Abstract

In this work, geopolymer foam composites containing waste basalt fibre (10, 30, and 50%wt) were exposed to elevated temperatures of 200, 400, 600, 800 and 1000∘C. With an increase in high temperature, the geopolymer foams material exhibits a decrease in compressive strength and bending strength. When heated above 600∘C, geopolymer foams materials exhibit a significant reduction in mechanical properties. It shows clearly with the naked eye that surface cracks in case of samples containing 10% of basalt filler. However, when increasing fillers with basalt fibres up to 30% and 50%, the cracking of the sample surface is no longer visible to the naked eye. Especially when the temperature increases, the mechanical properties also increase without decreasing in the sample of 50% by weighing to the binder. The results show that reinforcing the geopolymer foams with basalt ground fibre improves the mechanical properties at high temperatures.

1 Introduction

Cement and their variants are widely used in the construction industry. By 2030, about 4.83 billion tons of cement will be produced globally [1]. Cement is the primary aggregate to produce concrete. One of the weaknesses of concrete is its low fire-resistance compared to some other construction materials, and it causes global warming to affect the production of one tonne of cement generates one tonne of carbon dioxide [2].

Geopolymer is a break-through material. The production of one tonne of kaolinite-based geopolymeric cement generates only 0.18 tons of CO2, compared with 1 tonne of CO2 for Portland cement (six times less) [3]. Fly ash-based geopolymeric cement has attracted intensive research word-wide because it emits even less CO2, up to nine times less than Portland cement.

Geopolymer materials have several advantages such as high durability, suitable fire-resistant and thermal stability, excellent mechanical properties, and resistance to acid attacks. Low-density geopolymers could be considered as potential materials for applications in many fields such as thermal insulation, fire resistance and other high-temperature applications (Figure 1). Due to its low thermal conductivity, geopolymer designed for fire resistance applications could be exposed to high temperature for an extended period.

![Figure 1 Maximum application temperature of some insulation materials [4].](/document/doi/10.1515/secm-2020-0013/asset/graphic/j_secm-2020-0013_fig_001.jpg)

Maximum application temperature of some insulation materials [4].

The construction made of concrete usually has a large net mass [5]. The use of geopolymers of lower density is beneficial in term of reduced structural load-bearing with further benefits of acoustic and thermal insulation [6, 7]. Different foaming agents can be used to synthesise low-density geopolymers. Metallic aluminium powder is commonly used and is very reactive in alkaline environments and react at room temperatures [7, 8, 9].

Fibre reinforcement has been used in various hardened binders to improve mechanical properties [10, 11, 12, 13, 14, 15]. Reinforced geopolymer adds either steel fibres, glass fibres or carbon fibres or basalt fibres to carry mechanical properties and for high temperature resistant geopolymer composites [16, 17, 18, 19].

This study was conducted to study the physical and mechanical properties of geopolymers with enhanced fillers. Evaluating these properties is essential for better material use purposes.

2 Materials and Methods

2.1 Used materials

During the experiments, the following raw materials were used: binder, grounded basalt fibre and foaming agent. The used binder material was Baucis Lk, supplied by České Lupkové Závody (Czech Republic). This is an inorganic two-component aluminosilicate material based on metakaolin and potassium alkaline silicate solution [20]. Grounded basalt fibre was used in the experimental work as reinforcement material. To obtain grounded fibres, the stone wool Isover N (manufactured by Saint-Gobain Construction Product CZ a.s.) was milled (see Figure 2).

Photograph of basalt fibre grounded using the mill.

The preparation of geopolymer coatings was carried out using aluminium powder (foaming agent). This powder produces bubbles in the material volume, which increases porosity and reduces the weight of the geopolymer coating. The chemical composition and particle size of the aluminium powder are shown in Table 1.

The chemical composition and size of the aluminium powder.

| Name | Diameter | Al | FeO | SiO | Cu |

|---|---|---|---|---|---|

| D50 | 65μm | 98% | 0.35% | 0.4% | 0.02% |

2.2 Geopolymer synthesis

Geopolymers were synthesized using cement and the activator. The materials were homogenized with a stirrer for 5 minutes. After homogenization, the filler (basalt fibre) and aggregate (fine sand) were added to the mixture, and they were stirred for a further 5 minutes to full homogenization. Aluminium powder was added to the geopolymer slurry after 10 minutes of mixing period, and they were mixed for a further 30 s at high RPM. Immediately after mixing, samples were poured into test moulds. The synthesis of geopolymers was carried out according to Figure 3.

Schematic flowchart of geopolymer foams processing.

Afterwards, the polymer paste was poured into moulds of dimensions 40×40×160 mm (see Figure 4). In 2 to 8 minutes, geopolymer began to expand (pores formation) and finished after 20 to 30 minutes. Samples were cured at room temperature for 1 to 2 hours, and then the test specimens cut by hand-saw.

Prepared samples: a) in moulds of size 40×40×160 mm, b) after cut by hand-saw c) samples removed from moulds.

In this work, three samples of geopolymer foams with different weight percentages of basalt waste fibre (Table 2) were prepared and tested. All samples were made modules on 40×40×160 mm. They were cured after 28 days at room temperature. They were heated in a furnace at various temperatures of 200, 400, 600, 800 and 1000∘C. The heating rate of the furnace was set to 5∘C per minute until it reached the desired temperature, and the final temperature was kept for two hours. After they were holding them in the furnace until they lowered room temperature and then take to test.

Composition of geopolymer foams.

| Mix ratio by weight | |||

|---|---|---|---|

| Binder | Activator | Grounded basalt fibre | Aluminium powder |

| 1 | 0.9 | 0.1 | 0.015 |

| 1 | 0.9 | 0.3 | 0.015 |

| 1 | 0.9 | 0.5 | 0.015 |

2.3 Test procedures

The evaluation of the samples was carried out using mechanical tests, and subsequently, the structure of the tested samples was analysed. Drying of samples was done in a designated room at room temperature or an elevated temperature until the test requirements were met. The final result value was determined as the average of three measurements.

2.3.1 Apparent density

Apparent density was calculated with the following equation:

Where:

Apparent density (Kg/m3);

Mass is the mass of the specimen (Kg);

Volume is the volume of the specimen (m3);

2.3.2 Flexural strength and compressive strength

The strength was evaluated by a hydraulic press, universal Testing Mechanical INSTRON Model 4202 (Figure 5). Flexural strength was calculated from a three-point bending test on the samples of size 40×40×160 mm [21, 22]. Three cubes of 40 mm were cut from the test bar, and they were used for compressive strength testing. Continuously tested three samples were performed after 28 days.

Universal testing machine INSTRON (Model 4202): a) test set-up for flexural strength b) test set-up for compressive strength.

The compressive strength of geopolymer foams (fcm) was calculated by the equation:

Where:

fcm is compressive strength (MPa);

Fmax is the maximum applied load indicated by the testing machine (N);

Ac is the original cross-sectional area of a specimen in a compression test (mm2);

The flexural strength (Rmo) was calculated by the equation:

Where:

Rmo is the flexural strength (MPa);

Fmax is the maximum applied load indicated by the machine (N);

b is the average width of the specimen (mm);

h is the average depth of the specimen (mm);

L is span length (mm);

2.3.3 Weight loss

Weight loss was calculated using the equation:

Where:

WL is the weight loss (%);

W0 is the initial mass (g);

W is the remaining mass at any given time(g);

2.3.4 Dry shrinkage

Dry shrinkage was calculated using the following equation:

Where:

SL is the dry shrinkage (%);

L0 is the length of the specimen (mm);

L is the remaining length of the specimen at any given time (mm);

2.3.5 Water Absorption

Water absorption is used to measure the permeability of geopolymer foams. The test made on the specimen (40×40×80) mm. All the samples were kept in room temperature for 28 days before they were tested. Each result was calculated from the average of three samples. According to ASTMC642 06 regulation, the samples were cured in an oven at a temperature of 100 to 110∘C for not less than 24 h and determine the mass A. The samples were soaked in water for interval 24h. Surface-dry the sample by removing surface moisture with a towel, and determine the mass B.

Water absorption was calculated using the following equation:

Where:

A is the mass of the dry sample (g);

B is the mass of the wet sample (g);

3 Results and discussion

As part of this work, research was carried out that is relevant to building materials and those that have fireproofing properties. The physical characteristics of the material at room temperature and subjected to elevated temperatures were characterized. The density, water absorption, pore size, compressive and flexural strength were tested, and the weight loss and shrinkage of the materials after heating were examined. The building material that is to constitute a fire barrier must be characterized by the smallest possible change in physical parameters - otherwise a building disaster may occur during a fire. Compressive and flexural stregth testing will give an answer as to whether the material will continue to withstand when exposed to high temperatures.

3.1 Characterization of materials in room temperature

The addition of fibres contributes to the increase in the geopolymer foam density. However, it is not a significant increase (Figure 6). Furthermore, the addition of the fibre leads to reduced water absorption (Figure 7).

The density of geopolymer foams with increasing basalt waste fibre concentration at room temperature.

The absorption coefficient of geopolymer foams with increasing basalt waste fibre concentration.

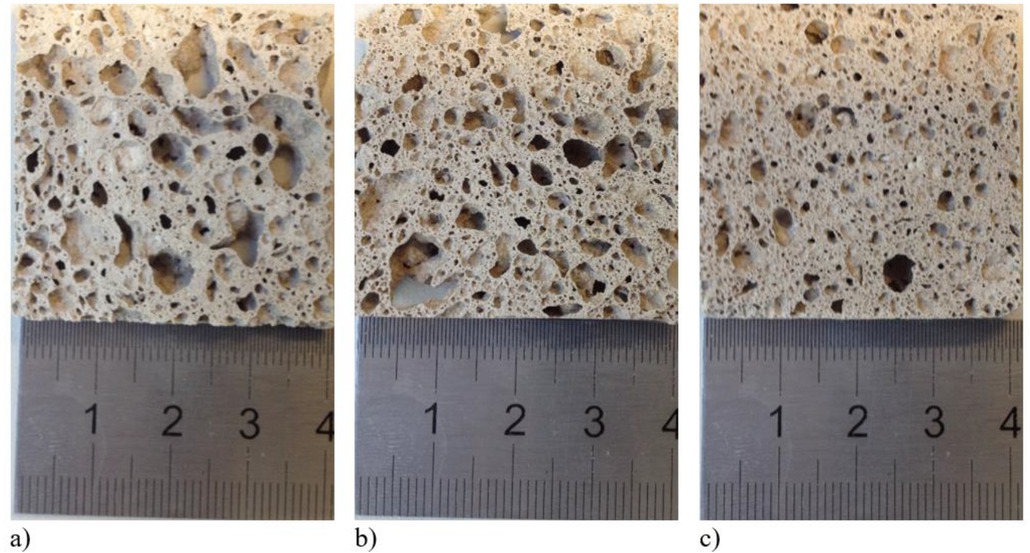

The fibre content also affects the pore size (Figure 8). The smallest pores occur in samples with a 50% fibre content (Figure 8c), the largest in samples with a content of 10% (Figure 8a).

Pores size of geopolymer foams with various content of reinforcing fibre a) 10%, b) 30%, c) 50 % (total image width: 40 mm).

3.2 Characterization of material subjected to elevated temperature

All samples exhibit a colour change after heating from 200∘C to 1000∘C as follow: grey at 200∘C, blackish-grey from 400∘C to 800∘C, yellowish-grey at 1000∘C (Figure 9). There are visible cracks on samples containing 10% which were heated up to 600, 800 and 1000∘C (Figure 9a). Samples reinforced with a larger amount of basalt fibre tend to crack less (Figure 9b and 9c). It is clearly seen that the fibers contribute to a change in the transfer of stress associated with sintering the material and thus inhibit the propagation of cracks from the places where these stresses arise.

Colour change and cracks occurrence of geopolymer foams with different content of basalt waste fibre a) 10%, b) 30% and c) 50% after heating at various temperatures.

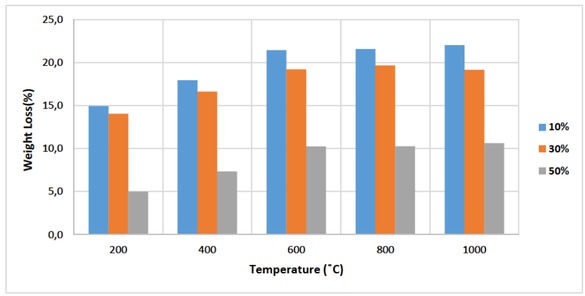

The temperature of the material has a significant influence on the absorption coefficient. It decreases rapidly at 200∘C, 400∘C, and 600∘C. However, at 600∘C, 800∘C, 1000∘C, it doesn’t decrease, and it’s stable (Figure 10). This is particularly evident in the case of a sample with 50% fibre content, where coefficient doesn’t decrease at range from 400∘C to 1000∘C. A similar situation occurs in the case of weight loss of tested samples at different temperatures (Figure 11).Weight loss increases in range from 200∘C to 600∘C. A further increase in temperature does not result in weight loss. The weight loss of unreinforced and the low fiber content samples is associated with the evaporation of water and gases in the pores, which are much larger than those of samples reinforced with more fibers. For the same reason, there is a significant change in the water absorption of samples with low (or no) fiber content.

The absorption coefficient of geopolymer foams with different content of basalt waste fibre at high temperature.

Weight loss of geopolymer foams with different content of basalt waste fibre at high temperature.

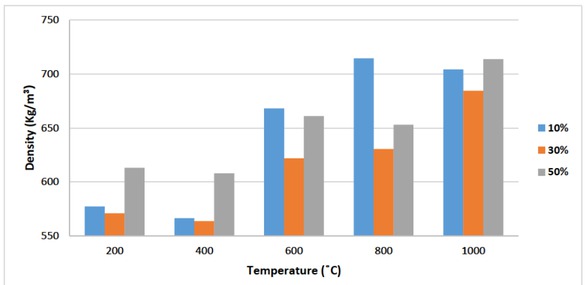

Temperature also has a significant impact on the density (Figure 13) and shrinkage (Figure 12) of geopolymer composites – both increase with the temperature. The fastest growth is visible at high temperatures, above 400∘C. In the case of density changes, a slight decrease was observed in all samples at a temperature of 400∘C. The highest density changes at increasing temperature were observed in samples with less (10% and 30%) fibre content. Shrinkage is associated with the chemical nature of the material from which geopolymers are made. At high temperature there is a transformation from an amorphous to a crystalline phase. This happens following the crystallization of amorphous sodium aluminosilicates into nephelin.

Shrinkage by the length of geopolymer foams with different content of basalt waste fibre at high temperature.

The density of geopolymer foams with different content of basalt waste fibre at high temperature.

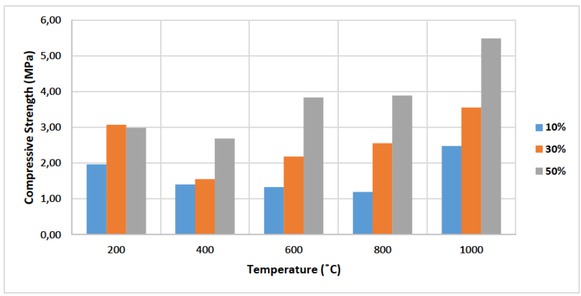

Figures 14 and 15 show changes in strength (compression and flexural, respectively) depending on the temperature. The increasing dependence of strength on the temperature in the range from 400∘C to 1000∘C was observed. However, samples with a temperature of 200∘C than 400∘ C were characterized by much higher strength. This is particularly evident in the case of samples with a lower fibre content (10% and 30%). Samples with 50% fibre content are characterized by the highest strength at temperatures above 400∘C. At 1000∘C, a sudden increase in strength in the sample with a 50% fibre content was observed (at 1000∘C the compressive strength is 83.61% higher than compressive strength at 200∘C). Samples reinforced with a higher fiber content are characterized by higher bending strength due to the smaller number of pores, which dramatically affect the strength of the material, increasing its fragility. In addition, the crystallization of aluminosilicate mentioned above occurs at a high temperature, which further promotes mechanical strength.

Change of compressive strength of geopolymer foams vs. heating temperatures.

Evolution of Flexural strength of geopolymer foams vs. heating temperatures.

4 Conclusions

The results showed that the reinforcement of geopolymers with different content of basalt fibres influences the mechanical properties of the obtained composites. The high fibre content improves practically all of the tested parameters, making the material also stable at very high temperatures. Through the reinforcement of the geopolymer composite with the right amount of basalt fibres, it’s possible to obtain heat-resistant material. The research showed the influence of the content of introduced fibres in the formation of pores, crack propagation and in the formation of structural changes of the material, which ultimately result in its mechanical properties.

The obtained results are promising and lead us to further research towards the development of fireproof composite materials based on geopolymers.

Acknowledgement

The results of the project “Application of geopolymer composites as fire, AGK”, registration number VI20172019055, were obtained through the financial support of the Ministry of the Interior in the programme “The Safety Research of the Czech Republic, 2015-2020 (BV III/1-VS)”.

References

[1] (2018). Cement: global production 1990-2030. Available: https://www.statista.com/statistics/373845/global-cement-production-forecast/Search in Google Scholar

[2] Davidovits J. Global warming impact on the cement and aggregates industries. World Resour Rev. 1994;6:263–78.Search in Google Scholar

[3] Davidovits J. "Geopolymer chemistry and applications," in Geopolymer Chemistry & Applications, ed: Geopolymer Institute, 2008.Search in Google Scholar

[4] Liefke E. Industrial applications of foamed inorganic polymers. Geopolymere. 1999;99:189–200.Search in Google Scholar

[5] Just A, Middendorf B. Microstructure of high-strength foam concrete. Mater Charact. 2009;60(7):741–8.10.1016/j.matchar.2008.12.011Search in Google Scholar

[6] Feng J, Zhang R, Gong L, Li Y, Cao W, Cheng X. "Development of porous fly ash-based geopolymer with low thermal conductivity," Materials & Design (1980-2015), vol. 65, pp. 529-533, 2015.10.1016/j.matdes.2014.09.024Search in Google Scholar

[7] Chiu YP, Lu YM, Shiau YC. "Applying inorganic geopolymers added with aluminium powder to fire-resistant fillers," Materials Research Innovations, vol. 19, pp. S5-642-S5-649, 2015.10.1179/1432891714Z.0000000001168Search in Google Scholar

[8] Caijun Shi B. "Composition of materials for use in cellular lightweight concrete and methods thereof," ed: advanced materials technologies, 2002.Search in Google Scholar

[9] Škvára F. Ros tislav Šulc, Zdeněk Tišler, Petr Skřičík, Vít Šmilauer, and Z. Z. Cílová, "Preparation and properties of fly ash-based geopolymer foams," vol. 58, pp. 188-197, 2014.Search in Google Scholar

[10] Almeida JH, Angrizani CC, Botelho EC, Amico SC. "Effect of fiber orientation on the shear behavior of glass fiber/epoxy composites," Materials & Design (1980-2015), vol. 65, pp. 789-795, 2015.10.1016/j.matdes.2014.10.003Search in Google Scholar

[11] Alomayri T, Low IM. Synthesis and characterization of mechanical properties in cotton fiber-reinforced geopolymer composites. Journal of Asian Ceramic Societies. 2013;1(1):30–4.10.1016/j.jascer.2013.01.002Search in Google Scholar

[12] Alomayri T, Shaikh FU, Low IM. Mechanical and thermal properties of ambient cured cotton fabric-reinforced fly ash-based geopolymer composites. Ceram Int. 2014;40(9):14019–28.10.1016/j.ceramint.2014.05.128Search in Google Scholar

[13] Alomayri T, Vickers L, Shaikh FU, Low IM. Mechanical properties of cotton fabric reinforced geopolymer composites at 200–1000∘C. Journal of Advanced Ceramics. 2014;3(3):184–93.10.1007/s40145-014-0109-xSearch in Google Scholar

[14] V. Sathish Kumar, Blessen Skariah Thomas, and Alex Christopher., "An Experimental Study on the Properties of Glass Fibre Reinforced Geopolymer Concrete," 2012.Search in Google Scholar

[15] Hung TD, Louda P, Kroisová D, Bortnovsky O, Xiem NT. "New generation of geopolymer composite for fire-resistance," in Advances in Composite Materials-Analysis of Natural and Man-Made Materials, ed: InTech, 2011.Search in Google Scholar

[16] Hung TD, et al. New generation of geopolymer composite for fire-resistance. Advances in Composite Materials-Analysis of Natural and Man-Made Materials. InTech; 2011.Search in Google Scholar

[17] Masi G, Rickard WD, Bignozzi MC, van Riessen A. The effect of organic and inorganic fibres on the mechanical and thermal properties of aluminate activated geopolymers. Compos, Part B Eng. 2015;76:218–28.10.1016/j.compositesb.2015.02.023Search in Google Scholar

[18] Timakul P, Rattanaprasit W, Aungkavattana P. Improving compressive strength of fly ash-based geopolymer composites by basalt fibers addition. Ceram Int. 2016;42(5):6288–95.10.1016/j.ceramint.2016.01.014Search in Google Scholar

[19] D. Tran, P. Louda, O. Bortnovsky, and P. Bezucha, "Mechanical Properties of Silica-Based Geopolymer Composites Cured at Ambient Conditions in Accordance with Size-Independent Method," 2010.Search in Google Scholar

[20] AS. České lupkové závody. (2019). BAUCIS LK. Available: http://www.cluz.cz/en/baucis-lkSearch in Google Scholar

[21] "ASTM C348 - 08, Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars.," in ASTM C348 - 08: Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars., ed, 2008, pp. 1-6.Search in Google Scholar

[22] "ASTM C78/C78M - 10, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)." in ASTM C78/C78M - 10: Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ed, 2010, pp. 1-4.Search in Google Scholar

© 2020 V. Su Le et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Microstructure and compressive behavior of lamellar Al2O3p/Al composite prepared by freeze-drying and mechanical-pressure infiltration method

- Al3Ti/ADC12 Composite Synthesized by Ultrasonic Chemistry in Situ Reaction

- Microstructure and photocatalytic performance of micro arc oxidation coatings after heat treatment

- The effect of carbon nanotubes on the mechanical and damping properties of macro-defect-free cements

- Toughening Mechanism of the Bone — Enlightenment from the Microstructure of Goat Tibia

- Characterization of PVC/MWCNTs Nanocomposite: Solvent Blend

- Study on Macroscopic and Mesoscopic Mechanical Behavior of CSG based on Inversion of Mesoscopic Material Parameters

- Bearing properties and influence laws of concrete-filled steel tubular arches for underground mining roadway support

- Comparing Test Methods for the Intra-ply Shear Properties of Uncured Prepreg Tapes

- Investigation of Microstructural, Mechanical and Corrosion Properties of AA7010-TiB2 in-situ Metal Matrix Composite

- A Comparative Study of Structural Changes in Conventional and Unconventional Machining and Mechanical Properties Evaluation of Polypropylene Based Self Reinforced Composites

- Research on Influence mechanism of composite interlaminar shear strength under normal stress

- Mechanical properties of geopolymer foam at high temperature

- Synthesis and mechanical properties of nano-Sb2O3/BPS-PP composites

- Multiscale acoustic emission of C/SiC mini-composites and damage identification using pattern recognition

- Modifying mechanical properties of Shanghai clayey soil with construction waste and pulverized lime

- Relationship between Al2O3 Content and Wear Behavior of Al+2% Graphite Matrix Composites

- Static mechanical properties and mechanism of C200 ultra-high performance concrete (UHPC) containing coarse aggregates

- A Parametric Study on the Elliptical hole Effects of Laminate Composite Plates under Thermal Buckling Load

- Morphology and crystallization kinetics of Rubber-modified Nylon 6 Prepared by Anionic In-situ Polymerization

- Effects of Elliptical Hole on the Correlation of Natural Frequency with Buckling Load of Basalt Laminates Composite Plates

- Effect of interphase parameters on elastic modulus prediction for cellulose nanocrystal fiber reinforced polymer composite

- Mixed Matrix Membranes prepared from polysulfone and Linde Type A zeolite

- Fabrication and low-velocity impact response of pyramidal lattice stitched foam sandwich composites

- Design and static testing of wing structure of a composite four-seater electric aircraft

- CSG Elastic Modulus Model Prediction Considering Meso-components and its Effect

- Optimization of spinning parameters of 20/316L bimetal composite tube based on orthogonal test

- Chloride-induced corrosion behavior of reinforced cement mortar with MWCNTs

- Statistical Law and Predictive Analysis of Compressive Strength of Cemented Sand and Gravel

- Young’s modulus and Poisson’s ratio of the deformable cement adhesives

- Reverse localization on composite laminates using attenuated strain wave

- Impact of reinforcement on shrinkage in the concrete floors of a residential building

- Novel multi-zone self-heated composites tool for out-of-autoclave aerospace components manufacturing

- Effect of notch on static and fatigue properties of T800 fabric reinforced composites

- Electrochemical Discharge Grinding of Metal Matrix Composites Using Shaped Abrasive Tools Formed by Sintered Bronze/diamond

- Fabrication and performance of PNN-PZT piezoelectric ceramics obtained by low-temperature sintering

- The extension of thixotropy of cement paste under vibration: a shear-vibration equivalent theory

- Conventional and unconventional materials used in the production of brake pads – review

- Inverse Analysis of Concrete Meso-constitutive Model Parameters Considering Aggregate Size Effect

- Finite element model of laminate construction element with multi-phase microstructure

- Effect of Cooling Rate and Austenite Deformation on Hardness and Microstructure of 960MPa High Strength Steel

- Study on microcrystalline cellulose/chitosan blend foam gel material

- Investigating the influence of multi-walled carbon nanotubes on the mechanical and damping properties of ultra-high performance concrete

- Preparation and properties of metal textured polypropylene composites with low odor and low VOC

- Calculation Model for the Mixing Amount of Internal Curing Materials in High-strength Concrete based on Modified MULTIMOORA

- Electric degradation in PZT piezoelectric ceramics under a DC bias

- Cushioning energy absorption of regular polygonal paper corrugation tubes under axial drop impact

- Erratum

- Study on Macroscopic and Mesoscopic Mechanical Behavior of CSG based on Inversion of Mesoscopic Material Parameters

- Effect of interphase parameters on elastic modulus prediction for cellulose nanocrystal fiber reinforced polymer composite

- Statistical Law and Predictive Analysis of Compressive Strength of Cemented Sand and Gravel

- Retraction

- Assessment of nano-TiO2 and class F fly ash effects on flexural fracture and microstructure of binary blended concrete

Articles in the same Issue

- Regular Articles

- Microstructure and compressive behavior of lamellar Al2O3p/Al composite prepared by freeze-drying and mechanical-pressure infiltration method

- Al3Ti/ADC12 Composite Synthesized by Ultrasonic Chemistry in Situ Reaction

- Microstructure and photocatalytic performance of micro arc oxidation coatings after heat treatment

- The effect of carbon nanotubes on the mechanical and damping properties of macro-defect-free cements

- Toughening Mechanism of the Bone — Enlightenment from the Microstructure of Goat Tibia

- Characterization of PVC/MWCNTs Nanocomposite: Solvent Blend

- Study on Macroscopic and Mesoscopic Mechanical Behavior of CSG based on Inversion of Mesoscopic Material Parameters

- Bearing properties and influence laws of concrete-filled steel tubular arches for underground mining roadway support

- Comparing Test Methods for the Intra-ply Shear Properties of Uncured Prepreg Tapes

- Investigation of Microstructural, Mechanical and Corrosion Properties of AA7010-TiB2 in-situ Metal Matrix Composite

- A Comparative Study of Structural Changes in Conventional and Unconventional Machining and Mechanical Properties Evaluation of Polypropylene Based Self Reinforced Composites

- Research on Influence mechanism of composite interlaminar shear strength under normal stress

- Mechanical properties of geopolymer foam at high temperature

- Synthesis and mechanical properties of nano-Sb2O3/BPS-PP composites

- Multiscale acoustic emission of C/SiC mini-composites and damage identification using pattern recognition

- Modifying mechanical properties of Shanghai clayey soil with construction waste and pulverized lime

- Relationship between Al2O3 Content and Wear Behavior of Al+2% Graphite Matrix Composites

- Static mechanical properties and mechanism of C200 ultra-high performance concrete (UHPC) containing coarse aggregates

- A Parametric Study on the Elliptical hole Effects of Laminate Composite Plates under Thermal Buckling Load

- Morphology and crystallization kinetics of Rubber-modified Nylon 6 Prepared by Anionic In-situ Polymerization

- Effects of Elliptical Hole on the Correlation of Natural Frequency with Buckling Load of Basalt Laminates Composite Plates

- Effect of interphase parameters on elastic modulus prediction for cellulose nanocrystal fiber reinforced polymer composite

- Mixed Matrix Membranes prepared from polysulfone and Linde Type A zeolite

- Fabrication and low-velocity impact response of pyramidal lattice stitched foam sandwich composites

- Design and static testing of wing structure of a composite four-seater electric aircraft

- CSG Elastic Modulus Model Prediction Considering Meso-components and its Effect

- Optimization of spinning parameters of 20/316L bimetal composite tube based on orthogonal test

- Chloride-induced corrosion behavior of reinforced cement mortar with MWCNTs

- Statistical Law and Predictive Analysis of Compressive Strength of Cemented Sand and Gravel

- Young’s modulus and Poisson’s ratio of the deformable cement adhesives

- Reverse localization on composite laminates using attenuated strain wave

- Impact of reinforcement on shrinkage in the concrete floors of a residential building

- Novel multi-zone self-heated composites tool for out-of-autoclave aerospace components manufacturing

- Effect of notch on static and fatigue properties of T800 fabric reinforced composites

- Electrochemical Discharge Grinding of Metal Matrix Composites Using Shaped Abrasive Tools Formed by Sintered Bronze/diamond

- Fabrication and performance of PNN-PZT piezoelectric ceramics obtained by low-temperature sintering

- The extension of thixotropy of cement paste under vibration: a shear-vibration equivalent theory

- Conventional and unconventional materials used in the production of brake pads – review

- Inverse Analysis of Concrete Meso-constitutive Model Parameters Considering Aggregate Size Effect

- Finite element model of laminate construction element with multi-phase microstructure

- Effect of Cooling Rate and Austenite Deformation on Hardness and Microstructure of 960MPa High Strength Steel

- Study on microcrystalline cellulose/chitosan blend foam gel material

- Investigating the influence of multi-walled carbon nanotubes on the mechanical and damping properties of ultra-high performance concrete

- Preparation and properties of metal textured polypropylene composites with low odor and low VOC

- Calculation Model for the Mixing Amount of Internal Curing Materials in High-strength Concrete based on Modified MULTIMOORA

- Electric degradation in PZT piezoelectric ceramics under a DC bias

- Cushioning energy absorption of regular polygonal paper corrugation tubes under axial drop impact

- Erratum

- Study on Macroscopic and Mesoscopic Mechanical Behavior of CSG based on Inversion of Mesoscopic Material Parameters

- Effect of interphase parameters on elastic modulus prediction for cellulose nanocrystal fiber reinforced polymer composite

- Statistical Law and Predictive Analysis of Compressive Strength of Cemented Sand and Gravel

- Retraction

- Assessment of nano-TiO2 and class F fly ash effects on flexural fracture and microstructure of binary blended concrete