Multicriteria-based optimization and multi-variable non-linear regression analysis of concrete containing blends of nano date palm ash and eggshell powder as cementitious materials

Abstract

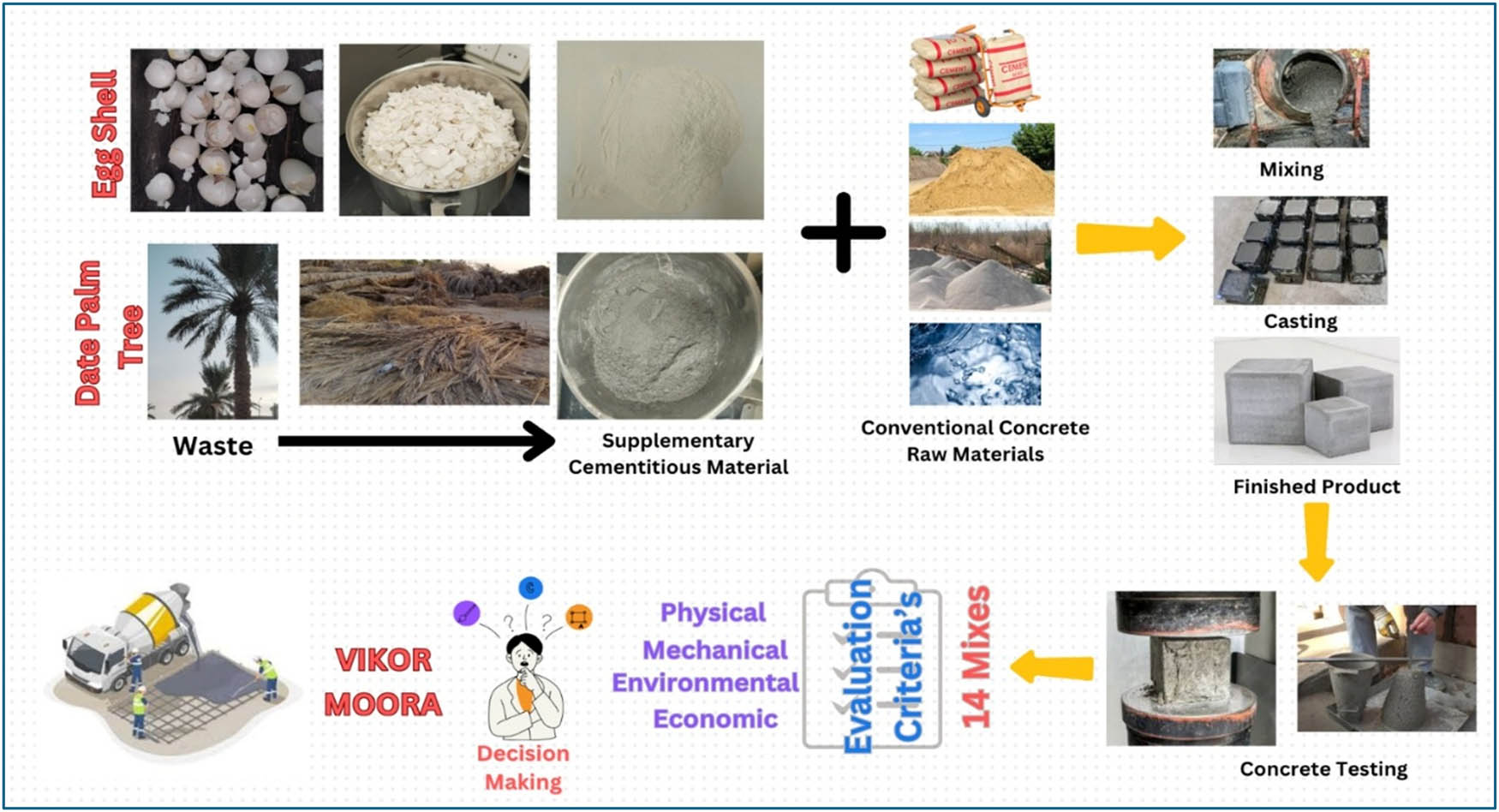

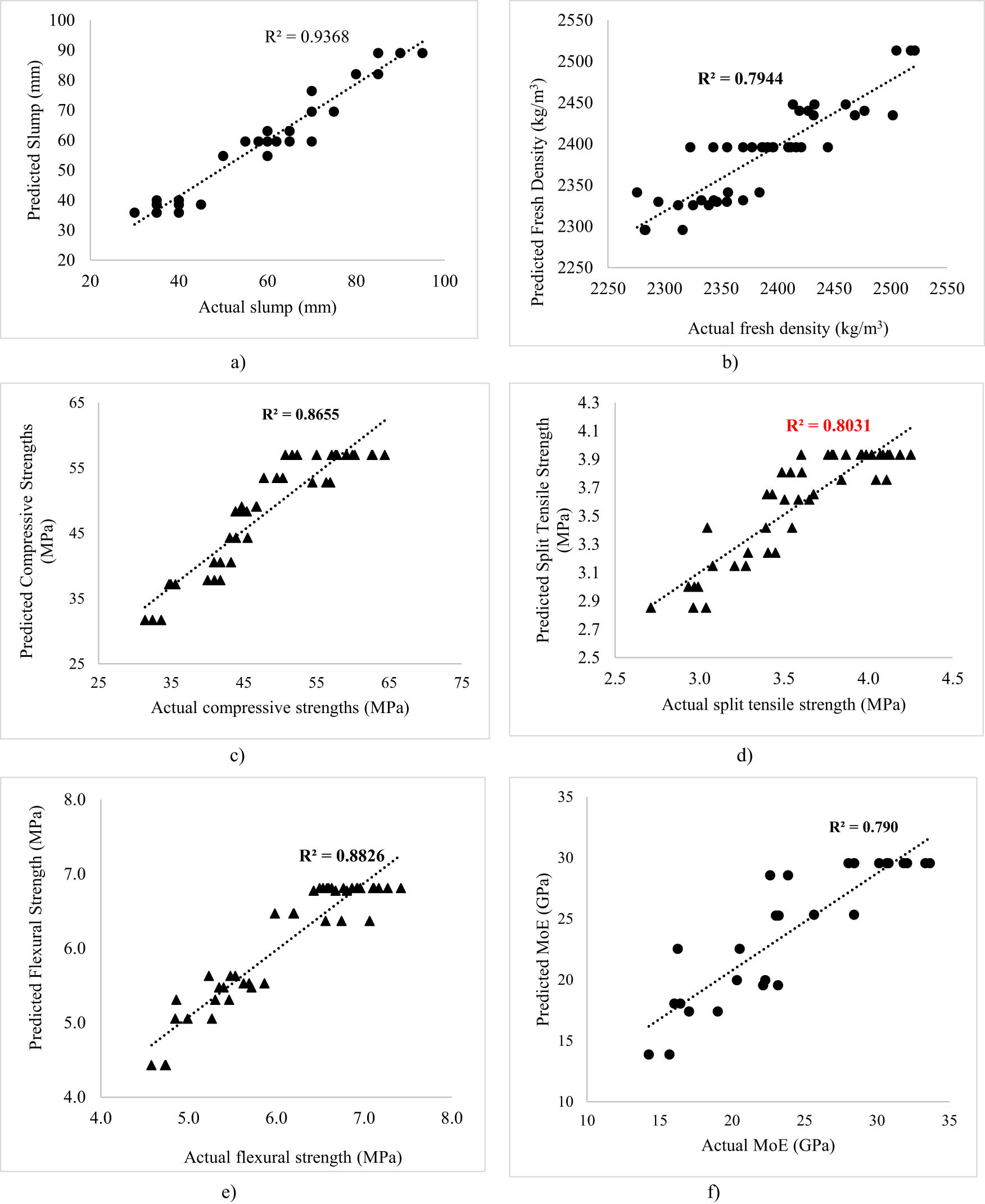

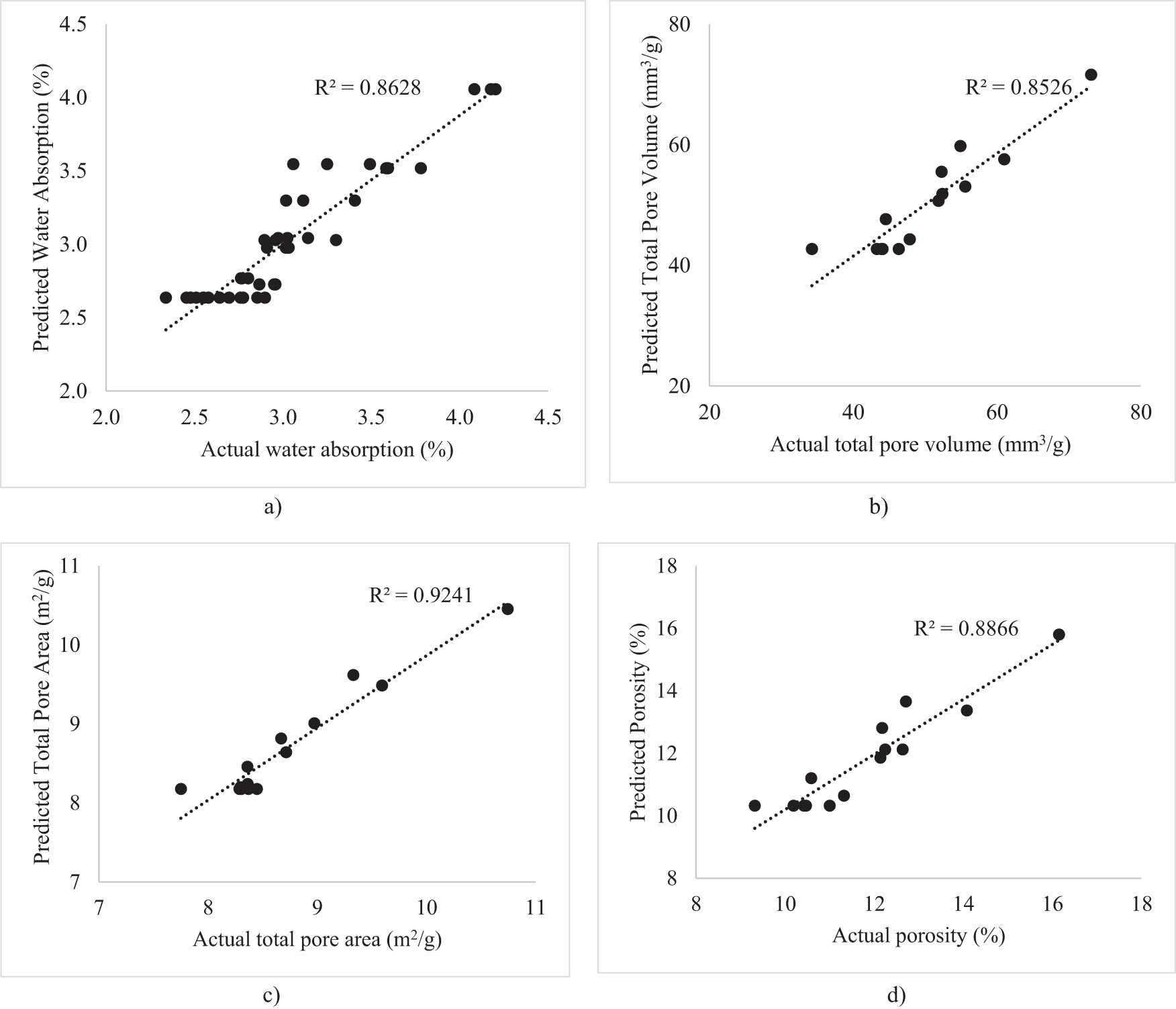

The persistence of global concerns regarding the environmental effects of cement production, particularly its significant contribution to CO2 emissions, led to the search for different supplementary cementitious materials (SCMs). Hence, this research utilized date palm ash (DPA) as an SCM to produce concrete. Nano eggshell powder (NESP) was also incorporated as an additive to binder materials in the concrete to hasten the pozzolanic reaction in the concrete. DPA was used to replace between 0 and 40% of the cement by volume, and the NESP was added in dosage between 0 and 4% by weight of binders. Multi-criteria decision making (MCDM) technique was adopted by employing different methods that include MOORA and VIKOR to select the optimal mix proportions containing DPA and NESP. Furthermore, multi-variable non-linear regression (MNLR) analysis was used to develop mathematical models for predicting the concrete’s properties using the proportions of DPA and NESP as the variables. The findings from the MCDM showed that Mix M8 consistently ranked highest across both MOORA and VIKOR analyses, demonstrating superior performance due to optimal incorporation of 40% DPA and 2% NESP. The developed MNLR models attained high accuracy in predicting with good-to-excellent R² values ranging between 0.79 and 0.94 for most properties.

Graphical Abstract

1 Introduction

Infrastructural advancement is crucial for urban development, and concrete is the primary material used in production due to its advantages over other building materials like glass, steel, and timber, leading to a global demand for concrete as the most commonly used manmade construction material. In previous studies [1,2], some researchers reported that the global concrete production exceeds 12 billion tons annually [3,4,5]. Concrete’s high acceptability and usability are due to its affordability, ease of moldability, higher strength-to-cost ratio, durability, and extended lifespan [6,7]. Concrete, despite its numerous benefits, has significant environmental and natural materials sustainability issues, with cement being a major contributor to global CO2 emissions [7]. The primary constituent materials for making concrete are cement as the binder material, aggregates (fine and coarse) for volume stability and strength, and water for hydration reaction and mixing [8]. In terms of materials sustainability, more than 40% of the global natural resources, such as aggregates, water, and timber, are utilized by the construction industries [9,10,11]. Cement is the primary contributor of greenhouse gas emissions (GHGs) from the construction industry, where it contributes to about 90% of the total CHG emissions linked to concrete production [12]. CO2 is the main GHG coming from cement production, and other minor GHGs from the cement production process include nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter (PM 2.5). These GHGs endanger human and other animals' health and foster the formation of haze, smog, and acid rain [13,14]. In terms of global CO2 emission, the cement industry is ranked as the second contributor [15,16,17], where about 8% of the global GHG CO2 emissions are associated with the cement industries alone [14,18,19,20]. The construction industry faces a significant challenge in finding an effective solution to reduce clinker and cement production by blending industrial waste materials and by-products with clinker during cement production or using them as partial substitutes [19,21]. Researchers in the construction and building sector are exploring sustainable materials from industrial or agricultural wastes and by-products with cementitious and pozzolanic properties for use as supplementary cementitious materials (SCMs). To find alternatives to cement, studies are being conducted on converting agricultural waste materials into inorganic fine powder through high temperatures and grinding, thereby reducing GHG CO2 emissions. Agricultural ashes, such as rice husk ash, palm oil fuel ash, bagasse ash, date palm ash (DPA), etc., have been found to contain high silica (SiO2) proportion, exhibiting pozzolanic reactivity, which makes them a good SCM, thus enhancing the performance of cementitious composites [22,23,24].

Date palm tree residues are one of the major agriculturally based solid waste in Saudi Arabia, with over 1 million tons of waste from the date trees every year. A single date tree yields roughly 40 kg of waste from its leaves, trunk, fronds, and mesh every year [24,25,26,27,28]. The date tree waste is normally discarded into landfills or burnt down under uncontrolled burning, hence creating environmental and air pollution [29,30]. The date tree residue can be effectively recycled and managed by incineration at high temperatures and grinding into finer inorganic ash, known as DPA. According to previous studies, DPA has been found to contain high silica (SiO2), alumina (Al2O3), and a reasonable amount of calcium oxide, which, when compared to the criteria of ASTM C618 [31], can be categorized as an effective pozzolanic material in cementitious composites [24,27,32,33]. Incorporating DPA as an SCM in cement composite can promote both material and environmental sustainability by reducing the amount of cement needed for construction purposes, thereby lowering the GHG CO2 emissions from the cement industry and contributing to a circular economy [27,34]. Previous studies have shown that the partial substitution of up to 10% cement with DPA in concrete enhanced its mechanical performance, especially compressive strength, and improved its durability performance by densifying the concrete’s microstructure. However, above the 10% replacement level, DPA triggers a decline in the concrete’s performance [34,35,36]. Adamu et al. [27] linked this declined performance of the concrete to the slower and lower pozzolanic reaction of the DPA. They recommended that for effective usage of DPA in concrete to achieve improvement in the concrete’s properties, the DPA should be mixed with other highly reactive pozzolanic material that contains higher cementing properties (CaO) [27]. Al-Kutti et al. [32] used a combination of DPA and fly ash as SCMs in concrete, where they substituted 10% cement with DPA and 25% cement with fly ash. They found that in comparison to concrete mix with 100% cement and the mix with 75% cement + 25% fly ash, the concrete with 65% cement + 25% fly ash + 10% DPA has higher strengths by 23 and 20%, respectively. In terms of the pozzolanic reaction, there was accelerated calcium silicate hydrates and aluminate formation inside the cementitious matrix.

Nano eggshell powder (NESP) is used as a cementitious and pozzolanic additive in concrete due to its high CaCO3/CaO dosage. It reacts with cement hydration products and other SCMs to produce excess calcium silicate (C–S–H) and aluminate (C–A–H) gels, enhancing strength and durability [1,37,38]. NESP is produced from eggshell waste, a common waste material in poultry farms, bakeries, and restaurants, which is typically discarded into dustbins and landfills [39,40]. NESP has been used as blends with other agriculturally based SCMs that contain high amounts of SiO2 and or Al2O3, where the NESP contributed significantly to the generation of more Ca(OH)2 that subsequently reacts with the SiO2 and Al2O3 from the other pozzolanic material to yield excess C–S–H and C–A–H [24,27]. NESP, due to its fine size, exhibits properties similar to nanomaterials from the graphene family, like graphene nanoplatelets, which have large surface areas and act as nanofillers in cementitious composite [41,42].

The blends of NESP with other agriculturally based SCMs have resulted in enhancement in pozzolanic reactions, durability performance, and mechanical characteristics, as reported by Amin et al. [43] for the blends of NESP with sugarcane bagasse ash, Hamada et al. [44] and Rasid et al. [45] for the blends of NESP with palm oil fuel ash, Jhatial et al. [46] for the blends of rice husk ash and NESP, Hakeem et al. [47] for the blends of NESP and rice straw ash, and Adamu et al. [27] for the blends of DPA and NESP.

Recent advancements in construction materials research have increasingly focused on utilizing the multi-criteria decision making (MCDM) approach to manage the complexities of decision-making processes that involve multiple and often conflicting criteria. Ahmed et al. [48] applied a comprehensive MCDM approach that combined OSM-AHP-TOPSIS to rank supplementary construction materials. This method facilitated a detailed evaluation by integrating both technical properties and sustainability performance indicators. Similarly, Moro [49] employed MCDM techniques to assess concrete mixes produced using both basic and recycled materials, such as SCMs and recycled concrete aggregate. The assessment focused on factors like cost, durability, mechanical performance, and environmental impact. The study emphasized the flexibility of MCDM in ranking the mixtures based on different property weightings and highlighted the consistency of MCDM compared to life cycle assessment approaches, particularly when durability was integrated into the analysis. The findings reinforced the utility of MCDM for optimizing material selection in sustainable construction practices. Chilukuri et al. [50] also implemented MCDM techniques – including TOPSIS, EDAS, and WPM – to select the most sustainable and thermally efficient steel slag lime blocks. Their results consistently ranked Mix M-6 as the top choice across all MCDM approaches, considering various physical, mechanical, thermal, and sustainability-related criteria. Janga et al. [51] aimed to address gaps in previous research by using MCDM methods to evaluate various material mixtures. Their study explored a detailed set of criteria involving fresh, mechanical, and durability performance, thermal, and environmental effects. The sustainability of the materials was assessed in the context of CO2 emissions and energy consumption over their lifespan, adopting four MCDM approaches used for comparison. Their target was to find the most effective mix design for a fly ash-based geopolymer with outstanding performance qualities. Adamu et al. [52] investigated the effects of crumb rubber (CR) and nano-silica (NS) on the properties of roller-compacted concrete pavement. Fine aggregate was replaced with CR in the proportion of 0–30% by volume, and NS was added in dosages of 0–3% by mass of binder. The MCDM approach was used to determine the optimal mix based on factors such as fresh properties, mechanical performance, and durability. De Angelis et al. [53] introduced MCDM analysis using the TOPSIS process to compare four building components, balancing opposing environmental and structural performance conditions. These studies collectively demonstrate the critical role that MCDM techniques play in improving the decision-making process for selecting and optimizing construction materials, contributing to more sustainable and efficient practices in the industry.

Date palm waste, a common waste in Middle East countries like Saudi Arabia, is being explored as an alternative to cement in concrete and mortar production. Various solid waste materials (SCMs) such as fly ash, silica fume, and slag have been used in concrete, but the use of DPA as an SCM in cementitious composites is still in its infancy. This study aims to blend DPA with NESP as SCMs in concrete, aiming to improve pozzolanic reaction during cement hydration and enhance its properties. The study also employs MCDM and multi-variable nonlinear regression (MNLR) techniques to evaluate the performance of concrete mixes with varying contents of DPA and NESP. The MNLR analysis is used to develop predictive models for estimating concrete properties using DPA and NESP as variables.

The clear focus of the research is the application of existing MCDM methods, MOORA and VIKOR, to a unique problem in sustainable concrete design. While MCDM techniques have been widely used in various disciplines [54,55,56] their application to optimize concrete mixes incorporating DPA and NESP is relatively unexplored. Thus, research bridges a gap in the literature by exploring the effectiveness of the methods balancing conflicting sustainability and structural performance criteria, providing a structured approach to evaluating concrete mixes.

Further, the integration of MOORA and VIKOR ensures a robust decision-making process, where MOORA provides clarity and computational efficiency, while VIKOR identifies compromise solutions between conflicting objectives. In this study, the combined use of MOORA and VIKOR ensures a comprehensive evaluation, leveraging the strengths of each method to address the complex and multi-dimensional nature of concrete mix design. The sensitivity analysis further strengthens the methodology by demonstrating the stability and reliability of the results, adding rigor to the decision-making process.

Finally, the main objectives focus on the concrete mixes developed, incorporating DPA and NESP, contributing to the advancement of sustainable construction materials. By optimizing these mixes for both environmental sustainability and mechanical performance, the research offers a practical solution for reducing embodied carbon while maintaining structural integrity. The resulting material not only addresses sustainability goals but also provides valuable insights into the use of innovative materials in construction.

2 Materials and methods

2.1 Materials

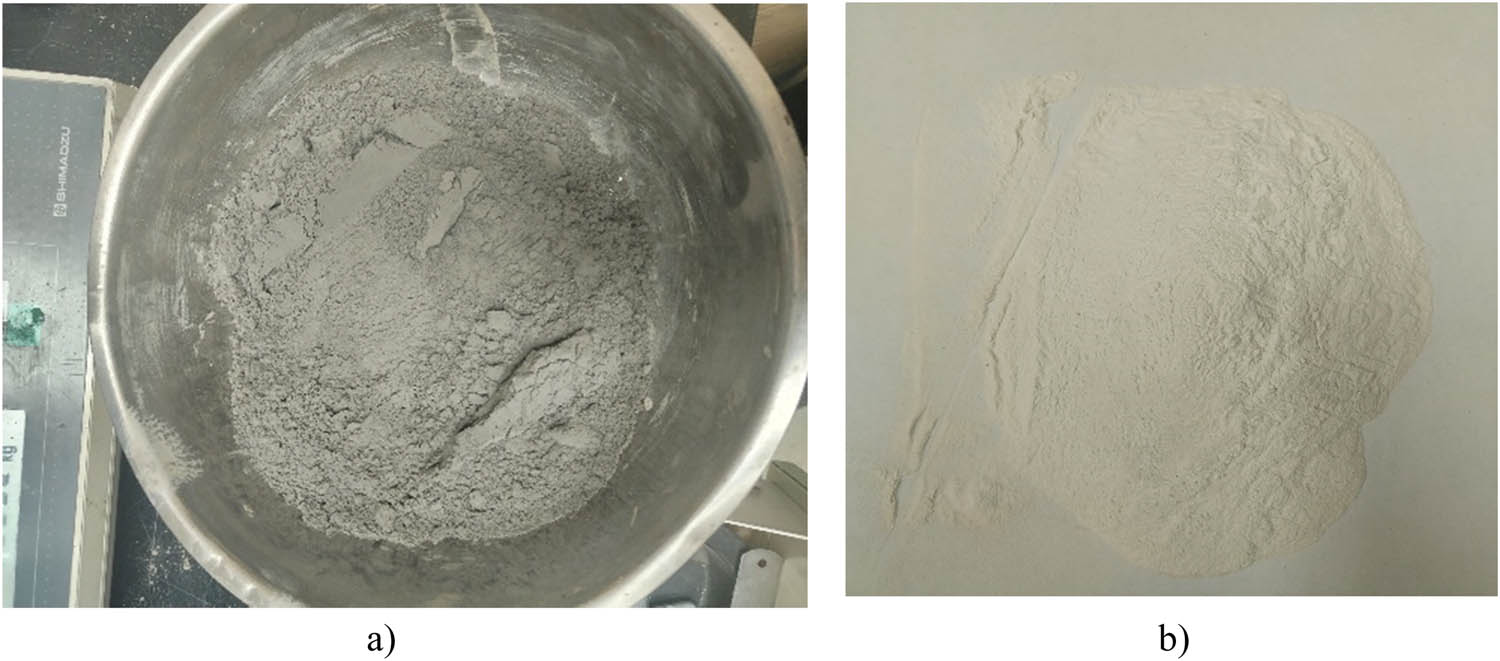

The constituent materials employed to execute this research include ordinary Portland cement (OPC), fine aggregate, coarse aggregate, DPA, eggshell powder (NESP), and water. The OPC was Type I, and its properties are summarized in Table 1. The DPA was acquired from burning down and processing the date palm tree waste, which was incinerated on the farm using open burning. The ash was subjected to additional processing where it was kept in the furnace for 2 h at a temperature of 600°C to lower the unburnt carbon and convert it to an inorganic material; this process of burning was adopted by Amin et al. [57] and Adamu et al. [27]. After burning, the ash was left to cool inside the furnace before grinding to finely powdered form. The fine powder was subjected to sieving, and the particles that passed through the 150 µm sieve were collected and used as the DPA, as shown in Figure 1a.

Properties of cement, DPA, and NESP [27]

| Oxides | Composition (%) | ||

|---|---|---|---|

| OPC | DPA | NESP | |

| SiO2 | 19.17 | 52.35 | 0.03 |

| Al2O3 | 5.39 | 6.27 | 0.02 |

| Fe2O3 | 3.4 | 13.36 | — |

| CaO | 65.18 | 11.72 | 97.46 |

| MgO | 0.91 | 0.10 | 0.69 |

| K2O | 1.22 | 15.52 | 0.07 |

| SO3 | 3.51 | 1.50 | 0.35 |

| MnO | 0.18 | 0.11 | — |

| Na2O | 0.17 | — | 0.17 |

| P2O5 | 0.09 | — | 0.47 |

| Specific gravity | 3.15 | 2.14 | 2.36 |

Processed DPA and NESP: (a) DPA and (b) NESP.

The properties of the DPA are highlighted in Table 1, and based on its chemical compositions, in accordance with ASTM C618 [58] guidelines, the DPA can be categorized as good pozzolanic material as the sum of its Al2O3, SiO2, and Fe2O3 are greater than 70%, and with CaO more than 10% it can be classified to have cementing properties.

The NESP was obtained by processing waste eggshells. After the eggshells were collected, they were rigorously washed to remove the inner inorganic membranes and other dirt and dust from its surface. The washed eggshells were then crushed with hand to smaller particles and air dried for 48 h to completely dry it. After drying, the eggshells were milled to finely powdered sizes and subjected to sieving. Subsequently, the very fine particles that passed through the 63 μm sieve size was adopted as the NESP (Figure 1b). The chemical composition of the NESP is shown in Table 1.

A clean river was obtained from local suppliers and used as fine aggregate. The aggregate used is well graded, as shown in Figure 2, and it falls within the limits specified by ASTM C33/C33M [59]. The fine aggregate has the following properties: specific gravity (2.63), bulk density (1,565 kg/m3), and absorption (1.87%).

![Figure 2

Gradation of aggregates [27].](/document/doi/10.1515/ntrev-2025-0141/asset/graphic/j_ntrev-2025-0141_fig_002.jpg)

Gradation of aggregates [27].

For the coarse aggregate, crushed gravels with sizes not exceeding 19 mm were obtained from local quarry and used for making the concrete. The coarse aggregate grading also shows that it is well graded with sizes falling within the specified range for ASTM C33. The properties of the coarse aggregate include bulk density of 1,455 kg/m3, specific gravity of 2.67, and absorption of 0.67%.

2.2 Mixture proportions

In this study, DPA was employed as a partial alternative to cement in several ratios between 0 and 40% by volume replacement. The NESP was utilized as a supplement to cementitious materials in the concrete in quantities between 0 and 4% by weight of cementitious materials. For comparison and to generate the mix proportions, the control concrete mix was designed based on the procedures of ACI 211.1R [60]. To obtain the optimal number of mixes required for the investigation, and to scale down the number of mixes and save cost and time, the response surface methodology (RSM) technique was employed to design the mix proportions [61]. Design Expert software was used to carry out the RSM approach to design the mixes. The central composite design (CCD), which is one of the most used design methods for the RSM technique, was selected to design the mix. To use the CCD method, a minimum of two input variables are required, and each of the inputs should be varied into five levels [61]. In this study, two variables were used, i.e., DPA and NESP, with each having five variations, i.e., DPA (0, 10, 20, 30, and 40%) and NESP (0, 1, 2, 3, and 4%). Based on the inputs and their proportions of variations, the CCD produced 13 mixes, which is by default. In Table 2, 14 mixes that comprise the 13 mixes generated using the RSM and the reference mix (control mix) with their constituent materials are presented.

| Mix | DPA (%) | NESP (%) | Quantity (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| OPC | DPA | NESP | Fine aggregate | Coarse aggregate | Water | Superplasticizer | |||

| M1 | 0 | 0 | 490 | 0.0 | 0.0 | 750 | 905 | 170 | 4.90 |

| M2 | 30 | 1 | 343 | 113.4 | 4.6 | 750 | 905 | 170 | 4.61 |

| M3 | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

| M4 | 0 | 2 | 490 | 0.0 | 9.8 | 750 | 905 | 170 | 5.00 |

| M5 | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

| M6 | 10 | 1 | 441 | 37.8 | 4.8 | 750 | 905 | 170 | 4.84 |

| M7 | 20 | 4 | 392 | 75.6 | 18.7 | 750 | 905 | 170 | 4.86 |

| M8 | 40 | 2 | 294 | 151.2 | 8.9 | 750 | 905 | 170 | 4.54 |

| M9 | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

| M10 | 10 | 3 | 441 | 37.8 | 14.4 | 750 | 905 | 170 | 4.93 |

| M11 | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

| M12 | 20 | 0 | 392 | 75.6 | 0.0 | 750 | 905 | 170 | 4.68 |

| M13 | 30 | 3 | 343 | 113.4 | 13.7 | 750 | 905 | 170 | 4.70 |

| M14 | 20 | 2 | 392 | 75.6 | 9.4 | 750 | 905 | 170 | 4.77 |

2.3 Sample preparations and test methods

The sample preparations for this study, including the batching, mixing, and casting, were executed according to the provisions of ASTM C192 [62]. The mixing of the concrete was executed in the laboratory with the aid of a rotating drum-type mixer. After mixing was completed and a homogeneous mix was achieved, the fresh concrete’s density and workability were assessed. Upon completion of the fresh properties testing, the fresh concrete mixture was poured into the specified molds, which were tightened and oiled before casting. The freshly cast concrete was stored for a period of 24 h in the laboratory to harden completely before demolding and curing in water.

The specifications of ASTM C143/C143M [63] were followed to determine the workability of the fresh concrete using the slump test method. The fresh density test was executed in compliance with the methods specified in ASTM C138/C138M [64]. After hardening and curing for 28 days, the compressive strength of the concrete was determined in compliance with BS EN 12390-3 [65] specifications using 100 cube samples. The split tensile strength (STS) testing was performed in line with the guidelines of BS EN 12390-6 [66] using concrete cylinders with dimensions of 200 mm height by 100 mm diameter, which were stored in water for 28 days ahead of testing. The flexural strength (FS) testing was executed by adopting the procedures of ASTM C78/C78M [67], where small beams with a size of 100 mm × 100 mm × 500 mm were produced and tested after curing for 28 days in water. The elastic modulus test was performed in line with the recommendations of ASTM C469 [68], using concrete cylinders with 300 mm height and 150 mm diameter. The concrete’s durability was assessed through water absorption and mercury intrusion porosimetry (MIP) tests. Regarding the test for water absorption, the method listed in ASTM C642 [69] was adopted, where 100 mm cubes were prepared and stored for 28 days in the water ahead of testing. The MIP test was carried out as per the specifications of ASTM D4284 [70].

2.4 MCDM approach

The MCDM approach in evaluating concrete developed from the incorporation of DPA and NESP entails a comprehensive assessment of various properties, categorized into beneficial and non-beneficial attributes. The non-beneficial properties include water absorption (WA), porosity (P), total pore volume (TPV), total pore area (TPA), embodied CO₂ emission (eCO₂), fresh density (FD), and cost. Conversely, the beneficial properties consist of slump (S), compressive strength (CS), eco-strength, STS (MPa), FS, and modulus of elasticity (MoE). This study aims to identify the optimal concrete mix by analyzing each parameter, with non-beneficial properties focused on reducing emissions, while beneficial properties provide insights into structural and mechanical characteristics.

To facilitate the decision-making process, two distinct MCDM methods – MOORA and VIKOR – are employed. The selection of MOORA and VIKOR for this study was guided by their unique strengths in addressing multi-criteria decision-making challenges. MOORA was chosen for its simplicity and computational efficiency in handling diverse criteria while normalizing data and ranking alternatives, making it particularly suitable for studies involving mixed beneficial and non-beneficial attributes. It excels in providing a straightforward comparison of alternatives without requiring extensive mathematical complexity, which aligns with the study’s focus on evaluating sustainability and performance criteria. VIKOR was selected for its strength in handling conflicting objectives and identifying compromise solutions. This method is particularly advantageous when the goal is to balance trade-offs between sustainability and mechanical performance, as it ranks alternatives based on proximity to the ideal solution while considering group utility and individual regret. VIKOR’s ability to emphasize compromise solutions makes it valuable in cases where no single alternative excels in all criteria, reflecting the inherent complexity of concrete mix design.

This diverse approach ensures a robust and thorough evaluation of the concrete alternatives based on multiple criteria. Weights for each criterion are established using the entropy method, beginning with the calculation of entropy weights derived from the normalized values of the alternatives for each property. The first step involves calculating the entropy weight [50,51,52], denoted as

where n represents the number of alternatives and

with

The methodology for MCDM using the MOORA (multi-objective optimization on the basis of ratio analysis) and VIKOR (VlseKriterijumska Optimizacija I Kompromisno Resenje) methods involves a systematic approach to evaluate alternatives based on multiple criteria.

2.4.1 MOORA

MOORA is one of the MCDM methods used to evaluate and rank alternatives based on multiple conflicting criteria. It involves constructing a decision matrix with alternatives and their performance measures, followed by normalizing the data to make criteria comparable. The method calculates performance ratios for each alternative, distinguishing between beneficial (higher values preferred) and non-beneficial (lower values preferred) criteria. Finally, these ratios are aggregated to rank the alternatives, helping decision-makers identify the most suitable option.

The evaluation of concrete developed from the incorporation of DPA and NESP involves two categories of criteria: beneficial and non-beneficial properties. The beneficial properties include water absorption, porosity, total pore volume, total pore area, embodied CO₂ emission, fresh density, and cost. These attributes are aimed at enhancing sustainability and performance. Conversely, the non-beneficial properties consist of slump, compressive strength, STS, FS, MoE, and Eco-Strength, which provide insights into the structural and mechanical characteristics of the concrete. The complete MOORA method is outlined below in a detailed, step-by-step manner, supported by relevant equations [71,72].

The first step of the MOORA method consists of the formation of a decision matrix. Construct a decision matrix

where

In the next step, normalize the decision matrix by calculating the Euclidean norm for each criterion:

Subsequently, calculate the normalized decision matrix:

Further, compute the weighted standard decision matrix using weights

Then, calculate the total scores for the beneficial properties (indexed from 1 to

Finally, compute the contribution index

The last step consists of ranking the alternatives based on the contribution index (

2.4.2 VIKOR method

The VIKOR method is an MCDM technique utilized to examine alternatives based on multiple criteria, especially when there are conflicting objectives. In the context of evaluating concrete developed through the incorporation of DPA and NESP, the VIKOR method can be applied. Additionally, the MOORA method is comprehensively explained below in a detailed, step-by-step manner supported by relevant equations [73,74].

The first step consists of creating a decision matrix DDD, where each alternative represents a specific concrete mix, and each column corresponds to the different properties (criteria):

where

In the second step, the values are normalized in the decision matrix. For beneficial properties, normalization is done as

For non-beneficial properties, it is done as follows:

where

In another step, the ideal

Further, for each alternative

where

Next, the VIKOR index

Here,

Finally, rank the alternatives based on the VIKOR index

Experimental and MCDM summary.

3 Results and discussion

3.1 Experimental results

The experimental results in this study were discussed in detail in our previous studies [24,27] and are summarized here for ease of understanding of the modeling results. Table 3 provides a summary of the experimental results. Substituting cement partially with DPA caused a decrease in the slump and fresh density of the concrete. The reduction in the slump was linked to the coarser texture of the DPA particles, which increased the internal friction and viscosity of the cement paste, thus reducing the workability of the concrete, while the reduction in the density was credited to the inferior density or specific gravity of the DPA relative to the cement it partly substituted [24,27]. The presence of NESP in the mixes reduced the concrete’s workability; the larger surface area of the NESP led to greater water absorption during mixing, which in turn reduced workability. NESP slightly increased the fresh density of the concrete, and this was credited to the fact that the NESP was used as a supplement that increases the quantities and bulk density of the constituent materials of the mixes [24]. Using DPA as a partial cement replacement resulted in a drop in the compressive strength, FS, STS, and MoE, and an increase in water absorption and porosity of the concrete. A comparison of the strengths and MoE values between mix M1 (0% DPA and 0% NESP) and mix M12 (20% DPA and 0% NESP) helps explain this. Mix 12 has lower values of strengths and MoE and higher water absorption, pore volume, and porosity in contrast to the values for mix M1. The diminishment in mechanical strengths and MoE and increase in porosity were related to the fall in the hydration reaction in the concrete due to the slower pozzolanic reaction of the DPA despite containing significant quantities of SiO2 and Al2O3. This increases the porosity and hinders strength development in the concrete [24,27]. The addition of NESP to the concrete, with or without DPA, resulted in an increase in mechanical strengths, MoE, and a reduction in water absorption and porosity of the concrete, which can be observed by comparing the strengths, MoE, water absorption, and porosity values of mix M1 (0% DPA and 0% NESP) with that of mix M4 (0% DPA and 2% NESP), this increment in mechanical properties and reduction in water absorption and porosity was linked to the high CaO of the NESP, which led to its contribution to cementitious properties in the concrete. Additionally, finer NESP particles allowed for pore filling, which densified the concrete’s microstructure and improved its strength [24,27]. From Table 3, the integration of DPA and NESP in the concrete substantially increases its mechanical strength MoE and reduces the pore volume, porosity, and water absorption of the concrete. In the whole experimental results, the mix produced with 20% DPA and 2% NESP has the highest mechanical strengths, MoE, and lower water absorption and porosity compared to the other mixes. Additionally, mixes blending with up to 30% DPA and up to 3% NESP such as mixes M2, M6, M10, and M13, have higher mechanical properties and lower water absorption and porosity compared to mix M1 (0% DPA and 0% NESP). The improvements in mechanical properties due to blending DPA and NESP were due to the combined effects of both materials. The NESP contributed to surplus CaO, which increases Ca(OH)2 production in the hydration process, whereas the DPA provided additional SiO2 during the hydration. Through a pozzolanic reaction, Ca(OH)2 combines with SiO2 and Al2O3 from the DPA, forming excess C–S–H and C–S–A–H gels, the primary agents for densifying the concrete’s microstructure and developing strength [24,27].

Experimental results

| Mix | DPA (%) | NESP (%) | S (mm) | FD (kg/m3) | CS (MPa) | STS (MPa) | FS (MPa) | MoE (GPa) | WA (%) | TPV (mm3/g) | TPA (m2/g) | P (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 0 | 0 | 90 | 2436 | 40.92 | 3.38 | 5.73 | 22.67 | 3.18 | 52.30 | 8.97 | 12.18 |

| M2 | 30 | 1 | 53 | 2326 | 41.97 | 3.19 | 5.49 | 21.32 | 3.27 | 54.90 | 9.33 | 12.71 |

| M3 | 20 | 2 | 65 | 2356 | 57.53 | 4.19 | 7.23 | 31.41 | 2.45 | 43.30 | 8.31 | 10.19 |

| M4 | 0 | 2 | 83 | 2515 | 46.08 | 3.50 | 6.13 | 23.13 | 2.99 | 55.60 | 8.36 | 12.64 |

| M5 | 20 | 2 | 60 | 2396 | 59.49 | 4.01 | 6.75 | 31.01 | 2.57 | 43.94 | 8.45 | 10.42 |

| M6 | 10 | 1 | 70 | 2468 | 49.22 | 3.54 | 6.64 | 23.25 | 2.92 | 47.88 | 8.36 | 11.32 |

| M7 | 20 | 4 | 38 | 2339 | 44.17 | 3.33 | 5.03 | 18.03 | 3.05 | 52.39 | 8.72 | 12.25 |

| M8 | 40 | 2 | 35 | 2294 | 32.49 | 2.91 | 4.68 | 14.98 | 4.15 | 73.10 | 10.74 | 16.15 |

| M9 | 20 | 2 | 60 | 2409 | 58.04 | 3.86 | 7.05 | 30.75 | 2.61 | 44.07 | 8.37 | 10.47 |

| M10 | 10 | 3 | 63 | 2441 | 55.90 | 4.00 | 6.79 | 27.05 | 2.78 | 44.52 | 8.29 | 10.59 |

| M11 | 20 | 2 | 58 | 2410 | 63.25 | 3.73 | 6.86 | 33.50 | 2.72 | 34.25 | 7.75 | 9.32 |

| M12 | 20 | 0 | 72 | 2332 | 35.09 | 2.97 | 5.21 | 16.23 | 3.65 | 61.00 | 9.59 | 14.08 |

| M13 | 30 | 3 | 40 | 2349 | 44.68 | 3.58 | 5.41 | 18.40 | 3.05 | 51.85 | 8.67 | 12.14 |

| M14 | 20 | 2 | 58 | 2372 | 51.58 | 4.08 | 6.55 | 28.24 | 2.75 | 46.35 | 8.29 | 11.00 |

3.2 MCDM

Based on the data collected from experiments, various MCDM methods were utilized to identify the optimal mix of concrete incorporating DPA and NESP. Employing four different techniques allowed for a comprehensive evaluation of multiple alternatives while considering various performance criteria, thus supporting informed decision-making. The entropy method played a crucial role in this process by assigning weights to each criterion, reflecting their relative importance in the decision-making framework.

This method enhances the understanding of the decision-making process by illuminating the trade-offs and implications associated with different criteria. The computation of entropy weights, as described in equations (1) to (3) of the methodology section, is vital for establishing a weighted decision matrix. Table 4 displays the raw data collected during the experiments, providing a foundation for analysis. Following this, Table 5 presents the normalized decision matrix, which facilitates the subsequent determination of weights. Finally, Table 6 summarizes the entropy weights assigned to each criterion, which are essential for ranking the alternatives across the various MCDM techniques. This structured approach not only aids in identifying the most suitable concrete mix but also ensures that decision-makers are equipped with a robust framework for evaluating sustainability and performance.

Raw data for MCDM analysis

| Mix | S (mm) | FD (kg/m3) | CS (MPa) | STS (MPa) | FS (MPa) | MoE (GPa) | WA (%) | TPV (mm3/g) | TPA (m2/g) | P (%) | eCO2 (kgCO2/m3) | Eco-Str (MPa/kgCO2 m3) | Cost ($/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 90 | 2,436 | 40.92 | 3.38 | 5.73 | 22.67 | 3.18 | 52.30 | 8.97 | 12.18 | 449.15 | 0.09 | 118.8 |

| M2 | 53 | 2,326 | 41.97 | 3.19 | 5.49 | 21.32 | 3.27 | 54.90 | 9.33 | 12.71 | 342.75 | 0.12 | 104.81 |

| M3 | 65 | 2,356 | 57.53 | 4.19 | 7.23 | 31.41 | 2.45 | 43.30 | 8.31 | 10.19 | 378.98 | 0.15 | 109.57 |

| M4 | 83 | 2,515 | 46.08 | 3.50 | 6.13 | 23.13 | 2.99 | 55.60 | 8.36 | 12.64 | 450.33 | 0.10 | 118.96 |

| M5 | 60 | 2,396 | 59.49 | 4.01 | 6.75 | 31.01 | 2.57 | 43.94 | 8.45 | 10.42 | 378.98 | 0.16 | 109.57 |

| M6 | 70 | 2,468 | 49.22 | 3.54 | 6.64 | 23.25 | 2.92 | 47.88 | 8.36 | 11.32 | 419.09 | 0.12 | 114.19 |

| M7 | 38 | 2,339 | 44.17 | 3.33 | 5.03 | 18.03 | 3.05 | 52.39 | 8.72 | 12.25 | 380.11 | 0.12 | 109.72 |

| M8 | 35 | 2,294 | 32.49 | 2.91 | 4.68 | 14.98 | 4.15 | 73.10 | 10.74 | 16.15 | 307.62 | 0.11 | 100.19 |

| M9 | 60 | 2,409 | 58.04 | 3.86 | 7.05 | 30.75 | 2.61 | 44.07 | 8.37 | 10.47 | 378.98 | 0.15 | 109.57 |

| M10 | 63 | 2,441 | 55.90 | 4.00 | 6.79 | 27.05 | 2.78 | 44.52 | 8.29 | 10.59 | 415.24 | 0.13 | 114.34 |

| M11 | 58 | 2,410 | 63.25 | 3.73 | 6.86 | 33.50 | 2.72 | 34.25 | 7.75 | 9.32 | 378.98 | 0.17 | 109.57 |

| M12 | 72 | 2,332 | 35.09 | 2.97 | 5.21 | 16.23 | 3.65 | 61.00 | 9.59 | 14.08 | 377.85 | 0.09 | 109.43 |

| M13 | 40 | 2,349 | 44.68 | 3.58 | 5.41 | 18.40 | 3.05 | 51.85 | 8.67 | 12.14 | 343.85 | 0.13 | 104.96 |

| M14 | 58 | 2,372 | 51.58 | 4.08 | 6.55 | 28.24 | 2.75 | 46.35 | 8.29 | 11.00 | 378.98 | 0.14 | 109.57 |

Normalization matrix

| Mix | S (mm) | FD (kg/m3) | CS (MPa) | STS (MPa) | FS (MPa) | MoE (GPa) | WA (%) | TPV (mm3/g) | TPA (m2/g) | P (%) | eCO2 (kgCO2/m3) | Eco-Str (MPa/kgCO2 m3) | Cost ($/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 0.106 | 0.07 | 0.060 | 0.067 | 0.066 | 0.066 | 0.066 | 0.066 | 0.069 | 0.067 | 0.060 | 0.051 | 0.066 |

| M2 | 0.062 | 0.073 | 0.061 | 0.063 | 0.064 | 0.062 | 0.064 | 0.063 | 0.066 | 0.065 | 0.079 | 0.068 | 0.074 |

| M3 | 0.076 | 0.072 | 0.084 | 0.083 | 0.084 | 0.092 | 0.085 | 0.080 | 0.074 | 0.081 | 0.071 | 0.085 | 0.071 |

| M4 | 0.098 | 0.067 | 0.067 | 0.069 | 0.071 | 0.068 | 0.070 | 0.062 | 0.074 | 0.065 | 0.060 | 0.057 | 0.066 |

| M5 | 0.070 | 0.071 | 0.087 | 0.079 | 0.078 | 0.091 | 0.082 | 0.079 | 0.073 | 0.079 | 0.071 | 0.088 | 0.071 |

| M6 | 0.082 | 0.069 | 0.072 | 0.070 | 0.077 | 0.068 | 0.072 | 0.072 | 0.074 | 0.073 | 0.06 | 0.066 | 0.068 |

| M7 | 0.045 | 0.072 | 0.064 | 0.066 | 0.058 | 0.053 | 0.069 | 0.066 | 0.071 | 0.067 | 0.071 | 0.065 | 0.071 |

| M8 | 0.041 | 0.074 | 0.047 | 0.057 | 0.054 | 0.044 | 0.050 | 0.047 | 0.057 | 0.051 | 0.088 | 0.059 | 0.078 |

| M9 | 0.070 | 0.070 | 0.085 | 0.076 | 0.082 | 0.090 | 0.080 | 0.079 | 0.074 | 0.079 | 0.071 | 0.08 | 0.071 |

| M10 | 0.074 | 0.069 | 0.082 | 0.079 | 0.079 | 0.079 | 0.075 | 0.078 | 0.074 | 0.078 | 0.065 | 0.075 | 0.068 |

| M11 | 0.068 | 0.070 | 0.092 | 0.074 | 0.080 | 0.098 | 0.077 | 0.101 | 0.079 | 0.088 | 0.071 | 0.093 | 0.071 |

| M12 | 0.084 | 0.073 | 0.051 | 0.059 | 0.060 | 0.047 | 0.057 | 0.057 | 0.064 | 0.058 | 0.071 | 0.052 | 0.071 |

| M13 | 0.047 | 0.072 | 0.065 | 0.071 | 0.063 | 0.054 | 0.069 | 0.067 | 0.071 | 0.068 | 0.079 | 0.073 | 0.074 |

| M14 | 0.068 | 0.071 | 0.075 | 0.081 | 0.076 | 0.083 | 0.076 | 0.075 | 0.074 | 0.075 | 0.071 | 0.076 | 0.071 |

Normalized weights

| S (mm) | FD (kg/m3) | CS (MPa) | STS (MPa) | FS (MPa) | MoE (GPa) | WA (%) | TPV (mm3/g) | TPA (m2/g) | P (%) | eCO2 (kgCO2/m3) | Eco-Str (MPa/kgCO2 m3) | Cost ($/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.210 | 0.001 | 0.115 | 0.039 | 0.057 | 0.194 | 0.055 | 0.097 | 0.018 | 0.058 | 0.032 | 0.111 | 0.006 |

3.2.1 MOORA method

In the MOORA method, the initial step involves constructing a decision matrix that evaluates each concrete mix against a variety of performance metrics. These metrics include water absorption, total pore volume, total pore area, porosity, embodied CO₂ emission, fresh density, cost, eco-strength, slump, compressive strength, STS, FS, and modulus of elasticity. Each mix is assigned values for these criteria based on experimental data, creating a comprehensive overview of their performance characteristics.

Once the decision matrix is established, the next step is to normalize the data to ensure comparability among the various criteria. This normalization process is essential as it standardizes the data, allowing for meaningful comparisons across different metrics that may have distinct units or scales. Typically, this involves transforming the raw data into a common scale, which facilitates the calculation of performance ratios (Table 7).

Computation of contribution index

| Mix | S (mm) | FD (kg/m3) | CS (MPa) | STS (MPa) | FS (MPa) | MoE (GPa) | WA (%) | TPV (mm3/g) | TPA (m2/g) | P (%) | eCO2 (kgCO2/m3) | Eco-Str (MPa/kgCO2 m3) | Cost ($/m3) | Yi | Rank |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 0.016 | 0.027 | 0.005 | 0.016 | 0.010 | 0.001 | 0.002 | 0.021 | 0.081 | 0.025 | 0.010 | 0.014 | 0.047 | −0.123 | 6 |

| M2 | 0.016 | 0.028 | 0.005 | 0.017 | 0.008 | 0.001 | 0.002 | 0.028 | 0.048 | 0.026 | 0.009 | 0.014 | 0.044 | −0.094 | 5 |

| M3 | 0.012 | 0.022 | 0.005 | 0.013 | 0.009 | 0.001 | 0.002 | 0.035 | 0.059 | 0.036 | 0.012 | 0.018 | 0.065 | −0.162 | 13 |

| M4 | 0.015 | 0.028 | 0.005 | 0.017 | 0.010 | 0.001 | 0.002 | 0.024 | 0.075 | 0.029 | 0.010 | 0.015 | 0.048 | −0.124 | 7 |

| M5 | 0.013 | 0.022 | 0.005 | 0.014 | 0.009 | 0.001 | 0.002 | 0.036 | 0.054 | 0.037 | 0.012 | 0.017 | 0.064 | −0.156 | 12 |

| M6 | 0.014 | 0.024 | 0.005 | 0.015 | 0.009 | 0.001 | 0.002 | 0.027 | 0.063 | 0.031 | 0.010 | 0.016 | 0.048 | −0.126 | 8 |

| M7 | 0.015 | 0.027 | 0.005 | 0.016 | 0.009 | 0.001 | 0.002 | 0.027 | 0.035 | 0.027 | 0.010 | 0.013 | 0.037 | −0.075 | 2 |

| M8 | 0.020 | 0.037 | 0.006 | 0.021 | 0.007 | 0.001 | 0.002 | 0.024 | 0.032 | 0.020 | 0.008 | 0.012 | 0.031 | −0.033 | 1 |

| M9 | 0.013 | 0.022 | 0.005 | 0.014 | 0.009 | 0.001 | 0.002 | 0.035 | 0.054 | 0.036 | 0.011 | 0.018 | 0.064 | −0.154 | 11 |

| M10 | 0.014 | 0.023 | 0.005 | 0.014 | 0.009 | 0.001 | 0.002 | 0.031 | 0.057 | 0.035 | 0.012 | 0.017 | 0.056 | −0.141 | 10 |

| M11 | 0.013 | 0.017 | 0.004 | 0.012 | 0.009 | 0.001 | 0.002 | 0.038 | 0.053 | 0.039 | 0.011 | 0.017 | 0.070 | −0.170 | 14 |

| M12 | 0.018 | 0.031 | 0.005 | 0.018 | 0.009 | 0.001 | 0.002 | 0.021 | 0.065 | 0.022 | 0.009 | 0.013 | 0.034 | −0.080 | 3 |

| M13 | 0.015 | 0.026 | 0.005 | 0.016 | 0.008 | 0.001 | 0.002 | 0.030 | 0.036 | 0.028 | 0.010 | 0.013 | 0.038 | −0.084 | 4 |

| M14 | 0.014 | 0.024 | 0.005 | 0.014 | 0.009 | 0.001 | 0.002 | 0.031 | 0.053 | 0.032 | 0.012 | 0.016 | 0.059 | −0.136 | 9 |

Following normalization, the contribution index (

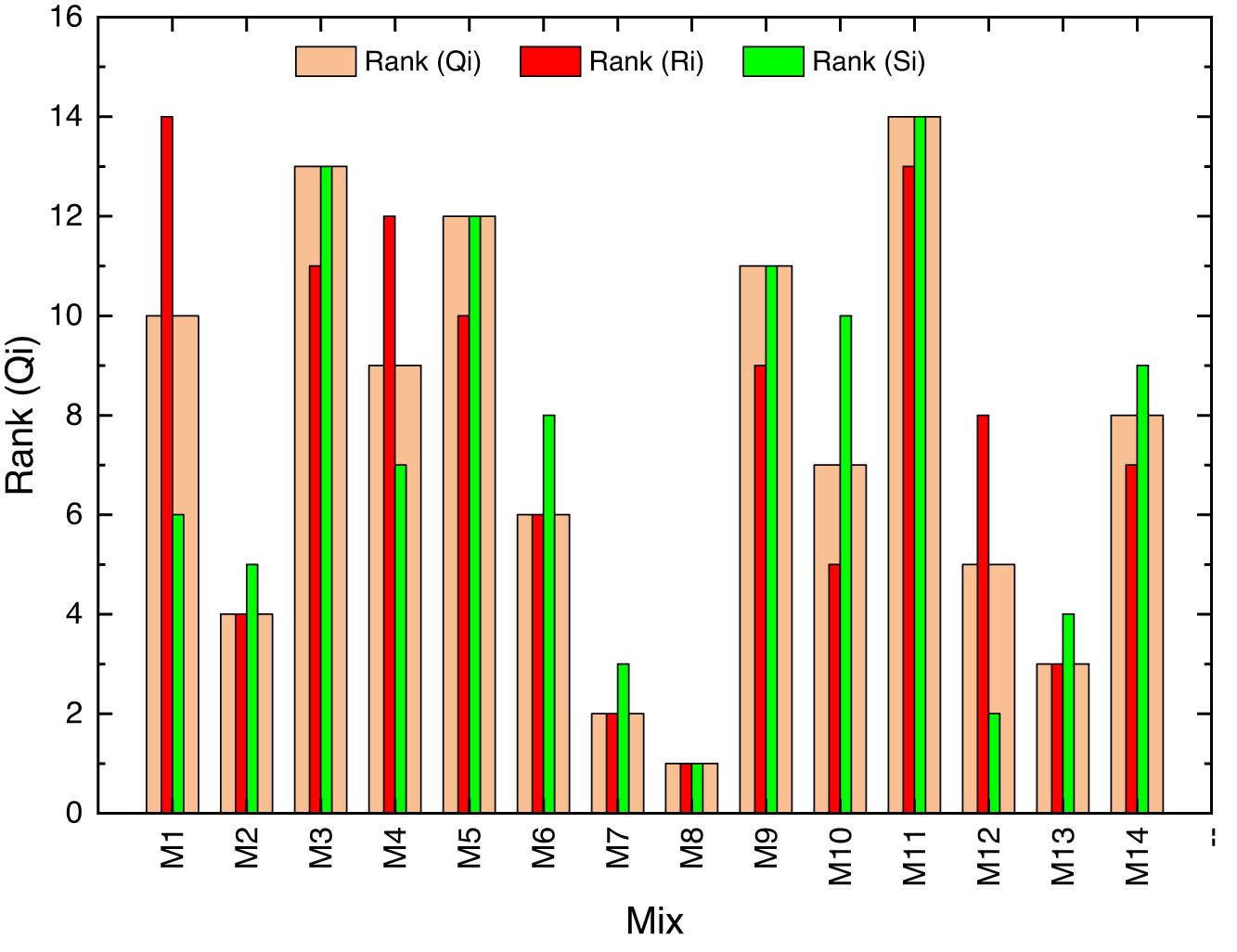

The results from the MOORA analysis produce a ranking of the concrete mixes, identifying the most effective formulations. Mix M8 stands out as the top performer, achieving the highest rank due to its optimal incorporation of 40% DPA and 2% NESP. This mix not only exhibited superior performance across multiple criteria but also illustrated the potential for improved sustainability using renewable materials. Conversely, Mix M11, which received a lower rank, showed reduced mechanical properties and higher water absorption, suggesting that its formulation may not fully capitalize on the advantages of the incorporated materials.

The ranking further emphasizes the significance of optimizing the ratios of NESP and DPA to attain desirable concrete properties. For example, Mix M7, containing 20% DPA and 4% NESP, also received a high ranking, indicating that higher proportions of NESP can enhance mechanical strength and overall performance when balanced effectively with DPA.

Overall, the application of the MOORA method in this study offers a robust framework for evaluating and ranking the concrete mixes based on their performance metrics. The clear ranking of alternatives aids decision-makers in identifying the optimal mix formulation that satisfies performance requirements while also addressing considerations of cost and environmental sustainability.

3.2.2 VIKOR method

After conducting the MOORA method for evaluating concrete mixes incorporating eggshell powder (NESP) and DPA, the VIKOR method was subsequently applied to further analyze the alternatives. The results from the VIKOR analysis, presented in Table 8, provide insights into the performance of each mix based on various criteria, allowing for a detailed comparison with the MOORA rankings.

Computation of positive ideal solution (

| Mix | S i | R i | Q i |

|---|---|---|---|

| M1 | 0.49148 | 0.210904 | 0.780779 |

| M2 | 0.389501 | 0.070301 | 0.319529 |

| M3 | 0.784765 | 0.172074 | 0.863818 |

| M4 | 0.51622 | 0.18534 | 0.725248 |

| M5 | 0.751273 | 0.167857 | 0.830064 |

| M6 | 0.554967 | 0.134212 | 0.60716 |

| M7 | 0.301709 | 0.051933 | 0.210523 |

| M8 | 0.062556 | 0.032697 | 0 |

| M9 | 0.738161 | 0.165184 | 0.81398 |

| M10 | 0.65789 | 0.126397 | 0.652609 |

| M11 | 0.826367 | 0.194026 | 0.952643 |

| M12 | 0.273124 | 0.140603 | 0.440594 |

| M13 | 0.36258 | 0.05701 | 0.264614 |

| M14 | 0.637683 | 0.138886 | 0.674422 |

In the VIKOR method, each mix was evaluated by calculating the positive ideal solution

The ranking of the mixes according to

From the analysis, Mix M8 emerged as the top performer in the VIKOR evaluation, receiving the highest rank of 1 due to its optimal characteristics, including a significant reduction in water absorption and total pore volume. This mix not only achieved superior performance metrics but also showcased the potential for enhanced sustainability by effectively utilizing both NESP and DPA. In comparison, Mix M7, which ranked second, demonstrated commendable properties as well, particularly due to its balanced formulation of 20% DPA and 4% NESP, emphasizing the importance of optimal ratios in enhancing mechanical strength.

Comparing the VIKOR results to those from the MOORA method, notable similarities and differences emerge. For instance, Mix M8 was also ranked first in the MOORA analysis, indicating a consistent performance across both methods. However, Mix M11, which ranked lower in the VIKOR method (14th), was similarly positioned at 14th in the MOORA ranking. This consistent ranking across methodologies reinforces the reliability of the evaluation process and highlights Mix M11’s deficiencies in terms of mechanical properties and sustainability metrics.

Additionally, the VIKOR method provided a more nuanced perspective on the trade-offs between beneficial and non-beneficial criteria. Mix M2, which ranked fourth in VIKOR and fifth rank in MOORA, indicates its ability to maintain a balance between performance and cost, showcasing its potential as a cost-effective option. Conversely, Mix M3, ranked 13th in both evaluations, reflects the challenges of higher water absorption and porosity, demonstrating that not all formulations with increased DPA and NESP will yield positive results.

In summary, the application of the VIKOR method, alongside the MOORA method, provided a comprehensive evaluation of the concrete mixes incorporating NESP and DPA. The clear rankings from both methods assist decision-makers in identifying optimal formulations that satisfy performance requirements while addressing cost and sustainability concerns. This dual-method approach enhances the robustness of the findings, allowing for a more informed decision-making process in selecting the most effective concrete mix for future applications.

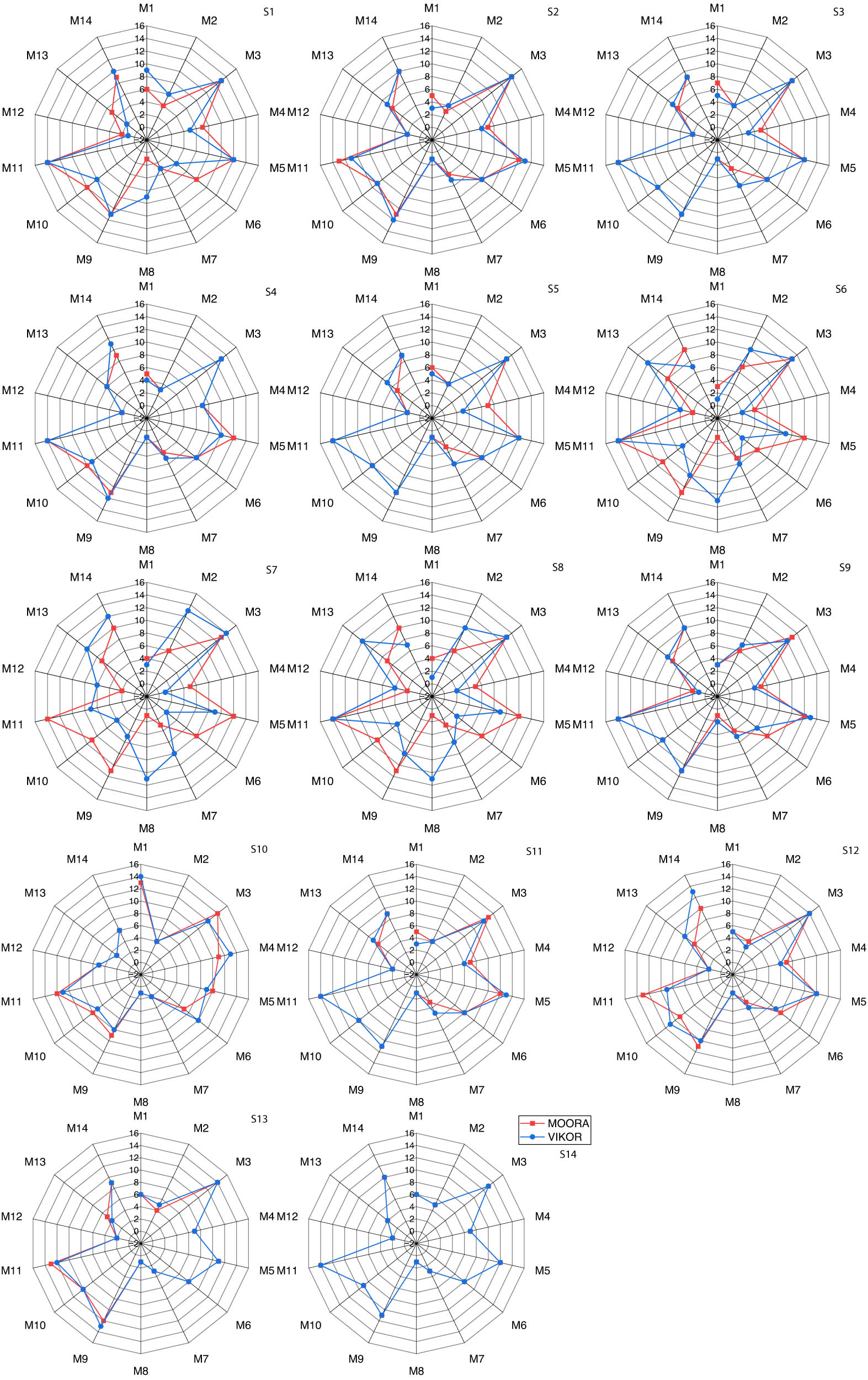

3.2.3 Scenario analysis

The scenario analysis conducted using the MOORA and VIKOR methods reveals critical insights into the evaluation of concrete mixes incorporating eggshell powder (NESP) and DPA. Table 9 presents weight scenarios of each criterion.

Weights assigned for each scenario

| Scenarios | S (mm) | FD (kg/m3) | CS (MPa) | STS (MPa) | FS (MPa) | MoE (GPa) | WA (%) | TPV (mm3/g) | TPA (m2/g) | P (%) | eCO2 (kgCO2/m3) | Eco-Str (MPa/kgCO2 m3) | Cost ($/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 | 0.077 |

| S2 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 |

| S3 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 |

| S4 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 |

| S5 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 |

| S6 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 |

| S7 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 |

| S8 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 |

| S9 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 |

| S10 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 | 0.083 |

| S11 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 | 0.083 |

| S12 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 | 0.083 |

| S13 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 | 0.083 |

| S14 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.083 | 0.500 |

The sensitivity analysis was conducted by changing one weight coefficient at a time to a higher value (e.g., 0.500) while keeping all other weights constant. This approach allows us to examine the impact of each criterion on the overall ranking of alternatives. By isolating one criterion in each scenario, the analysis ensures that the effect of emphasizing that specific parameter is clearly understood. For example, in one scenario, the weight for “compressive strength” is increased while others remain unchanged, revealing how much this criterion influences the decision-making process.

This method is sufficient for a good quality sensitivity analysis because it provides a focused way to test how rankings respond to changes in priorities. It helps identify if the results are stable or if they vary significantly when a specific criterion is given more importance. This ensures that the decision-making process is robust and reliable, even if certain parameters are prioritized differently.

Each scenario was designed to reflect different priorities among performance metrics, thereby simulating realistic conditions that stakeholders may encounter. The results shown in Figure 5 indicate that the rankings of concrete mixes are highly sensitive to the weight assigned to specific criteria, which underscores the inherent subjectivity in decision-making processes.

Scenario analysis based on varying weights of each criterion.

For instance, under Scenario 1, where equal weights were applied across all performance metrics, Mix M1 emerged with a moderate rank, highlighting its balanced but unremarkable performance. However, when the focus shifted in Scenario 2 to prioritize water absorption and other relevant characteristics, Mix M1 improved in rank, demonstrating how slight adjustments in emphasis can significantly influence perceived performance. This variability raises concerns about the robustness of the evaluation outcomes and highlights the necessity for clear guidelines in determining which metrics should take precedence based on specific project goals.

Moreover, the analysis revealed that Mix M8 consistently ranked at the top across multiple scenarios, indicating its superior properties. In stark contrast, Mix M11 struggled to achieve competitive rankings in both methods, exposing its weaknesses in meeting performance benchmarks. This discrepancy between high- and low-performing mixes emphasizes the importance of optimizing the formulation of concrete to harness the benefits of DPA and NESP effectively.

A notable aspect of this analysis is the sensitivity of both MOORA and VIKOR methods to changes in weight allocation among performance metrics. This sensitivity raises critical questions about the reliability of the rankings produced. The rankings fluctuated not only between the two methods but also across different scenarios, suggesting that stakeholders must approach these results with caution. It is essential to recognize that the choice of metrics and their respective weights can significantly alter the decision landscape, which may lead to different conclusions regarding the optimal concrete mix.

Ultimately, the combined use of MOORA and VIKOR provides a comprehensive framework for evaluating concrete mixes; however, the findings emphasize the need for a nuanced understanding of how varying priorities affect decision outcomes. The insights gleaned from this scenario analysis are invaluable, but they also highlight the complexity involved in selecting the most effective concrete formulations. Decision-makers must navigate these complexities judiciously, balancing performance requirements with considerations of sustainability and cost-effectiveness to make informed choices that align with project objectives.

3.3 Multi-variable regression analysis (MRA)

An MNLR analysis is a statistical approach that is employed to determine the mathematical models for predicting the relationships between a response/property (dependent variable) and an independent variable when the linear constraints of multi-variable linear regression (MLR) are not suitable for the coefficients to conform to [75,76]. An MNLR is more complex and can be presented in different equation forms, which include polynomials to second or higher degrees, power curves, exponentials, coefficient ratios, or logarithmic functions [77,78]. The properties of concrete exhibit a non-linear behavior due to its heterogeneous mix composition consisting of aggregates, cement pastes, and water, each having its unique behavior. This causes the concrete to behave erratically under environmental conditions, stress, and strain [79,80]. As such, the properties of concrete are considered to have a non-linear behavior and are modeled using either a single NLR when only one variable is involved or MNLR when there is more than one variable [81].

The basic MLR equation can be presented in the form of a global equation shown in equation (18), while the generalized equation for the MNLR is shown as equation (19) [82,83]:

where Ŷ represents the dependent variable of the MLR, β is the coeffect values of the independent variables, and X is the independent variable:

where Ŷ denotes the response/dependent variable, X denotes the independent variables, θ i and θ ij represent the coefficients of the first- and second-order polynomials, respectively, and θ 0 represents the coefficient value for which X = 0

In this study, the MNLR technique was employed for developing the relationships and model equations between the independent variables that are DPA and NESP and the responses that include the fresh, mechanical, and durability properties of the concrete. The developed mathematical models are presented as equations (20)–(29):

where the independent variables are denoted by D and N, which stand for the DPA and NESP, respectively, in %; S is the slump in mm; Ɣ F is the fresh density in kg/m3; F C, F S, and F F stand for the compressive, split tensile, and FSs, respectively, in MPa; MoE is the modulus of elasticity in GPa; WA represents the water absorption in %; P V denotes the total pore volume in mm3/g; P A is the total pore area in m2/g; and P P is the porosity in %.

To verify the degree of accuracy and predictability and validate each of the established MLNR models, the analysis of variance (ANOVA) was computed and summarized in Table 10. The statistical significance of each of the models was verified using the Fisher values (F-values) and probability values (P-value). A model with a P-value less than 0.05 is said to be statistically significant, and if the P value is greater than 0.05, then the model is not statistically significant. A statistically significant model explains that the null hypothesis is false and should be rejected, while a statistically nonsignificant model explains that the null hypothesis is true [83,84]. In this study, the null hypothesis is that there is no relationship existing between the variables (DPA and NESP) and the responses/outputs (properties of the concrete). From the ANOVA summary in Table 10, all the models have P-values less than 0.05; hence, the null hypotheses for each of the models are found to be false and rejected. Hence, the developed models can be used to predict the properties of the concrete. The models for the fresh properties (slump and fresh density), mechanical properties (strengths and MoE), and water absorption have very low P-values, thus explaining the high significance of the models. The models for the microstructural durability (total pore volume, total pore area, and porosity) are less significant compared to the fresh and mechanical property models. The coefficient of determination (R 2) is also used to assess and verify the degree of correlation and variability between the experimental data and predicted models. A good model should have a good R 2 value. The R 2 value ranges between 0 and 1, with the model having R 2 of 1 being said to be perfectly correlated with the measured data, and the model with zero R 2 has no degree of correlation with the measured data [28,85,86]. All the generated models for the concrete containing DPA and NESP have reasonably good to high R 2 values, as shown in Table 10. The model for the concrete slump has the greatest R 2 value of 0.937. This model can be said to have a very high level of correlation, with only about 6.3% of the total experimental data not perfectly correlated with the model. The model for the MoE has the least R 2 value of 0.79. The MoE model can be said to have a reasonably good degree of correlation, with only about 21% of the total experimental data not perfectly correlated with the model. Therefore, the established MNLR models can be used to predict the fresh, mechanical, and durability properties of the concrete using DPA and NESP as the independent variables with excellent to good precisions.

ANOVA summary for the MNLR models

| Properties | Symbol | SS | MS | SE | F-value | P-value | R 2 |

|---|---|---|---|---|---|---|---|

| Slump (mm) | Ƨ | 9507.33 | 1901.47 | 4.22 | 106.77 | 1.49 × 10₋20 | 0.937 |

| Fresh density (kg/m3) | Ɣ F | 136659 | 27332 | 31.35 | 27.82 | 1.98 × 10₋11 | 0.794 |

| Compressive strength (MPa) | F C | 3023 | 605 | 3.61 | 46.35 | 2.62 × 10₋14 | 0.866 |

| STS (MPa) | F S | 5.55 | 1.11 | 0.19 | 29.51 | 8.62 × 10₋12 | 0.804 |

| FS (MPa) | F F | 24.95 | 4.99 | 0.30 | 54.56 | 8.42 × 10₋16 | 0.883 |

| Modulus of elasticity (GPa) | MoE | 783 | 157 | 3.08 | 16.56 | 8.17 × 10₋7 | 0.790 |

| Water absorption (%) | Ɯ | 7.41 | 1.48 | 0.18 | 45.35 | 1.49 × 10₋14 | 0.863 |

| Total pore volume (mm3/g) | Ʈ V | 968 | 194 | 4.57 | 9.25 | 0.0035 | 0.853 |

| Total pore area (m2/g) | Ʈ A | 6.69 | 1.34 | 0.26 | 19.65 | 0.00026 | 0.925 |

| Porosity (%) | Ƥ | 36.23 | 7.25 | 0.76 | 12.52 | 0.0013 | 0.887 |

To verify the accuracy of correlation and variability between the developed models and measured data diagrammatically, the predicted against actual plots were generated. The predicted versus actual plots for the fresh and mechanical properties of the concrete are presented in Figure 6, while that of the durability properties is depicted in Figure 7. For an excellently fitted and correlated model the data points in its predicted versus actual plots will perfectly fall on the straight baseline angled at 45° from the origin. The predicted versus actual plots for the slump have the best fitness, as shown in Figure 6a, which justifies its superior R 2 value among the generated models. In the durability properties models, as depicted in Figure 7, the model for the total pore areas has the best fit, as revealed in Figure 7c, which also justified its high R 2 value of 0.925. The predicted versus actual plot for the MoE has the most scattered points with reference to the straight reference line. This explained and justified its lowest R 2 value and inferior degree of correlation within the established models.

Predicted versus actual plots for fresh and mechanical properties: (a) slump, (b) densities, (c) compressive strength, (d) STS, (e) FS, and (f) modulus of elasticity.

Predicted versus actual plots for durability properties: (a) water absorption, (b) total pore volume, (c) total pore area, and (d) porosity.

4 Conclusions

This study explores the use of the blends of DPA as an SCM and NESP as an additive to cementitious materials in concrete to improve the concrete’s properties and reduce the environmental impacts of cement production and usage. The MCDM technique was adopted, and MNLR analysis was employed. The following conclusions were arrived at:

Substituting a portion of cement with DPA without adding any NESP led to a reduction in the mechanical properties and durability of the concrete.

The addition of only NESP as an additive, up to 2% of cement weight, improved the mechanical strengths and durability of the concrete by decreasing pore volume and porosity in its microstructure.

Using DPA and NESP together as cementitious materials in the concrete notably increased its mechanical properties and minimized pore volume, which enhanced its durability performance, whereas blending between 10 and 30% DPA with up to 1–3% NESP improved the concrete’s properties. A blend of 20% DPA and 2% NESP produces optimal performance in the concrete.

Mix M8 consistently ranked highest across both MOORA and VIKOR analyses, demonstrating superior performance due to optimal incorporation of 40% DPA and 2% NESP, which enhanced both mechanical properties and sustainability.

The evaluation highlighted the importance of balancing NESP and DPA ratios, as seen in Mix M7’s strong performance, while Mix M11 and Mix M3 showed lower rankings due to increased water absorption and porosity, indicating that higher material proportions do not always yield better results.

The scenario analysis shows how metric weighting impacts concrete mix rankings. Mix M1 improved when water absorption was prioritized, highlighting the need for clear metric guidelines. Mix M8 consistently excelled, while Mix M11 underperformed, underscoring the importance of optimizing formulations. The sensitivity of MOORA and VIKOR to weight changes suggests that decision-makers should carefully balance performance, sustainability, and cost in their choices.

The developed MNLR models accurately predict the concrete properties, with high R² values ranging from 0.79 to 0.94. These models are statistically significant, and the established mathematical equations can serve as reliable tools for future predictions of concrete properties with different proportions of DPA and NESP.

The study acknowledges certain limitations in the methods and their applications. MOORA and VIKOR, while effective, rely on assumptions like equal weight normalization and independent criteria, which may oversimplify complex interactions. Further, the study focused on specific criteria, excluding aspects like long-term durability and lifecycle costs, and the sensitivity analysis primarily tested one-at-a-time weight variations.

Future work could explore hybrid MCDM approaches, such as combining AHP, TOPSIS, or ANP with MOORA or VIKOR, to handle more complex trade-offs. Expanding the scope to include additional criteria, like durability and lifecycle impacts, and testing DPA and NESP under diverse conditions would further enhance the robustness and applicability of sustainable concrete design.

Acknowledgments

The authors would like to thank Prince Sultan University for supporting this research through the SEED project with grant number SEED-2024-CE-174. The authors would like to thank the Structures and Materials Research Laboratory at Prince Sultan University for their viable support.

-

Funding information: This work was supported by the research grants [SEED-2024-CE-174]; Prince Sultan University, Saudi Arabia.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analysed during this study are included in this published article.

References

[1] Sohu S, Bheel N, Jhatial AA, Ansari AA, Shar IA. Sustainability and mechanical property assessment of concrete incorporating eggshell powder and silica fume as binary and ternary cementitious materials. Environ Sci Pollut Res. 2022;29(39):58685–97.10.1007/s11356-022-19894-5Search in Google Scholar PubMed

[2] Alkhrissat T. Impact of adding waste polyethylene (PE) and silica fume (SF) on the engineering properties of cement mortar. Case Stud Chem Environ Eng. 2024;9:100731.10.1016/j.cscee.2024.100731Search in Google Scholar

[3] Alsaif A. Utilization of ceramic waste as partially cement substitute–A review. Constr Build Mater. 2021;300:124009.10.1016/j.conbuildmat.2021.124009Search in Google Scholar

[4] Elemam WE, Agwa IS, Tahwia AM. Reusing ceramic waste as a fine aggregate and supplemental cementitious material in the manufacture of sustainable concrete. Buildings. 2023;13(11):2726.10.3390/buildings13112726Search in Google Scholar

[5] Elemam WE, Abdelraheem AH, Mahdy MG, Tahwia AM. Optimizing fresh properties and compressive strength of self-consolidating concrete. Constr Build Mater. 2020;249:118781.10.1016/j.conbuildmat.2020.118781Search in Google Scholar

[6] Mokal MP, Mandal R, Nayak S, Panda SK. Efficacy of high-volume fly ash and slag on the physicomechanical, durability, and analytical characteristics of high-strength mass concrete. J Build Eng. 2023;76:107295.10.1016/j.jobe.2023.107295Search in Google Scholar

[7] Orozco C, Babel S, Tangtermsirikul S, Sugiyama T. Comparison of environmental impacts of fly ash and slag as cement replacement materials for mass concrete and the impact of transportation. Sustain Mater Technol. 2024;39:e00796.10.1016/j.susmat.2023.e00796Search in Google Scholar

[8] Awoyera P, Adesina A, Olalusi OB, Viloria A. Reinforced concrete deterioration caused by contaminated construction water: An overview. Eng Fail Anal. 2020;116:104715.10.1016/j.engfailanal.2020.104715Search in Google Scholar

[9] Tahir F, Alzahrani S, Noori Y, Al-Ghamdi SG. Environmental impacts and the future prospects of waste utilization in the concrete production. Mater Today: Proc. 2024. 10.1016/j.matpr.2024.05.150.Search in Google Scholar

[10] Dhandapani Y, Santhanam M, Kaladharan G, Ramanathan S. Towards ternary binders involving limestone additions—A review. Cem Concr Res. 2021;143:106396.10.1016/j.cemconres.2021.106396Search in Google Scholar

[11] Khankhaje E, Kim T, Jang H, Kim C-S, Kim J, Rafieizonooz M. A review of utilization of industrial waste materials as cement replacement in pervious concrete: An alternative approach to sustainable pervious concrete production. Heliyon. 2024;29(39):58685–97.10.1016/j.heliyon.2024.e26188Search in Google Scholar PubMed PubMed Central

[12] Miller SA, Juenger M, Kurtis KE, Weiss J. Cement and Alternatives in the Anthropocene. Annu Rev Environ Resour. 2024;49:15.1–15.27.10.1146/annurev-environ-112621-070104Search in Google Scholar

[13] Li M, Zhang M, Du C, Chen Y. Study on the spatial spillover effects of cement production on air pollution in China. Sci Total Environ. 2020;748:141421.10.1016/j.scitotenv.2020.141421Search in Google Scholar PubMed

[14] Yang Y, Liu Y, Liu L, Liu Z, Wu H. Monitoring global cement plants from space. Remote Sens Environ. 2024;302:113954.10.1016/j.rse.2023.113954Search in Google Scholar

[15] Feng Z, Shen D, Huang Q, Zhang T. Effect of fly ash on early-age properties and viscoelastic behaviors of supersulfated cement concrete under different degrees of restraint. Constr Build Mater. 2023;401:132895.10.1016/j.conbuildmat.2023.132895Search in Google Scholar

[16] Juenger M, Winnefeld F, Provis JL, Ideker J. Advances in alternative cementitious binders. Cem Concr Res. 2011;41(12):1232–43.10.1016/j.cemconres.2010.11.012Search in Google Scholar

[17] Sun Z, Nie S, Zhou J, Li H, Chen Z, Xu M, et al. Hydration mechanism of calcium sulfoaluminate-activated supersulfated cement. J Clean Prod. 2022;333:130094.10.1016/j.jclepro.2021.130094Search in Google Scholar

[18] Friedlingstein P, O'sullivan M, Jones MW, Andrew RM, Bakker DC, Hauck J, et al. Global carbon budget 2023. Earth Syst Sci Data. 2023;15(12):5301–69.10.5194/essd-15-5301-2023Search in Google Scholar

[19] Andrew RM. Global CO2 emissions from cement production. Earth Syst Sci Data. 2018;10(1):195–217.10.5194/essd-10-195-2018Search in Google Scholar

[20] Al-Nawasir R, Al-Humeidawi B, Khan MI, Khahro SH, Memon ZA. Effect of glass waste powder and date palm seed ash based sustainable cementitious grouts on the performance of semi-flexible pavement. Case Stud Constr Mater. 2024;21:e03453.10.1016/j.cscm.2024.e03453Search in Google Scholar

[21] Wu K, Shi H, Guo X. Utilization of municipal solid waste incineration fly ash for sulfoaluminate cement clinker production. Waste Manag. 2011;31(9-10):2001–8.10.1016/j.wasman.2011.04.022Search in Google Scholar PubMed

[22] Raheem AA, Ikotun BD. Incorporation of agricultural residues as partial substitution for cement in concrete and mortar–A review. J Build Eng. 2020;31:101428.10.1016/j.jobe.2020.101428Search in Google Scholar

[23] Mydin MAO, Sor NH, Althoey F, Özkılıç YO, Abdullah MM, Isleem HF, et al. Performance of lightweight foamed concrete partially replacing cement with industrial and agricultural wastes: Microstructure characteristics, thermal conductivity, and hardened properties. Ain Shams Eng J. 2023;14(11):102546.10.1016/j.asej.2023.102546Search in Google Scholar

[24] Adamu M, Ibrahim YE, Alanazi H. Optimization of sustainable concrete properties modified with blends of date palm ash and eggshell powder using response surface methodology. Dev Built Environ. 2024;17:100359.10.1016/j.dibe.2024.100359Search in Google Scholar

[25] A. News. Buraidah date festival in full swing. Arab News. https://www.arabnews.com/node/2350511/saudi-arabia (accessed 13/9/2023).Search in Google Scholar

[26] Nasser RA, Salem MZ, Hiziroglu S, Al-Mefarrej HA, Mohareb AS, Alam M, et al. Chemical analysis of different parts of date palm (Phoenix dactylifera L.) using ultimate, proximate and thermo-gravimetric techniques for energy production. Energies. 2016;9(5):374.10.3390/en9050374Search in Google Scholar

[27] Adamu M, Alanazi H, Ibrahim YE, Abdellatief M. Mechanical, microstructural characteristics and sustainability analysis of concrete incorporating date palm ash and eggshell powder as ternary blends cementitious materials. Constr Build Mater. 2024;411:134753.10.1016/j.conbuildmat.2023.134753Search in Google Scholar

[28] Adamu M, Ibrahim YE. Environmental sustainability and cost-benefit analysis of concrete containing date palm ash and eggshell powder: A response surface methodology approach. Case Stud Chem Environ Eng. 2024;9:100636.10.1016/j.cscee.2024.100636Search in Google Scholar

[29] Yahya SA, Iqbal T, Omar MM, Ahmad M. Techno-economic analysis of fast pyrolysis of date palm waste for adoption in Saudi Arabia. Energies. 2021;14(19):6048.10.3390/en14196048Search in Google Scholar

[30] Faiad A, Alsmari M, Ahmed MM, Bouazizi ML, Alzahrani B, Alrobei H. Date palm tree waste recycling: Treatment and processing for potential engineering applications. Sustainability. 2022;14(3):1134.10.3390/su14031134Search in Google Scholar

[31] Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM C618, West Conshohocken, PA, USA, 2022.Search in Google Scholar

[32] Al-Kutti W, Nasir M, Johari MAM, Islam AS, Manda AA, Blaisi NI. An overview and experimental study on hybrid binders containing date palm ash, fly ash, OPC and activator composites. Constr Build Mater. 2018;159:567–77.10.1016/j.conbuildmat.2017.11.017Search in Google Scholar

[33] Thomas BS, Yang J, Mo KH, Abdalla JA, Hawileh RA, Ariyachandra E. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J Build Eng. 2021;40:102332.10.1016/j.jobe.2021.102332Search in Google Scholar

[34] Al-Kutti W, Islam AS, Nasir M. Potential use of date palm ash in cement-based materials. J King Saud Univ-Eng Sci. 2019;31(1):26–31.10.1016/j.jksues.2017.01.004Search in Google Scholar

[35] Nasir M, Al-Kutti W. Performance of date palm ash as a cementitious material by evaluating strength, durability, and characterization. Buildings. 2018;9(1):6.10.3390/buildings9010006Search in Google Scholar

[36] Blaisi NI. Environmental assessment of utilizing date palm ash as partial replacement of cement in mortar. J Hazard Mater. 2018;357:175–9.10.1016/j.jhazmat.2018.06.013Search in Google Scholar PubMed

[37] Nandhini K, Karthikeyan J. Sustainable and greener concrete production by utilizing waste eggshell powder as cementitious material–A review. Constr Build Mater. 2022;335:127482.10.1016/j.conbuildmat.2022.127482Search in Google Scholar

[38] Sathiparan N. Utilization prospects of eggshell powder in sustainable construction material–A review. Constr Build Mater. 2021;293:123465.10.1016/j.conbuildmat.2021.123465Search in Google Scholar

[39] Teara A, Ing DS. Mechanical properties of high strength concrete that replace cement partly by using fly ash and eggshell powder. Phys Chem EarthParts a/b/c. 2020;120:102942.10.1016/j.pce.2020.102942Search in Google Scholar

[40] Zaid O, Hashmi SRZ, El Ouni MH, Martínez-García R, de Prado-Gil J, Yousef SEA. Experimental and analytical study of ultra-high-performance fiber-reinforced concrete modified with egg shell powder and nano-silica. J Mater Res Technol. 2023;24:7162–88.10.1016/j.jmrt.2023.04.240Search in Google Scholar

[41] Pan S, Feng J, Safaei B, Qin Z, Chu F, Hui D. A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets. Nanotechnol Rev. 2022;11(1):1658–69.10.1515/ntrev-2022-0107Search in Google Scholar

[42] Feng J, Safaei B, Qin Z, Chu F. Nature-inspired energy dissipation sandwich composites reinforced with high-friction graphene. Compos Sci Technol. 2023;233:109925.10.1016/j.compscitech.2023.109925Search in Google Scholar

[43] Amin M, Attia MM, Agwa IS, Elsakhawy Y, Abu El-hassan K, Abdelsalam BA. Effects of sugarcane bagasse ash and nano eggshell powder on high-strength concrete properties. Case Stud Constr Mater. 2022;17:e01528.10.1016/j.cscm.2022.e01528Search in Google Scholar

[44] Hamada H, Tayeh B, Yahaya F, Muthusamy K, Al-Attar A. Effects of nano-palm oil fuel ash and nano-eggshell powder on concrete. Constr Build Mater. 2020;261:119790.10.1016/j.conbuildmat.2020.119790Search in Google Scholar

[45] Rasid NNA, Khalid NHA, Mohamed A, Sam ARM, Majid ZA, Huseien GF. Ground palm oil fuel ash and calcined eggshell powder as SiO2–CaO based accelerator in green concrete. J Build Eng. 2023;65:105617.10.1016/j.jobe.2022.105617Search in Google Scholar

[46] Jhatial AA, Goh WI, Mo KH, Sohu S, Bhatti IA. Green and sustainable concrete–the potential utilization of rice husk ash and egg shells. Civ Eng J. 2019;5(1):74–81.10.28991/cej-2019-03091226Search in Google Scholar

[47] Hakeem IY, Amin M, Agwa IS, Abd-Elrahman MH, Ibrahim OMO, Samy M. Ultra-high-performance concrete properties containing rice straw ash and nano eggshell powder. Case Stud Constr Mater. 2023;19:e02291.10.1016/j.cscm.2023.e02291Search in Google Scholar

[48] Ahmed M, Qureshi M, Mallick J, Ben Kahla N. Selection of sustainable supplementary concrete materials using OSM‐AHP‐TOPSIS approach. Adv Mater Sci Eng. 2019;2019(1):2850480.10.1155/2019/2850480Search in Google Scholar

[49] Moro C. Comparative analysis of multi-criteria decision making and life cycle assessment methods for sustainable evaluation of concrete mixtures. Sustainability. 2023;15(17):12746.10.3390/su151712746Search in Google Scholar

[50] Chilukuri SK, Raut AN, Kumar S, Singh RJ, Sakhare V. Enhancing thermal performance and energy Efficiency: Optimal selection of steel slag crumb rubber blocks through Multi-Criteria decision Making. Constr Build Mater. 2023;409:134094.10.1016/j.conbuildmat.2023.134094Search in Google Scholar

[51] Janga S, Raut AN, Murmu AL. Assessment of thermal and mechanical properties of fly ash based geopolymer blocks with a sustainability perspective using multi-criteria decision-making approach. J Build Eng. 2024;88:109261.10.1016/j.jobe.2024.109261Search in Google Scholar

[52] Adamu M, Raut AN, Ibrahim YE, Janga S, Khed VC. Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica. Nanotechnol Rev. 2024;13(1):20240046.10.1515/ntrev-2024-0046Search in Google Scholar

[53] De Angelis A, Cheche N, De Masi R, Pecce M, Vanoli G. Multi-criteria analysis for sustainable buildings. In Proceedings of Italian Concrete Days 2016. Springer; 2018. p. 3–16.10.1007/978-3-319-78936-1_1Search in Google Scholar

[54] Petrović G, Pavlović J, Madić M, Marinković D. Optimal synthesis of loader drive mechanisms: a group robust decision-making rule generation approach. Machines. 2022;10(5):329.10.3390/machines10050329Search in Google Scholar

[55] Madić M, Petrović G, Petković D, Antucheviciene J, Marinković D. Application of a robust decision-making rule for comprehensive assessment of laser cutting conditions and performance. Machines. 2022;10(2):153.10.3390/machines10020153Search in Google Scholar

[56] Božanić D, Epler I, Puška A, Biswas S, Marinković D, Koprivica S. Application of the DIBR II–rough MABAC decision-making model for ranking methods and techniques of lean organization systems management in the process of technical maintenance. Facta Univ Ser: Mech Eng. 2024;22(1):101–23.10.22190/FUME230614026BSearch in Google Scholar

[57] Amin M, Zeyad AM, Tayeh BA, Agwa IS. Effects of nano cotton stalk and palm leaf ashes on ultrahigh-performance concrete properties incorporating recycled concrete aggregates. Constr Build Mater. 2021;302:124196.10.1016/j.conbuildmat.2021.124196Search in Google Scholar

[58] Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM C618, West Conshohocken, PA, United States, 2015.Search in Google Scholar

[59] Standard specification for concrete aggregates. ASTM C33/C33M, West Conshohocken, PA, USA, 2023.Search in Google Scholar

[60] Standard practice for selecting proportions for normal, heavyweight, and mass concrete. ACI 211.1R, Michigan, USA, 2002.Search in Google Scholar

[61] Montgomery DC. Design and analysis of experiments. John wiley & sons; 2017.Search in Google Scholar

[62] Standard practice for making and curing concrete test specimens in the laboratory. ASTM C192, West Conshohocken, PA, USA, 2018.Search in Google Scholar

[63] Standard test method for slump of hydraulic-cement concrete. ASTM C143/C143M, West Conshohocken, PA, USA, 2012.Search in Google Scholar

[64] Standard test method for density (unit weight), yield, and air content (gravimetric) of concrete. ASTM C138/C138M, West Conshohocken, PA, USA, 2017.Search in Google Scholar

[65] Testing hardened concrete. Compressive strength of test specimens. BS EN 12390-3, London, United Kingdom, 2009.Search in Google Scholar

[66] Testing hardened concrete - Tensile splitting strength of test specimens, BS EN 12390-6, London, United Kingdom, 2009.Search in Google Scholar

[67] Standard test method for flexural strength of concrete (using simple beam with third-point loading). ASTM C78/C78M, West Conshohocken, PA, USA, 2015.Search in Google Scholar