Abstract

Making environmentally friendly, long-lasting roller compacted concrete (RCC) was the primary focus of the laboratory experiments using disposed waste material (demolished buildings) and lowering the amount of fine aggregate adopting the ACI 327. The best way to dispose waste materials of demolished buildings such as ceramic tiles, clay bricks, and thermostone hollow blocks without using a sanitary landfill was to collect them, crush them with a crushing machine, and grade them by sieving to a fine aggregate. Reference mixture (RM) and six other environmentally friendly, long-lasting RCC mixtures were produced with partial fine aggregate volume replacements of 10 and 20% waste material. Following the production of the mixtures, the strength (compressive, splitting tensile, and flexural), porosity, absorption of water, and dry density were all tested. The results in accordance with the study’s conclusions are the RCC containing (20%) by ceramic tiles as fine aggregate increases RCC’s durability up to (5.76%) (2.96%) (2.83%) of strength (compressive, splitting tensile and flexural) at 28 days of testing, in opposition to the typical blend, then the blend that includes (10%) of ceramic tiles as fine aggregate with % growth up to (3.39%) (1.64%) (1.42%). While the clay bricks with 10% can be adopted, the results were slightly lower than the RM but still in the specification range (minimum recommendation of ACI 327 = 28 MPa). For the mixtures with 10 and 20% thermostone blocks fine aggregate, the results showed reduction in strength compared to the RM.

1 Introduction

Roller compacted concrete pavement (RCCP) is an alternative to conventional concrete that benefits both the economy and the environment. This is because the roller compacted concrete (RCC) mix only has 12% cementitious materials, while traditional concrete has 15% cementitious materials [1]. Because of its cheaper cost and quicker construction time, RCCP became an increasingly popular alternative to the more traditional jointed plain concrete pavements, known as JPCP [2,3,4]. The RCCP technique is the result of the combination of three distinct innovations: soil compaction, asphalt pavement, and concrete pavement [5]. Since it combines the advantages of soil, concrete, and pavement technologies for asphalt, RCCP is an option for pavement that is both quick to plan and construct and relatively inexpensive [3,6,7]. The most significant distinction between RCCP and normal concrete is found in the mixing processes [1]. RCC mixed using the soil compaction method have more fine aggregates and less cement and water than JPCP but have the same properties, RCC and conventional concrete share several properties, as they are both composed of similar materials, primarily cement, aggregates, and water. Both types of concrete can achieve a wide range of compressive strengths, depending on the mix design and curing conditions, and can have similar density characteristics when designed appropriately [3]. On the contrary, RCCP construction procedures are the same as those of asphalt pavement engineering. RCCP is normally installed with asphalt paving stones and compressed with conventional vibratory drum/rubber-tired rollers [3,6,8]. In general, RCCP is applicable to both as a base course and a surface course. When RCCP used as the base layer, almost the same quantity of cement is required as for regular concrete and dry lean concretes [8,9,10,11,12]. When RCCP is used as a surface layer, a greater compressive strength in the range of 28–41 MPa at 28 days after water curing is often sought [13]. The modern world’s increasing waste production has resulted in a number of ecological issues [14]. In recent years, there has been an increased emphasis on incorporating sustainability into the roadway industry, primarily by reducing the use of nonrenewable resources, the Ministry of Transportation (MTO) of Ontario, Canada is committed to the sustainable maintenance of high-quality road infrastructure. In recent years, the MTO has adopted pavement preservation strategies with the aim of optimizing cost savings in repair operations and ensuring the maintenance of pavement condition. Pavement preservation treatments are widely acknowledged as sustainable practices due to their capacity to enhance pavement quality and durability, thereby prolonging the lifespan of pavements. Simultaneously, these treatments contribute to a reduction in energy consumption and greenhouse gas emissions. Pavement preservation is a strategic approach that is implemented proactively and with careful planning. Its primary objective is to prolong the lifespan of pavement while also offering a cost-effective solution for managing pavement infrastructure [15]. Optimal mix design, creative paving techniques, and a decrease in the demand for virgin resources could all contribute to a more sustainable pavement [16,17]. To Reduce the harmful effects of construction debris on the environment, waste materials may be utilized in a variety of applications, including sustainable RCCP, there are a number of environmental issues related to construction waste, such as a shortage of landfill space, rising wastage rates, landfill contamination, and rising energy needs for waste disposal and transportation [18]. Several studies are looking into the viability of using waste products as cement substitutes, such as pulverized fly ash, furnace slag, and waste glass powder [19,20,21]. The most prevalent pavement sustainability practice is to lessen the demand for new aggregates, recycled materials can be used as a replacement for some or all of the virgin material. Utilizing these recycled aggregates (RA) has many advantages, including a decrease in the price of aggregates quarried from nature, a cost savings in the field of transportation associated with virgin materials, problems with getting rid of solid waste, and a cut down on carbon emissions [22,23]. In addition, waste with a high fineness mechanical property increases durability [24]. The most beneficial aspects of the study are reducing the costs of trash removal, which were forecast to rise due to higher taxes on dumps and preserve tens of thousands of vital materials essential for environmental safety by using different percentages of recycled demolishing waste materials (clay brick, ceramic tiles, and thermostone hollow block) as partial replacement of fine aggregate in the project meeting the required durability and strength specifications in the field and in the lab.

2 Experimental method

2.1 Properties of materials and formulation of mixtures

The RCC blend included elements listed below:

Ordinary Portland cement (type I): Table 1 displays some of the chemical and physical properties of cement.

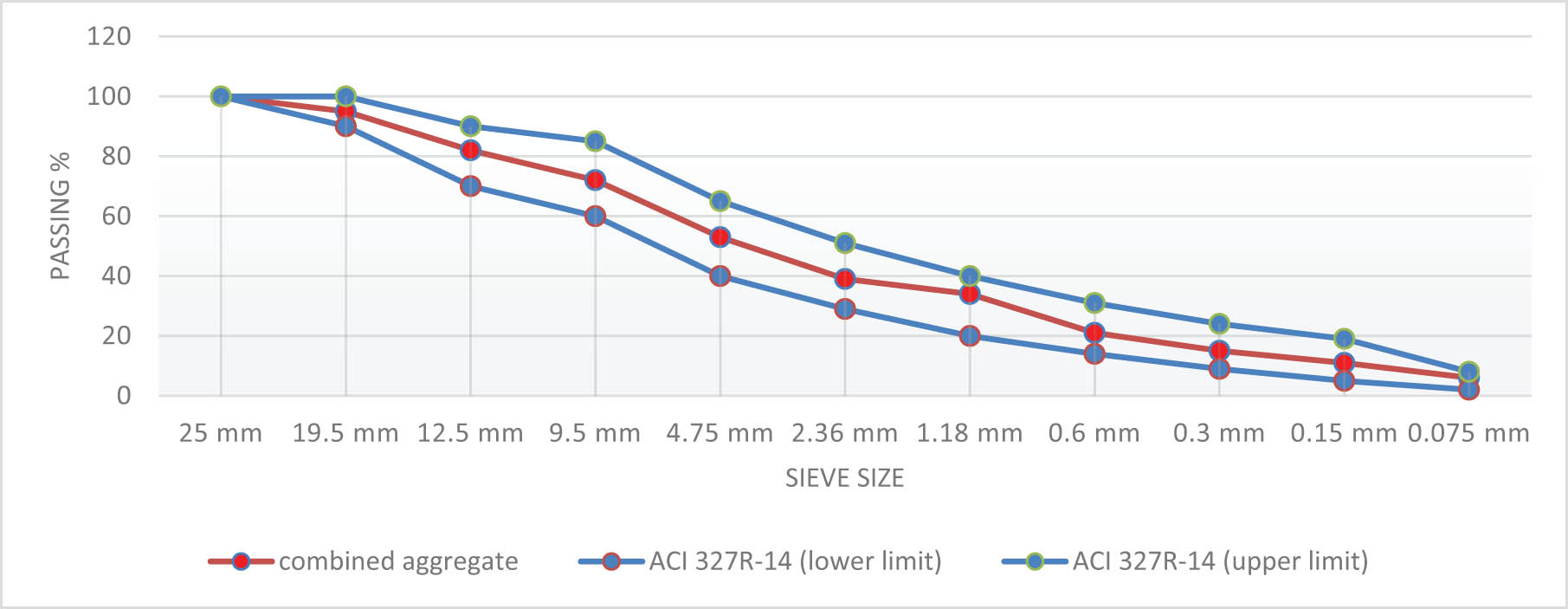

Combined aggregate: Crushed coarse aggregate (with a maximum nominal particle size of 19 mm) and natural sand (with a particle size of 4.75 mm or less) were used. The ASTM C33 [25] grading standards were used to evaluate the relative particle sizes of fine and coarse aggregates. Fine aggregate characteristics are shown in Table 2, while coarse aggregate characteristics are shown in Table 3. In this study, the grading of combined aggregate was determined in accordance with the requirements laid out by the ACI 327 for combined aggregate used in RCC (Figure 1).

Limestone filler: Materials fine enough for passing through a 200 mesh sieve.

Waste demolished materials: Materials (ceramic tiles, clay bricks, and thermostone blocks) from different construction locations had been collected for use in production of environmentally friendly, long-lasting RCC samples as fine aggregate volume replacement by 10 and 20% after preparation is shown in Figure 2 and conforms to the requirements following ASTM C33 [25], as illustrated in Table 4. The absorption test for these recycled materials was done by utilizing the ASTM C128 [27] method and the ASTM C33 [25] grading standards were used to evaluate the relative particle sizes of the recycled materials and the grading analysis is shown in Tables 5–7.

Gradation of combined aggregate.

Preparation of fine aggregates from demolished buildings.

Properties of ordinary Portland cement

| Tests | Result | ASTM C150 [26] | ||

|---|---|---|---|---|

| Physical properties | Setting time, min | Initial | 120 | ≥45.0 |

| Setting time, min | Final | 285 | ≤600 | |

| Compressive strength, MPa | 3 days | 19 | ≥12.0 | |

| Compressive strength, MPa | 7 days | 25 | ≥19.0 | |

| Autoclave expansion % | 0.040 | 0.8 Max. | ||

| Chemical oxide | Calcium oxide CaO, % | 60.60 | — | |

| Silicon oxide SiO2, (%) | 20.27 | — | ||

| Magnesium oxide MgO, % | 2.24 | ≤6.0 | ||

| Aluminum oxide Al2O3, % | 5.27 | — | ||

| Ferric oxide Fe2O3, % | 3.40 | — | ||

| Sulphur trioxide SO3, % | 2.01 | 2.3 Max. for C3A <8% | ||

| Insoluble residue IR, % | 0.56 | ≤1.50 | ||

| Loss on Ignition LOI, % | 2.55 | ≤3.0 | ||

| C3A adopting bogue equation, % | 5.65 | ≥3.5 | ||

Various characteristics of natural sand aggregate

| Grading analysis | Tests | Results | ||

|---|---|---|---|---|

| Sieve size, mm | Passing, % | ASTM C33 | ||

| 10 | 100 | 100 | SO3, % | 0.23 |

| 4.75 | 97 | 95–100 | ||

| 2.36 | 91 | 80–100 | Specific gravity | 2.59 |

| 1.18 | 75 | 50–85 | ||

| 0.6 | 52 | 25–60 | Water absorption, % | 1.75 |

| 0.3 | 27 | 5–30 | ||

| 0.15 | 7 | 0–10 | ||

Various characteristics of coarse crushed aggregate of 4.75–19 mm

| Grading analysis | Tests | Results | ||

|---|---|---|---|---|

| Sieve size, mm | Passing, % | ASTM C33 | ||

| 25 | 100 | 100 | SO3, % | 0.075 |

| 19.5 | 96 | 90–100 | Specific gravity | 2.62 |

| 9.5 | 49 | 20–55 | water absorption, % | 0.58 |

| 4.75 | 6 | 0–10 | ||

Characteristics of prepared waste fine aggregates

| Parameter | Absorption, % | Specific gravity | SO3, % | Clay lumps, % |

|---|---|---|---|---|

| Ceramic tiles (CFA) | 8.8 | 2.44 | 0.15 | 0.55 |

| Clay bricks (BFA) | 27 | 2.49 | 0.02 | 0.85 |

| Thermostone (THFA) | 42 | 1.14 | 0.48 | 0.6 |

| ASTM C33 | — | — | –* | 3% Max. |

SO3% = 0.5% Max in IQS No. 45.

Recycled BFA gradation with specifications

| Sieve size (mm) | Passing % | (ASTM C33/C33M-18) |

|---|---|---|

| 9.5 | 100 | 100 |

| 4.75 | 95 | 95–100 |

| 2.36 | 80 | 80–100 |

| 1.18 | 57 | 50–85 |

| 0.600 | 38 | 25–60 |

| 0.300 | 15 | 5–30 |

| 0.150 | 5 | 0–10 |

| 0.075 | 0 | 0–3 |

Recycled CFA gradation with specifications

| Sieve size (mm) | Passing % | (ASTM C33/C33M-18) |

|---|---|---|

| 9.5 | 100 | 100 |

| 4.75 | 97 | 95–100 |

| 2.36 | 85 | 80–100 |

| 1.18 | 58 | 50–85 |

| 0.600 | 35 | 25–60 |

| 0.300 | 13 | 5–30 |

| 0.150 | 3 | 0–10 |

| 0.075 | 0 | 0–3 |

Recycled THFA gradation with specifications

| Sieve size (mm) | Passing % | (ASTM C33/C33M-18) |

|---|---|---|

| 9.5 | 100 | 100 |

| 4.75 | 97 | 95–100 |

| 2.36 | 86 | 80–100 |

| 1.18 | 59 | 50–85 |

| 0.600 | 40 | 25–60 |

| 0.300 | 17 | 5–30 |

| 0.150 | 7 | 0–10 |

| 0.075 | 0 | 0–3 |

2.2 Mixture content adopting the ACI 327

This study was done on seven different RCC mixtures that included waste materials and a reference mixture (RM). This research employed cement, natural sand, crushed stone, and a variety of waste materials to produce RCC mixes, aggregates (ceramic tiles, clay bricks, and Thermostone blocks) with 10% (MC10, MB10, and MTh10) and 20% (MC20, MB20, and MTh20) replacement by volume of fine aggregate, respectively.

Cement was chosen as a percentage by weight of all dry components, at 12%, and the amounts of coarse crushed stone, natural sand, and filler were determined via gradation tests, yielding totals of 50%, 44%, and 6%, respectively. The ideal water content and density for RCC were attained by following the ASTM D1557 [28] standard. The water content specified by ACI 327 and ACI 211 [29] was used to determine the optimum moisture content (OMC%) relative to maximum dry density (max dry kg/m3) for each type of waste fine aggregates using the modified Proctor test (method C) in accordance with ASTM D1537. Using data from experiments with moisture levels from 4.5 to 8.5, a modified Proctor curve with five points was created. Including the cement and water, each Proctor point requires the addition of 6 kg of aggregates (2.64 kg of fine aggregate, 3.0 kg of coarse aggregate, and 0.36 kg of filler).

2.3 Test machines and instruments

The instruments utilized in this work were compressive strength machine (Matest C079-05D 3,000 kN Italian made) for compressive and tensile strength tests and Matest flexural testing machine (200 kN Italian made) for flexural strength test. Vibrating hammer (VH; INGCO 1400 W 2,200 impacts/min rotary hammer Chinese made) was used for compacting process. For tamping procedure, cylinder plate (diameter: 146 ± 3 mm; weight: 3 ± 1 kg) and tamping beam plate (dimensions: 98 mm × 398 mm; weight: 8.4 kg, local manufacturing) were used. Also, laboratory crusher machine (Besmak BAG-415 Turkish made) was used for crushing the waste materials. Laboratory oven and saw cutter were used for drying and cutting the specimens for density, absorption, and porosity tests, as indicated in Figure 3.

Instruments and machines used in laboratory work.

2.4 Casting method

Utilizing the ASTM C1435 [30] method for casting and using VH for compacting which recommended by the ACI 327 guide for producing the RCC test specimens. This recommended procedure also studied by many interested researches [31,32,33,34,35,36,37], they recommend to use VH safely since their results the close to field test using vibratory drum compactor, take into account the production of rectangular plates with the same weight distribution and thickness as cylinder plates [38,39,40,41], and the instructions given in Figure 4.

Compaction steps with VH.

2.5 Molding and investigational lab tests

Materials were mixed according to ACI 327 using an electric drum mixer, and compacted in accordance with ASTM C1435 [30] using a VH. The RCC specimens that were used.

Compressive strength and splitting tensile test cylinder (15 × 30 cm). Tested in accordance with ASTM C39 [43] and ASTM C496 [44] after being cured by immersion in a water tank at 23 ± 2°C from the time of molding until the time of testing as per ASTM C192 [42]. 84 cylinders were used with 12 cylinders for each mix, and 3 for each test (compressive, tensile, and density tests).

Flexural strength test: 10 cm × 10 cm × 40 cm prisms were cured by immersion in a water tank at a temperature setting of 23 ± 2°C from the time of molding until the time of testing in accordance with ASTM C78 [45]. 42 prisms were used, with 6 prisms for each mix for flexural strength test.

ASTM C642 [46] details the procedure for determining the absorption, porosity, and density of RCC specimens. Parts of cylinders and prisms with a volume greater than 300 cm3) were tested for absorption, porosity, and density after the original specimens were broken down into smaller pieces. Twenty-eight-days and 90-days old specimens were used in the experiment. For the calculations of density, absorption, and porosity Eqs (1)–(3) were used. The steps involved in preparing a specimen for testing and conducting the experiment are depicted in Figure 5.

where A is the mass of oven-dried sample in air, g, C is the mass of surface dry sample in the air after immersion and boiling, g, D is the apparent mass of sample in water after immersion and boiling, g, G1 is the bulk dry density, G2 is the apparent density.

Shows the experimental lab tests.

3 Results and discussion

3.1 Proctor tests results

Figure 6 presents the variations in the OMC when natural fine aggregate (NFA) was partially replaced with other RAs. The cause for change in the OMC may be due to the following factors: higher water absorption, porosity, and angular particle shapes, and surface texture [47,48,49,50,51]. From the modified Proctor test results, it is easy to see that the OMC of the THFA (MTh10 and MTh20) mixtures is the highest compared with other mixtures, because of higher water absorption and porosity of THFA compared with other types of aggregates. Also, it could be observed that the CFA mixtures (MC10 and MC20) yielded the minimum OMC compared with other mixtures since CFA has a lower water absorption compared with other types of aggregates, taking into consideration the dry conditions of the material.

Density vs moisture content plot for different mixtures.

3.2 Lab test results for compressive, splitting tensile, and flexural strengths

Compressive, splitting tensile, and flexural strength properties at 28 and 90 days were presented and discussed for the RM as well as all other RCC mixes containing partial- replacement of fine aggregate by volume 10 and 20% of waste recycling material.

3.2.1 Compressive strength results

The laboratory investigation demonstrates that the compressive strength of fine aggregate was reduced when evaluated using BFA replacement, and the result was similarly reduced when utilizing THFA. However, when CFA was used, there was an increase (as illustrated in Figure 7). The RCCP mixtures containing BFA (MB10 and MB20) and THFA (MTh10 and MTh20) were reduced by increasing the replacement ratio of NFA with fine recycled aggregate (FRA) compared to the RM. The interfacial transition zone (ITZ) was responsible for this decrease. The ITZ is the bond between the aggregates and pastes. It is usually weaker than either the aggregates or the hydrated cement paste. ITZ occurs between the aggregate and the mortar in mixes made with natural aggregate, but between the original aggregate and old mortar and new mortar in mixes made with RA [52,53,54,55,56,57]. Additionally, FRA particles are more angular, irregular, and porous than NFA; open porosity in FRA increases the specific surface area. This may be the reason for the low values of compressive strength [41]. Also, the lower compressive strength could be caused by old cement mortar on the surface of FRA, which could make it have more voids and soak up more water than NFA [58,59,60]. The increase in compressive strength for RCC mixtures with 10% and 20 ceramic fine aggregate (MC10 and MC20) compared with RCC mixture with natural fine aggregate (RM) could be because of its bond capability and nature and more obvious surface and the waste ceramic WC material s behavior as micro fillers in concrete ceramic fine aggregate [61,62]. At 90 days’ age, for mixtures with CFA, BFA, and THFA, there in an increase in compressive strength than that at 28 days’ age. This was due to the effect of FRA and cement hydration development [63,64]. Finally, Figure 8 depicts the percentage variation in RCC mixtures containing various FRAs vs the RM at 28 and 90 days.

The compressive strength of different RCC mixtures.

Compressive strength variation percentage for RCC mixtures containing different FRAs vs the reference mix.

3.2.2 Tensile strength results

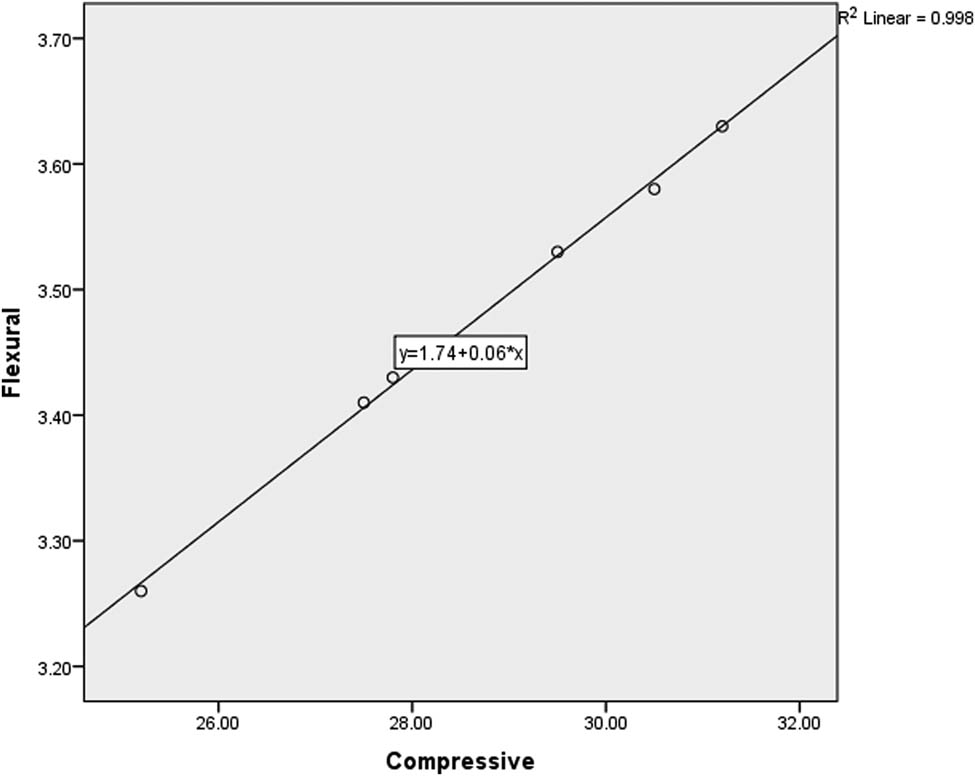

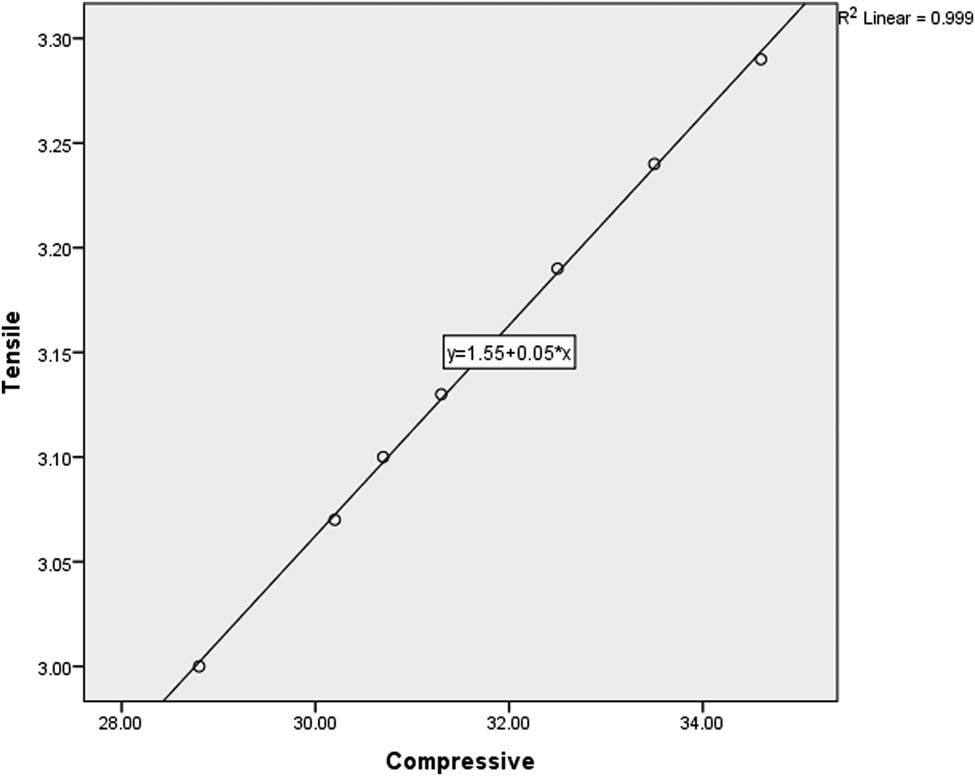

Figure 9 displays the results of splitting tensile strength tests conducted on RCC samples after 28 and 90 days of curing. The results showed that the splitting tensile strength for the reference mix was 3.04 MPa at 28 days of curing. The mixtures MC10 and MC20 showed an increase in splitting strength equal to 1.46 and 2.36%, respectively. Although in the mixtures MB10 and MB20, the result showed a decrease in tensile strength with 2.30 and 2.36%, respectively. While for MTh10 and MTh20 mixtures, the result also showed a decrease in tensile strength with 3.62 and 7.57%, respectively. After 90 days of curing, the tensile strength of CFA (MC10 and MC20) mixtures continued to be the highest compared with other mixtures. Although, the tensile strength of the BFA (MB10 and MB20) and THFA (MTh10 and MTh20) mixtures is still lower than that of the RM and CFA mixtures. The reduction in BFA and THFA mixtures results may be due to the quality of FRA being poor compared with NFAs due to higher water absorption capacity resulting from the old paste attached to the FRA surface [53,65–68]. While the increase in tensile strength for CFA mixtures could be attributed to the WC materials’ behavior as micro fillers in concrete [69]. Figure 10 depicts the percentage variation in RCC mixtures containing various FRAs vs the RM at 28 and 90 days. Also, the relation between compressive strength and tensile strength are shown in Figures 11 and 12 for the 28 days and 90 days results, respectively.

Different RCC mixtures’ splitting tensile strength.

Splitting tensile strength variation percentage for RCC mixtures containing different FRAs vs the RM.

Statistical relation between compressive strength and tensile strength at 28 days.

Statistical relation between compressive strength and tensile strength at 90 days.

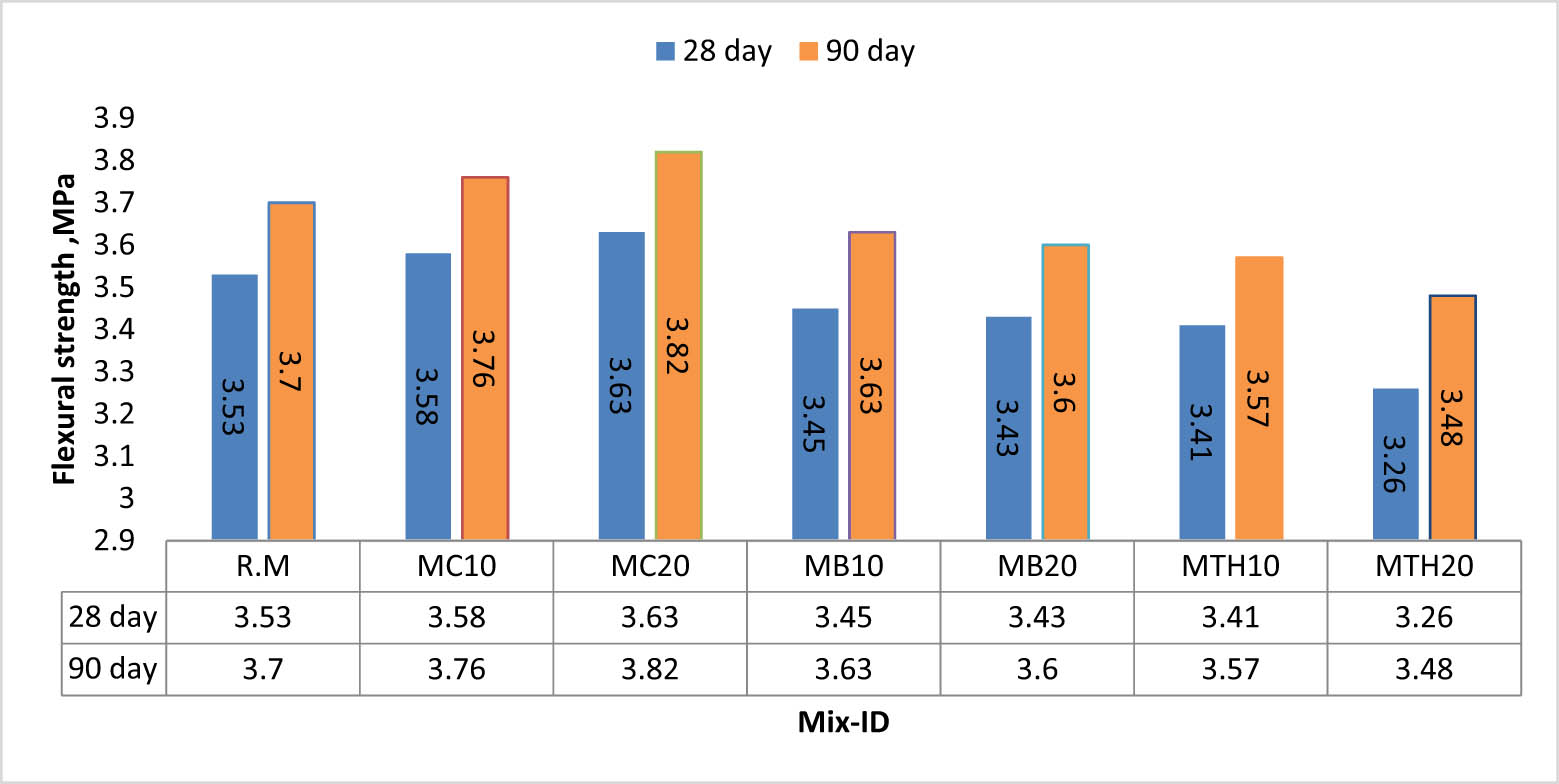

3.2.3 Flexural strength results

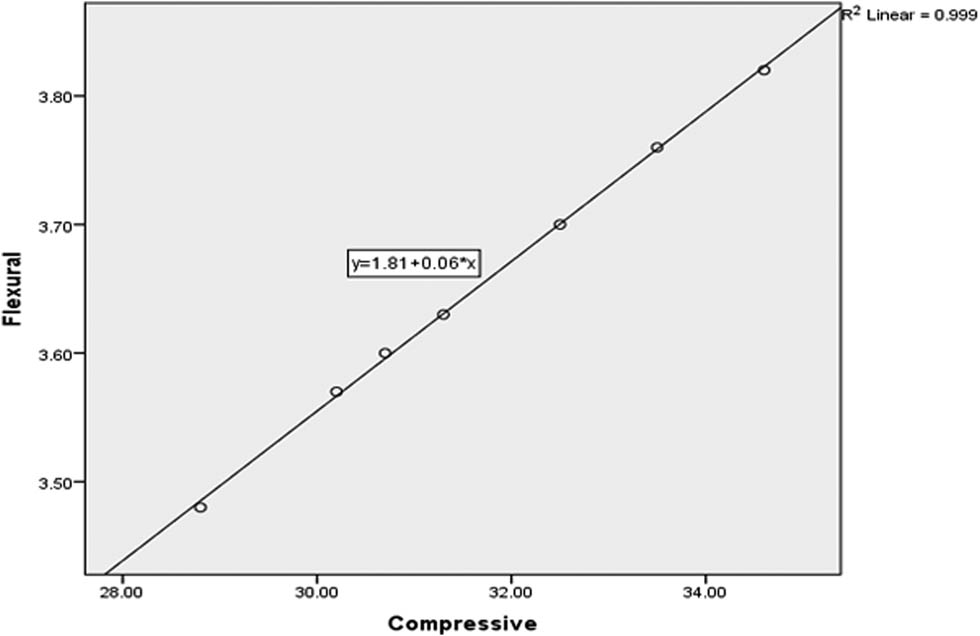

RCC samples were tested for flexural strength at 28 and 90 days, and the results are shown in Figure 13. As can be seen from the results, the flexural strength of the reference mix was 3.53 MPa at 28 days and 3.70 at 90 days, which was within the specified flexural strength (3.5–7 MPa) recommended by ACI327R, 2015. The percentage reduction in BFA (MB10 and MB20) mixtures was 2.27 and 2.83%, respectively. While the percentage reduction for THFA (MTh10 and MTh20) mixtures was 3.40 and 7.65%, respectively. For CFA (MC10 and MC20) mixtures, the results show an increase in flexural strength, which was 1.42 and 2.83%, respectively. At 90 days curing, the results show that the reduction in flexural strength of MB10 and MB20 mixtures was 1.89 and 2.70%, respectively. While the reduction for MTh10 and MTh20 mixtures still gives the lowest results of 3.51 and 5.35%, respectively. In the MC10 and MC20 mixtures, there was still an increase which is 1.62 and 3.24%, respectively, and still the CFA mixtures give the highest values. The results show that for both MB10 and MB20, and MTh10 and MTh20 mixtures, the flexural strength decreased as the proportion of FRA to NFA increased [63,70,71]. The results indicate that RCCP mixes containing FRA have lower flexural strength compared to the RM. This was due to the irregular shape of FRA (it has edges open), which leads to faster absorption compared with NFA because of the presence of old cement paste on the surface of FRA [71]; additionally, the decrease in the flexural strength may be due to the fact that the FRA may be of lower quality than the NFA used. The increase in flexural strength with CFA mixtures could be attributed to that WC materials act like tiny fillers in concrete [62]. Figure 14 depicts the percentage variation in RCC mixtures containing various FRAs vs the RM at 28 and 90 days. Also, the relation between compressive strength and flexural strength is shown in Figures 15 and 16 for the 28 days and 90 days results, respectively.

The flexural strength of different RCC mixtures.

Flexural strength variation percentage for RCC mixtures containing different FRAs vs the RM.

Statistical relation between compressive strength and flexural strength at 28 days.

Statistical relation between compressive strength and flexural strength at 90 days.

3.3 Density, absorption, and porosity findings

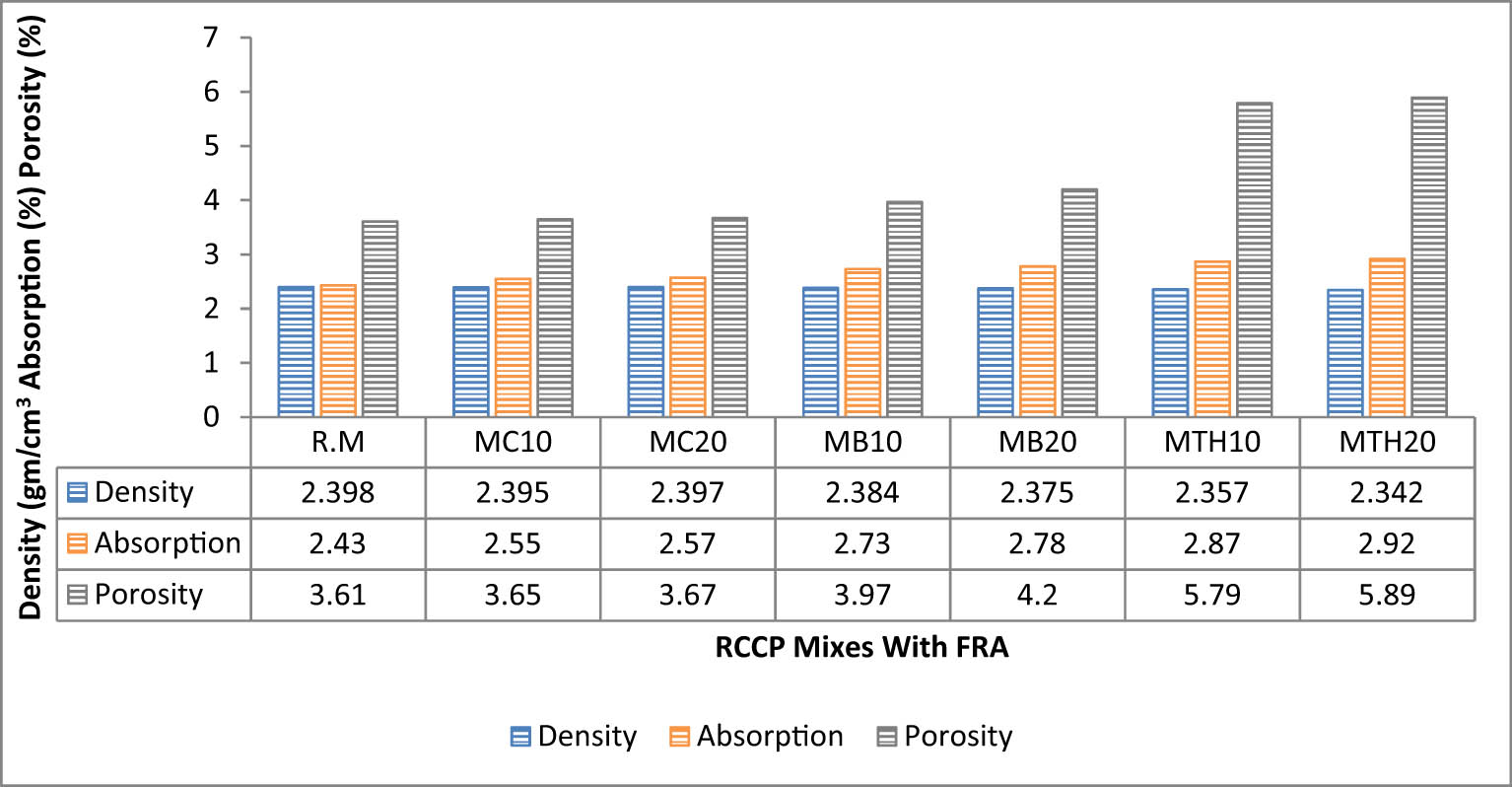

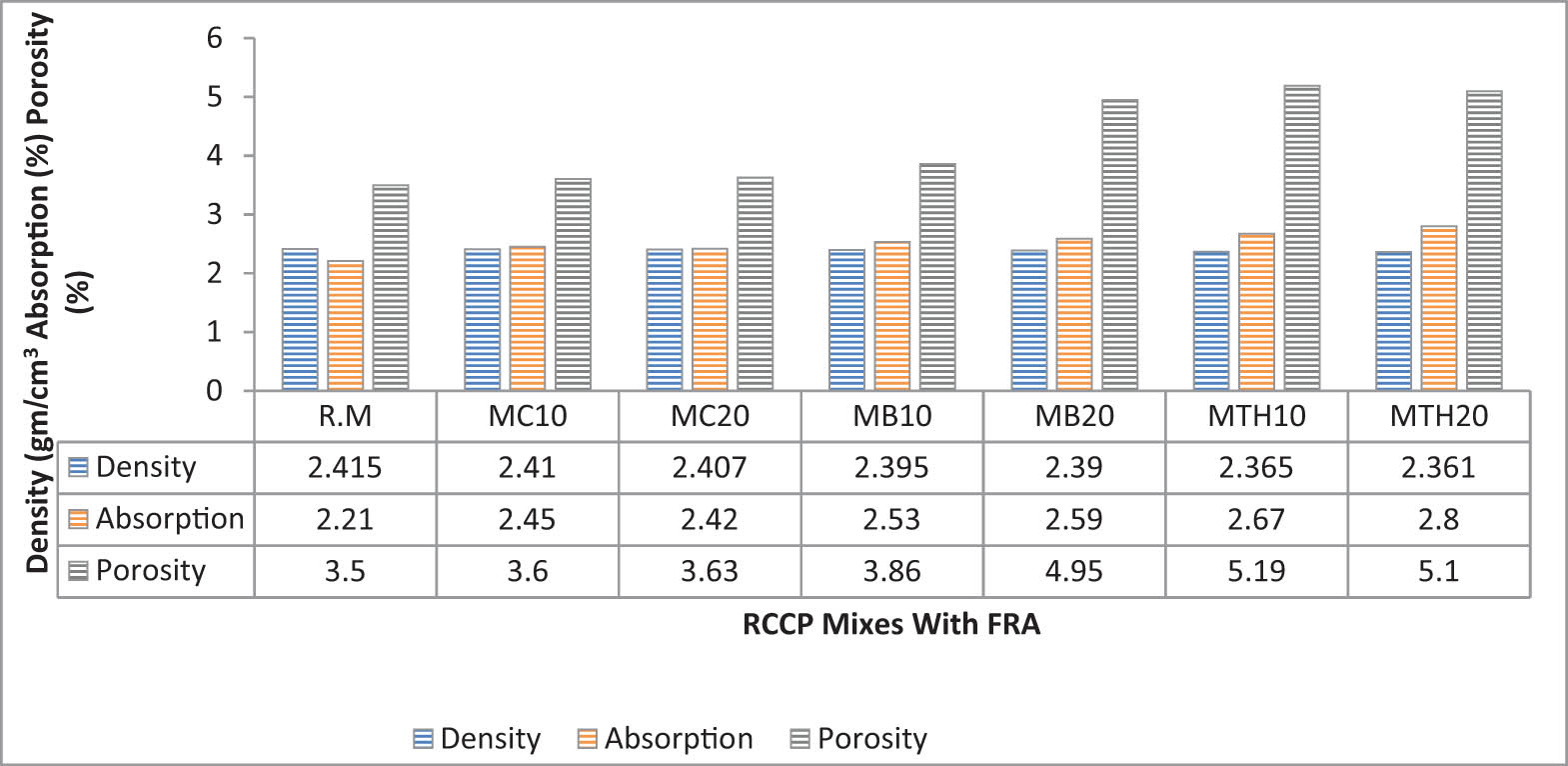

Figures 17 and 18 depict the density, absorption, and porosity results for RCC samples that were cured for 28 and 90 days. The findings indicate that density dropped, and porosity and water absorption increased with an increased replacement percentage in mixes containing FRA compared with the RM. This was because RA had rougher surfaces and shapes that were not uniform [72–75]. Compared to natural aggregate, RA is more porous and absorbent due to its large surface area and the presence of old mortars on the surface of RA particles, natural aggregate is less porous and less absorbent. The specific gravity of these RAs is lower than that of natural aggregate, which is another reason why they are less dense and absorb more water [76].

Density and absorption and porosity of FRA with RM at 28 days.

Density and absorption and porosity of FRA with RM at 90 days.

4 Conclusion

The RCC’s fortifications have increased in strength using 10% of waste fine aggregate material (ceramic tiles) as a partial substitute fine aggregate volume to 3.39, 1.64, and 1.42% for compressive, splitting tensile, and flexural strengths, respectively, utilizing ceramic tiles at 28 days in comparison with the RM, and up to 3.08, 1.57, and 1.62% at 90 days.

The RCC’s fortifications have increased in strength using 20% of waste fine aggregate material (ceramic tiles) as a partial substitute fine aggregate weight to the values 5.76, 2.96, and 2.83% for compressive, splitting tensile, and flexural strengths, respectively, utilizing ceramic tiles at 28 days in comparison with the RM, and up to 6.46, 3.13, and 3.24% at 90 days.

The 10% replacement of (clay bricks) fine aggregate showed a decrease in strength in comparison with that of the RM, but still in the acceptable range recommended by ACI guide.

The 20% replacement of (clay bricks) fine aggregate showed a decrease in strength lower than that of the RM to the values 5.76, 2.96, and 2.83% for compressive, splitting tensile, and flexural strengths, respectively, at 28 days in comparison with that of the RM, and 5.54, 2.82, and 2.70% at 90 days.

The THFA replacement mixtures containing 10 or 20% showed a decrease in strength in comparison to that of the RM at 28 and 90 days.

The ability to create Durable RCC employing 10% and 20% sustainable demolished waste material (ceramic tiles) as fine aggregate partial replacement with an improvement in mechanical strength.

The ability to create Durable RCC employing 10% sustainable demolished waste material (clay bricks) as fine aggregate partial replacement with an acceptable values in strength.

Acknowledgements

The author is grateful to the staff in the Civil Department at the Engineering College, Baghdad University, as well as to the staff in the Civil Department at the Engineering College, Wasit University.

-

Funding information: The authors state no funding is involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest

References

[1] Abbas ZK. Roller compacted concrete: Literature review. J Eng. 2022;28(6):65–83.10.31026/j.eng.2022.06.06Suche in Google Scholar

[2] Aghaeipour A, Madhkhan M. Mechanical properties and durability of roller compacted concrete pavement (RCCP)–a review. Road Mater Pavement Des. 2020;21(7):1775–98.10.1080/14680629.2019.1579754Suche in Google Scholar

[3] Harrington D, Abdo F, Adaska W, Hazree C. Guide for roller-compacted concrete pavements. Ames (IL), USA: National Concrete Pavement Technology Center; 2010.Suche in Google Scholar

[4] Khayat KH, Libre NA. Roller compacted concrete: field evaluation and mixture optimization. Rolla (MO), USA: Missouri University of Science and Technology; 2014.Suche in Google Scholar

[5] ACI. Guide to roller compacted concrete pavements. Farmington Hills (MI), USA: American Concrete Institute. ACI-327R; 2015.Suche in Google Scholar

[6] Lee SW, Cho Y, Park C. Mechanical performance and field application of low cement based concrete under compaction energy. KSCE J Civ Eng. 2014;18:1053–62.10.1007/s12205-014-0353-1Suche in Google Scholar

[7] Gauthier P, Marchand J. Design and construction of roller compacted concrete pavements in Quebec. Quebec, Canada: Roller Compacted Concrete Committee; 2005.Suche in Google Scholar

[8] Chhabra RS, Ransinchung GDRN, Islam SS. Performance analysis of cement treated base layer by incorporating reclaimed asphalt pavement material and chemical stabilizer. Constr Build Mater. 2021;298:123866.10.1016/j.conbuildmat.2021.123866Suche in Google Scholar

[9] Yrjanson WA, Packard RG. Econocrete pavements: Current practices. 59th Annual Meeting of the Transportation Research Board; 1980 Jan 21–25; Washington DC, USA. Transportation Research Board, 1980. p. 6–13.Suche in Google Scholar

[10] Greene J, Nazef A, Choubane B. Thirty-year performance evaluation of two-layer concrete pavement system. Transp Res Rec. 2011;2226(1):21–9.10.3141/2226-03Suche in Google Scholar

[11] Kasu SR, Manupati K, Muppireddy AR. Investigations on design and durability characteristics of cement treated reclaimed asphalt for base and subbase layers. Constr Build Mater. 2020;252:119102.10.1016/j.conbuildmat.2020.119102Suche in Google Scholar

[12] Singh Sr, Ransinchung GDRN. Durability properties of pavement quality concrete containing fine RAP. Adv Civ Eng Mater. 2018;7(1):271–90.10.1520/ACEM20180012Suche in Google Scholar

[13] ACI. Guide to roller compacted concrete pavements. Farmington Hills (MI), USA: American Concrete Institute. ACI-327R; 2014.Suche in Google Scholar

[14] Khoshnava SM, Rostami R, Mohamad Zin R, Štreimikienė D, Mardani A, Ismail M. The role of green building materials in reducing environmental and human health impacts. Int J Environ Res Public Health. 2020;17(7):2589.10.3390/ijerph17072589Suche in Google Scholar PubMed PubMed Central

[15] Chan S, Lane B, Kazmierowski T, Lee W. Pavement preservation: A solution for sustainability. Transp Res Rec. 2011;2235(1):36–42.10.3141/2235-05Suche in Google Scholar

[16] Mohammed MS, Elkady H, Abdel-Gawwad HA. Utilization of construction and demolition waste and synthetic aggregates. J Build Eng. 2021;43:103207.10.1016/j.jobe.2021.103207Suche in Google Scholar

[17] Sobhan K, Mashnad M. Roller-compacted fiber concrete pavement foundation with recycled aggregate and waste plastics. Transp Res Rec. 2001;1775(1):53–63.10.3141/1775-08Suche in Google Scholar

[18] Abbas ZK. Properties of roller-compacted concrete pavement containing different waste material fillers. J Eng. 2022;28(9):86–106.10.31026/j.eng.2022.09.06Suche in Google Scholar

[19] Sakale R, Jain S, Singh S. Experimental investigation on strength of glass powder replacement by cement in concrete with different dosages. Int J Adv Res Comput Sci Softw Eng. 2015;5(12):386–90.Suche in Google Scholar

[20] Liu G, Florea MVA, Brouwers HJH. Characterization and performance of high volume recycled waste glass and ground granulated blast furnace slag or fly ash blended mortars. J Clean Prod. 2019;235:461–72.10.1016/j.jclepro.2019.06.334Suche in Google Scholar

[21] Abbas ZK, Abbood AA, Awad HK. Some properties of mortar and concrete using brick, glass and tile waste as partial replacement of cement. Int J Sci Res (IJSR). 2017;6(5):1210–5.Suche in Google Scholar

[22] Shi X, Mukhopadhyay A, Zollinger D. Sustainability assessment for portland cement concrete pavement containing reclaimed asphalt pavement aggregates. J Clean Prod. 2018;192:569–81.10.1016/j.jclepro.2018.05.004Suche in Google Scholar

[23] Piao Z, Mikhailenko P, Kakar MR, Bueno M, Hellweg S, Poulikakos LD. Urban mining for asphalt pavements: A review. J Clean Prod. 2021;280:124916.10.1016/j.jclepro.2020.124916Suche in Google Scholar

[24] Abbas ZK, Abbood AA, Mahmood RS. Producing low-cost self-consolidation concrete using sustainable material. Open Eng. 2022;12(1):850–8.10.1515/eng-2022-0368Suche in Google Scholar

[25] ASTM C33/C33M-16. Standard Specification for Concrete Aggregates. West Conshohocken (PA), USA: ASTM International; 2016.Suche in Google Scholar

[26] ASTM C150/C150M-18. Standard Specification for Portland Cement. West Conshohocken (PA), USA: ASTM International; 2018.Suche in Google Scholar

[27] ASTM C128-15. Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate. West Conshohocken (PA), USA: ASTM International; 2015.Suche in Google Scholar

[28] ASTM D1557-12. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2,700 KN-m/m3). West Conshohocken (PA), USA: ASTM International; 2012.Suche in Google Scholar

[29] ACI 211-3R. Guide for Selecting Proportions for No-Slump Concrete. Vol. 9. Farmington Hills (MI), USA: American Concrete Institute; 2002.Suche in Google Scholar

[30] ASTM C1435/C1435M-14. Standard practice for molding roller-compacted concrete in cylinder molds using a vibrating hammer. Annual Book of ASTM Standards. West Conshohocken (PA), USA: American Society for Testing and Materials; 2014.Suche in Google Scholar

[31] Selvam M, NSSP K, Kandasami RK, Singh S. Assessing the effect of different compaction mechanisms on the internal structure of roller compacted concrete. Constr Build Mater. 2023;365:130072.10.1016/j.conbuildmat.2022.130072Suche in Google Scholar

[32] Selvam M, Singh S. Comparative investigation of laboratory and field compaction techniques for designing roller compacted concrete pavements (RCCP). Int J Pavement Eng. 2023;24(1):2177850.10.1080/10298436.2023.2177850Suche in Google Scholar

[33] Omran A, Harbec D, Tagnit-Hamou A, Gagne R. Production of roller-compacted concrete using glass powder: Field study. Constr Build Mater. 2017;133:450–8.10.1016/j.conbuildmat.2016.12.099Suche in Google Scholar

[34] Rahmani E, Sharbatdar MK, Beygi MHA. A comprehensive investigation into the effect of water to cement ratios and cement contents on the physical and mechanical properties of Roller Compacted Concrete Pavement (RCCP). Constr Build Mater. 2020;253:119177.10.1016/j.conbuildmat.2020.119177Suche in Google Scholar

[35] Ferrebee EC, Brand AS, Kachwalla AS, Roesler JR, Gancarz DJ, Pforr JE. Fracture properties of roller-compacted concrete with virgin and recycled aggregates. Transp Res Rec. 2014;2441(1):128–34.10.3141/2441-17Suche in Google Scholar

[36] Çaliş G, Yildizel SA. Investigation of roller compacted concrete: Literature review. Chall J Concr Res Lett. 2019;10(3):63–74.10.20528/cjcrl.2019.03.003Suche in Google Scholar

[37] Shafigh P, Hashemi M, Nam BH, Koting S. Optimum moisture content in roller-compacted concrete pavement. Int J Pavement Eng. 2020;21(14):1769–79.10.1080/10298436.2019.1567919Suche in Google Scholar

[38] Muscalu MT, Radu A, Budescu M, Ţăranu N, Florescu E. Use of recycled materials in the construction of roller compacted concrete (RCC) pavements. Adv Mater Res. 2013;649:262–5.10.4028/www.scientific.net/AMR.649.262Suche in Google Scholar

[39] Hashemi M, Shafigh P, Karim MRB, Atis CD. The effect of coarse to fine aggregate ratio on the fresh and hardened properties of roller-compacted concrete pavement. Constr Build Mater. 2018;169:553–66.10.1016/j.conbuildmat.2018.02.216Suche in Google Scholar

[40] Hesami S, Modarres A, Soltaninejad M, Madani H. Mechanical properties of roller compacted concrete pavement containing coal waste and limestone powder as partial replacements of cement. Constr Build Mater. 2016;111:625–36.10.1016/j.conbuildmat.2016.02.116Suche in Google Scholar

[41] Lahucik J, Dahal S, Roesler J, Amirkhanian AN. Mechanical properties of roller-compacted concrete with macro-fibers. Constr Build Mater. 2017;135:440–6.10.1016/j.conbuildmat.2016.12.212Suche in Google Scholar

[42] ASTM C192/C192M-16. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. West Conshohocken (PA), USA: ASTM International; 2016.Suche in Google Scholar

[43] ASTM C39/C39M-15a. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. West Conshohocken (PA), USA: ASTM International; 2015.Suche in Google Scholar

[44] ASTM C496/C496M-11. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. West Conshohocken (PA), USA: ASTM International; 2011.Suche in Google Scholar

[45] ASTM C78/C78M-16. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). West Conshohocken (PA), USA: ASTM International; 2016.Suche in Google Scholar

[46] ASTM C642-13. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. West Conshohocken (PA), USA: ASTM International; 2013.Suche in Google Scholar

[47] Medina C, De Rojas MS, Frías M. Reuse of sanitary ceramic wastes as coarse aggregate in eco-efficient concretes. Cem Concr Compos. 2012;34(1):48–54.10.1016/j.cemconcomp.2011.08.015Suche in Google Scholar

[48] Nepomuceno MCS, Isidoro RAS, Catarino JPG. Mechanical performance evaluation of concrete made with recycled ceramic coarse aggregates from industrial brick waste. Constr Build Mater. 2018;165:284–94.10.1016/j.conbuildmat.2018.01.052Suche in Google Scholar

[49] Hansen TC. Recycling of Demolished Concrete and Masonry. Report of Technical Committee 37-DRC Demolition and Reuse of Concrete, RILEM (The International Union of Testing and Research Laboratories for Materials and Structures). London, UK: E&FN Spon; 1992.10.1201/9781482267075Suche in Google Scholar

[50] Khaloo AR. Properties of concrete using crushed clinker brick as coarse aggregate. Mater J. 1994;91(4):401–7.10.14359/4058Suche in Google Scholar

[51] Wongkeo W, Thongsanitgarn P, Ngamjarurojana A, Chaipanich A. Compressive strength and chloride resistance of self-compacting concrete containing high level fly ash and silica fume. Mater Des. 2014;64:261–9.10.1016/j.matdes.2014.07.042Suche in Google Scholar

[52] Tam VWY, Gao XF, Tam CM. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem Concr Res. 2005;35(6):1195–203.10.1016/j.cemconres.2004.10.025Suche in Google Scholar

[53] Etxeberria M, Vázquez E, Marí A, Barra M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem Concr Res. 2007;37(5):735–42.10.1016/j.cemconres.2007.02.002Suche in Google Scholar

[54] Kong D, Lei T, Zheng J, Ma C, Jiang J, Jiang J. Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr Build Mater. 2010;24(5):701–8.10.1016/j.conbuildmat.2009.10.038Suche in Google Scholar

[55] Kou SC, Poon CS. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr Build Mater. 2012;35:69–76.10.1016/j.conbuildmat.2012.02.032Suche in Google Scholar

[56] Fumoto T, Yamada M. Influence of quality of recycled fine aggregate on properties of concrete. Osaka, Japan: Faculty of Engineering, Osaka City University; 2002. p. 97–103.Suche in Google Scholar

[57] Abbas ZK, Abd SK. Study of using of recycled brick waste (RBW) to produce environmental friendly concrete: A review. J Eng. 27(11):2021:1–14.10.31026/j.eng.2021.11.01Suche in Google Scholar

[58] Abbas ZK, Abbood AA. The influence of incorporating recycled brick on concrete properties. IOP Conf Ser: Mater Sci Eng. 2021;1067:012010.10.1088/1757-899X/1067/1/012010Suche in Google Scholar

[59] Debieb F, Courard L, Kenai S, Degeimbre R Roller compacted concrete with contaminated recycled aggregates. Constr Build Mater. 2009, 23(11):3382–7.10.1016/j.conbuildmat.2009.06.031Suche in Google Scholar

[60] Zhao Z, Remond S, Damidot D, Xu W. Influence of fine recycled concrete aggregates on the properties of mortars. Constr Build Mater. 2015;81:179–86.10.1016/j.conbuildmat.2015.02.037Suche in Google Scholar

[61] Kurda R, de Brito J, Silvestre JD. Influence of recycled aggregates and high contents of fly ash on concrete fresh properties. Cem Concr Compos. 2017;84:198–213.Suche in Google Scholar

[62] Gonzalez-Corominas A, Etxeberria M. Properties of high performance concrete made with recycled fine ceramic and coarse mixed aggregates. Constr Build Mater. 2014;68:618–26.10.1016/j.conbuildmat.2014.07.016Suche in Google Scholar

[63] Bommisetty J, Keertan TS, Ravitheja A, Mahendra K. Effect of waste ceramic tiles as a partial replacement of aggregates in concrete. Mater Today Proc. 2019;19:875–7.10.1016/j.matpr.2019.08.230Suche in Google Scholar

[64] Banthia N, Chan C. Use of recycled aggregate in plain fiber-reinforced shotcrete. Concr Int. 2000;22(6):41–5.Suche in Google Scholar

[65] Evangelista L, De Brito J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem Concr Compos. 2007;29(5):397–401.10.1016/j.cemconcomp.2006.12.004Suche in Google Scholar

[66] Katz A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem Concr Res. 2003;33(5):703–11.10.1016/S0008-8846(02)01033-5Suche in Google Scholar

[67] Chakradhara Rao M, Bhattacharyya SK, Barai SV. Influence of field recycled coarse aggregate on properties of concrete. Mater Struct. 2011;44:205–20.10.1617/s11527-010-9620-xSuche in Google Scholar

[68] Amer AA, Ezziane K, Bougara A. Rheological and mechanical behavior of concrete made with pre-saturated and dried recycled concrete aggregates. Constr Build Mater. 2016;123:300–8.10.1016/j.conbuildmat.2016.06.107Suche in Google Scholar

[69] Khalid MQ, Abbas ZK. Producing sustainable roller compacted concrete by using fine recycled concrete aggregate. J Eng. 2023;29(5):126–45.10.31026/j.eng.2023.05.10Suche in Google Scholar

[70] Poon CS, Shui ZH, Lam L, Fok H, Kou SC. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem Concr Res. 2004;34(1):31–6.10.1016/S0008-8846(03)00186-8Suche in Google Scholar

[71] Khalid MQ, Abbas ZK. Recycled concrete aggregated for the use in roller compacted concrete: A literature review. J Eng. 2023;29(3):142–53.10.31026/j.eng.2023.03.10Suche in Google Scholar

[72] Khan ZA, Abbas ZK. Some properties of RCC containing silica sand powder exposed to MgSO4 solution. IOP Conf Ser: Mater Sci Eng. . 2021;1094:012051.10.1088/1757-899X/1094/1/012051Suche in Google Scholar

[73] Kurad R, Silvestre JD, de Brito J, Ahmed H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J Clean Prod. 2017;166:485–502.10.1016/j.jclepro.2017.07.236Suche in Google Scholar

[74] Pederneiras CM, Durante MDP, Amorim ÊF, Ferreira RLS. Incorporation of recycled aggregates from construction and demolition waste in paver blocks. Rev IBRACON Estrut Mater. 2020;13:012051.10.1590/s1983-41952020000400005Suche in Google Scholar

[75] Kurda R, de Brito J, Silvestre JD. Influence of recycled aggregates and high contents of fly ash on concrete fresh properties. Cem Concr Compos. 2017;84:198–213.10.1016/j.cemconcomp.2017.09.009Suche in Google Scholar

[76] Klak FS, Saleh H, Tais AS. Recycling of crushed clay bricks as fine aggregate in concrete and cement mortar. Aust J Struct Eng. 2023;24(1):67–76.10.1080/13287982.2022.2098600Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil

Artikel in diesem Heft

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil