Abstract

In the present study, the resistance characteristics of Shanghai clayey soil-expanded polystyrene (EPS) mixture have been explored, using unconfined compressive and consolidation and rebound tests. EPS beads were mixed homogenously with clay soil in accordance with different mass ratios of beads to soil, that is, 0, 0.02, and 0.03%. Four particle sizes of EPS were used in the mixtures, that is, 0.5, 1, 3, and 7 mm, to reconstruct the samples. The experimental results indicated that (1) under the condition of unconfined compressive test, with the increase of EPS particle size, the compressive strength of reinforced soil increases significantly, but the compressive strength of reinforced soil decreases compared with the control sample, and it also decreases with high content compared to low EPS content; (2) under the consolidation and rebound test, compression index and rebound index of reinforced soil increased obviously compared with the control sample, but the compression modulus of reinforced soil decreases significantly; (3) in addition, the ductility of reinforced soil decreases with the increase of EPS particle size but increases compared with the control sample. At the same time, the stiffness of reinforced soil is much decreased compared with the control sample. Finally, the cause of deformation characteristics of reinforced soil was explained based on the feature of EPS material and the interaction between soil particles and particles of EPS beads.

1 Introduction

Expanded polystyrene (EPS), also known as geofoam, has been applied in construction and geotechnical engineering for more than 50 years. The use of EPS can be dated back to the 1960s when the Norwegian Road Research Laboratory applied lightweight-fill function of this material to construct road embankments over soft soils [1]. The main function of EPS in the application of civil engineering resides in two aspects compared with conventional geomaterials. First, EPS has the relative low mass density, which typically ranges from about 10–40 kg/m3. The low mass density is useful in eliminating vertical and horizontal stresses on buried structures, utilities, and compressible soils [1]. This lightweight-fill can, therefore, be used to reduce the settlements caused by geotechnical construction and to mitigate its potential damage to adjacent structures and facilities. The big difference between EPS and traditional geomaterials in unit weight makes EPS an extremely attractive fill material. Second, EPS can also be used as compressive inclusion in civil engineering structures undergoing static, monotonic, or dynamic loading [2]. Because once stress is applied, EPS is somewhat compressible, and its controllable compression can be used to reduce soil pressure against buried structures and accordingly the deformation induced by loadings applied on the structures. Loadings that induced compression can be divided into a lot of classification: static and dynamic lateral earth pressures, swell and frost-heave pressures, settlement of support soils, faulting, liquefaction, landslides, and traffic loads [3]. Furthermore, the other characteristics such as durability, stability, and resistance to moisture and deterioration have also long been recognized as main advantages of EPS. It is precisely because of the above attributes, EPS has long been reportedly and widely used in many geotechnical projects. For example slope stabilization [4,5], road construction over poor soils [6], bridge abutment [7,8], buried pipelines [9], earth retaining structures [10], noise and vibration damping [11], mitigating thermal distresses in permafrost regions [12], and reduction of transmitted lateral swelling pressures on retaining structures due to swelling soils [13].

Although there are so many usefulness of EPS in civil engineering, it is easily available and inexpensive in economy. It is reported that there are more than 14 million tons of annual production of EPS in the world, the most of which was finally delivered to landfill [14]. It includes 2.3 million tons of production from USA, 2.5 million tons from west Europe including 0.3 million tons as EPS waste being landfilled. In addition, there are annually 38 million m3 of ground area being occupied by EPS waste in England. In China, a huge number of EPS waste was incinerated or buried annually. Therefore, it has posed a serious environmental challenge and should be solved as soon as possible. The selection of EPS as admixture to modify the characteristic of soil for the purpose of engineering construction can not only consume large amount of EPS waste benefiting environmental protection but also meet the need for additives necessary to change the engineering features of soil.

EPS geofoam was authorized to be used for pavement thermal insulation material in USA in 1960s [15]. It was also used in the field of engineering construction in North Europe in the late 1960s. In 1971, EPS was initially substituted for 1 m thick ordinary padding in FLOM bridge approach modification works by Norway National Road Research Laboratory, which successfully controls the differential settlement of bridgehead segment. After moving into 1980s, EPS material was gradually applied to highway projects in countries such as Japan, Sweden, and the Netherlands [16]. Starting from 1980s, EPS was set out to be researched as subbase material for lightweight embankment. EPS was, for the first time, used for bridge abutment filling process of highway constructions in Germany in March 1995 [17]. In recent 10 years, EPS was widely used in lightweight embankment material for road and railway construction in Europe, Asia, and parts of USA [18,19,20,21,22,23,24,25,26], along with being used in retaining walls and other buried structures under conditions of protective static load [27]. The mechanical properties such as compressive strength and bending strength of EPS-cement reinforced soil were researched, and the test results showed that the bending strength and compressive strength of the treated soil were all somewhat decreased, whereas they were increased with curing period [28]. The sand and clay randomly mixed with different particle size of EPS beads were tested with shear and unconfined compressive experiment, respectively, and the result showed that with the increase of EPS content, the internal friction angle, swelling, and unconfined compressive strength of sand decrease, and the samples with small size of EPS beads show a relatively low unconfined compressive strength [29]. Currently, the research on EPS beads is still in its preliminary stage in china. The direct shear test on reinforced samples with three types of EPS size showed that there is low shear strength with samples of small size of EPS beads [30]. The consolidation and undrained triaxial compressive test on samples with different sizes of EPS suggested that the cohesion and effective cohesion are all decreased with the increase of EPS bead size, whereas its strength becomes small with the increase of size [31]. The triaxial compressive test under the condition of consolidation and undraining for the purpose of determining the effect of EPS bead size on the strength of mixed lightweight sands shows that with the increase of the EPS size, the density and bulk density are sharply decreased, whereas the wet density of it almost keep unchanged [32]. The compressive strength with EPS-reinforced soil was also researched, and the result showed that the EPS content is the main reason that affects the density of reinforced soil, and the unconfined compressive test of EPS-reinforced soil decreases with the increase of EPS content [33].

In aspect of consolidation and deformation of EPS, it is considered to be an ideal buffering material because the EPS geofoam is lightweight, high compressive, stable, durable, low hygroscopic, and good heat insulating; therefore, pressure relief retaining wall based on decompression effect of EPS geofoam was creatively put forward [34,35,36]. It is also considered that the use of lightweight geofoam material as padding behind retaining wall could reduce the vertical load. If it is combined with bonding material, EPS can be used to reduce settlement that develops little or no lateral loading [37]. References [38,39,40,41,42,43] are a series of Standard Test Method of American Society for Testing and Materials for testing of soil properties.

Although there were so many research on EPS, they are mostly focused on the effect of EPS on sand. Few researches were centered on clay soil. Furthermore, the compression and rebound characteristics of EPS-reinforced soil were much less researched, and their action mechanism is still less understood. This study is focused on unconfined compressive test and consolidation and rebound test to research the variation of strength indexes with the variation of EPS bead size and content in samples.

2 Materials and methods

This section describes the sources and properties of the materials used in the experiment as well as the equipment used in the experiment and the standard specifications taken for the experiment. Shanghai clayey soils were collected from a construction site in Zhangjiang high-tech park, Pudong New Area, Shanghai. Figure 1 shows the particle size distribution of the studied soils according to ASTM D422 (American Society of Testing and Materials) [38]. The soils were classified as CM (medium plasticity clay) according to the Unified Soil Classification System. Maximum dry density and liquid and plastic limits were determined based on ASTM D854 [39] and ASTM D4318 [40], respectively. The standard Proctor compaction test was carried out on the clay sample based on ASTM D698 [41]. Table 1 shows a summary of basic properties of Shanghai clayey soil. Figure 1 shows the grading curve of Shanghai clayey soil analyzed by Laser Particle Sizer from Malvern Instruments Ltd., Shanghai.

Grain-size distribution of Shanghai clayey soil.

Physical properties of Shanghai clayey soil

| Optimum water content

|

Liquid limit

|

Plastic limit

|

Plastic index

|

Maximum dry density

|

Specific gravity

|

Uniformity coefficient

|

Coefficient of curvature

|

|---|---|---|---|---|---|---|---|

| 19.4 | 39.4 | 19.3 | 19.9 | 1.65 | 2.72 | 4.33 | 1.97 |

Four different sizes of spherical EPS beads, that is, 0.5, 1, 3, and 7 mm, were applied to reconstruct the samples. Figure 2 shows the four types of EPS beads. Properties of the EPS beads are presented in Table 2. Unconfined compressive test and consolidation and rebound test were performed on the samples according to ASTM D2166 [42] and ASTM D2435 (1999) [43], respectively.

Four sizes of EPS beads used in the tests.

Physical properties of EPS

| Density

|

Bulk density

|

Specific gravity (

|

Poisson ratio (v) | Void ratio e | Elastic modulus (MPa) | Average volume water absorption | Coefficient of thermal expansion (mm/°C) | Coefficient of heat conduction(W/m K) | Modulus of elasticity (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| 10–40 | 80–100 | 0.03 | 0.08 | 0.5 | 2.5–11.5 | 1.54 | 0.05–0.07 | 0.042 | 6.2–12.4 |

This section mainly describes the preparation process of samples. After particle size classification, soil samples were dried by an oven at 105°C for 24 h. In unconfined compressive test and consolidation and rebound test, EPS beads were randomly mixed with Shanghai clayey soil in accordance with different mass ratios of beads to soil, that is, 0, 0.02, and 0.03%. As the dry clay soil and EPS beads did not mix well with each other, and for purpose of making standard samples that could keep their shape without disintegration, minimum moisture content and maximum percentage of EPS beads were determined by trial and error, which were 20.4% (1% greater than the optimum moisture content) and 0.03%, respectively. Before compaction of the mixture of Shanghai clayey soil, EPS beads and water in the cylindrical mold, they were placed in an airtight plastic bag for 24 h. Samples with maximum dry density determined by proctor compaction test are used for all the tests.

This section mainly describes the preparation process and test method of samples for unconfined compressive strength and rebound test. For unconfined compressive test, the size of sample is cylindrical with 80 mm high and 39 mm in diameter. For consolidation and rebound test, the size of samples is also cylindrical but with 20 mm high and 79.8 mm in diameter. After the preparation of all the samples, they were placed into a standard humidor for 7 d curing before starting the test. The equipment for unconfined compressive test was manufactured by Nanjing Hydraulic and Electric Instrument Engineering Company Limited (Nanjing City, Jiangsu Province, China), which was coded as PY-3 strain control unconfined compression apparatus, with loading rate of 2.5 mm/min and range for displacement measurement being from 0 to 30 mm. Nine sets of samples were tested on unconfined compressive apparatus, and each test was repeated three times to obtain their average for measurement for the purpose of eliminating their accidental error as much as possible. Figure 3 shows the broken sample, Figure 4 shows the consolidation test site, and Figure 5 shows the rebound test site. The detailed test arrangement is showed in Table 3.

The broken sample in unconfined compressive test.

The consolidation test site.

The rebound test site.

Arrangement of samples for unconfined compressive test

| Size of EPS bead (mm) | Content of EPS bead (%) | Unconfined compressive strength (kPa) | Number of samples tested |

|---|---|---|---|

| Control sample | 0.00 | 83.88 | 3 |

| 0.5 | 0.02 | 50.79 | 3 |

| 0.5 | 0.03 | 40.91 | 3 |

| 1 | 0.02 | 57.85 | 3 |

| 1 | 0.03 | 47.97 | 3 |

| 3 | 0.02 | 63.65 | 3 |

| 3 | 0.03 | 56.58 | 3 |

| 7 | 0.02 | 73.74 | 3 |

| 7 | 0.03 | 66.65 | 3 |

The equipment used for consolidation and rebound test is the type YS-2 dual odometer made by Nanjing Hydraulic and Electric Instrument Engineering Company Limited. The arrangement of samples tested is the same as the unconfined compressive test, as shown in Table 3.

3 Result and analysis

3.1 Effects of EPS size on mechanical properties of soil

This paragraph states the function of EPS size for modifying the mechanical properties of soil. Figure 6 shows the relationship between axial train and stress under the condition of 0.02% admixture of EPS bead. It can be seen from the diagram that with the increase of the size of EPS beads, the peak strength increases, but they are all less than that of the control sample. The peak strength with the size of 0.5 mm is lowered by approximately 39% compared with that of that control sample. In addition, the yield strains of EPS bead-reinforced samples are all increased to some degree. However, the yield strain with size of 0.5 mm is increased by 50% more than that of the control sample. Figure 7 indicates the association of axial strain with axial strength and the condition of 0.03% in unconfined compressive test. The diagram suggests that there appears the similar variation trend as with 0.02%. The peak strength with the size of 0.5 mm decreases by 51% compared with that of the control sample. However, the yield strain with the size of 0.05 mm is also increased by 50%.

The stress–strain curves of different particle sizes with EPS reinforcement ratio of 0.02%.

The stress–strain curves of different particle sizes with EPS reinforcement ratio of 0.03%.

This section states the change of strength. The strength of reinforced soil mixed with all sizes of EPS beads is lower than that of the control sample, which may be due to the bonding force between soil particles being greater than that between soil particles and EPS beads. The smooth surface of EPS beads may provide less friction than that of soil particle, which finally lead to the decrease of compressive strength. However, the yield strain of reinforced soil has been greatly increased, which is because the elastic modulus is generally less than that of soil. The above features may be significant in retaining wall engineering because the EPS-reinforced soil can resist against more deformation without failure. In addition, under the condition of the same mass of EPS beads, the strength of the reinforced soil is increased with the increase of the size of EPS beads. This may be because the specific area of the bigger size beads is small that has the relatively small contact area with soil particle. Due to the friction between the surface of EPS beads and the surface of soil particles being smaller than that between soil particles, the decrease in friction between bigger EPS beads and soil particles is less than the decrease in friction between smaller EPS beads and soil particles in the case of same mass of EPS content.

3.2 Effects of EPS content on compressive strength of soil

This paragraph explains the Figures 8–11. Figure 8 shows the relationship between axial strain and stress in the case of different contents of EPS beads with the size of 0.5 mm. It can be seen from Figure 8 that with the increase of the content of EPS beads, the uniaxial compressive strength decreases. When the content increases from 0.02 to 0.03%, the strength decreases by approximately 20%. The yielding strain is almost same in two contents. This means that the variation in EPS percent can only affect the strength of reinforced soil but did not affect the yielding strain. Figures 9–11 show the similar trend except the difference in strength in different contents. The strength with the size of 7 mm and content of 0.02% is 73.7 kPa, whereas it is 50.8 kPa with the size of 0.5 mm and content of 0.02%, which decreased by approximately 31% from 0.5 to 7 mm. The decrease in strength of EPS-reinforced soil with the increase of the content may be because, first, the elastic modulus of EPS is less than that of soil, and second, the increase in the contact area between soil particle surface and EPS bead surface caused by high content leads to the decrease in bonding force between soil particle and EPS particle. After all, it has been reported from other reference that the frictional force between soil particles is greater than that between EPS particle and soil particle [1].

The stress–strain curves of different reinforcement ratios with EPS particle size of 0.5 mm.

The stress–strain curves of different reinforcement ratios with EPS particle size of 1 mm.

The stress–strain curves of different reinforcement ratios with EPS particle size of 3 mm.

The stress–strain curves of different reinforcement ratios with EPS particle size of 7 mm.

3.3 Effects of EPS on ductility and stiffness

This section describes the ductility and stiffness for mixed soil. Ductility is a measure of a material’s ability to undergo significant plastic deformation before rupture. We use ductility ratio (DR) to express the magnitude of ductility for different material. DR can be calculated by the following formula:

where Δr is the axial failure strain of reinforced soil sample, and Δu is the axial failure strain of unreinforced soil sample. The DR of nine groups of samples is calculated according to the DR formula based on the control sample, namely taking the strain of the control sample before rupture as denominator, the strain of reinforced soils before rupture as numerator, as shown in Table 4. The ductility of reinforced soil is increased compared with that of the control sample, namely DR > 1, with the increase exceeding 50% at most.

DR of samples

| Soil sample (mm) | Content of EPS bead (%) | Axial strain (%) | DR |

|---|---|---|---|

| Control sample | 0.00 | 0.015 | 1 |

| 0.5 | 0.02 | 0.0225 | 1.5 |

| 0.5 | 0.03 | 0.0225 | 1.5 |

| 1 | 0.02 | 0.0225 | 1.5 |

| 1 | 0.03 | 0.0225 | 1.5 |

| 3 | 0.02 | 0.02 | 1.3 |

| 3 | 0.03 | 0.02 | 1.3 |

| 7 | 0.02 | 0.0175 | 1.17 |

| 7 | 0.03 | 0.0175 | 1.17 |

In the process of EPS molding, the pentane of polystyrene particles is heated and vaporized, and many closed cavities are formed in the expansion of the particles, and hence, the structure of EPS presents uniform closed cavities. More than 90% of the internal air, relatively light mass, and a certain structural strength, can withstand a certain amount of pressure to resist deformation. Thus, the ductility of reinforced soil can be improved. It is helpful for the filling structure because the lateral force applied on the retaining structure become small with all else being equal.

Stiffness is the ability of a material or structure to resist against elastic deformation under applied stress. It is a representation of the degree of difficulty in elastic deformation of a material or structure. The stiffness of a material is usually measured by the modulus of elasticity, E. In the range of macroscopic elasticity, stiffness is the proportional coefficient of load to displacement of material or ratio of stress to strain, that is, the force required to cause unit displacement.

Stiffness can be calculated by the following formula:

where P is the applied force, δ is the axial strain. For convenience, P takes the half values of peak strength in unconfined compressive test, whereas δ is the corresponding axial strain.

Figure 12 shows the relationship between the size of EPS beads in samples and stiffness. It can be seen from Figure 12 that the stiffness of the control sample is much greater than that of reinforced soil, the decrease with the content of 0.03% being at approximately 36%. It also decreases with the increase of content of EPS bead, it being decreased by about 14% at varied sizes. While, in reinforced soils, the stiffness is increased with the increase of the size of EPS beads, which is increased by approximately 77% from the size of 0.5–7 mm, at varied contents.

The relationship between the size of EPS beads in samples and stiffness.

3.4 The curve of consolidation and rebound test

This paragraph explains the method and result for consolidation and rebound test. In consolidation test, we select the following loading grades: 0, 10, 50, 100, 200, and 400 kPa. The settling time for each stage of load and unload is 24 h. The sequence for loading and unloading in the test is 0–10–50–100–200–100–50–10–50–100–200–400 kPa. The initial void ratio of the control sample and reinforced samples is calculated with the following formula:

where

where

where

where

where

where

Figure 13 shows the results of consolidation and rebound test. Figure 13a–i shows the results for the control sample and EPS bead-reinforced soil samples. It can be seen from the diagrams that the void ratio of reinforced samples is much greater than that of the control sample, more than doubling of the control sample. It indicated that the pore volume in reinforced soil is greatly increased. Rebound coefficient for all reinforced soil is increased to a different degree, depending on the size and content of EPS beads. It suggests that in rebound test, the elasticity of reinforced soil is also increased because the elastic deformation of them is larger than that of the control sample, which also means the plastic deformation of reinforced soil is decreased compared to the elastic deformation. This change is meaningful for the practical engineering because, for example, in filling structure of retaining wall, the side pressure may be decreased, which can reduce the load applied on the retaining structure. The detailed analysis on the deformation characteristic of reinforced soil is shown in Figure 14.

The relationship between consolidation pressure applied and the corresponding void ratio: (a) Control sample, (b) EPS beads of 0.5 mm with the content of 0.02%, (c) EPS beads of 1 mm with the content of 0.02%, (d) EPS beads of 3 mm with the content of 0.02%, (e) EPS beads of 7 mm with the content of 0.02%, (f) EPS beads of 0.5 mm with the content of 0.03%, (g) EPS beads of 1 mm with the content of 0.03%, (h) EPS beads of 3 mm with the content of 0.03%, and (i) EPS beads of 7 mm with the content of 0.03%. Note: Void ratio is a dimensionless quantity, being an absolute value.

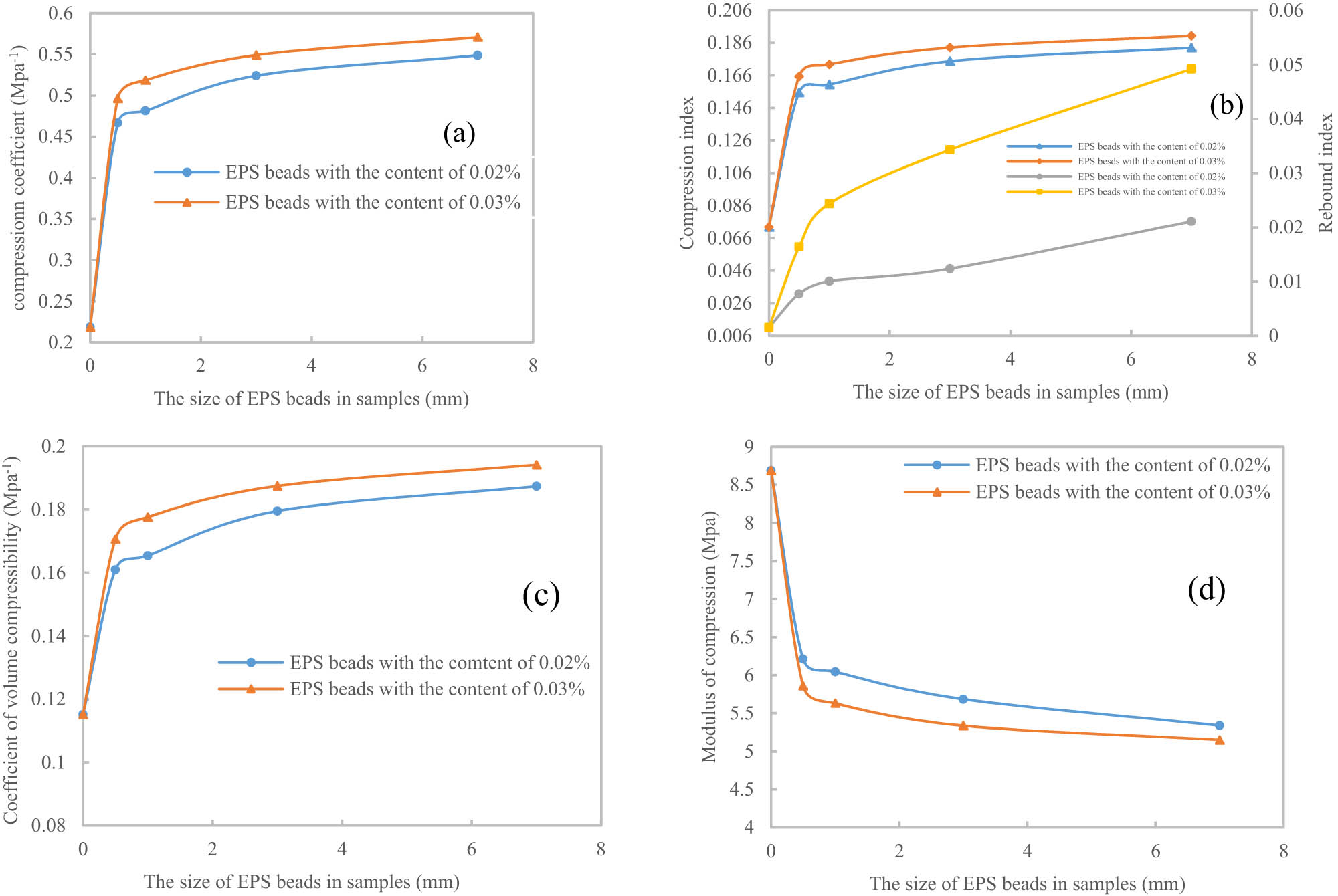

The relationship between the size of EPS beads and the compressibility indexes of soil: (a) the relationship between the size of EPS beads and compression coefficient, (b) the relationship between the size of EPS beads and compression index and rebound index, (c) the relationship between the size of EPS beads and coefficient of volume compressibility, and (d) the relationship between the size of EPS beads and modulus of compression.

This section mainly describes in detail the relationship between soil compressibility and size of EPS. In Figure 14a, the relationship between the size of EPS beads and the compressibility coefficient of soil is presented. It can be seen from the diagram that the compression coefficient with the content of 0.03% is larger than that of 0.02%. The increment under different sizes of EPS beads is averagely 5%. However, compared to control samples, the compression coefficient of EPS-reinforced soil is at least increased by 127%, which shows that with the increase of EPS content, the compression coefficient is increased to a large degree. With the increase of size of EPS bead, the compression coefficient shows the trend of increase. It increases about 13% under the two cases of 0.02 and 0.03%.

In Figure 14b, the relationship between the size of EPS beads in admixture and compression index and rebound index is presented. Therefore, we can see from this figure that the compression index with the reinforced soil is also increased to a large degree compared with the control sample, which is increased by more than 107%. Moreover, it is also higher with 0.03% of content than with 0.02%, and with the increase of the size of EPS bead, the compression index also increases but to a small degree. In order to compare the compression index with the rebound index, their curves are showed in the same figure. With the increase of the content, the rebound index is also increased, and it also increased with the increase of the size of EPS beads. It increases by 150% at the size of 7 mm. Compared to the compression index, the rebound index decreases to a large degree. Regardless of the compression index or rebound index, compared to the control sample, they are all increased.

In Figure 14c, the relationship between the size of EPS beads and coefficient of volume compressibility are presented. It can be seen from the diagram, the coefficient of volume compressibility with reinforced soils is greatly increased. Moreover, it increases with the increase of the content, the increment being approximately 6%, and it also increases with the increase of the size of EPS bead both in the two cases of 0.02 and 0.03%. In Figure 14d, the modulus of compression is presented. The variation trend is reverse to coefficient of volume compressibility. Therefore, it will not be further detailed.

3.5 Explanation of function of EPS bead

This paragraph states the role of EPS bead on modifying the property of soil. EPS is a new type of engineering material. Its main characteristics resides in that it a lightweight material with a relatively high strength. Then it has approximately 20 kg/m3 of density, which is almost only 1/100 of common material. In addition, it also has a stable chemical characteristic and water stability, namely hydrophobicity. It is reported that there is also a good hot stability with it. Most importantly, it has a much higher elasticity of it than that of common soil. Just because of above characteristics, EPS has a special function that can be used to improve the features of soil, so that it better adapts to the engineering project such as back pressure on retaining wall and structure involved in water pressure, gravitational weight, lateral earth pressure, buoyancy force, earthquake, and impact force.

The randomly mixed EPS bead with soil could change the features of soil, the internal reasons may be that the interaction between the particles of EPS and soil particles functions. It is reported that the frictions among soil particles are greater than those of EPS particles [1]. Therefore, this may lead to the decrease of reinforced soil in strength. However, because EPS has a higher elasticity, the reinforced soil expresses the better elasticity. Hence, in unconfined compressive test, the reinforced soil shows the lower strength but higher ductility, namely the larger yielding strength.

In consolidation and rebound test, because of its side constraints that permit no deformation in lateral direction, the characteristics of higher elasticity with EPS is much further played. The relatively close bonding between soil particle and EPS bead, namely the close bonding between the surface of EPS bead and the surface of soil particles, and high elasticity lead to the results obtained in the test. That is, compression index and rebound index with reinforced soil of different contents and sizes are all greater than those of the control sample. This may lead to a significant application in related engineering project due to the reduced side pressure on retaining structure or on embankment, etc. In addition, the characteristics of EPS bead of relatively large volume with small gravitational density make it a good filling material in filling engineering. Therefore, it is very important for our study to be used in practical engineering.

4 Conclusion

In this study, the effects of EPS beads on the unconfined compressive characteristics and consolidation parameters were studied. From above tests and analysis, we obtain the following conclusions: The unconfined compressive strength decreases with the increase of the content of EPS bead, whereas it increases with the increase of the size of EPS bead; at the same time, the compression coefficient becomes higher with reinforced soil regardless of the increase of the content or size of EPS bead; the compression index and the rebound index with reinforced soil also become higher than those of the control sample; the coefficient of volume compressibility with reinforced soil also increase compared to that of the control sample, but the compression modulus decreases; finally, the ductility of reinforced soil, namely the yielding strain, increases compared with that of the control sample but decreases with the increase of the size. The stiffness of reinforced soils decreases to a large degree compared with that of the control sample, whereas it decreases with the content of EPS beads, and it increases with the increase of the size.

It is believed that the increase of ductility and decrease of stiffness is due to the low rigidity of EPS beads in comparison with soil particles. Reduction in the unconfined compressive strength and compression modulus is attributed to the adhesion between clay particles and EPS beads that is smaller than cohesion between clay particles. As to the deformation characteristics related to the size of EPS beads, it is believed that the higher specific surface area may play a bigger role in the variation of geotechnical property. The conclusions drawn from the present investigation can be generalized to many projects in geotechnical engineering, such as backfill in retaining wall, reducing the settlement of embankment, in addition, due to property of EPS beads modified soil: lightweight, adjustable density and strength, good constructability, and environmental performance, making it a desirable substitutes for some conventional backfill, which can significantly speed up construction duration and reduce the settlement after construction whether in theory, in practice, or in design.

Acknowledgements

Thanks to Huang Xiaoru for helping us by getting the grading curve of Shanghai clayey soil. Thanks to Hu Da for helping us carry and handle the test material, and we also thank Xiong Kun, Xv Chao, and Xv Chenguang for helping us make the samples.

-

Funding information: We thank China National Department of Science and Technology for the funding support from the project “The research on long term resistance of weather and corrosion of MICP reinforced Shanghai clay soil“ (DL2021013001). We also thank the Open Fund of Key Laboratory of Geotechnical and Underground Engineering (Tongji University), Ministry Education for the financial support (KLE-TJGE-B2007).

-

Author contributions: Qu Jili and Tao Huan are responsible for original conception. Qu Weiwing and Han Guoqi are responsible for materials collection and subsequent sample preparation and experiments doing jobs. Liu Hongmei and Abulimiti are responsible for tests monitoring, data recording and manipulation. Zhong Yu and Andrian Batugin are responsible for data processing and paper writing. Finally, Qu Jili and Batugin review and approve the final source manuscript.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The data used to support the findings of this study are available from the corresponding author upon request.

References

[1] Shirazi AN, Haydarian H, Alireza Nasehi S. Shear and compression behaviors of sandy and clayey soils mixed with different sizes of expanded polystyrene beads. Geotech Geol Eng. 2018;36:3823–30.10.1007/s10706-018-0575-ySuche in Google Scholar

[2] Horvath JS. Expanding the use of expanded polystyrene (EPS) geofoam in practice. Proceedings of the Geotechnical Engineering Seminar. Waltham: ASCE; 2005. p. 7–80.Suche in Google Scholar

[3] Zou Y, Small JC, Leo CJ. Behavior of EPS geofoam as flexible pavement subgrade material in model tests. Geo-synth Int. 2000;7(1):1–22.10.1680/gein.7.0163Suche in Google Scholar

[4] Arellano D, Tatum JB, Stark TD, Horvath JS, Leshchinsky D. A framework for design guideline for expanded polystyrene block geofoam in slope stabilization and repair. J Trans Res Board. 2010;2170:100–8.10.3141/2170-12Suche in Google Scholar

[5] Negussey D. Slope stabilization with geofoam. Report to FHWA and the EPS industry, Geofoam Research Center. Syracuse: Syracuse Press; 2002.Suche in Google Scholar

[6] Duskov M. Use of expanded polystyrene (EPS) in flflexible pavements on poor subgrades. Proceedings of the International Conference on Geotechnical Engineering for Coastal Development. Yokohama: 1991. p. 783–8.Suche in Google Scholar

[7] McDonald P, Brown PG. Ultra lightweight polystyrene for bridge approach fill. Proceedings of the 19th Southeast Asian Geotechnical Conference. Singapore: 1993. p. 663–8.Suche in Google Scholar

[8] Elragi A. Selected engineering properties and application of EPS geofoam. PhD dissertation. Syracuse: State University of New York; 2000.Suche in Google Scholar

[9] Yoshizaka K, Sakanoue T. Experimental study on soil-pipeline interaction using EPS backfill. Proceedings of the Pipeline Engineering and coNstruction International Conference. Baltimore; 2003, p. 1126–34.10.1061/40690(2003)129Suche in Google Scholar

[10] Negussey D, Sun M. Reducing lateral pressure by geo-foam (EPS) substitution. Proceedings of the International Symposium on EPS Construction Method. Tokyo: 1996. p. 202–11.Suche in Google Scholar

[11] Koerner RM. Designing with geosynthetics. Upper Saddle River: Prentice Hall; 2005.Suche in Google Scholar

[12] Wen Z, Sheng Y, Ma W, Qi JL. In situ experimental study on thermal protection effects of the insulation method on warm permafrost. Cold Reg Sci Technol. 2008;53(3):369–81.10.1016/j.coldregions.2007.06.004Suche in Google Scholar

[13] Ikizler SB, Aytekin M, Nas E. Laboratory study of expanded polystyrene (EPS) geofoam used with expansive soils. Geotext Geomembr. 2008;26(2):189–95.10.1016/j.geotexmem.2007.05.005Suche in Google Scholar

[14] Herki BA, Khatib JM. Valorisation of waste expanded polystyrene inconcrete using a novel recycling technique. Eur J Environ Civ Eng. 2017;21(11):1384–402.10.1080/19648189.2016.1170729Suche in Google Scholar

[15] Hazarika H. Stress-strain modeling of EPS geofoam for large-strain applications. Geotext Geomembr. 2006;24(2):79–90.10.1016/j.geotexmem.2005.11.003Suche in Google Scholar

[16] Jinmei D. Testing Research on engineering characteristics of lightweight soil mixed with expanded polystyrene. Thesis for Doctorate. Nanjing: Hohai University; 2005. p. 7–10.Suche in Google Scholar

[17] Beinbrech G, Hillmann R. EPS in road construction current situation in Germany. Geotext Geomembr. 1977;15:39–45.10.1016/S0266-1144(97)00006-XSuche in Google Scholar

[18] Stark TD, Arellano D, Horvath JS, Leshchinsky D. Geofoam application in design and construction of highway embankments. Transport Res Board. 2004;65:1–792.Suche in Google Scholar

[19] Frydenlund TE, Aaboe R. Expanded polystyrene-the light solution. Proceedings of the International Symposium on EPS Construction Method. Tokyo; 1996.Suche in Google Scholar

[20] Frydenlund TE, Aaboe R. Long term performance and durability of EPS as a lightweight filling material. Proceedings of 3rd International Geofoam Conference. Salt Lake City, Utah; 2001.Suche in Google Scholar

[21] Miki G. EPS construction method in Japan. Proceedings of the International Symposium on EPS Construction Method. Tokyo, Japan; 1996.Suche in Google Scholar

[22] Bartlett SF, Negussey D, Kimball M. Design and use of geofoam on the i-15 reconstruction project. Transportation Research Board; January 9th to 13th 2000. p. 22.Suche in Google Scholar

[23] Bartlett SF, Lawton EC, Farnsworth CB, Newman MP. Design and evaluation of expanded polystyrene geofoam embankments for the I-15 reconstruction project. Draft report prepared for Utah Department of Transportation Research Division, University of Utah, Department of Civil and Environmental Engineering. Salt Lake City, Utah; 2012. p. 203.Suche in Google Scholar

[24] Farnsworth CF, Bartlett SF, Negussey D, Stuedlein A. Construction and post-construction settlement performance of innovative embankment systems, I-15 reconstruction project. J Geotech Geoenviron Eng, Salt Lake City, Utah. 2008;134:289–301.10.1061/(ASCE)1090-0241(2008)134:3(289)Suche in Google Scholar

[25] Riad HL, Ricci AL, Osborn PW, D’Angelo DA, Horvath JS. Design of lightweight fills for road embankments on Boston’s central artery/tunnel project. Proceedings: Fifth International Conference on Case Histories in Geotechnical Engineering. New York, NY: 13–17 April 2004.Suche in Google Scholar

[26] Snow R, Webb J, Sander M. Light rail on geofoam West Valley UTA TRAX project. 2010 AREMA Conference and Exposition. Orlando Florida; 2010.Suche in Google Scholar

[27] Duškov M. Measurements on a flexible pavement structure with an EPS Geofoam sub-base. Geotext Geomembr. 1997;15:5–27.10.1016/S0266-1144(97)00004-6Suche in Google Scholar

[28] Herki BA, Khatib JM. Valorisation of waste expanded polystyrene in concrete using a novel recycling technique. European. J Environ Civ Eng. 2017;21(11):1384–402.10.1080/19648189.2016.1170729Suche in Google Scholar

[29] Shirazi AN, Haydarian H, Nasehi SA. Shear and compression behaviors of sandy and clayey soils mixed with different sizes of expanded polystyrene beads. Geotech Geol Eng. 2018;36:3823–30.10.1007/s10706-018-0575-ySuche in Google Scholar

[30] Hou TS, Xv GL. Influence of TIF size on the shear strength of lightweight soil. J Geotech Eng. 2011;33(10):1634–41.Suche in Google Scholar

[31] Xie SM, Xv GL, Ye SX, Hu HZ. Research on deformation and strength characteristics of lightweight soil under different particle size of EPS by triaxial test. J Hydroelectric Engergy. 2013;31(2):138–41.Suche in Google Scholar

[32] Xie SM, Xv GL, Ye SX, Hu HZ. Experimental research on influence of EPS beads size on strength of mixed lightweight sand. J Rock Mech Eng. 2013;32(2):3056–63.Suche in Google Scholar

[33] Zhuang XS, Yuan LS, Mei LF. Experimental research on compressive strength of polypropylene fibre-EPS mixture. J Hydroelectric Engergy. 2014;32(7):97–104.Suche in Google Scholar

[34] Wang YM, Bathurst RJ. Research on horizontal slice method model of influence of eps cushion on stress and strain of retaining wall under vibration. J Civ Eng. 2008;41(10):73–80.Suche in Google Scholar

[35] Horvath JS. Proceeding-Geosynthetics’91 [C]. New Orleans: Industrial Fabrics Association International; 1991. p. 409–24.Suche in Google Scholar

[36] Horvath JS. Proceedings of the International Symposium on EPS Construction Method [C]. Tokyo: EPS Tokyo 1996; 1996. p. 71–81.Suche in Google Scholar

[37] Horvath JS. The compressible inclusion function of EPS geofoam. Geotext Geomembr. 1997;15:77–120.10.1016/S0266-1144(97)00008-3Suche in Google Scholar

[38] American Society for Testing and Materials D422. Standard test method for particle size analysis of soils. West Conshohocken, PA: ASTM Int.; 1999.Suche in Google Scholar

[39] American Society for Testing and Materials D854. Standard test method for specific gravity of soils. West Conshohocken, PA: ASTM Int.; 1999.Suche in Google Scholar

[40] American Society for Testing and Materials D4318. Standard test method for liquid limit, plastic limit and plasticity index of soils. West Conshohocken, PA: ASTM Int.; 1999.Suche in Google Scholar

[41] American Society for Testing and Materials D698. Standard test method for laboratory compaction characteristic. West Conshohocken, PA: ASTM Int.; 1999.Suche in Google Scholar

[42] American Society for Testing and Materials D2166. Standard test method for unconfined compressive strength of cohesive soils. West Conshohocken, PA: ASTM Int.; 1999.Suche in Google Scholar

[43] American Society for Testing and Materials D2345. Standard test method for one-dimensional consolidation properties of soil using incremental loading. West Conshohocken, PA: ASTM Int.; 1999.Suche in Google Scholar

© 2022 Qu Jili et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete

Artikel in diesem Heft

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete