Abstract

Modern materials science has faced the problem of reducing the cost of raw materials and labor costs while obtaining basic construction materials (cement concrete) with increased performance properties. The article aims to substantiate the use of carbon nanotubes of fly ash as a cement concrete modifier to be reasonable for solving the above problem. Experimental studies are carried out using standard and special methods. The technological properties of cement concrete mixtures are determined in accordance with the European and American standards. The study investigates the impact of carbon nanotubes of fly ash on the structure and properties of the mineral Portland cement binder. The article provides the examination of structural and rheological characteristics of nano-modified cement concrete mixtures. The effect of a carbon nano-modifier on the strength, deformation, and performance properties of cement concrete mixtures is defined. As a result, the optimal composition of nano-modified cement concrete mixture has been developed that meets the criteria of concrete compressive strength and flowability. Positive research results allow determining the areas of application of the obtained compositions in civil engineering.

1 Introduction

Reduction in the construction cost is among the primary tasks, and it primarily depends on the loss in value of construction materials. In civil engineering, the basic construction material is cement concrete and its derivatives. In turn, the cost of cement binder is the most expensive in producing cement concrete mixtures. It is several times higher than the cost of other components such as coarse and fine aggregates (crushed stone and sand) and water. Accordingly, savings on the binder will directly reduce the cost of the cement concrete mixture and the construction in general.

Modern civil engineering more and more resorts to high-tech concrete mixtures that provide strength and performance properties of structures throughout their wear-life. Along with high workability, these mixtures should have such characteristics as fast concrete strength development and high physical and mechanical properties. They should correspond to the class of “high-functional concretes.” The solvation of the issue is complex and requires using several types of modifiers, consisting of mineral additives, thinners, superplasticizers, etc. [1]. As a rule, superplasticizers make the modified concrete expensive. Moreover, the previously studied modified concretes have such disadvantages as shrinkage and creep above the norm, the lowered modulus of elasticity, cracking in the supporting structures, reduced frost resistance, etc.

The reinforced properties have nano-modified concretes made of various industrial wastes such as aggregated microsilica of slag fillers of ferroalloy plants, granulated blast-furnace slag, fly ash, etc. Currently, the advanced domestic and foreign experience proves the effectiveness of nanomodification technologies in construction materials. Primary nanomaterials (carbon tubes) of fly ash of thermal power plants (TPPs) have proved to reinforce the performance properties up to 40%. However, there were very few such studies carried out.

Moreover, numerous studies have established the effectiveness of polymer-cement binders, which differ from ordinary Portland cement (PC) by reinforced physical and mechanical properties and durability [2,3]. The introduction of fly ash into a cement concrete mixture allows achieving a binder saving of about 30% without reducing the quality of concrete. The possibility to replace the cement binder increases by 40–50% when it is possible to increase the hardening time. In contrast to other mineral additives, ash introduced into a concrete mixture improves its workability. As a rule, the dependence between the flowability of a concrete mixture and the content of ash in it is progressive, and the optimal content should correspond to the tasks set [4,5]. In turn, such properties of a cement concrete mixture with fly ash additive allow it to be applicable in self-compacting concretes (SCCs).

SSC mixtures are widely used in civil engineering to produce reinforced concrete and concrete structures of a wide range putting into effect the following principles:

Cut out vibrations in pouring reinforced concrete structures;

Improve working conditions by cutting out vibration and noise during construction work;

Improve the quality of pouring densely reinforced structures;

Improve the quality of the concrete surface and the ability to create any specific geometric surfaces.

There were studies in Ukraine and European countries aimed to reinforce the performance properties of concrete by introducing fibrous additives into the cement, such as polymer fibers, basalt fibers, fly ash fiber of TPP. Concretes with the addition of basalt fiber and fly ash fiber show higher indicators of strength, water, and frost resistance. However, the introduction of various fibers into a concrete mixture does not properly affect its workability and compactibility.

The purpose of this research is to develop a mineral PC binder modified by carbon nanotubes of fly ash, which will ensure the reinforced performance properties and durability of concrete based on it. To achieve the purpose, it is necessary to fulfill the following objectives:

Substantiate the expediency of carbon nanotubes (CNTs) of fly ash used as a mineral binder (PC) modifier;

Develop a rational technology for the CNT uniform distribution and effective dispersion in PC;

Investigate the CNT effect on the structure and properties of a mineral PC binder;

Develop the optimal composition of nano-modified concrete mixture according to the criteria of concrete compressive strength and flowability;

Study structural and rheological characteristics of nano-modified concrete mixtures;

Define the effect of a carbon nano-modifier on the strength, deformation, and performance properties of cement concrete;

Determine the area of application of the obtained material in civil engineering.

2 Materials and methods

The production of strong and durable concrete involves lowering the water–cement ratio. In turn, it increases energy consumption and workability when pouring and vibrating concrete mixtures and produces hard mixtures that away. The latter significantly contributes to the complexity of the technological process. However, the production of high workability concrete mixtures requires increasing water consumption, which, as a rule, leads to a decrease in their strength and durability. In the mid-70s of the last century, the development of effective plasticizers and superplasticizers contributed to the partial solvation of the problem. Their use in concrete compositions provided a plasticizing and water-reducing effect [6,7].

Unfortunately, there were numerous disadvantages along with the clear advantages. Superplasticizers had a retarding effect on concrete setting and hardening. First- and second-generation superplasticizers segregated cement concrete mixtures if their transportation took more than 60–90 min. Pumping concrete mixtures with superplasticizers by concrete pumps over a distance of more than 250 m resulted in their segregation. The particle-size distribution of a mineral part of concrete should meet the requirements for pump concrete mixtures [8]. Polyfunctional modifier additives have brought concrete mixture technology to a new level [9]. Modifier additives correctly selected allow controlling cement concrete properties as follows:

CNTs are well miscible with cement and do not stick together, which allows their use without additional dispersion [10].

The effect of introducing CNTs, nanoparticles, is expressed in quantum mechanical manifestations.

CNT high surface area serves as substrates for calcium silicate hydrate gel (C–S–H gel) precipitation. On the other hand, CNTs used in concrete mixtures prevent water and mixture segregation.

Based on the above, the article puts forward the following research hypothesis: the required level of quality of concrete mixtures and concretes for construction can be ensured by their modification with a complex of CNT and superplasticizer additives where the basis for the latter is sodium naphthalene sulfonate (PNS). The introduction of hydroxide/sulfate sodium, which acts as an alkaline activator, is also required. Alkaline hardening activator and CNTs that act as centers for hydrosilicate gel precipitations can compensate for the low strength of concrete due to a partial replacement (up to 35%) of PC with ground granulated blast-furnace slag (GGBFS) or ash-and-slag mixture (ASM).

When experimenting with concrete mixtures, the authors of the article used PC 500 produced by PAO (Public Joint Stock Company) Heidelberg Cement Ukraine as a binder (S cement = 357 cm2/kg; SC = 26.2%, R 28 = 51.2 MPa). Tables 1 and 2 provide the chemical and mineralogical composition of PC clinker, and Table 3 presents the physical and mechanical properties of cement.

Chemical composition of PC clinker

| Cement brand | Oxide contents (%) | Loss on ignition (LOI) | ||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | R2O | SO3 | ||

| PC 500 | 21.4 | 5.8 | 3.4 | 61.5 | 1.7 | 0.7 | 2.5 | 1.2 |

Mineralogical composition of clinker

| Cement brand | Contents of minerals (%) | |||

|---|---|---|---|---|

| C3S | β-C2S | C3A | C4AF | |

| PC 500 | 57.4 | 27.9 | 5.1 | 9.6 |

Physical and mechanical properties of PC

| PC brand | Density (kg/m3) | Fineness of cement (cm2/kg) | Standard consistency (%) | Setting time (hour-minute) | Ultimate strength (activity) (MPa) | ||

|---|---|---|---|---|---|---|---|

| Start | End | σ bending | σ compression | ||||

| PC 500 | 3,100 | 357.0 | 26.2 | 1-00 | 3-40 | 6.4 | 51.2 |

The authors of the article used ground ASM of Burshtynska TPP as a mineral additive and CNTs as a nano-modifier. Tables 4 and 5 provide the chemical composition and properties of the ASM and CNTs.

Chemical composition of CNTs

| Material | Element content (%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Al | Si | S | Cl | Ca | Ti | Cr | Mn | Fe | Ni | Cu | |

| CNT | 68.61 | 8.35 | 0.1 | 0.17 | 0.01 | 3 | 0.03 | 0.01 | 0.97 | 0.10 | 0.17 | 18.30 | 0.18 |

Chemical composition of ASM of Burshtynskaya TPP

| Material | Oxide contents (%) Physical properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | SO3 | LOI | Density (kg/dm3) | Specific surface (m2/kg) | |

| ASM | 68.61 | 8.35 | 0.1 | 0.17 | 0.01 | 19.13 | 0.03 | 3.6 | 2.92 | 414 |

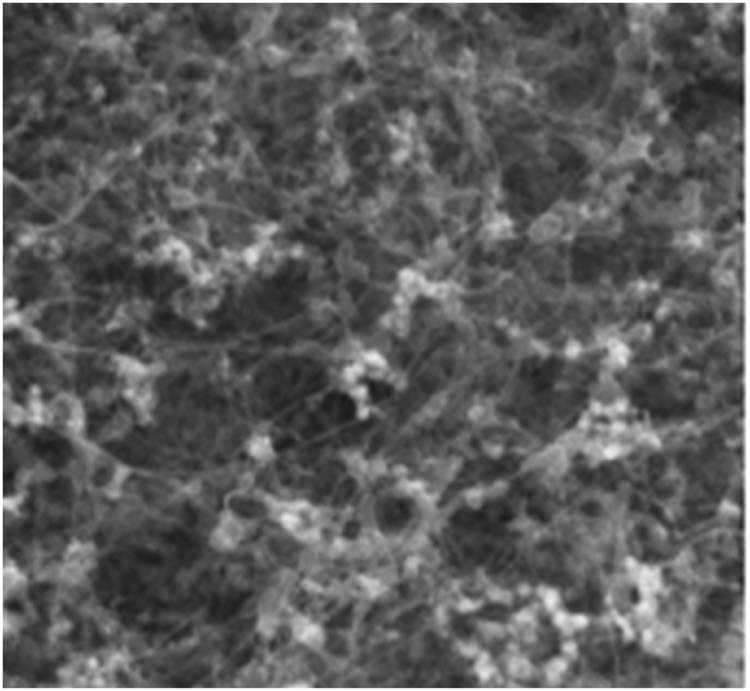

The appearance of carbon nanotubes is shown in Figure 1.

Appearance of carbon nanotubes.

The aggregates were as follows: crushed stone (fraction 5–20 mm); quartz sand (Mk = 2.4); and quartz sand (Mk = 1.1). Table 5 presents chemical composition of ash and slag mixture, and the chemical composition of aggregates is provided in Table 6.

Chemical composition of aggregates

| Material | Oxide contents (wt%) | |||||

|---|---|---|---|---|---|---|

| SiO2 | Na2O | CaO | Fe2O3 | SO3 | LOI | |

| Quartz sand (Mk = 2.4) | 97.65 | 0.04 | 0.88 | 1.29 | >0.1 | 0.05 |

| Quartz sand (Mk = 1.1) | 97.25 | 0.87 | 0.7 | 1.01 | 0.02 | 0.17 |

| Crushed stone | 64.0 | 20.3 | 0.9 | 14.4 | — | 0.38 |

A superplasticizer based on sodium naphthalene sulfonate is used as a chemical additive (Table 7).

Nomenclature and characteristics of plasticizing additives

| Type, designation | Trademark | Chemical formula | Dispersion mechanism |

|---|---|---|---|

| Sodium naphthalene sulfonate, PNS |

|

|

|

As a polymer additive, the authors used a high-molecular weight organic compound (HMWOC) and CNTs. The additive is produced by adding CNTs to HMWOC by the dispersion method (for uniform distribution of CNTs in the polymer).

To fulfill the objectives set, we have developed the structural and logical scheme of theoretical and experimental research, which includes four successive blocks:

Theoretical prerequisites for producing road nano-polymer concrete with specified quality parameters;

Development of the method to produce nano-polymer modifier; study of its influence on the rheological properties of cement pastes and technological properties of concrete mixtures; hardening of cement pastes and concrete mixtures;

Advanced composition of nano-polymer concrete; examination of performance and physical and mechanical properties;

Development of nano-polymer concrete production technology.

Experimental studies are carried out using standard and special methods. The authors studied the rheological properties of cement pastes (plastic viscosity and shear yield stress) in accordance with DIN 53018 by a rotational viscometer Rheotest RN 4.1 with a “cone-plate” measuring system [12], (German Institute for Standardization, 1976). The results processed was in accordance with the Bingham plastic model.

where τ 0 denotes a shear yield stress (Pa), μ is a plastic viscosity (Pa s), and γ is a shear rate (c−1).

Technological properties of concrete mixtures are determined following the European Guidelines for SCC [13].

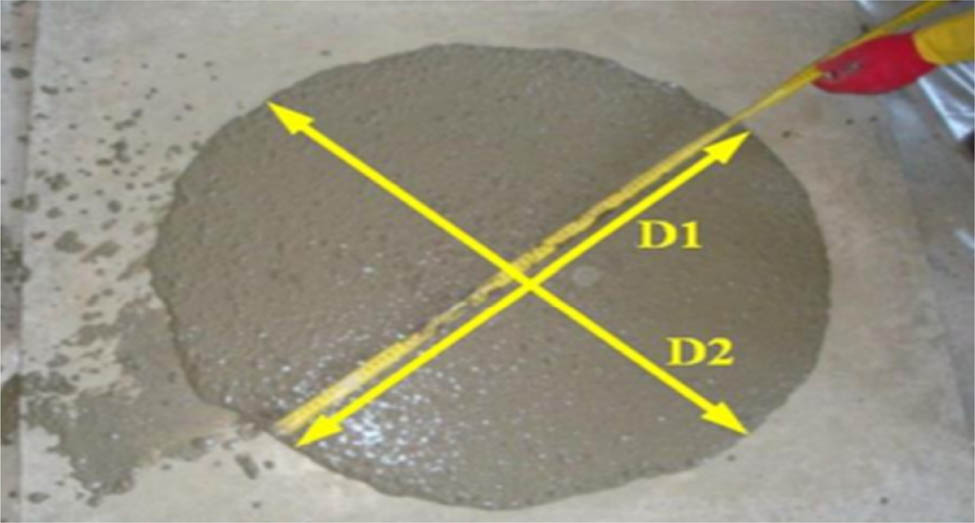

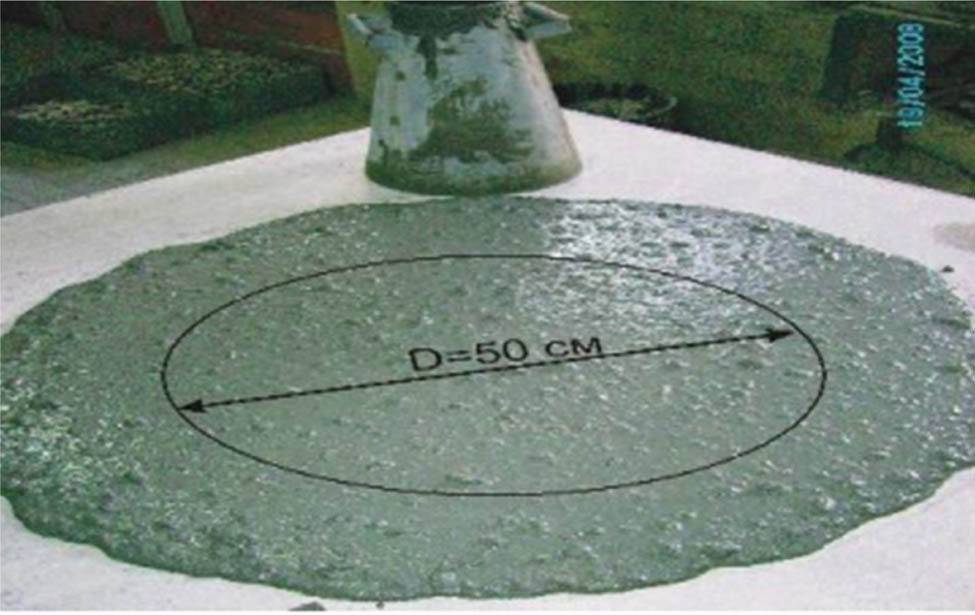

Flowability parameters of cement pastes were determined according to Viscometer Suttard by the flow diameter. Parameters of the technological properties of concrete mixtures are characteristics such as flowability (mobility), expressed by a slump flow diameter (flow spread S, mm) and a flowing time of the concrete mixture of the cone to reach a diameter of 500 mm (slump flow time, T 500, s) (Figures 2 and 3). A mini-cone was used to determine the flowability parameters of mixtures, which had the following dimensions: the diameter of the lower base – 140 mm, the upper one – 70 mm, the height – 200 mm, and the volume – 2 L. The results are brought to standard values using correction factors.

Determination of the flow diameter of the mixture (flow spread S, mm).

Determination of the flowing time of the mixture (slump flow time, T 500, s).

Physical and mechanical properties were determined according to the standard methods. The strength properties of concrete were determined on cubic specimens with an edge size of 0.07 and 0.04 m (ultimate compressive strength) and on prism specimens with a size of 0.04 m × 0.04 m × 0.16 m (ultimate tensile strength) (Figure 4).

Determination of SCC resistance to segregation in a three-section cylinder.

The samples hardened under normal conditions at a temperature of t = 20 ± 20°C for 28 days. Accelerated hardening was carried out in a laboratory steaming chamber equipped with a device for automatic regulation, according to the mode: 3 + 8 + 2 h at t = 80 ± 2.5°C. Determination of the shrinkage deformation factors during concrete drying was carried out on prismatic specimens with dimensions of 0.04 m × 0.04 m × 0.16 m, not isolated from moisture exchange with the environment.

Frost resistance of concrete was determined at the design age [14,15]. Cube specimens were streamed and subsequently soaked in water for 27 days, then they were dried to constant weight. Then, they were placed in a 5% sodium chloride solution (NaCl) for 24 h (first saturation). After that, specimens were placed in the same solution for 4 h. Control and main specimens of concrete were saturated with water at a temperature of 18 ± 2°C before testing for strength and freezing, respectively.

The concrete corrosion resistance was determined on prism specimens with the size of 0.04 m × 0.04 m × 0.16 m. Concrete specimens hardened in 1 day under normal conditions and then gained strength in water for 14 days. The aggressive media were 5% HCl solution, 5% MgCl2 solution, and 5% Na2SO4 solution; in other words, acid, magnesia, and sulfate corrosion were modeled. Dispersion of HMWOC and CNTs was carried out in a laboratory bead mill. The mill was filled with glass balls with a diameter of 2–5 mm to 70–80% of the volume.

3 Results

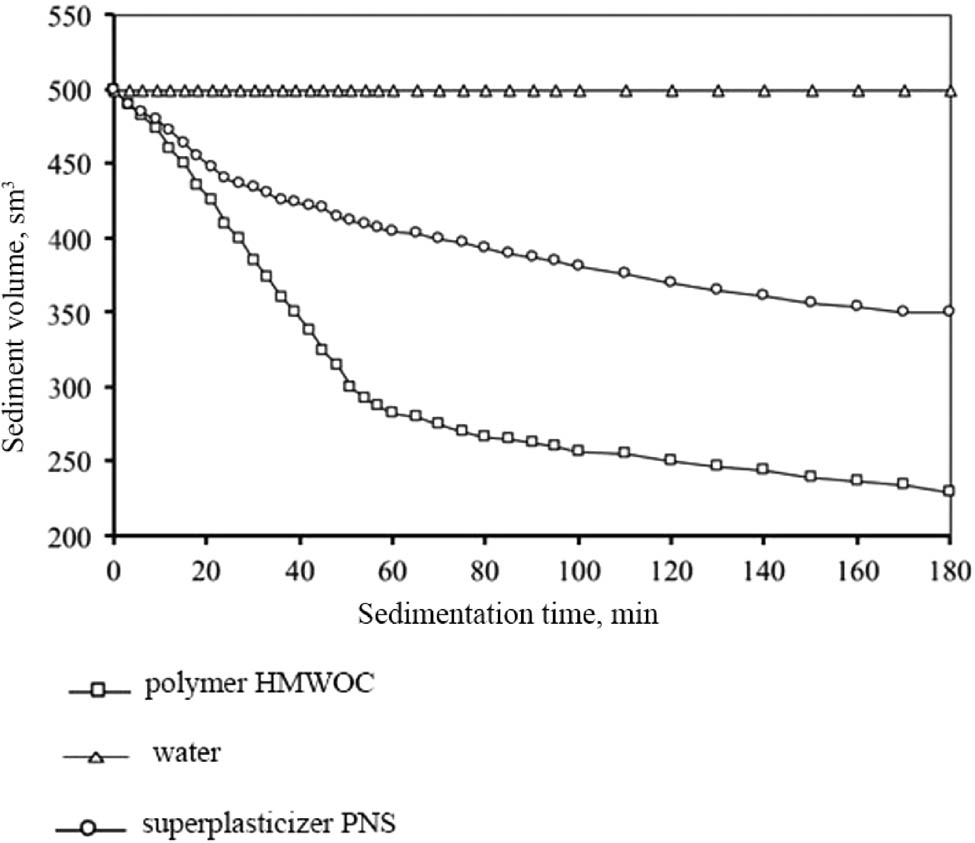

The authors have investigated how dispersion medium affects the efficiency of CNTs uniform distribution in a laboratory disperser (dispersion duration – 60 min). The dispersion medium was as follows: tap water, superplasticizer based on PNS (pH = 6.5; C = 2.5%), and HMWOC. Suspension self-heating temperature, achieved during dispersion and due to the work of friction, exclusively influences the degree of CNTs distribution. An increase in temperature (from 20 to 37°C within 3 h) shows the distribution process, primarily due to a decrease in the suspension viscosity. A decrease in viscosity is characterized by the contraction of sediment volume during sedimentation (Figure 5).

Kinetics of CNT sedimentation dispersed in the medium: HMWOC polymer, tap water, superplasticizer.

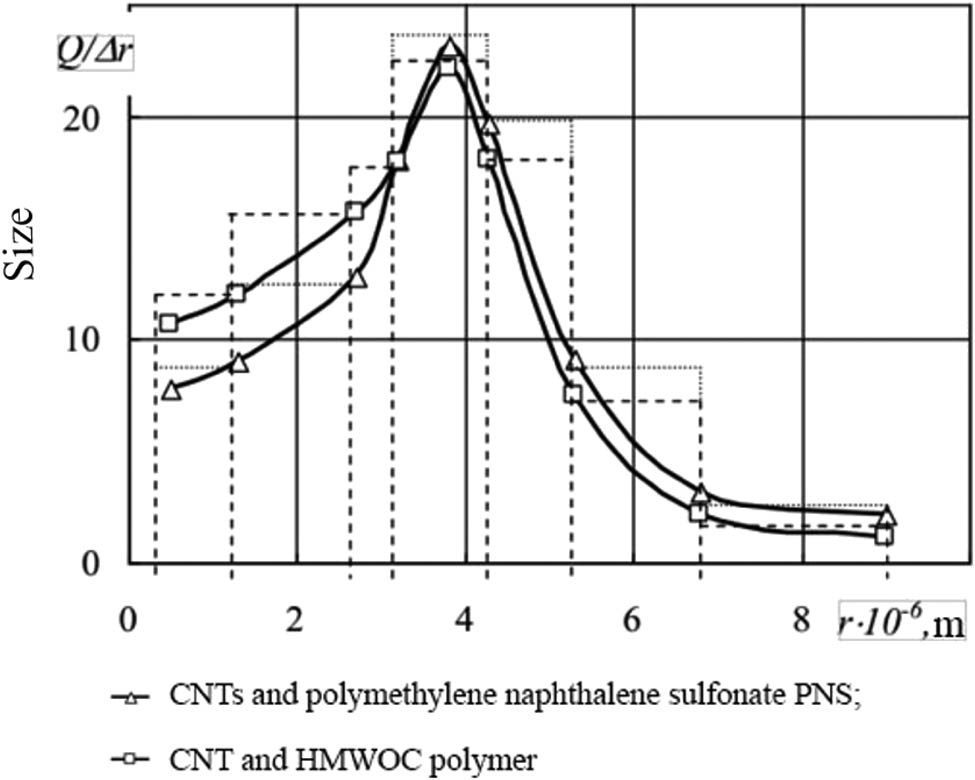

The suspension obtained, like colloidal systems, has a large specific surface area and is thermodynamically stable. The dispersion of CNTs in an HMWOC polymer medium results in the formation of a colloidal system, which retains sedimentation stability for more than 10 days. Based on the experimental data obtained, the authors plotted a sedimentation curve ‒ the dependence of the sediment weight P vs settling time τ. The sedimentation curve obtained was processed graphically, by constructing tangents at the points of the curve, corresponding to different values of the settling time. As a result, we received data for constructing the differential curves of particle-size distribution in different mediums. Figure 6 shows the differential curves of the distribution of CNT particles. According to the curve of particle-size distribution, dispersion of the particles of obtained nano-modifier is in the range of 6.0–0.5 µm. A large part of the obtained nano-modifier are represented by particles of colloidal size, which are placed in the HMWOC polymer solution.

Differential curves of dispersed phase particle distribution in medium.

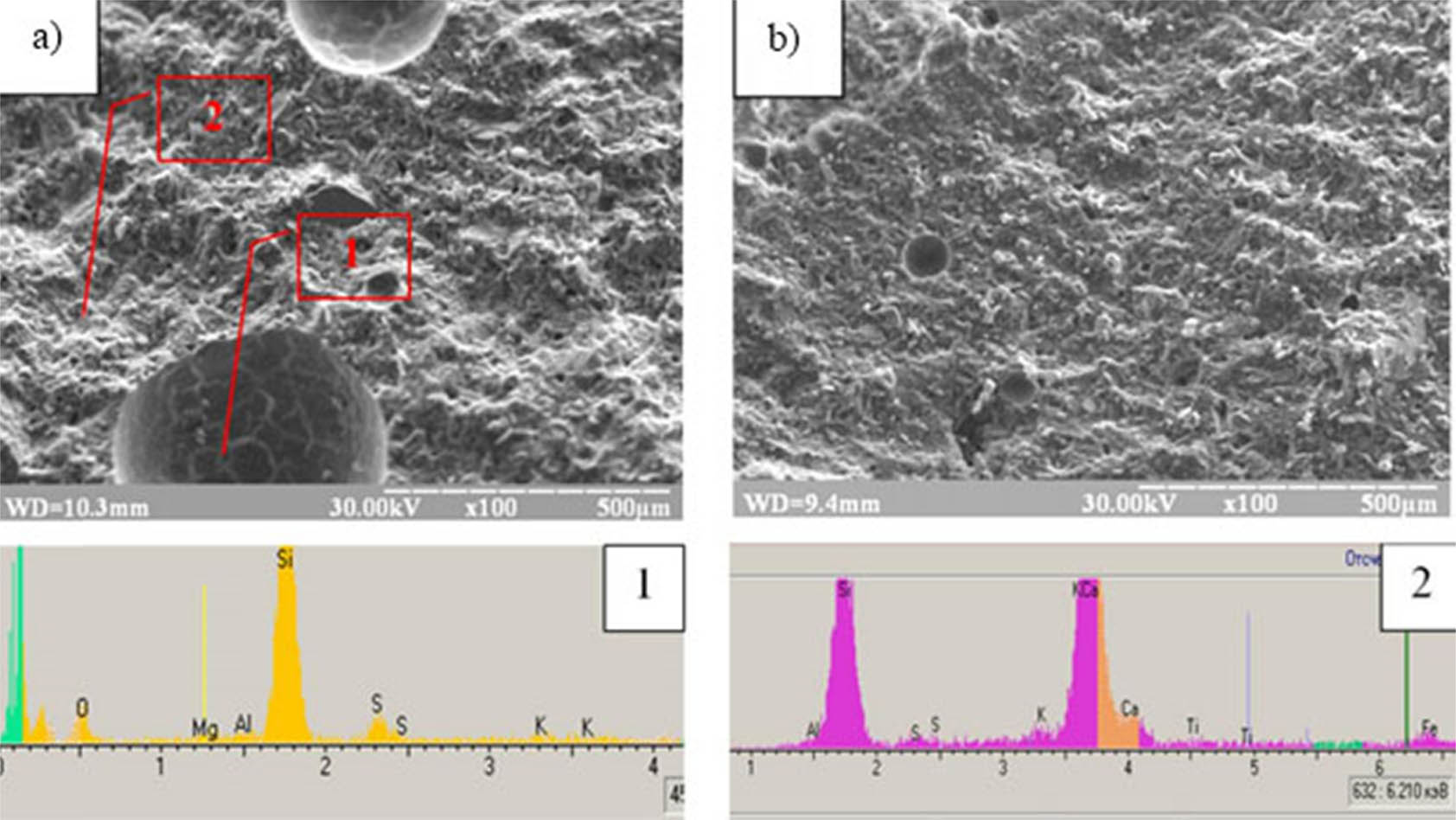

Energy dispersive spectroscopy (EDS) found that the microstructure of the cement paste contains large spherical inclusions up to 500 μm in size (Figure 7a). In cement paste with the HMWOC polymer, such inclusions are absent (Figure 7b). The composition of the cement paste is as follows:

Appearance and EDS of cement paste samples: (a) CNTs are dispersed in the PNS medium and (b) CNTs are dispersed in the HMWOC medium.

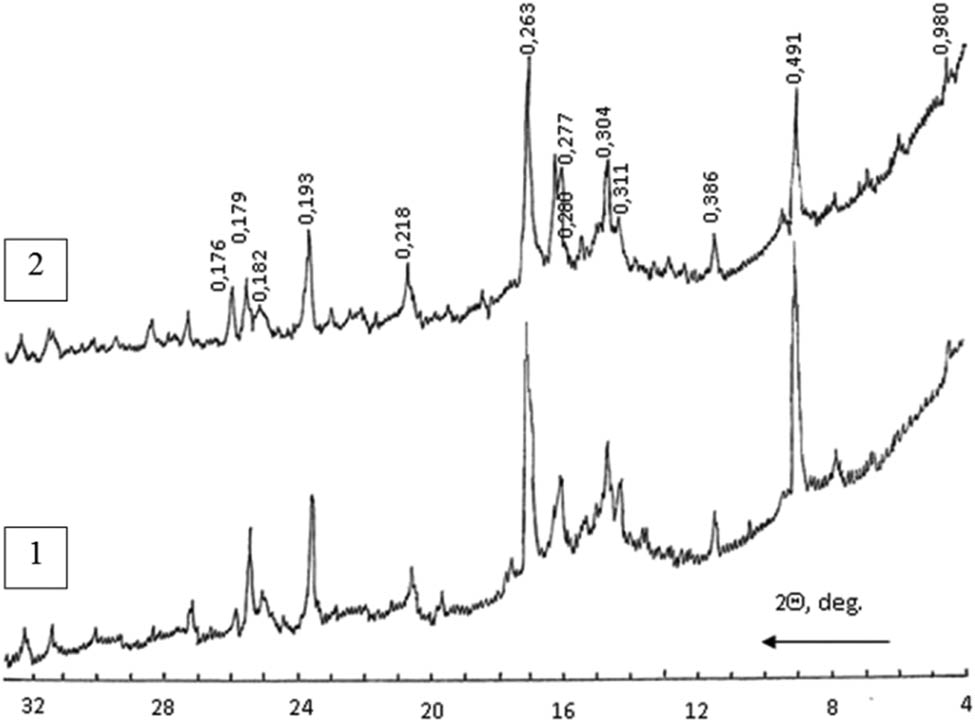

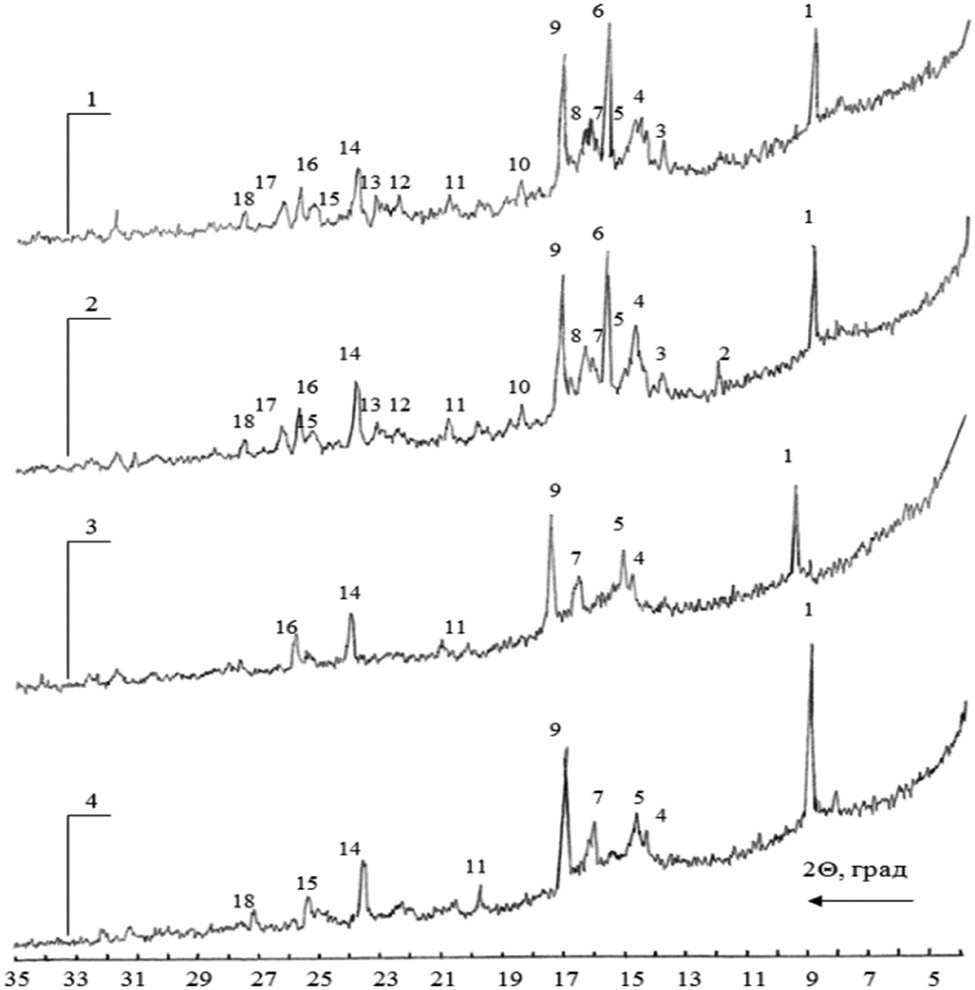

Figure 8 provides the results of X-ray diffraction analysis of cement paste samples (age 90 days) that indicate a fairly high degree of PC hydration.

X-ray diffraction patterns of cement paste samples: (1) CNTs are dispersed in PNS and (2) CNTs are dispersed in HMWOC.

The rheological properties of cement pastes with different contents of CNTs were determined by the following parameters: yield stress τ 0 (Pa), plastic viscosity μ (Pa s), and ultimate compressive strength at different times of paste hardening. These properties were investigated by a rotational viscometer Rheotest RN. The processing of the results was carried out according to the Bingham plastic model:

where τ is the shear stress, Pa; and γ is the shear rate, c−1.

The test results are shown in Table 8.

Composition and properties of cement pastes with CNT nano-modifier

| Mixture | Content of components (g) | W/B | τ 0 (Pa) | Compressive strength (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PC | Slag | CNT | PNS | HMWOC | 3 days | 7 days | 28 days | |||

| 1 | 100 | — | — | — | — | 0.26 | 59.7 | 18.5 | 27.4 | 52.4 |

| 2 | 100 | — | — | 1.2 | 2.5 | 0.24 | 58.3 | 21.3 | 31.5 | 57.6 |

| 3 | — | 100 | 7.5 | 1.2 | 2.5 | 0.28 | 57.9 | 3.5 | 6.7 | 14.4 |

| 4 | 100 | — | 7.5 | 1.2 | 2.5 | 0.21 | 56.5 | 33.2 | 41.8 | 67.3 |

It was found that the maximum value of the plastic viscosity with a shear rate of 30 c−1 has the control composition (1) with the water-binder ratio W/B = 0.26, corresponding to the value of normal density. The water demand of the cement paste with PNS (2) reduces to W/B = 0.24. In this case, the value of the plastic viscosity also decreases. The addition of CNTs significantly reduces the water demand of the cement paste, and the equilibrium plastic viscosity at a shear rate of 240–270 c−1 is the lowest among all the studied compositions of cement pastes. CNTs reduce the water demand and plastic viscosity of the cement paste, while increasing the compressive strength after 7 days of specimen hardening. This effect, along with the addition of CNTs, will contribute to the resistance index of the nano-modified concrete mixture to separation and increase the strength and performance durability.

When nano-modifier CNT is introduced, there is an inverse relationship between the amount of adsorbed nano-modifier and the cone sediment. The study of the persistence of the cement paste flowability with CNTs required first to determine the adsorption value of the nano-modifier by various mono-minerals of PC clinker and mineral additives. The following materials were used:

Mono-minerals of PC clinker (chemical composition is shown in Table 1);

Portland cement (PC) (activity 525 kgf/cm2);

HMWOC polymer;

CNT nano-modifier.

It is known that polyelectrolytes are capable of adsorbing on both oppositely charged adsorbents and adsorbents carrying the same charge as the polymer. There is no large difference in the adsorption of polycarboxylate esters on various clinker minerals. This is due to a low specific Coulomb interaction with surface active centers due to the lower specific charge density on the polymer backbone ([430–1,340] × 10−6 Equiv/g) compared with PNS ([3,780–4,110] × 10−6 Equiv/g). It was also found that cement paste with CNTs is characterized by higher strength indicators, for example, the ultimate compression strength is higher than in composition No. 1 (without additive) both in the early (by 22%) and late periods of hardening (5.3%).

The authors estimated the adsorption of nano-modifier CNTs with the surface of PC particles and mineral additives by the change in CNTs in the liquid phase before and after interaction with the solid phase (SF-26 spectrophotometer, wavelength 315 nm) [16]. Water–cement mixtures were prepared at W/C = 2.5, and the content of the CNT additive was 0.5% as large as weight. It was found that partial replacement of PC with a mineral additive led to a decrease in the adsorption value. A significant decrease in the adsorption value is observed when sodium sulfate is preliminarily introduced into the liquid phase of the cement mixture. In this case,

CNTs and PNS can meet the requirements for concrete mixtures used in the construction of new roads and airfields or their repair. Further, the authors studied how CNTs affect the preservation of the cement paste flowability with additives ‒ GBFS and ground ASM. Compositions 2 and 4 contain CNTs and an alkaline activator, respectively: GBFS ‒ sodium hydroxide (SN) and ASM ‒ sodium sulfate (SS) (Table 9).

Compositions and preparation of cement pastes

| No. | The procedure for preparing cement paste | Component consumption (%) | W/C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| PC | Mineral addition | PNS | SN | SS | |||||

| GBFS | ASM | CNT | |||||||

| 1 | [PC + GBFS + W + PNS] | 56 | 24 | — | — | 1.5 | — | — | 0.3 |

| 2 | [PC + GBFS + W] + [CNT + PNS + SN] | 24 | — | 7.5 | 1.5 | — | |||

| 3 | [PC + ASM + W + PNS] | — | 24 | — | — | — | |||

| 4 | [PC + ASM + W] + [PNS + SN] | — | 24 | 7.5 | — | 1.5 | |||

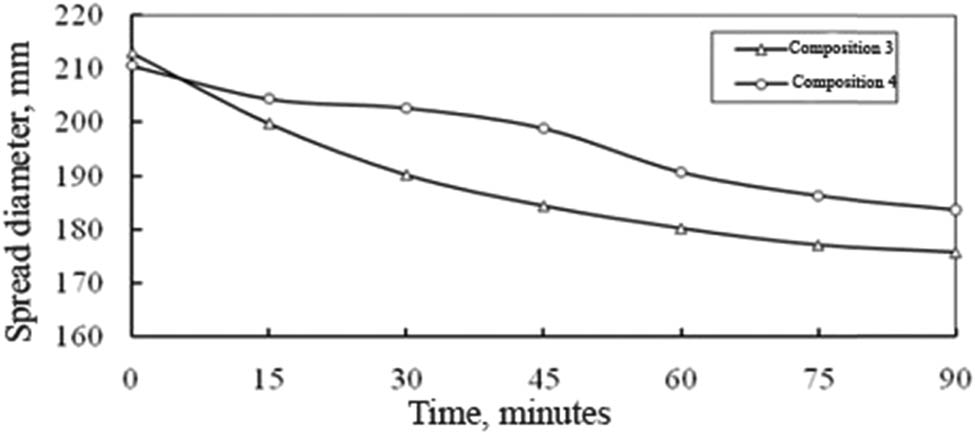

Thus, CNTs and sodium sulfate used in the composition have a smaller decrease in the cement paste flowability over time, which contains ground ASM (composition No. 4) (12.7% for 90 min of exposure) than the composition without CNTs (composition No. 3) (Figure 9). This is due to, as indicated above, the competition between the anions of

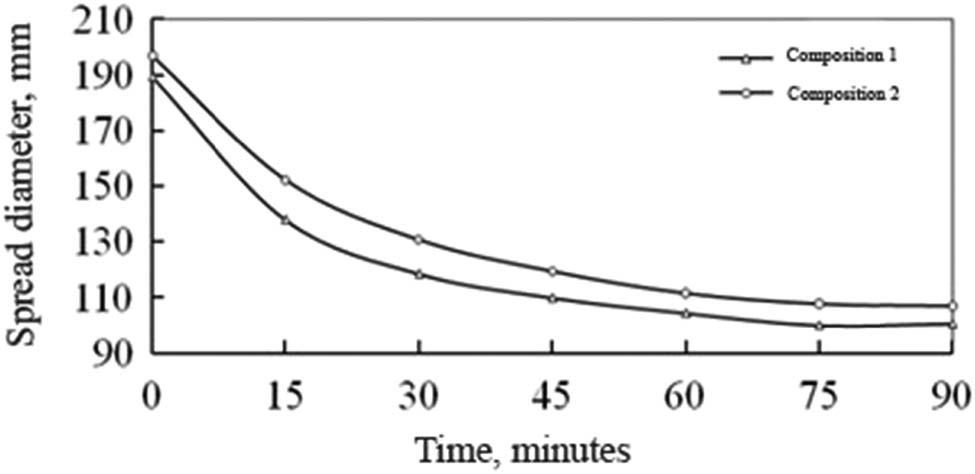

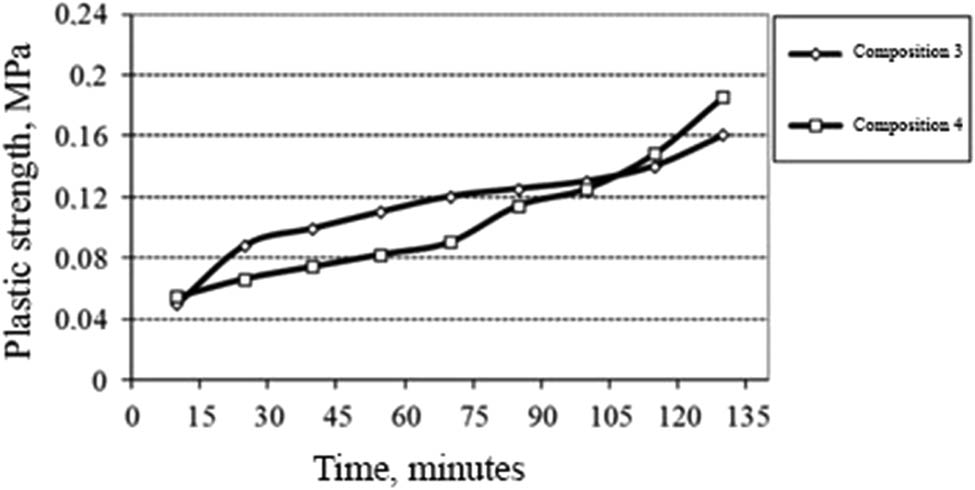

The analysis of the data in Figures 9 and 10 shows that new formations appear that have a larger specific surface area and adsorption capacity in relation to the CNT nano-modifier. In addition, a highly alkaline environment can negatively affect the efficiency of CNTs. For cement paste with CNTs and partial replacement of PC with ASM, the intensifying effect of the alkaline activator appears after 90 min of hardening (Figure 11). Until this time, cement paste with CNTs without an alkaline hardening activator has a higher plastic strength.

Change in the flowability of cement pastes with CNTs and ASM (composition No. 3) and without CNTs (composition No. 4) over time.

Change in the flowability of cement pastes with CNTs and GBFS (composition No. 2) and without CNTs (composition No.1) over time.

Plastic strength of cement paste with nano-carbon modifier and addition of ASM: composition No. 3 with CNT and composition No. 4 without CNT.

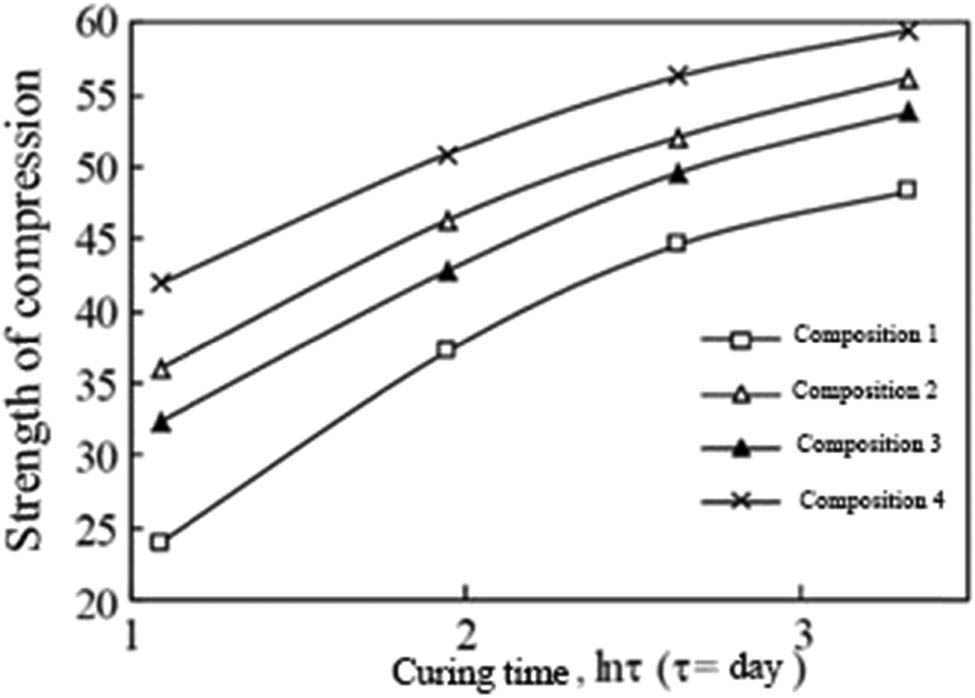

The results of the hardening of cement pastes indicate the positive effect of the nano-carbon modifier on the ultimate compression strength (Figure 12, Table 10).

Kinetics of strength growth of cement pastes.

Physical and mechanical properties of cement pastes

| Indicator | The value of the indicator for the composition No. | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Average density (kg/m3) | 2,224 | 2,245 | 2,236 | 2,255 |

| Water absorption by weight (%) | 7.75 | 6.8 | 7.12 | 6.05 |

| Compressive strength at the age of 3 days (MPa) | 23.9 | 36.0 | 32.3 | 41.9 |

| Compressive strength at the age of 7 days (MPa) | 37.2 | 45.2 | 42.8 | 50.9 |

| Compressive strength at the age of 14 days (MPa) | 44.6 | 52.1 | 49.6 | 56.3 |

| Compressive strength at the age of 28 days (MPa) | 48.3 | 56.2 | 53.8 | 59.5 |

Figure 13 and Table 11 provide the composition of the cement paste hydration according to X-ray analysis.

X-ray patterns of cement paste samples.

Characteristics of X-ray patterns of cement paste samples

| No. | Ѳ (°) | D (nm) | Mineral | Hydration % of cement paste samples, composition No. | |||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||||

| 1 | 9.0 | 0.492 | Ca(OH)2 (portlandite) | 82 | 87 | 71 | 145 |

| 2 | 11.95 | 0.370 | 3CaO·Al2O3·3CaSO4·30-32H2O (ettringite) | — | 29 | — | — |

| 3 | 19.8 | 0.323 | 25 | 18 | — | — | |

| 4 | 14.5 | 0.307 | CSH(іі) (calcium hydrosilicate) | 13 | 15 | 19 | 15 |

| 5 | 14.68 | 0.303 | 54CaO·16SiO2·Ai l2O3·MgO | 17 | 27 | 32 | 30 |

| 6 | 15.6 | 0.285 | CSH(іі) | 110 | 109 | — | — |

| 7 | 16.1 | 0.277 | 54CaO·16SiO2·Al2O3·MgO | 25 | 25 | 30 | 30 |

| 8 | 16.3 | 0.274 | 15 | 30 | — | — | |

| 9 | 17.0 | 0.263 | Ca(OH)2 | 107 | 106 | 90 | 110 |

| 10 | 18.3 | 0.245 | 54CaO·16SiO2·Al2O3·MgO | 20 | 17 | — | — |

| 11 | 20.65 | 0.218 | 15 | 20 | 13 | 17 | |

| 12 | 22.25 | 0.203 | 3CaO·Al2O3·3CaSO4·30-32H2O | 14 | 10 | 40 | — |

| 13 | 23.0 | 0.197 | 54CaO·16SiO2·Al2O3·MgO | 18 | 12 | — | — |

| 14 | 23.55 | 0.192 | Ca(OH)2 | 35 | 50 | 28 | 45 |

| 15 | 24.9 | 0.183 | CSH(іі) | 13 | 15 | — | 25 |

| 16 | 25.4 | 0.179 | Ca(OH)2 | 27 | 35 | — | — |

| 17 | 25.9 | 0.176 | 54CaO·16SiO2·Al2O3·MgO | 23 | 24 | — | — |

| 18 | 27.15 | 0.168 | Ca(OH)2 | 14 | 15 | — | 18 |

On analyzing the X-ray data of the cement paste, it is obvious that the introduction of the nano-carbon modifier does not change its basic mineral composition. Chemically interacting with minerals, it has a positive effect on the strength indicators, providing sufficient hardness with a partial replacement of PC with mineral additives (fly ash and GBFS). To optimize the concrete composition for the consumption of mineral materials and nano-modified additives, studies were carried out using the method of planning an experiment (PFE 3k). For the tests, the authors used the following concrete composition worked out in kg/m3 during laboratory studies: PC M500 ‒ 442 kg; granite crushed stone of fraction 5–10 mm ‒ 796 kg; quartz sand ‒ 885 kg; CNT ‒ 24.5 kg; water ‒ 287 L; superplasticizer PNS ‒ 6.63 kg. Comparative tests on the control composition of concrete mixtures (2) and with a nano-carbon modifier (2) show that the flowability of the mixture (2) is 11% higher than (1) (Tables 12 and 13).

Composition of nano-modified concrete mixtures

| Mixture | Contents of components (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| PC | Aggregate | CNT | GBFS | PNS | NaOH | W/C | ||

| П | Ц | |||||||

| 1 | 442 | 885 | 796 | 33.5 | 0 | 6.64 | 0 | 0.48 |

| 2 | 287 | 746 | 155 | 6.65 | ||||

Properties of nano-modified concrete mixtures

| Mixture | Properties | |||

|---|---|---|---|---|

| Cone flow diameter Dp (mm) | Penetration ability PA = H2/H1 | Viscosity T 500, c | Segregation resistance SR (%) | |

| 1 | 538 | 0.86 | 2.0 | 13.7 |

| 2 | 565 | 0.82 | 2.0 | 9.5 |

The data in Tables 12 and 13 indicate that the introduction of CNTs into the cement system is preferable in combination with a superplasticizer. If the granulometric composition of aggregates is optimized, this combination makes it possible to obtain high-strength road concrete (more than 80 MPa), characterized by sufficient viscosity. The authors determined how the composition of CNTs influences the concrete mixture flowability. Compositions of concrete with CNTs, fly ash, and GBFS were used for testing. Table 14 represents the compositions tested.

Compositions of nano-modified concrete mixtures

| No. | Component consumption (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| PC | P | C | CNT | ASM | GBFS | PNS | W | NaOH | |

| 1 | 287 | 885 | 796 | 24.5 | — | 155 | 553 | 287 | 6.65 |

| 2 | 155 | — | — | ||||||

| 3 | — | — | |||||||

| 4 | 442 | — | — | 6.64 | — | ||||

The results analyzed (Table 15) show that the additive NaOH (composition No. 1) displays a greater value in the concrete mixture than the original composition (compositions No. 2 and 3).

Determination of concrete mixture flowability

| Composition number | Flowability T 350, c | Dp (mm) |

|---|---|---|

| 1 | 3 | 450 |

| 2 | 2 | 345 |

| 3 | 2 | 200 |

| 4 | 2 | 500 |

The maximum value of flowability is observed in composition No. 4. The reason is that the composition has no CNT added, and this caused a higher water demand and led to an increase in the mixture flowability. Since the flow diameter increased due to the introduction of NaOH, it was inadvisable to introduce an alkaline component when using CNTs. It negatively affects the rheological properties of concrete mixtures. The rheological properties of concrete mixtures with an activator are shown in Table 16.

Compositions of concrete mixtures

| No. | Component consumption (kg/m3) | W/C | W/B | ||||||

|---|---|---|---|---|---|---|---|---|---|

| PC | Sand | Crushed stone | Mineral additive | PNS | CNT | ||||

| DGSH | ASM | ||||||||

| 1 | 400 | 785 | 845 | 67.5 | — | 6.9 | — | 0.6 | 0.45 |

| 2 | 400 | 785 | 845 | — | 67.5 | 4.0 | |||

| 3 | 400 | 785 | 845 | — | — | 4.0 | |||

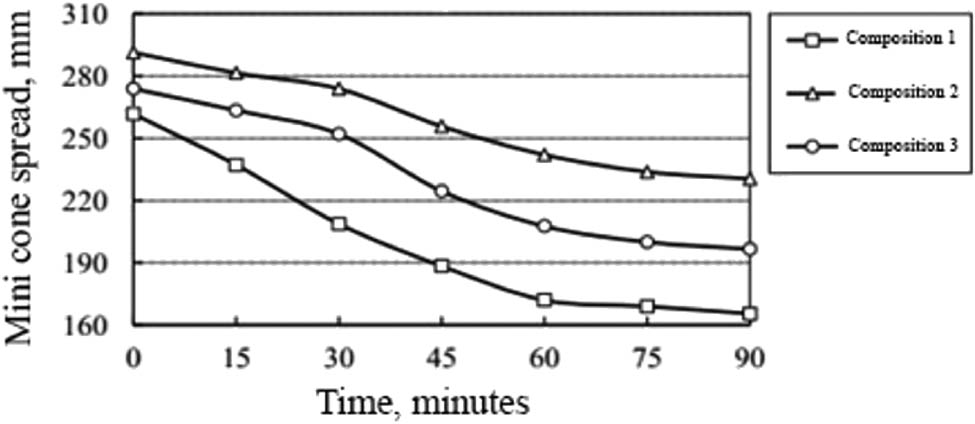

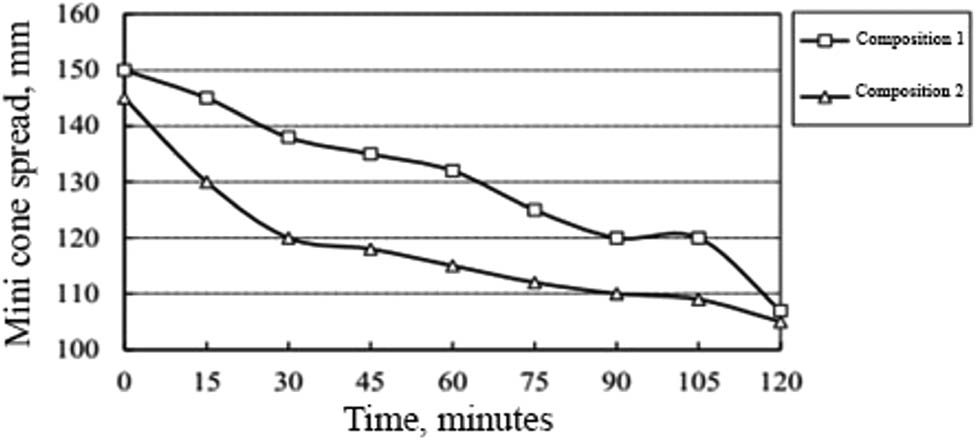

The maximum flowability was noted in the concrete mixture with ASM (composition 2). The decrease in flowability after 90 min from the moment of preparation was 20.5%. In the concrete mixture with GBFS only (composition 1) used as a mineral additive, the loss of flowability after 90 min was 28% of the initial value (Figure 14). The fastest loss of flowability is observed in the concrete mixture where there are no mineral additives but only CNT and PNS (composition 3).

Change in flowability of nano-modified concrete mixtures with time.

Further, the authors examined how the mixing method influences the change in the concrete mixture mobility over time. There were two compositions of the mixtures studied and presented in Table 17. The mixtures contain nano-modifier CNT, ASM (30%), and superplasticizer PNS. The research results are given in Table 17 and Figure 15.

Composition and procedure for the preparation of concrete mixtures

| Order of mixing components | Component consumption (kg/m3) | W/C | ||||

|---|---|---|---|---|---|---|

| PC | CNTs | Sand, S | Crushed stone, C | Additive, PNS | ||

| PC + S + C + W + CNT | 545 | 190 | 660 | 870 | 1% mц | 0.39 |

| PC + CNT + S + C + W | 0.38 | |||||

Change in the flowability of concrete mixtures depending on the preparation technology over time.

It was found that the concrete mixture prepared by the separate technology (composition No. 1) had initial flowability of 3.3% higher than composition 2. To confirm the results obtained, the indicators of the concrete mixture flowability were determined using a standard mini-cone and “L-box.” The test results are shown in Table 18. The flowability of composition No. 1 is 17% higher than it is in composition No. 2. This is due to the fact that there is a competitive adsorption of

Indicators of flowability of concrete mixes

| Composition No. | Mini-cone flowability (mm) | Spreading time T 350 (s) | Spreading time (L-box) (s) |

|---|---|---|---|

| 1 | 420 | 3 | 12 |

| 2 | 470 | 2 | 12 |

Comparative tests of concretes with a control composition (1) and with a carbon nano-modifier (2) show that the use of CNTs increases the concrete strength at various times (Table 19). It also increases the modulus of elasticity and shrinkage upon drying.

Properties of nano-modified concrete

| Mixture | Properties | |||||

|---|---|---|---|---|---|---|

| Compressive strength (MPa) | Elastic modulus E b (90 days.) (GPa) | Shrinkage ε cd (mm/m) | Water absorption (%) | |||

| 3 days | 28 days | 90 days | ||||

| 1 | 12.2 | 25.7 | 36.4 | 40.2 | 0.58 | 1.95 |

| 2 | 21.4 | 32.4 | 45.8 | 45.3 | 0.41 | 1.32 |

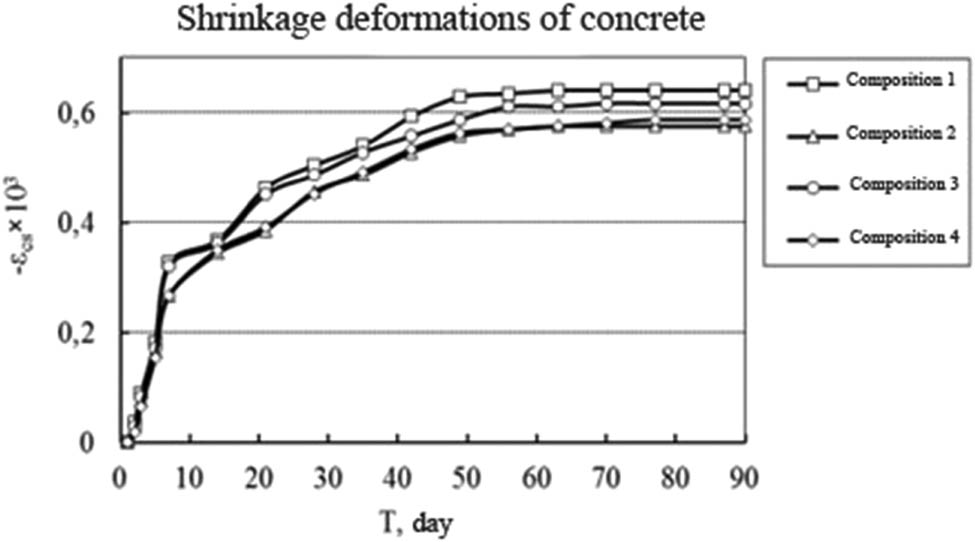

The concrete compressive strength was determined on cube specimens at the age of 3, 28, and 90 days. Concrete shrinkage deformation at the age of 90 days of composition No. 2 ([PNS + CNT] + ASM) amounted to 57.6 × 10−5, which was 10% less compared to composition No. 1 ([C-3 + NaOH] + GBFS) (Figure 16).

Relative shrinkage deformation of samples of nano-modified concrete.

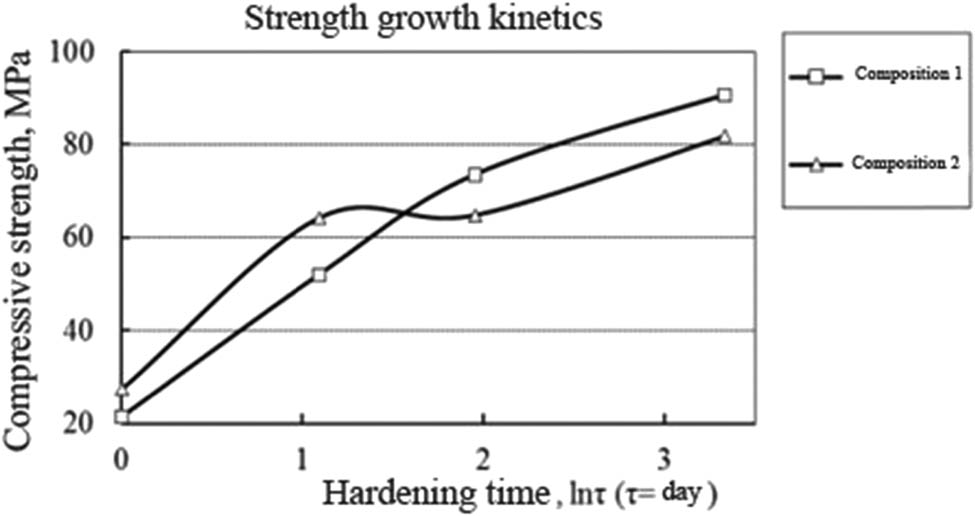

The mechanical properties of nano-modified concretes developed show that the use of GGBFS practically does not reduce the ultimate compressive strength of concrete both at the initial stages of hardening and at the design age (composition 2: R 3 = 28 MPa and R 28 = 51 MPa; composition 3: R 3 = 34 MPa and R 28 = 53 MPa). Table 20 and Figure 17 provide the indicators of physical and mechanical properties of concretes obtained by various mixing technologies.

Physical and mechanical properties of nano-modified concretes prepared by different technologies

| Indicator name | Indicator value for composition | |

|---|---|---|

| 1 | 2 | |

| Average density (kg/m3) | 2,330 | 2,320 |

| Water absorption (%) | 3.15 | 4.44 |

| Compressive strength at the age of 1 day (MPa) | 21.41 | 27.28 |

| Compressive strength at the age of 3 days (MPa) | 52.02 | 64.18 |

| Compressive strength at the age of 7 days (MPa) | 73.57 | 64.8 |

| Compressive strength at the age of 28 days (MPa) | 90.73 | 81.77 |

Kinetics of concrete strength growth.

The authors determined the ability of the developed, nano-modified concretes to withstand the effects of alternating freezing-thawing. The results obtained indicate that concretes with CNTs have reinforced performance properties ‒ frost resistance of 300 cycles (when samples are saturated in a NaCl solution). Corrosion resistance of these concretes was examined on prism specimens with a size of 0.04 m × 0.04 m × 0.16 m.

Studies have shown that nano-modified concretes have a sufficiently high corrosion resistance to the action of various aggressive media. Having been exposed for 6 months in an aggressive medium, concrete with CNTs of composition No. 1 (separate preparation technology) showed a slight decrease in the corrosion resistance coefficient – to values of 0.89 and 0.90. At the same time, the destruction of samples was less intensive in hydrochloric acid solution, and the coefficient K c decreased to a value of 0.87 with CNTs. Concretes prepared by conventional technology also proved to be resistant to the development of corrosion of the third type.

4 Discussion

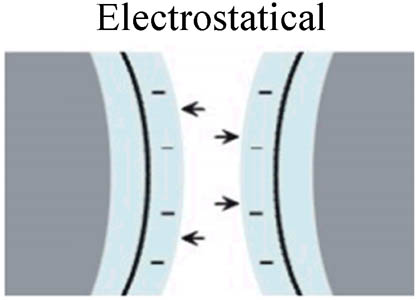

The ability of water (its molecules) to form bonds with the surface of adsorbent materials and directly with molecules is a fundamental part of adsorption in aqueous solutions [17,18]. In turn, the adsorption mechanism of the plasticizing action of surfactants involves the reaction of groups of ions and their adsorption on the surface of the solid phase and its hydrophilization [19]. The adsorption of organic molecules (polar) is possible only as a result of chemical action (or Coulomb action) since oxides, hydroxides, and aluminosilicate require a certain amount of energy when removing water molecules from their surface [20,21]. Superplasticizers are anionic polyelectrolytes that concentrate on cement clinker minerals C3A and C4AF and their hydration products [22,23]. The above is also a product of electrostatic action. Adsorption layers of the additive (its molecules) directly increase the potential to 28 mV on the surface [24,25,26]. On the contrary, if spatial polymer molecules of modifiers are used, the dispersion and stabilization of cement pastes occur as a result of the steric effect of cement particle repulsion [25].

The side hydrophobic polyester chains of polycarboxylate molecules increase the duration of the plasticization action in 3–4 times compared to various formaldehydes or lignosulfonates [26,27]. We have found that dispersion of the nano-carbon modifier of fly ash in the HMWOC polymer reduces the sedimentation rate. The above is associated with the uniform distribution of CNTs in HMWOC and the formation of colloidal particles. When a PNS superplasticizer is added, a colloidal system is formed and retains sedimentation stability for more than 10 days. The sediment volume is 15–20 cm3 after 7 days, stabilized by a surfactant [28].

It was found that the maximum value of the plastic viscosity with a minimum shear rate of 30 c−1 uses the binder ratio W/B = 0.26 (the composition of the cement paste corresponds to the value of standard density). The addition of CNTs reduces the water demand of the cement paste to W/B = 0.21. The main structural role of nano-aggregates is precisely to compact the cement hardening system. Ultrafine mineral additives, nano-carbon tubes, fly ash, and basalt dust play a physicochemical and structure-forming role at the structural level of cement mixtures. The increase in the early strength of the cement paste was observed in the composition with the partial replacement by slag (35%) and NaOH. In contrast to it, CNTs increase both early and grade strength.

Fluoroscopy showed the PC hydration. Low indices of diffraction reflections of alite also indicate the above. Furthermore, X-ray structural analysis showed the presence of Portlandite directly in the very structure of the stone. Various authors noted that the introduction of mineral additives of thermally-activated kaolin, microsilica, or ground limestone together with a superplasticizer provides less loss of concrete flowability during the first 2 h after preparation than without a mineral additive [26,29,30]. CNTs and PNS used in the composition of the nano-modifier have proven to decrease the flowability of cement paste with ASM over time compared to the composition without NaOH. In cement paste with CNTs and the addition of GBFS, the effect of sodium hydroxide on the preservation of flowability is much less pronounced.

Nano-modified concrete mixtures allow changing the surface properties (hydrophilicity, electric charge, structure of the electric double layer, and concentration of surface-active centers), and activate the structure formation of cement dispersions and its solid microstructure [31,32]. The study made it possible to determine the area of optimal concrete mixtures by the content of constituent components and the nano-carbon modifier that ensure the production of concrete mixtures with the cone flow diameter of 365 mm. The compressive strength of concrete produced is 62 MPa.

CNTs of fly ash increase the concrete strength both in the early and late periods of hardening and reduce the concrete mixture flowability. Regression equations have also proven the above. Mineral additives from industrial wastes (GBFS and ASM) used in the compositions of nano-modified concretes increase frost resistance up to 300 cycles. The corrosion resistance coefficient of 0.90 and 0.89 (aging for 6 months in an aggressive medium) indicates the high-performance properties of the concrete obtained and its possibility to be used as enclosing and supporting structures in civil engineering.

5 Conclusion

The cement concrete mixture with ASM of Burshtynskaya TPP and CNT of fly ash was investigated for the first time. HMWOC and CNTs were used as a polymer additive for the first time, which was a suspension with 45% concentration obtained by dispersing CNTs into the HMWOC polymer and adding a PNS superplasticizer in a bead mill (for uniform distribution in the CNT polymer).

The study has revealed that the concrete mixture prepared by the separate mixing technology is characterized by 3.3% higher initial flowability compared to the concrete mixture prepared by the conventional technology. Comparative tests on the concretes of control composition and with CNTs showed that the addition of CNTs allows a partial replacement (35%) of PC with GBFS. Moreover, it increases the concrete compression strength both in the early and late periods of hardening. As a result, there is also an increase in the modulus of elasticity and shrinkage of concrete upon drying. The study has found that a colloidal system is formed in the medium of HMWOC and PNS superplasticizer and retains its properties for more than 10 days.

The study has proven that the use of an alkaline activator can increase the concrete compression strength both in the early and late periods of hardening if ASM is used as a mineral additive and partially replaces PC. The results of the rheological properties of cement pastes with CNTs indicate that the replacement of PC with GBFS (35%) increases the water demand and plastic viscosity of the cement paste insignificantly. The PNS plasticizer additive positively affects the composition. A relatively small content of CNTs reduces the water demand and plastic viscosity of the cement paste, and this ensures producing a nano-modified concrete mixture with a high segregation coefficient.

The developed additive (carbon nano-modifier) can decrease the flowability of the cement paste with ASM to 12.7% within 90 min of exposure. This effect is due to the penetration of CNT anions into the centers of adsorption of the surface of PC and mineral additives. As a result, a smaller amount of unadsorbed nano-modifier remains in the liquid phase. The effect of CNTs on the decrease in flowability is expressed to a lesser extent in cement paste with the addition of blast-furnace granulated slag. The study made it possible to determine the area of optimal concrete mixtures by the content of constituent components and the nano-carbon modifier that ensured the production of concrete mixtures with the cone flow diameter of 365 mm. The compressive strength of concrete produced was 62 MPa.

The use of CNTs of fly ash for producing nano-modified road cement concrete will improve the quality and durability of the concrete and reinforced concrete structures used in civil engineering, ensuring their performance reliability and the possibility to use large-tonnage production wastes as their constituents ‒ fly ash and GBFS.

Acknowledgments

The authors gratefully acknowledge the financial support from the Science and Technology Department of Ningxia, the Scientific Research Fund of North Minzu University (No. 2020KYQD40) and China Scholarship Council under Grant (No. 202008100027, No. 202108100024).

-

Funding information: The authors gratefully acknowledge the financial support from the Science and Technology Department of Ningxia, the Scientific Research Fund of North Minzu University (No. 2020KYQD40) and China Scholarship Council under (Grant No. 202008100027 and 202108100024).

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Kaze CR, Lecomte-Nana GL, Kamseu E, Camacho PS, Yorkshire AS, Provis JL, et al. Mechanical and physical properties of inorganic polymer cement made of iron-rich laterite and lateritic clay: A comparative study. Cem Concr Res. 2021;140:140. 10.1016/j.cemconres.2020.106320.Search in Google Scholar

[2] Goodarzi I, Mirhosseini SM, Zeighami E. Experimental study of the freeze and thaw effects on the mechanical behaviour of self-compacting high-performance fibre-reinforced concrete containing active powders and/or carbon nanotubes. Aust J Struct Eng. 2022;23:37–50. 10.1080/13287982.2021.1998994.Search in Google Scholar

[3] YuM B. Structural design of modern concrete: Defining principles and technological platforms. Constr Mater. 2014;3:6–14.Search in Google Scholar

[4] Bolotskikh N. Self-compacting fine-grained concretes and fiber-reinforced concretes based on highly filled modified cement binders. Kazan: N. P. Ogarev Mordovia State University; 2006. p. 18–33.Search in Google Scholar

[5] Britchenko I, Savchenko L, Naida I, Tregubov O. Areas and means of formation of transport regional complexes and mechanisms for managing their competitiveness in Ukraine. Ikonomicheski Izsledvania. 2020;29:61–82.Search in Google Scholar

[6] Liu X, Lai G, Guan J, Qian S, Wang Z, Cui S, et al. Technical optimization and life cycle assessment of environment-friendly superplasticizer for concrete engineering. Chemosphere. 2021;281:281. 10.1016/j.chemosphere.2021.130955.Search in Google Scholar

[7] Breilly D, Fadlallah S, Froidevaux V, Colas A, Allais F. Origin and industrial applications of lignosulfonates with a focus on their use as superplasticizers in concrete. Constr Build Mater. 2021;301:301. 10.1016/j.conbuildmat.2021.124065.Search in Google Scholar

[8] Collepardi M, Borsoi A, Collepardi S, Troli R. Recent developments of special self-compacting concretes; 2004. [updated 2004 Apr 20; cited 2021 Oct 25]. https://www.encosrl.it/OLDSITE/pubblicazioni-scientifiche/pdf/high/36.pdf.Search in Google Scholar

[9] Komarinsky MV. Cast and self-compacting concrete mixtures. Constr Unique Build Struct. 2015;11:106–18.Search in Google Scholar

[10] Koshevar VD. Dispersing energy in non-aqueous media. Factor of specific interaction at interphase interfaces. Colloïd J. 2005;67:808–14.10.1007/s10595-005-0156-7Search in Google Scholar

[11] Mahmood HF, Dabbagh H, Mohammed AA. Comparative study on using chemical and natural admixtures (grape and mulberry extracts) for concrete. Case Stud Constr Mater. 2021;33:15–436. 10.1016/j.cscm.2021.e00699.Search in Google Scholar

[12] German Institute for Standardization. DIN 53018-1. Viscometry; Measurement of the dynamic viscosity of Newtonian fluids with rotational viscometers; Principles [Internet]. [updated 1976 Mar 13; cited 2022 Jan 11] https://www.filebays.org/53530-DIN-53018-1-pdf.html.10.62756/jmsi.1674-8042.2022001Search in Google Scholar

[13] The European Guidelines for Self-Compacting Concrete. [updated 2005 Aug 17; cited 2022 Jan 11]. https://www.theconcreteinitiative.eu/images/ECP_Documents/EuropeanGuidelinesSelfCompactingConcrete.pdf.Search in Google Scholar

[14] Nesvetaev GV, Davidiuk AN. Self-compacting concretes: strength and composition design. Build Mater. 2009;5:54–7.Search in Google Scholar

[15] Zhang C, Yu Z. Adsorption properties of heavy metal ions for carbon nanotube reinforced porous concrete. J Funct Mater. 2019;50:07111–14. 10.3969/j.issn.1001-9731.2019.07.020.Search in Google Scholar

[16] Jiang S, Bai B, Zhang P, Nie Q. Experiment on frost resistance of carbon polypropylene hybrid fibers reinforced lightweight aggregate concrete. J Beijing Jiaotong Univ. 2014;38:97–101. 10.11860/j.issn.1673-0291.2014.03.017.Search in Google Scholar

[17] Byung-Gi K, Shiping J, Carmel J, Pierre-Claude A. The adsorption behavior of PNS superplasticizer and its relation to fluidity of cement paste. Cem Concr Res. 2000;30:887–93. 10.1016/S0008-8846(00)00256-8.Search in Google Scholar

[18] Fang H, Zou F, Liu W. Mechanical performance of concrete pavement reinforced by CFRP grids for bridge deck applications. Composites, Part B. 2017;110:315–35.10.1016/j.compositesb.2016.11.015Search in Google Scholar

[19] Zaichenko NM. High-strength fine-grained concretes with modified mineral admixtures of fly ash and milled slag of power station. Research, Production, Utilization: International Conference; 2007 Jun 7–8. Prague: University of Economics; 2007. p. 745–56.Search in Google Scholar

[20] Koganovsky AM, Klimenko NA, Shevchenko TM, Roda IG. Adsorption of organic substances from water. Lviv: Chem; 1990. p. 256.Search in Google Scholar

[21] Savchenko L, Achkevych O, Achkevych V, Slipukha T. Development of system for stabilizing movement of power unit with rear mounted mower. Eng Rural Dev. 2021;20:750–5.10.22616/ERDev.2021.20.TF164Search in Google Scholar

[22] Sheinich LA, Popruga PV. High-strength concretes for monolithic house building. Kyiv: NDIBK. 2007;311–4.Search in Google Scholar

[23] Torresan I, Magarotto R, Zeminian N. Interaction between superplasticizers and limestone blended cements-rheological study. Int Concr Abstr Portal. 2000;195:229–48.Search in Google Scholar

[24] Merlin F. Adsorption and heterocoagulation of nonionic surfactants and latexparticles on cement hydrates. J Colloid Interface Sci. 2005;281:1–10.10.1016/j.jcis.2004.08.042Search in Google Scholar PubMed

[25] Cerny V. Possibilities of lightweight high strength concrete production from sintered fly ash aggregate. Int Conf Rehabil Reconstr Build. 2017;195:9–16.10.1016/j.proeng.2017.04.517Search in Google Scholar

[26] Rahman SS, Khattak MK. Roller compacted geopolymer concrete using recycled concrete aggregate. Constr Build Mater. 2021;238:122624. 10.1016/j.conbuildmat.2021.122624.Search in Google Scholar

[27] Gao L, Wang Z, Xie J. Study on the sound absorption coefficient model for porous asphalt pavements based on a CT scanning technique. Constr Build Mater. 2020;230:10–9.10.1016/j.conbuildmat.2019.117019Search in Google Scholar

[28] Mukharjee BB, Barai SV. Influence of incorporation of colloidal nano-silica on behaviour of concrete. Iran J Sci Technol Trans Civ Eng. 2020;44:657–68. 10.1007/s40996-020-00382-0.Search in Google Scholar

[29] Huang JS. Data-driven machine learning approach for exploring and assessing mechanical properties of carbon nanotube-reinforced cement composites. Compos Struct. 2021;267:107–13.10.1016/j.compstruct.2021.113917Search in Google Scholar

[30] Wang S. Flexural performance of reinforced carbon nanofibers enhanced lightweight cementitious composite (CNF-LCC) beams. Eng Struct. 2021;238:218–45.10.1016/j.engstruct.2021.112221Search in Google Scholar

[31] Gao F. Investigation of moisture migration of MWCNTs concrete after different heating-cooling process by LF-NMR. Eng Struct. 2021;238:245–68.10.1016/j.conbuildmat.2021.123146Search in Google Scholar

[32] Nesvetaev GV, Lopatina YY. Design of macrostructure of self-compacting concrete mixture and its mortar component. Sci. 2015;7:1–14.Search in Google Scholar

© 2022 Andrii Bieliatynskyi et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete

Articles in the same Issue

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete