Quantitative analysis of microstructure and mechanical properties of Nb–V microalloyed high-strength seismic reinforcement with different Nb additions

-

Sheng Huang

, Zhiying Li

Abstract

HRB500E seismic steel bars are mainly used in high-rise buildings near the seismic zone. The influence of different niobium contents (0–0.023%) on the microstructure and mechanical properties of HRB500E seismic reinforcement was studied. Results showed that the grain size of ferrite was between 3.6 and 8.3 μm when only V was added. Meanwhile, as the niobium content increases, the ferrite particles are further refined. After adding niobium, the grain contribution increased by 9%. The addition of niobium significantly refined the grain size of HRB500E seismic reinforcement. The second-phase nano-elliptic precipitate is NbC. The precipitated phase is dispersed on the grain boundary and the matrix, and the dislocation density on the matrix promotes the precipitation of NbC particles along the dislocation line. The second-phase precipitation of niobium can form an effective pinning effect and then refine the pearlite spacing. The microhardness and the tensile strength also significantly improved. The yield strength increased from 509 to 570 MPa.

1 Introduction

With the continuous development of China’s construction industry in recent years, the requirements for the comprehensive performance of steel bars have gradually increased. During an earthquake, buildings deform under earthquake load. The steel bar bears huge local stress and strain at the crack place of concrete. At this time, the safety performance of the building has an important relationship with the comprehensive mechanical properties of the reinforcement [1,2,3,4,5,6]. Seismic reinforcement can produce huge deformation of buildings, has high strain capacity, can delay the collapse time of buildings, and can provide escape time for people. Thus, it can reduce casualties and property damage [7,8,9,10,11,12].

Several scholars at home and abroad have focused on the microalloying of seismic reinforcement [13,14,15,16,17,18]. However, many problems remain to be solved in the industrial production of seismic reinforcement. The analysis of the research status of high-strength seismic reinforcement of buildings, as well as the existing problems and improvement measures, is also needed [19,20,21,22,23,24]. Compared with V, Nb can reduce the cost and optimize all aspects of performance. The characteristic of niobium is to prevent the growth of austenite grain. NbC and NbNC precipitate in austenite during the hot rolling process, and the ferrite grain size after transformation is refined. Moreover, NbC formed at the dislocation can pin the grain boundary and improve the strength of the steel. Nb addition is an important method of microalloying in steel bars. In the study of H-type Nb–V microalloyed steel, Koo et al. [25] and others found that Nb played a key role in the process of TMCP and austenite regulation. Many scholars [26,27] obtain fine ferrite by optimizing the processing parameters of different steps in the controlled rolling and controlled cooling process, and it is necessary to control the evolution of the microstructure during the thermomechanical treatment process. Although some research work has been done on the controlled rolling and cooling process of other steel grades in the literature, there is no systematic study on the change of the Nb content to analyze the pearlite sheet spacing on the microstructure, yield strength, and tensile strength. Therefore, the latest trend should be followed to obtain the better structure and mechanical properties. The present study investigated the effects of adding different contents of Nb and V on the microstructure and mechanical properties of HRB500E seismic reinforcement.

2 Materials and experimental method

The experimental steel was made by adding Nb and V in a 50 kg intermediate frequency induction furnace. After melting, a steel ingot with a taper of 1° and a diameter of 10 cm is cast. The smelted sample weighs 25 kg. Choose MgO crucible formed by isostatic pressing. Four test steels were designed. The Nb content increased from 0 to 0.023%.

Inductively coupled plasma spectroscopy/mass spectrometry (ICP-AES/MS); inorganic carbon and sulfur analyzer; inorganic oxygen, nitrogen, and hydrogen analyzer were used to test the composition of the test steel, taking into account the segregation of the sample composition. Each sample was tested with three sample components to get the average value. The chemical composition of the investigated steels is presented in Table 1.

Chemical composition of test steel (wt%)

| No | C | Si | Mn | S | P | N | V | Nb |

|---|---|---|---|---|---|---|---|---|

| 1# | 0.22 | 0.58 | 1.43 | 0.012 | 0.028 | 0.008 | 0.08 | 0 |

| 2# | 0.22 | 0.56 | 1.42 | 0.011 | 0.028 | 0.009 | 0.07 | 0.013 |

| 3# | 0.23 | 0.59 | 1.42 | 0.008 | 0.027 | 0.010 | 0.08 | 0.017 |

| 4# | 0.22 | 0.61 | 1.43 | 0.012 | 0.029 | 0.008 | 0.08 | 0.023 |

The conical specimen was forged into a cylindrical shape, and a specimen of 10 mm × 15 mm × 20 mm was cut out, and the plane strain compression test was performed on the Gleeble-3800 thermal simulator. The specimen was heated at 20°C·s−1 to 1,150°C for 300 s. Rolling with a compression strain rate of 0.4 s−1 and strain of 0.1 was carried out at the rate of 5°C·s−1 to 1,000, 980, 950, and 900°C, and a total of four rollings were carried out. Then, the sample was cooled down to 700°C at a cooling rate of 20°C·s−1, held for 30 s, and then cooled to 200°C at 0.5°C·s−1. Wire cutting and metallographic sample cutting were carried out on the experimental steel of four heats. To obtain good experimental results. The top and bottom of the ingot were removed using a wire cutting lathe. The external, middle, and internal positions of the experimental sample were selected for wire cutting to select the metallographic phase. Metallographic samples were mechanically polished and corroded with a 4% nitric acid alcohol solution. The microstructure of metallographic samples was observed under the OLYMPUSGX71 metallographic microscope at many different positions. After mechanical thinning and ion thinning, the morphology and precipitation of the second phase were observed by high-resolution transmission electron microscopy (Tecnai G2 F20 S-TWIN). The accelerating voltage is 200 kV. The volume fraction of ferrite and pearlite and the average grain size of ferrite were determined using nano measure 1.2 image analysis software and ipwin32 software. The hardness testing machine was operated under a loading force of 0.1 kg and a dwelling time of 15 s. MICROHARDNESS TESTER HV-100 was used to measure 20 tissue positions randomly selected from each sample. The average value was selected as the final hardness value.

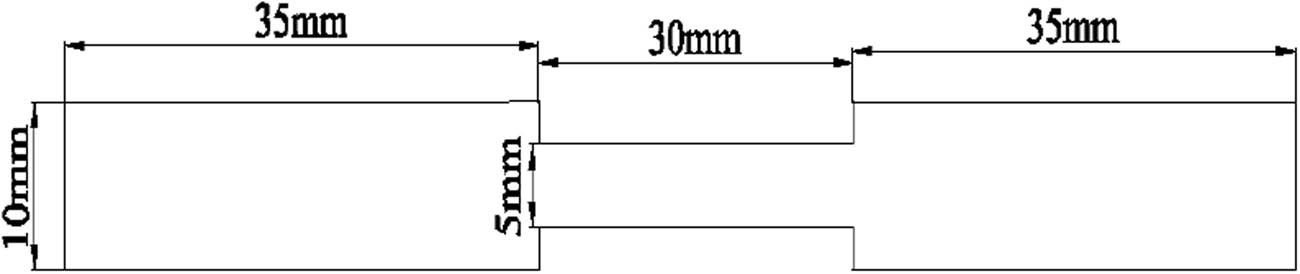

Figure 1 shows the size of the tensile sample. Following the tensile test requirements of the national standard GB/T 1499.2-2018 and the room temperature tensile test method specified in the national standard GB/T 228.1-2010, the room temperature tensile test is performed on the MTS810 universal tensile testing machine at a strain rate of 10−2 s−1. The inclusion at the dimple of the fracture was observed and analyzed by scanning electron microscopy (SEM) and energy-dispersive spectrometry (EDS).

Tensile standard specimen size of test steel.

3 Results and discussion

3.1 Effect of Nb content on microstructure

Figure 2 displays the metallographic structure of four types of test steel with different Nb contents. Their basic structures are the same, both ferrite and pearlite. The structure is evenly distributed, the pearlite is mostly lamellar and the ferrite is mostly polygonal. However, their phase proportion and distribution as well as grain size are different.

Metallographic structure of test steel: (a) 1# test steel, (b) 2# test steel, (c) 3# test steel, and (d) 4# test steel.

Figure 3 shows the scanned electron microscopy images of the four types of test steels. In the lamellar pearlite structure, the gray-white line is cementite, and the gray-black area is the ferrite matrix. In the no.1 test steel without Nb, the particle size is relatively thick and the distribution is concentrated, which is prone to stress concentration. After adding Nb, lamella and grain size distribution is relatively uniform, and grain refinement is apparent. The mechanical analysis shows that the addition of Nb improves the plasticity and tensile strength of the alloy. Thus, the requirements of seismic reinforcement are meet.

SEM image of test steel: (a) and (b) 1# test steel, (c) and (d) 2# test steel, (e) and (f) 3# test steel, and (g) and (h) 4# test steel.

The SEM morphology and representative EDS of No. 4 steel are depicted in Figure 4. The elliptical precipitates distributed in the ferrite grain boundaries are shown in Figure 4(a) and (b). The size of the precipitated phase is about 60 nm. The precipitates were analyzed by the energy spectrum. The mass fractions of Nb and C were 38.63 and 46.20%, respectively, indicating that these precipitates were Nb-rich carbides. Many fine precipitates were also found, which need further analysis by transmission electron microscopy.

Typical SEM images of (a) and (b) elliptical precipitates and (c) the corresponding EDS analysis in steel 4.

The volume fractions of ferrite and pearlite in four types of test steels were counted and calculated by using image analysis software. The volume ratios of ferrite to pearlite in No. 1, 2, 3, and 4 test steels are 96.08, 104.08, 112.77, and 117.39%, respectively. This result indicates that the volume fraction of ferrite increases with the increasing Nb content, and the grain size of ferrite decreases with the increasing Nb content. In the absence of Nb, the test steel contains more pearlite than ferrite. Vanadium can increase the volume fraction of precipitates and decrease the distance between precipitates. After adding Nb, the ferrite increases obviously, the austenite grain is refined, the ferrite nucleation is promoted, the pearlite formation is restrained, and the grain size is refined. The plasticity of ferrite increases because it is a soft phase. The cooling rate is possibly too fast for pearlite nucleation, but ferrite nucleation has been completed.

3.2 Effect of Nb on ferrite grain size

Figure 5 shows the histogram of ferrite grain size distribution of the four test sheets of steel with different Nb contents.

Distribution of the ferrite grain size of four types of test steels.

The aforementioned statistical data show that the volume fraction of ferrite increases with the increasing Nb content. Results show that the ferrite grain size of No. 1 steel with only V addition is 3.6–8.3 μm, mainly concentrated in 4.6–7.6 μm. In No. 2 test steel with 0.013% Nb, the grain size of ferrite is 2.6–5.3 μm, mainly concentrated in 2.6–4.6 μm. In No. 3 test steel with 0.017% Nb, the grain size of ferrite is 2.4–4.8 μm, mainly concentrated in 2.4–3.6 μm. The grain size of ferrite in No. 4 test steel with 0.023% Nb is 2.6–4.3 μm, mainly concentrated in 2.6–3.1 μm. The ferrite grains are effectively refined with the increase in Nb content. With the increase in Nb, the Nb content in the matrix increases. The second phase (NBC, Nb(CN), etc.) containing Nb precipitated in the ferrite can pin the grain boundaries, form Coriolis air masses, and hinder the coarsening and growth of grains. The nucleation force of ferrite increases with the increase of dislocation resistance.

The contribution of grain refinement is estimated by the Hall–Petch formula (equation (1)) [28]:

where k is a constant (MPa·mm−0.5) and d is the average size of ferrite grains (μm). After statistical calculations, the average grain size of 1# to 4# test ferrite is 5.2, 3.3, 3.1, and 3.0 μm. Calculated detailed contributions are 249.6, 313.3, 323.3, and 328.6 MPa, respectively. The refining contribution of test steel without niobium accounts is about 49% of yield strength, and that of test steel with niobium is about 58% of yield strength.

In such a low niobium content and hot rolling process, the microalloying element niobium mainly exists as carbide or carbonitride precipitates in the microstructure. The precipitated niobium in the second phase eliminates the adverse effects of solid solution niobium, and when more niobium is added to steel, more niobium carbonitride will be formed and fine parent austenite grains will be formed. Fine austenite and more Nb carbonitride provide more nucleation sites for ferrite transformation and promote ferrite transformation. It can be seen from TEM (Figure 10) images that the second phase precipitates at ferrite grain boundaries. These nucleation points can effectively cut austenite grains during ferrite nucleation, prevent austenite from growing, and thus play a role in refining ferrite grains. At the same time, the precipitated phase is easily adsorbed on the crystal surface, which can not only reduce the difference of surface energy of each crystal plane but also reduce the growth rate of these planes and also hinder the crystal growth and promote the ferrite grain refinement.

The formation of Nb-containing particles increases with the increasing Nb content. Crystal growth results from the competition between continuous grain formation and growth during nucleation. The increase in the second phase containing Nb particles obviously promotes nucleation efficiency and heterogeneous nucleation.

According to the thermodynamic analysis [29], the solubility product formula of Nb in austenite and ferrite (equations (2) and (3) [29]) shows that the precipitation temperature of NBC increases with the increase of Nb.

4 Effect of Nb on the mechanical properties of test steel

4.1 Effect of pearlite spacing on hardness and strength

Figure 6 shows the TEM distribution of pearlite lamellar spacing. Measurement results show that the distance between the plates decreases from 0.125 to 0.077 μm. The mechanical properties of lamellar pearlite mainly depend on the distance between pearlites. During pearlite transformation, cementite rich in Nb and V may precipitate at the beginning. The lamellar formation of pearlite is the result of the growth of cementite in the form of branching. The continuous branching and growing of cementite promote the formation of ferrite on the side of cementite and then grows, forming lamellar pearlite.

TEM distribution of lamellar spacing of four types of test steel balls: (a) 1# test steel, (b) 2# test steel, (c) 3# test steel, and (d) 4# test steel.

In the process of slow cooling, a large amount of niobium precipitates in the form of carbide, which can form an effective pinning effect. The undercooled austenite consumes the carbon element in microalloyed steel, and the mobility of carbon atoms is weakened, which hinders the long-range diffusion of carbon. As a result, the undercooled austenite is unstable and easily transformed into fine pearlite, thus reducing the lamellar spacing of pearlite.

Figure 7 shows the microstructure and hardness of the test steel. The pearlite structure of the test steel exerts a great influence on the hardness, whereas the ferrite has no obvious effect. The microstructure of pearlite was analyzed. The effect of pearlite spacing on hardness and tensile strength is shown in Figure 8. This figure shows that the hardness and tensile strength increase as the spacing decreases. The lamellar spacing of pearlite gradually decreases as the Nb content in the four test sheets of steel increases. This result can be ascribed to the capacity of the second phase precipitation of Nb to form an effective pinning effect, refine the grain size, and then refine the lamellar spacing of pearlite. Ferrite increases with the increasing Nb content because the nucleation point of ferrite increases. The plastic deformation is completed on ferrite. The cementite layer prevents dislocation slip, and the maximum slip distance is the sheet spacing. The spacing between the slices gradually decreases. The more the interface between ferrite and cementite per unit volume of steel, the greater the resistance to dislocation movement and the greater the plastic deformation resistance. As a result, both hardness and tensile strength increase.

Microhardness of test steel.

Effect of pearlite spacing on hardness and tensile strength.

4.2 Effect of Nb on tensile properties

Figure 9 shows the microstructure of the tensile ports of the four samples.

Morphology of tensile port of test steel: (a) sample 1 fracture, 1,000×; (b) sample 2, 1,000×; (c) sample 3, 1,000×; and (d) sample 4, 1,000×.

When the stress reaches the limit, the inclusions in the sample fracture and form tiny holes with the increase in load. Dimples gradually form until the fracture of the specimen. The fracture morphology of the four sheets of steel shows that the fracture exhibits plastic deformation and is conical, which is a typical ductile fracture. The necking phenomenon is obvious before fracture. From the inside to the outside, the cone-shaped fracture is composed of fiber, radiation, and shear-lip areas. The depth of the dimple determines the plasticity and strength of the test steel. There are large areas of ductile dimples and a small number of shear planes in No. 1 and No. 4 steels. The density of dimples at the fracture of sample No. 2 increased, and the depth of dimples became deeper. The dimples of sample No. 3 are evenly dispersed, and the wide and shallow dimples dominate. The measured elongation of 1–4 samples is 10, 14, 12, and 11%, respectively. The dimple depth is large, which indicates that large plastic deformation occurs during loading, and the relative fracture toughness is also relatively high. Under the action of external force, dislocations move to the second-phase particles and accumulate. When the bonding force between the second-phase grains and the matrix can be overcome, a new surface forms and, finally, the fracture morphology of dimples forms.

The dimple size is often related to the shape, size, distribution, and quantity of inclusions, as well as the type and size of the microstructure. The SEM analysis indicates that the four types of test steels exhibit plastic fracture, and a large number of macroscopic plastic deformation occurs before fracture. The engineering stress during fracture is greater than the yield strength of the materials. SEM observation reveals a large number of dimples in the four test samples, and inclusions or particles of the precipitated phase can be observed at the bottom of the dimples. The brightness of the torn edge is greater at the edge of the dimple, and the brightness is lower at the flat bottom of the dimple. Bright second-phase particles can be found in the center of the dimple.

Figure 10 shows the TEM and EDS images of the second-phase precipitates of No. 4 test steel.

TEM and EDS of precipitates in test steel: (a) and (b) Second phase particle and (c) EDS.

It is consistent with the energy spectrum of Figure 4, the precipitates are Nb-rich nano carbides. The second-phase NbC precipitates randomly near the ferrite matrix, dislocation, and grain boundary. The precipitate was elliptical, and the size was about 60 nm, which had a significant effect on precipitation strengthening. The precipitation at the grain boundary can prevent the growth of austenite grain. The precipitates in the grain boundary can effectively nail the grain boundary and make them difficult to move. Compared with dislocations and microalloyed carbonitrides in the matrix, the coarsening and growth of austenite are more effectively prevented. However, the presence of a large number of precipitates near the grain boundary can cause great damage to the toughness of the test steel. Therefore, the amount and the size of precipitates should be controlled, and the damage can be reduced by increasing the deformation and reducing the precipitation temperature. The number of precipitates in the steel is larger and the size is smaller. Thus, the properties of the test steel are relatively excellent.

Table 2 presents the mechanical properties of the four test sheets of steel. The Nb content exerts different degrees of influence on the yield strength and the tensile strength of seismic reinforcement. With the increasing Nb content, the yield strength increases from 509 to 570 MPa, and the tensile strength also increases obviously. The Nb content is between 0.013 and 0.023% with a large increase. The aforementioned phenomenon can be ascribed to the fact that the solid solution strengthening of Nb improves the strength and plasticity simultaneously. However, the increase in the tensile strength is less than the effect of grain refinement on yield strength, leading to the reduction in yield ratio. The main reason is that in addition to fine-grain strengthening, the precipitation of microalloyed Nb and V in the steel can also significantly improve the mechanical properties of the steel [30]. The strength-to-yield ratio of the four types of test steel meets the requirement of seismic reinforcement (i.e., >1.25).

Mechanical properties of samples with different Nb contents

| No. | Nb (%) | R m (MPa) | R el (MPa) | R m/R el | A (%) |

|---|---|---|---|---|---|

| 1# | 0 | 716 | 509 | 1.407 | 10 |

| 2# | 0.013 | 719 | 537 | 1.339 | 14 |

| 3# | 0.017 | 740 | 552 | 1.341 | 12 |

| 4# | 0.023 | 745 | 570 | 1.307 | 11 |

5 Conclusion

The results show that the microstructure of the tested steel is ferrite and pearlite. The addition of niobium can promote the nucleation efficiency of ferrite, lead to a more uniform distribution, refine the grains, and increase the contribution of refinement by 9%. The tensile fracture is a typical ductile fracture with good plasticity.

The Nb content increases from 0 to 0.023%, and the lamellar spacing of pearlite increases from 0.077 to 0.125 μm. The pearlite microhardness of HRB500E seismic reinforcement increases from 282 to 325 HV, the tensile strength increases by 29 MPa, and the yield strength increases by 61 MPa.

The fine elliptical nano precipitates along the ferrite grain boundaries and intragranular are NbC, which effectively pin the grain boundaries and refine the grains.

Acknowledgements

The authors gratefully acknowledge financial support from the institution of by National Natural Science Foundation of China (Grant no. 52074095, 51864013 and 51704083).

-

Funding information: This work was supported by National Natural Science Foundation of China (Grant no. 52074095, 51864013 and 51704083).

-

Author contributions: Sheng Huang: writing – original draft, writing – review and editing, formal analysis, methodology, project administration; Changrong Li: writing – review and editing, methodology, formal analysis; Zhiying Li: data curation; Zeyun Zeng: resources; Yongqiang Zhai: supervision; Jie Wang: visualization; Zhanlin Liu: investigation; Changling Zhuang: software, validation.

-

Conflict of interest: The authors declare no conflict of interest.

-

Data availability statement: All authors can confirm that all data used in this article can be published the Journal “High Temperature Materials and Processes.”

References

[1] Fang, M. G. , S. P. Lin , G. X. Yang , Q. F. Chen , S. D. Deng , and B. R. Sun . Yield-strength ratio of the steel used in construction. Heat Treatment of Metals, Vol. 36, No. 11, 2011, pp. 51–53.Search in Google Scholar

[2] Sekhar, K. C. , B. P. Kashyap , and S. Sangal . Characterization of pearlite morphology and associated micro-cracks in en9 grade carbon steel by atomic force microscopy. Advanced Materials Research, Vol. 2066, 2012, pp. 67–71.10.4028/www.scientific.net/AMR.585.67Search in Google Scholar

[3] Huang, H. H. , G. W. Yang , Z. Gang , X. Mao , X. Gan , and Q. Yin . Effect of Nb on the microstructure and properties of Ti–Mo microalloyed high-strength ferritic steel. Materials Science and Engineering: A, Vol. 736, No. 24, 2018, pp. 148–155.10.1016/j.msea.2018.08.092Search in Google Scholar

[4] Hu, J. , X. D. Lin , N. M. Ya , G. Sun , H. Xie , and R. D. Misra . Effect of microalloying with molybdenum and boron on the micro-structure and mechanical properties of ultra-low-C Ti bearing steel. Materials Science and Engineering, Vol. 640, No. 29, 2015, pp. 259–266.10.1016/j.msea.2015.05.087Search in Google Scholar

[5] Yang, G. W. , X. J. Sun , Q. L.Yong , Z. D. Li , and X. X. Li . Austenite grain refinement and isothermal growth behavior in a low carbon vanadium microalloyed steel. Journal of Iron & Steel Research International, Vol. 21, No. 8, 2014, pp. 757–764.10.1016/S1006-706X(14)60138-2Search in Google Scholar

[6] Mao, X. P. , Q. L. Chen , and X. J. Sun . Metallurgical interpretation on grain refinement and synergistic effect of Mn and Ti in Ti-microalloyed strip produced by TSCR. Journal of Iron and Steel Research (International), Vol. 21, No. 1, 2014, pp. 30–40.10.1016/S1006-706X(14)60006-6Search in Google Scholar

[7] Zhao, Y. , F. Shen , Y. X Liu , and H. Wu . Effect of heat treatment on structure and anti-seismic performance of 16 Mn steel. Heat Treatment of Metals, Vol. 31, No. 7, 2006, pp. 74–76.Search in Google Scholar

[8] Pavlina, E. J. , J. G. Speer , and C. Tyne . Equilibrium solubility products of molybdenum carbide and tungsten carbide in iron. Scripta Materialia, Vol. 66, No. 5, 2012, pp. 243–246.10.1016/j.scriptamat.2011.10.047Search in Google Scholar

[9] Bu, F. Z. , X. M. Wang , L. Chen , S. W. Yang , C. J. Shang , and R. Misra . Influence of cooling rate on the precipitation behavior in Ti–Nb–Mo microalloyed steels during continuous cooling and relationship to strength. Materials Characterization, Vol. 102, 2015, pp. 146–155.10.1016/j.matchar.2015.03.005Search in Google Scholar

[10] Yong, W. K. , H. K. Jae , S. G. Hong , and S. L. Chong . Effects of rolling temperature on the microstructure and mechanical properties of Ti–Mo microalloyed hot-rolled high strength steel. Material Science and Engineering, Vol. 605, No. 27, 2015, pp. 244–252.10.1016/j.msea.2014.03.054Search in Google Scholar

[11] Lei, R. S. , G. R. Chen , and M. P. Wang . Effect of Nb solute concentration on crystallite size refinement and strength enhancement in mechanically alloyed Cu–Nb alloys. Rare Metal Materials and Engineering, Vol. 47, No. 9, 2018, pp. 2607–2614.10.1016/S1875-5372(18)30196-6Search in Google Scholar

[12] Popov, V. A. , E. V. Shelekhov , A. S. Prosviryakov , M. Y. Presniakov , B. R. Senatulin , and A. D. Kotov . Particulate metal matrix composites development on the basis of in situ synthesis of TiC reinforcing nanoparticles during mechanical alloying. Journal of Alloys & Compounds, Vol. 707, 2017, pp. 365–370.10.1016/j.jallcom.2016.10.051Search in Google Scholar

[13] Wen, X. L. , Z. Mei , B. Jiang , L. C. Zhang , and Y. Z. Liu . Effect of normalizing temperature on microstructure and mechanical properties of a Nb–V microalloyed large forging steel. Materials Science & Engineering A, Vol. 671, 2016, pp. 233–243 10.1016/j.msea.2016.06.059Search in Google Scholar

[14] Zhao. J. W. , Z. Y. Jiang , and C. S. Lee . Enhancing impact fracture toughness and tensile properties of a microalloyed cast steel by hot forging and post-forging heat treatment processes. Materials & Design, Vol. 47, 2013, pp. 227–233.10.1016/j.matdes.2012.11.051Search in Google Scholar

[15] Li, H. P. , G. Kang , F. H. Li , C. Z. Zhang , H. C. Cui , and M. S. Li . Non-isothermal phase-transformation kinetics model for evaluating the austenization of 55CrMo steel based on Johnson-Mehl-Avrami equation. Materials & Design, Vol. 92, No. Feb, 2016, pp. 731–741.10.1016/j.matdes.2015.12.110Search in Google Scholar

[16] Luo, X. , X. H. Chen , and Z. Wang . High toughness independent of low-medium heat inputs in coarse-grain heat-affected zone of a designed HSLA steel. Steel Research International , Vol. 88, No. 11, 2017, pp. 1–11.10.1002/srin.201700019Search in Google Scholar

[17] Ji, D. , X. S. Zhou , Y. C. Liu , Y. C. Liu , C. Li , C. X. Liu , et al. Effects of quenching-partitioning-tempering treatment on microstructure and mechanical performance of Nb–V–Ti microalloyed ultra-high strength steel. Materials Science & Engineering A, Vol. 690, 2017, pp. 283–293.10.1016/j.msea.2017.03.020Search in Google Scholar

[18] Tian, Y. , Q. Li , Z. D. Wang , and G. D. Wang . Effects of ultra fast cooling on microstructure and mechanical properties of pipeline steels. Journal of Materials Engineering & Performance, Vol. 24, No. 9, 2014, pp. 3307–3314.10.1007/s11665-015-1605-zSearch in Google Scholar

[19] Khalaj, G. , H. Pouraliakbar , N. Arab , and M. Najmeddin . Correlation of passivation current density and potential by using chemical composition and corrosion cell characteristics in HSLA steels. Measurement, Vol. 75, 2015, pp. 5–11.10.1016/j.measurement.2015.07.048Search in Google Scholar

[20] Zhang, C. , M. Gao , and X. Y. Zeng . Effect of microstructural charac-teristics on high cycle fatigue properties of laser-arc hybrid welded AA6082 aluminum alloy. Journal of Materials Processing Technology, Vol. 231, 2016, pp. 479–487.10.1016/j.jmatprotec.2016.01.019Search in Google Scholar

[21] Yan, S. , X. H. Liu , W. J. Liu , H. F. Lan , and H. Y. Wu . Microstructural evolution and mechanical properties of low-carbon steel treated by a two-step quenching and partitioning process. Materials Science and Engineering, Vol. 640, 2015, pp. 137–146.10.1016/j.msea.2015.05.058Search in Google Scholar

[22] Qin, S. , Y. Liu , Q. Hao , Y. Wang , N. Chen , X. Zuo , et al. The mechanism of high ductility for novel high-carbon quenching–partitioning–tempering martensitic steel. Metallurgical and Materials Transactions A, Vol. 46, No. 9, 2015, pp. 4047–4055.10.1007/s11661-015-3021-2Search in Google Scholar

[23] Dong, J. , C. Li , C. Liu , Y. Huang , L. Yu , and H. Li. Microstructural and mechanical properties development during quenching-partitioning-tempering process of Nb–V–Ti microalloyed ultra-high strength steel. Materials Science and Engineering: A, Vol. 705, 2017, pp. 249–256.10.1016/j.msea.2017.08.081Search in Google Scholar

[24] Graux, A. , S. Cazottes , D. De Castro , D. San Martín , C. Capdevila , J. M. Cabrera , et al. Precipitation and grain growth modelling in Ti–Nb microalloyed steels . Materialia, Vol. 5, 2019, id. 100233.10.1016/j.mtla.2019.100233Search in Google Scholar

[25] Koo, B. S. , C. W. Lee , and Y. H. Lim . Study on Nb–V microalloyed steel for 460 MPa grade H-section columns. Journal of Constructional steel Research, Vol. 170, 2020, id. 106112.10.1016/j.jcsr.2020.106112Search in Google Scholar

[26] Mohebbi, M. S. , M. Rezayat , M. H. Parsa , S. Nagy and M. Nosko . The impact of Nb on dynamic microstructure evolution of an Nb-Ti microalloyed steel. Materials Science and Engineering: A, Vol. 723, 2018, pp. 194–203.10.1016/j.msea.2018.03.054Search in Google Scholar

[27] Mohebbi, M. S. , M. Rezayat , M. H. Parsa , S. Nagy and M. Nosko . Microstructure evolution during controlled rolling of an Nb–Ti microalloyed steel. Steel Research International. Vol. 92, No. 4, 2020. 10.1002/srin.202000487Search in Google Scholar

[28] Yong, Q. L. Secondary phases in iron material. Beijing: Metallurgical Industry Press; 2006.Search in Google Scholar

[29] Palmiere, E. J. , C. I. Garcia , and A. Ardo . Compositional and microstructural changes which attend reheating and grain coarsening in steels containing niobium. Metallurgical & Materials Transactions A, Vol. 25, No. 2, 1994, pp. 277–286.10.1007/BF02647973Search in Google Scholar

[30] Xu, G. , X. L. Gan , G. J. Ma , F. Luo , and H. Zou . The development of Ti-alloyed high strength microalloy steel. Materials & Design, Vol. 31, No. 6, 2010, pp. 2891–2896.10.1016/j.matdes.2009.12.032Search in Google Scholar

© 2021 Sheng Huang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Fused deposition modeling of poly(ether ether ketone) scaffolds

- Investigation of the microstructure evolution in TP347HFG austenitic steel at 700°C and its characterization method

- Hot deformation behavior and processing maps of 9Cr3W3Co oxide dispersion-strengthened steel

- Evolution of physicochemical properties of quick lime at converter-smelting temperature

- Influence of phase distribution of converter slag microzones on the occurrence of P

- Investigation on ultrasonic assisted friction stir welding of aluminum/steel dissimilar alloys

- Analysis of oxide scale thickness and pores position of HCM12A steel in supercritical water

- Behavior of MnS inclusions during homogenization process in low-alloyed steel FAS3420H

- Preparation and cutting performance of nano-scaled Al2O3-coated micro-textured cutting tool prepared by atomic layer deposition

- Prediction of hot metal temperature based on data mining

- Effect of TiO2 content in slag on Ti content in molten steel

- Performance evaluation of titanium-based metal nitride coatings and die lifetime prediction in a cold extrusion process

- Effect of different drilling techniques on high-cycle fatigue behavior of nickel-based single-crystal superalloy with film cooling hole

- Effect of CO2 injection into blast furnace tuyeres on the pulverized coal combustion

- Microstructure and properties of Co–Al porous intermetallics fabricated by thermal explosion reaction

- Evolution regularity of temperature field of active heat insulation roadway considering thermal insulation spraying and grouting: A case study of Zhujidong Coal Mine, China

- Evolution of reduction process from tungsten oxide to ultrafine tungsten powder via hydrogen

- A thermodynamic assessment of precipitation, growth, and control of MnS inclusion in U75V heavy rail steel

- Effect of basicity on the reduction swelling properties of iron ore briquettes

- Effect of Cr and Al alloying on the oxidation resistance of a Ti5Si3-incorporated MoSiBTiC alloy

- Microstructure and mechanical properties of 2060 Al–Li alloy welded by alternating current cold metal transfer with high-frequency pulse current

- Effects of composition and strain rate on hot ductility of Cr–Mo-alloy steel in the two-phase region

- Effect of K and Na on reduction swelling performance of oxidized roasted briquettes

- Dephosphorization mechanism and phase change in the reduction of converter slag

- Parametric investigation and optimization for CO2 laser cladding of AlFeCoCrNiCu powder on AISI 316

- Optimization of heat transfer and pressure drop of the channel flow with baffle

- Quantitative analysis of microstructure and mechanical properties of Nb–V microalloyed high-strength seismic reinforcement with different Nb additions

- Visualization of the damage evolution for Ti–3Al–2Mo–2Zr alloy during a uniaxial tensile process using a microvoids proliferation damage model

- Research on high-temperature mechanical properties of wellhead and downhole tool steel in offshore multi-round thermal recovery

- Dephosphorization behavior of reduced iron and the properties of high-P-containing slag

- Jet characteristics of CO2–O2 mixed injection using a dual-parameter oxygen lance nozzle for different smelting periods

- Effects of ball milling on powder particle boundaries and properties of ODS copper

- Heat transfer behavior in ultrahigh-speed continuous casting mold

- Solidification microstructure characteristics of Cu–Pb alloy by ECP treatment

- Luminescence properties of Eu2+ and Sm3+ co-doped in KBaPO4

- Research on high-temperature oxidation resistance, hot forming ability, and microstructure of Al–Si–Cu coating for 22MnB5 steel

- The differential analysis for temperature distribution diagnostics of arc current-carrying region in sheet slanting tungsten electrode inert gas welding with the electrostatic probe

- Reactions at the molten flux-weld pool interface in submerged arc welding

- The effect of liquid crystalline graphene oxide compared with non-liquid crystalline graphene oxide on the rheological properties of polyacrylonitrile solution

- Study on manganese volatilization behavior of Fe–Mn–C–Al twinning-induced plasticity steel

- Physical modeling of bubble behaviors in molten steel under high pressure

- Rapid Communication

- The new concept of thermal barrier coatings with Pt + Pd/Zr/Hf-modified aluminide bond coat and ceramic layer formed by PS-PVD method

- Topical Issue on Science and Technology of Solar Energy

- Solution growth of chalcopyrite Cu(In1−xGax)Se2 single crystals for high open-circuit voltage photovoltaic device

- Copper-based kesterite thin films for photoelectrochemical water splitting

Articles in the same Issue

- Research Articles

- Fused deposition modeling of poly(ether ether ketone) scaffolds

- Investigation of the microstructure evolution in TP347HFG austenitic steel at 700°C and its characterization method

- Hot deformation behavior and processing maps of 9Cr3W3Co oxide dispersion-strengthened steel

- Evolution of physicochemical properties of quick lime at converter-smelting temperature

- Influence of phase distribution of converter slag microzones on the occurrence of P

- Investigation on ultrasonic assisted friction stir welding of aluminum/steel dissimilar alloys

- Analysis of oxide scale thickness and pores position of HCM12A steel in supercritical water

- Behavior of MnS inclusions during homogenization process in low-alloyed steel FAS3420H

- Preparation and cutting performance of nano-scaled Al2O3-coated micro-textured cutting tool prepared by atomic layer deposition

- Prediction of hot metal temperature based on data mining

- Effect of TiO2 content in slag on Ti content in molten steel

- Performance evaluation of titanium-based metal nitride coatings and die lifetime prediction in a cold extrusion process

- Effect of different drilling techniques on high-cycle fatigue behavior of nickel-based single-crystal superalloy with film cooling hole

- Effect of CO2 injection into blast furnace tuyeres on the pulverized coal combustion

- Microstructure and properties of Co–Al porous intermetallics fabricated by thermal explosion reaction

- Evolution regularity of temperature field of active heat insulation roadway considering thermal insulation spraying and grouting: A case study of Zhujidong Coal Mine, China

- Evolution of reduction process from tungsten oxide to ultrafine tungsten powder via hydrogen

- A thermodynamic assessment of precipitation, growth, and control of MnS inclusion in U75V heavy rail steel

- Effect of basicity on the reduction swelling properties of iron ore briquettes

- Effect of Cr and Al alloying on the oxidation resistance of a Ti5Si3-incorporated MoSiBTiC alloy

- Microstructure and mechanical properties of 2060 Al–Li alloy welded by alternating current cold metal transfer with high-frequency pulse current

- Effects of composition and strain rate on hot ductility of Cr–Mo-alloy steel in the two-phase region

- Effect of K and Na on reduction swelling performance of oxidized roasted briquettes

- Dephosphorization mechanism and phase change in the reduction of converter slag

- Parametric investigation and optimization for CO2 laser cladding of AlFeCoCrNiCu powder on AISI 316

- Optimization of heat transfer and pressure drop of the channel flow with baffle

- Quantitative analysis of microstructure and mechanical properties of Nb–V microalloyed high-strength seismic reinforcement with different Nb additions

- Visualization of the damage evolution for Ti–3Al–2Mo–2Zr alloy during a uniaxial tensile process using a microvoids proliferation damage model

- Research on high-temperature mechanical properties of wellhead and downhole tool steel in offshore multi-round thermal recovery

- Dephosphorization behavior of reduced iron and the properties of high-P-containing slag

- Jet characteristics of CO2–O2 mixed injection using a dual-parameter oxygen lance nozzle for different smelting periods

- Effects of ball milling on powder particle boundaries and properties of ODS copper

- Heat transfer behavior in ultrahigh-speed continuous casting mold

- Solidification microstructure characteristics of Cu–Pb alloy by ECP treatment

- Luminescence properties of Eu2+ and Sm3+ co-doped in KBaPO4

- Research on high-temperature oxidation resistance, hot forming ability, and microstructure of Al–Si–Cu coating for 22MnB5 steel

- The differential analysis for temperature distribution diagnostics of arc current-carrying region in sheet slanting tungsten electrode inert gas welding with the electrostatic probe

- Reactions at the molten flux-weld pool interface in submerged arc welding

- The effect of liquid crystalline graphene oxide compared with non-liquid crystalline graphene oxide on the rheological properties of polyacrylonitrile solution

- Study on manganese volatilization behavior of Fe–Mn–C–Al twinning-induced plasticity steel

- Physical modeling of bubble behaviors in molten steel under high pressure

- Rapid Communication

- The new concept of thermal barrier coatings with Pt + Pd/Zr/Hf-modified aluminide bond coat and ceramic layer formed by PS-PVD method

- Topical Issue on Science and Technology of Solar Energy

- Solution growth of chalcopyrite Cu(In1−xGax)Se2 single crystals for high open-circuit voltage photovoltaic device

- Copper-based kesterite thin films for photoelectrochemical water splitting