Abstract

The rheology of cement paste under vibration follows the transformation from Bingham model to Hershel-Bulkly model to Power-Law model. Most of the existing research is obtained through a large number of experiments in the data fitting process, and cannot express the time-varying characteristics of viscosity. Furthermore, thixotropy of cement paste is based on static experiment and cannot be applied under vibration. In this paper a shear-vibration equivalent theory is proposed, which consider the effect of vibration is the same as the shear effect on the viscosity change of cement paste. Combining vibrational shear equivalent theory and HI theory, the rheological changes of cement paste under vibration are obtained through numerical simulation. This theory has been verified by a series of experiments with numerical simulations, and can be used to study the rheology of concrete under vibration.

1 Introduction

Cement paste is a particle stream formed by mixing water and cement particles and concrete consists of cement paste and aggregates. Research on cement paste and fresh concrete is closely linked. The change of rheological properties of fresh concrete under vibration mainly comes from cement paste. Both cement paste and fresh concrete can be streamlined as water-containing particles. The internal structures of the two vary over time due to their internal chemical reactions, which in turn changes the rheological properties. In the case of external force, its internal structures are destroyed and the rheological properties are also changed. Therefore, it can be observed in the experiment that the same proportion of cement paste and fresh concrete exhibit different behaviors [1, 2]. Barnes et al. [3, 4] defines thixotropy as “a gradual decrease of the viscosity under shear stress followed by a gradual recovery of the structure when the stress is removed”. It can be considered that the cement paste has thixotropic properties. Hattori and Izumi [5], Tattersall and Banfill [6] studied the thixotropic properties of cement paste, and established Hattori-Izumi theory (HI theory). Based on the research of Hattori et al., Wallevik [7, 8] made some necessary improvements to HI theory. According to HI theory, the thixotropy of cement paste is related to coagulation, dispersion, and re-coagulation between cement particles. It shows that without external force, the coagulation of cement particles makes the junctions of cement paste increase with time. When the shearing action is applied, it leads to dispersion of the coagulated particles, resulting in the reduction of viscosity. When the shearing action is removed, re-coagulation happens and the viscosity rises again.

On the other hand, many researches have showed that the rheological properties of concrete change under vibration [9, 10, 11, 12]. Tattersall used a vertical tube method to study fresh concrete under vibration. Fresh concrete without vibration remained in the straight pipe due to the existence of the yield value, while it flowed under vibration because the yield value of fresh concrete decreased. The fluidity of fresh concrete will be significantly improved under vibration. Popovics [13] suggested that the effect of arch bridges produced by aggregates in fresh concrete would be destroyed during vibration and then improved the workability of fresh concrete. On the other hand, cement paste in fresh concrete flows under vibration, which makes the distribution of aggregates more uniform and improves the workability of fresh concrete as well. In most literature, fresh concrete was considered as a Bingham fluid, and under low-intensity vibration, the rheological model would be transformed to Hershel-Bulkley model and finally to Power-Law model.

As is mentioned above, the rheological properties of concrete will change under vibration. Since the main influence of rheological properties of concrete comes from cement paste, it’s reasonable to suppose that there are rheological changes of cement paste under vibration. HI theory and Wallevik proposed a simple way to estimate the rheological properties change under shear. However, they obtained the results by measuring the rheological properties of cement paste with rotational rheometers, which means the theory can be acceptable only in shear condition. Current study established the rheological model through data fitting and ignored the internal structure of fresh concrete, more specifically, the change of rheological properties of cement paste. In this paper, the shear-vibration equivalent theory is proposed, which makes HI theory applicable under vibration. It is verified by a series of experiments which considers both the shear effect and vibration effect. Combined with the shear-vibration equivalent theory with HI theory, the process that the rheological model of cement paste changes from Bingham model to Hershel-Bulkley model and finally to Power-Law model is explained.

2 Shear-Vibration Equivalent theory

2.1 Traditional rheological test method of cement paste

For non-Newtonian fluids, the ratio of shear stress to shear rate is defined as the apparent viscosity. As Bingham fluid, the apparent viscosity of the cement paste can be calculated by the following formula [14, 15, 16, 17]:

Where η is the apparent viscosity of cement paste, τ and

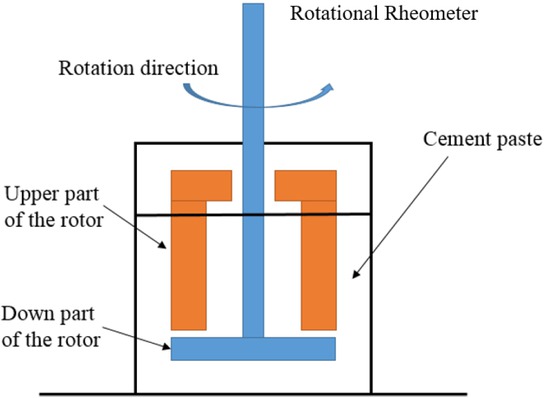

In most researches, the apparent viscosity of cement paste is usually measured by the rotational rheometers, as is the same in this paper. The schematic diagram of the rotary viscometer is shown in Figure 1.

The schematic of rotational rheometers

When the rotor rotates, the cement paste in contact with the rotor will maintain the same speed as the rotor, and the speed of fluid in contact with the vessel wall will be zero due to the action of friction. The shear strain will generate inside the fluid which will cause shear stress. The following relationship will be obtained:

Where M is the torque of viscometer rotor, h is immersion depth of the rotor in cement paste, r is the horizontal distance from one point in the fluid to the center of the rotor and ω is the angular velocity at this point.

By transforming formula (2), the Reiner-Riwlin equation [15] is obtained:

2.2 Experiment procedure under vibration

2.2.1 Experiment procedure

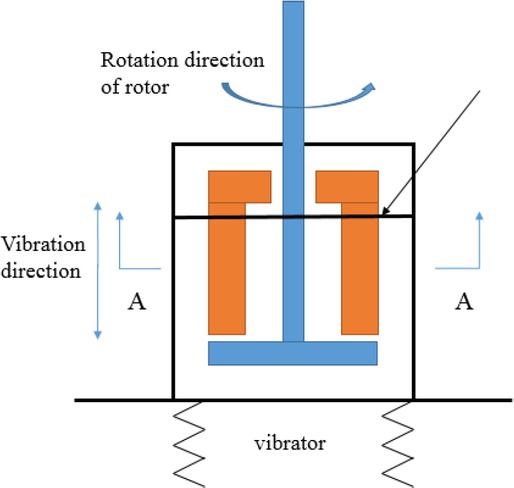

The method of measuring the viscosity of cement paste under vibration is to place the self-made viscometer on the vibrator and measure the viscosity of the cement paste during the vibrating process, as is shown in Figure 2.

Viscosity measurement of cement paste under vibration

The container is fixed on the vibrating table, and the speed of the container is the same as the vibrator obviously. During the vibration process, the energy generated by the vibrator is transmitted in the form of waves. Due to the limited size of the container, the intensity of vibration can be assumed as the equivalent inside the container. When the vibrator starts, the cement paste in contact with the inner wall of the container will maintain the same speed as the vibrator and the speed of fluid in contact with the rotor will be zero in vibration direction due to the interaction of friction, which will result in uneven internal movement of the cement paste. Thus shear stress will be generated inside the cement paste and the inner structure of the cement paste will be destroyed. As a result, the rheology changes during the process.

2.2.2 A brief introduction of HI theory

HI theory assumes that the apparent viscosity is related to the number of junctions in the cement paste, as is shown in formula (4):

Where ηHI is the apparent viscosity calculated by HI theory, B3 is the friction coefficient between cement paste particles and has a physical unit of N·s. Jt is the number of junctions between particles, and is calculated as formula (5):

Where n3 is particle numbers in a unit volume of cement paste. H is coagulation rate. t represents for time and U0 is the ratio of the number of bonded particles to the total number of particles in the fluid. Combining formula (4) and (5), the viscosity of fluid is calculated as follows:

Due to the difficulty to obtain the parameters in formula (6), Wallevik made some necessary modifications, and expressed the plastic viscosity and yield value of cement paste as a function of shear rate and time, providing a method to calculate the viscosity of cement paste under shear. The parameters ma, mb, a1, a2, U0, τ0, η are only determined by the characteristics of cement paste, also known as HI parameters. The detailed deduction can be referred to literatures [5, 7, 8].

2.2.3 Introduction of shear-vibration equivalent theory

Unfortunately, the HI theory is not suitable in the vibration process mentioned above, because the vibration of the vibrator also leads to relative movement of the cement particles and changes the rheological properties of the fluid, namely, the viscosity and yield stress.

This thesis proposes a shear-vibration equivalent theory which considers that the effect of the vibration process of cement paste is as the same with the effect of the shear process. In other words, the vibration process can be transformed into the shear process. The following is the analysis of the cement paste under both vibration and shear.

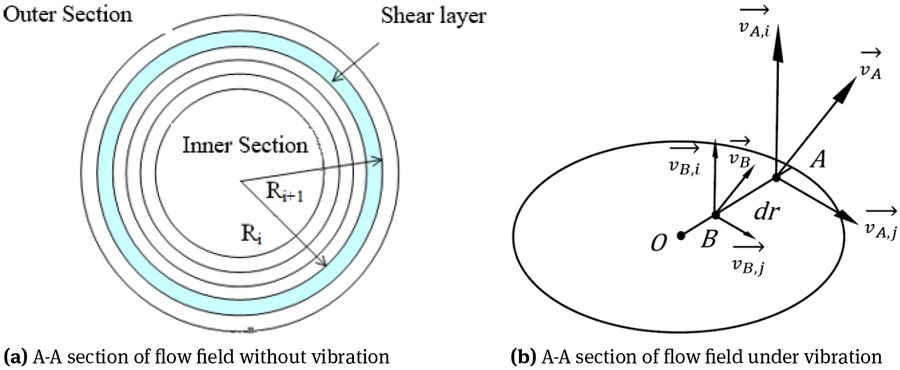

According to Li [18], the flow field of cement paste without vibration (A-A section of Figure 2. without vibration) is shown in Figure 3(a), which is layered radially according to the central symmetry of the flow field. The viscosity of cement paste in each layer is considered the same. It is proved that this simplification is reliable. Based on the simplification of Li, the isometric of Figure 2 A-A section is shown in Figure 3(b). It should be noted that the flow field of Figure 3(b) is under both shear and vibration. A and B represent for two adjacent points in the radial direction. The distance between the two points is dr. Then the shear rate between two points can be approximated as formula (7) and (8).

Flow field of cement paste

Where

The vibration process and shear process can be transferred into pure shear process. The total shear rate is composed of shear rate generated by vibration process and shear rate generated by shear process, as is shown in formula (9).

Where

the intensity of vibration. However, for a sinusoidal vibration process, it is difficult to calculate its vibration intensity directly, so a new parameter

Now, HI theory is suitable under both vibration and shear condition. However, there is still something to modify in the calculation. First, the memory modules Γ and coagulation rate H are calculated by the total shear rate, which are shown in formula (11) and (12):

At last, replacing

3 Results

Based on the shear-vibration equivalent theory and HI theory mentioned above, we designed the experiment described below. Firstly, measuring the apparent viscosity of cement paste at 20Hz vibration frequency using a self-made viscometer to calibrate the parameters of the logarithmic calculation in Table 1 and the newly added parameter

parameters in HI theory

| Parameters | ma | mb | a1 | a2 | U0 | τ0 | η |

|---|---|---|---|---|---|---|---|

| unit | s | s | - | - | - | Pa | Pa·s |

Settings of experiment

| Type of cement | Water-cement ratio | Rotor speed | Vibration time | Vibration frequency |

|---|---|---|---|---|

| PO 42.5 | 0.4 | 40rpm | 50s | 20Hz |

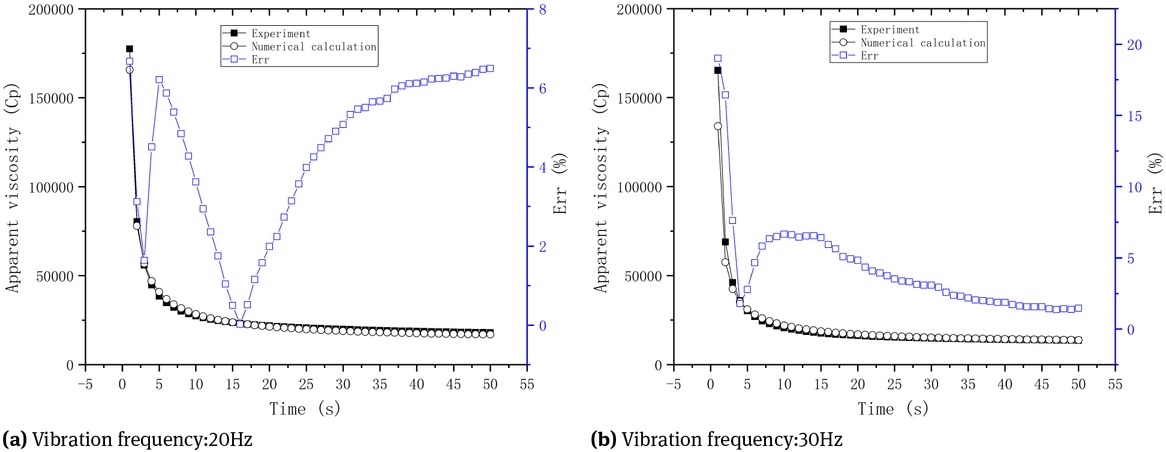

The measured viscosity in experiment and numerical calculation of cement paste under vibration of 20Hz frequency is shown in Figure 4(a). The parameter settings of numerical calculation are given in Table 3. It can be seen from Figure 4(a) that the error of the whole process is less than 7%, and the experiment results agree well with the numerical results. Keeping the experiment settings unchanged and only adjusting the numerical calculation parameter

Experiment and numerical calculation of apparent viscosity

Parameters in numerical calculation

| Parameters | ma | mb | a1 | a2 | U0 | τ0 | μ | R1 | R2 | |

|---|---|---|---|---|---|---|---|---|---|---|

| value | 30 | 0 | 530 | 300 | 0.9 | 1 | 6 | 10 | 0.1 | 0.16 |

Through the calibration and comparison of Figure 4(a), it is proved that the shear-vibration equivalent theory is reliable when applied with HI theory. And the consistency of apparent viscosity in experiment and numerical calculation by only changing the newly added parameter

4 Discussion

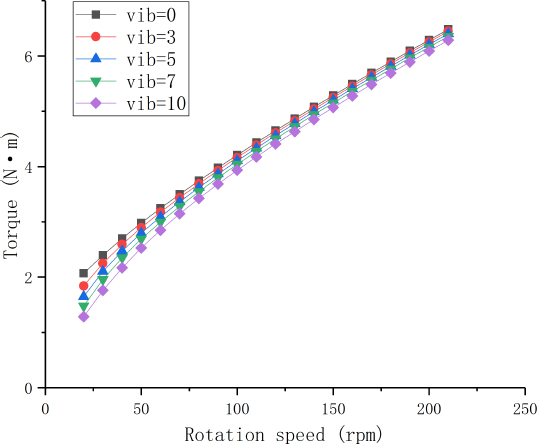

In this chapter, we use the combination of shear-vibration equivalent theory and HI theory to study the effect of vibration intensity on the rheological properties of cement paste. In other words, the parameter

In Figure 5, curves of apparent viscosity calculated under the conditions

Apparent viscosity at

Since the viscosity of the cement paste is affected by the combination of time and shearing action, it is not reasonable to use only one test to change the rotational speed of the rotary viscometer to obtain multiple sets of data, because the data measured by this method are affected by the previous shear history.

In this paper, a set of simulation tests is used to obtain only a set of data at one single speed to reduce the impact of other factors on the data. The details are as follows:

Select the rotary viscometer and get its dimension parameters. Select the type and proportion of cement and vibration state. Based on the above selection, obtain the parameters of PFI theory.

The rotational speed is selected to calculate the change of apparent viscosity and torque of cement paste with time until the apparent viscosity and torque of the cement paste tend to be stable.

Calculate the average value of the viscosity of the cement paste and the average value of the torque.

Repeat steps 2 and 3, obtain the torque and viscosity values at a series of speeds, which are shown in Figure 6.

Torque at

When

Function fittings on torque curves

| Function | |

|---|---|

| 0 | T = 1.842 + 0.02272*n |

| 3 | T = 0.7184 + 0.1519*n0.6782 |

| 5 | T = 0.3131 + 0.2094*n0.6294 |

| 7 | T = 0.251*n0.6036 |

| 10 | T = 0.2048*n0.6406 |

Through the above description, the following conclusions can be obtained:

Non-vibration cement paste can be considered as Bingham fluid approximately. When vibration is applied to cement paste, its rheological properties obey Hershel-Bulkley model. With the further increase of vibration intensity, it can be approximated as Power-Law model.

As the intensity of vibration increases, the difference between the apparent viscosity under vibration and without vibration increases.

As shear rate increases, the curve of apparent viscosity under vibration approaches to the curve without vibration.

The above conclusions are consistent with the conclusions which Tattersall [1] suggested in the experiment. It can be considered that combining vibration with the thixotropy of cement paste is able to express the rheological changes of cement paste to some extent.

5 Conclusion

Cement paste is a suspension of cement particles in water. It shows different characteristics compared to pure fluid, namely, the viscosity and yield value of cement paste change with time. In this paper, the combination of vibration and shearing action is utilized to obtain the viscosity change process of cement paste. From the microscopic structure, the mechanism of the change of rheological properties of cement paste under vibration is explained, and the calculation method of viscosity of cement paste under vibration is acquired. A consistent theory is proposed for cement paste under vibration and without vibration. The correctness and credibility of this theory are verified by experiments.

In conclusion, cement paste under vibration has the following characteristics:

As the intensity of vibration increases, the rheological model of cement paste changes from Bingham model to Hershel-Bulkley model and then to Power-Law model.

When measuring the viscosity of cement paste under vibration state by rotational rheometer, as the intensity of vibration increases, the measured viscosity can be regarded as the viscosity of the cement paste under vibration, for the reason that the shear rate produced by the rotational rheometer is negligible.

As the intensity of vibration increases, the effect from vibration is getting smaller and smaller on the apparent viscosity of cement paste. In other words, there is a peak in the effect of vibration on the viscosity of cement paste. Above this value, the apparent viscosity no longer decreases with increasing vibration intensity.

The peak value of the effect of vibration intensity on apparent viscosity of cement paste is not given in this paper, and further study is needed in the future.

References

[1] Tatterasll GH, Baker PH. Investigation on the effect of vibration on the workability of fresh concrete using a vertical pipe apparatus. Mag Concr Res. 1989;41(169):3–9.10.1680/macr.1989.41.146.3Suche in Google Scholar

[2] Safiwi MI, Iwaki I, Miura T. Study on the applicability of vibration in fresh high fluidity concrete. Cement Concr Res. 2005;35(9):1824–45.10.1016/j.cemconres.2004.10.031Suche in Google Scholar

[3] Barnes HA, Hutton JF, Walters K. An Introduction to Rheology. Amsterdam: Elservier Science; 1989.Suche in Google Scholar

[4] Barnes HA. Thixotropy-a review. Non-Newtonian Fluid Mech. 1997;70(1-2):1–33.10.1016/S0377-0257(97)00004-9Suche in Google Scholar

[5] Hattori K, Izumi K. Rheology of fresh cement and concrete. Proceeding of the International Conference Organized by The British Society of Rheology. London, UK: University of Liverpool; 1991.p.82-92.Suche in Google Scholar

[6] Tattersall GH. The Rheology of Fresh Concrete. Pitman Advanced Pub.; 1983.Suche in Google Scholar

[7] Wallevik JE. Rheology of particle suspensions — fresh concrete, mortar and cement paste with various types of lignosulfonates. The Norwegian University of Science and Technology; 2003.Suche in Google Scholar

[8] Wallevik JE. Rheological properties of cement paste: thxiotropic behavior and structural breakdown. Cement Concr Res. 2009;39(1):14–29.10.1016/j.cemconres.2008.10.001Suche in Google Scholar

[9] Popovics S. A review of the concrete consolidation by vibration. Matrtays Et Construction. 1973;6(6):453–63.10.1007/BF02473784Suche in Google Scholar

[10] Juradin S, Krstulovic P. The vibration rheometer: the effect of vibration on fresh concrete and similar materials. Materialsissenschaft und Werkstoffechnik. 2012;43(8):733–42.10.1002/mawe.201200769Suche in Google Scholar

[11] Date S, Goryozono Y, Hashimoto S. Study on Consolidation of Concrete with Vibration. Phys Procedia. 2012;25(4):325–32.10.1016/j.phpro.2012.03.091Suche in Google Scholar

[12] Juraduing S. Determination of rheological properties of fresh concrete and similar materials in a vibration rheometer. Mater Res. 2012;15(1):103–13.10.1590/S1516-14392011005000100Suche in Google Scholar

[13] Remond S, Pizette P. A DEM hard-core soft-shell model for the simulation of concrete flow. Cement Concr Res. 2014;58(15):169–78.10.1016/j.cemconres.2014.01.022Suche in Google Scholar

[14] Vasilic K, Schmidt W, Kühne HC, Haamkens F, Mechtcherine V, Roussel N. Flow of fresh concrete through reinforced elements: experimental validation of the porous analogy numerical method. Cement Concr Res. 2016;88:1–6.10.1016/j.cemconres.2016.06.003Suche in Google Scholar

[15] Baker PH, Tattersall GH. The effect of vibration on the rheological properties of fresh concrete. Mag Concr Res. 1988;40(143):79–89.10.1680/macr.1988.40.143.79Suche in Google Scholar

[16] Wallevik OH, Wallevik JE. Rheology as a tool in concrete science: the use of rheographs and workability boxes. Cement Concr Res. 2011;41(12):1279–88.10.1016/j.cemconres.2011.01.009Suche in Google Scholar

[17] Reiner M, Eyring H. Deformation and Flow. An Elementary Introduction to Theoretical Rheology. Phys Today. 1950;3(4):35–6.10.1063/1.3066868Suche in Google Scholar

[18] Li X, Wang C, Yu Y. Rheological distribution algorithm of cement paste based on particle-flow-interaction theory. Journal of Zhejiang University. 2019;53(12):2264–70.Suche in Google Scholar

© 2020 X. Li et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Microstructure and compressive behavior of lamellar Al2O3p/Al composite prepared by freeze-drying and mechanical-pressure infiltration method

- Al3Ti/ADC12 Composite Synthesized by Ultrasonic Chemistry in Situ Reaction

- Microstructure and photocatalytic performance of micro arc oxidation coatings after heat treatment

- The effect of carbon nanotubes on the mechanical and damping properties of macro-defect-free cements

- Toughening Mechanism of the Bone — Enlightenment from the Microstructure of Goat Tibia

- Characterization of PVC/MWCNTs Nanocomposite: Solvent Blend

- Study on Macroscopic and Mesoscopic Mechanical Behavior of CSG based on Inversion of Mesoscopic Material Parameters

- Bearing properties and influence laws of concrete-filled steel tubular arches for underground mining roadway support

- Comparing Test Methods for the Intra-ply Shear Properties of Uncured Prepreg Tapes

- Investigation of Microstructural, Mechanical and Corrosion Properties of AA7010-TiB2 in-situ Metal Matrix Composite

- A Comparative Study of Structural Changes in Conventional and Unconventional Machining and Mechanical Properties Evaluation of Polypropylene Based Self Reinforced Composites

- Research on Influence mechanism of composite interlaminar shear strength under normal stress

- Mechanical properties of geopolymer foam at high temperature

- Synthesis and mechanical properties of nano-Sb2O3/BPS-PP composites

- Multiscale acoustic emission of C/SiC mini-composites and damage identification using pattern recognition

- Modifying mechanical properties of Shanghai clayey soil with construction waste and pulverized lime

- Relationship between Al2O3 Content and Wear Behavior of Al+2% Graphite Matrix Composites

- Static mechanical properties and mechanism of C200 ultra-high performance concrete (UHPC) containing coarse aggregates

- A Parametric Study on the Elliptical hole Effects of Laminate Composite Plates under Thermal Buckling Load

- Morphology and crystallization kinetics of Rubber-modified Nylon 6 Prepared by Anionic In-situ Polymerization

- Effects of Elliptical Hole on the Correlation of Natural Frequency with Buckling Load of Basalt Laminates Composite Plates

- Effect of interphase parameters on elastic modulus prediction for cellulose nanocrystal fiber reinforced polymer composite

- Mixed Matrix Membranes prepared from polysulfone and Linde Type A zeolite

- Fabrication and low-velocity impact response of pyramidal lattice stitched foam sandwich composites

- Design and static testing of wing structure of a composite four-seater electric aircraft

- CSG Elastic Modulus Model Prediction Considering Meso-components and its Effect

- Optimization of spinning parameters of 20/316L bimetal composite tube based on orthogonal test

- Chloride-induced corrosion behavior of reinforced cement mortar with MWCNTs

- Statistical Law and Predictive Analysis of Compressive Strength of Cemented Sand and Gravel

- Young’s modulus and Poisson’s ratio of the deformable cement adhesives

- Reverse localization on composite laminates using attenuated strain wave

- Impact of reinforcement on shrinkage in the concrete floors of a residential building

- Novel multi-zone self-heated composites tool for out-of-autoclave aerospace components manufacturing

- Effect of notch on static and fatigue properties of T800 fabric reinforced composites

- Electrochemical Discharge Grinding of Metal Matrix Composites Using Shaped Abrasive Tools Formed by Sintered Bronze/diamond

- Fabrication and performance of PNN-PZT piezoelectric ceramics obtained by low-temperature sintering

- The extension of thixotropy of cement paste under vibration: a shear-vibration equivalent theory

- Conventional and unconventional materials used in the production of brake pads – review

- Inverse Analysis of Concrete Meso-constitutive Model Parameters Considering Aggregate Size Effect

- Finite element model of laminate construction element with multi-phase microstructure

- Effect of Cooling Rate and Austenite Deformation on Hardness and Microstructure of 960MPa High Strength Steel

- Study on microcrystalline cellulose/chitosan blend foam gel material

- Investigating the influence of multi-walled carbon nanotubes on the mechanical and damping properties of ultra-high performance concrete

- Preparation and properties of metal textured polypropylene composites with low odor and low VOC

- Calculation Model for the Mixing Amount of Internal Curing Materials in High-strength Concrete based on Modified MULTIMOORA

- Electric degradation in PZT piezoelectric ceramics under a DC bias

- Cushioning energy absorption of regular polygonal paper corrugation tubes under axial drop impact

- Erratum

- Study on Macroscopic and Mesoscopic Mechanical Behavior of CSG based on Inversion of Mesoscopic Material Parameters

- Effect of interphase parameters on elastic modulus prediction for cellulose nanocrystal fiber reinforced polymer composite

- Statistical Law and Predictive Analysis of Compressive Strength of Cemented Sand and Gravel

- Retraction

- Assessment of nano-TiO2 and class F fly ash effects on flexural fracture and microstructure of binary blended concrete

Artikel in diesem Heft

- Regular Articles

- Microstructure and compressive behavior of lamellar Al2O3p/Al composite prepared by freeze-drying and mechanical-pressure infiltration method

- Al3Ti/ADC12 Composite Synthesized by Ultrasonic Chemistry in Situ Reaction

- Microstructure and photocatalytic performance of micro arc oxidation coatings after heat treatment

- The effect of carbon nanotubes on the mechanical and damping properties of macro-defect-free cements

- Toughening Mechanism of the Bone — Enlightenment from the Microstructure of Goat Tibia

- Characterization of PVC/MWCNTs Nanocomposite: Solvent Blend

- Study on Macroscopic and Mesoscopic Mechanical Behavior of CSG based on Inversion of Mesoscopic Material Parameters

- Bearing properties and influence laws of concrete-filled steel tubular arches for underground mining roadway support

- Comparing Test Methods for the Intra-ply Shear Properties of Uncured Prepreg Tapes

- Investigation of Microstructural, Mechanical and Corrosion Properties of AA7010-TiB2 in-situ Metal Matrix Composite

- A Comparative Study of Structural Changes in Conventional and Unconventional Machining and Mechanical Properties Evaluation of Polypropylene Based Self Reinforced Composites

- Research on Influence mechanism of composite interlaminar shear strength under normal stress

- Mechanical properties of geopolymer foam at high temperature

- Synthesis and mechanical properties of nano-Sb2O3/BPS-PP composites

- Multiscale acoustic emission of C/SiC mini-composites and damage identification using pattern recognition

- Modifying mechanical properties of Shanghai clayey soil with construction waste and pulverized lime

- Relationship between Al2O3 Content and Wear Behavior of Al+2% Graphite Matrix Composites

- Static mechanical properties and mechanism of C200 ultra-high performance concrete (UHPC) containing coarse aggregates

- A Parametric Study on the Elliptical hole Effects of Laminate Composite Plates under Thermal Buckling Load

- Morphology and crystallization kinetics of Rubber-modified Nylon 6 Prepared by Anionic In-situ Polymerization

- Effects of Elliptical Hole on the Correlation of Natural Frequency with Buckling Load of Basalt Laminates Composite Plates

- Effect of interphase parameters on elastic modulus prediction for cellulose nanocrystal fiber reinforced polymer composite

- Mixed Matrix Membranes prepared from polysulfone and Linde Type A zeolite

- Fabrication and low-velocity impact response of pyramidal lattice stitched foam sandwich composites

- Design and static testing of wing structure of a composite four-seater electric aircraft

- CSG Elastic Modulus Model Prediction Considering Meso-components and its Effect

- Optimization of spinning parameters of 20/316L bimetal composite tube based on orthogonal test

- Chloride-induced corrosion behavior of reinforced cement mortar with MWCNTs

- Statistical Law and Predictive Analysis of Compressive Strength of Cemented Sand and Gravel

- Young’s modulus and Poisson’s ratio of the deformable cement adhesives

- Reverse localization on composite laminates using attenuated strain wave

- Impact of reinforcement on shrinkage in the concrete floors of a residential building

- Novel multi-zone self-heated composites tool for out-of-autoclave aerospace components manufacturing

- Effect of notch on static and fatigue properties of T800 fabric reinforced composites

- Electrochemical Discharge Grinding of Metal Matrix Composites Using Shaped Abrasive Tools Formed by Sintered Bronze/diamond

- Fabrication and performance of PNN-PZT piezoelectric ceramics obtained by low-temperature sintering

- The extension of thixotropy of cement paste under vibration: a shear-vibration equivalent theory

- Conventional and unconventional materials used in the production of brake pads – review

- Inverse Analysis of Concrete Meso-constitutive Model Parameters Considering Aggregate Size Effect

- Finite element model of laminate construction element with multi-phase microstructure

- Effect of Cooling Rate and Austenite Deformation on Hardness and Microstructure of 960MPa High Strength Steel

- Study on microcrystalline cellulose/chitosan blend foam gel material

- Investigating the influence of multi-walled carbon nanotubes on the mechanical and damping properties of ultra-high performance concrete

- Preparation and properties of metal textured polypropylene composites with low odor and low VOC

- Calculation Model for the Mixing Amount of Internal Curing Materials in High-strength Concrete based on Modified MULTIMOORA

- Electric degradation in PZT piezoelectric ceramics under a DC bias

- Cushioning energy absorption of regular polygonal paper corrugation tubes under axial drop impact

- Erratum

- Study on Macroscopic and Mesoscopic Mechanical Behavior of CSG based on Inversion of Mesoscopic Material Parameters

- Effect of interphase parameters on elastic modulus prediction for cellulose nanocrystal fiber reinforced polymer composite

- Statistical Law and Predictive Analysis of Compressive Strength of Cemented Sand and Gravel

- Retraction

- Assessment of nano-TiO2 and class F fly ash effects on flexural fracture and microstructure of binary blended concrete