Abstract

The high-temperature corrosion of turbine blades poses a serious threat to the efficiency of electrical gas power stations, which results in heavy economic losses. In the present study, the Inconel 738 low-carbon steel utilized in the turbine blades was coated on alumina (Al2O3) in a variety of percentages of carbon nanotubes (4, 6, and 8 wt%) using the plasma spray technique. The behavior of the Inconel 738LC alloy with and without artificial ash (67 wt% H2SO4 and 33 wt% V2O5) at different temperatures (650, 750, 850, and 950°C) was investigated. The cycles of hot corrosion and oxidation were achieved in an electric furnace for 10 cycles of 5 h each. After each cycle, the weight changes were measured and recorded. The SEM and XRD achieved for all the specimens were noted, before and post the corrosion.

1 Introduction

Gas power plants in Iraq represent an important resource of electrical energy. To ensure the highest performance and efficiency in these plants, numerous components and units must, of necessity, correctly work together. The gas turbine is the principal unit, the very heart as it were, containing a large variety of highly advanced materials called superalloys, which can resist extreme thermal and chemical environments [1]. The nickel-based superalloys display face-centered cubic (fcc) solid solutions (γ) with sufficient quantities of Al and Ti, to produce the Ni3(Ti, Al), fcc γ′ precipitate, and M23C6/M6C carbides that are present at the grain boundaries [2,3]. Turbine blade failure stops the turbines from working, producing a power plant outage that can stretch from 1 to 4 weeks or even longer at times, depending upon the amount of damage done and the technique adopted to restore the machine back to normal running, all causing severe financial losses [4]. A few of the causes that lead to failure, either rapidly or slowly, are hot exhaust gases, high pressure, high speed, and the presence of heavy fuel contaminants. The most dominant reasons for failure induced by the high temperatures and presence of dangerous pollutants include hot corrosion (HC) and erosion corrosion [5]. For HC to occur no electrolyte environment is required; it takes place because of the deposition of impurities and salts like sodium sulfate and vanadium oxides [6].

Vanadium, an impurity present in fuel oil, can cause huge corrosion problems due to the formalization of V2O5, the melting point of which is 670°C [7,8,9]. High-temperature coatings can raise the corrosion resistance of Ni-based superalloys. Hence, the NiBSs find extensive use in gas turbine blades [10,11]. In fact, TBC is a kind of ceramic coating that is spread onto the constituents or elements that comprise a system to ensure the highest protection possible, against the most intense and extreme operating temperatures. A TBC, therefore, is composed of a metal bond coat, a metal substrate, and a ceramic top coat. Under harsh and severely intense settings of working conditions, the intermediate bond coat (MCrAlY) plays a pivotal part in the adherence of the ceramic top coat and thus raises the resistance to attack, normally induced by the molten salt and oxygen [12,13,14]. As they are well known for their remarkable mechanical properties, carbon nanotubes (CNTs) are widely used to create aluminum-based composites; the CNTs have been found to function as bridges across the voids and cracks and are distributed uniformly in the aluminum matrix [15]. Due to these good qualities, the coatings are deposited via the plasma spraying technique onto most materials that act as the substrate and which possess a similar melting point, such as metal alloys, ceramics, and cermet. Indeed, the TBCs sprayed with plasma have low thermal conductivity values and exceptional chemical stability, even when the temperatures increase to high levels [16,17,18].

The thermal coating of Al2O3 and its effects on the electrochemical and mechanical properties had been studied and reviewed by many authors. Thermal coating of Al2O3 has many applications in different fields of industry [19,20,21,22,23]. The novelty of the current study can be summarized by the following statements. Due to their exceptional mechanical properties of CNTs are used to fabricate aluminum-based composites. Also, CNTs form bridges across the voids and cracks when uniformly dispersed in the aluminum matrix. The uniform dispersion of CNTs in the aluminum matrix led to improve mechanical properties such as mechanical strength, thermal conductance, and electrical conductivity. CNTs are the strongest materials ever discovered with tensile strength reported to be 50 times that of steel and also have conductivity 1,000 times that of copper.

2 Experimental work

Specimens were collected by cutting the turbine blade made of Inconel 738LC to the specific dimensions of 20 mm × 15 mm × 3.5 mm of length, width, and thickness, respectively. Once these specimens were cut, they were ground with SiC grinding papers. Next, alumina paste was used to polish them, the chemical composition of the specimens is given in Table 1, and all tests were conducted according to ASTM standards.

Chemical composition and mechanical properties of Inconel 738LC specimen

| Chemical composition | Element | Ti | Cr | Fe | Co | Nb | Mo | Ta | W | Ni | LEC |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt% | 3.2 | 15.7 | 0.07 | 8.1 | 0.8 | 1.8 | 1.5 | 2.5 | Bal. | 3.4 | |

| Mechanical properties | Corrosion resistance | Oxidation materials | High mechanical loads | Stable passivation | High-temperature application | ||||||

As displayed in Table 2, the specimens were coated with an intermediate coating layer termed the bond layer, which has a thickness of 150 μm. Next, the specimens were coated with an outer ceramic layer made up of alumina having different weight percentages from the CNTs.

Chemical composition of the bond layer

| Element | Ni | Cr | Al | Y | Co |

|---|---|---|---|---|---|

| wt% | 3.2 | 21 | 18 | 0.5 | Bal |

The plasma spraying technique involved the use of a special spraying unit (semi-automated), and the coating was accomplished by atmospheric plasma. The coating materials were combined in a ball mill once the bond layer coating was sprayed on the specimens whose surfaces were prepared before this step. The fuel contaminations were prepared by mixing 67 wt% of Na2SO4 and V2O5. The HC weight change tests were then performed at 650, 750, 850, and 950°C, prior to and after post-coating the specimens with the contamination, by ash (67 wt% Na2SO4 and V2O5).

3 Results and discussion

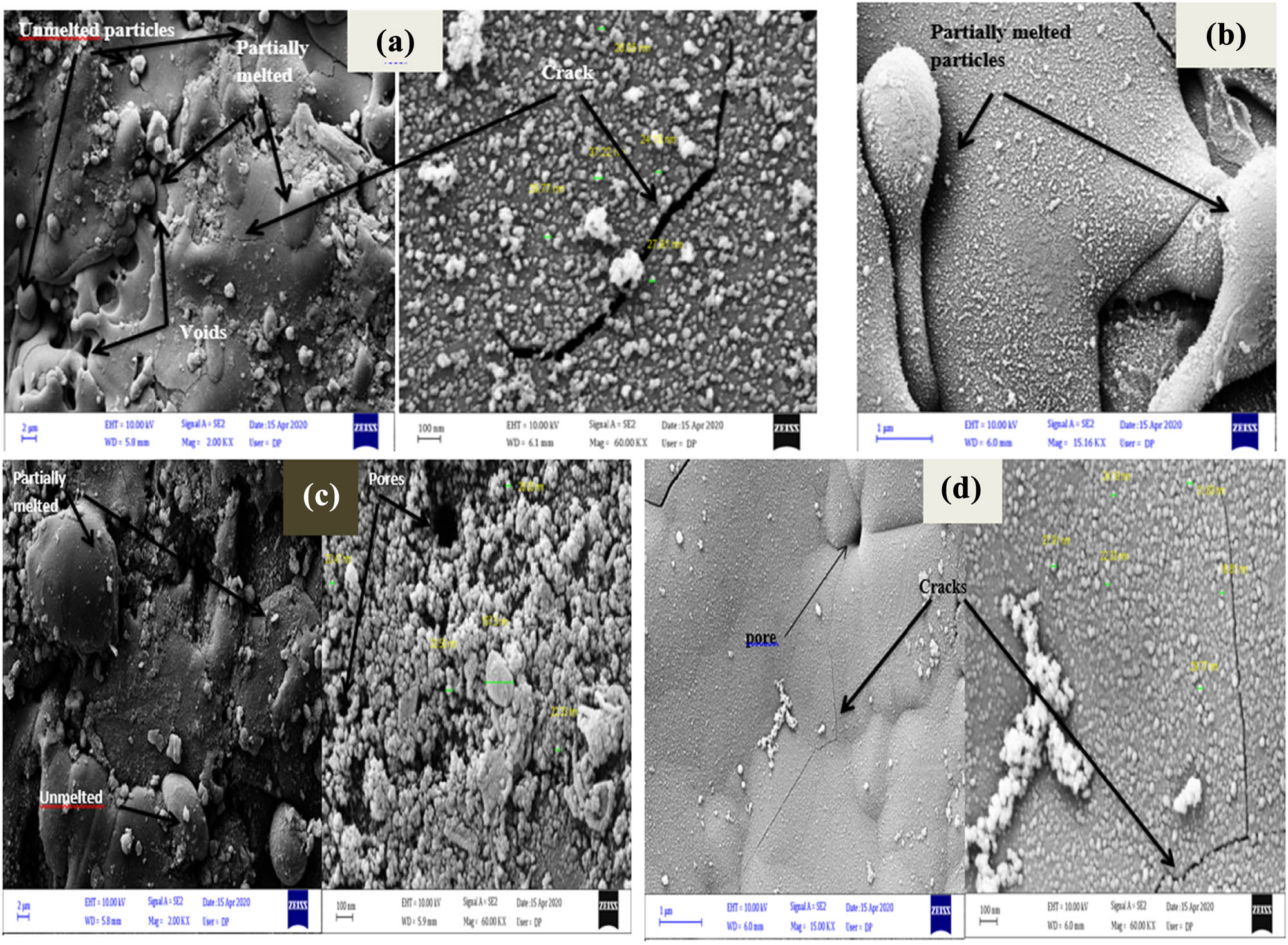

From Figure 1, the SEM of the coated specimens is shown; with (a) 100% Al2O3, (b) 96 wt% Al2O3–4 wt% CNTs, (c) 94 wt% Al2O3–6 wt% CNTs, and (d) 92 wt%; Al2O3–8 wt% CNTs. These images show that the coating layers are relatively high in porosity; the different coating layers show differences based on the degree of porosity. Microcracks may be present, initiated by the thermal stresses produced during the coating process. When porosity and microcracks are present, they prove to be detrimental to the coating properties. The SEM micrographs clearly showed partially melted and nonmelted particles or particle clusters, in almost all the coating layers.

SEM showed that the specimens coated with (a) 100 wt% A2O3, (b) 96 wt% Al2O3–4 wt% CNTs, (c) 94% Al2O3–6 wt% CNTs, and (d) 92 wt% Al2O3–8 wt% CNTs.

Agglomeration of the CNT particles or other particles in the nanoscale may be the cause for the poor or partial melting. Voids may be produced during the plasma spray process, as indicated through the SEM images. These voids result from a sequence of the plasma torch moving back and forth. They may be highly detrimental to the corrosion protection behavior as they could open a path for the passage of oxygen into the substrate. This action was used to analyze the SEM images and thus assess the porosity percentage of the coating layer. During the plasma spraying process, the pores and micro-cracks can arise from a variety of sources, for instance, the entrapped gases, incomplete filling in the splats, which showed quick solidification, the shrinking of the splats during the latter process, and so on. The porosity of the plasma sprayed coatings can range from below 2% to an excess of 20%, depending on the coating process parameters, as well as the properties of the coating powders utilized. Specimens coated with (b) 96 wt% Al2O3–4 wt% CNTs, (c) 94 wt% Al2O3–6 wt% CNTs, and (d) 92 wt% Al2O3–8 wt% CNTs possess a relatively lesser degree of porosity. The splats are smaller in size and irregular in shape. These images indicate that the coatings have displayed a less degree of porosity, as well as fewer microcracks.

Measurements of the roughness of the surface coating layers are shown in Table 3. The C-coated specimen showed the highest roughness values, while the B specimen revealed the lowest surface roughness values, by AFM. Porosity induced by the plasma spray coating revealed a relatively high degree of porosity due to this technique, which subsequently tends to raise the surface roughness. The roughness of a surface can have a significant part to play in its corrosion performance. Agglomeration, inevitable in nanoscale powders, could result also in raised surface roughness of the coated specimen. This result corresponds to that of the researcher [24]. In Figure 2, the three-dimensional images and the grain histogram are revealed by the AFM test. The average roughness enables the sharpness of the surface of the film to be described; this is defined as the mean height of the surface from the center of the plane, in a given area.

Measurements of roughness of coated specimens

| Specimens | A | B | C | D |

|---|---|---|---|---|

| Average roughness by AFM (nm) | 23.8 | 9.2 | 63.1 | 22.6 |

AFM showed the specimens coated with: (a) 100 wt% A2O3, (b) 96 wt% Al2O3–4 wt% CNTs, (c) 94 wt% Al2O3–6 wt% CNTs, and (d) 92 wt% Al2O3–8 wt% CNTs.

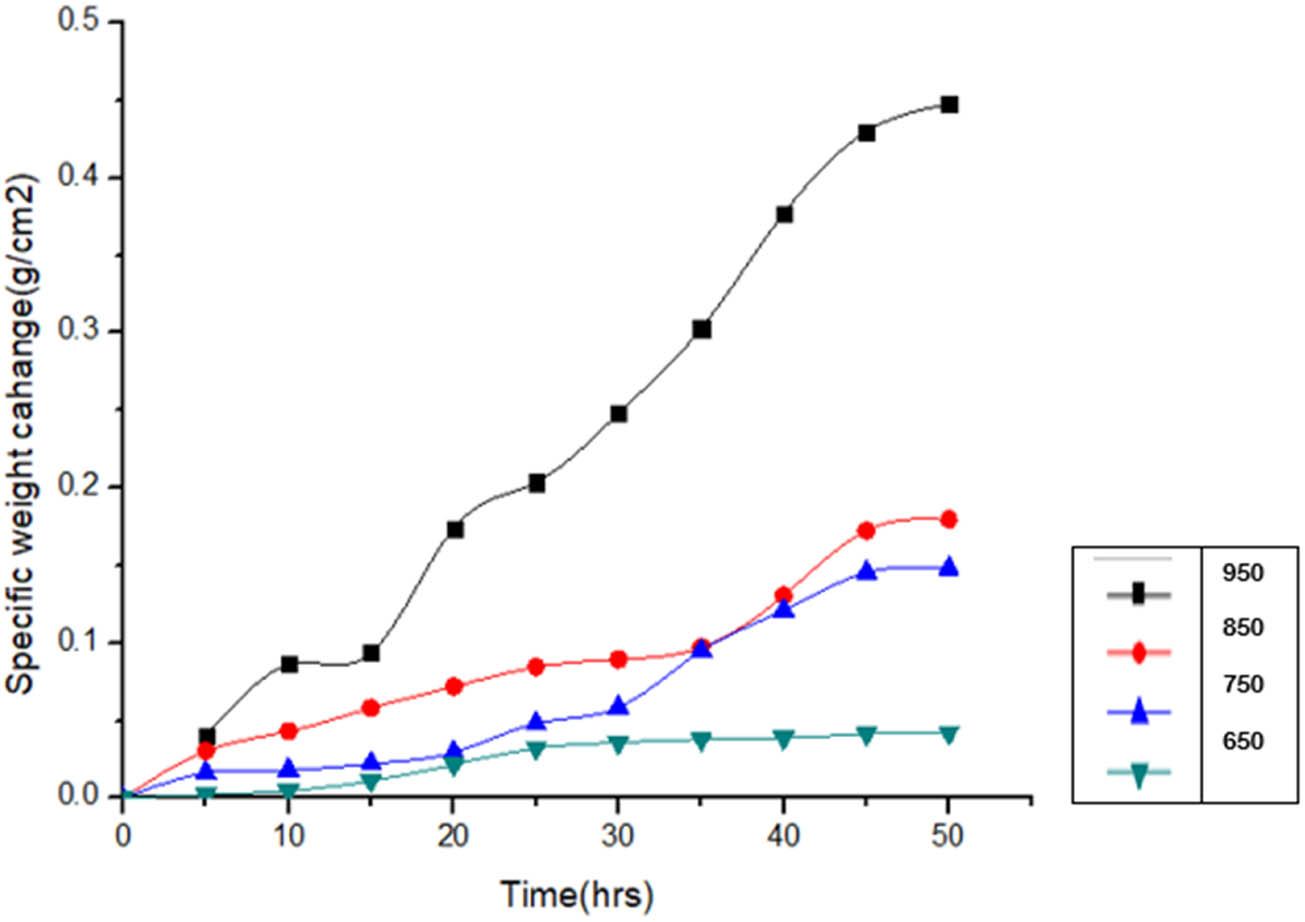

The coat is used to study the actions of the specimen that had undergone continuous changes in weight, during the test intervals. From Figure 3, the weight change per unit surface area is evident as a function of time and expressed in the number of cycles for the bare specimens. The curve shows clearly that the maximum weight gain occurs at 950℃, which is possibly due to the high oxidation rate at this temperature. With the increase in time, the thickness of the oxide layer also increased, i.e., the stresses in the layer increased because of the cracks and voids that were present.

Bare base alloy oxidation behavior at 950°C temperature at different times.

In Figure 4, the XRD results of the specimens exposed to oxidation reveal that 650, 750, 850, and 950℃ for 50 h are listed. The oxides formed include NiO, TiO2, and spinel phase NiCr2O4. All these oxide types are the pores that do not adhere very well to the base metal surface, and hence, they are not the protective oxide layer. The Cr2O3 that was visible at the interface between the alloy matrix was a layer abundant in nickel oxide. When the Cr2O3 sub-layer was continuous, an outer NiO scale was formed, with an interior layer, which sometimes appeared porous in nature, composed of NiO, and included the NiCr2O4 islands. The Nio layer stopped developing and the kinetics of oxidation barely displayed the growth of the Cr2O3 layer. When the spinel NiCr2O4 was introduced into the external layer, it caused a chemical reaction between the Cr2O3 and NiO layers. Some NiCr2O4 was produced by the oxygen moving ahead of the NiO front. In all the Cr alloys, (except for the most dilute ones) these NiCr2O4 islands continued to remain as a second phase in the scale, and their degree revealed the site of the original metal surface.

XRD patterns of bare specimens at 850℃ after 50 h postoxidation: (a) T = 650°C, (b) T = 750°C, (c) T = 850°C, and (d) T = 950°C.

The HC test performed was based on the weight change; test results were obtained at different times with different temperatures; weight change is a good indicator to study the corrosion rates under equivalent conditions. Weight change is measured per the corresponding time cycle. Figure 5 indicates the HC behavior (weight change) in artificial ash having a composition of 67 wt% V2O5 and 33 wt% Na2SO4 at 650, 750, 850, and 950℃. At 950℃, the specimen displayed much higher rates of weight gain, which continued until the last cycle. The weight change at 650°C showed that the specimen had reduced drastically in comparison with the other temperature. The change in weight observed in the specimens, in the presence of artificial ash, had increased, when compared with those of oxidation, without artificial ash salts.

The relation between weight change and different temperatures at the present artificial ash, after 50 h for coated specimens.

Subsequently, the XRD analysis was performed to investigate the corrosion products present on the outer surface of the specimens. The XRD patterns of the HC test after subjecting the specimens to artificial ash (33 wt% Na2SO4 and 67 wt% V2O5) and a salt environment at 650, 750, 850, and 950℃ for 50 h are revealed in Figure 6. From the XRD analysis, the presence of NiO and Cr2O3 was detected. Just above the substrate, a thin layer of NiO had been formed; above this layer, a continuous thin layer of Cr2O3 was noted, which had been formed with the outer portion of the scale, and containing the oxides of Ti Ni Cr, NiCr2O4, and Ni (VO3)2. Spinels, recognized by XRD analysis, were also visible in the scale. The spinel formation of NiCr2O4 through the reactions of the solid phases between the Cr2O3 and NiO in the oxide scales facilitates the oxidation resistance to advance. This occurs because the spinel phase typically possesses lower diffusion coefficients of the anions and cations than those corresponding values in the parent oxides. The XRD analysis also suggests the presence of Na2CrO4, and this finding concurs with the results of the research [25,26,27,28].

XRD patterns of specimens at different temperatures after 50 h, with artificial ash for coated specimens: (a) T = 650°C, (b) T = 750°C, (c) T = 850°C, and (d) T = 950°C.

From Figure 7, the SEM of the coated specimens for those covered with artificial ash for 950°C at 50 h is evident. These images clearly reveal that the coating layer retained its topography and soundness, implying its stability as a coating layer and that it may be acting as a barrier layer between the outside and substrate, thus averting the passage of the corrosive species and oxygen to the substrate.

SEM micrograph of Al2O3–8 wt% CNTs for specimen tested after 50 h at 950°C.

4 Conclusions

Based on the results of tests, the following conclusions can be drawn out:

The oxidation and HC rate correspondingly rise with the increase in temperature, and the substrate layer becomes porous and weakly adherent.

From the results of the SEM, cracks are visible on the surface of the specimens.

The coated specimens reveal good resistance to HC and the additional CNTs further enhance the properties of the coating layer.

The XRD results for the coated specimens with artificial ash are noted in several phases like the NaV3O8, NaVO, V2O5, and Na2SO4.

-

Funding information: The authors declared that no funding was received.

-

Author contributions: All authors have accepted responsibility for the entire content of this article and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Geddes B, Leon H, Huang X. Superalloys: Alloying and performance. Novelty (OH), USA: ASM International; 2010.10.31399/asm.tb.sap.9781627083133Suche in Google Scholar

[2] Amin MM. Oxidation behaviour of IN-738 LC superalloys in the presence of ionic salts at 1173 K. Port Electrochim Acta. 2003;21(4):389–98.10.4152/pea.200304389Suche in Google Scholar

[3] Karkush MO, Altaher TA. Remediation of contaminated soil with petroleum industrial wastewater. J Eng. 2017 Jan;23(2):13–20.10.31026/j.eng.2017.02.02Suche in Google Scholar

[4] Rani S. Common failures in gas turbine blade: A critical review. Int J Eng Sci Res Technol. 2018 Mar;3:799–803.Suche in Google Scholar

[5] Roberge PR. Handbook of corrosion engineering. 3rd ed. New York (NY), USA: McGraw-Hill Education; 2019.Suche in Google Scholar

[6] Najy FY, Al-Sultani KF, Murshdy JM. Study addition double inhibitor consist of MgO and SiO2 to residual oil to prevent hot corrosion of stainless steel (304 L) of boilers pipes in power generation station. Adv Nat Appl Sci. 2017 Feb;11(2):57–68.Suche in Google Scholar

[7] Porcayo-Calderon J, Bravo VS, Rodriguez-Diaz RA, Martinez-Gomez L. Effect of the NaVO3-V2O5 ratio on the high temperature corrosion of Chromium. Int J Electrochem Sci. 2015 Jun;10:4928–45.10.1016/S1452-3981(23)06677-4Suche in Google Scholar

[8] Rapp RA. Chemistry and electrochemistry of hot corrosion of metals. Mater Sci Eng. 1987 Mar;87:319–27.10.1016/0025-5416(87)90394-6Suche in Google Scholar

[9] Al-Sultani KF. A pilot system for evaluation of hot ash corrosion inhibition in power generation boilers [dissertation]. Baghdad: University of Technology; 2003.Suche in Google Scholar

[10] Bansal L, Rathi VK, Mudafale K. A review on gas turbine blade failure and preventive techniques. Int J Eng Res Gen Sci. 2018;6:54–62.Suche in Google Scholar

[11] Boyraz MT. IN 738 LC microstructure optimization with heat treatment and simulation to improve mechanical properties of turbine blades [dissertation]. Ankara: Middle East Technical University; 2018.Suche in Google Scholar

[12] Ahmad Z. High temperature corrosion. Rijeka, Croatia: InTechOpen; 2016.10.5772/61546Suche in Google Scholar

[13] Xu Z, Wang Z, Huang G, Mu R, He L. Morphology, bond strength and thermal cycling behavior of (Ni, Pt) Al/YSZ EB-PVD thermal barrier coatings. J Alloy Compd. 2015 Dec;651:445–53.10.1016/j.jallcom.2015.08.113Suche in Google Scholar

[14] Mohan P, Patterson T, Desai VH, Sohn YH. Degradation of free-standing air plasma sprayed CoNiCrAlY coatings by vanadium and phosphorus pentoxides. Surf Coat Technol. 2008 Dec;203(5–7):427–31.10.1016/j.surfcoat.2008.08.068Suche in Google Scholar

[15] Saether E, Frankland SJ, Pipes RB. Transverse mechanical properties of single-walled carbon nanotube crystals. Part I: determination of elastic moduli. Compos Sci Technol. 2003 Aug;63(11):1543–50.10.1016/S0266-3538(03)00056-3Suche in Google Scholar

[16] Wang L, Wang Y, Sun XG, He JQ, Pan ZY, Wang CH. Microstructure and indentation mechanical properties of plasma sprayed nano-bimodal and conventional ZrO2–8wt% Y2O3 thermal barrier coatings. Vacuum. 2012 Feb;86(8):1174–85.10.1016/j.vacuum.2011.10.029Suche in Google Scholar

[17] Xiang N, Song RG, Xu P, Wang C, Zhuang JJ, Zheng XH. Characterisation of micrometre-and nanostructured atmospheric plasma sprayed zirconia–8%yttria thermal barrier coatings. Mater Sci Technol. 2016 Apr;32(6):593–601.10.1179/1743284715Y.0000000133Suche in Google Scholar

[18] Ma XQ, Cho S, Takemoto M. Acoustic emission source analysis of plasma sprayed thermal barrier coatings during four-point bend tests. Surf Coat Technol. 2001 May;139(1):55–62.10.1016/S0257-8972(01)00995-1Suche in Google Scholar

[19] Prashar G, Vasudev H, Thakur L, Bansal A. Performance of thermally sprayed Hydroxyapatite coatings for biomedical implants: A comprehensive review. Surf Rev Lett. 2023;30(1):2241001.10.1142/S0218625X22410013Suche in Google Scholar

[20] Prashar G, Vasudev H. Structure-property correlation and high-temperature erosion performance of Inconel625-Al2O3 plasma-sprayed bimodal composite coatings. Surf Coat Technol. 2022 Jun;439:128450.10.1016/j.surfcoat.2022.128450Suche in Google Scholar

[21] Vasudev H, Thakur L, Singh H, Bansal A. Effect of addition of Al2O3 on the high-temperature solid particle erosion behaviour of HVOF sprayed Inconel-718 coatings. Mater Today Commun. 2022 Mar;30:103017.10.1016/j.mtcomm.2021.103017Suche in Google Scholar

[22] Vasudev H, Prashar G, Thakur L, Bansal A. Electrochemical corrosion behavior and microstructural characterization of HVOF sprayed inconel718-Al2O3 composite coatings. Surf Rev Lett. 2022 Feb;29(2):2250017.10.1142/S0218625X22500172Suche in Google Scholar

[23] Vasudev H, Prashar G, Thakur L, Bansal A. Microstructural characterization and electrochemical corrosion behaviour of HVOF sprayed Alloy718-nanoAl2O3 composite coatings. Surf Topogr Metrol Prop. 2021 Jul;9(3):035003.10.1088/2051-672X/ac1044Suche in Google Scholar

[24] Diez P, Smith RW. The influence of powder agglomeration methods on plasma sprayed yttria coatings. J Therm Spray Technol. 1993 Jun;2(2):165–72.10.1007/BF02652025Suche in Google Scholar

[25] Singh H, Puri D, Prakash S, Ghosh TK. Hot corrosion of a plasma sprayed Ni3Al coating on a Ni‐base superalloy. Mater Corros. 2007 Nov;58(11):857–66.10.1002/maco.200704072Suche in Google Scholar

[26] Saladi S, Menghani J, Prakash S. Effect of CeO2 on cyclic hot-corrosion behavior of detonation-gun sprayed Cr3C2-NiCr coatings on Ni-based superalloy. J Mater Eng Perform. 2015 Mar;24(3):1379–89.10.1007/s11665-015-1400-xSuche in Google Scholar

[27] Karkush MO, Almurshedi AD, Karim HH. Investigation of the impacts of nanomaterials on the micromechanical properties of gypseous soils. Arab J Sci Eng. 2023;48(1):665–75.10.1007/s13369-022-07058-zSuche in Google Scholar

[28] AL-Ani S, Karkush MO, Zhussupbekov A, Al-Hity AA. Influence of magnetized water on the geotechnical properties of expansive soil. In: Karkush MO, Choudhury D, editors. Modern applications of geotechnical engineering and construction. Singapore: Springer; 2021. p. 39–50.10.1007/978-981-15-9399-4_5Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil

Artikel in diesem Heft

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil