Abstract

The need for wood in the ship building industry continues to grow every year. An alternative raw material is needed to replace wood at a more affordable price, namely, bamboo laminated boards. However, bamboo has a weak connection between its segments, with a maximum length between components of less than 40 cm. To reduce these weaknesses, the connection between bamboo segments with laminated boards is carried out as follows: scarf joint, butt joint, finger joint, desk joint, and tongue and groove joint. The study aims to determine the connection’s effect on each connection variation’s strength. Tensile tests and bending tests were carried out on the test specimens. The average results obtained were quite varied for the tensile test, which were in the range of 81.36–118.62 MPa, while the results of buckling test were in the range of 395.28–475.89 MPa. This study revealed that the connection of the specimen with seven layers had a value of 118.62 MPa in the tensile strength test and 475.89 MPa in the buckling strength test, while 3 layers finger joint samples with the lowest buckling tensile strength value had a value of 81.36 MPa tensile strength and 395.28 MPa bending strength.

1 Introduction

Deforestation in Indonesia is getting more and more worrying day by day. Data from the Ministry of Forestry in 2007 showed that the forest destruction rate touched 1,090,000 hectares due to illegal logging. Worse still, the state suffered a significant loss, reaching 30.42 trillion IDR annually [1]. Deforestation is an ongoing problem that leads to massive loss of forest land, negatively impacting the environment and society and negatively affecting the future generations [2]. This causes the availability of raw materials for shipbuilding, especially those made of non-metallic materials or wood, to decrease.

The most used materials in construction today are wood and concrete [3]. Increasing global economic activity and population lead to high demand for wood and wood-based products. However, deforestation will result in fewer wood supplies, lessening carbon dioxide absorption [4]. The bamboo tree is the fastest growing plant that can reach maturity quickly. It has the advantage of being widely available because it is geographically present in dense woods and can grow quickly. In addition, bamboo is known for being lightweight, rigid, and suitable strength, even more robust than other composite materials such as fiberglass [3,5,6]. Due to its deteriorating properties and moisture absorption, bamboo cannot be used for structural purposes such as traditional boats, bridges, and dwellings that have been constructed using bamboo historically [7].

Bamboo as a composite material can be used for ship hulls [8]. Experimental tests have shown that bamboo fiber-reinforced plastic may be formed by combining bamboo fibers with supporting materials [9]. Composite materials are becoming increasingly popular due to these advances in technology. It is usual for bamboo to be used as raw material for the ship industry in several ways, directly, indirectly, and in the form of cuttings, but a process is needed to obtain strength and stiffness that meets standards, including the bamboo lamination process [10]. For applications that require high strength and lightweight composites, plant-based natural fibers could be used as an alternative to traditional materials [11].

The lamination of bamboo is done by combining several layers of material or bamboo slats glued together using an adhesive material into a beam element with the required span length and cross-sectional dimensions [12]. The type of bamboo that has been researched and can meet the requirements according to existing standards is apus-type bamboo.

There are a few drawbacks in using bamboo for laminated boards, the connections between the segments can be difficult to see. In previous studies, laminated boards using elements in their manufacture resulted in a strength reduction ratio of 25% [13]. In addition, to reduce high production costs, combination of bamboo hybrid laminate between bamboo and natural fiber can be applied [14].

Using bamboo on laminated boards with segments reduces the tensile strength of bamboo with components by about 25% than bamboo without elements. This segment is the weakest part of the bamboo trunk. However, plant-based natural fibers such as bamboo have great potential as a traditional alternative in composites for applications requiring high strength and lightweight [15].

Previous studies reported that laminated boards without joints with three, five, and seven layers produced the most substantial strength given by laminated boards with fiber direction of 0°, with the seven-layer laminates having a tensile strength value of 185 MPa and bending strength of 315 MPa. Compared to laminated board with 0° fiber direction, the tensile strength decreased by 52% at 45° fiber direction, and laminated board with 90° fiber direction also experienced 15.7% decrease in tensile strength [16].

This work covers several types of joints such as butt joint, desk joint, tongue and groove joint, scarf joint, and finger joint, as described in Sucipto’s “Laminated Wood and Jointing Boards” [17]. To test the behavior of the laminate board and the connection, tensile test and bending tests were performed. A comparison was made between the test results and the Indonesian Classification Bureau (BKI) standard value on laminated boards to ensure that they are safe for use as an alternative hull material in ships.

2 Materials and method

2.1 Material characteristics

The smeared bamboo used in this study as depicted in Figure 1 was at least 3 years old with an average diameter of 150 mm. Apus bamboo belongs to the genus Gigantochloa which has a dense clump. The scientific name of apus bamboo is Gigantochloa apus. Apus bamboo is also known as tali bamboo, awi tali, or pring tali. In comparison to bamboo apus with twigs, bamboo apus without twigs has superior mechanical properties. In this study, the type of bamboo used as the base material for the composite was rope bamboo, also known as apus bamboo (Gigantochloa apus). Table 1 provides the detailed information on the mechanical characteristics of apus bamboo.

Apus bamboo (Gigantochloa apus).

The mechanical properties of apus bamboo [18]

| No. | Type of test | Value (MPa) |

|---|---|---|

| 1 | Bending strength | 134.97 |

| 2 | Bearing strength | 24.18 |

| 3 | Compression strength parallel to the grain | 49.20 |

| 4 | Shear strength | 9.50 |

| 5 | Tensile strength parallel to grain | 228 |

| 6 | Modulus of elasticity | 12888.47 |

Composites are made with bamboo fiber which has been arranged as an epoxy resin polymer reinforcement. Epoxy resins listed in Table 2 are suitable for coating ships, oil rigs, storage tanks, and water pipes [19]. Epoxy glue (2 components) is a multi-purpose glue that glues wooden planks to wooden boats. The advantages of epoxy glue are that it is effortless to use, the quality is unquestionable, has strong adhesion, and is seawater resistant. The disadvantages of epoxy glue are that the film tends to be more challenging, has poor elasticity, and has a relatively high price [20].

Epoxy resin composition [21]

| No. | Material | Percentage |

|---|---|---|

| 1 | Bisphenol A (BPA) | 80–90 |

| 2 | Altered polyepoxides | 5–15 |

| 3 | Alcohol glycidyl ether | 5–15 |

| 4 | Mercaptans | 50–60 |

| 5 | Tertiary amine | 5–10 |

| 6 | Polyamide resin | 30–35 |

| 7 | Triethylenetetramine | <3 |

| 8 | Aliphatic amine | 1–10 |

The influence of the many layers of laminae in the composition of the laminated board has a significant impact, according to the data obtained in previous studies [22]. The more the number of layers of the lamina, the more the pressing strength during the process of making the laminated board. In previous studies, one of the benefits of compressed air is that it minimizes the formation of air cavities caused by the gluing of the epoxy resin, for pressing during the process of making laminated boards that have maximum strength. In this test, the specimen with a compression pressure of 2 MPa has full strength [22].

2.2 Test specimen manufacturing

Apus bamboo laminated joint boards are made in stages. First, 3 year old, 150 mm-diameter bamboo apus from Yogyakarta, Indonesia, are felled. After cutting apus bamboo, the stem must be cut 30 cm before the branch. Bamboo stems are peeled and split into blades. Splitting bamboo yields 30 mm × 20 mm slats. Using a four-sided tool, bamboo slats are laminated. This process yields 1.2, 1.8, and 3 mm thicknesses. Figure 2 shows drying bamboo slats. This ensures that no water remains in the bamboo or bamboo fibers.

Apus bamboo slats.

Aligned bamboo slats are glued with epoxy resin to make apus bamboo laminate board. In this process, bamboo slats are arranged parallel to the direction and according to their thicknesses and glued on top of bamboo slats that have been glued and put together again with epoxy resin until they reach 10 mm. In terms of specific strength, the bamboo slats-prepared laminated board is superior to other methods [23]. Figure 3 shows how Apus bamboo is glued between layers to form a laminate board, then pressed to densify the layers. Figure 4 shows how more glue was used to reduce space risk on a laminated board. The laminated boards are connected using the following methods: butt joints, finger joints, scar joints, tongue and groove joints, and desk joints. After the joints dry and harden, laminated boards are cut to the sizes specified in tensile and bending tests. Then, the surface is smoothed by sanding.

Apus bamboo gluing process.

Laminate board pressing process.

2.3 Specimen variation and mass fraction

This study uses three variations based on the orientation of the angular arrangement of laminated bamboo, as shown in Table 3. The mass fraction of a material is the ratio of its mass to the overall mass of the mixture. In this study, the mass fraction of the material in each specimen is almost similar because each sample has the same number of layers as shown in Table 3.

Comparison of specimen mass fraction

| Number of layers | Laminate board mass (%) | Apus bamboo mass (%) | Epoxy resin mass (%) |

|---|---|---|---|

| 3 layers | 100 | 65 | 35 |

| 5 layers | 100 | 68 | 32 |

| 7 layers | 100 | 70 | 30 |

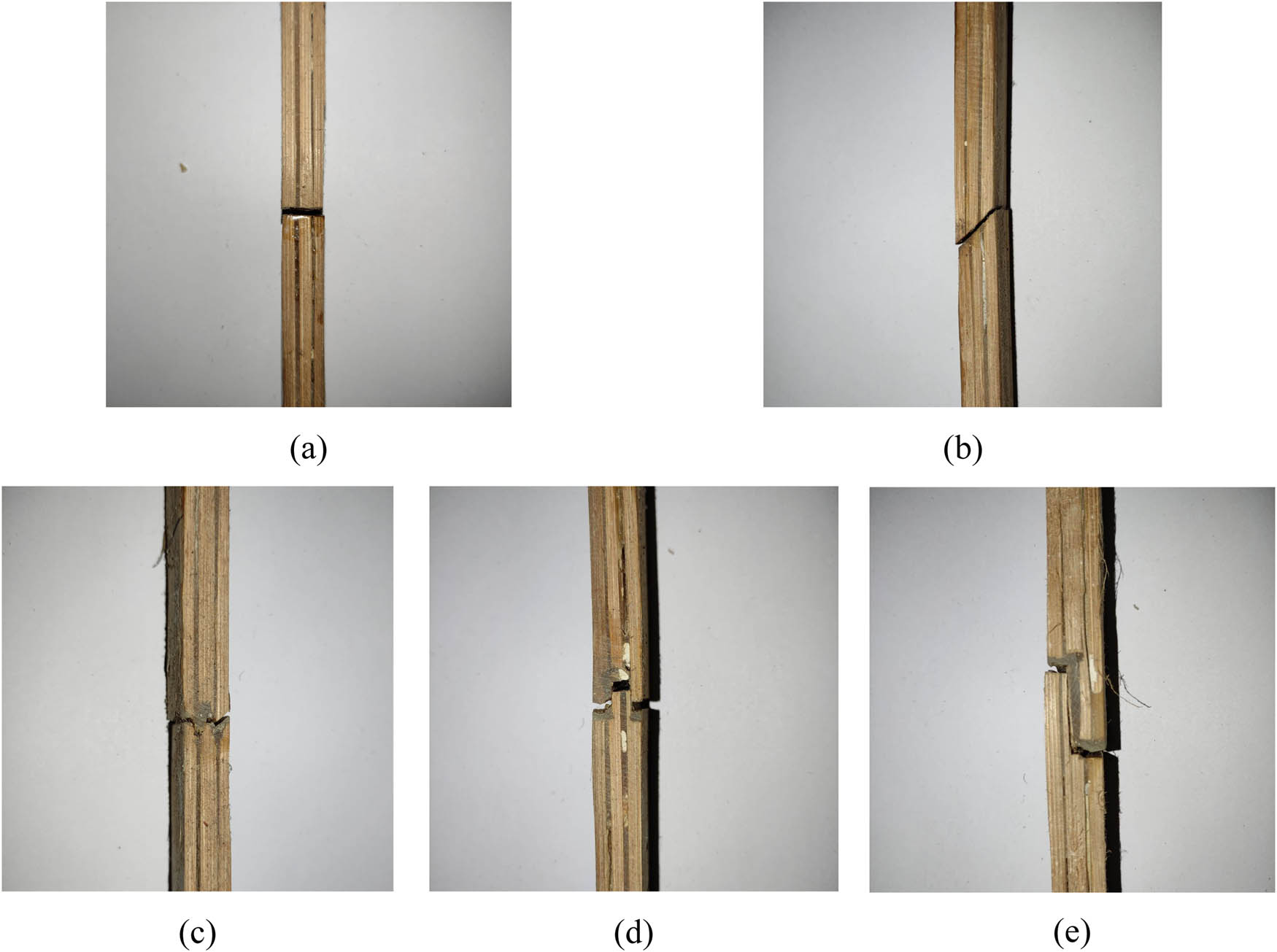

In this study, the variants of the laminated board joints have five sorts of connections: butt joints, finger joints, scarf joints, tongue and groove joints, and desk joints. In Figure 5, the laminated board is connected right in the center of the test specimen. It is also carried out directly on the laminate junction during the testing procedure to assess the influence of the laminated board connection on the tensile and bending strengths.

Laminate board connection variations: (a) butt joint, (b) scarf joint, (c) finger joint, (d) tongue and groove joint, and (e) desk joint.

2.4 Mechanical testing

2.4.1 Tensile test

Tensile testing was carried out at the Laboratory of Ship Material and Strength at Diponegoro University using the Universal Testing Machine (UTM) Type WEW-1000B as shown in Figure 6. This study used the ASTM D-3039 standard with a specimen size of 250 mm × 25 mm × 10 mm [24]. Five specimens were tested in this test. Tensile tests are carried out to complete the information and basic design of the strength of the material. Based on the tensile test, the following properties can be obtained such as, tensile strength, strain, and modulus of elasticity.

(a) Specimen size based on ASTM D-3039, (b) tensile test specimen, and (c) Universal Testing Machine (UTM) WEW-1000B.

2.4.2 Three-point bending test

The bending test was carried out at the Laboratory of Ship Material and Strength at Diponegoro University using the WEW-1000B Universal Testing Machine (UTM). Four specimens were tested. Based on Figure 7, the test standard used in the parallel bending test is ASTM D-7264 [25], with a specimen size of 130 mm × 13 mm × 10 mm. From the bending test, the following properties are obtained:

where

(a) Bending test specimen standards according to ASTM D-7264, (b) bending test specimens, and (c) specimen testing on the WEW-1000B UTM.

3 Results and discussion

3.1 Result of tensile test

Tensile test using WEW-1000B UTM has been conducted to measure the maximum load capacity in each joint variations. Tensile strength, strain, and modulus of elasticity are the test results. The maximum load results obtained from the machine can be calculated using the maximum stress formula, where

Tensile test results of different joint types

| No. | Joint types | Tensile strength (MPa) | ||

|---|---|---|---|---|

| 3 layers | 5 layers | 7 layers | ||

| 1 | Butt joint | 89.87 | 90.82 | 92.16 |

| 2 | Scarf joint | 90.24 | 91.42 | 96.98 |

| 3 | Finger joint | 81.36 | 84.00 | 88.35 |

| 4 | Tongue and groove joint | 89.92 | 90.89 | 110.35 |

| 5 | Desk joint | 103.66 | 109.32 | 118.62 |

The data in Table 4 and Figure 8 reveal that the specimens using desk joint type and 7 layers of bamboo produce the highest average tensile strength value of 118.64 MPa, which is 31% stronger than specimens using finger joint type and 3 layers of bamboo which has the lowest average tensile strength of 81.36 MPa.

Comparison of tensile stress of different joint types for (a) three layers, (b) five layers, and (c) seven layers.

The obtained results are consistent with previous research [30] in which the specimen with 7 layers of laminate has the highest tensile test results because the bonds between the fibers are more potent in the specimen with 7 layers and the bamboo slats used are thinner. The mass fraction between the epoxy resin and bamboo is smaller, that is 70:30%, which results in increasing the tensile strength. The area of the desk joint connection has the most expansive area resulting in increased bonding between the joints. In contrast, the specimen with the finger joint connection type with 3 layers is the weakest specimen due to the reduced mass fraction between the bamboo slats and the epoxy resin, which is 65:35%, resulting in reduced bonding. The number of air bubbles still left on the adhesive layer between bamboo joints.

From the test results, we can see that the influence of the type of connection and the number of layers affect the tensile strength of each specimen. Strain can be defined as the ratio of the increase in the object’s length to its initial size. Tensile strain occurs when the rod is pulled. From Table 5, we can see that each specimen subjected to a tensile test experiences an increase in length. The addition of the measurement itself can be used to find the tensile strain, where we can use the formula

Tensile strain of different joint types

| No. | Joint types | Tensile strain (%) | ||

|---|---|---|---|---|

| 3 layers | 5 layers | 7 layers | ||

| 1 | Butt joint | 1.06 | 1.07 | 1.08 |

| 2 | Scarf joint | 1.06 | 1.07 | 1.08 |

| 3 | Finger joint | 1.06 | 1.07 | 1.08 |

| 4 | Tongue and groove joint | 1.06 | 1.07 | 1.08 |

| 5 | Desk joint | 1.06 | 1.07 | 1.08 |

Data from Table 5 and Figure 9 show that the specimens with 7 layers have the highest average strain value of 1.08%, compared with the specimens with 3 and 5 layers, which experienced a decrease in strain.

Comparison of average strain of different layers of bamboo laminate.

Strain can occur because of the level of elasticity of a test material. The highest strain was obtained by the specimen with 7 layers, and this was because the mass fraction between bamboo and epoxy resin had the highest ratio. This strengthened the bond between the fibers, putting more strain on the laminated board.

If strain dictates flexibility, then the modulus of elasticity reveals a material’s stiffness. The higher the modulus of elasticity, the stiffer the material. After knowing the yield strength and strain values, the modulus of elasticity may be computed. Based on Table 6, it is clear that the specimen with 7 layers has the highest modules elasticity for all joint types. Figure 10 shows the modulus of elasticity distribution for specimens with different number of layers and joint types.

Modulus of elasticity for different joint types

| No. | Joint type | Modulus of elasticity (MPa) | ||

|---|---|---|---|---|

| 3 layers | 5 layers | 7 layers | ||

| 1 | Butt joint | 2113.91 | 2119.54 | 2136.71 |

| 2 | Scarf joint | 2124.03 | 2134.89 | 2247.20 |

| 3 | Finger joint | 1913.32 | 1963.30 | 2048.36 |

| 4 | Tongue and groove joint | 2114.51 | 2123.27 | 2556.22 |

| 5 | Desk joint | 2436.30 | 2554.25 | 2753.03 |

Comparison of the modulus of elasticity of different joint types for (a) 3 layers, (b) 5 layers, and (c) 7 layers.

The modulus of elasticity obtained from Table 6 shows that the desk joint connection with 7 layers has the highest strength value with an average of 2752.03 MPa. In comparison, the finger joint connection with 3 layers has the lowest strength value with an average of 1913.32 MPa. The increase in the modulus of elasticity for each type of connection is influenced by the number of layers in the laminate board arrangement. The more layers there are on the board, the modulus of elasticity increases and is directly proportional.

It can be seen from Figure 11 that there is a fracture in each tensile test specimen, wherein the fractures are located between the joints. Due to axial load, the fracture is initially started at the joint connection of the applied load on the testing specimen, in which the glue/adhesive layer breaks due to lower strength compared to bamboo material. The crack at adhesive layer surface then grows into delamination between the bamboo lamina. The desk joint seen in Figure 11e has the most substantial tensile strength due to its cross-sectional area, which is more significant than other types of connection. While the finger joint has the weakest tensile strength because the connection is quite complicated, and this type of connection allows air bubbles to be trapped between the joints of the boards.

Macrography of tensile test specimens: (a) butt joint, (b) scarf joint, (c) finger joint, (d) tongue and groove joint, and (e) desk joint.

3.2 Result of bending test

A bending test is carried out by bending or pressing a test material until it reaches its brittleness limit point. This research was conducted with a 3-point bending test (3-point bending). In this test, we can find the bending strength using the formula

In Table 7 and Figure 12, the results for the bending test show that specimens with a desk joint connection type and 7 layers of bamboo produce the highest average tensile strength value of 475.89 MPa, which is 17% stronger than the specimen with finger joint connection and 3 layers of bamboo and has the lowest average tensile strength of 395.28 MPa.

Result of bending test under different joints

| No. | Joint types | Bending strength (MPa) | ||

|---|---|---|---|---|

| 3 layers | 5 layers | 7 layers | ||

| 1 | Butt joint | 409.9 | 415.56 | 416.28 |

| 2 | Scarf joint | 415.48 | 416.45 | 417.42 |

| 3 | Finger joint | 395.28 | 400.78 | 402.55 |

| 4 | Tongue and groove joint | 401.42 | 402.80 | 409.98 |

| 5 | Desk joint | 420.73 | 426.70 | 475.89 |

Comparison of bending strength of different joint types for (a) 3 layers, (b) 5 layers, and (c) 7 layers.

The results obtained follow previous research studies where the highest tensile test results are in the variation with 7 layers because in the specimen with 7 layers, the bonds between the fibers are more robust and the bamboo slats used are thinner. The mass fraction between the epoxy resin and bamboo is smaller at 70:30, resulting in increased tensile strength. The desk joint connection has the most expansive area resulting in increased bonding between the joints. In contrast, the specimen with the finger joint connection type with 3 layers is the weakest because the mass fraction between the bamboo slats and the epoxy resin decreases to 65:35, which results in reduced bonding. Between the fibers, there are a number of air bubbles remaining on the bamboo joints which are glued together using epoxy resin.

As shown in Figure 13, there are similar fractures phenomena in each bending test specimen, wherein the fractures are mainly located between joints. Due to bending load, fracture is initially started at joint connection at bottom part of the applied load on the testing specimen, during which the glue/adhesive layer breaks due to lower strength compared to bamboo material. Surface cracks are initiated at the lower surface of the specimen under tension. Surface crack has a similar pattern for each joint type variation. In all laminated bamboo composites, lamina delamination occurs due to the non-adherence of fibers between the laminae and the matrix material due to the weak adhesive layer. In addition, desk joints have the most substantial tensile strength because the cross-sectional area of the connection is more extensive than other types of joints. Finger joints have the weakest tensile strength because the connection is quite complicated, which allows air bubbles to be trapped between the joints board.

Macrography of bending test specimens: (a) butt joint, (b) scarf joint, (c) finger joint, (d) tongue and groove joint, and (e) desk joint.

In a previous study [22], testing was carried out on the technical analysis of apus bamboo, where apus bamboo was tested without using reinforcing fiber, commonly referred to as raw material. The results of these tests for tensile strength and bending strength can be seen in Tables 8 and 9.

Comparison of tensile strength under different joint types

| No. | Joint type | Tensile strength (MPa) | ||

|---|---|---|---|---|

| 3 layers | 5 layers | 7 layers | ||

| 1 | Butt joint | 89.87 | 90.82 | 92.16 |

| 2 | Scarf joint | 90.24 | 91.42 | 96.98 |

| 3 | Finger joint | 81.36 | 84.00 | 88.35 |

| 4 | Tongue and groove joint | 89.92 | 90.89 | 110.35 |

| 5 | Desk joint | 103.66 | 109.32 | 118.62 |

| 6 | Manik et al. [22] | 168 | 177 | 185 |

Comparison of bending strength under different joint types

| No. | Joint type | Bending strength (MPa) | ||

|---|---|---|---|---|

| 3 layers | 5 layers | 7 layers | ||

| 1 | Butt joint | 409.9 | 415.56 | 416.28 |

| 2 | Scarf joint | 415.48 | 416.45 | 417.42 |

| 3 | Finger joint | 395.28 | 400.78 | 402.55 |

| 4 | Tongue and groove joint | 401.42 | 402.80 | 409.98 |

| 5 | Desk joint | 420.73 | 426.70 | 475.89 |

| 6 | Manik et al. [22] | 295 | 315 | 321 |

As shown in Table 8, all specimens with different joint types experienced an increase in strength due to the addition of layers. The tensile strength of the laminated board connection specimens increased but could not match the tensile strength of previous studies. For samples with desk joint connections, the effect of the number of layers increases the tensile strength of each specimen.

Meanwhile the bending test in Table 9 shows that all specimens experienced a very significant decrease, for example, with different joint types, the tensile strength was 29–48% stronger than in previous studies. The type of connection for which the bending strength significantly increases is the laminate board with the desk joint connection type. In contrast, the laminated board with the finger joint connection produces the lowest flexural strength but still meets the required standards.

As per the regulations of the BKI for both tensile testing and bending testing, the test specimens that meet the test standards are the specimens with 7 layer bench connection, whose tensile strength is 109.76 MPa and bending strength is 151.51 MPa. In comparison, the specimen with the 3-layer connection and finger joint type has a value of 73.78 MPa for tensile strength and 125.85 MPa for bending strength. These results are consistent with the study of Manik et al., in which 7-layer bamboo composites with a greater epoxy mass matrix exhibited better mechanical qualities than 3 and 5 layers [26].

4 Overall discussion

In practice, numerous bamboo boards can be joined together using mechanical joints to form a huge panel in the ship construction production procedure. Solid jointed boards and connecting boards made of entire sawn wood are used to make laminate joints. A connecting board constructed with linked connecting slats or short sawn wood is referred to as a non-solid jointed board. Butt joints, finger joints, scarf joints, tongue and groove joints, and desk joints are the five types of connecting blades and boards. Flat-based typical structures such as decks, walls, and superstructure members, among others, are better suited for this manufacturing approach in the early stages of construction. Furthermore, creating curve-based bamboo boards might be a more difficult process requiring specialized production procedures. For example, flat bamboo boards can be arranged and then joined together to create a deck with specific scantling calculations.

According to the BKI vol 5 rules for fiberglass reinforced plastic ship Section 1.C.4.1.1, it is known that ships filled with supporting fiber must have a standard tensile strength of at least 98

Comparison of tensile strength test results with BKI standard

| No. | Joint type | Tensile strength (MPa) | ||

|---|---|---|---|---|

| 3 layers | 5 layers | 7 layers | ||

| 1 | Butt joint | 89.87 | 90.82 | 92.16 |

| 2 | Scarf joint | 90.24 | 91.42 | 96.98 |

| 3 | Finger joint | 81.36 | 84.00 | 88.35 |

| 4 | Tongue and groove joint | 89.92 | 90.89 | 110.35 |

| 5 | Desk joint | 103.66 | 109.32 | 118.62 |

| 6 | BKI standard [27] | 98 | 98 | 98 |

Comparison of the results of the bending strength test with the BKI standard

| No. | Joint type | Bending strength (MPa) | ||

|---|---|---|---|---|

| 3 layers | 5 layers | 7 layers | ||

| 1 | Butt joint | 409.9 | 415.56 | 416.28 |

| 2 | Scarf joint | 415.48 | 416.45 | 417.42 |

| 3 | Finger joint | 395.28 | 400.78 | 402.55 |

| 4 | Tongue and groove joint | 401.42 | 402.80 | 409.98 |

| 5 | Desk joint | 420.73 | 426.70 | 475.89 |

| 6 | BKI standard [27] | 150 | 150 | 150 |

In the tensile test, variations that meet the BKI standard are specimens with five types of connections (butt joint, finger joint, scarf joint, tongue and groove joint, and desk joint) and different numbers of board layers (3, 5, and 7 layers) with diverse results. For both tensile and bending tests, the BKI requires 7-layer bench connection specimens with a tensile strength of 109.76 MPa and a bending strength of 151.51 MPa. The 3-layer finger joint has tensile and bending strengths of 73.78 and 125.85 MPa, respectively.

5 Concluding remarks

Several mechanical tests were conducted to investigate the mechanical behavior of different joint types of laminated bamboo composites. The results of testing on laminated bamboo composite are as follows.

Testing showed that the tensile test ranged from 81.36 to 118.62 MPa and the bending test was from 395.28 to 475.89 MPa. Experiments with 7 layers of bench connections gave 118.62 MPa in tensile tests and 475.89 MPa in buckling tests. The finger joint with 3 layers has lowest tensile and bending strengths. Thus, based on the results obtained, it can be concluded that connection variations dramatically affect the composite’s strength. It is also important that there are multiple layers on each laminated board that contribute to the strength of the laminate joint, tensile strength, and bending strength. A laminated board with 3, 5, or 7 layers is the specimen that meets the standards for both tensile and bending tests. The comparison of present results with BKI standards shows specimens with the finger joint connection with 3 layers have the lowest tensile and buckling strength.

Based on the findings of the data analysis and comparison with BKI standard rules as a safety requirement, apus bamboo laminated board composites with desk joint connections of 3, 5, and 7 layers may be utilized as ship hull material since they meet the minimal standards imposed by BKI.

Acknowledgement

The authors would like to express their gratitude to the Laboratory of Ship Material and Strength at Diponegoro University, Indonesia, for providing research facilities and assistance with experimental testing.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Wibowo A, Gintings AN. Forest degradation and conservation efforts. Jakarta: PT Penerbit IPB Press; 2010 (In Indonesian).Search in Google Scholar

[2] Wahyuni H, Suranto S. Impact of large-scale deforestation on global warming in Indonesia. J Ilm Ilmu Pemerintah. 2021 Mar 25;6(1):148–62.10.14710/jiip.v6i1.10083Search in Google Scholar

[3] Shah DU, Sharma B, Ramage MH. Processing bamboo for structural composites: Influence of preservative treatments on surface and interface properties. Int J Adhes Adhes. 2018;85:15–22. https://www.sciencedirect.com/science/article/pii/S0143749618301246.10.1016/j.ijadhadh.2018.05.009Search in Google Scholar

[4] Chaowana P. Bamboo: An alternative raw material for wood and wood-based composites. J Mater Sci Res. 2013 Mar 14;2(2):90–102.10.5539/jmsr.v2n2p90Search in Google Scholar

[5] Nie Y, Wei Y, Huang L, Liu Y, Dong F. Influence of slenderness ratio and sectional geometry on the axial compression behavior of original bamboo columns. J Wood Sci. 2021;67(1):36. 10.1186/s10086-021-01968-6.Search in Google Scholar

[6] Emamverdian A, Ding Y, Ranaei F, Ahmad Z. Application of bamboo plants in nine aspects. Sci World J. 2020;2020:7284203. 10.1155/2020/7284203.Search in Google Scholar PubMed PubMed Central

[7] Bahari SA, Krause A. Utilizing Malaysian bamboo for use in thermoplastic composites. J Clean Prod. 2016;110:16–24. https://www.sciencedirect.com/science/article/pii/S0959652615002735.10.1016/j.jclepro.2015.03.052Search in Google Scholar

[8] Corradi S, Isidori T, Corradi M, Soleri F, Olivari L. Composite boat hulls with bamboo natural fibres. Int J Mater Product Technol. 2009;36(1–4):73–89. https://www.inderscienceonline.com/doi/abs/. 10.1504/IJMPT.2009.027821.Search in Google Scholar

[9] Yamaguchi H, Fujii T. Bamboo fiber reinforced plastics. In: Wallenberger FT, Weston NE, editors. In: Natural fibers, plastics and composites. Boston (MA): Springer US; 2004. p. 305–19. 10.1007/978-1-4419-9050-1_17.Search in Google Scholar

[10] Li HT, Zhang QS, Huang DS, Deeks AJ. Compressive performance of laminated bamboo. Compos B Eng. 2013;54:319–28. https://www.sciencedirect.com/science/article/pii/S1359836813002898.10.1016/j.compositesb.2013.05.035Search in Google Scholar

[11] Abd El-baky MA, Attia MA. Water absorption effect on the in-plane shear properties of jute–glass–carbon-reinforced composites using Iosipescu test. J Compos Mater. 2018 Oct 30;53(21):3033–45. 10.1177/0021998318809525.Search in Google Scholar

[12] Budi AS. The effect of slat dimensions on the flexural collapse of Petung Bamboo Laminated Beams. Media Teknik Sipil. 2007;7(36):85–92 (In Indonesian).Search in Google Scholar

[13] Widodo AB, Panunggal E, Widjaja S, Rasyid DM, Soegiono S. Effect of bamboo node for construction application. IPTEK J Technol Sci. 2007;18(3):96–102.10.12962/j20882033.v18i3.166Search in Google Scholar

[14] Supomo H, Djatmiko EB, Supomo W, Permana RD. A bamboo-hybrid-slat laminate of fishing boat: Materials selection, scantling calculation and construction cost. Kapal: J Ilmu Pengetah dan Teknologi Kelaut. 2021;18(3):151–9.10.14710/kapal.v18i3.41559Search in Google Scholar

[15] Syafi’i MI. The effect of variation in length of straight lip connection and bolt on the flexural strength of laminated Bamboo Petung beams. Rekayasa Teknik Sipil. 2019;3(1):199–203 (In Indonesian).Search in Google Scholar

[16] Manik P, Suprihanto A, Nugroho S, Sulardjaka S. The effect of lamina configuration and compaction pressure on mechanical properties of laminated Gigantochloa apus composites. Eastern-Eur J Enterp Technol. 2021 Dec 22;6(12):114, 62–73 http://journals.uran.ua/eejet/article/view/243993.10.15587/1729-4061.2021.243993Search in Google Scholar

[17] Sucipto T. Laminate and Joint Board. Vol. 1. Departemen Kehutanan, Fakultas Pertanian, Universitas Sumatera Utara. Medan: Universitas Sumatera Utara; 2009. p. 5–11 (In Indonesian).Search in Google Scholar

[18] Abdullah AHD, Karlina N, Rahmatiya W, Mudaim S, Patimah, Fajrin AR. Physical and mechanical properties of five Indonesian bamboos. IOP Conf Ser: Earth Environ Sci. 2017;60:012014.10.1088/1755-1315/60/1/012014Search in Google Scholar

[19] Sandler SR, Karo W. Chapter 3 - Epoxy resins. In: Sandler SR, Karo W, editors. Polymer syntheses. 2nd ed. San Diego: Academic Press; 1994. p. 87–128. https://www.sciencedirect.com/science/article/pii/B9780080925554500074.10.1016/B978-0-08-092555-4.50007-4Search in Google Scholar

[20] Sousa JM, Correia JR, Cabral-Fonseca S. Durability of an epoxy adhesive used in civil structural applications. Constr Build Mater. 2018;161:618–33. https://www.sciencedirect.com/science/article/pii/S0950061817323875.10.1016/j.conbuildmat.2017.11.168Search in Google Scholar

[21] Plummer CJG, Bourban PE, Månson JAE. Polymer matrix composites: Matrices and processing. In: Buschow KHJ, Cahn RW, Flemings MC, Ilschner B, Kramer EJ, Mahajan S, et al. editors. Encyclopedia of materials: Science and technology. Oxford: Elsevier; 2001. p. 7388–96. https://www.sciencedirect.com/science/article/pii/B008043152601319X.10.1016/B0-08-043152-6/01319-XSearch in Google Scholar

[22] Tuswan T, Manik P, Samuel S, Suprihanto A, Sulardjaka S, Nugroho, et al. Corellation between lamina directions and the mechanical characteristics of laminated bamboo composite for ship structure. Curved Layer Struct. 2023;10(1):20220186.10.1515/cls-2022-0186Search in Google Scholar

[23] Kumar D, Mandal A. Review on manufacturing and fundamental aspects of laminated bamboo products for structural applications. Constr Build Mater. 2022;348:128691.10.1016/j.conbuildmat.2022.128691Search in Google Scholar

[24] ASTM International. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. In: Designation: D 3039/D 3039M – 00. West Conshohocken (PA): ASTM International; 2002. p. 13.Search in Google Scholar

[25] ASTM International. Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials 1. In: Designation: D 7264/D 7264M-07. West Conshohocken (PA): ASTM International; 2007. p. 11. http://www.ansi.org.Search in Google Scholar

[26] Manik P, Samuel S, Tuswan T, Jokosisworo S, Nadapdap RK. Mechanical properties of laminated bamboo composite as a sustainable green material for fishing vessel: Correlation of layer configuration in various mechanical tests. J Mech Behav Mater. 2022 Jan 1;31(1):673–90.10.1515/jmbm-2022-0075Search in Google Scholar

[27] Biro Klasifikasi Indonesia. Rules for fiberglass reinforced plastic ships. In: Rules For Classification And Construction; 2021. p. 1–4. www.bki.co.id.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil