSD technique was used to analyse the organization of the weld core area in the base material and the different welding methods. The test direction was perpendicular to the rolling direction of the sheet. Figure 10 shows the deformation characteristics of the conventional HRFSW weld nucleus, which is dominated by fine equiaxed grains with an average grain size of 6.24 μm. After the application of the magnetic field, the average grain size of the weld nucleus area is reduced to 4.96 μm, and the crystals become fine and equiaxed. The increased electromagnetic force induced by auxiliary stirring leads to strong plastic deformation and flow of the metal, resulting in an increase in internal grain dislocations. When the stored energy increases to the extent that recrystallization can occur, the nucleus forms inside the metal and is mechanically broken before it can grow, forming equiaxed fine grains. This is conducive to improving the strength of the joint. Low Angle Grain Boundaries (LAGBs, 2° ≤ θ < 15°) and High Angle Grain Boundaries (θ ≥ 15°) are represented by black and red, respectively. After comparing Figure 10(c) with Figure 10(d), it can be found that the high-angle grain boundaries increase significantly in SZ and TMAZ. The analysis shows that the increase of large angle grain boundaries indicates that the energy of the crystal increases, the recrystallization fraction increases, and the grain refinement effect is remarkable.

Microstructure and morphology with rotating speed of 12,000 rpm, traverse speed of 700 mm·min−1. (a) and (c): NZ of HRFSW; (b) and (d): NZ of MFA-HRFSW.

3.5 Electrochemical test and analysis

Figure 11(a) shows the Bode plot of the HRFSW and MFA-HRFSW samples in a 3.5 wt% solution. Figure 11(b) shows the electrochemical impedance spectra of the HRFSW and MFA-HRFSW samples in a 3.5 wt% solution. The experimental conditions were as follows: a rotation speed of 12000 rpm, a traverse speed of 700 mm·min−1, and a welding plunge depth of 0.1 mm. It can be seen that the impedance of the MFA-HRFSW samples is significantly greater than that of the HRFSW samples, and the corrosion resistance of the 6061-T6 aluminium alloy is improved with the application of the rotating magnetic field. Figure 11(c) shows the polarization curves of the HRFSW and MFA-HRFSW specimens in a 3.5 wt% solution. Both samples exhibit anodic characteristics, which is due to the anodic dissolution of the aluminium alloy during the initial stage of immersion in the solution [23]. The corrosion potential and the corrosion current density of the MFA-HRFSW and HRFSW samples are −0.67 and −0.66 V, and 3.25 and 4.24 μA·cm−2, respectively. The corrosion current density of the MFA-HRFSW samples is smaller than that of the HRFSW samples, indicating a reduced corrosion rate and therefore a higher corrosion resistance. According to the magnetoplastic effect [18,24], under the combined effects of stirring and the applied magnetic field, the slip of the atomic layers and the shaping of the metal change to a certain extent, and the fluidity of the metal inside the friction stir weld is enhanced. Thus, the dislocations originally on the slip surface form sub-grain boundary through sliding and climbing, and the sub-grain boundary structure then gives rise to a recrystallization structure by absorbing heat. The driving force behind the generation of magnetic eddy currents is the continuous accumulation of energy at the grain boundaries, which promotes an increase in the dislocation density within the grains. When the energy stored increases to a certain extent, combined with the thermal deformation process, dislocations are constantly introduced at the sub-grain boundaries, thereby forming a fine-grain structure. In the local high-strain region of the weld nugget zone, this accumulation of dislocations may lead to the initiation of the recrystallization process, thus forming ultra-fine grains, which is conducive to the improvement of the joint performance.

HRFSW sample and MFA-HRFSW sample with rotating speed of 12,000 rpm, traverse speed of 700 mm·min−1. (a): Bode (b): Nyquist; (c): the polarization curve of the connector.

4 Conclusions

A novel MFA-HRFSW is used to weld metal sheets. 1-mm-thick 6061-T6 aluminium alloy sheets were welded using HRFSW and MFA-HRFSW, and the microstructure, mechanical properties, and temperature fields of the obtained welded joints were investigated. The corrosion resistance of the samples was evaluated through electrochemical tests in a 3.5 wt% NaCl aqueous solution. A mathematical model of the MFA-HRFSW process was established, and the effects of the MFA-HRFSW process temperature and the equipment axial force were discussed. It was demonstrated that the MFA-HRFSW process is effective, and the main results are as follows:

Coaxial rotating magnetic field under the action of the thermal effect on the plate weld area, the traverse speed, and magnetic field strength are the two main factors affecting the auxiliary heat source. The thermal effect of the magnetic field generated during the welding process reduces the axial pressure on the tool as well as the deformation resistance of the plate.

The rotating magnetic field promotes the plasticized flow of the weld metal, the grains are finer and denser, and the macroscopic morphological quality of the weld is improved. These findings can promote the application of the MFA-HRFSW process for welding thin aluminium alloy plates in different scenarios. The hardness and tensile strength of the joint are considerably improved.

The electrochemical tests showed that the use of a rotating magnetic field during the HRFSW process facilitates the flow of plasticized metal, makes the joint organization more uniform, and increases the corrosion resistance.

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (NO. 52275339) and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (CN) (NO. KYCX22_3787).

-

Funding information: This research was financially supported by the National Natural Science Foundation of China (NO. 52275339) and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (CN) (NO. KYCX22_3787).

-

Author contributions: Xinyi Chen: investigation, writing – original draft, software, writing – review & editing. Shujin Chen: investigation, writing – review & editing, supervision, funding acquisition. Zhidong Yang: visualization, investigation. Ruihai Duan: software, investigation, resources, visualization. Yang Gao: investigation. Zhihong Liu: visualization, writing – review & editing. Shangdong Dong: methodology.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an on-going study.

References

[1] Mallieswaran, K., C. Rajendran, R. Padmanabhan, and S. Rajasekaran. Evaluation of nickel shot peening process on strength of friction stir welded AA2014-T6 aluminum alloy joints. Practical Metallography, Vol. 60, No. 7, 2023, pp. 442–460.10.1515/pm-2022-1038Search in Google Scholar

[2] Mallieswaran, K., R. Padmanabhan, and V. Balasubramanian. Friction stir welding parameters optimization for tailored welded blank sheets of AA1100 with AA6061 dissimilar alloy using response surface methodology. Advances in Materials and Processing Technologies, Vol. 4, No. 1, 2018, pp. 142–157.10.1080/2374068X.2017.1410690Search in Google Scholar

[3] Rajendran, C., M. Vinoth Kumar, T. Sonar, and K. Mallieswaran. Investigating the effect of PWHT on microstructural features and fatigue crack growth behavior of friction stir welded AA2024-T6 aluminum alloy joints. Forces in Mechanics, Vol. 8, 2022, id. 100107.10.1016/j.finmec.2022.100107Search in Google Scholar

[4] Shi, L., J. Chen, C. S. Wu, and L. Fu. Analysis of heat and mass transfer in ultrasonic vibration-enhanced friction stir welding of 2195 Al–Li alloy. Science and Technology of Welding and Joining, Vol. 26, No. 5, 2021, pp. 363–370.10.1080/13621718.2021.1917748Search in Google Scholar

[5] Ramamurthy, M., P. Balasubramanian, N. Senthilkumar, and G. Anbuchezhiyan. Influence of process parameters on the microstructure and mechanical properties of friction stir welds of AA2014 and AA6063 aluminium alloys using response surface methodology. Materials Research Express, Vol. 9, No. 2, 2022, id. 026528.10.1088/2053-1591/ac5777Search in Google Scholar

[6] Zhang, C. Q., Z. Qin, C. Rong, W. Shi, and S. Wang. The preliminary exploration of micro-friction stir welding process and material flow of copper and brass ultra-thin sheets. Materials, Vol. 13, No. No. 10, Art. No. 10, 2020.10.3390/ma13102401Search in Google Scholar PubMed PubMed Central

[7] Ahmed, M. M. Z., S. Ataya, M. M. El-Sayed Seleman, A. M. A. Mahdy, N. A. Alsaleh, and E. Ahmed. Heat input and mechanical properties investigation of friction stir welded AA5083/AA5754 and AA5083/AA7020. Metals, Vol. 11, No. 1, 2020, id. 68.10.3390/met11010068Search in Google Scholar

[8] Ma, Z. Q., X. Sun, S. Ji, Y. Wang, and Y. Yue. Influences of ultrasonic on friction stir welding of Al/Ti dissimilar alloys under different welding conditions. The International Journal of Advanced Manufacturing Technology, Vol. 112, No. 9–10, 2021, pp. 2573–2582.10.1007/s00170-020-06481-6Search in Google Scholar

[9] He, C. S., Q. Mofan, Z. Zhiqiang, and Z. Xiang. Effect of axial ultrasonic vibration on metal flow behavior during friction stir welding. Acta Metallurgica Sinica, Vol. 57, No. 12, 2021, pp. 1614–1626.Search in Google Scholar

[10] Zhang, Z. Q., C. He, Y. Li, L. Yu, S. Zhao, and X. Zhao. Effects of ultrasonic assisted friction stir welding on flow behavior, microstructure and mechanical properties of 7N01-T4 aluminum alloy joints. Journal of Materials Science & Technology, Vol. 43, 2020, pp. 1–13.10.1016/j.jmst.2019.12.007Search in Google Scholar

[11] Wada, T., Y. Morisada, Y. F. Sun, H. Fuji, Y. Kawahito, M. Natsushita, et al. Friction stir welding of medium carbon steel with laser-preheating. ISIJ International, Vol. 60, No. 1, 2020, pp. 153–159.10.2355/isijinternational.ISIJINT-2019-394Search in Google Scholar

[12] Song, K. H., T. Tsumura, and K. Nakata. Development of microstructure and mechanical properties in laser-FSW hybrid welded Inconel 600. Materials Transactions, Vol. 50, No. 7, 2009, pp. 1832–1837.10.2320/matertrans.M2009058Search in Google Scholar

[13] Kaushik, P. and D. Kumar Dwivedi. Induction preheating in FSW of Al-steel combination. Materials Today: Proceedings, Vol. 46, 2021, pp. 1091–1095.10.1016/j.matpr.2021.01.438Search in Google Scholar

[14] Ahmad, B., A. Galloway, and A. Toumpis. Numerical optimisation of laser assisted friction stir welding of structural steel. Science and Technology of Welding and Joining, Vol. 24, No. 6, 2019, pp. 548–558.10.1080/13621718.2019.1570682Search in Google Scholar

[15] Deng, H., Y. Chen, Y. Jia, Y. Pang, T. Zhang, S. Wang, et al. Microstructure and mechanical properties of dissimilar NiTi/Ti6Al4V joints via back-heating assisted friction stir welding. Journal of Manufacturing Processes, Vol. 64, 2021, pp. 379–391.10.1016/j.jmapro.2021.01.024Search in Google Scholar

[16] Liu, X., C. Wu, and G. K. Padhy. Characterization of plastic deformation and material flow in ultrasonic vibration enhanced friction stir welding. Scripta Materialia, Vol. 102, 2015, pp. 95–98.10.1016/j.scriptamat.2015.02.022Search in Google Scholar

[17] Konovalov, A., D. Pshonkin, E. Kunitsyna, R. MorguNov, and E. BeaugNon. Softening of the Al-Mg-Si-Fe alloy under magnetostriction of FeAl microinclusions. Journal of Applied Physics, Vol. 125, No. 2, 2019, id. 023903.10.1063/1.5064448Search in Google Scholar

[18] Konovalov, S., D. Zagulyaev, X. Z. Chen, V. Gromov, and Y. Ivanov. Variations in defect substructure and fracture surface of commercially pure aluminum under creep in weak magnetic field. Chinese Physics B, Vol. 26, No. 12, 2017, id. 126203.10.1088/1674-1056/26/12/126203Search in Google Scholar

[19] Qin, D. Q., L. Fu, and Z. K. Shen. Visualisation and numerical simulation of material flow behaviour during high-speed FSW process of 2024 aluminium alloy thin plate. The International Journal of Advanced Manufacturing Technology, Vol. 102, No. 5–8, 2019, pp. 1901–1912.10.1007/s00170-018-03241-5Search in Google Scholar

[20] Cheng, J. F., G. Li, H. Wang, P. Li, and C. Li. Influence of high pulsed magnetic field on the dislocations and mechanical properties of Al2O3/Al composites. Journal of Materials Engineering and Performance, Vol. 27, No. 3, 2018, pp. 1083–1092.10.1007/s11665-018-3191-3Search in Google Scholar

[21] Chen, X. Y., S. Chen, Z. Liu, Y. Gao, and H. Zhang. Magnetic field-assisted ultra-high-speed friction stir welding. Materials Letters, Vol. 331, 2023, id. 133447.10.1016/j.matlet.2022.133447Search in Google Scholar

[22] Wahid, M. A., A. N. Siddiquee, Z. A. Khan, and N. Sharma. Analysis of cooling media effects on microstructure and mechanical properties during FSW/UFSW of AA 6082-T6. Materials Research Express, Vol. 5, No. 4, 2018, id. 046512.10.1088/2053-1591/aab8e3Search in Google Scholar

[23] Gupta, R. K., H. Das, and T. K. Pal. Influence of processing parameters on induced energy, mechanical and corrosion properties of FSW butt joint of 7475 AA. Journal of Materials Engineering and Performance, Vol. 21, No. 8, Aug. 2012, pp. 1645–1654.10.1007/s11665-011-0074-2Search in Google Scholar

[24] Zhang, X. and Z. P. Cai. Effect of magnetic field on the nanohardness of monocrystalline silicon and its mechanism. JETP Letters, Vol. 108, No. 1, 2018, pp. 23–29.10.1134/S0021364018130040Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Endpoint carbon content and temperature prediction model in BOF steelmaking based on posterior probability and intra-cluster feature weight online dynamic feature selection

- Thermal conductivity of lunar regolith simulant using a thermal microscope

- Multiobjective optimization of EDM machining parameters of TIB2 ceramic materials using regression and gray relational analysis

- Research on the magnesium reduction process by integrated calcination in vacuum

- Microstructure stability and softening resistance of a novel Cr-Mo-V hot work die steel

- Effect of bonding temperature on tensile behaviors and toughening mechanism of W/(Ti/Ta/Ti) multilayer composites

- Exploring the selective enrichment of vanadium–titanium magnetite concentrate through metallization reduction roasting under the action of additives

- Effect of solid solution rare earth (La, Ce, Y) on the mechanical properties of α-Fe

- Impact of variable thermal conductivity on couple-stress Casson fluid flow through a microchannel with catalytic cubic reactions

- Effects of hydrothermal carbonization process parameters on phase composition and the microstructure of corn stalk hydrochars

- Wide temperature range protection performance of Zr–Ta–B–Si–C ceramic coating under cyclic oxidation and ablation environments

- Influence of laser power on mechanical and microstructural behavior of Nd: YAG laser welding of Incoloy alloy 800

- Aspects of thermal radiation for the second law analysis of magnetized Darcy–Forchheimer movement of Maxwell nanomaterials with Arrhenius energy effects

- Use of artificial neural network for optimization of irreversibility analysis in radiative Cross nanofluid flow past an inclined surface with convective boundary conditions

- The interface structure and mechanical properties of Ti/Al dissimilar metals friction stir lap welding

- Significance of micropores for the removal of hydrogen sulfide from oxygen-free gas streams by activated carbon

- Experimental and mechanistic studies of gradient pore polymer electrolyte fuel cells

- Microstructure and high-temperature oxidation behaviour of AISI 304L stainless steel welds produced by gas tungsten arc welding using the Ar–N2–H2 shielding gas

- Mathematical investigation of Fe3O4–Cu/blood hybrid nanofluid flow in stenotic arteries with magnetic and thermal interactions: Duality and stability analysis

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part II

- Effects of heat treatment on microstructure and properties of CrVNiAlCu high-entropy alloy

- Enhanced bioactivity and degradation behavior of zinc via micro-arc anodization for biomedical applications

- Study on the parameters optimization and the microstructure of spot welding joints of 304 stainless steel

- Research on rotating magnetic field–assisted HRFSW 6061-T6 thin plate

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part II

- Microwave hybrid process-based fabrication of super duplex stainless steel joints using nickel and stainless steel filler materials

- Special Issue on Polymer and Composite Materials and Graphene and Novel Nanomaterials - Part II

- Low-temperature corrosion performance of laser cladded WB-Co coatings in acidic environment

- Special Issue for the conference AMEM2025

- Effect of thermal effect on lattice transformation and physical properties of white marble

Articles in the same Issue

- Research Articles

- Endpoint carbon content and temperature prediction model in BOF steelmaking based on posterior probability and intra-cluster feature weight online dynamic feature selection

- Thermal conductivity of lunar regolith simulant using a thermal microscope

- Multiobjective optimization of EDM machining parameters of TIB2 ceramic materials using regression and gray relational analysis

- Research on the magnesium reduction process by integrated calcination in vacuum

- Microstructure stability and softening resistance of a novel Cr-Mo-V hot work die steel

- Effect of bonding temperature on tensile behaviors and toughening mechanism of W/(Ti/Ta/Ti) multilayer composites

- Exploring the selective enrichment of vanadium–titanium magnetite concentrate through metallization reduction roasting under the action of additives

- Effect of solid solution rare earth (La, Ce, Y) on the mechanical properties of α-Fe

- Impact of variable thermal conductivity on couple-stress Casson fluid flow through a microchannel with catalytic cubic reactions

- Effects of hydrothermal carbonization process parameters on phase composition and the microstructure of corn stalk hydrochars

- Wide temperature range protection performance of Zr–Ta–B–Si–C ceramic coating under cyclic oxidation and ablation environments

- Influence of laser power on mechanical and microstructural behavior of Nd: YAG laser welding of Incoloy alloy 800

- Aspects of thermal radiation for the second law analysis of magnetized Darcy–Forchheimer movement of Maxwell nanomaterials with Arrhenius energy effects

- Use of artificial neural network for optimization of irreversibility analysis in radiative Cross nanofluid flow past an inclined surface with convective boundary conditions

- The interface structure and mechanical properties of Ti/Al dissimilar metals friction stir lap welding

- Significance of micropores for the removal of hydrogen sulfide from oxygen-free gas streams by activated carbon

- Experimental and mechanistic studies of gradient pore polymer electrolyte fuel cells

- Microstructure and high-temperature oxidation behaviour of AISI 304L stainless steel welds produced by gas tungsten arc welding using the Ar–N2–H2 shielding gas

- Mathematical investigation of Fe3O4–Cu/blood hybrid nanofluid flow in stenotic arteries with magnetic and thermal interactions: Duality and stability analysis

- Topical Issue on Conference on Materials, Manufacturing Processes and Devices - Part II

- Effects of heat treatment on microstructure and properties of CrVNiAlCu high-entropy alloy

- Enhanced bioactivity and degradation behavior of zinc via micro-arc anodization for biomedical applications

- Study on the parameters optimization and the microstructure of spot welding joints of 304 stainless steel

- Research on rotating magnetic field–assisted HRFSW 6061-T6 thin plate

- Special Issue on A Deep Dive into Machining and Welding Advancements - Part II

- Microwave hybrid process-based fabrication of super duplex stainless steel joints using nickel and stainless steel filler materials

- Special Issue on Polymer and Composite Materials and Graphene and Novel Nanomaterials - Part II

- Low-temperature corrosion performance of laser cladded WB-Co coatings in acidic environment

- Special Issue for the conference AMEM2025

- Effect of thermal effect on lattice transformation and physical properties of white marble