Abstract

As aggregate material typically comprises 65–75% of concrete volume and has a significant effect on its mechanical properties, aggregate type considerably affects concrete behavior at high temperatures. In this study, 80 concrete cylinders and 60 cubes were cast to investigate the residual strength of normal concrete that contains lightweight expanded clay aggregate (LECA) with different volumetric replacement ratios (0, 10, 20, and 30%) of the coarse aggregate. After the fire flame exposure effect of steady-state temperatures (300, 400, 500, and 600°C), and a sudden cooling process, the mechanical tests (compressive strength, tensile strength, and modulus of elasticity; Ec), as well as mass loss and thermal conductivity, were carried out on the specimens. The results indicate that increasing the LECA content in the mixture leads to better strength retention after exposure to fire. After exposure to a steady-state temperature of 600°C, the amount of decrease in mass, residual compressive and tensile strengths, and the residual amount of Ec were 7.61, 7.5, 7.16, and 6.24%; 57.1, 66.8, 69.8, and 72.0%; 22.4, 32.7, 41.8, and 48.6%;, and 16.0, 22.3, 23.4, and 24.3%, respectively, for the considered volumetric replacement ratios of 0, 10, 20, and 30%. Also, the values of the thermal conductivity were 1.4889, 1.1667, 1.0912, and 1.0410 W/m K, respectively.

1 Introduction

Fire is one of the disaster events that results in loss of life or damage to property. The duration of an accidental fire in a building is shorter, but the quantity of heat it generates is more intense, causing damage to the structure. In addition to accidental fire, specific buildings are exposed to high temperatures such as jet aircraft takeoff zones, rocket launch pads, nuclear reactors, chimneys, cement factories, coke ovens, hot water and crude oil storage tanks, and metallurgical or chemical industries. The thermal conductivity of concrete is determined by the conductivity of its components, specifically the cement paste and the aggregate. It is well known that the conductivity of concrete decreases with the increase in the temperature [1]. Aggregate materials are generally thermally stable up to 300–350°C. At high temperatures, physical properties, chemical properties, and thermal stability/integrity are the most influential aggregate parameters on the behavior of concrete. However, the mixing ratio, the aggregates’ thermophysical characteristics, and the hydrating cement paste’s properties all impact the concrete’s thermal properties [2,3].

Even though concrete is more durable than steel, it deteriorates in terms of mechanical properties when exposed to high temperatures [4]. Several researchers studied the response and behavior of reinforced concrete structures under different load and fire condition states [5–8].

LECA is an abbreviation for lightweight expanded clay aggregate. It is a product of porous ceramic that exhibits a uniform pore structure consisting of small, sealed cells and a compact, robust outer layer. The production process involves the utilization of fundamental components such as clay minerals, which are subjected to high-temperature treatment in rotary kilns. Upon completion of the preparation, molding, and firing process of the raw material, it undergoes a notable volumetric expansion due to temperature exposure ranging from 1,100 to 1,200°C. The internal cellular structure of LECA grains, which contains thousands of air-filled voids, provides thermal and acoustic insulation. Expanded clay aggregates are employed in a variety of industries due to their technical properties and several advantages over other industrial raw materials. Because of its good insulating features, LECA was added to the concrete mixture to increase its properties [9]. LECA’s chemical composition primarily comprises of SiO2, Al2O3, Fe2O3, CaO, and certain alkalis like Na2O and K2O [10]. The analysis reveals that the SiO2 content in the overall composition exhibited variations ranging from 53.3 to 70%, while Al2O3 exhibited fluctuations ranging from 15.05 to 27%. Similarly, Fe2O3 demonstrated fluctuations ranging from 1 to 14.3%, and CaO exhibited variations ranging from 0.2 to 3.92% [11]. The thermal conductivity of the material falls within the range of 0.097–0.123 W/m K [12–25]. The wide Applicability of LECA is shown in Table 1.

Wide applicability of LECA [9]

| Wide applicability | Average density* (kg/m3) | LECA gradation (mm) |

|---|---|---|

| Prefabricated panels and slabs, lightweight block, LECA lightweight concrete (LWC), light filler, agriculture and aquaculture. LECA mortar and water purification system | 510 | (0–4) |

| Drainage, sewage system, landscaping, agriculture and aquaculture, and weight filler concrete | 320 | (4–10) |

| Lightweight concrete, prefabricated panels and aquaculture, lightweight block, and ornamentation | 250 | (10–25) |

| Floor and roof sloping, road construction, and lightweight filler | 270 | (0–25) |

*Average density allowable tolerance is ±50 kg/m3.

Compared to normal strength concrete (NSC), LWC has much better resistance to high temperatures and fire. This is one of the important advantages of LWC. Because concrete is a mix of components with varied thermal properties, moisture, and porosity-dependent properties, the mechanical properties and load-carrying capacity of concrete parts may change substantially during the fire. Unlike NSC, LWC can resist fire better because its lightweight particles include pores that may be used to relieve the pressure created by the fire. LWC is less damaged at high temperatures in both the hot and residual stages, hence buildings composed of LWC may fare better in fires [26].

Used in its unsaturated nature, lightweight aggregate (LWA) proved to be more resistant than its saturated counterpart. In certain cases, particularly at higher temperatures, the pre-saturation nature of LWA that is widely utilized in practice may cause spalling of such lightweight matrices. Volcanic eruption or combustion produces LWAs like ceramist, pumice, and expanded clay. As a consequence, they have high heat resistance and low heat conductivity. As a result, concrete made with such aggregates should have better mechanical properties at high temperatures than normal aggregate concrete [27].

The thermal performance of lightweight aggregate concrete (LWAC) is better in contrast to ordinary concrete, considerably decreasing the buildings’ energy consumption [28,29]. Because the spaces in the LWAs assist the release of vapor and lower the tension caused by the evaporated water, LWAC has greater resilience to fire when compared to normal-weight concrete [30].

The bond produced between the cement pastes and the aggregates is severely degraded at temperatures over 300°C [31]. The addition of silica fume to LWAC may strengthen the bond between the LWAs and cement paste, increase concrete compressive strength, and decrease cement content; silica fume may also minimize porosity inside the LWAC structure.

LECA was improved to be a significant partial or full replacement for normal aggregate in the construction of several structural elements that were subjected to different types of loading (static or dynamic) and different types of disaster just as fire flame effect [32–35].

This study aims to investigate concrete behavior with various amounts (0, 10, 20, and 30%) of coarse aggregate replaced by LECA after being subjected to different levels of fire flame effect (300, 400, 500, and 600°C). The behavior is evaluated by the concrete’s remaining mechanical properties (compressive strength, tensile strength, and modulus of elasticity; Ec), mass loss, and thermal conductivity.

2 Experimental work

2.1 Constitutive materials

2.1.1 Cement

For casting all samples ordinary Portland cement (CEM I 42.5R) produced in Iraq by Mass brand was used in the concrete mix. The physical and chemical test results are shown in Tables 2 and 3, respectively. The test results agreed with Iraqi Specification No. 5/2019 [36].

Cement physical composition

| Physical properties | Test results | Iraqi specification limit no. 5/2019 |

|---|---|---|

| Setting time (Vicat’s method) | ||

| Initial setting time (h:min) | 2:12 | ≥45 min |

| Final setting time (h:min) | 4:50 | ≤10 h |

| Expansion (autoclave method) | 0.01% | ≤0.8% |

| Specific surface area (Blaine’s method) (m2/kg) | 365 | ≥250 |

| Compressive strength (MPa) | ||

| For 2 days | 16.22 | ≥10 MPa |

| For 28 days | 48.80 | ≥42.5 MPa |

Cement chemical composition

| Chemical composition | Content % | Iraqi specification limit no. 5/2019 |

|---|---|---|

| MgO | 3.33 | ≤5% |

| L.O.I | 2.02 | ≤4% |

| SO3 | 2.01 | ≤2.8% |

| C3A | 6.37 | — |

| I.R. | 0.64 | ≤1.5% |

2.1.2 Fine aggregate

Natural sand was used for casting all samples with a maximum size of 4.75 mm. The test results are shown in Table 4 according to the limits of Iraqi Specification No. 45/1984 and its modifications [37]. According to the results of the sieve analysis, the adopted sand is classed as Zone 2.

Fine aggregate properties

| Tests | Cumulative passing (%) | Iraqi specification limit no. 45/1984 and its modifications | ||||

|---|---|---|---|---|---|---|

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | |||

| Sieve size (mm) | 10.0 | 100 | 100 | 100 | 100 | 100 |

| 4.75 | 97.2 | 90–100 | 90–100 | 90–100 | 95–100 | |

| 2.36 | 81.16 | 60–95 | 75–100 | 85–100 | 95–100 | |

| 1.18 | 65.36 | 30–70 | 55–90 | 75–100 | 90–100 | |

| 0.60 | 55.64 | 15–34 | 35–59 | 60–79 | 80–100 | |

| 0.30 | 27.32 | 5–20 | 8–30 | 12–40 | 15–50 | |

| 0.15 | 3.16 | 0–10 | 0–10 | 0–10 | 0–15 | |

| Sulfate contained (SO3) % | 0.39 | 0.5 (max.) | ||||

| Absorption% | 3.1 | — | ||||

| Specific gravity | 2.67 | — | ||||

2.1.3 Coarse aggregate

Crushed gravel siliceous aggregate of 10 mm maximum size was used in the concrete mixes. The graded crushed gravel was washed and dispersed in the air till the saturated dry surface condition was satisfied. The results of the test are shown in Table 5 according to the limits of Iraqi specification no. 45/1984 and its modifications [37].

Coarse aggregate properties

| Tests | % Passing by weight | Iraqi specification limit no. 45/1984 and its modification | |||

|---|---|---|---|---|---|

| 5–40 | 5–20 | 5–14 | |||

| Sieve Size (mm) | 75 | 100 | 100 | Not limited | Not limited |

| 63 | 100 | Not limited | Not limited | Not limited | |

| 37.5 | 100 | 95–100 | 100 | Not limited | |

| 20 | 100 | 35–70 | 95–100 | 100 | |

| 14 | 100 | Not limited | Not limited | 90–100 | |

| 10 | 83.4 | 10–40 | 30–60 | 50–85 | |

| 5 | 2.48 | 0–5 | 0–10 | 0–10 | |

| 2.36 | 0.36 | Not limited | Not limited | Not limited | |

| Sulfate contained (SO3) % | 0.06 | 0.1 (max.) | |||

| Absorption% | 0.65 | — | |||

| Specific gravity | 2.66 | — | |||

2.1.4 LECA

LECA with diameters between 4 and 10 mm as shown in Figure 1 was used. Tables 6 and 7 show the test results of LECA properties and grading, respectively.

LECA.

LECA properties

| Properties | Experimental value |

|---|---|

| Density (kg/m3) | 320 |

| Specific gravity | 0.55 |

| Water absorption% | 21.6 |

| Fineness modulus | 3 |

LECA grading

| Sieve size (mm) | % Passing by weight |

|---|---|

| 37.5 | 100 |

| 20 | 100 |

| 14 | 100 |

| 10 | 95.36 |

| 5 | 2.18 |

| 2.36 | 0.6 |

2.1.5 Silica fume

A very fine pozzolanic material (microsilica), product of Conmix, had adopted to produce self-compacted concrete (SCC) as an additive (pozzolanic material). The chemical and physical compositions of the silica are conformed to the ASTM C1240 [38], and the limitations are described in Tables 8 and 9.

Chemical properties of microsilica fume

| Oxide composition | Abbreviation | Oxide content (%) | Requirement of ASTM C1240 specification |

|---|---|---|---|

| Silica | SiO2 | 95.62 | 85.0 (min) |

| Sodium oxide | Na2O | 0.19 | — |

| Iron oxide | Fe2O3 | 0.048 | — |

| Alumina | Al2O3 | 0.034 | — |

| Lime | CaO | 1.44 | — |

| Magnesia | MgO | 0.38 | — |

| Potassium oxide | K2O | 1.12 | — |

| Sulfate | SO3 | 0.51 | — |

| Phosphorus pentoxide | P2O5 | 0.21 | — |

| Titanium dioxide | TiO2 | 0.0081 | — |

| Loss on ignition | L.O.I. | 3.74 | 6.0 (max) |

Physical properties of microsilica fume

| Physical properties | Results of MS | Requirement of ASTM C1240 Specification |

|---|---|---|

| Color | Grey to medium grey | |

| Strength Active Index with Portland cement at 7 days, min. percent of control | 129 | ≥105 |

| Specific surface area (m2/kg) | 22,000 | ≥15,000 |

| Percentage of retained on 45 μm (No. 325), max. (%) | 8 | ≤10 |

2.1.6 Superplasticizer

Sika’s ViscoCrete-5930 was the commercial name of the superplasticizer utilized in the concrete mixes to induce SCC for all specimens in this study. It is a high-performance superplasticizer additive for concrete that is based on an aqueous solution of modified polycarboxylate and agrees with ASTM-C-494 [39], types G and F, as well as BS EN 934 part 2 [40]. For optimal water reduction, the superplasticizer is added to the gaging water or poured it into the concrete mixer simultaneously with the water and mixed for at least 60 s. Table 10 shows the technical properties of ViscoCrete-5930 at 5–35°C.

Technical properties of ViscoCrete-5930

| 1 | Color | Turbid |

|---|---|---|

| 2 | Specific gravity | 1.095 ± 0.02 |

| 3 | Dosage | 0.8–2% liter by weight |

| 4 | Freezing point | ≈30°C |

| 5 | Cleaning | Washed with water |

| 6 | Form | Viscous liquid |

| 7 | Health and safety | Not classified as hazardous material |

| 8 | Fire | Non-flammable |

| 9 | Air entrainment | Typically, less than 2% additional air is entrained |

2.2 Tested specimens

This study involved casting and testing 60 cubes and 80 cylinders. The mix proportions are shown in Table 11. Cubes of 150 × 150 × 150 mm were used to measure compressive strength according to B.S.1881: part 116 [41]. Cylinders of 150 × 300 mm were used to measure splitting tensile strength and Ec following ASTM C496/C496M-17 [42] and ASTM C469/C469M-14 [43], respectively. Cubes of 100 × 100 × 100 mm were used to measure thermal conductivity. The curing process of the specimens is illustrated in Figure 2.

Details of considered mixes

| Mix type | Mix proportion (kg/m3) | SP (L/m3) | SF* (%) | fcu** (MPa) | ||||

|---|---|---|---|---|---|---|---|---|

| Water | Cement | Sand | Gravel | LECA | ||||

| M0 | 185 | 441 | 750 | 950 | 0 | 4 | 2 | 60.1 |

| M10 | 185 | 441 | 750 | 855 | 18.8 | 4 | 2 | 57.0 |

| M20 | 185 | 441 | 750 | 760 | 37.6 | 4 | 2 | 53.0 |

| M30 | 185 | 441 | 750 | 665 | 56.4 | 4 | 2 | 48.9 |

*Replacement by weight of cement.

**These values are the average of three control specimens.

Specimen curing process.

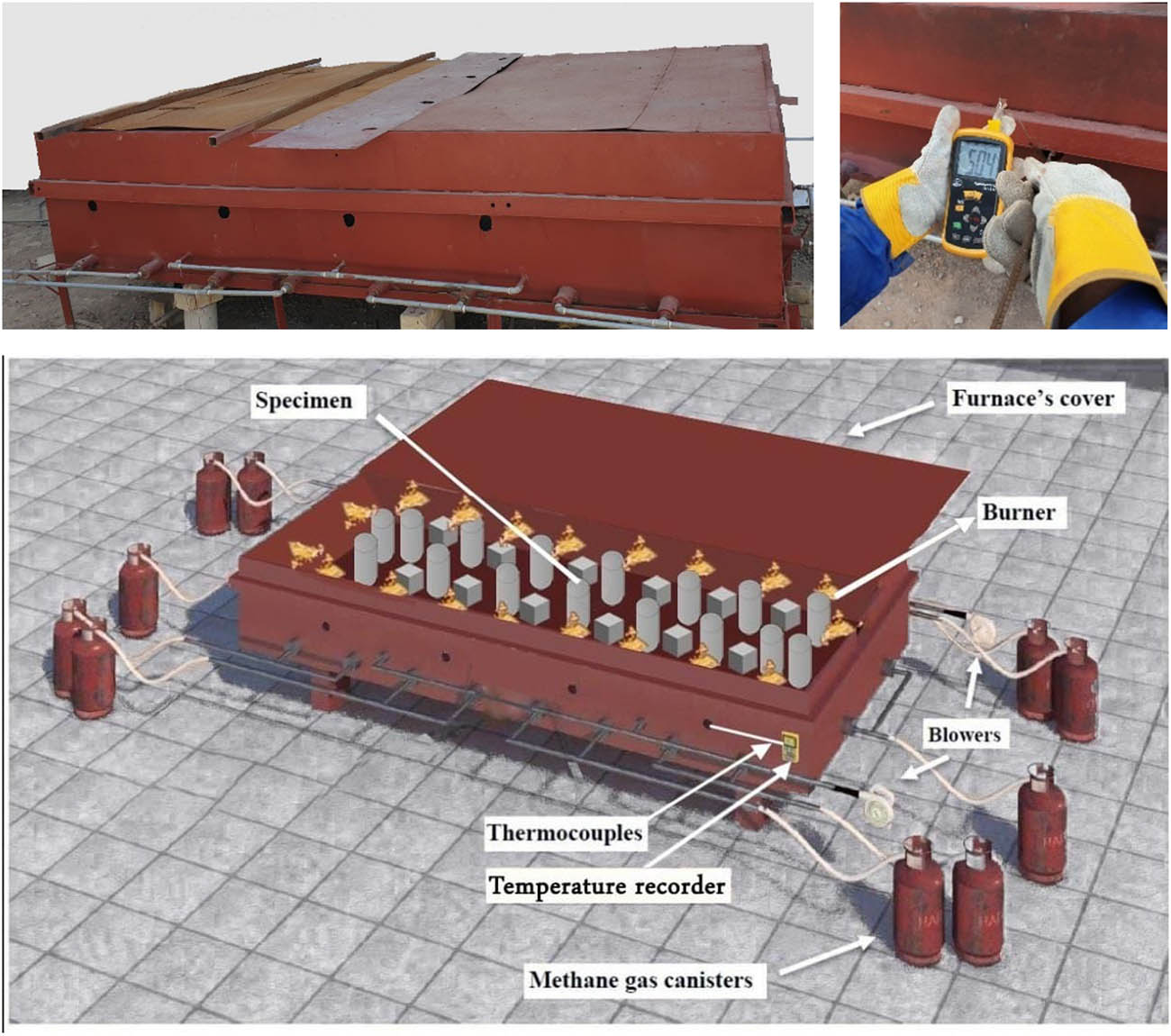

3 Burning and cooling

The specimens were burned by a direct fire flame under the same conditions (a steady-state temperature of 300, 400, 500, and 600°C, and a 1 h exposure time). ASTM E-119 Standard [44] was adopted for temperature–time relation requirements. The specimens were put inside a gas furnace, which has a fire chamber, steel framework, and steel columns (outer dimensions of 3.50 m in length, 2.00 m in width, and 0.80 m in height) with 20 gas burners, 8 for each pair of opposing longitudinal sides and 2 for each transverse side, connected to 10 methane gas canisters in the sidewalls at the base to deliver heat during the burning test (i.e., one methane gas canister for every two gas burners). Two blowers supplied furnace air during the fire test to maintain fire intensity and heat distribution as shown in Figure 3. The top cover is detachable which permits specimens to be put within the furnace. A digital thermometer reader (DT-612) with sensor wire type K was used to check the temperature of the specimen and furnace space over time. The fire flame was turned off after the burning stage, and the specimens were suddenly cooled by spraying them with water.

Specimens burning.

4 Results and discussion

4.1 Mass loss

The amount of mass loss for each considered concrete mix is shown in Table 12. As expected, all four mixes lose more weight as the steady-state temperature increases. The results show that the mass loss decreases when the amount of LECA content increases, as illustrated in Figure 4. This may be due to the increase in the effects of spalling [45,46,47], whose risk and intensity decrease as the content of LWA increases.

Percentage of mass loss

| Temp. (°C) | Mix type | |||||||

|---|---|---|---|---|---|---|---|---|

| M0 | M10 | M20 | M30 | |||||

| Density (kg/m3) | Mass loss (%) | Density (kg/m3) | Mass loss (%) | Density (kg/m3) | Mass loss (%) | Density (kg/m3) | Mass loss (%) | |

| 30 | 2,326 | — | 2,267 | — | 2,207 | — | 2,148 | — |

| 300 | 2,215 | 4.77 | 2,175 | 4.06 | 2,126 | 3.67 | 2,078 | 3.26 |

| 400 | 2,203 | 5.29 | 2,152 | 5.07 | 2,102 | 4.76 | 2,051 | 4.52 |

| 500 | 2,185 | 6.06 | 2,135 | 5.82 | 2,084 | 5.57 | 2,035 | 5.26 |

| 600 | 2,149 | 7.61 | 2,097 | 7.50 | 2,049 | 7.16 | 2,014 | 6.24 |

Specimens mass loss after fire exposure.

4.2 Compressive strength

The compressive strength of hardened concrete is a commonly known mechanical property that exhibits characteristics that can be associated with its strength. The results of this test were based on the average of three cubes at the test age for each adopted concrete mix. Table 13 shows the specimens’ residual compressive strength. The remaining compressive strength decreases more as the burning steady-state temperatures increase as shown in Figure 5. However, as the amount of LECA in the mix increased, the retention factor rose. The retention factor is the ratio of the remaining compressive strength of specimens after being exposed to a fire flame to the specimens’ compressive strength kept at room temperature. Concrete compressive strength drops sharply when exposed to high temperatures (after 300°C), that belongs to several reasons. One reason is the dehydration of concrete by losing free water, interlayer water, and chemically combined water which are essential for the strength and bonding of the concrete matrix. Another reason is the thermal expansion of concrete and its constituents, which causes internal stresses and cracks that weaken the concrete structure. A third reason is the chemical decomposition of some concrete components, such as calcium hydroxide and calcium silicate hydrate, which reduces the cementitious properties of the concrete [48,49]. The rate and extent of strength loss depend on the type and composition of concrete, as well as the heating rate and duration. Concrete that contains LECA has lower thermal conductivity and higher porosity. LECA’s porous structure provides a hideout for the evaporating water, resulting in less cracking and damage inside the concrete and it can better resist heat transfer and spalling [50], which may explain why increasing the LECA content in concrete leads to better strength retention.

Residual compressive strength

| Temp. (°C) | Mix type | |||||||

|---|---|---|---|---|---|---|---|---|

| M0 | M10 | M20 | M30 | |||||

| fcu (MPa) | Residual (%) | fcu (MPa) | Residual (%) | fcu (MPa) | Residual (%) | fcu (MPa) | Residual (%) | |

| 30 | 60.1 | — | 57.0 | — | 53.0 | — | 48.9 | — |

| 300 | 51.0 | 84.9 | 50.0 | 87.7 | 47.8 | 90.2 | 44.6 | 91.2 |

| 400 | 46.5 | 77.4 | 46.8 | 82.1 | 45.5 | 85.8 | 42.6 | 87.1 |

| 500 | 41.2 | 68.6 | 43.5 | 76.3 | 41.8 | 78.9 | 39.0 | 79.8 |

| 600 | 34.3 | 57.1 | 38.1 | 66.8 | 37.0 | 69.8 | 35.2 | 72.0 |

Compressive strength retention after fire exposure.

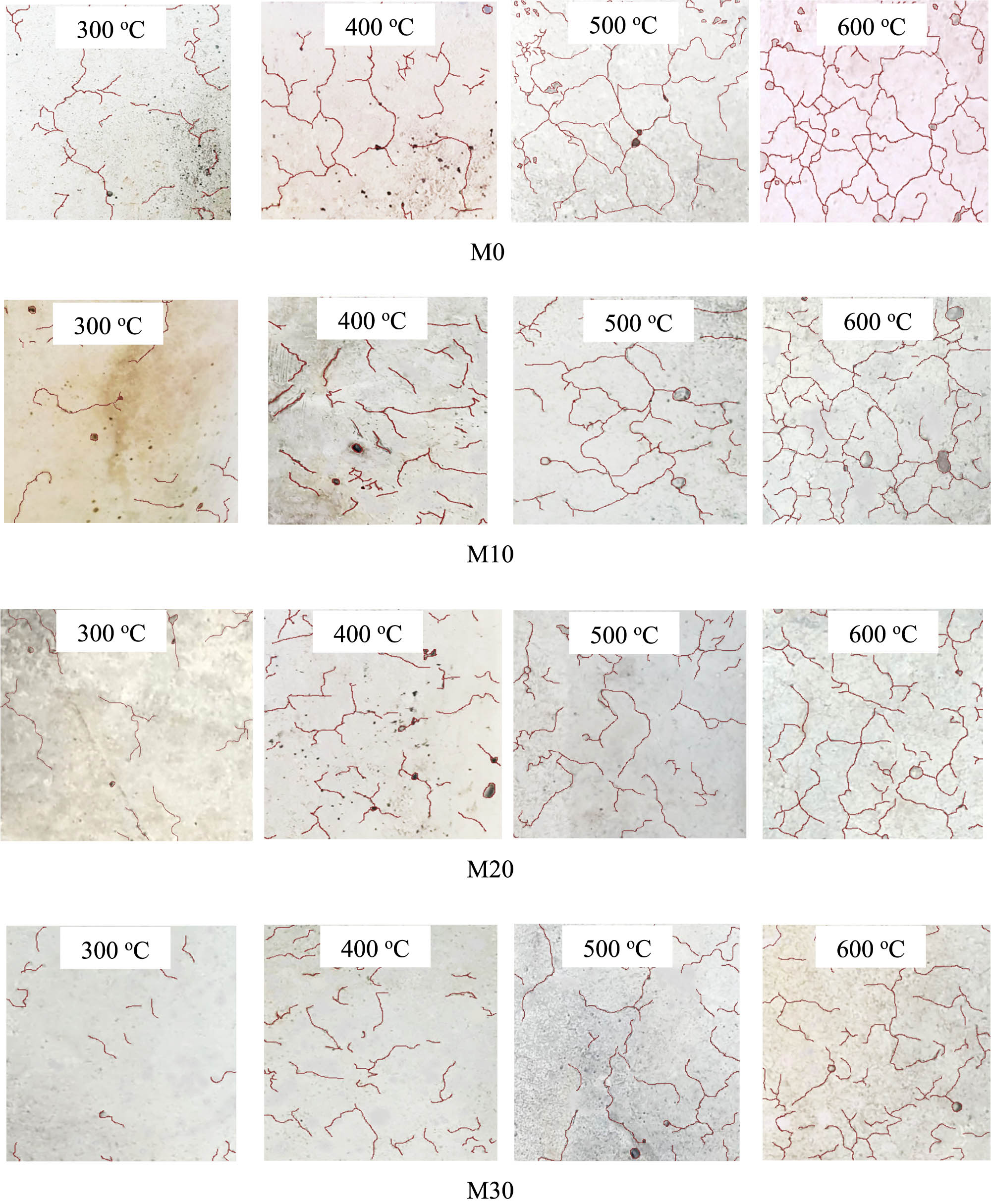

4.3 Tensile strength

Cylindrical specimens of 150 × 300 mm, according to ASTM C496/C496M-17 [42], were subjected to a splitting tensile test before and after being exposed to a fire flame. Table 14 depicts the tensile strength retention of the burned specimens. It is clear from Table 14 and Figure 6 that the specimen’s tensile strength reduces considerably as the burning steady-state temperatures increase. However, increasing the content of LECA in concrete leads to better strength retention. Thermal stress-induced cracking is one of the primary effects of exposure to high temperatures [50,51]. With a rise in the specimen’s maximum temperature, these cracks tend to get wider and deeper as shown in Figure 7 and 8. It is understood that the porosity of mixtures that contain LECA will reduce thermal stresses and thus fewer cracks will occur, resulting in greater strength retention.

Residual splitting tensile strength

| Temp. (°C) | Mix type | |||||||

|---|---|---|---|---|---|---|---|---|

| M0 | M10 | M20 | M30 | |||||

| f t (MPa) | Residual (%) | f t (MPa) | Residual (%) | f t (MPa) | Residual (%) | f t (MPa) | Residual (%) | |

| 30 | 4.46 | — | 4.16 | — | 3.88 | — | 3.56 | — |

| 300 | 2.36 | 52.9 | 2.64 | 63.5 | 2.78 | 71.6 | 2.76 | 77.5 |

| 400 | 1.78 | 39.9 | 2.12 | 51.0 | 2.35 | 60.6 | 2.41 | 67.7 |

| 500 | 1.39 | 31.2 | 1.72 | 41.3 | 1.89 | 48.7 | 1.90 | 53.4 |

| 600 | 1.00 | 22.4 | 1.36 | 32.7 | 1.62 | 41.8 | 1.73 | 48.6 |

Tensile strength retention after fire exposure.

Cracks pattern of the burned specimens at steady-state temperature of 500°C.

Concrete surface texture of the specimens after fire exposure.

4.4 Static Ec

The Ec stands out among the concrete’s important mechanical properties. Following ASTM specification (C469/C469M-14) [43], it could be obtained by a compressive test on the cylinders of concrete. For hardened concrete, it is the stress-to-strain ratio changes in the elastic range. It can be known as the secant in the stress–strain curve at the point congruous to 40% from the ultimate strength [52]. The experiment results indicate that the Ec decreases significantly when exposed to high fire temperatures. LECA contains thousands of small voids in the clay, forming a honeycomb structure that gives LECA its low density, high porosity, and low thermal conductivity. These properties mean that LECA can insulate the concrete from heat transfer, prevent spalling and cracking due to thermal stress, and retain its mechanical strength and thermal insulation properties better than normal aggregate under fire exposure [53]. So, mixtures containing LECA keep their stiffness better due to less heat degradation. The variations in the specimens’ residual Ec are depicted in Table 15 and Figure 9.

Residual Ec

| Temp. (°C) | Mix type | |||||||

|---|---|---|---|---|---|---|---|---|

| M0 | M10 | M20 | M30 | |||||

| Ec (MPa) | Residual (%) | Ec (MPa) | Residual (%) | Ec (MPa) | Residual (%) | Ec (MPa) | Residual (%) | |

| 30 | 31,606 | — | 27,896 | — | 25,687 | — | 23,453 | — |

| 300 | 18,056 | 57.1 | 17,744 | 63.6 | 17,163 | 66.8 | 16,228 | 69.2 |

| 400 | 14,030 | 44.4 | 14,242 | 51.1 | 13,894 | 54.1 | 13,222 | 56.4 |

| 500 | 9,208 | 29.1 | 10,109 | 36.2 | 9,657 | 37.6 | 9,151 | 39.0 |

| 600 | 5,061 | 16.0 | 6,222 | 22.3 | 6,023 | 23.4 | 5,704 | 24.3 |

Ec retention after fire exposure.

4.5 Thermal conductivity

Concrete’s thermal conductivity is influenced by the thermal properties of its phases, particularly the paste, and aggregates. As aggregates mainly account for 70% of the concrete volume, the incorporation of low thermal conductivity aggregates may lead to a considerable improvement in the concrete’s thermal insulation capabilities [54,55]. Figure 10 shows the test of the thermal conductivity and Table 16 shows the thermal conductivity experimental results for all mixes. The experiment findings showed that the concrete thermal conductivity reduces by increasing the content of the LECA and hence enhances its thermal insulation. The enhanced thermal insulation capabilities are mostly due to the poor thermal conductivity of the air confined in the porous structure of the LECA [56,57].

Thermal conductivity test.

Experimental results of the thermal conductivity

| Mix type | Thermal conductivity (W/m K) |

|---|---|

| M0 | 1.4889 |

| M10 | 1.1667 |

| M20 | 1.0912 |

| M30 | 1.0410 |

5 Conclusion

The following are the major findings:

The density, compressive strength, tensile strength, and Ec of concrete are all decreased when LECA is used as a partial volumetric replacement for the coarse aggregate, and the amount of reduction in these properties increases with the increase in the content of LECA.

Adding LECA as a partial volumetric replacement for the coarse aggregate reduces the mass loss due to the fire flame effect for all the considered burning steady-state temperatures.

Concrete’s residual compressive strength decreases with burning steady-state temperature, whereas greater LECA content led to better strength retention. Where the residual compressive strength at 600°C was 57.1 and 72.0% for the replacement ratios 0 and 30%, respectively.

The tensile strength reduces significantly as the specimen’s burning steady-state temperature increases. However, increasing the LECA content in concrete leads to better strength retention.

The Ec reduces at high temperatures. The concrete that contains LECA was more resistant to damage, and increasing the LECA content in concrete leads to better behavior.

Also, by increasing the LECA content, the thermal conductivity of the concrete decreases, thus increasing the thermal insulation of the concrete.

Deeper investigation is recommended including the mesoscopic scale of LECA that is used in concrete to resist fire exposure.

Acknowledgements

The author is grateful to the staff in the Civil Department at the Engineering College, Baghdad University, as well as the staff in the Construction Tests Laboratory at the Kut Technical Institute.

-

Funding information: The authors state no funding is involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Riley M. Possible new method for the assessment of fire-damaged concrete. Mag Concr Res. 1991;43(155):87–92.10.1680/macr.1991.43.155.87Search in Google Scholar

[2] Bentz D. Transient plane source measurements of the thermal properties of hydrating cement pastes. Mater Struct. 2007;40(10):1073–80.10.1617/s11527-006-9206-9Search in Google Scholar

[3] Bentz DP, Peltz MA, Duran-Herrera A, Valdez P, Juarez CA. Thermal properties of high-volume fly ash mortars and concretes. J Build Phys. 2011;34(3):263–75.10.1177/1744259110376613Search in Google Scholar

[4] Demirboğa R, Akif Kaygusuz M, Polat R. Effect of glass fiber‐reinforced polymer and epoxy injection on compressive strength of elevated temperature damaged concrete. Fire Mater. 2013;37(2):100–13.10.1002/fam.2116Search in Google Scholar

[5] Mohammed SD. Influence of fire-flame duration and temperature on the behavior of reinforced concrete beam containing water absorption polymer sphere: Numerical investigation. J Eng. 2022;28(11):67–84.10.31026/j.eng.2022.11.06Search in Google Scholar

[6] Mohammed SD, Fawzi NM. Fire flame influence on the behavior of reinforced concrete beams affected by repeated load. J Eng. 2016;22(9):206–23.10.31026/j.eng.2016.09.13Search in Google Scholar

[7] Hammadi AA, Izzat AF, Farhan JA. Effect of fire flame (high temperature) on the self compacted concrete (SCC) one way slabs. J Eng. 2012;18(10):1083–99.10.31026/j.eng.2012.10.01Search in Google Scholar

[8] Hammadi F. Effect of fire flame (high temperature) on the behavior of axially loaded reinforced SCC short columns. J Eng. 2012;18(8):889–904.10.31026/j.eng.2012.08.03Search in Google Scholar

[9] Leca AE. Catalog [Internet]. 2017. Available from: [https://leca.ae/Catalog/].Search in Google Scholar

[10] Alexander MG. Engineering and transport properties of the interfacial transition zone in cementitious composites. Champs-sur-Marne, France: Rilem Publications; 1999.Search in Google Scholar

[11] Rashad AM. Mitigating the elevated temperature effects and predicting the residual strength of loaded RC short columns [Doctoral dissertation]. Structural Engineering, Faculty of Engineering, Cairo University; 2005.Search in Google Scholar

[12] Nkansah MA, Christy AA, Barth T, Francis GW. The use of lightweight expanded clay aggregate (LECA) as sorbent for PAHs removal from water. J Hazard Mater. 2012;217:360–5.10.1016/j.jhazmat.2012.03.038Search in Google Scholar PubMed

[13] Bundschuh J, Armienta M, Birkle P, Bhattacharya P, Matschullat J, Mukherjee A. Natural arsenic in groundwaters of Latin America. Boca Raton (FL), USA: CRC Press; 2008.Search in Google Scholar

[14] Shafigh P, Hassanpour M, Razavi SV, Kobraei M. An investigation of the flexural behaviour of reinforced lightweight concrete beams. Int J Phys Sci. 2011;6(10):2414–21.Search in Google Scholar

[15] Kilinç K, Karasu B, Kaya G, Kivrak S. A preliminary research on the properties of lightweight expanded clay aggregate. In: Arioz O, editor. Proceedings of the 11th International Congress on the Chemistry of Cement (ICCC 2008); 2008 Sep 8–13; Montreal, Canada: ICCC; 2008. p. 1–10.Search in Google Scholar

[16] Baker M, Simkins S, Spokas L, Veneman P, Xing B. Comparison of phosphorus sorption by light-weight aggregates produced in the United States. Pedosphere. 2014;24(6):808–16.10.1016/S1002-0160(14)60068-0Search in Google Scholar

[17] Rashad AM. Lightweight expanded clay aggregate as a building material–An overview. Constr Build Mater. 2018;170:757–75.10.1016/j.conbuildmat.2018.03.009Search in Google Scholar

[18] Sepehr MN, Kazemian H, Ghahramani E, Amrane A, Sivasankar V, Zarrabi M. Defluoridation of water via light weight expanded clay aggregate (LECA): Adsorbent characterization, competing ions, chemical regeneration, equilibrium and kinetic modeling. J Taiwan Inst Chem Eng. 2014;45(4):1821–34.10.1016/j.jtice.2014.02.009Search in Google Scholar

[19] Al-Bahar S, Bogahawatta V. Letters, notes, and comments-development of lightweight aggregates in Kuwait. Arab J Sci Eng. 2006;31(1):231.Search in Google Scholar

[20] Islam MS, Sharmin N, Moniruzzaman M, Akhtar US. Effect of soda lime silica glass waste on the basic properties of clay aggregate. Int J Sci Eng Res. 2016;7(4):149–53.Search in Google Scholar

[21] Sajedi F, Shafigh P. High-strength lightweight concrete using LECA, silica fume, and limestone. Arab J Sci Eng. 2012;37:1885–93.10.1007/s13369-012-0285-3Search in Google Scholar

[22] Sarkar SL, Satish C, Leif B. Interdependence of microstructure and strength of structural lightweight aggregate concrete. Cem Concr Compos. 1992;14(4):239–48.10.1016/0958-9465(92)90022-NSearch in Google Scholar

[23] Paul S, Babu G. Mechanical properties of lightweight aggregate geo polymer concrete using lightweight expanded clay aggregate. Trans Eng Sci. 2014;2(10):33–5.Search in Google Scholar

[24] Zhang M-H, Gjørv OE. Penetration of cement paste into lightweight aggregate. Cem Concr Res. 1992;22(1):47–55.10.1016/0008-8846(92)90135-ISearch in Google Scholar

[25] Zendehzaban M, Sharifnia S, Hosseini SN. Photocatalytic degradation of ammonia by light expanded clay aggregate (LECA)-coating of TiO2 nanoparticles. Korean J Chem Eng. 2013;30:574–9.10.1007/s11814-012-0212-zSearch in Google Scholar

[26] Buchanan AH, Abu AK. Structural design for fire safety. Chicheser, UK: John Wiley & Sons; 2017.10.1002/9781118700402Search in Google Scholar

[27] Ma Q, Li Z, Li B, Wang L, Wang Y. Mechanical properties of concrete at high temperature – A review. Constr Build Mater. 2015;93:371–83.10.1016/j.conbuildmat.2015.05.131Search in Google Scholar

[28] Real S, Diaz E, Real E, Gonzalez M. Contribution of structural lightweight aggregate concrete to the reduction of thermal bridging effect in buildings. Constr Build Mater. 2016;121:460–70.10.1016/j.conbuildmat.2016.06.018Search in Google Scholar

[29] ASTM International. Standard specification for lightweight aggregates for structural concrete. ASTM C330/C330M-17a. West Conshohocken (PA), USA: ASTM International; 2017.Search in Google Scholar

[30] Tanyildizi H, Coskun A. The effect of high temperature on compressive strength and splitting tensile strength of structural lightweight concrete containing fly ash. Constr Build Mater. 2008;22(11):2269–75.10.1016/j.conbuildmat.2007.07.033Search in Google Scholar

[31] Committee ACI, editor. Guide for determining the fire endurance of concrete elements. Detroit: American Concrete Institute; 1982. (ACI 216R-81).Search in Google Scholar

[32] Abbu M, Al-Attar A, Abd Alrahman S, Al-Gburi M. The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures. J Mech Behav Mater. 2023;32(1):20220249.10.1515/jmbm-2022-0249Search in Google Scholar

[33] Najaf E, Orouji M, Zahrai SM. Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber. Nonlinear Eng. 2022;11(1):58–70.10.1515/nleng-2022-0008Search in Google Scholar

[34] Dakhela ZH, Mohammed SD. Response of composite steel-concrete cellular beams of different concrete deck types under harmonic loads. J Mech Behav Mater. 2022;31(1):127–34.10.1515/jmbm-2022-0014Search in Google Scholar

[35] Dakhel ZH, Mohammed SD. Castellated beams with fiber-reinforced lightweight concrete deck slab as a modified choice for composite steel-concrete beams affected by harmonic load. Eng Technol & Appl Sci Res. 2022;12(4):8809–16.10.48084/etasr.4987Search in Google Scholar

[36] Central Organization for Standardization and Quality Control (COSQC). Standard specification for Portland cement. IQ.S 5:2019. Baghdad, Iraq: COSQC; 2019.Search in Google Scholar

[37] Central Organization for Standardization and Quality Control (COSQC). Specification No.45 for natural sources of aggregate used in concrete and construction works. IQ.S 45:1984. Baghdad, Iraq: COSQC; 1984.Search in Google Scholar

[38] ASTM International. Standard specification for use of silica fume as a mineral admixture in cement concrete, mortar, and grout. ASTM C1240-03a. West Conshohocken (PA), USA: ASTM International; 2003.Search in Google Scholar

[39] ASTM International. Standard specification for chemical admixtures for concrete 1. ASTM C494/C494M-05a. West Conshohocken (PA), USA: ASTM International; 2005.Search in Google Scholar

[40] British Standards Institution. BS EN 934-2. Admixtures for Concrete, Mortar and Grout. Concrete Admixtures-Definitions, Requirements, Conformity, Marking and Labeling. London, UK: BSI; 2001.Search in Google Scholar

[41] British Standards Institution (BSI). Testing hardened concrete Part 3: Compressive strength of test specimens. BS EN 12390-3:2002. London, UK: BSI; 2002.Search in Google Scholar

[42] ASTM International. C496/C496M-17. Standard test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. West Conshohocken (PA), USA: ASTM International; 2017.Search in Google Scholar

[43] ASTM International. ASTM C469, Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. West Conshohocken (PA), USA: ASTM International; 2014.Search in Google Scholar

[44] American Society for Testing and Materials. E 119-83. Standard Methods of Fire Tests of Building Construction and Materials. West Conshohocken (PA), USA: ASTM International; 1983.Search in Google Scholar

[45] Sarker PK, Kelly S, Yao Z. Effect of fire exposure on cracking, spalling and residual strength of fly ash geopolymer concrete. Mater Des. 2014;63:584–92.10.1016/j.matdes.2014.06.059Search in Google Scholar

[46] Phan LT. Pore pressure and explosive spalling in concrete. Mater Struct. 2008;41(10):1623–32.10.1617/s11527-008-9353-2Search in Google Scholar

[47] Shah A, Ries J, Sagiroglu S, Ceylan H. Spalling behaviour of nano SiO2 high strength concrete at elevated temperatures. MATEC Web Conf. 2013;6:01009.10.1051/matecconf/20130601009Search in Google Scholar

[48] Kuehnen R, Youssef MA, El-Fitiany SF. Influence of natural fire development on concrete compressive strength. Fire. 2022;5(2):34.10.3390/fire5020034Search in Google Scholar

[49] Guo Z, Shi X. Experiment and Calculation of Reinforced Concrete at Elevated Temperatures. Oxford, UK: Butterworth-Heinemann Elsevier Ltd; 2011.10.1016/B978-0-12-386962-3.10001-4Search in Google Scholar

[50] Dabbaghi F, Dehestani M, Yousefpour H. Residual mechanical properties of concrete containing lightweight expanded clay aggregate (LECA) after exposure to elevated temperatures. Struct Concr. 2022;23(4):2162–84.10.1002/suco.202000821Search in Google Scholar

[51] Krishna DA, Priyadarsini R, Narayanan S. Effect of elevated temperatures on the mechanical properties of concrete. Procedia Struct Integr. 2019;14:384–94.10.1016/j.prostr.2019.05.047Search in Google Scholar

[52] Mesbah HA, Lachemi M, Aitcin PC. Determination of elastic properties of high-performance concrete at early ages. Mater J. 2002;99(1):37–41.10.14359/11314Search in Google Scholar

[53] Kumar R, Lakhani R, Kumar A. Physico-mechanical and thermal properties of lightweight structural concrete with light expanded clay aggregate for energy-efficient buildings. In: Gupta AK, Shukla SK, Azamathulla H, editors. Advances in Construction Materials and Sustainable Environment. Lecture Notes in Civil Engineering. Singapore: Springer; 2021. p. 175–85.10.1007/978-981-16-6557-8_14Search in Google Scholar

[54] Chi J, Huang R, Yang C-C, Chang J-J. Effect of aggregate properties on the strength and stiffness of lightweight concrete. Cem Concr Compos. 2003;25(2):197–205.10.1016/S0958-9465(02)00020-3Search in Google Scholar

[55] Neville AM. Properties of concrete. Vol. 4. Longman London; 1995.Search in Google Scholar

[56] Demirboğa R, Gül R. The effects of expanded perlite aggregate, silica fume and fly ash on the thermal conductivity of lightweight concrete. Cem Concr Res. 2003;33(5):723–7.10.1016/S0008-8846(02)01032-3Search in Google Scholar

[57] EuroLightCon L. LWAC material properties state-of-the-art. Economic design and construction with light weight aggregate concrete. Delft, Netherlands: Delft University of Technology; 1998. p. 47–8.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil