Abstract

Composite sections are found to be a novel technique in modern day scenario of construction. This stands tall than the ordinary and conventional type of constructions. Columns as a structural element play a vital role in structural frame. This research comments on the behavior of composite columns. The main objective of this study is to analyze the behavior of steel-encased concrete composite columns as experimentally under axial compression and the mode of failure under ultimate failure and yield point. The steel-concrete composite system combines the formability and rigidity of reinforced concrete with the ductility and strength of structural steel to meet the demand for earthquake-resistant constructions. Three specimens were chosen for this study: one was a composite column, the other two were ordinary RC columns and structural steel columns. The raw materials' natural properties are assessed. As a result, material testing for cement, fine aggregate, and coarse aggregate was completed, as well as a concrete mix design. A comparative analysis of the local and post-local buckling behavior of different composite sections has been studied and the column sections have been designed according to Eurocode 4 (ENV 1994) to determine the plastic resistance of the section. These three specimens underwent compression test and the results are tabulated and compared. The corrosion resistance and fireproof nature (resistance to fire at higher temperatures) that are transmitted into the member are related to the steel being encased within the concrete. These are the two major drawbacks of any steel construction combined with an earthquake-resistant structure. Rather than a traditional steel construction, earthquake structures benefit from this type of load handling capabilities. The portion can be used before it completely collapses if proper design factors are taken into account.

1 Introduction

Composite construction development is inevitable due to its performance, behavior, and its load carrying capacity. Although, the composite construction reduces the time and cost for the medium-rise to high-rise buildings, the usage of different materials in combination yields better results than conventional. In particular, composite beams and slabs are used in the construction places wherever required, since the connections are employed to act together as monolithic. Usually, the composite columns are found either in the form of rolled steel sections embedded in concrete or hollow sections with in filled concrete [1]. Furthermore, the design for evaluating the strength of the components takes into account the composite action in contemporary practice. Since there is no provision for strength, steel column components encased in concrete were used in the fire and corrosion protection of the structural components. In contrast to ordinary joists, rolled steel joists were employed in the column so that the lateral ties offers confining effect in the conventional columns [2–4].

In the composite construction, the plain steel sections usually act as a support to resist the pre-construction loads including with the dead weight of the structure at the stage of construction like a scaffolding. Light weight and high strength could be driven through composite components. Further, it was reported that the steel-encased concrete composite structural systems increased extensively in the tall building construction and it was also found that the fire resistance of the encased steel tubes with concrete offers is well [5,6]. Marine buildings built with composite materials may be more cost-effective and easier to maintain. Steel stanchions encased in steel reinforcement and concrete are used to protect structural components against fire in steel frame construction [7]. By properly distributing the inducing stresses in the composite column, reducing the column's effective slenderness can increase its buckling load capacity. Figure 1 explains about the application area of composite in the field of civil engineering. In some other study, it was recommended that the composite structural components for the construction of high-rise and medium-rise construction without any justification. Steel-encased concrete composite construction does not gain much attention than conventional one due to its construction and design practice [8], and the composite column made of I-shaped thin-walled steel section embedded in concrete [9]. In most of the study, in order to prevent and improve the performance of local buckling the transverse links was used to connect the flanges at regular intervals [10].

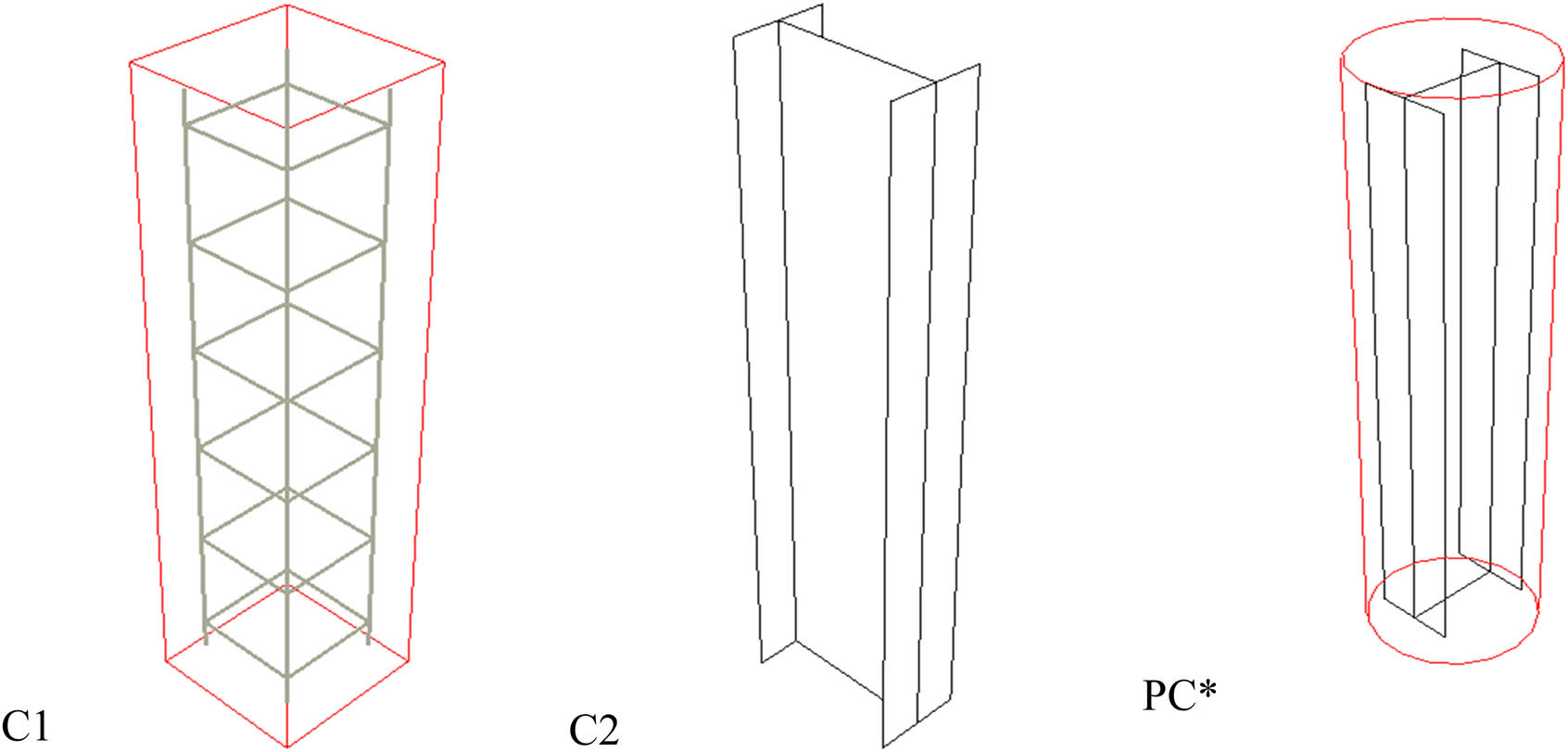

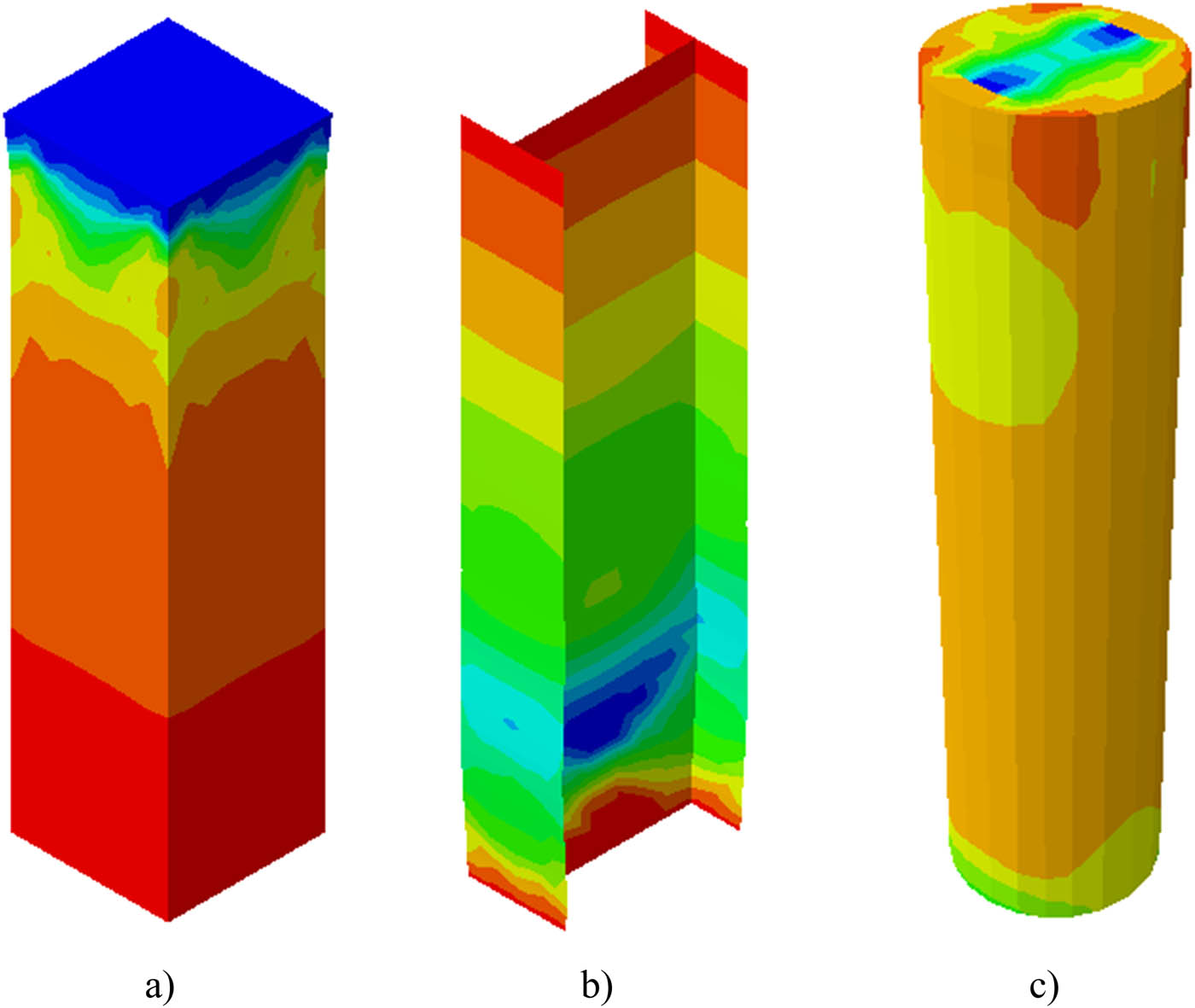

Geometrical configurations in modeling.

Hence, it could be suggested that the implementation of steel-encased concrete composite column for multi-storey buildings is proposed to carry the axial and lateral loads developed in the structural systems which were resisted by shear walls. Composite construction offers much on ductility, strength, and stiffness of the structural components. Steel tube with infilled concrete avoids the formwork and causes reduction in construction time automatically [11]. The confinement effect also boosts the load carrying capability of the infilled concrete tubes. Confinement efficiency is determined by the shape of the steel tube and column, structural steel yield strength, and concrete's characteristic compressive strength [8]. Addition of steel plates in the composite structures made of steel sections infilled with concrete is increased tremendously under seismic action due to its high stiffness, energy absorption capacity and strength, and ductility. Mirza et al. found that the addition of steel plate as confinement in composite component enhances the ductility in which the inward buckling is observed in the steel plate may leads high impact resistance. Hot rolled steel sections with concrete is advisable in the composite construction. No formwork could be required in the composite construction with efficient time management [12,13] and the properties were investigated using finite element analyses on composite column [14–16].

Indian standard medium beam (ISMB) 100 is inserted into concrete with a circular section in this study to properly transmit the load with higher load carrying capability and to advise design practices from various codes. The effectiveness of the composite effect will also be evaluated in comparison to traditional reinforced concrete and steel columns.

2 Experimental investigation

Concrete mix in the proportion of 1:1.6:2.56 is used and designed using IS 10262 (2009) in which water–cement ratio is 0.45. Cement (OPC 53) and aggregates confirming Indian Standards IS 4031-6 (1988) and IS 2386 (1963), respectively, are shown in Table 1. The characteristic compressive and split tensile strength at 28 days are 32.8 and 3.18 MPa. Specimen details of the experiment are given in Table 2 and are subjected to axial compression.

Properties of materials

| Test | Cement | Fine aggregate | Coarse aggregate |

|---|---|---|---|

| Consistency, (%) | 33 | — | — |

| Initial setting time, (min) | 42 | — | — |

| Final setting time, (min) | 275 | — | — |

| Specific gravity | 3.15 | 2.6 | 2.65 |

| Fineness | 2.9 | 3.07 | 7.3 |

Experimental details

| Specimen ID | Depth (mm) | Width (mm) | Thickness (mm) | Remarks | |

|---|---|---|---|---|---|

| Flange | Web | ||||

| C1 | 150 | 150 | — | — | Conventional RC** column, 4# 10 mm dia. |

| C2 | 150 | 80 | 7.6 | 4.8 | Conventional steel column, ISMB 150 |

| PC* | 100 | 75 | 7.2 | 4.0 | Column — ISMB 100 encased with concrete |

* Proposed composite column; **Reinforced concrete.

Both ISMB sections and reinforcement yield stress (f y) are 250 and 415 MPa, respectively. The characteristic compressive strength of concrete (f ck) is 30 MPa. Concrete effective cover is 25 mm. Strain gauges were located at the middle of the specimen along the length.

3 Analytical studies

Designs of the columns PC*, C1, and C2 were carried out by confirming Eurocode 4 (1994), IS 456 (2000), and IS 800 (2007), respectively [17].

Case 1 – Conventional RCC column (C1):

Factored axial load of the RC column is as follows:

Area of concrete (A c) and steel (A sc) are 22,500 and 314.15 mm2, respectively.

Length (l), breadth (B), and depth (D) of the column are 600, 150, and 150 mm, respectively. Four numbers of longitudinal reinforcement (dia. 10 mm) are provided.

Case 2 – Conventional steel column (C2):

Factored axial load of steel column (ISMB 150) is as follows:

Length (l), area (A e), non-dimensional parameter (λ), ϕ, reduction factor (χ), and F cd are 600 mm, 1,900 mm2, 0.406, 0.617, 0.92, and 170 MPa, respectively (IS 800).

Case 3 – Proposed composite column (PC * ):

Plastic resistance of composite column is as follows:

Area and partial safety factors in equation (1) are presented in Table 3.

Area and partial safety factors of materials

| Properties | Structural steel | Concrete |

|---|---|---|

| Partial safety factor | γ a = 1.10 | γ c = 1.5 |

| Area (mm2) | A a = 1460 | A c = 16211.46 |

4 Numerical analysis

Finite element analysis (FEA) is carried out on the specimens given in Table 4 under axial compression using commercial FE tool (Abaqus). Concrete damaged plasticity model is used for the concrete, since steel follows the bi-linear stress–strain curve. Bottom of the specimen is pinned, since it is in practice during experimentation. For convergence of the solution to appropriate conclusions, the physical domain under inquiry is subjected to limitations, called boundary conditions, in FEA. In FEA, symmetric boundary conditions are constraints that reduce the amount of computer memory and simulation time used. Steel and concrete properties were taken, respectively [18,19]. Newton–Raphson method is used in the numerical increments. ISMB sections were modelled using shell elements, and the shell element analysis produced solid elements that were very close approximations. Hence, employing shell elements instead of solid elements could reduce much on computational cost. Reinforcement and ISMB 100 were embedded in concrete to simulate the effect of composite in C1 and C2, respectively. Element size is fixed based on the mesh sensitivity analysis and experimental results [20]. Figure 1 depicts the geometrical configuration of composite modeling. Element size of concrete, ISMB sections, and reinforcement is 20 mm for all C1, C2, and PC*. Eight noded solid element with reduced integration, four noded shell element with reduced integration, and two noded beam element are employed for concrete, ISMB sections, and reinforcement, respectively.

5 Results and discussion

Factored axial load of PC*, C1, and C2 are 607.46, 498.06, and 515.91, respectively. It can be clearly noted that the factored axial load of PC* is increased by 71.8 and 88.1% with respect to C1 and C2, respectively. From Table 4, it can be observed that the increase load carrying capacity of PC is 16 and 12, and 35 and 48.9 % for C1 and C2, respectively, with respect to numerical and experimental. So, the composite effect can be found from analytical equation itself and the same is reflected in the experimentation and FEA. Ultimate load of the specimens are tabulated in Table 4. So, the proposed composite column (PC*) is exhibiting the higher load carrying capacity than others. Table 4 details the ultimate load carrying capacity of the specimens investigated.

Ultimate load carrying capacity of specimens

| Specimen ID | Ultimate load (kN) | ||

|---|---|---|---|

| Experimental | Analytical | Numerical | |

| PC* | 637.6 | 607.46 | 577.41 |

| C1 | 471.8 | 353.57 | 498.06 |

| C2 | 428.2 | 323 | 515.91 |

* Proposed composite column.

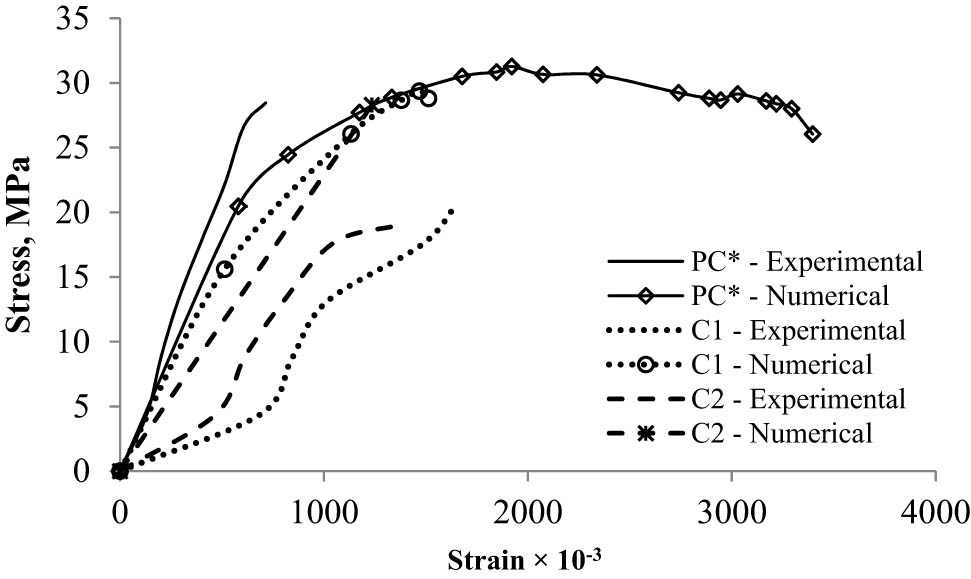

The stress–strain behavior of the specimens is exhibited in Figure 2. FEA resulted in good agreement with the experimentation. From Figure 2, it can be noted that experimentally measured stress values of C1, C2, and PC are 20.71 19.1, and 28.45 MPa, respectively, whereas the characteristic compressive strength of concrete is 32.8 MPa. Also, it can be clearly noted that the numerically obtained stress values of C1, C2, and PC are 28.3, 28.66, and 31.28 MPa, respectively from Figure 2. The ultimate strain difference (at peak stress) between the experimentation and numerical is very minimal. Especially, the obtained numerical result is in better agreement with the experimental result. So, the numerical models constructed were well suited and could be used to capture other physical quantities.

Stress–strain behavior.

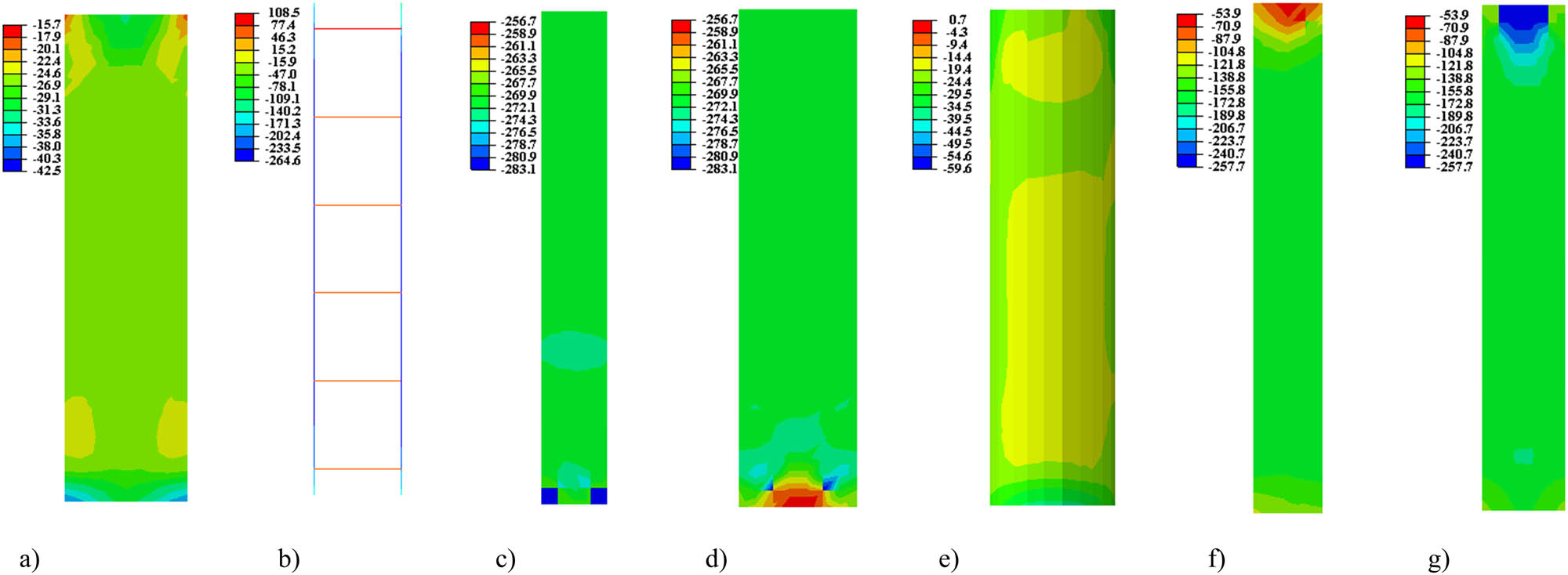

Figure 3a–g exhibits the stress distribution at peak load for C1-Concrete, C1-Rebar, C2-Web, C2-Flange, PC-Concrete, PC-Web, and PC-Flange, respectively [21]. Stress reaches around 30 MPa in concrete for C1 and PC specimens in Figure 3a–e. Observed maximum stress in reinforcement (C1), ISMB 150 (C2), and ISMB 100 (PC) is 264.6, 283.1 and 257.7 MPa, respectively. Stress in PC varies from 8 to 25 MPa lesser than C1 and C2, respectively, due to the development of composite effect and the geometrical effect [22].

Stress distribution at peak load: (a) C1-Concrete, (b) C1-Rebar, (c) C2-Web, (d) C2-Flange, (e) PC-Concrete, (f) PC-Web, and (g) PC-Flange.

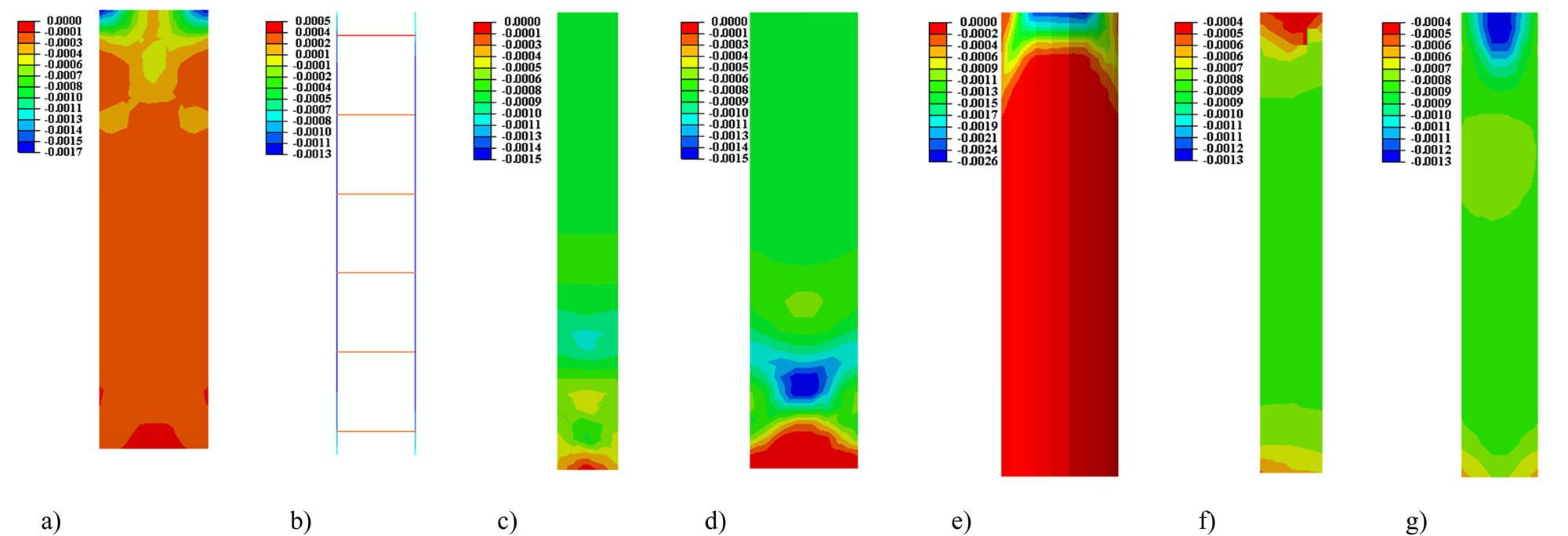

Figure 4a–g exhibits the strain distribution at peak load along the length of the specimens C1-Concrete, C1-Rebar, C2-Web, C2-Flange, PC-Concrete, PC-Web, and PC-Flange, respectively. Strains in concrete and reinforcement are 0.0017 and 0.0013, respectively, since the maximum load reaches lateral tie confinement before yielding strain in concrete of 0.002. Strains in ISMB 150 and 100 are 0.0015 and 0.0013, respectively, whereas the change in strain is in negligible amount. It reveals that the maximum usage of ISMB 100 in the PC is due to composite effect. At the same time, the maximum strain of 0.0026 is observed in PC-Concrete. So, the yielding point beyond 0.0026 is found to be achieved due to the compatibility between the ISMB 100 section and concrete and leads to better composite effect with almost no confinement [23]. Figure 5 shows the final failure profile of the specimens.

Strain distribution at peak load: (a) C1-Concrete, (b) C1-Rebar, (c) C2-Web, (d) C2-Flange, (e) PC-Concrete, (f) PC-Web, and (g) PC-Flange.

Final failure profile: (a) C1, (b) C2, and (c) PC.

6 Conclusion

Experiments have been carried out on conventional RC column, conventional steel column, and the composite column to increase the ultimate load carrying capacity in which the composite column is the proposed one. Analytical evaluations on load carrying capacity based on the codes IS 456, IS 800, and Eurocode 4 were carried out. The composite column is found to be a better load carrying specimen PC than the other from the analytical solution which itself reveals the high load carrying capacity due to the composite effect and the same is resulted from experiment and FEA. It can concluded that the increase in load carrying capacity of the proposed section is quite high than the conventional concrete and steel columns. Also, from the FEA results, the stress and strain distribution along the length exhibits the pattern in practice and the observed values also indicate the composite effect of the proposed column in good manner.

Acknowledgments

Research outcomes of the manuscript was supported by Aarupadai Veedu Institute of Technology, Chennai. We would also like to extend our thanks to the authors for providing the technical support needed.

-

Funding information: This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

-

Author contributions: Leema Rose Ayyasamy: validation, editing, reviewing, and supervision; A. Mohan and Dhanasingh Sivalinga Vijayan: collecting research data, writing – original draft, methodology, and modeling in abacus; Agoramoorthy Sattainathan Sharma: experimental work, grammar, and English correction; Parthiban Devarajan: modeling and rewriting; Aravind Sivasuriyan: experimental work and data acquisition.

-

Conflict of interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this article.

-

Consent to participate: No human subjects or animals are used for the research in the manuscript. Hence there no consent to participate required.

-

Consent to publish: No human subjects or animals are used for the research in the manuscript. Hence there no consent to publish required.

-

Ethical approval section: Not applicable.

-

Data availability statement: The authors declare that (the/all other) data supporting the findings of this study are available within the article and its supplementary information files.

References

[1] Chen SF, Teng JG, Chan SL. Design of biaxially loaded short composite columns of arbitrary section. J Struct Eng. 2001 Jun;127(6):678–85.10.1061/(ASCE)0733-9445(2001)127:6(678)Suche in Google Scholar

[2] Weng CC, Yen SI. Comparisons of concrete-encased composite column strength provisions of ACI code and AISC specification. Eng Struct. 2002;24(1):59–72.10.1016/S0141-0296(01)00067-0Suche in Google Scholar

[3] Ellobody E, Young B, Lam D. Behaviour of normal and high strength concrete-filled compact steel tube circular stub columns. J Constr Steel Res. 2006;62(7):706–15.10.1016/j.jcsr.2005.11.002Suche in Google Scholar

[4] Chen CC, Lin NJ. Analytical model for predicting axial capacity and behavior of concrete encased steel composite stub columns. J Constr Steel Res. 2006;62(5):424–33.10.1016/j.jcsr.2005.04.021Suche in Google Scholar

[5] Chicoine T, Massicotte B, Tremblay R. Long-term behavior and strength of partially encased composite columns made with built-up steel shapes. J Struct Eng. 2003;129(2):141–50.10.1061/(ASCE)0733-9445(2003)129:2(141)Suche in Google Scholar

[6] El-Tawil S, Deierlein GG. Strength and ductility of concrete encased composite columns. J Struct Eng [Internet]. 1999 Sep;125(9):1009–19.10.1061/(ASCE)0733-9445(1999)125:9(1009)Suche in Google Scholar

[7] Vijayan DS, Revathy J. Experimental investigation on the static performance of GFRP strengthened prestressed concrete beams. World Appl Sci J. 2016;34(10):1366–9.Suche in Google Scholar

[8] Mursi M, Uy B. Strength of concrete filled steel box columns incorporating interaction buckling. J Struct Eng. 2003;129(5):626–39.10.1061/(ASCE)0733-9445(2003)129:5(626)Suche in Google Scholar

[9] Wright HD. Local stability of filled and encased steel sections. J Struct Eng. 1995 Oct;121(10):1382–8.10.1061/(ASCE)0733-9445(1995)121:10(1382)Suche in Google Scholar

[10] Kim C-S, Park H-G, Chung K-S, Choi I-R. Eccentric axial load capacity of high-strength steel-concrete composite columns of various sectional shapes. J Struct Eng. 2014;140(4):04013091.10.1061/(ASCE)ST.1943-541X.0000879Suche in Google Scholar

[11] Dundar C, Tokgoz S, Tanrikulu AK, Baran T. Behaviour of reinforced and concrete-encased composite columns subjected to biaxial bending and axial load. Build Environ. 2008;43(6):1109–20.10.1016/j.buildenv.2007.02.010Suche in Google Scholar

[12] Mirza SA, Lacroix EA. Comparative strength analyses of concrete-encased steel composite columns. J Struct Eng. 2004 Dec;130(12):1941–53.10.1061/(ASCE)0733-9445(2004)130:12(1941)Suche in Google Scholar

[13] Lee J, Nguyen HT, Kim S-E. Buckling and post buckling of thin-walled composite columns with intermediate-stiffened open cross-section under axial compression. Int J Steel Struct. 2009;9(3):175–84.10.1007/BF03249492Suche in Google Scholar

[14] Vijayan DS, Revathy DJ. Flexural behavior of reinforced and pre-stressed concrete beam using finite element method. Int J Appl Eng Res. 2015;10. 10.17485/ijst/2016/v9i42/101824. http://www.ripublication.com.Suche in Google Scholar

[15] Mehrabani R, Shanmugam NE. Finite element analysis of the behaviour and ultimate strength of battened columns encased in concrete. IES J Part A Civ Struct Eng. 2014;7(4):263–80.Suche in Google Scholar

[16] Yonas TY, Temesgen W, Senshaw FW. Finite element analysis of slender composite column subjected to eccentric loading. Int J Appl Eng Res. 2018;13(15):11730–7.Suche in Google Scholar

[17] IS 456. Plain concrete and reinforced. New Delhi: Bureau of Indian Standards; 2000. p. 1–114.Suche in Google Scholar

[18] Dar MA, Subramanian N, Dar AR, Anbarasu M, Lim JBP, Atif M. Behaviour of partly stiffened cold-formed steel built-up beams: experimental investigation and numerical validation. Adv Struct Eng. 2019;22(1):172–86.10.1177/1369433218782767Suche in Google Scholar

[19] Hafezolghorani M, Hejazi F, Vaghei R, Jaafar MSB, Karimzade K. Simplified damage plasticity model for concrete. Struct Eng Int. 2017;27(1):68–78.10.2749/101686616X1081Suche in Google Scholar

[20] Parthiban D, Vijayan DS. Study on stress–strain effect of reinforced metakaolin based GPC under compression. Mater Today: Proc; 2020. p. 822–8. 10.1016/j.matpr.2019.10.162.Suche in Google Scholar

[21] Vaverková MD, Radziemska M, Bartoň S, Cerdà A, Koda E. The use of vegetation as a natural strategy for landfill restoration. Land Degrad Dev. 2018;29(10):3674–80.10.1002/ldr.3119Suche in Google Scholar

[22] Koda E, Kiersnowska A, Kawalec J, Osiński P. Landfill slope stability improvement incorporating reinforcements in reclamation process applying observational method. Appl Sci. 2020;10(5). 10.3390/app10051572.Suche in Google Scholar

[23] IS 456. Plain and reinforced concrete – code of practice. New Delhi: Bureau of Indian Standards; 2000. p. 1–114.Suche in Google Scholar

© 2022 Leema Rose Ayyasamy et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete

Artikel in diesem Heft

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete