Abstract

In this work, the influence of using hybrid fibers on the mechanical properties of two types of concrete: high-strength concrete (HSC) and lightweight concrete (LWC) was studied. Using hybrid fibers instead of using only one type reduced the negative effect on concrete mechanical performance. The glass fiber (GF) and polypropylene fiber (PPF) were used in different contents ranged from 0.2 to 1% as weight % of binder content. Moreover, combinations of both fibers “GF + PPF” were used in contents % of “0.3 + 0.5%,” “0.5 + 0.5%,” “0.3 + 1%,” and “0.5 + 1%.” LWC mixes were prepared by replacing 40% of the coarse aggregate of reference mix with volcanic material (pumice) as a volumetric replacing. To produce HSC, the water-to-cement ratio was reduced to 0.3, 10% silica fume was added, and 1% super plasticizer was used to obtain the consistency. Compressive strength, splitting strength, and flexural strength tests were carried out. The results showed that using 0.7% GF displayed the highest increases in compressive, splitting tensile, and flexural strength of HSC and LWC mixes. Furthermore, GF exhibited better performance and higher values in compressive, splitting tensile, and flexural strength tests in comparison with PPF. The optimum hybrid fiber content displaying the highest increment of all tested properties in both concrete types, HSC and LWC, was “0.5% GF + 0.5% PPF.”

1 Introduction

Concrete is one of the most commonly used building materials in construction around the world due to easily molded to any anticipated durable structural shape. Nowadays, steel bars in reinforced concrete were replaced by different other materials such as short fibers [1,2,3]. Many properties of concrete can be improved by adding fibers such as strength and ductility. Moreover, adding fibers to plain concrete showed controlling shrinkage cracking and improved the tensile properties of concrete matrix [4,5]. ACI Committee [6] defines “fiber-reinforced concrete” (FRC) as “hydraulic cement concrete incorporating fine or fine and coarse aggregates and irregular discrete fibers,” the fibers could be steel, plastic, glass or natural materials, and all have been used in concrete in various forms and sizes [6]. The randomly oriented fibers prevent the micro-cracking mechanism and limit crack propagation. Adding short discrete fibers to the concrete mixture improved the compressive strength, durability, tensile strength, flexural strength, and impact strength by producing a homogeneous and isotropic matrix [1,2,7].

Murthy et al. [7] recognized that replacing fine aggregate by using 25 µm and 5 cm long glass fiber (GF) up to 1.5% in normal grade concrete caused boosting in the mechanical strength. Moreover, Sangeetha and Sumathi [8] investigated using glass fiber in reinforced polymer concrete of 42 concrete columns; the results showed increasing in strength and ductility of concrete columns. Kumar et al. [9] utilized GF in geopolymer concrete composites based on fly ash and alkaline liquid; the test results of mechanical properties observed higher strength in less curing time compared with the Portland cement concrete.

Fauzan et al. [10] stated that high-strength concrete (HSC) is mainly a brittle material, with low tensile strength, utilizing steel fibers from waste tiers improved this brittleness, and enhanced tensile strength and other mechanical properties.

Polypropylene fibers (PPF) belong to the modern generation of large-scale, it comes in the fourth largest volume production just after polyesters, polyamides and acrylics manufactured chemical fibers. Polypropylene fiber has low density equal to (0.9 g/cc), moreover, it has high crystalline, high stiffness and excellent bacterial/chemical resistance, therefore, its commonly used in many industrial applications such as industrial ropes, packaging materials and furnishing product [11].

In fiber high-strength concrete (FHSC), fibers improved toughness in compression by decreasing the rapid and explosive failure risk under the static loading as well as energy absorption under the dynamic loading [12]. Where using polypropylene macro fibers in high performance concrete column succeeded to reduce the fragility and shrinkage. The matrix parameter of fibers in concrete like material type, geometry, proportion of adding, orientation, and fiber distribution, effect the properties and performance of fiber reinforced concrete [13]. The volume fraction and specific surface area should be considered as the most affected important parameters in fiber reinforced concrete, as well as the aspect ratio, which is defined as the fiber length divided by its equivalent diameter [14].

1.1 Hybrid FRC

When two or more types of fibers are intelligently combined to produce a composite that composite is called a hybrid or hybridization. Concrete is a complicated material with multiple phases ranging in size from microns to millimeters to centimeters, such as C–S–H gels, sand, and gravel consequently. Reinforcing concrete with single type of fiber can improve characteristics to a certain amount [12]. Whereas the hybrid fibers can provide more worth able technical qualities by incorporating of two or more different types of fibers into a common cement matrix to improve the overall properties of concrete in comparison with presence of single fiber [14]. Moreover, reinforcing the concrete by using hybrid fiber gives the opportunity to design a stronger, stiffer, more flexible, and ductile system to improve the first crack resistance in the post-cracking zone and ultimate strength in comparison with single FRC [15,16]. The presence of three-fiber hybrid increased compressive strength till 85 MPa and increased flexural toughness in comparison with the control mix [17].

Since using recycled aggregates in normal concrete exhibited increasing shrinkage, porosity and decreasing the mechanical properties in comparison with that of normal concrete [18] investigated adding polypropylene and steel fibers to recycled aggregate concrete to enhance these mechanical properties. Where the researchers produced recycled aggregate concrete containing 30%, 50% recycled coarse aggregate gained from the demolished buildings. The results showed that the compressive strength increased with the addition of 1% steel fiber in the recycled aggregate concrete. While the flexural and impact performance of steel FRC was improved as the volume fractions of steel fiber increased. Moreover, using the hybrid FRC presented the best results in their mechanical performance [18].

Moreover, Tayeh and Agwa produced light weight aggregate concrete contained 65% pumice lightweight coarse aggregate by using different curing condition with elevated temperatures from ambient temperature to 200°C, 400°C, and 600°C for 2 h of exposure time. The results showed that flexural and tensile strengths increased by 53% and 38% for mixtures containing 0.4% glass fiber. However, the compressive and flexural strengths of the lightweight concrete (LWC) that exposed to elevated temperature improved by adding glass fiber and PPF due to fixing the pores and cracks that formed in the concrete structure [19].

In recent years, hybrid fiber has been considered one of the most favorable materials for strengthening and repairing concrete constructions. In general, plain concrete has poor tensile strength and low crack resistance. Fiber hybridization uses various fibers types to support the resistance of these cracks in concrete construction.

The main goal of this article is to study the consequence presence of hybrid fibers in LWC and HSC mixtures and study the progress in strength compared with using single fiber and reference mixes for each concrete type. Twenty-five concrete mixes were casted, and compressive strength, splitting tensile, and flexural strength were tested.

2 Materials’ specifications

The materials utilized in this article were as follows.

2.1 Cement

The cement that used in this study was Ordinary Portland Cement (OPC-Type1), provided from Badoosh Cement Factory’s. Tables 1 and 2 show the physical, mechanical, and chemical characteristics of the cement, following the Iraqi Standards and Specifications (IQS) [20].

Physical and mechanical characteristics of cement

| Characteristics | Test results of cement used | IQS, No. 5 [20,25] |

|---|---|---|

| Specific surface area, Blaine method | 2,800 | >2,300 cm2/g |

| Standard consistency, (%) | 27.5 | — |

| Setting time, Vicat device | ||

| Initial setting, (min) | 137 | >45 min |

| Final setting, (min) | 165 | <600 min |

| Fineness on sieve No. 170, (%) | 3 | <22% |

| Compressive strength of 50 mm cubic mortar samples, (N/mm 2 ) | ||

| 3 days | 23.8 | >15 N/mm2 |

| 7 days | 29.6 | >23 N/mm2 |

| Tensile strength, (N/mm 2 ) | ||

| 3 days | 1.63 | >1.6 N/mm2 |

| 7 days | 2.48 | >2.4 N/mm2 |

Chemical analysis of cement

| Compound composition | (%) cement used | IQS, No. 5 [20] (%) |

|---|---|---|

| Al2O3 | 5.80 | 3.0–8.0 |

| SiO2 | 21.35 | 17.0–25.0 |

| Fe2O3 | 2.60 | 0.5–6.0 |

| CaO | 62.30 | 60.0–67.0 |

| SO3 | 2.50 | 2.5–2.8 |

| MgO | 3.33 | Not more than 5% |

| C3S | 34.50 | 31.3–41.05 |

| C2S | 28.00 | 28.61–37.9 |

| C3A | 10.20 | 11.96–12.3 |

| C4AF | 7.82 | 7.72–8.02 |

2.2 Coarse aggregate

The washed rounded coarse aggregates that used in this study were provided from Al-Mosul city, Iraq, with the maximum aggregate size of 12.5 mm. Table 3 shows the results of the sieve analysis of the coarse material used. The aggregate percentage passing of coarse aggregate utilized, as shown in Table 3, was within the 5–14 mm (Fine) requirements of the British Standard [21]. The coarse aggregate utilized had a specific gravity of 2.66 and an absorption capacity of 0.4%, respectively.

Sieve analysis of the used coarse aggregate

| Sieve size (mm) | Passing (%) | BS standard [21] | ||

|---|---|---|---|---|

| Fine | Medium | Coarse | ||

| 14 | 100 | 90–100 | 40–80 | 25–55 |

| 10 | 84.30 | 50–85 | 30–60 | 10–40 |

| 4.75 | 8.60 | 0–10 | 0–10 | 0–5 |

| 2.36 | 0.0 | — | — | — |

2.3 Fine aggregate

Natural sand was used in all concrete mixes, as fine aggregate, with a maximum size of 4.75 mm collected from the Khazer region in Mosul, Iraq. Table 4 shows the sieve analysis of the sand utilized following the BS 882 standard within the range of fine constraints [21]. The sand used had a specific gravity of 2.68, an absorption capacity of 2.88, and the material finer than sieve No. 200 was 80%.

Sieve analysis of fine aggregate used and specification of BS [21]

| Sieve size (mm) | Passing (%) | BS [21] | |||

|---|---|---|---|---|---|

| Limits | Fine | Medium | Coarse | ||

| 4.75 | 100 | 89–100 | — | — | — |

| 2.36 | 89.0 | 60–100 | 80–100 | 65–100 | 60–100 |

| 1.18 | 74.5 | 30–100 | 70–100 | 45–100 | 30–90 |

| 0.60 | 55.5 | 15–100 | 55–100 | 35–80 | 15–45 |

| 0.30 | 21.5 | 5–70 | 5–70 | 5–48 | 5–40 |

| 0.015 | 3.5 | 0–15 | — | — | — |

2.4 Volcanic pumice (VP)

VP was utilized as an alternative aggregate to gravel in LWC mixtures which collected from Hatay region in Turkey. It has a light gray color, as shown in Figure 1. The utilized VP has a low density of 835 kg/m3, allowing it to float on water. The chemical composition of the VC showed in Table 5.

The used VP.

The chemical composition of VP

| Oxide | Weight (%) |

|---|---|

| Cao | 14.1 |

| SiO2 | 49.5 |

| Al2O3 | 16.4 |

| Fe2O3 | 14.7 |

| MgO | 1.9 |

| SO3 | 0.2 |

| K2O | 1.3 |

| Na2O | 0.1 |

2.5 Silica fume

The silica fume that used in this study was SikaFume-HR brand, provided from Beirut-Lebanon, which manufactures with a fineness of 0.1 µm. Table 6 shows the technical data of SikaFume-HR that provided from the production factory. In this study, silica fume has used in concrete mixes to increase the strength through the pozzolanic reaction with Ca(OH)2 crystals for strengthening the bond between the cement paste and the aggregate surface at the transition zone.

Technical data of SikaFume-HR

| Property | Result |

|---|---|

| Composition | A latently hydraulic blend of active ingredient |

| Appearance | Grey powder |

| Dry bulk density | 0.05–0.1 kg |

| Dosage | 2–10% by weight of cement |

2.6 Chemical admixtures

A super plasticizer (Sika ViscoCrete-SF 18) was used as a high-range water purifier, minimizing admixture and viscosity-modifying agent. The used proportion was 1% as weight % of cement. Table 7 shows the characteristics of the used super plasticizer as provided by the manufacturer.

The characteristics of super-plasticizer used

| Property | Sika ViscoCrete-SF 18 |

|---|---|

| Chemical base | Modified poly carboxylates based polymer |

| Appearance/color | Light brownish liquid |

| pH value | 3–7 |

| Density | 1.1 g/cm3 ± 0.02 (at +20°C) |

| Dosage | 1.0–2.0% by weight of cement |

2.7 Water

All concrete mixes and samples curing processes were carried out in this article using normal tap water without any additions or treatments.

2.8 Fibers

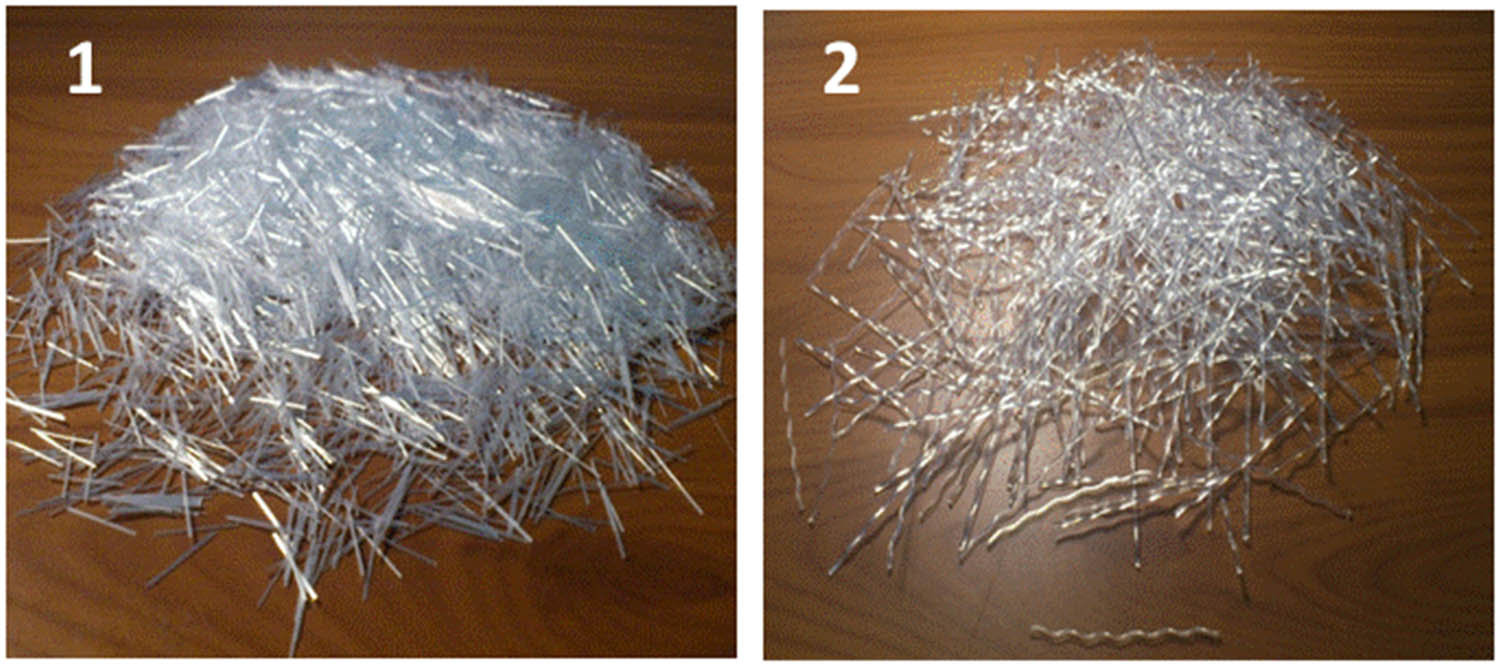

In this study, two types of fibers were used, PPF (with crimped shape) and GF; the details are presented in Table 8 and Figure 2. Using fibers in concrete exposed many advantages, such as easy processing, low specific gravity, almost zero water adsorption, good chemical resistance, wide availability, and low cost.

Details of GF and PPF

| Type of fiber | Glass | Polypropylene |

|---|---|---|

| Length (mm) | 12 | 25 |

| Diameter (mm) | 0.014 | 1.0 |

| Aspect ratio | 857.1 | 25 |

| Density (kg/m3) | 2,600 | 910 |

Fibers used in this study: (1) GF and (2) PPF.

2.9 Mixing and preparing specimens

All batches of concrete were mixed using a drum mixer with a capacity of 0.071 m3. Each batch was used to cast six 100 mm × 100 mm × 100 mm cube specimens, six 100 mm × 200 mm cylinder specimens, and four 100 mm × 100 mm × 400 mm prism specimens for compressive strength, splitting tensile strength, and flexural strength testing, respectively, in iron molds. All molds were cleaned and the internal surfaces were lubricated before using.

Table 9 summarizes the proportion of mixes, where the normal reference concrete mix (M0), produced following the American Concrete Institute s mix design standards [22], to achieve (C25) concrete mix with (w/c) equal to 0.5, super plasticizer was used in 1% as wt% of cement and the mix proportion of cement: sand: gravel was 1:1.86:3.36, whereas, LWC mixes (M1 to M12) produced by replacing 40% of the volume of coarse aggregate with volcanic pumice VP, with different proportions of fibers (singular and hybrid) as shown in Table 9.

Mix Proportion of reference concrete and LWC mixes

| Mix no. | Fibers (%) | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m3) | Coarse aggregate | VP (kg/m3) | |

|---|---|---|---|---|---|---|---|

| GF | PPF | ||||||

| M0 | — | — | 200 | 400 | 745.6 | 1344.4 | 0 |

| M1 | 0.1 | — | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M2 | 0.3 | — | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M3 | 0.5 | — | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M4 | 0.7 | — | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M5 | — | 0.25 | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M6 | — | 0.5 | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M7 | — | 0.75 | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M8 | — | 1.0 | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M9 | 0.3 | 0.5 | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M10 | 0.5 | 0.5 | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M11 | 0.3 | 1 | 200 | 400 | 745.6 | 806.6 | 537.7 |

| M12 | 0.5 | 1 | 200 | 400 | 745.6 | 806.6 | 537.7 |

Moreover, another thirteen high strength concrete mixes were prepared (M13 to M25), as shown in Table 10. Where, (M13) represents the high-strength concrete reference mix, w/c ratio was reduced to 0.3 with 1% super plasticizer and 10% of silica fume (as wt.% of cement) was used. In the same way, the HSC mixes (M14 to M25) were prepared by using different proportions of fibers (singular and hybrid) to study the influence of hybrid fibers on the mechanical properties of HSC mixes as shown in detail in Table 10.

Mix proportion of HSC mixes

| Mix no. | Fibers (%) | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m3) | Coarse aggregate (kg/m3) | Silica fume (kg/m3) | |

|---|---|---|---|---|---|---|---|

| GF | PPF | ||||||

| M13 | — | — | 120 | 400 | 745.6 | 1344.4 | 40 |

| M14 | 0.1 | — | 120 | 400 | 745.6 | 1344.4 | 40 |

| M15 | 0.3 | — | 120 | 400 | 745.6 | 1344.4 | 40 |

| M16 | 0.5 | — | 120 | 400 | 745.6 | 1344.4 | 40 |

| M17 | 0.7 | — | 120 | 400 | 745.6 | 1344.4 | 40 |

| M18 | — | 0.25 | 120 | 400 | 745.6 | 1344.4 | 40 |

| M19 | — | 0.5 | 120 | 400 | 745.6 | 1344.4 | 40 |

| M20 | — | 0.75 | 120 | 400 | 745.6 | 1344.4 | 40 |

| M21 | — | 1.0 | 120 | 400 | 745.6 | 1344.4 | 40 |

| M22 | 0.3 | 0.5 | 120 | 400 | 745.6 | 1344.4 | 40 |

| M23 | 0.5 | 0.5 | 120 | 400 | 745.6 | 1344.4 | 40 |

| M24 | 0.3 | 1 | 120 | 400 | 745.6 | 1344.4 | 40 |

| M25 | 0.5 | 1 | 120 | 400 | 745.6 | 1344.4 | 40 |

3 Results and discussion

3.1 Compressive strength test results

Standard compressive cube tests using 100 mm × 100 mm × 100 mm samples were conducted to determine concrete compressive strength at 28-day age. The compressive strength of six samples were found of LWC and HSC, which presented in Figures 3 and 4, respectively. The effect of fiber type and content on compressive strength (as gaining or loosing % in strength) are presented in Tables 11 and 12. The results showed that, in general, increase the fiber content exposed increasing in compressive strength in both LWC and HSC mixes, similar results obtained by others [8,9,11]. Moreover, for the same fiber proportion (0.5%), using the glass fibers displayed growing in compressive strength up to 43% in LWC and 19.6% in HSC (mixes M3 in Table 11 and M16 in Table 12) in comparison with polypropylene fibers in the same proportion (0.5%), which displayed a reduction in strength of the LWC mixes up to −5% and in HSC mixes the reduction was −3%, (mixes M3 in Table 11 and M16 in Table 12) in comparison with polypropylene fibers at the same content (0.5%), which displayed a reduction in strength in LWC and HSC mixes within 5 and 3%, respectively (mixes M6 in Table 11 and M19 in Table 12). That could be related to the higher aspect ratio (length/ diameter ratio) of GF which equal to 857.1 in comparison with 25 for polypropylene fibers and that extremely improved the mechanical properties of glass fibers. Furthermore, dropping in strength of LWC and HSC mixes, that contain PPF, could be also related to the low stiffness and low ductility of PPF which affected negatively on strength. Similar results obtained by others [23,24].

28-Day compressive strength test results of LWC mixes.

28-Day compressive strength test results of HSC mixes.

Compressive strength test results of LWC mixes

| Mix no. | Fibers (%) | 28-Day compressive strength (MPa) | Gaining ( +) or losing (−) % in compressive strength | |

|---|---|---|---|---|

| GF | PPF | |||

| M0 | — | — | 22.00 | — |

| M1 | 0.1 | — | 24.50 | +11.4 |

| M2 | 0.3 | — | 29.00 | +31.8 |

| M3 | 0.5 | — | 31.50 | +43.2 |

| M4 | 0.7 | — | 32.20 | +46.4 |

| M5 | — | 0.25 | 21.35 | −3.0 |

| M6 | — | 0.50 | 20.80 | −5.0 |

| M7 | — | 0.75 | 20.20 | −8.0 |

| M8 | — | 1.00 | 19.60 | −10.0 |

| M9 | 0.3 | 0.5 | 25.52 | +16.0 |

| M10 | 0.5 | 0.5 | 27.82 | +26.4 |

| M11 | 0.3 | 1.0 | 24.20 | +10.0 |

| M12 | 0.5 | 1.0 | 26.40 | +20.0 |

Compressive strength test results of HSC mixes

| Mix no. | Fibers (%) | 28-Day compressive strength (MPa) | Gaining (+) or losing (–) % in compressive strength | |

|---|---|---|---|---|

| GF | PPF | |||

| M13 | — | — | 61.20 | — |

| M14 | 0.1 | — | 62.10 | +1.50 |

| M15 | 0.3 | — | 68.30 | +11.60 |

| M16 | 0.5 | — | 73.20 | +19.60 |

| M17 | 0.7 | — | 75.30 | +23.00 |

| M18 | — | 0.25 | 60.35 | −1.00 |

| M19 | — | 0.50 | 59.34 | −3.00 |

| M20 | — | 0.75 | 58.43 | −4.00 |

| M21 | — | 1.0 | 57.95 | −5.00 |

| M22 | 0.3 | 0.5 | 76.10 | +24.30 |

| M23 | 0.5 | 0.5 | 78.45 | +28.20 |

| M24 | 0.3 | 1.0 | 73.00 | +19.28 |

| M25 | 0.5 | 1.0 | 77.25 | +26.22 |

The results displayed clearly that the optimal content of hybrid fibers as a combination was 0.5% GF + 0.5% PPF, and other proportion contents (mixes M22, M24, and M25) have not shown an effectiveness to use the content of these high fibers in comparison with the efficiency of using only GF with lower total fiber content (mix M7).

Adding GF to either LWC or HSC control mixes or that already have PPF caused strength improvement. On the contrary, adding PPF to the mixes that containing GF caused reduction in strength in LWC and HSC mixes (Tables 11 and 12). That could be correlated with the low elastic modulus of the PPF in comparison with the GF which has high elastic modulus, in addition to the higher aspect ratio (length/diameter ratio) of GF comparing with PPF as mentioned before.

Fibers also affect the followability and workability and reduce the backing density, which increases the internal defects’ concrete. Moreover, mixing of long size fibers (PPF) with other in short size (GF) cannot give accurately prediction effect on the mechanical properties of concrete because fiber dispersion and fiber orientation also affect the compressive strength of concrete [25].

3.2 Splitting tensile strength test results

The splitting tensile strength test results of LWC and HSC mixes reinforced with glass, polypropylene, and hybrid fibers are shown in Tables 13 and 14, respectively.

Splitting tensile strength test results of LWC mixes

| Mix no. | Fibers (%) | 28-Day splitting tensile strength (MPa) | Increasing % in splitting tensile strength | |

|---|---|---|---|---|

| GF | PPF | |||

| M0 | — | — | 2.1 | — |

| M1 | 0.1 | — | 2.3 | 9.0 |

| M2 | 0.3 | — | 2.6 | 23.8 |

| M3 | 0.5 | — | 2.9 | 36.7 |

| M4 | 0.7 | — | 3.1 | 47.6 |

| M5 | — | 0.25 | 2.3 | 9.0 |

| M6 | — | 0.50 | 2.4 | 14.3 |

| M7 | — | 0.75 | 2.5 | 18.0 |

| M8 | — | 1.0 | 2.4 | 12.4 |

| M9 | 0.3 | 0.5 | 2.7 | 26.6 |

| M10 | 0.5 | 0.5 | 2.9 | 36.7 |

| M11 | 0.3 | 1.0 | 2.5 | 20.9 |

| M12 | 0.5 | 1.0 | 2.7 | 26.2 |

Splitting tensile strength results of HSC mixes

| Mix no. | Fibers (%) | 28-Day splitting tensile strength (MPa) | Increasing % in splitting tensile strength | |

|---|---|---|---|---|

| GF | PPF | |||

| M13 | — | — | 5.2 | — |

| M14 | 0.1 | — | 5.4 | 2.8 |

| M15 | 0.3 | — | 5.8 | 11.5 |

| M16 | 0.5 | — | 6.0 | 15.6 |

| M17 | 0.7 | — | 6.3 | 21.2 |

| M18 | — | 0.25 | 5.4 | 3.8 |

| M19 | — | 0.50 | 5.5 | 5.8 |

| M20 | — | 0.75 | 5.9 | 12.5 |

| M21 | — | 1.0 | 6.1 | 17.3 |

| M22 | 0.3 | 0.5 | 5.9 | 13.3 |

| M23 | 0.5 | 0.5 | 6.2 | 18.7 |

| M24 | 0.3 | 1.0 | 5.9 | 14.4 |

| M25 | 0.5 | 1.0 | 5.8 | 11.1 |

In LWC mixes, increasing the GF contents caused increasing in splitting tensile strength values. Where, the highest splitting tensile strength value obtained with a maximum volume fraction of GF equal to (0.7%) (mix M4 in Table 13). This increment could be related to the high tensile strength of the GF, which bridge and arrested the cracks that initiated in the matrix consequently enhance the splitting tensile strength of LWC mixes, similar results were obtained by others [24,26].

Moreover, the LWC mixes reinforced with the PPF, the optimal content of PPF was 0.75% which gave the highest splitting tensile strength equal to 2.5 MPa (mix M7 in Table 13). While, the HSC mixes reinforced with the PPF, the optimal content of PPF was 1%, which gave the highest splitting tensile strength equal to 6.1 MPa (Mix M21 in Table 14). The optimal content of hybrid fibers was (0.5% GF + 0.5% PPF) that recorded the highest tensile strength in LWC and HSC mixes (Mixes M10 and M23 in Tables 13 and 14, respectively).

3.3 Flexural strength (modulus of rupture) test results

The flexural strength measured values at 28-day age are given in Tables 15 and 16 for all concrete mixes. The 28-day flexural strengths ranged from 3.6 to 4.5 MPa for LWC mixes, (Table 15) and from 12.1 to 14.35 MPa for HSC mixes (Table 16).

Flexural strength test results of LWC mixes

| Mix no. | Fibers (%) | 28-Day flexural strength (MPa) | Increasing % in flexural strength | |

|---|---|---|---|---|

| GF | PPF | |||

| M0 | — | — | 3.60 | — |

| M1 | 0.1 | — | 3.82 | 6.10 |

| M2 | 0.3 | — | 3.95 | 9.70 |

| M3 | 0.5 | — | 4.30 | 19.40 |

| M4 | 0.7 | — | 4.50 | 25.00 |

| M5 | — | 0.25 | 3.62 | 0.50 |

| M6 | — | 0.5 | 3.68 | 2.20 |

| M7 | — | 0.75 | 3.80 | 5.50 |

| M8 | — | 1.0 | 3.67 | 1.90 |

| M9 | 0.3 | 0.5 | 3.99 | 9.16 |

| M10 | 0.5 | 0.5 | 4.20 | 16.6 |

| M11 | 0.3 | 1 | 3.89 | 8.00 |

| M12 | 0.5 | 1 | 4.10 | 13.8 |

Flexural strength test results of HSC mixes

| Mix no. | Fibers (%) | Flexural strength at age 28 days (MPa) | Increasing % in flexural strength | |

|---|---|---|---|---|

| GF | PPF | |||

| M13 | — | — | 12.1 | — |

| M14 | 0.1 | — | 12.4 | 2.50 |

| M15 | 0.3 | — | 12.9 | 6.60 |

| M16 | 0.5 | — | 13.2 | 9.00 |

| M17 | 0.7 | — | 13.3 | 9.90 |

| M18 | — | 0.25 | 12.4 | 2.50 |

| M19 | — | 0.5 | 12.9 | 6.60 |

| M20 | — | 0.75 | 13.2 | 9.00 |

| M21 | — | 1.0 | 13.6 | 11.57 |

| M22 | 0.3 | 0.5 | 13.7 | 13.20 |

| M23 | 0.5 | 0.5 | 14.35 | 18.60 |

| M24 | 0.3 | 1 | 13.84 | 14.3 |

| M25 | 0.5 | 1 | 13.44 | 2.8 |

The results display that using fiber reinforcement is very useful to boost the flexural strength of both LWC and HSC mixes. The optimal flexural strength increments of LWC were 25, 5.5, and 16.6% due to the inclusion of 0.7% GF, 0.75% PPF, and the combination of 0.5 GF + 0.5% PPF, respectively. Likewise, the optimal fibers content that gave the highest flexural strength values were 0.7% GF, 1% PPF and (0.5%GF + 0.5% PPF) for hybrid fibers in both LWC in Table 15, and HSC mixes in Table 16. The hypothesis behind that related to arresting the early tensile cracks in concrete by fibers which resulting in high tensile and flexural strength [27]. Using the GF in concrete mixes displayed greater enhancement in compressive, tensile and flexural strength comparing with PPF, this might be ascribed to enhanced bonding of GF with binder matrix.

4 Conclusions

According to test results of this investigation, the following conclusions can be drawn:

Increasing the GF content exposed increasing in compressive strength in both FRC, LWC and HSC.

Increasing fiber contents in LWC and HSC mixes reinforced with GF or PPF, displayed increasing in splitting tensile strength values.

Using 0.7% GF in LWC and HSC increased the compressive strength up to 46 and 23%, respectively.

Using PPF caused reduction in compressive strength of both, LWC and HSC within 5 and 3%, respectively.

Using 0.7% GF increased the splitting tensile strength of LWC and HSC up to 47.62 and 21.1%, respectively, and increased the flexural strength of the LWC mix by 25%.

The hybrid fibers with the content of 0.5% GF + 0.5% PPF were the best hybrid proportion and affected positively on the splitting tensile strength of LWC and HSC up to 36.67 and 18.65%, respectively.

Acknowledgements

All the laboratory works were done in the laboratory of Building and Construction department/Technical Engineering College/Northern Technical University, Mosul, Iraq. The authors would like to thank all laboratory staff in University of Mosul, Iraq, and Lulea University of Technology, Lulea, Sweden, for the financial support to this work.

-

Funding information: The authors state no funding involved.

-

Author contributions: The TRR requires that all authors take public responsibility for the content of the work: the authors confirm contribution to the article as follows: (1) preparing and designing the experimental works by Mohammed Hadeed; (2) writing the draft paper by Majid Al-Gburi and revised by Abeer Humad; (3) all authors reviewed the results and approved the final version of the article; (4) all authors approved the version to be published; and (5) Majid Al-Gburi (corresponding author) follows the publishing processes.

-

Conflict of interest: All authors have participated in (1) conception and design, or analysis and interpretation of the data; (2) drafting the article or revising it critically for important intellectual content; and (3) approval of the final version. This article has not been submitted to, nor is under review at, another journal or other publishing venue. The authors have no affiliation with any organization with a direct or indirect financial interest in the subject matter discussed in the article. The authors M.H., A.H.M., and M.A.G. have affiliations with organizations with direct or indirect financial interest in the subject matter discussed in the article.

References

[1] Annamaneni KK, Dobariya BV, Krasnikovs A. Concrete, reinforced by carbon fibre composite structure, load bearing capacity during cracking. Environ Technol Resour Proc Int Sci Pract Conf. 2021;2:232–7.10.17770/etr2021vol2.6655Search in Google Scholar

[2] Xiao SH, Lin JX, Li LJ, Guo YC, Zeng JJ, Xie ZH, et al. Experimental study on flexural behavior of concrete beam reinforced with GFRP and steel-fiber composite bars. J Build Eng. 2021;43:103087.10.1016/j.jobe.2021.103087Search in Google Scholar

[3] Ge W, Song W, Ashour AF, Lu W, Cao D. Flexural performance of FRP/steel hybrid reinforced engineered cementitious composite beams. J Build Eng. 2020;31:101329.10.1016/j.jobe.2020.101329Search in Google Scholar

[4] Khabaz A. Performance evaluation of corrugated steel fiber in cementitious matrix. Constr Build Mater. 2016;128:373–83.10.1016/j.conbuildmat.2016.10.094Search in Google Scholar

[5] Sikarskas D, Antonovič V, Malaiškiene J, Boris R, Stonys R, Šahmenko G. Modification of the Structure and Properties of Lightweight Cement Composite with PVA Fibers. Materials. 2021;14:5983.10.3390/ma14205983Search in Google Scholar PubMed PubMed Central

[6] ACI Committee 544, State-of-The-Art Report on Fiber Reinforced Concrete, ACI 544 1R-96. Farmington Hills (MI); ACI Committee; 2022.Search in Google Scholar

[7] Murthy Y, Sharda AI, Jain G. Performance of Glass Fiber Reinforced Concrete. Int J Eng Innovative Technol. 2012;1:246–8.Search in Google Scholar

[8] Sangeetha P, Sumathi R. Behaviour of glass fiber wrapped concrete columns under uniaxial compression. Int J Adv Eng Technol. 2010;I:74–83.Search in Google Scholar

[9] Kumar VS, Thomas BS and Christopher A. An Experimental Study on the Properties of Glass Fibre Reinforced Geopolymer Concrete. Int J Eng Res Appl. 2012;2:722–6.Search in Google Scholar

[10] Fauzan RK, Fitrah ON, Lovina CAN, Al Jauhari Z. Experimental study on the effect of steel fiber waste type on high strength concrete. GEOMATE J. 2019;16(58):14–9.10.21660/2019.58.4772Search in Google Scholar

[11] Nair MJ, Varghese R. Influence of glass fiber and polypropylene fiber on M30 grade concrete and its durability study. Int J Innovative Res Sci Eng Technol. 2017;6(5).Search in Google Scholar

[12] Torres-Ortega R, Edgar B, Candelaria T, Yineth G, Ibeth C. High-strength concrete with natural aggregates, silica fume, and polypropylene macrofibers. Cienc e Ingeniería Neogranadina. 2021;31(2):27–40.10.18359/rcin.4394Search in Google Scholar

[13] Mahdi ZR. Behavior of fiber reinforced high performance concrete columns [dissertation]. Baghdad: University of Technology; 2006.Search in Google Scholar

[14] Eren YA. Determination of mechanical properties of hybrid fiber reinforced concrete [dissertation]. Ankara: Middle East Technical University; 2004.Search in Google Scholar

[15] Bentur A, Mindess S. Fiber reinforced cementitious composites. Kent: Elsevier Applied Science; 1990.Search in Google Scholar

[16] Ramli M, Thanon E. Study the hybridization of different fibers on the mechanical properties of concrete: A mini review. Asian J Appl Sci. 2011;4(5):489–92.10.3923/ajaps.2011.489.492Search in Google Scholar

[17] Banthia N, Gupta R. Hybrid fiber reinforced concrete (HyFRC): fiber synergy in high strength matrices. Mat Struct. 2004;37:707–16.10.1007/BF02480516Search in Google Scholar

[18] Altun MG, Oltulu M. Effect of different types of fiber utilization on mechanical properties of recycled aggregate concrete containing silica fume. J Green Build. 2020;15(1):119–36.10.3992/1943-4618.15.1.119Search in Google Scholar

[19] Tayeh BA, Agwa IS. Investigating the mechanical and microstructure properties of fibre-reinforced lightweight concrete under elevated temperatures. Case Stud Constr Mater. 2020;13:e00459.10.1016/j.cscm.2020.e00459Search in Google Scholar

[20] IQS No. 5. Standard Specifications for Portland Cement. Baghdad, Iraq: Iraqi Organization for Standards and Specifications; 1984.Search in Google Scholar

[21] BS:882. Aggregates from Natural Source of Concrete. London, UK: British Standard Institution; 1992.Search in Google Scholar

[22] ACI 211.1-91. Standard Practice for Selecting Proportions for Normal, Heavyweight and Mass Concrete. Farmington Hills (MI), USA: ACI Committee; 1991.Search in Google Scholar

[23] Banthia N, Sappakittipakorn M. Toughness enhancement in steel fiber reinforced concrete through fiber hybridization. Cem Concr Res. 2007;37(9):1366–72.10.1016/j.cemconres.2007.05.005Search in Google Scholar

[24] Ali B, Qureshi LA. Influence of glass fibers on mechanical and durability performance of concrete with recycled aggregates. Constr Build Mater. 2019;228:116783.10.1016/j.conbuildmat.2019.116783Search in Google Scholar

[25] Kasagani H, Rao CBK. Effect of graded fibers on stress strain behaviour of glass fiber reinforced concrete in tension. Constr Build Mater. 2018;183:592–604.10.1016/j.conbuildmat.2018.06.193Search in Google Scholar

[26] Moghadam A, Izadifard RA. Effects of steel and glass fibers on mechanical and durability properties of concrete exposed to high temperatures. Fire Saf J. 2020;113:102978.10.1016/j.firesaf.2020.102978Search in Google Scholar

[27] Teng S, Afroughsabet V, Ostertag, CP. Flexural behavior and durability properties of high performance hybrid-fiber-reinforced concrete. Constr Build Mater. 2018;182:504–15.10.1016/j.conbuildmat.2018.06.158Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil